Introduction: Navigating the Global Market for 4 wheeled electric vehicled

In the rapidly evolving landscape of electric mobility, sourcing the right four-wheeled electric vehicle (EV) poses unique challenges for B2B buyers. With increasing demand for sustainable transportation solutions across diverse markets, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of this market is crucial. This comprehensive guide delves into various types of four-wheeled electric vehicles, ranging from compact city cars to robust off-road models, while also exploring their applications across sectors such as logistics, tourism, and personal transport.

Buyers will gain insights into essential considerations for supplier vetting, helping to ensure that partnerships are established with reliable manufacturers who meet international quality standards. Additionally, the guide provides a thorough analysis of pricing structures, allowing businesses to make informed financial decisions without compromising on quality or performance.

By equipping B2B buyers with actionable insights, this guide empowers them to navigate the complexities of the four-wheeled electric vehicle market confidently. Whether you’re looking to enhance your fleet, expand product offerings, or invest in sustainable solutions, understanding these critical factors will enable you to make informed purchasing decisions that align with your business objectives.

Understanding 4 wheeled electric vehicled Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| All-Wheel Drive SUVs | Enhanced traction, off-road capabilities, higher ground clearance | Fleet vehicles, tourism, off-road logistics | Pros: Improved safety, versatility; Cons: Range reduction compared to 2WD models. |

| Compact Electric Vehicles | Smaller size, urban-friendly, often lower cost | City deliveries, ride-sharing services | Pros: Cost-effective, easier parking; Cons: Limited cargo space, shorter range. |

| Heavy-Duty Electric Trucks | High payload capacity, robust construction | Construction, logistics, heavy transport | Pros: Strong performance, long range; Cons: Higher upfront costs, charging infrastructure needs. |

| All-Terrain Electric Vehicles | Designed for rugged terrains, powerful motors | Outdoor recreation, agricultural use | Pros: Excellent maneuverability, durability; Cons: Generally pricier, may require specialized maintenance. |

| Luxury Electric Vehicles | High-end features, advanced technology, superior comfort | Corporate fleets, executive transport | Pros: Prestige, advanced tech; Cons: High initial investment, maintenance costs. |

What Are the Characteristics and Suitability of All-Wheel Drive SUVs?

All-wheel drive (AWD) SUVs are designed to provide superior traction and stability, making them ideal for diverse terrains and weather conditions. They often feature higher ground clearance, which is beneficial for navigating rural areas or off-road conditions. For B2B buyers, these vehicles are suitable for fleet operations in regions with challenging climates or terrains, such as tourism companies and logistics providers who need reliable transport in winter or rainy seasons. However, potential buyers should consider the trade-off in range compared to two-wheel drive models.

How Do Compact Electric Vehicles Serve Urban Applications?

Compact electric vehicles (EVs) are characterized by their smaller size, making them well-suited for urban environments where parking and maneuverability are crucial. They are typically more affordable than larger models, appealing to businesses focused on cost efficiency, such as delivery services and ride-sharing companies. While they offer the advantage of lower operational costs and easier navigation in congested areas, buyers should be aware of their limited cargo capacity and shorter driving range, which may affect service delivery in larger metropolitan areas.

What Are the Advantages of Heavy-Duty Electric Trucks for Logistics?

Heavy-duty electric trucks are engineered for high payload capacity and durability, making them essential for industries such as construction and logistics. These vehicles can handle substantial loads while providing the environmental benefits of electric power. B2B buyers in sectors requiring significant transport capabilities will find these trucks advantageous, especially with advancements in charging infrastructure. However, the higher initial costs and the need for robust charging solutions can be considerations in the purchasing decision.

Why Choose All-Terrain Electric Vehicles for Outdoor and Agricultural Use?

All-terrain electric vehicles are built to navigate rugged landscapes, equipped with powerful motors and advanced suspension systems. They are particularly beneficial for outdoor recreation businesses, agricultural operations, and industries requiring versatile transport solutions in challenging environments. While these vehicles offer exceptional stability and performance, buyers should be prepared for potentially higher costs and specialized maintenance requirements, which could impact long-term investment.

How Do Luxury Electric Vehicles Enhance Corporate Fleets?

Luxury electric vehicles combine high-end features with advanced technology, making them ideal for corporate fleets and executive transport. Their superior comfort and prestige can enhance brand image and employee satisfaction. B2B buyers should consider the initial investment and ongoing maintenance costs, which can be higher than standard models. However, the long-term savings from lower fuel and operational costs can offset these expenses, especially for businesses focused on sustainability and high-end client services.

Key Industrial Applications of 4 wheeled electric vehicled

| Industry/Sector | Specific Application of 4 wheeled electric vehicled | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Electric utility vehicles for farm operations | Reduced operational costs and lower emissions | Battery capacity, terrain adaptability, and maintenance support |

| Tourism | Eco-friendly transport for resort guests | Enhanced guest experience and sustainability image | Range, charging infrastructure, and comfort features |

| Construction | Site transport and equipment delivery | Improved efficiency and reduced fuel costs | Load capacity, durability, and off-road capability |

| Logistics and Delivery | Last-mile delivery vehicles | Increased efficiency and reduced carbon footprint | Range, payload capacity, and urban maneuverability |

| Public Services | Electric vehicles for municipal services (e.g., waste collection) | Cost savings and environmental compliance | Reliability, fleet integration, and service support |

How Are 4 Wheeled Electric Vehicles Beneficial in Agriculture?

In the agricultural sector, four-wheeled electric vehicles (EVs) are increasingly being utilized for utility tasks such as transporting goods and equipment across large farm areas. By switching to electric options, businesses can significantly lower their operational costs through reduced fuel consumption and maintenance. Additionally, these vehicles minimize carbon emissions, aligning with global sustainability goals. Buyers should consider battery capacity to ensure adequate range for extensive farm operations, as well as the vehicle’s adaptability to various terrains commonly found in agricultural settings.

