Introduction: Navigating the Global Market for volvo Tractor Trailer Trucks

In the ever-evolving landscape of global logistics, sourcing reliable Volvo tractor trailer trucks can be a daunting challenge for B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. With a diverse range of models designed for various applications—from long-haul journeys to heavy-duty tasks—understanding the nuances of each option is crucial for making informed purchasing decisions. This comprehensive guide delves into the intricacies of Volvo’s offerings, highlighting key models like the VNL, VNR, and VNX, each engineered to meet specific operational needs while ensuring safety, comfort, and fuel efficiency.

This resource aims to equip international buyers with the knowledge necessary to navigate the complexities of truck sourcing. It covers essential topics such as the types of Volvo tractor trailer trucks available, their applications in different industries, and best practices for supplier vetting. Additionally, we provide insights into cost considerations and financing options that can significantly impact your purchasing strategy. By leveraging this guide, businesses can confidently select the right Volvo trucks that align with their operational goals, ultimately enhancing productivity and profitability in their respective markets.

Understanding volvo Tractor Trailer Trucks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Volvo VNL | Aerodynamic design, advanced safety features | Long-haul transportation | Pros: Fuel-efficient, comfortable; Cons: Higher initial investment. |

| Volvo VNR | Responsive handling, designed for regional haul | Regional freight and distribution | Pros: Agility and efficiency; Cons: Limited to shorter routes. |

| Volvo VNX | Heavy-duty construction, built for extreme demands | Heavy cargo transport | Pros: High strength and control; Cons: Heavier, may require more fuel. |

| Volvo VHD | Purpose-built for vocational tasks | Construction, waste management | Pros: Robust and versatile; Cons: Not ideal for long distances. |

| Volvo VNR Electric | Zero-emission, high-performing electric truck | Urban logistics and eco-friendly transport | Pros: Sustainable and cost-effective; Cons: Limited range per charge. |

What Are the Key Characteristics of the Volvo VNL?

The Volvo VNL is engineered for long-haul operations, featuring an aerodynamic design that enhances fuel efficiency. It is equipped with advanced safety features, making it a preferred choice for companies prioritizing driver safety and operational cost savings. This model is well-suited for international logistics and freight companies that require reliable performance over extended distances. When considering a purchase, buyers should evaluate the total cost of ownership, including fuel efficiency and maintenance.

How Does the Volvo VNR Stand Out for Regional Hauls?

The Volvo VNR is tailored for regional transportation, offering responsive handling and optimized comfort for drivers. It is ideal for businesses involved in local freight and distribution, where agility and efficiency are paramount. Buyers should consider the truck’s suitability for their specific routes and load types, as its design focuses on short to medium-haul operations. Additionally, the VNR’s advanced technology can contribute to improved productivity.

What Makes the Volvo VNX Suitable for Heavy Loads?

Built for heavy-duty applications, the Volvo VNX is designed to handle extreme loads and challenging conditions. Its robust construction provides the strength and control necessary for industries such as mining and heavy construction. Buyers should assess their specific cargo requirements and terrain when considering this model, as its capabilities can significantly impact operational efficiency. The VNX is a solid investment for businesses needing reliable performance under demanding circumstances.

In What Scenarios Is the Volvo VHD Most Effective?

The Volvo VHD is purpose-built for vocational tasks, making it an excellent choice for industries like construction and waste management. It offers versatility and robustness, allowing it to handle various applications effectively. Buyers should evaluate the truck’s suitability for their operational needs, particularly in terms of load capacity and job type. While it may not be the best option for long-distance hauls, its durability makes it a valuable asset for local operations.

What Advantages Does the Volvo VNR Electric Offer for Urban Logistics?

The Volvo VNR Electric is a cutting-edge solution for businesses looking to minimize their environmental impact. With zero emissions and a range of up to 275 miles per charge, it is designed for urban logistics and eco-conscious transportation needs. Companies focusing on sustainability will find this model appealing, but they must also consider the charging infrastructure and range limitations. The VNR Electric represents a forward-thinking investment for businesses aiming to transition to greener operations.

Key Industrial Applications of volvo Tractor Trailer Trucks

| Industry/Sector | Specific Application of Volvo Tractor Trailer Trucks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Long-haul freight transport | Enhanced fuel efficiency and reduced operational costs | Evaluate fuel types (diesel, electric), maintenance support, and warranty options. |

| Construction | Transporting heavy machinery and materials | Increased payload capacity and reliability | Assess load capacity, durability under harsh conditions, and availability of service centers. |

| Agriculture | Hauling agricultural products and equipment | Efficient transport of perishable goods and machinery | Consider temperature control options, cargo space, and compliance with local regulations. |

| Food and Beverage | Distribution of food products | Timely delivery and reduced spoilage | Look for temperature-controlled options and tracking systems for logistics management. |

| Retail | Supply chain logistics for retail distribution | Improved inventory management and timely deliveries | Focus on fleet management solutions and connectivity features for real-time tracking. |

How Are Volvo Tractor Trailer Trucks Used in Logistics and Transportation?

