Introduction: Navigating the Global Market for electric vehicle transaxle

The global market for electric vehicle transaxles is rapidly evolving, presenting both opportunities and challenges for B2B buyers in regions like Africa, South America, the Middle East, and Europe. As the demand for electric and hybrid vehicles increases, sourcing efficient electric transaxles has become critical for manufacturers and suppliers aiming to enhance vehicle performance and sustainability. This comprehensive guide delves into the intricacies of electric vehicle transaxles, exploring various types, their applications across different sectors, and essential supplier vetting processes.

Understanding the complexities involved in selecting the right transaxle can significantly impact operational efficiency and cost-effectiveness. This guide empowers international B2B buyers by providing actionable insights into pricing structures, technological advancements, and market trends. By navigating through detailed sections covering the benefits of different transaxle designs, compatibility with electric motors, and emerging applications in commercial transport, readers will be equipped to make informed purchasing decisions.

Moreover, as electric mobility continues to gain traction, recognizing the specific needs of diverse markets—such as those in Nigeria and Vietnam—will be crucial for successful procurement strategies. This resource serves as a vital tool for stakeholders looking to stay ahead in a competitive landscape, ensuring they can leverage the latest innovations in electric vehicle technology while aligning with their business goals.

Understanding electric vehicle transaxle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Integrated Electric Transaxle | Combines motor, gearbox, and differential in one unit | Passenger vehicles, light commercial vehicles | Pros: Space-saving, efficient power distribution. Cons: Higher initial cost. |

| Multi-speed Electric Transaxle | Offers multiple gear ratios for varied performance | Performance EVs, high-speed applications | Pros: Enhanced performance and efficiency. Cons: Increased complexity and weight. |

| Single-speed Electric Transaxle | Features a fixed gear ratio for simplicity | Urban delivery vehicles, low-speed applications | Pros: Simplified design, lower maintenance. Cons: Limited performance range. |

| High-torque Electric Transaxle | Designed for heavy-duty applications with high torque output | Commercial trucks, off-road vehicles | Pros: Robust performance, suitable for heavy loads. Cons: Heavier and less efficient at lower speeds. |

| Modular Electric Transaxle | Customizable components for specific vehicle needs | Specialty vehicles, agricultural machines | Pros: Flexibility in design, tailored solutions. Cons: Potentially longer lead times for customization. |

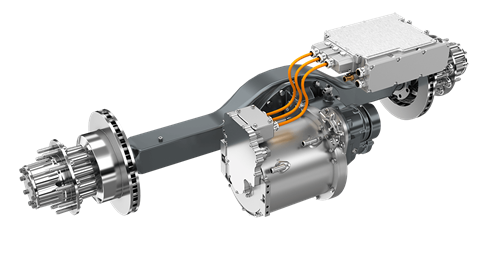

What are the Characteristics of Integrated Electric Transaxles?

Integrated electric transaxles are compact systems that combine the electric motor, gearbox, and differential into a single unit. This design significantly reduces the number of components, leading to lighter vehicles and improved efficiency. They are particularly suitable for passenger vehicles and light commercial vehicles where space is a premium. B2B buyers should consider the trade-off between initial costs and long-term savings in maintenance and energy efficiency.

How Do Multi-speed Electric Transaxles Enhance Performance?

Multi-speed electric transaxles feature several gear ratios, allowing for optimized performance across various driving conditions. This type is ideal for performance electric vehicles and applications requiring high-speed capabilities. B2B purchasers should weigh the advantages of enhanced performance against the increased complexity and potential weight that may affect overall vehicle efficiency.

Why Choose Single-speed Electric Transaxles for Urban Applications?

Single-speed electric transaxles utilize a fixed gear ratio, making them a straightforward and cost-effective solution for urban delivery vehicles and low-speed applications. Their simplicity leads to lower maintenance needs and reduced costs. However, B2B buyers must acknowledge that this simplicity comes at the expense of performance range, which may not be suitable for all operational needs.

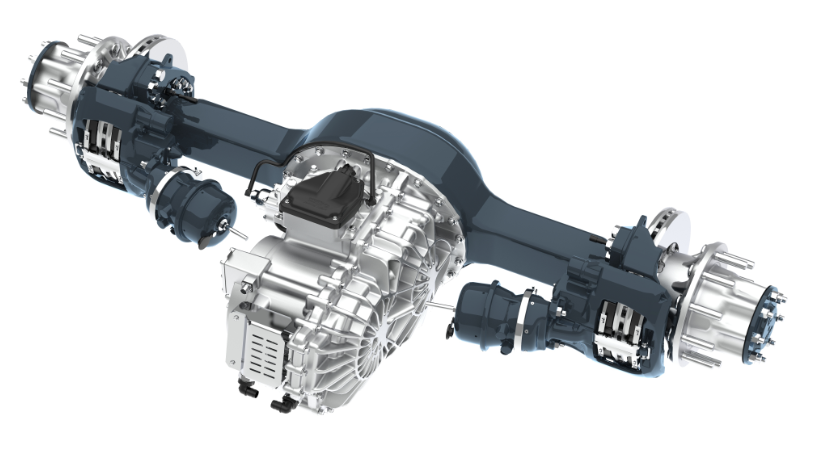

What Makes High-torque Electric Transaxles Suitable for Heavy-duty Applications?

High-torque electric transaxles are engineered to handle demanding applications, providing substantial torque output necessary for commercial trucks and off-road vehicles. Their robust design allows for effective performance under heavy loads. Buyers in the commercial sector should consider the benefits of durability and power against potential inefficiencies at lower speeds, which may impact fuel consumption.