What Role Do Electric Vehicles Play in Tourism?

In the tourism industry, four-wheeled electric vehicles serve as eco-friendly transport solutions for resort guests. They enhance the overall guest experience by providing quiet, clean, and comfortable rides while exploring natural attractions. This not only improves customer satisfaction but also strengthens the resort’s commitment to sustainability, appealing to environmentally-conscious travelers. When sourcing these vehicles, businesses should prioritize range and the availability of charging infrastructure, as well as comfort features to ensure a pleasant experience for guests.

How Are Electric Vehicles Transforming Construction Sites?

Construction companies are leveraging four-wheeled electric vehicles for site transportation and equipment delivery. These vehicles contribute to improved operational efficiency, allowing for quick movement of personnel and materials without the high fuel costs associated with traditional combustion engines. Additionally, they help in reducing noise pollution and emissions on construction sites, which is increasingly important for regulatory compliance. Buyers in this sector should focus on load capacity, durability to withstand rough conditions, and off-road capabilities to navigate various construction environments.

Why Are Electric Vehicles Important for Last-Mile Delivery?

In logistics and delivery, four-wheeled electric vehicles are becoming vital for last-mile delivery operations. Their use enhances efficiency by allowing companies to reduce transportation costs and minimize their carbon footprint, particularly in urban areas where emissions regulations are tightening. The compact size and maneuverability of these vehicles are key advantages in densely populated regions. When sourcing, businesses should evaluate range, payload capacity, and the vehicle’s ability to navigate urban landscapes effectively.

How Do Electric Vehicles Benefit Public Services?

Municipalities are increasingly adopting four-wheeled electric vehicles for various public services, including waste collection and maintenance operations. These vehicles offer significant cost savings over time due to lower fuel and maintenance expenses, while also helping municipalities comply with environmental regulations. Reliability is crucial in this sector, as is the ability to integrate these vehicles into existing fleets. Buyers should also consider service support options to ensure long-term operational efficiency.

3 Common User Pain Points for ‘4 wheeled electric vehicled’ & Their Solutions

Scenario 1: Limited Range and Charging Infrastructure Concerns

The Problem: One significant challenge faced by B2B buyers of four-wheeled electric vehicles (EVs) is the concern over limited driving range and insufficient charging infrastructure, particularly in regions like Africa and South America where urban development is uneven. Buyers often worry that their fleet may become stranded due to inadequate charging stations, leading to operational disruptions and increased costs. This is especially critical for businesses that rely on timely deliveries or transportation services in remote areas.

The Solution: To address this issue, B2B buyers should prioritize sourcing electric vehicles with extended range capabilities and ensure access to fast-charging stations. When evaluating models, look for vehicles that offer a minimum range of 300 miles, as this can reduce anxiety regarding range limitations. Additionally, consider partnerships with charging infrastructure providers to establish a network of charging stations along key routes or at operational hubs. Implementing a strategic plan for charging, including the installation of on-site chargers, can enhance operational efficiency. Furthermore, investing in vehicles equipped with advanced battery management systems can maximize range and optimize charging times, thus keeping your fleet operational and reducing downtime.

Scenario 2: Off-Road Capability for Diverse Terrain

The Problem: In many regions, businesses require vehicles that can handle rough and varied terrains, particularly in rural or undeveloped areas. Traditional electric vehicles may lack the necessary off-road capabilities, which can limit their usability for logistics companies, agriculture, or tourism-related businesses. Buyers often find it challenging to identify vehicles that balance electric efficiency with the ruggedness needed for such applications.

The Solution: Buyers should focus on four-wheeled electric vehicles designed specifically for off-road performance. Look for models that feature all-wheel drive, high ground clearance, and advanced traction control systems. For instance, vehicles like the electric Mercedes G-Class or the upcoming electric Range Rover have demonstrated exceptional off-road capabilities and can serve as benchmarks for rugged performance. Additionally, conducting field tests in real-world conditions before purchasing can help assess a vehicle’s off-road proficiency. Establishing relationships with manufacturers who offer customization options can also allow for adaptations tailored to specific operational needs, enhancing the vehicle’s versatility for challenging terrains.

Scenario 3: Maintenance and Support Challenges

The Problem: As electric vehicles become more prevalent, B2B buyers are concerned about the availability of maintenance and support services. Many regions, especially in developing markets, may not have the necessary infrastructure or trained personnel to service electric vehicles effectively. This can lead to increased operational risks and costs, as buyers might face longer downtimes if vehicles require repairs or software updates.

The Solution: To mitigate these risks, buyers should select reputable manufacturers known for their extensive service networks and support capabilities. Before purchasing, inquire about the availability of local service centers and the training provided to technicians. Establishing a preventive maintenance schedule can also be beneficial, ensuring that vehicles are regularly checked for optimal performance. Additionally, investing in vehicles with comprehensive warranties and robust support packages can provide peace of mind. Buyers might also consider collaborating with local technical schools or training programs to develop a skilled workforce capable of maintaining electric vehicles, thus ensuring long-term operational sustainability.

Strategic Material Selection Guide for 4 wheeled electric vehicled

What Are the Key Materials for 4 Wheeled Electric Vehicles?

When selecting materials for four-wheeled electric vehicles (EVs), manufacturers must consider various factors, including performance, cost, and compliance with international standards. Here, we analyze four common materials used in the construction of electric vehicles, focusing on their properties, advantages, disadvantages, and implications for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

How Does Aluminum Benefit Electric Vehicle Manufacturing?

Aluminum is a popular choice for electric vehicle frames and body panels due to its lightweight nature and excellent strength-to-weight ratio. It typically has a temperature rating of around -200°C to 600°C and offers good corrosion resistance, making it suitable for various climates.