In the logistics and transportation sector, Volvo Tractor Trailer Trucks are primarily utilized for long-haul freight transport. Their aerodynamic design and fuel-efficient engines significantly reduce operational costs, making them ideal for international shipping routes. Buyers from regions like Africa and South America should consider the availability of service centers and parts, as well as compatibility with various fuel types, including renewable options, to ensure compliance with local regulations.

What Role Do Volvo Trucks Play in Construction?

In the construction industry, Volvo Tractor Trailer Trucks are essential for transporting heavy machinery and materials to job sites. Their robust build and high payload capacity enable them to handle the demanding requirements of construction logistics. For international buyers, especially in the Middle East where construction is booming, evaluating the truck’s durability in harsh environments and the availability of maintenance support is crucial for sustained operations.

How Do Volvo Trucks Support Agricultural Operations?

For agricultural applications, Volvo Tractor Trailer Trucks are used to haul agricultural products and equipment. Their reliability and efficiency are vital for transporting perishable goods, ensuring timely delivery to markets. Buyers in Europe and South America should focus on trucks with temperature control options and ample cargo space to meet the specific needs of transporting fresh produce while adhering to local agricultural regulations.

Why Are Volvo Trucks Important in the Food and Beverage Industry?

In the food and beverage sector, Volvo Tractor Trailer Trucks facilitate the distribution of food products, ensuring timely deliveries to retailers and minimizing spoilage. The integration of temperature-controlled systems is essential for maintaining product quality during transport. International buyers should prioritize trucks equipped with advanced tracking systems to enhance logistics management and ensure compliance with food safety standards.

How Do Volvo Trucks Enhance Retail Supply Chain Logistics?

In retail, Volvo Tractor Trailer Trucks are crucial for supply chain logistics, enabling efficient inventory management and timely deliveries. Their connectivity features allow for real-time tracking, helping businesses optimize their logistics operations. For buyers in regions like Brazil and Vietnam, focusing on fleet management solutions and the scalability of the truck’s capabilities can significantly improve operational efficiency and customer satisfaction.

3 Common User Pain Points for ‘volvo Tractor Trailer Trucks’ & Their Solutions

Scenario 1: High Fuel Costs Impacting Profit Margins

The Problem: Many B2B buyers are grappling with soaring fuel prices, which significantly erode profit margins. For fleet operators, the cost of fuel is one of the largest operational expenses, often consuming a substantial portion of their budget. Volvo Tractor Trailer Trucks, while known for their robust performance, can sometimes fall short in fuel efficiency if not properly specified or utilized. This discrepancy can lead to frustration when the expected savings on fuel do not materialize.

The Solution: To combat high fuel costs, buyers should focus on selecting models that emphasize fuel efficiency, such as the Volvo VNL, which is designed with an aerodynamic shape and advanced fuel-saving technologies. Additionally, leveraging Volvo’s telematics system can provide real-time data on fuel consumption patterns. By analyzing this data, fleet managers can identify inefficient driving behaviors and implement training programs for drivers. Regular maintenance, including tire pressure checks and engine tuning, will also ensure the trucks operate at peak efficiency.

Scenario 2: Navigating Compliance with Emission Regulations

The Problem: As governments worldwide tighten regulations on emissions, B2B buyers in the trucking industry face the challenge of ensuring their fleets comply without incurring excessive costs. Non-compliance can lead to fines, operational restrictions, and damage to reputation, making it essential for fleet operators to invest in vehicles that meet or exceed these standards.

The Solution: Buyers should consider Volvo’s commitment to sustainable solutions, including their electric and hybrid models, such as the Volvo VNR Electric. These vehicles not only comply with the latest emission standards but also position companies as environmentally responsible. Additionally, fleet operators should stay informed about local regulations and engage with Volvo’s service teams for updates on compliance requirements. By integrating a proactive compliance strategy into their operations, businesses can mitigate risks and enhance their brand image.

Scenario 3: Challenges with Driver Comfort and Retention

The Problem: The trucking industry is facing a driver shortage, exacerbated by high turnover rates. Many drivers report dissatisfaction due to uncomfortable working conditions, which can lead to decreased productivity and increased hiring costs for B2B buyers. If drivers are not comfortable in their cabs, they are less likely to perform well and more likely to seek employment elsewhere.

The Solution: Investing in Volvo’s VNL and VNR models can directly address this issue, as these trucks are engineered with driver comfort in mind. Features like ergonomic seating, spacious cabins, and advanced climate control systems enhance the driving experience. Moreover, buyers should consider implementing a driver feedback system to gather insights on what features are most appreciated and what additional comforts could be integrated. Regularly updating the fleet with newer models can also demonstrate a commitment to driver welfare, helping to attract and retain talent in a competitive market.