How Can Modular Electric Transaxles Cater to Specialty Needs?

Modular electric transaxles offer customization options, allowing manufacturers to tailor components according to specific vehicle requirements. This flexibility makes them ideal for specialty vehicles and agricultural machines. B2B buyers should evaluate the benefits of tailored solutions against the potential for longer lead times, which could affect project timelines and delivery schedules.

Key Industrial Applications of electric vehicle transaxle

| Industry/Sector | Specific Application of electric vehicle transaxle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Electric tractors and farming equipment | Enhances fuel efficiency and reduces operational costs | Compatibility with existing systems and local terrain |

| Public Transportation | Electric buses and shuttles | Lower emissions and operational costs | Compliance with local regulations and maintenance support |

| Logistics and Warehousing | Automated guided vehicles (AGVs) | Increases efficiency and reduces labor costs | Durability and reliability under heavy loads |

| Construction | Electric construction vehicles | Improves site safety and reduces environmental impact | Power requirements and adaptability to various terrains |

| E-mobility Solutions | Electric bikes and scooters | Expands urban mobility options and reduces congestion | Battery integration and lightweight design |

How is Electric Vehicle Transaxle Used in Agriculture?

In the agriculture sector, electric vehicle transaxles are increasingly utilized in electric tractors and farming equipment. These transaxles enable seamless integration of electric motors with traditional agricultural machinery, leading to enhanced fuel efficiency and reduced operational costs. For international buyers, especially in regions like Africa and South America, sourcing transaxles that can handle diverse terrains and varying load capacities is crucial. Additionally, compatibility with existing systems and ease of maintenance are key considerations.

What Role Does Electric Vehicle Transaxle Play in Public Transportation?

Electric buses and shuttles leverage electric vehicle transaxles to optimize their powertrains. By integrating the electric motor with the transmission and differential, these vehicles can achieve lower emissions and significantly reduce operational costs. For B2B buyers in the Middle East and Europe, compliance with local environmental regulations is paramount, alongside the need for robust maintenance support to ensure long-term reliability in public transport operations.

How are Electric Vehicle Transaxles Enhancing Logistics and Warehousing?

In logistics and warehousing, electric vehicle transaxles are vital for automated guided vehicles (AGVs). These systems rely on efficient power transmission to navigate complex environments, increasing operational efficiency and reducing labor costs. Buyers from regions such as Africa and South America should prioritize sourcing transaxles that demonstrate high durability and reliability, particularly under heavy loads, to minimize downtime and enhance productivity.

What Benefits Do Electric Vehicle Transaxles Offer in Construction?

Electric construction vehicles utilize electric vehicle transaxles to improve site safety and reduce environmental impact. The integration of electric motors allows for quieter operation and zero emissions, which is particularly beneficial in urban construction settings. Buyers in Europe and the Middle East must consider the power requirements of their projects and the adaptability of transaxles to various terrains to ensure optimal performance in diverse construction environments.

How are Electric Vehicle Transaxles Transforming E-Mobility Solutions?

In the e-mobility sector, electric bikes and scooters are increasingly equipped with electric vehicle transaxles. This integration enhances the vehicles’ performance and range while providing a compact design ideal for urban commuting. For international buyers, sourcing transaxles that support battery integration and feature lightweight designs is essential to meet the growing demand for efficient and sustainable urban mobility solutions.

3 Common User Pain Points for ‘electric vehicle transaxle’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality Electric Vehicle Transaxles

The Problem: B2B buyers often struggle to find reliable suppliers of electric vehicle transaxles that meet their quality standards. In regions like Africa and South America, where the EV market is still developing, buyers may encounter challenges such as limited supplier options, inconsistent product quality, and insufficient technical support. This can lead to concerns about product reliability, which is crucial for maintaining fleet operations or meeting customer expectations in competitive markets.

The Solution: To overcome sourcing challenges, B2B buyers should prioritize building relationships with reputable manufacturers that specialize in electric vehicle components. Start by conducting thorough research to identify suppliers with a proven track record in the industry. Look for certifications and industry standards that their products adhere to, which can be a strong indicator of quality. Additionally, consider engaging in direct communication with potential suppliers to discuss their production processes and quality control measures. Request samples or prototypes to evaluate performance before making bulk purchases. Joining industry associations or participating in trade shows can also provide valuable networking opportunities to connect with reliable suppliers.

Scenario 2: Integration Challenges with Existing Vehicle Platforms

The Problem: Integrating electric vehicle transaxles into existing vehicle platforms poses significant technical challenges for manufacturers. Buyers often face difficulties in ensuring compatibility between the transaxle and other vehicle systems such as battery management and power electronics. This is particularly relevant for companies in regions with a growing interest in retrofitting conventional vehicles for electric use, where mismatches can lead to performance issues and increased costs.

The Solution: To facilitate smoother integration, it is essential to engage in thorough pre-integration planning. Buyers should work closely with the transaxle supplier to understand the specifications and operational requirements of the unit. Collaborating with engineering teams can help in adapting existing vehicle designs to accommodate the new transaxle. Utilizing simulation software can also provide insights into how the transaxle will perform within the vehicle’s powertrain, allowing for necessary adjustments before physical integration. Furthermore, investing in training for technical staff on the latest electric vehicle technologies can enhance their capability to troubleshoot and optimize the integration process.