Pros: Aluminum enhances vehicle efficiency by reducing weight, which can improve range and performance. It is also recyclable, aligning with sustainability goals.

Cons: The manufacturing process can be complex, leading to higher costs compared to steel. Additionally, aluminum can be less durable in high-impact scenarios.

Impact on Application: Aluminum is ideal for components that require weight savings without compromising structural integrity, such as body panels and chassis.

Considerations for International Buyers: Compliance with standards like ASTM and DIN is crucial. Buyers should also consider local recycling capabilities and the availability of aluminum supply chains.

What Role Does Steel Play in Electric Vehicle Construction?

Steel remains a staple in electric vehicle manufacturing, particularly for structural components. It boasts high strength, temperature resistance, and excellent impact resistance, making it suitable for safety-critical applications.

Pros: Steel is cost-effective and widely available, providing durability and robustness. It can be easily formed and welded, facilitating manufacturing processes.

Cons: Steel is heavier than aluminum, which can negatively impact the vehicle’s range. It is also susceptible to corrosion unless treated.

Impact on Application: Steel is commonly used in the frame and underbody of electric vehicles, where strength and safety are paramount.

Considerations for International Buyers: Compliance with international standards such as JIS and ASTM is essential. Buyers should also evaluate local steel sourcing and treatment processes to ensure corrosion resistance.

Why is Composite Material Gaining Popularity in Electric Vehicles?

Composite materials, such as carbon fiber and fiberglass, are increasingly used in electric vehicles for components like body panels and interior parts. They offer excellent strength, lightweight properties, and design flexibility.

Pros: Composites can significantly reduce weight, improving energy efficiency and performance. They also provide superior corrosion resistance.

Cons: The cost of composite materials is generally high, and their manufacturing processes can be complex. Additionally, recycling options for composites are limited compared to metals.

Impact on Application: Composites are ideal for applications where weight reduction is critical, such as in body panels and aerodynamic components.

Considerations for International Buyers: Buyers should be aware of compliance with standards and certifications for composite materials. They should also consider the availability of specialized manufacturing processes in their regions.

How Do Battery Materials Influence Electric Vehicle Design?

The materials used in electric vehicle batteries, such as lithium-ion and nickel-metal hydride, are crucial for performance and longevity. These materials must withstand high temperatures and are subject to specific safety regulations.

Pros: Lithium-ion batteries offer high energy density and longer life cycles, making them the preferred choice for EVs. They also have a lower self-discharge rate.

Cons: The raw materials for these batteries can be expensive and subject to market fluctuations. Additionally, battery disposal and recycling present environmental challenges.

Impact on Application: Battery materials directly affect vehicle range, charging times, and overall performance.

Considerations for International Buyers: Compliance with safety and environmental regulations is critical. Buyers should also consider local infrastructure for battery recycling and disposal.

Summary Table of Material Selection for 4 Wheeled Electric Vehicles

| Material | Typical Use Case for 4 wheeled electric vehicled | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body panels, chassis | Lightweight, corrosion-resistant | Higher manufacturing costs | Medium |

| Steel | Frame, underbody | Cost-effective, durable | Heavier, corrosion-prone | Low |

| Composite | Body panels, interior parts | High strength-to-weight ratio | High cost, complex manufacturing | High |

| Battery Materials | Energy storage systems | High energy density, longevity | Expensive raw materials, disposal issues | High |

This analysis provides international B2B buyers with actionable insights into material selection for four-wheeled electric vehicles, enabling informed decisions that align with performance, cost, and compliance requirements in their respective markets.

In-depth Look: Manufacturing Processes and Quality Assurance for 4 wheeled electric vehicled

What Are the Main Stages of Manufacturing 4-Wheeled Electric Vehicles?

The manufacturing of four-wheeled electric vehicles (EVs) involves several critical stages that ensure the final product meets performance, safety, and quality standards. Understanding these stages is essential for B2B buyers looking to partner with reliable suppliers.

Material Preparation: What Materials Are Used in EV Manufacturing?

The first stage in manufacturing involves sourcing and preparing materials. Key materials for electric vehicles include high-strength steel, aluminum, and composites for the chassis; lithium-ion batteries; and various electronic components. Suppliers must ensure that all materials meet stringent quality standards and regulations. The material selection process often involves evaluating the durability, weight, and cost-effectiveness of each component. For example, lightweight materials can enhance range and efficiency, which is crucial for competitive performance.

How Are Components Formed and Shaped for Electric Vehicles?

The forming stage typically includes processes such as stamping, welding, and machining. Advanced techniques, such as hydroforming and die-casting, are often used to create complex shapes with high precision. For battery manufacturing, processes like cell assembly and module integration are critical. Each component must be designed for optimal performance, and any deviation in specifications can lead to significant failures in the field.

What Does the Assembly Process Entail for Electric Vehicles?

The assembly stage is where all the manufactured components come together. This process often includes:

- Chassis Assembly: This involves joining the frame, suspension, and drivetrain components.

- Battery Installation: Battery packs are integrated into the vehicle structure, requiring careful handling to avoid damage.

- Electrical Systems Integration: Wiring, control units, and software systems are installed and tested to ensure functionality.

- Quality Checks: Throughout the assembly process, various quality checks are performed to detect any issues early.

Automation plays a significant role in modern EV assembly lines, increasing efficiency while maintaining high-quality standards.

What Finishing Touches Are Applied to 4-Wheeled Electric Vehicles?

Finishing processes enhance both the aesthetic appeal and the durability of electric vehicles. This stage typically includes painting, surface treatment, and applying protective coatings. Each vehicle undergoes a final inspection to ensure that it meets all specifications. This final check is crucial for identifying any surface imperfections or functional issues before the vehicle is delivered to customers.