By understanding and addressing these common pain points, B2B buyers can make informed decisions that enhance operational efficiency, ensure compliance, and foster a motivated workforce.

Strategic Material Selection Guide for volvo Tractor Trailer Trucks

What Are the Key Materials Used in Volvo Tractor Trailer Trucks?

When selecting materials for Volvo tractor trailer trucks, several factors come into play, including performance, cost, and compliance with international standards. Below, we analyze four common materials used in the construction of these trucks, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Steel Contribute to the Performance of Volvo Trucks?

Steel is a primary material in the manufacturing of Volvo tractor trailer trucks, particularly for the chassis and structural components.

- Key Properties: Steel offers high tensile strength and durability, withstanding high temperatures and pressures, making it suitable for heavy-duty applications. It also has good corrosion resistance when treated.

- Pros & Cons: Steel is relatively inexpensive and easy to manufacture, but it can be heavy, which may affect fuel efficiency. Additionally, while treated steel can resist corrosion, untreated steel may rust in humid environments, which is a consideration for buyers in tropical regions.

- Impact on Application: Steel is compatible with various media, including fuel and lubricants, ensuring reliability in performance.

- Considerations for International Buyers: Compliance with standards such as ASTM A36 or EN 10025 is crucial. Buyers from regions like Africa and South America should consider the local availability of treated steel to mitigate corrosion issues.

What Role Does Aluminum Play in Weight Reduction for Volvo Trucks?

Aluminum is increasingly used in Volvo tractor trailer trucks, especially for body panels and components that benefit from weight reduction.

- Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It performs well under a range of temperatures and is non-magnetic.

- Pros & Cons: The primary advantage of aluminum is its weight savings, which can enhance fuel efficiency. However, it is more expensive than steel and can be more complex to manufacture, requiring specialized welding techniques.

- Impact on Application: Aluminum is suitable for applications where weight is critical, such as in the construction of trailers and cargo bodies.

- Considerations for International Buyers: Buyers should be aware of standards like ASTM B221 for aluminum extrusions. In regions like the Middle East, where high temperatures are common, aluminum’s thermal properties can be beneficial.

How Does Composite Material Enhance Safety and Efficiency in Volvo Trucks?

Composite materials, including fiberglass and carbon fiber, are used in specific applications within Volvo trucks, such as in certain body panels and interior components.

- Key Properties: Composites are lightweight, resistant to corrosion, and offer high strength-to-weight ratios. They can also be engineered for specific thermal and acoustic properties.

- Pros & Cons: Composites provide significant weight savings and improved fuel efficiency. However, they are generally more expensive and can have longer manufacturing lead times.

- Impact on Application: Composites are particularly useful in applications requiring sound insulation or thermal management, enhancing driver comfort.

- Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM D638 for tensile properties. In Europe, the acceptance of composites is growing, but buyers in regions like Africa may need to consider local manufacturing capabilities.

What Benefits Does High-Performance Rubber Offer for Volvo Trucks?

High-performance rubber is crucial for tires and suspension components in Volvo tractor trailer trucks.

- Key Properties: Rubber provides excellent flexibility, shock absorption, and resistance to wear and tear. It performs well under varying temperature conditions.

- Pros & Cons: The advantages of rubber include its durability and ability to handle heavy loads. However, it can degrade under extreme temperatures and may require regular maintenance.

- Impact on Application: Rubber is essential for ensuring ride comfort and stability, directly impacting vehicle performance.

- Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM D2000. In regions with diverse climates, selecting the right type of rubber can enhance performance and longevity.

Summary Table of Material Selection for Volvo Tractor Trailer Trucks

| Material | Typical Use Case for Volvo Tractor Trailer Trucks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and structural components | High strength and durability | Heavy, potential corrosion issues | Med |

| Aluminum | Body panels and lightweight components | Weight savings | Higher cost, complex manufacturing | High |

| Composite | Body panels and interior components | Lightweight, corrosion-resistant | Expensive, longer lead times | High |

| High-Performance Rubber | Tires and suspension components | Excellent flexibility and durability | Can degrade in extreme temperatures | Med |

This guide provides a comprehensive overview of the materials used in Volvo tractor trailer trucks, aiding international B2B buyers in making informed decisions that align with their operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for volvo Tractor Trailer Trucks

What Are the Main Stages in the Manufacturing Process of Volvo Tractor Trailer Trucks?

The manufacturing process of Volvo tractor trailer trucks involves several critical stages, each designed to ensure the highest quality and performance standards. Understanding these stages can help B2B buyers appreciate the complexities involved in producing reliable commercial vehicles.

-

Material Preparation: The first step in the manufacturing process is the preparation of raw materials. Volvo prioritizes high-grade materials, such as advanced steel and aluminum alloys, which provide strength while minimizing weight. This stage includes sourcing materials from certified suppliers and conducting initial inspections to ensure compliance with quality standards.