Scenario 3: Maintenance and Performance Optimization Concerns

The Problem: B2B buyers often face challenges related to the maintenance and performance optimization of electric vehicle transaxles. In regions with limited access to specialized service providers, maintaining optimal performance can be a daunting task. Buyers may experience issues such as reduced efficiency or unexpected breakdowns, which can lead to operational delays and increased costs.

The Solution: To address maintenance concerns effectively, buyers should establish a proactive maintenance schedule based on the manufacturer’s recommendations. This includes regular inspections and servicing of critical components like the electric motor and gearbox. Additionally, implementing remote monitoring technologies can help in diagnosing issues before they escalate, thus minimizing downtime. Buyers should also consider investing in partnerships with local service providers that can offer specialized training on electric vehicle maintenance. By ensuring that service teams are knowledgeable about the specific needs of electric transaxles, companies can enhance their operational efficiency and extend the lifespan of their vehicles.

Strategic Material Selection Guide for electric vehicle transaxle

What Are the Key Materials Used in Electric Vehicle Transaxles?

Electric vehicle transaxles are critical components that integrate various functions, including transmission, differential, and electric motor assembly. The selection of materials used in these transaxles significantly influences their performance, durability, and overall cost-effectiveness. Here, we analyze four common materials used in electric vehicle transaxles: aluminum alloys, steel, composites, and plastics.

How Do Aluminum Alloys Contribute to Electric Vehicle Transaxle Performance?

Aluminum alloys are widely used in the construction of electric vehicle transaxles due to their lightweight properties and excellent corrosion resistance. Key properties include a low density, good thermal conductivity, and the ability to withstand moderate temperatures and pressures.

Pros: The primary advantages of aluminum alloys are their lightweight nature, which contributes to improved vehicle efficiency and range, and their resistance to corrosion, which enhances durability.

Cons: However, aluminum alloys can be more expensive than traditional steel options, and they may require more complex manufacturing processes, such as precision machining, which can increase production costs.

Impact on Application: Aluminum’s compatibility with electric components is beneficial, as it minimizes electromagnetic interference.

Considerations for International Buyers: Buyers in regions like Africa and South America should consider local availability and cost variations, as well as compliance with international standards such as ASTM for material specifications.

What Role Does Steel Play in Electric Vehicle Transaxles?

Steel is another commonly used material in electric vehicle transaxles, particularly for components that require high strength and durability. It offers excellent mechanical properties, including high tensile strength and resistance to deformation under load.

Pros: Steel’s durability and cost-effectiveness make it a popular choice for heavy-duty applications. It can also be treated to improve corrosion resistance, enhancing its lifespan in various environments.

Cons: On the downside, steel is significantly heavier than aluminum, which can negatively impact the overall weight of the vehicle, reducing efficiency. Additionally, steel components may require further treatment or coatings to prevent rusting, which adds to manufacturing complexity.

Impact on Application: Steel’s strength is advantageous for components subjected to high stress, but its weight can limit application in lightweight electric vehicles.

Considerations for International Buyers: Buyers should ensure that the steel grades used comply with regional standards, such as DIN in Europe or JIS in Japan, to ensure quality and performance.

How Do Composites Enhance Electric Vehicle Transaxle Design?

Composites, particularly fiber-reinforced plastics, are increasingly being explored for use in electric vehicle transaxles. These materials offer a unique combination of lightweight properties and high strength.

Pros: The main advantage of composites is their lightweight nature, which can significantly reduce the overall weight of the transaxle, improving vehicle efficiency. They also offer excellent corrosion resistance and can be molded into complex shapes.

Cons: However, composites can be more expensive to produce and may have lower thermal stability compared to metals, which can limit their use in high-temperature applications.

Impact on Application: Composites are particularly suitable for non-structural components where weight savings are critical, but their thermal limitations must be considered.

Considerations for International Buyers: Buyers should assess the availability of composite materials in their regions and ensure compliance with relevant standards for performance and safety.

What Advantages Do Plastics Offer in Electric Vehicle Transaxles?

Plastics, especially engineering-grade thermoplastics, are sometimes used for non-load-bearing components in electric vehicle transaxles. They are lightweight and can be easily molded into intricate designs.

Pros: The key advantages of plastics include their low weight, cost-effectiveness, and resistance to corrosion. They also provide good insulation properties, which are beneficial in electric applications.

Cons: However, plastics generally have lower mechanical strength and thermal resistance compared to metals, which can limit their application in high-stress environments.

Impact on Application: Plastics are suitable for components that do not bear heavy loads but require good insulation and corrosion resistance.

Considerations for International Buyers: Buyers should be aware of the specific grades of plastics that meet international standards and are suitable for automotive applications, particularly regarding temperature and stress resistance.

Summary of Material Selection for Electric Vehicle Transaxles

| Material | Typical Use Case for electric vehicle transaxle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Housing and structural components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | Medium |

| Steel | Load-bearing components | High strength and durability | Heavier, requires corrosion treatment | Low |

| Composites | Non-structural components | Lightweight and moldable | Higher cost, lower thermal stability | High |

| Plastics | Insulation and non-load-bearing parts | Cost-effective and corrosion-resistant | Lower strength and thermal resistance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions when sourcing materials for electric vehicle transaxles.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle transaxle

What Are the Key Manufacturing Processes for Electric Vehicle Transaxles?

Manufacturing electric vehicle transaxles involves several critical stages, each designed to ensure that the final product meets the high-performance and quality standards required in the automotive industry. The main stages of manufacturing include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Vehicle Transaxles?