What International Standards and Industry-Specific Certifications Apply to Quality Assurance in Electric Vehicle Manufacturing?

Quality assurance is critical in the manufacturing of electric vehicles, and adherence to international standards like ISO 9001 is essential. This standard focuses on quality management systems and ensures that manufacturers consistently provide products that meet customer and regulatory requirements.

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) standards for certain components are also significant. These certifications demonstrate compliance with safety and environmental regulations, which can be a deciding factor for B2B buyers in various regions.

How Are Quality Control Checkpoints Structured in Electric Vehicle Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that every vehicle meets stringent quality standards. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet quality specifications.

- In-Process Quality Control (IPQC): Quality checks during the manufacturing process help identify defects early on, minimizing waste and rework.

- Final Quality Control (FQC): A comprehensive inspection of the finished product before it leaves the factory ensures that all components function correctly and meet performance standards.

What Common Testing Methods Are Used to Ensure Electric Vehicle Quality?

Testing methods are vital for confirming the reliability and safety of electric vehicles. Common testing procedures include:

- Durability Testing: Vehicles undergo rigorous testing to simulate real-world driving conditions, ensuring they can withstand various environments.

- Battery Performance Testing: This includes assessing battery capacity, charging speeds, and overall lifespan.

- Safety Testing: This includes crash tests and electrical safety assessments to ensure compliance with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying the quality control processes of suppliers is essential to ensure that the products meet required standards. This can be achieved through:

- Supplier Audits: Conducting regular audits allows buyers to assess the supplier’s manufacturing practices and quality management systems.

- Requesting Quality Reports: Suppliers should provide documentation of their quality control processes and results from testing and inspections.

- Third-Party Inspections: Engaging independent inspection services can offer an unbiased view of the supplier’s quality assurance practices.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various quality control nuances. Different regions may have specific regulations and standards that must be adhered to. For example, European buyers might focus more on CE certification, while Middle Eastern markets may prioritize compliance with local regulations.

Additionally, language barriers and cultural differences can affect communication regarding quality expectations. Establishing clear communication channels and understanding the local regulatory landscape is crucial for successful partnerships.

Conclusion: Why Is a Robust Manufacturing and Quality Assurance Process Crucial for B2B Buyers?

A robust manufacturing and quality assurance process is essential for ensuring that four-wheeled electric vehicles meet the high standards expected by B2B buyers. By understanding the various stages of manufacturing, relevant quality standards, and effective QC strategies, buyers can make informed decisions when selecting suppliers. This knowledge not only helps in securing high-quality products but also fosters long-term partnerships built on trust and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4 wheeled electric vehicled’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure four-wheeled electric vehicles (EVs). As the demand for sustainable transport solutions rises globally, particularly in regions like Africa, South America, the Middle East, and Europe, it’s essential to approach sourcing with a structured plan. This checklist will help you navigate the complexities of selecting the right electric vehicles that meet your organization’s needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first crucial step in the sourcing process. Consider factors such as vehicle range, charging time, and terrain capabilities. For instance, if your operations require off-road capabilities, ensure that the vehicles can handle rugged terrains without compromising performance.

- Range Requirements: Determine the distance your vehicles need to travel on a single charge.

- Terrain Capabilities: Specify if you need all-wheel drive or features for off-road performance.

Step 2: Identify Your Budget Constraints

Understanding your budget is vital for making informed decisions. Electric vehicles can vary significantly in price based on features and specifications. Set a realistic budget that includes not only the purchase price but also potential maintenance and operational costs.

- Total Cost of Ownership: Consider long-term costs, including charging infrastructure and battery replacement.

- Incentives and Subsidies: Research any government incentives that could offset initial costs.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request comprehensive company profiles, including their experience in the electric vehicle sector and references from other buyers in similar industries.

- Supplier Reputation: Investigate the supplier’s market reputation through reviews and case studies.

- After-Sales Support: Assess the level of support they offer post-purchase, including warranties and service options.

Step 4: Verify Compliance with Local Regulations

Ensure that the vehicles you consider comply with local regulations and standards. This step is critical to avoid legal issues and ensure safety.

- Safety Standards: Check if the vehicles meet regional safety standards and emissions regulations.

- Import Regulations: Be aware of any tariffs or restrictions that may apply when importing vehicles into your country.

Step 5: Request Test Drives and Demonstrations

Before finalizing your decision, request test drives or demonstrations. This allows you to evaluate the vehicles firsthand, ensuring they meet your performance expectations.

- Performance Assessment: Pay attention to handling, comfort, and specific features during the test.

- User Experience: Involve potential drivers in the evaluation process to gather insights on usability.

Step 6: Review Financing Options

Explore various financing options available for acquiring electric vehicles. Many suppliers offer flexible financing solutions that can ease the financial burden.

- Leasing vs. Buying: Consider whether leasing or outright purchase aligns better with your financial strategy.

- Partnership Opportunities: Look for partnerships with local financial institutions that specialize in green financing.

Step 7: Final Selection and Contract Negotiation

Once you’ve narrowed down your options, it’s time for the final selection and negotiation. Ensure that the contract clearly outlines all terms, including delivery timelines, payment schedules, and warranty details.

- Clear Terms: Ensure all specifications and agreements are documented to avoid misunderstandings.

- Negotiation Leverage: Use your research on competitor pricing and features to negotiate better terms.

By following this checklist, you can streamline the sourcing process and make informed decisions that align with your organization’s goals for sustainability and efficiency in electric vehicle procurement.

Comprehensive Cost and Pricing Analysis for 4 wheeled electric vehicled Sourcing

What Are the Key Cost Components for Sourcing 4-Wheeled Electric Vehicles?