-

Forming: Once materials are prepared, they undergo various forming processes. This includes stamping, bending, and welding components to create the truck’s chassis and body. Advanced machinery, such as robotic welders, is utilized to maintain precision and consistency. The use of computer-aided design (CAD) systems allows for intricate designs that enhance aerodynamics and fuel efficiency.

-

Assembly: The assembly stage is where the truck begins to take shape. Components such as the engine, transmission, and suspension systems are integrated into the chassis. This process is highly systematic, with dedicated assembly lines for different models. Skilled technicians oversee the assembly, ensuring that each part fits seamlessly and meets Volvo’s rigorous standards.

-

Finishing: The final stage of manufacturing involves finishing processes, including painting, polishing, and installing the interior components. Volvo employs environmentally friendly paint systems that not only enhance the truck’s appearance but also protect against corrosion. Quality checks are performed at each step to guarantee that the final product meets all specifications.

How Does Volvo Ensure Quality Assurance in Its Manufacturing Processes?

Quality assurance is paramount in the production of Volvo tractor trailer trucks, with several international and industry-specific standards guiding the processes.

-

Adherence to International Standards: Volvo complies with ISO 9001 standards, which outline requirements for an effective quality management system. This certification ensures that the company consistently meets customer and regulatory requirements. Additionally, industry-specific certifications such as CE mark for European markets and API standards for components further validate the quality of the trucks.

-

Quality Control Checkpoints: The quality control process is structured around several critical checkpoints:

– Incoming Quality Control (IQC): This phase involves inspecting raw materials and components as they arrive at the factory. Only materials that pass rigorous testing are accepted for production.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to ensure that all components are assembled correctly and function as intended. This includes performance testing of systems like the engine and brakes.

– Final Quality Control (FQC): Before delivery, each truck undergoes a comprehensive inspection, including road tests to evaluate performance, safety features, and compliance with regulations. -

Common Testing Methods: Volvo employs a range of testing methods, including stress testing, fatigue testing, and environmental testing. These methods simulate real-world conditions to assess the durability and reliability of the trucks under various operational scenarios.

What Are the Best Practices for B2B Buyers to Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensure that the products meet their specific requirements.

-

Conducting Audits: Regular audits of the manufacturing facilities can provide valuable insights into the supplier’s adherence to quality standards. Buyers should request audit reports that detail the findings and corrective actions taken by the manufacturer.

-

Reviewing Quality Control Reports: Suppliers should provide detailed quality control reports that outline the results of inspections and tests conducted throughout the manufacturing process. These reports should include data on defect rates, compliance with standards, and any corrective measures implemented.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and quality assurance practices. These agencies can conduct inspections at various stages of production and deliver comprehensive reports to buyers.

How Do Quality Control and Certification Nuances Affect International B2B Transactions?

Quality control and certification nuances play a significant role in international B2B transactions. Buyers should be aware of the following considerations:

-

Understanding Regional Regulations: Different regions may have varying regulations and standards for commercial vehicles. It is essential for buyers to understand these differences to ensure compliance and avoid legal issues.

-

Navigating Certification Processes: Certifications may differ based on the market. For example, products sold in Europe often require CE certification, while those in North America may need to meet different standards. Buyers should ensure that their suppliers are equipped to handle these requirements.

-

Cultural and Communication Barriers: International transactions may involve cultural and communication differences that can impact quality control practices. Establishing clear communication channels and understanding cultural nuances can help mitigate potential issues.

Conclusion

In summary, the manufacturing processes and quality assurance practices for Volvo tractor trailer trucks are designed to deliver high-performance, reliable vehicles. By understanding the stages of manufacturing, quality control measures, and the nuances of international certifications, B2B buyers can make informed decisions when sourcing from suppliers. This knowledge not only enhances procurement strategies but also ensures that the trucks meet the operational needs of their businesses.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘volvo Tractor Trailer Trucks’

Introduction

Sourcing Volvo Tractor Trailer Trucks requires a structured approach to ensure you make informed decisions that align with your business needs. This guide provides a step-by-step checklist that will help you navigate the complexities of procurement, ensuring you select the right model, supplier, and financing options for your operations.

1. Define Your Technical Specifications

Begin by outlining the specific technical requirements for your fleet. Consider factors such as load capacity, engine specifications, fuel efficiency, and intended routes. Knowing these details will help you narrow down the appropriate models, such as the Volvo VNL for long hauls or the VNR for regional transport.

2. Research Available Models

Investigate the different Volvo models available in the market, including the VNL, VNR, VNX, and VHD. Each model serves unique purposes, such as long-haul transportation or vocational tasks. Understanding the strengths and weaknesses of each model will aid in matching them to your operational needs.

3. Evaluate Potential Suppliers

Before finalizing any purchase, it is vital to assess potential suppliers. Request detailed company profiles, customer references, and case studies from other businesses in your industry. Look for suppliers with a proven track record of reliability and support, as these factors can significantly impact your operational efficiency.