The manufacturing process begins with material preparation, where high-grade materials are sourced based on the specific requirements of the transaxle design. Common materials include aluminum and high-strength steel, chosen for their lightweight properties and durability. Advanced techniques such as computer-aided design (CAD) and computer-aided manufacturing (CAM) are employed to optimize the design for manufacturability, ensuring that components can be produced efficiently and accurately.

What Forming Techniques Are Used in Transaxle Manufacturing?

Once materials are prepared, the next stage is forming. This involves various techniques such as casting, forging, and machining. Casting processes, like die-casting and sand casting, are commonly used to create complex geometries for components like the housing and gearbox. Forging may be employed for parts requiring high strength, such as shafts and gears. Precision machining is then utilized to achieve the necessary tolerances and surface finishes, critical for the efficient operation of the transaxle.

How Is Assembly Conducted for Electric Vehicle Transaxles?

The assembly stage integrates all components into a cohesive unit. This process may involve automated assembly lines, where robotic systems ensure high accuracy and efficiency. Key components, including the electric motor, gearbox, and differential, are assembled using precise alignment techniques to minimize friction and wear during operation. Additionally, torque specifications are strictly adhered to, ensuring that all fasteners are secured to the manufacturer’s standards.

What Finishing Processes Are Essential for Transaxle Quality?

Finishing processes play a vital role in enhancing the performance and longevity of electric vehicle transaxles. These processes may include surface treatment, coating, and quality inspection. Surface treatments, such as anodizing or powder coating, are applied to prevent corrosion and improve wear resistance. Each transaxle undergoes a thorough inspection to confirm that all specifications and tolerances are met before moving to the quality assurance stage.

What Quality Assurance Standards Are Relevant for Electric Vehicle Transaxles?

Quality assurance is paramount in the manufacturing of electric vehicle transaxles. International standards, such as ISO 9001, ensure that manufacturers maintain consistent quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are crucial for compliance, especially for international buyers. These standards provide assurance that the products meet regulatory requirements and are safe for use.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure that any defects are identified and rectified early. Incoming Quality Control (IQC) assesses raw materials before they are used in production, while In-Process Quality Control (IPQC) monitors the manufacturing stages. Final Quality Control (FQC) involves comprehensive testing of the completed transaxles, including performance tests, dimensional checks, and functional assessments.

What Common Testing Methods Are Used for Electric Vehicle Transaxles?

Various testing methods are utilized to validate the performance and reliability of electric vehicle transaxles. These include:

- Functional Testing: Simulates real-world operating conditions to ensure performance meets specifications.

- Durability Testing: Assesses the transaxle’s ability to withstand long-term use and extreme conditions.

- Vibration Testing: Evaluates the transaxle’s performance under various vibration scenarios to identify potential failure points.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to verify the quality control practices of suppliers. This can include:

- Conducting Audits: Regular on-site audits allow buyers to assess the manufacturing processes and QC systems in place.

- Requesting Reports: Suppliers should provide documentation of their quality management practices, including inspection reports and compliance certificates.

- Utilizing Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the manufacturing processes and product quality.

What Are the Quality Control and Certification Nuances for International Buyers?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Regulatory requirements may vary significantly across regions, necessitating a thorough understanding of local standards and certifications. Buyers should ensure that suppliers are compliant with both international and local regulations, which can affect the import and sale of electric vehicle transaxles.

Furthermore, buyers should be aware of potential language barriers and cultural differences that may impact communication regarding quality standards. Establishing clear expectations and maintaining open lines of communication will help mitigate risks associated with cross-border transactions.

Conclusion: Ensuring Quality in Electric Vehicle Transaxles

In summary, the manufacturing processes and quality assurance practices for electric vehicle transaxles are complex and multifaceted. By understanding these processes, B2B buyers can make informed decisions when sourcing transaxles, ensuring that they partner with suppliers who prioritize quality, compliance, and reliability. Through rigorous verification of manufacturing and QC practices, international buyers can secure high-performance transaxles that meet the demands of modern electric vehicles.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle transaxle’

To assist B2B buyers in procuring electric vehicle transaxles, this practical sourcing guide provides a step-by-step checklist designed to streamline the selection process and ensure the acquisition of high-quality components.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your electric vehicle application is crucial. Consider parameters such as power output (e.g., 0.5 to 30 kW), torque ratings, and load capacity. Clearly defined specifications will help you identify suitable transaxles that meet your performance needs and align with your vehicle’s design.

Step 2: Research Industry Standards and Compliance

Before engaging with suppliers, familiarize yourself with the relevant industry standards and compliance requirements for electric vehicle components. Look for certifications such as ISO, SAE, or local regulations that ensure the product’s safety and performance. This knowledge will help you assess whether potential suppliers adhere to necessary quality benchmarks.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers who have a proven track record in manufacturing electric transaxles and can demonstrate their expertise through successful projects.

- Supplier Experience: Check how long they have been in the market and their experience with electric vehicle components.

- Technical Support: Ensure they offer robust technical support and after-sales service.

Step 4: Request Samples and Perform Testing

Once you have shortlisted potential suppliers, request product samples for evaluation. Testing these samples is vital to verify performance under real-world conditions. Consider factors such as efficiency, noise levels, and thermal management during your assessment.

- Performance Metrics: Measure key performance indicators relevant to your specifications.

- Compatibility Checks: Ensure that the transaxle integrates seamlessly with your existing vehicle systems.