When sourcing 4-wheeled electric vehicles (EVs), understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials like lithium for batteries, steel for the chassis, and various electronic components significantly impacts the overall price. The fluctuation of material costs can vary based on global supply chain dynamics, particularly for rare materials.

-

Labor: Labor costs differ widely based on geographic location. Countries with lower labor costs can provide competitive pricing but may affect quality. Conversely, higher labor costs in developed regions often correlate with superior craftsmanship and adherence to safety standards.

-

Manufacturing Overhead: This includes expenses related to factory operations, energy costs, and administrative overhead. Efficient manufacturing processes can help mitigate these costs, which should be factored into the pricing model.

-

Tooling: The investment in tooling is significant, especially for custom or specialized vehicles. This cost can be amortized over higher production volumes, making it a critical factor for buyers looking to negotiate prices based on order quantities.

-

Quality Control (QC): Rigorous quality control processes ensure the vehicles meet international safety and performance standards. The costs associated with QC can vary depending on the complexity of the vehicle and the certifications required for different markets.

-

Logistics: Transportation costs to deliver vehicles from the manufacturing facility to the end buyer can be substantial, particularly for international shipments. Factors like shipping methods, distance, and tariffs can all influence logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their risks and investments. Understanding the typical margins in the EV sector can help buyers negotiate better deals.

How Do Price Influencers Affect 4-Wheeled Electric Vehicle Sourcing?

Several factors can influence pricing for 4-wheeled electric vehicles:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should negotiate terms that allow for bulk purchasing to achieve cost savings.

-

Specifications/Customization: Custom features or specifications can increase costs. Buyers should assess their needs and identify essential features versus optional ones to optimize their budgets.

-

Materials and Quality Certifications: The choice of materials affects both cost and quality. Vehicles that meet stringent international certifications often carry a premium but offer peace of mind regarding safety and reliability.

-

Supplier Factors: The supplier’s reputation, production capabilities, and financial stability can impact pricing. It’s essential to conduct due diligence to ensure the supplier can meet demands without compromising on quality.

-

Incoterms: The agreed-upon Incoterms dictate who is responsible for shipping, insurance, and tariffs, which can significantly affect total costs. Buyers should be familiar with these terms to avoid unexpected expenses.

What Are the Best Tips for Buyers to Ensure Cost-Efficiency in Sourcing Electric Vehicles?

To achieve cost efficiency in sourcing 4-wheeled electric vehicles, consider the following strategies:

-

Negotiation: Develop a strong negotiation strategy based on market research and competitor pricing. Understanding the market landscape can empower buyers to secure favorable terms.

-

Total Cost of Ownership (TCO): Evaluate not just the upfront costs but also the long-term operational costs, including maintenance, energy consumption, and resale value. A lower initial price may not always equate to better value.

-

Pricing Nuances for International Buyers: Factors such as currency fluctuations, import taxes, and local regulations can impact pricing. Buyers should factor in these elements and consider establishing relationships with local suppliers to mitigate risks.

-

Flexibility in Specifications: Being open to alternative specifications or models can provide access to better pricing. Suppliers may have excess inventory of certain models that can be offered at a discount.

Disclaimer on Indicative Prices

Prices for 4-wheeled electric vehicles can vary widely based on market conditions, specifications, and supplier agreements. The figures mentioned in the guide are indicative and should be validated through direct discussions with manufacturers and suppliers to ensure accuracy and relevance to specific purchasing contexts.

Alternatives Analysis: Comparing 4 wheeled electric vehicled With Other Solutions

Exploring Alternatives to 4 Wheeled Electric Vehicles

In the evolving landscape of electric mobility, businesses are faced with various options to meet their transportation needs. While four-wheeled electric vehicles (EVs) offer a compelling solution, it is essential to consider alternative technologies that may also align with specific operational requirements. This analysis compares 4 wheeled electric vehicles with two viable alternatives: electric scooters and electric all-terrain vehicles (ATVs). Each solution presents unique advantages and challenges that B2B buyers must evaluate.

| Comparison Aspect | 4 Wheeled Electric Vehicles | Electric Scooters | Electric All-Terrain Vehicles |

|---|---|---|---|

| Performance | High torque and speed, suitable for varied terrains | Moderate speed, best for urban commuting | Excellent off-road capability, variable speed |

| Cost | Generally high (e.g., £42,000 – £154,000) | Low (e.g., £1,500 – £5,000) | Moderate to high (£4,000 – £10,000) |

| Ease of Implementation | Requires charging infrastructure; limited charging points in some regions | Minimal infrastructure needed; easily charged at home | Requires specialized charging stations and maintenance facilities |

| Maintenance | Regular servicing, battery checks | Minimal maintenance; battery replacement every few years | Moderate; rugged design but requires servicing for heavy use |

| Best Use Case | Long-distance travel, family transport, off-road adventures | Urban commuting, short trips, recreational use | Off-road adventures, rugged terrains, utility tasks |

What Are the Benefits and Drawbacks of Electric Scooters?

Electric scooters are an increasingly popular option for urban mobility. They offer a cost-effective solution for short-distance travel, making them ideal for businesses looking to reduce transportation expenses. Their lightweight design and ease of use allow for quick maneuverability in crowded environments. However, their performance is limited, and they are not suited for long-distance travel or off-road conditions. Additionally, electric scooters may not provide adequate cargo space for businesses needing to transport goods or equipment.

How Do Electric All-Terrain Vehicles Compare?

Electric all-terrain vehicles (ATVs) provide an excellent alternative for businesses that require robust off-road capabilities. These vehicles are designed to handle rugged terrains, making them perfect for agricultural, construction, or recreational applications. Their performance is superior in challenging environments, and they can navigate obstacles with ease. However, the initial investment and maintenance costs can be significant, and they may require specialized charging infrastructure. Furthermore, ATVs are not typically designed for urban settings, limiting their versatility compared to 4 wheeled electric vehicles.