4. Verify Compliance with Local Regulations

Ensure that the trucks you are considering comply with local regulations regarding emissions, safety standards, and vehicle specifications. This is particularly crucial in international markets where regulations can vary significantly. Non-compliance could lead to fines or disruptions in your logistics operations.

5. Assess Financing Options

Explore various financing options, including leasing, loans, or outright purchases. Each option has its advantages and disadvantages, depending on your cash flow and operational strategy. Consult with financial advisors to determine which option best suits your budget and long-term goals.

6. Conduct a Cost-Benefit Analysis

Perform a thorough cost-benefit analysis to evaluate the total cost of ownership for the trucks you are considering. Include factors such as fuel consumption, maintenance costs, and resale value in your calculations. This step will help you understand the long-term financial implications of your purchase.

7. Arrange for Test Drives and Inspections

Before making a final decision, arrange for test drives and thorough inspections of the trucks. This hands-on experience will provide insights into the vehicle’s performance, comfort, and handling. Additionally, having a trusted mechanic inspect the trucks can uncover any potential issues that may not be immediately apparent.

By following this checklist, B2B buyers can ensure a comprehensive approach to sourcing Volvo Tractor Trailer Trucks, ultimately leading to informed purchasing decisions that enhance operational efficiency and profitability.

Comprehensive Cost and Pricing Analysis for volvo Tractor Trailer Trucks Sourcing

What Are the Key Cost Components in Sourcing Volvo Tractor Trailer Trucks?

When sourcing Volvo tractor trailer trucks, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: High-quality materials are vital for durability and performance. Volvo’s commitment to safety and efficiency means that materials may be sourced from premium suppliers, affecting overall costs.

-

Labor: Skilled labor is necessary for assembly and quality control. The labor costs can vary significantly based on the region, with higher costs typically seen in developed markets.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can help minimize these costs, which is crucial for keeping the final price competitive.

-

Tooling: Custom tooling may be required for specific configurations or modifications, impacting the initial investment. Buyers should consider whether standard models meet their needs to avoid additional tooling costs.

-

Quality Control (QC): Rigorous QC processes ensure that each truck meets Volvo’s high standards, which can add to the overall cost but is essential for reliability.

-

Logistics: Transportation costs from manufacturing facilities to the buyer’s location can vary based on distance, mode of transport, and import duties, especially for international buyers.

-

Margin: The supplier’s profit margin will also influence the final price. Understanding the supplier’s pricing strategy can aid in negotiations.

How Do Price Influencers Affect Volvo Truck Pricing?

Several factors can influence the pricing of Volvo tractor trailer trucks, particularly for international B2B buyers:

-

Volume/MOQ: Purchasing in larger quantities often yields discounts. Buyers should assess their needs to negotiate better terms based on minimum order quantities (MOQs).

-

Specifications and Customization: Custom features or specifications can significantly affect the price. Buyers should evaluate whether standard models suffice to avoid unnecessary costs.

-

Materials and Quality Certifications: Trucks that meet specific industry standards or certifications may come at a premium. However, investing in certified models can lead to long-term savings through enhanced reliability and reduced maintenance.

-

Supplier Factors: The choice of supplier can impact price due to differences in sourcing strategies, operational efficiencies, and regional market dynamics.

-

Incoterms: Understanding international shipping terms (Incoterms) is crucial. These terms dictate who is responsible for costs and risks during transport, which can influence the overall cost structure.

What Are Effective Buyer Tips for Sourcing Volvo Trucks?

To maximize value and minimize costs when sourcing Volvo tractor trailer trucks, consider the following tips:

-

Negotiate Wisely: Engage in thorough negotiations, leveraging volume purchases and long-term relationships to secure better pricing and terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors such as fuel efficiency, maintenance costs, and potential resale value. Volvo trucks are designed for fuel efficiency, which can lead to significant savings over time.

-

Understand Pricing Nuances for International Buyers: Different regions may have unique pricing structures due to local demand, tariffs, and economic conditions. Conduct market research to understand local pricing dynamics.

-

Consider Total Logistics Costs: Factor in shipping, handling, and potential import duties when evaluating costs. Opt for suppliers with efficient logistics capabilities to minimize these expenses.

-

Stay Informed on Market Trends: Keep abreast of industry news, technological advancements, and market fluctuations that may affect pricing. This knowledge can provide leverage during negotiations.

Disclaimer on Indicative Prices

While prices for Volvo tractor trailer trucks can vary widely based on the factors discussed, it is crucial to obtain quotes from multiple suppliers for the most accurate and competitive pricing. Always verify current pricing and availability as market conditions fluctuate.