Step 5: Analyze Pricing and Total Cost of Ownership

Cost is a significant factor in the procurement process. While comparing prices, consider the total cost of ownership, which includes initial purchase price, installation costs, maintenance, and potential energy savings over time. This comprehensive analysis will help you make informed financial decisions.

- Long-term Savings: Evaluate how the efficiency of the transaxle could lead to reduced operational costs.

- Warranty and Support: Consider the warranty terms and the supplier’s commitment to customer support.

Step 6: Verify Supply Chain Stability

Understanding the stability of your supplier’s supply chain is essential for ensuring consistent product availability. Investigate their sourcing practices, inventory management, and potential risks that could impact delivery times. A reliable supplier should have contingency plans to mitigate supply chain disruptions.

- Local vs. Global Suppliers: Assess the advantages of sourcing locally versus globally, particularly in terms of lead times and shipping costs.

- Lead Time Expectations: Clarify expected lead times for orders to align with your project timelines.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that all terms are clearly defined in the purchase agreement. This should include pricing, delivery schedules, warranty coverage, and return policies. Having a well-documented agreement protects both parties and sets clear expectations moving forward.

Following this structured approach will empower B2B buyers to make informed decisions when sourcing electric vehicle transaxles, ultimately leading to successful procurement outcomes.

Comprehensive Cost and Pricing Analysis for electric vehicle transaxle Sourcing

What Are the Key Cost Components in Electric Vehicle Transaxle Sourcing?

When sourcing electric vehicle transaxles, understanding the cost structure is crucial for international buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials, such as high-strength steel for the casing and lightweight composites for internal components, significantly impacts costs. Advanced materials enhance performance but can raise the price.

-

Labor: Labor costs vary by region. Skilled labor in manufacturing hubs can be more expensive, but it often results in higher quality production, thus affecting the overall cost structure.

-

Manufacturing Overhead: This includes utilities, facility costs, and equipment maintenance. Efficient manufacturing processes can reduce overhead costs, making it a crucial area for suppliers to optimize.

-

Tooling: The initial investment in specialized tooling for electric transaxle production is substantial. Custom tooling for unique designs or specifications can drive up costs, particularly for low-volume orders.

-

Quality Control: Implementing rigorous QC processes ensures product reliability and compliance with international standards. These costs are essential to factor in, especially for buyers in regions with stringent regulations.

-

Logistics: Shipping costs vary based on the Incoterms agreed upon and the distance from the supplier. For international buyers, understanding these logistics can lead to more efficient and cost-effective sourcing strategies.

-

Margin: Supplier margins will vary based on the competitive landscape, demand, and negotiation strength. Understanding typical margins in the market can help buyers gauge fair pricing.

How Do Price Influencers Affect the Cost of Electric Vehicle Transaxles?

Several key factors influence pricing beyond the basic cost components:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Higher volumes typically lead to lower per-unit costs, making it advantageous for buyers to negotiate bulk orders.

-

Specifications/Customization: Custom designs or specific performance requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Material Quality and Certifications: The inclusion of high-grade materials and necessary certifications (such as ISO) can add to costs but may be essential for compliance in certain markets.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can influence pricing. Established suppliers with a track record of quality may command higher prices but offer better reliability.

-

Incoterms: Understanding shipping terms is vital for managing costs. Incoterms dictate who bears the risk and costs during transport, impacting the total landed cost of the transaxles.

What Are the Best Negotiation Tips for B2B Buyers of Electric Vehicle Transaxles?

To secure the best pricing and terms, buyers should consider the following strategies:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate the long-term costs associated with maintenance, reliability, and efficiency. A higher upfront cost may be justified if the product leads to lower operational costs.

-

Leverage Volume for Negotiation: Utilize volume purchases to negotiate better pricing. Suppliers are often more willing to offer discounts for larger orders.

-

Request Multiple Quotes: Comparing offers from different suppliers can provide leverage in negotiations. It allows buyers to gauge market rates and negotiate better terms.

-

Be Transparent About Needs: Clearly communicating specific requirements and expectations can prevent misunderstandings and hidden costs later in the procurement process.

-

Stay Informed on Market Trends: Keeping abreast of developments in the electric vehicle industry can provide insights into pricing fluctuations and emerging technologies, which can be advantageous during negotiations.

Conclusion

Understanding the cost structure and price influencers for electric vehicle transaxles is essential for international B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe. By focusing on these elements and employing effective negotiation strategies, buyers can secure advantageous deals while ensuring the quality and performance of their electric vehicle components.

Disclaimer: Prices and cost structures can vary widely based on market conditions, supplier capabilities, and specific buyer requirements. Always conduct thorough market research and consult multiple suppliers to obtain the most accurate pricing information.