Conclusion: How to Choose the Right Electric Vehicle Solution for Your Business

When selecting the appropriate electric vehicle solution, B2B buyers should assess their specific operational needs and environmental conditions. Four-wheeled electric vehicles are ideal for businesses needing a reliable and versatile option for longer distances and family transport. In contrast, electric scooters offer an economical choice for short urban commutes, while electric ATVs excel in off-road scenarios. By carefully weighing the performance, cost, ease of implementation, maintenance, and use cases of each alternative, businesses can make informed decisions that align with their strategic goals and enhance their operational efficiency.

Essential Technical Properties and Trade Terminology for 4 wheeled electric vehicled

What Are the Key Technical Properties of Four-Wheeled Electric Vehicles?

When considering the procurement of four-wheeled electric vehicles (EVs), understanding their technical properties is crucial for making informed purchasing decisions. Below are some of the essential specifications that B2B buyers should evaluate:

-

Range

– Definition: The maximum distance a vehicle can travel on a single charge.

– Importance: Range is a critical factor, particularly for businesses that require transportation over long distances. A vehicle with a higher range minimizes downtime for charging and enhances operational efficiency. -

Charging Time

– Definition: The duration required to fully charge the vehicle’s battery.

– Importance: Fast charging capabilities can significantly reduce downtime. Businesses must assess how quickly vehicles can be charged to maintain productivity, especially in logistics and transportation sectors. -

Motor Power (kW)

– Definition: The output power of the vehicle’s electric motor, usually measured in kilowatts (kW).

– Importance: Higher motor power translates to better acceleration and performance, which is essential for vehicles used in demanding environments or for heavy loads. Evaluating motor power helps in selecting vehicles that meet specific operational needs. -

Battery Capacity (kWh)

– Definition: The total energy storage capacity of the vehicle’s battery, measured in kilowatt-hours (kWh).

– Importance: A larger battery capacity generally offers a longer range and better performance. For B2B buyers, understanding battery capacity ensures the selected vehicle aligns with usage patterns and energy requirements. -

Towing Capacity

– Definition: The maximum weight that the vehicle can tow safely.

– Importance: This is particularly relevant for businesses that require hauling goods or equipment. Knowing the towing capacity aids in making strategic decisions regarding fleet operations. -

Ground Clearance

– Definition: The distance between the lowest point of the vehicle and the ground.

– Importance: Adequate ground clearance is vital for off-road capabilities and navigating rugged terrains, which is often necessary in agricultural or construction settings.

Which Trade Terminology Should B2B Buyers Understand When Purchasing Electric Vehicles?

Understanding industry-specific jargon can help buyers navigate the procurement process effectively. Here are some common terms related to four-wheeled electric vehicles:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts and equipment that may be marketed by another manufacturer.

– Importance: Knowing the OEM can help buyers assess the quality and reliability of the vehicle, ensuring they are investing in a reputable brand. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding the MOQ is crucial for budget planning and inventory management, especially for businesses looking to build a fleet of vehicles. -

RFQ (Request for Quotation)

– Definition: A document issued by a buyer to request pricing information from suppliers.

– Importance: Issuing an RFQ allows businesses to compare prices and terms from multiple suppliers, facilitating better negotiation and cost management. -

Incoterms (International Commercial Terms)

– Definition: A set of rules defining the responsibilities of sellers and buyers in international transactions.

– Importance: Familiarity with Incoterms helps B2B buyers understand shipping costs, risks, and responsibilities, which is vital for international procurement. -

Telematics

– Definition: The integration of telecommunications and monitoring systems in vehicles.

– Importance: Telematics provides real-time data on vehicle performance and location, which can be leveraged for fleet management and operational efficiency. -

Lifecycle Assessment

– Definition: A technique to assess the environmental impacts associated with all the stages of a product’s life.

– Importance: Conducting a lifecycle assessment can help businesses make sustainable purchasing decisions, aligning with corporate social responsibility goals.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions when investing in four-wheeled electric vehicles, ensuring they meet both operational and strategic objectives.

Navigating Market Dynamics and Sourcing Trends in the 4 wheeled electric vehicled Sector

What Are the Key Market Dynamics and Trends in the 4-Wheeled Electric Vehicle Sector?

The global market for four-wheeled electric vehicles (EVs) is experiencing a significant transformation, driven by increasing environmental awareness, technological advancements, and shifting consumer preferences. Key drivers include government incentives for sustainable transport, rising fuel costs, and a growing demand for vehicles that offer enhanced performance and safety features. As international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, navigate this evolving landscape, understanding these dynamics is crucial.

Emerging B2B tech trends include the integration of advanced technologies like AI for enhanced vehicle performance and the use of big data analytics for predictive maintenance. Additionally, sourcing strategies are shifting towards collaborations with tech firms specializing in battery technology and charging infrastructure. This trend is particularly relevant for markets in regions with developing infrastructure, such as parts of Africa and South America, where establishing a robust EV ecosystem is vital for market penetration.

Moreover, the four-wheeled EV sector is witnessing an increasing focus on all-terrain capabilities, catering to diverse consumer needs across different geographies. For instance, buyers in rural or rugged areas are prioritizing all-wheel-drive models that can perform in challenging conditions. This trend indicates a growing opportunity for B2B partnerships focused on producing vehicles that not only meet urban driving needs but also excel in off-road environments.

How Does Sustainability and Ethical Sourcing Impact the 4-Wheeled Electric Vehicle Market?

Sustainability is at the forefront of the four-wheeled electric vehicle industry, influencing buyer decisions and shaping sourcing practices. As international regulations tighten around emissions and environmental impact, the importance of ethical supply chains has never been more critical. B2B buyers are increasingly scrutinizing the sourcing of materials, particularly lithium and cobalt, which are essential for battery production. Ensuring these materials are sourced responsibly is vital for maintaining corporate social responsibility and meeting regulatory standards.