Alternatives Analysis: Comparing volvo Tractor Trailer Trucks With Other Solutions

Exploring Alternatives to Volvo Tractor Trailer Trucks

In the world of logistics and transportation, choosing the right tractor trailer truck is crucial for operational efficiency and cost management. While Volvo Tractor Trailer Trucks are recognized for their performance and innovative features, various alternatives can also fulfill similar requirements. This section compares Volvo trucks against two viable alternatives: Freightliner Trucks and Electric Trucks, focusing on critical aspects such as performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Volvo Tractor Trailer Trucks | Freightliner Trucks | Electric Trucks |

|---|---|---|---|

| Performance | High fuel efficiency, robust safety features, advanced technology. | Reliable performance, strong engine options, good fuel economy. | Zero-emission, instant torque, quiet operation. |

| Cost | Higher upfront cost, but long-term savings on fuel and maintenance. | Competitive pricing, often lower than Volvo; good resale value. | Higher initial investment; potential savings on fuel and tax incentives. |

| Ease of Implementation | Requires training for advanced features; extensive dealer network for support. | Familiarity in North American markets; ease of access to parts and service. | Infrastructure for charging may be a challenge; requires planning for long-haul routes. |

| Maintenance | Advanced diagnostics; higher long-term reliability; premium service costs. | Generally lower maintenance costs; widely available service options. | Lower maintenance due to fewer moving parts; battery replacements can be costly. |

| Best Use Case | Ideal for long-haul and regional transport with a focus on safety and comfort. | Suited for various applications, including regional and local deliveries. | Best for urban deliveries and short-haul routes, especially where emissions are a concern. |

Analyzing Freightliner Trucks as an Alternative

Freightliner Trucks are a popular choice in the North American market, known for their reliability and strong performance. They often come at a lower initial price compared to Volvo trucks, making them appealing for businesses looking to manage upfront costs. Maintenance is generally more affordable, with widespread availability of parts and service centers. However, they may lack some of the advanced safety and technology features that Volvo offers, which could be a consideration for companies prioritizing driver safety and comfort.

Understanding Electric Trucks as a Sustainable Option

Electric trucks are rapidly gaining traction as a sustainable alternative to traditional diesel trucks. They provide zero emissions, making them an attractive option for companies focused on reducing their environmental impact. The instant torque delivery of electric vehicles allows for efficient performance in urban settings. However, the higher initial cost and the need for a robust charging infrastructure can pose challenges, particularly for long-haul operations. Despite these hurdles, electric trucks are becoming increasingly viable, especially with the growing emphasis on sustainability in the logistics industry.

Choosing the Right Solution for Your Business Needs

When selecting a tractor trailer truck, B2B buyers should consider their specific operational requirements, budget constraints, and long-term goals. Volvo Tractor Trailer Trucks excel in performance and safety, making them suitable for companies that prioritize these factors. On the other hand, Freightliner Trucks may appeal to those looking for cost-effective solutions without compromising too much on performance. For businesses aiming to enhance their sustainability profile, electric trucks present an innovative option, albeit with some logistical challenges. Ultimately, understanding the unique advantages and limitations of each alternative will empower buyers to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for volvo Tractor Trailer Trucks

What Are the Essential Technical Properties of Volvo Tractor Trailer Trucks?

When considering Volvo tractor trailer trucks for your fleet, understanding their technical properties is crucial for making informed purchasing decisions. Here are some key specifications that significantly influence performance and operational efficiency:

-

Engine Type and Power Output: Volvo trucks typically feature advanced engine options such as the D13 or D16 series, which provide varying horsepower ratings from 405 to over 600 HP. The engine type directly affects fuel efficiency, load capacity, and overall performance. A higher horsepower rating is essential for heavy-duty applications, ensuring reliability in long-haul transport.

-

Transmission Options: Volvo offers both automated and manual transmission options, including the I-Shift automated transmission system. This technology enhances driver comfort and fuel efficiency by optimizing gear shifts based on load and terrain. For B2B buyers, understanding transmission choice is vital as it impacts driving ease, maintenance costs, and driver retention.

-

Chassis and Suspension Design: The chassis of Volvo trucks is engineered for durability and stability, often featuring air-ride suspension systems. This design improves ride quality, reduces wear on cargo, and enhances safety during transport. For businesses transporting sensitive goods, investing in trucks with superior suspension systems can lead to lower damage rates and higher customer satisfaction.

-

Fuel Efficiency Ratings: Volvo trucks are designed with aerodynamic features and advanced fuel-saving technologies, which can yield fuel efficiency ratings of up to 10-12 MPG. This is particularly important for businesses looking to reduce operational costs. When comparing options, evaluating fuel efficiency can lead to significant long-term savings.

-

Safety Features: Volvo prioritizes safety, integrating features such as collision avoidance systems, lane departure warnings, and advanced braking systems. A focus on safety not only protects drivers but also minimizes liability risks for companies. Understanding these features can help businesses comply with international safety regulations, especially in regions with stringent transport laws.

What Are Common Trade Terms Used in the Volvo Truck Industry?

In the B2B marketplace for Volvo tractor trailer trucks, familiarity with industry terminology is essential for effective communication and negotiation. Here are several key terms you should know:

-

OEM (Original Equipment Manufacturer): This term refers to the company that manufactures the original parts used in the truck. When purchasing Volvo trucks, understanding OEM specifications ensures you are buying genuine parts, which is critical for maintaining warranty coverage and vehicle performance.