Alternatives Analysis: Comparing electric vehicle transaxle With Other Solutions

Exploring Alternatives to Electric Vehicle Transaxles: A Comparative Analysis

In the rapidly evolving landscape of electric vehicle (EV) technology, electric vehicle transaxles stand out for their efficiency and compact design. However, several alternative solutions also address similar needs within the automotive and mobility sectors. Understanding these alternatives is crucial for B2B buyers aiming to make informed decisions tailored to their operational requirements and market demands.

| Comparison Aspect | Electric Vehicle Transaxle | Hub Motors | Conventional Transmission Systems |

|---|---|---|---|

| Performance | High torque delivery, efficient power distribution | Instant torque, high efficiency in small applications | Variable torque, often less efficient in hybrids |

| Cost | Moderate to high initial investment | Lower initial costs, but may need multiple units for larger vehicles | Generally lower upfront costs but can incur higher maintenance costs |

| Ease of Implementation | Requires integration into the vehicle design | Simple installation, often retrofittable | Complex installation, requires skilled labor |

| Maintenance | Low maintenance due to fewer moving parts | Moderate maintenance, potential for wear in multiple motors | Higher maintenance needs, more moving parts and systems |

| Best Use Case | Ideal for hybrid and electric vehicles requiring compact designs | Best for light electric vehicles (e-bikes, scooters) | Suitable for traditional internal combustion engine vehicles |

Analyzing Hub Motors as an Alternative to Electric Vehicle Transaxles

Pros: Hub motors are located within the wheel hub, providing direct drive and eliminating the need for complex drivetrain components. They deliver instant torque, making them highly efficient for small electric vehicles such as e-bikes and scooters. The simplicity of their design allows for easier retrofitting into existing vehicles, which can be a significant advantage in markets seeking to upgrade without extensive modifications.

Cons: While hub motors are cost-effective for smaller applications, scaling them for larger vehicles can become expensive, as multiple units may be required. Additionally, they may not deliver the same performance characteristics as transaxles in terms of torque and power distribution in larger electric vehicles.

Evaluating Conventional Transmission Systems

Pros: Traditional transmission systems have been optimized over decades for internal combustion engines and can be less expensive to implement in vehicles already designed for them. They are widely understood and supported by existing infrastructure and service networks, making them a familiar choice for many manufacturers.

Cons: However, conventional systems are generally less efficient when integrated into hybrid or electric vehicles. They consist of more moving parts, leading to higher maintenance costs and potential reliability issues. Moreover, they do not provide the same level of torque delivery and power efficiency as electric vehicle transaxles, which can limit vehicle performance.

Conclusion: How to Choose the Right Solution for Your Needs

When evaluating alternatives to electric vehicle transaxles, B2B buyers should consider their specific use cases, budget constraints, and long-term operational goals. Electric vehicle transaxles offer high performance and efficiency for hybrid and electric vehicles, while hub motors may be more suitable for lighter applications. Conventional transmission systems might still hold value in traditional vehicle designs, but they may not be the best fit for the future of mobility. By carefully analyzing these factors, buyers can select the most appropriate technology to enhance their vehicle offerings and align with market trends.

Essential Technical Properties and Trade Terminology for electric vehicle transaxle

What Are the Key Technical Properties of Electric Vehicle Transaxles?

When evaluating electric vehicle transaxles, understanding specific technical properties is essential for B2B buyers. These properties not only influence performance but also impact the overall cost and reliability of the vehicle. Below are critical specifications that should be considered:

1. Power Rating (kW)

The power rating, measured in kilowatts (kW), indicates the maximum power output of the electric motor integrated within the transaxle. A higher power rating typically translates to better acceleration and overall vehicle performance. For B2B buyers, selecting a transaxle with an appropriate power rating is crucial to match the vehicle’s intended application, whether it’s for passenger cars, commercial transport, or specialized machinery.

2. Torque Output (Nm)

Torque, measured in Newton-meters (Nm), reflects the rotational force produced by the electric motor. This specification is vital for understanding how quickly the vehicle can accelerate and how well it can handle different loads. For buyers, knowing the torque output helps in assessing the transaxle’s suitability for specific driving conditions and operational requirements.

3. Load Capacity (kg)

The load capacity refers to the maximum weight the transaxle can support while maintaining optimal performance. This metric is particularly important for commercial applications where vehicles may carry heavy loads. A transaxle with a higher load capacity ensures durability and efficiency, reducing the risk of mechanical failure.

4. Gear Ratio

The gear ratio determines how power is transferred from the motor to the wheels, influencing speed and acceleration. A carefully selected gear ratio can enhance vehicle efficiency and performance. For B2B buyers, understanding gear ratios allows for better alignment of transaxle selection with vehicle design and operational needs.

5. Material Grade

The material grade of the components within the transaxle affects its strength, weight, and resistance to wear. Common materials include aluminum and high-strength steel, which offer a balance of durability and weight savings. Selecting a transaxle with suitable material grades is essential for ensuring long-term reliability and performance in various environments.

What Are Common Trade Terms in the Electric Vehicle Transaxle Industry?

Familiarity with industry terminology is equally important for B2B buyers involved in the procurement process. Here are several key terms that are frequently encountered:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that may be marketed by another company under its brand name. In the context of electric vehicle transaxles, understanding OEM relationships helps buyers identify reliable suppliers and ensure compatibility with existing vehicle designs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. Knowing the MOQ is crucial for businesses to plan their inventory and budget accordingly. This term is particularly significant for smaller manufacturers looking to enter the electric vehicle market.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing information for specific products or services. For buyers, submitting an RFQ helps in comparing prices and terms from different suppliers, ensuring they get the best deal for electric vehicle transaxles.

4. Incoterms (International Commercial Terms)

Incoterms are standardized international shipping terms that define the responsibilities of buyers and sellers in a transaction. Understanding these terms is vital for B2B transactions involving electric vehicle transaxles, as they dictate who bears the risk and cost at various stages of shipping.

5. Lead Time

Lead time refers to the time taken from placing an order to the delivery of goods. This term is critical for buyers in planning their production schedules and ensuring timely availability of electric vehicle components.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market demands in the growing electric vehicle industry.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle transaxle Sector

What Are the Key Market Dynamics and Trends in the Electric Vehicle Transaxle Sector?