Additionally, the adoption of ‘green’ certifications and materials is becoming a competitive differentiator. Buyers are now looking for manufacturers who can demonstrate sustainability in their production processes, from using recycled materials to implementing energy-efficient manufacturing practices. This focus not only enhances brand reputation but also aligns with the values of an increasingly eco-conscious consumer base. As a result, international B2B buyers are encouraged to prioritize partnerships with suppliers who emphasize sustainability and ethical sourcing, thereby fostering a positive environmental impact.

What Is the Brief Evolution of the 4-Wheeled Electric Vehicle Industry?

The evolution of the four-wheeled electric vehicle industry has been marked by significant technological advancements and changing market dynamics. Initially, electric vehicles were perceived as niche products, primarily limited to urban environments and short-range applications. However, advancements in battery technology, such as the development of lithium-ion batteries, have dramatically improved range and performance, making electric vehicles more appealing to a broader audience.

As consumer interest in sustainability grew, so did the market’s focus on electric vehicles, with major automotive manufacturers investing heavily in EV technology. The introduction of government incentives and stricter emissions regulations has further accelerated this shift, leading to a surge in both production and sales. Today, the four-wheeled electric vehicle market is characterized by a diverse range of offerings, from compact urban cars to rugged off-road models, catering to various consumer needs and preferences across the globe.

This evolution presents a wealth of opportunities for international B2B buyers to engage with innovative manufacturers and technology partners, ultimately driving growth in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of 4 wheeled electric vehicled

-

How do I choose the right supplier for 4-wheeled electric vehicles?

Selecting the right supplier involves assessing their experience, product quality, and compliance with international standards. Start by verifying their certifications, such as ISO 9001 or CE marking, which indicate adherence to quality management systems. Additionally, request samples and customer references to gauge product performance. Evaluate their production capacity to ensure they can meet your order quantities and timelines. Finally, consider suppliers who offer comprehensive after-sales support, including warranties and maintenance services, to ensure a smooth operational partnership. -

What are the typical payment terms for purchasing 4-wheeled electric vehicles in B2B transactions?

Payment terms can vary significantly depending on the supplier and the region. Common terms include a 30% deposit upon order confirmation, with the remaining balance due before shipment or upon delivery. Some suppliers may offer more flexible terms, such as letter of credit or escrow services, particularly for larger orders. It’s essential to negotiate terms that balance risk and cash flow, ensuring that both parties are protected. Always review the supplier’s payment policies and any associated fees to avoid surprises. -

What minimum order quantities (MOQ) should I expect when sourcing electric vehicles?

Minimum order quantities can vary widely based on the supplier and the specific vehicle model. Generally, MOQs for 4-wheeled electric vehicles may range from 10 to 100 units for standard models, while custom specifications could require higher quantities. It’s advisable to discuss your needs directly with suppliers to negotiate MOQs that align with your business requirements. Some suppliers may offer flexibility, especially for first-time buyers or long-term partnerships, so be sure to explore these options. -

What customization options are available for 4-wheeled electric vehicles?

Many manufacturers offer a range of customization options, including color, battery capacity, and specialized features such as enhanced off-road capabilities or luxury interiors. Customization can also extend to branding, allowing you to incorporate your company’s logo and design elements. When discussing customization, be clear about your requirements and budget, as some modifications may impact lead times and costs. Engage with suppliers early in the design process to ensure that your specifications are feasible and align with production capabilities. -

How can I ensure quality assurance (QA) for my electric vehicle purchases?

To ensure quality assurance, request detailed documentation from your supplier regarding their QA processes, including inspection reports and testing certifications. Conduct factory audits or inspections to verify compliance with quality standards during production. Many suppliers will provide warranties or guarantees, which can serve as additional assurance of product quality. Establish clear communication channels with your supplier for reporting and resolving any quality issues that may arise post-delivery. -

What logistics considerations should I keep in mind when importing electric vehicles?

When importing 4-wheeled electric vehicles, consider shipping methods, customs regulations, and potential tariffs. Choose between sea freight for cost-effectiveness or air freight for speed, depending on your timeline and budget. Research the import regulations specific to your country, as electric vehicles may have unique compliance requirements. Collaborate with a logistics provider experienced in handling automotive imports to navigate the complexities of customs clearance and ensure timely delivery. -

What are the key advantages of 4-wheeled electric vehicles for businesses?

4-wheeled electric vehicles offer several advantages, including reduced operational costs due to lower fuel and maintenance expenses. They are environmentally friendly, aligning with global sustainability goals, which can enhance your brand image. Additionally, electric vehicles often provide advanced technology features, such as regenerative braking and connectivity options, improving overall user experience. For businesses, these benefits can translate into long-term savings and a competitive edge in the market. -

How do I assess the total cost of ownership (TCO) for electric vehicles?

To assess the total cost of ownership for 4-wheeled electric vehicles, consider not only the initial purchase price but also ongoing costs such as charging infrastructure, maintenance, insurance, and potential tax incentives. Evaluate the vehicle’s energy efficiency and expected battery life to estimate energy costs over time. Additionally, factor in resale value and any applicable incentives or rebates for electric vehicle purchases in your region. Conducting a TCO analysis will provide a comprehensive view of the financial implications of your investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 4 Wheeled Electric Vehicled Manufacturers & Suppliers List

1. CycleBoard – X-Quad 3000 All-Terrain Electric Vehicle

Domain: cycleboard.com

Registered: 2005 (20 years)

Introduction: {“name”:”X-Quad 3000 All-terrain 4 wheeled Electric Vehicle”,”price”:”$4095.00″,”top_speed”:”27 MPH*”,”motor_power”:”Dual 1500W Motors (3000w)”,”range”:”50 miles+ per charge”,”hill_climbing”:”Inclines up to 30%*”,”warranty”:”36-month warranty on frame, handle, motor & most major components”,”features”:[{“feature”:”4-wheel independent double wishbone suspension”},{“feature”:”Golf Mode for optimized…

2. Subaru – Solterra, Mercedes – G 580 EQ

Domain: drivingelectric.com

Registered: 2009 (16 years)

Introduction: 1. Subaru Solterra: Prices from £52,495, Maximum WLTP combined range: 289 miles, Features: four-wheel drive, off-road-oriented features, X-MODE, Grip Control, 150kW charging capability.