-

MOQ (Minimum Order Quantity): This indicates the smallest amount of product that a supplier is willing to sell. For international buyers, knowing the MOQ is essential for budgeting and supply chain planning, particularly when ordering spare parts or accessories for your fleet.

-

RFQ (Request for Quotation): An RFQ is a document that companies use to invite suppliers to bid on specific products or services. Crafting a detailed RFQ for Volvo trucks can help ensure you receive accurate pricing and delivery timelines, facilitating better procurement decisions.

-

Incoterms: These are international commercial terms that define the responsibilities of buyers and sellers in global transactions. Familiarity with Incoterms is crucial for international buyers, as they dictate shipping costs, insurance, and risk management during transport.

-

TCO (Total Cost of Ownership): This term encompasses all costs associated with owning and operating a truck over its lifetime, including purchase price, fuel, maintenance, and depreciation. Understanding TCO helps businesses evaluate the long-term financial impact of their investment in Volvo trucks.

-

Telematics: This refers to the technology that integrates telecommunications and monitoring systems in vehicles. Volvo trucks are equipped with advanced telematics that provide real-time data on vehicle performance, location, and maintenance needs, enabling fleet managers to optimize operations and improve efficiency.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when investing in Volvo tractor trailer trucks, ultimately enhancing operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the volvo Tractor Trailer Trucks Sector

What Are the Current Market Dynamics and Key Trends in the Volvo Tractor Trailer Trucks Sector?

The global market for Volvo tractor trailer trucks is shaped by several key drivers, including increased demand for efficient freight transportation, technological advancements in vehicle design, and a strong emphasis on sustainability. As international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, navigate this dynamic landscape, they must be aware of emerging trends such as the electrification of transport fleets and the integration of smart technologies. The introduction of models like the Volvo VNR Electric, which boasts a zero-emission footprint, highlights a significant shift towards sustainability in logistics.

Moreover, the emphasis on connectivity and real-time diagnostics is transforming the procurement process. Advanced telematics systems enable fleet managers to monitor vehicle performance, optimize routes, and reduce operational costs. Buyers are increasingly looking for trucks that not only meet their immediate needs but also align with long-term goals of efficiency and sustainability. Additionally, the demand for used Volvo trucks is gaining traction, particularly in emerging markets where budget constraints drive purchasing decisions.

How Is Sustainability and Ethical Sourcing Reshaping the Procurement Landscape for Volvo Trucks?

Sustainability has become a critical consideration for B2B buyers in the Volvo tractor trailer truck sector. The environmental impact of transportation is under scrutiny, prompting businesses to seek trucks that minimize their carbon footprint. This shift is evident in Volvo’s commitment to producing electric and hybrid models, which not only reduce emissions but also lower fuel costs over time.

Ethical sourcing practices are also gaining momentum, as buyers increasingly prioritize supply chains that reflect their corporate social responsibility values. Certifications related to environmental standards can enhance brand reputation and appeal to eco-conscious consumers. Buyers should look for suppliers who utilize sustainable materials and practices in their manufacturing processes. This not only supports a healthier planet but also aligns with global trends towards more transparent and ethical business practices.

What Is the Brief Evolution of Volvo Trucks in the Global Market?

Volvo Trucks has a rich history dating back to its founding in 1927, initially focusing on producing quality vehicles that prioritize safety and durability. Over the decades, the company has continually innovated, introducing advanced technologies such as dynamic steering systems and enhanced fuel-efficient engines. The transition towards electrification began in earnest in the 21st century, with Volvo leading the charge in developing sustainable transport solutions.

This evolution reflects broader market trends, as the demand for more efficient and environmentally friendly vehicles has surged globally. Today, Volvo stands as a leader in the commercial truck sector, recognized for its commitment to quality, safety, and sustainability. For international B2B buyers, understanding this evolution is essential for making informed purchasing decisions that align with their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of volvo Tractor Trailer Trucks

-

How do I determine the right Volvo tractor trailer truck model for my business needs?

Choosing the right Volvo tractor trailer truck involves assessing your specific transport requirements, such as load capacity, distance, and terrain. For long hauls, models like the Volvo VNL are ideal due to their aerodynamic design and fuel efficiency. If your operations are regional, the Volvo VNR offers agility and comfort. Additionally, consider electric options like the VNR Electric for sustainable operations. Consulting with Volvo dealers or industry experts can provide tailored advice based on your operational goals. -

What are the key features to look for in a Volvo tractor trailer truck?

When evaluating Volvo tractor trailer trucks, focus on features like fuel efficiency, safety technology, and driver comfort. Volvo trucks are known for their leading-edge safety systems, including collision avoidance and lane-keeping assistance. Also, assess the comfort of the cab, as driver satisfaction can significantly impact productivity. Connectivity options for real-time diagnostics and tracking can enhance fleet management and operational efficiency, making them vital for modern transport operations. -

What customization options are available for Volvo tractor trailer trucks?