The electric vehicle (EV) transaxle market is witnessing significant growth driven by global trends toward sustainability and electrification. Key factors propelling this market include increasing demand for electric and hybrid vehicles, advancements in battery technology, and government regulations aimed at reducing carbon emissions. In regions such as Africa, South America, the Middle East, and Europe, the push for cleaner transportation solutions is leading to heightened investments in electric vehicle infrastructure. This is particularly evident in countries like Nigeria and Vietnam, where urbanization is driving the need for efficient and sustainable transport options.

Emerging sourcing trends include a shift toward integrated solutions that combine electric motors, gearboxes, and differential systems into single units. This trend not only enhances efficiency but also simplifies the supply chain for B2B buyers. Furthermore, as manufacturers prioritize modular designs, international buyers can expect more customizable options that cater to specific vehicle requirements. Collaborations between traditional automotive suppliers and tech companies are also on the rise, promoting innovations such as smart transaxles equipped with IoT capabilities for real-time performance monitoring.

How Is Sustainability and Ethical Sourcing Addressed in the Electric Vehicle Transaxle Market?

Sustainability is a paramount concern in the electric vehicle transaxle sector. The environmental impact of sourcing materials, particularly rare earth elements used in electric motors, is increasingly scrutinized. B2B buyers are urged to partner with suppliers who demonstrate a commitment to ethical sourcing practices, including transparency in their supply chains. Certifications such as ISO 14001 (Environmental Management) and adherence to the Responsible Minerals Initiative can serve as indicators of a supplier’s dedication to sustainability.

Moreover, the use of recycled materials in the production of transaxles is gaining traction, aligning with the broader industry shift towards circular economy principles. Buyers should prioritize suppliers who utilize ‘green’ materials and eco-friendly manufacturing processes to minimize the ecological footprint of their products. This focus not only contributes to the reduction of waste and resource consumption but also enhances brand reputation among environmentally conscious consumers.

What Is the Brief Evolution of Electric Transaxles and Its Significance for B2B Buyers?

The electric transaxle has evolved significantly since its inception, becoming a critical component in modern electric and hybrid vehicles. Initially adopted in niche applications, the technology has matured, driven by the need for more efficient powertrains. The integration of the electric motor, transmission, and differential into a single assembly has transformed vehicle design, allowing for lighter, more compact configurations.

For B2B buyers, understanding this evolution is crucial for making informed sourcing decisions. The shift towards more integrated and efficient systems offers opportunities for cost savings and improved vehicle performance. As the market continues to innovate, buyers can leverage advancements in electric transaxle technology to enhance their product offerings and meet the growing demand for sustainable transportation solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle transaxle

-

How do I solve compatibility issues when sourcing electric vehicle transaxles?

To address compatibility concerns, it is crucial to provide detailed specifications of your vehicle’s powertrain requirements to potential suppliers. This includes parameters such as power output, torque, and dimensions. Collaborate closely with the supplier to ensure the transaxle meets your specific needs, and consider requesting prototypes or samples for testing. Additionally, reviewing technical documentation and certifications can help confirm compatibility with your vehicle’s design. -

What is the best electric vehicle transaxle for commercial applications?

The optimal electric vehicle transaxle for commercial use typically features a robust design with high power and torque ratings, allowing for efficient performance under load. Look for transaxles that integrate advanced technologies, such as locking differentials and integrated braking systems, which enhance vehicle control and safety. Evaluate options based on the specific demands of your application, such as load capacity and terrain, and consult with manufacturers for tailored solutions. -

How can I assess the reliability of a supplier for electric vehicle transaxles?

To evaluate a supplier’s reliability, consider their industry experience, customer reviews, and certifications. Request references from other clients in similar markets and assess their track record in delivering quality products on time. Additionally, visiting their manufacturing facilities or requesting quality assurance documentation can provide insights into their production processes and adherence to international standards. -

What customization options are available for electric vehicle transaxles?

Many suppliers offer customization options to meet specific performance and design requirements. Customization may include adjustments in gear ratios, power output, or the integration of additional features such as regenerative braking systems. When discussing customization, provide your specifications clearly and inquire about the feasibility, lead times, and associated costs to ensure the final product aligns with your vehicle’s needs. -

What are the typical minimum order quantities (MOQs) for electric vehicle transaxles?

Minimum order quantities for electric vehicle transaxles can vary widely depending on the manufacturer and the complexity of the product. Generally, MOQs can range from a few units for standard models to several hundred for specialized designs. When negotiating with suppliers, clarify their MOQ policies and explore opportunities for smaller initial orders, especially if you are testing a new product line or market. -

What payment terms should I expect when sourcing electric vehicle transaxles internationally?

Payment terms can differ based on supplier policies and the nature of the transaction. Common arrangements include advance payments, partial upfront payments with balance upon delivery, or net 30/60 days after receipt of goods. It is advisable to negotiate terms that align with your cash flow needs while ensuring the supplier feels secure in the transaction. Consider using secure payment methods like letters of credit for larger orders. -

How do I ensure quality assurance for electric vehicle transaxles?

To guarantee quality assurance, request detailed quality control processes and certifications from suppliers. Ask for documentation on testing procedures, including performance benchmarks and compliance with international standards. Additionally, conducting third-party inspections or audits can provide further assurance that the transaxles meet your quality expectations before shipment. -

What logistics considerations should I keep in mind when importing electric vehicle transaxles?