2. Mercedes G 580 with EQ Technology: Prices from £180,860, Maximum WLTP combined range: 285 miles, Power: 579bhp, Torque: 1,164Nm, 0-62mph in 4.7 seconds, 112kWh battery, 200kW peak charging speed.

3. Kia EV9: Pri…

3. AEMotion – Tilting Electric Vehicle

Domain: newatlas.com

Registered: 1999 (26 years)

Introduction: The AEMotion tilting electric vehicle features a top speed of 115 km/h (71.5 mph) and a maximum lean angle of 35 degrees. It measures 2.3 x 0.79 x 1.71 meters and weighs 230 kg (including batteries). The vehicle is equipped with a fixed battery providing up to 200 km (124 miles) per charge, along with swappable battery units offering 70 km (43.5 miles) each. It is steered using a motorcycle-style …

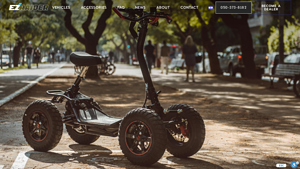

4. EZ Raider – Electric All-Terrain Vehicles

Domain: ezraider.com

Registered: 2015 (10 years)

Introduction: EZ Raider is a strong, lightweight, electric-powered ATV designed for off-road mobility. Key models include:

– EZRaider LW: A lightweight electric ATV suitable for various terrains.

– EZRaider HD2: A heavy-duty all-terrain model with rear-wheel drive (RWD) and a 9,000W motor, capable of handling sand, mud, rocks, and snow.

– EZRaider HD4: The most powerful model with an 18,000W motor and 4X4 ca…

5. BMW – 2025 iX

Domain: cars.usnews.com

Registered: 1995 (30 years)

Introduction: [{‘model’: ‘2025 BMW iX’, ‘price’: ‘$87,250’, ‘overall_score’: ‘8.9/10’, ‘battery’: ‘111.5-kWh’, ‘horsepower’: ‘516 or 610’, ‘features’: [‘12.3-inch digital instrument cluster’, ‘heated steering wheel’, ‘quad-zone automatic climate control’]}, {‘model’: ‘2025 Rivian R1S’, ‘price’: ‘$75,900’, ‘overall_score’: ‘8.9/10’, ‘horsepower’: ‘533 (base) to 1,025 (Quad-Motor)’, ‘features’: [‘vegan leather in…

6. Reddit – Electric Vehicles for Off-Road Enthusiasts

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the practicality of electric vehicles (EVs) for 4×4 and off-road enthusiasts. Key points include concerns about the lack of charging infrastructure for off-road use, the potential for EVs to offer great range during slow driving, and mentions of upcoming electric models from Jeep and Toyota. The conversation highlights the unique challenges and considerations for off…

7. Polaris – Key Off-Road Models

Domain: polaris.com

Registered: 1992 (33 years)

Introduction: {“models”:[{“name”:”2026 RANGER 1000″,”starting_price”:”$14,299″,”seating_options”:”3 Seat – 6 Seat”},{“name”:”2026 GENERAL XP 1000″,”starting_price”:”$23,999″,”seating_options”:”2 Seat – 4 Seat”},{“name”:”2025 RZR XP”,”starting_price”:”$19,999″,”seating_options”:”2 Seat – 4 Seat”},{“name”:”2026 SPORTSMAN 570″,”starting_price”:”$7,999″,”seating_options”:”1 Seat”},{“name”:”2025 RANGER XD 1500 NORTH…

8. Life4 – Four-Wheel Electric Vehicle

Domain: iamelectric.eu

Introduction: Life4 four-wheel electric vehicle

– Price: Original price 2,300.00 €, Current price 1,850.00 €

– Warranty: 24 months

– Motor: 500W

– Battery: Gel, 60V 20Ah

– Battery charging time: 6-8 hours

– Battery life: 500 cycles

– Maximum speed: 25 km/h

– Maximum range: up to 50 km (1 person, 70kg)

– Weight: 92 kg

– Permissible gross weight: 221 kg

– Dimensions: 1480x650x1200 mm

– Brakes: Front/Rear – Drums

…

Strategic Sourcing Conclusion and Outlook for 4 wheeled electric vehicled

In conclusion, the strategic sourcing of four-wheeled electric vehicles (EVs) presents a unique opportunity for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Key takeaways include the increasing demand for all-wheel drive capabilities, which provide enhanced performance in diverse terrains and conditions, an essential consideration for buyers in rural and off-road markets. Furthermore, the evolving landscape of electric vehicle technology highlights the importance of sourcing vehicles that balance range, charging speed, and overall value.

As the market continues to innovate, investing in strategic sourcing will allow businesses to stay ahead of competition while meeting the growing consumer demand for sustainable transport solutions. Buyers should prioritize partnerships with manufacturers committed to quality and reliability, ensuring a robust supply chain that can adapt to market changes.

Looking forward, the global shift toward electric mobility is not just a trend but a fundamental change in transportation. International B2B buyers are encouraged to engage with suppliers early, explore the latest offerings, and leverage emerging technologies to enhance their fleets. Embrace this transformative journey and position your business as a leader in the electric vehicle market.