Volvo offers a range of customization options to meet specific business needs. Buyers can choose from different engine sizes, transmission types, and cabin configurations. Additional features like enhanced safety packages, infotainment systems, and specialized cargo handling equipment can also be integrated. Engaging with a Volvo dealer is crucial for understanding the full spectrum of customization options and ensuring that the vehicle aligns perfectly with your operational requirements. -

What are the minimum order quantities (MOQ) for purchasing Volvo tractor trailer trucks?

The minimum order quantities for Volvo tractor trailer trucks can vary based on the dealer and region. Typically, for bulk purchases, dealers may offer better pricing or financing options. It’s advisable to directly communicate with local dealers to understand their specific MOQ policies and negotiate terms that suit your business needs. Depending on your operational scale, consider forming alliances with other businesses to meet MOQ requirements collectively. -

What payment terms can I expect when purchasing Volvo tractor trailer trucks?

Payment terms for purchasing Volvo trucks generally depend on the dealer and your credit profile. Common arrangements include upfront payments, financing options, or leasing agreements. Many dealers offer flexible financing solutions that can accommodate international buyers, including installment plans. It’s essential to review the terms carefully and consider consulting with financial advisors to choose the most advantageous payment method for your business. -

How do I ensure quality assurance when sourcing Volvo tractor trailer trucks internationally?

To ensure quality assurance when sourcing internationally, conduct thorough research on the dealer’s reputation and experience with Volvo trucks. Request documentation on compliance with international standards and certifications. It’s also beneficial to arrange for inspections of the vehicles prior to purchase. Establishing clear contracts that outline warranties, service agreements, and return policies can further protect your investment and ensure quality. -

What logistics considerations should I keep in mind when importing Volvo tractor trailer trucks?

When importing Volvo trucks, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Engage with logistics providers experienced in heavy equipment transport to navigate potential challenges. Understanding import duties and taxes in your country is crucial for accurate budgeting. Additionally, ensure that the trucks are shipped with appropriate documentation to facilitate smooth customs clearance. -

How can I find reliable suppliers for Volvo tractor trailer trucks in my region?

Finding reliable suppliers for Volvo trucks involves researching authorized dealers and distributors in your region. Utilize online platforms, industry directories, and trade shows to identify potential partners. Engage with other businesses in the transportation sector for referrals and reviews. It’s also beneficial to assess the supplier’s experience, customer service reputation, and after-sales support to ensure a long-term partnership that meets your operational needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Volvo Tractor Trailer Trucks Manufacturers & Suppliers List

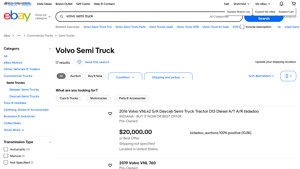

1. Volvo – VNL 760 Pre-Owned

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 2019 Volvo VNL 760 Pre-Owned $20,000.00 or Best Offer Located in Mineral, VA Free local pickup; Volvo VNL 780 Pre-Owned $19,999.00 Buy It Now Located in Pompano Beach, FL Free local pickup; 2019 Volvo VNL62T860 Pre-Owned $24,500.00 or Best Offer Located in Fort Lauderdale, FL Free local pickup; 2016 Volvo VNL42 S/A Daycab Semi Truck Tractor D13 Diesel A/T A/R bidadoo Pre-Owned $20,000.00 or Best O…

2. Volvo Trucks – Premium Heavy-Duty Vehicles

Domain: tecequipment.com

Registered: 2006 (19 years)

Introduction: Volvo Trucks are premium heavy-duty trucks known for their uncompromising quality, industry-leading safety features, and world-class driver comfort. Key features include:

– Fuel-efficient design with innovative technology to increase fuel efficiency.

– Leading-edge safety features for driver and road safety.

– Optimized driving and living environments for maximum driver comfort.

– Unparalleled con…

Strategic Sourcing Conclusion and Outlook for volvo Tractor Trailer Trucks

In the evolving landscape of logistics and transportation, strategic sourcing of Volvo Tractor Trailer Trucks offers significant advantages for international buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The superior engineering of Volvo’s models, such as the VNL and VNR series, emphasizes fuel efficiency, advanced safety features, and comfort, making them ideal for long-haul and regional operations.

By focusing on strategic sourcing, companies can leverage Volvo’s commitment to sustainability through innovative technologies like electric and renewable fuel options, aligning with global trends toward greener logistics. This approach not only enhances operational efficiency but also positions businesses as leaders in sustainability within their respective markets.

As you consider your procurement strategy, now is the time to engage with trusted Volvo dealers to explore tailored solutions that meet your unique transportation needs. Embrace the opportunity to elevate your fleet with Volvo’s cutting-edge technology and robust designs. The future of transportation is evolving—partner with Volvo Trucks to drive your success forward.