When importing electric vehicle transaxles, consider shipping methods, lead times, and customs regulations that may affect delivery. Collaborate with logistics partners who are familiar with handling automotive components to ensure proper handling and compliance. Additionally, account for potential tariffs, duties, and insurance costs, and maintain clear communication with your supplier regarding shipping schedules to avoid delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Electric Vehicle Transaxle Manufacturers & Suppliers List

1. E-Comer – Electric Transaxles

Domain: e-comer.com

Registered: 2023 (2 years)

Introduction: Electric Transaxles for Construction, Agriculture, eMobility, Cleaning, Material Handling sectors. Battery Powered Axles with power from 0.5 to 30kW. Scalable drivetrain system for electric vehicles. Compact gearboxes include differential (optional locking), rigid axle, brake system, and electric motor in an all-in-one solution for quick vehicle installation.

2. Rotontek – Electric Transaxle Solutions

Domain: rotontek.com

Registered: 2016 (9 years)

Introduction: An electric transaxle is a vital component in hybrid and fully electric vehicles, integrating the functionalities of the transmission, differential, and drive axles with an electric motor. It improves power efficiency and is essential for the functioning of modern electric and hybrid vehicles. Key components include the electric motor, transmission or gearbox, and differential, with some models fe…

3. EV Technician – EV Transmission Training

Domain: evtechnician.com

Registered: 2016 (9 years)

Introduction: EV Technician Training program offers education on how electric vehicle (EV) transmissions work, highlighting the differences between internal combustion engine vehicles (ICEVs) and EVs. The program emphasizes the unique single-speed transmission in EVs, which allows for instant torque and accommodates a wide range of speeds without the need for multi-stage gear shifting. The global demand for EVs…

4. Edmunds – Electric Car Transmissions

Domain: edmunds.com

Registered: 1996 (29 years)

Introduction: Electric cars have transmissions, primarily single-speed transmissions, which differ from traditional multi-speed transmissions found in internal combustion engine (ICE) vehicles. Key terms for electric car transmissions include single-speed gear reducer, single-speed fixed gear, one-speed gearbox, and single-stage transmission. Electric motors provide maximum torque from zero rpm, allowing for to…

5. eBay – Electric Transaxle Listings

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Electric Transaxle listings on eBay include various options such as: 1. 800 Watt Heavy Duty/BRAKE 24 Volt Cart Wheel DC Go Kart – Pre-Owned, priced at $125.00 with free delivery. 2. 24V 350W Brush Electric Motor Transaxle for Mobility Scooter Wheelchair – Brand New, priced at $168.75 with free delivery. 3. 24V 350W Electric Motor Transaxle for Mobility Scooter Travel Wheelchair DIY – Brand New, pr…

6. United Autos – Electric Vehicle Transmissions

Domain: unitedautosonline.com

Registered: 2019 (6 years)

Introduction: Electric cars have transmissions that are different from internal combustion engine transmissions. Most electric vehicles use a single gear transmission, allowing for a broader powerband. For example, the Porsche Taycan features a two-speed gearbox, but most electric motors operate with a single gear. Electric motors achieve peak torque at zero RPM and can operate safely at up to 20,000 RPM, which…

7. ZF – eTERRAMATIC Electric Transaxle

Domain: zf.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “eTERRAMATIC Electric Transaxle”, “technology”: “Electric-hydrostatic CVT Technology for BEV or FEV vehicle architecture”, “key_facts”: [“Easy vehicle integration with all HMI and CU components”, “Electric central drive modular with conventional TERRAMATIC series”, “Electronic drive control unit same performance as for ICE technology”], “benefits”: [“Fully electric, hydrostatic CV…

8. Xtrac – P1227 Integrated Lightweight Electric Vehicle Transmission

Domain: xtrac.com

Registered: 1997 (28 years)

Introduction: The Xtrac P1227 Integrated Lightweight Electric Vehicle (ILEV) transmission is designed for single speed, lightweight, and power-dense electric vehicle applications. Key specifications include:

– Compatibility with YASA P400, Avid AF130 or AF230, Integral Powertrain, or BorgWarner HVH-250-090-SOM or HVH-250-115-DOM motors (other motors possible with RPM < 10,000 and peak torque < 500Nm).

– Instal…

Strategic Sourcing Conclusion and Outlook for electric vehicle transaxle

How Can Strategic Sourcing Optimize Your Electric Vehicle Transaxle Procurement?

In the rapidly evolving landscape of electric vehicle technology, strategic sourcing of electric transaxles is paramount for B2B buyers seeking to enhance their competitive edge. By understanding the integration of components such as electric motors, transmissions, and differentials, businesses can streamline their procurement processes, ensuring they select transaxles that meet performance and efficiency standards. This not only optimizes vehicle performance but also contributes significantly to sustainability goals—an increasingly important factor in global markets.

Moreover, as electric vehicles gain traction in regions like Africa, South America, the Middle East, and Europe, the demand for high-quality electric transaxles is set to increase. By establishing strong supplier relationships and leveraging advanced sourcing strategies, companies can gain access to innovative technologies and competitive pricing, ultimately leading to cost savings and improved product offerings.

Looking ahead, the market for electric transaxles is poised for significant growth, driven by advancements in battery technology and increasing consumer demand for electric vehicles. International B2B buyers are encouraged to proactively engage with suppliers and invest in scalable, efficient transaxle solutions to stay ahead of the curve. Embrace this opportunity to position your business as a leader in the electric vehicle revolution.