Introduction: Navigating the Global Market for 6×4 Euro 3 Dump Truck

In the ever-evolving landscape of global construction and mining, sourcing a reliable 6×4 Euro 3 dump truck can pose significant challenges for B2B buyers. With stringent emissions regulations and varying market demands across regions like Africa, South America, the Middle East, and Europe, navigating this market requires a strategic approach. This guide provides comprehensive insights into the diverse types of 6×4 Euro 3 dump trucks available, their specific applications in various industries, and essential factors for supplier vetting.

International buyers will benefit from a detailed exploration of critical aspects such as cost considerations, performance metrics, and maintenance requirements, ensuring they make informed purchasing decisions. Additionally, the guide emphasizes the importance of understanding regional market dynamics, helping buyers align their choices with local regulations and operational needs. Whether you’re operating in the bustling construction sectors of Nigeria or the expansive mining industries of Saudi Arabia, this guide serves as a valuable resource for optimizing your procurement strategy.

By leveraging the insights presented here, businesses can streamline their sourcing processes, mitigate risks, and ultimately enhance their operational efficiency. With the right information at hand, B2B buyers can confidently navigate the global market for 6×4 Euro 3 dump trucks, ensuring their investments yield maximum returns in productivity and compliance.

Understanding 6×4 Euro 3 Dump Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard 6×4 Dump Truck | 6×4 axle configuration, 350-450 HP | Construction, mining | Pros: High load capacity; versatile. Cons: May require higher maintenance. |

| Heavy-Duty 6×4 Truck | Enhanced suspension, 500+ HP | Heavy construction, quarrying | Pros: Superior durability; ideal for rough terrains. Cons: Higher initial investment. |

| Multi-Functional Dump Truck | Equipped with hydraulic systems, various body types | Waste management, recycling | Pros: Adaptable for different tasks; efficient. Cons: Complexity may lead to higher repair costs. |

| Tipper 6×4 Dump Truck | Specialized tipping mechanism, varying capacities | Material transport, demolition | Pros: Efficient unloading; reduces labor. Cons: Limited to specific applications. |

| Euro 3 Compliant Truck | Meets Euro 3 emissions standards | Urban construction, roadworks | Pros: Environmentally friendly; compliance with regulations. Cons: Limited availability in some regions. |

What Are the Characteristics of Standard 6×4 Dump Trucks?

Standard 6×4 dump trucks are characterized by their robust 6×4 axle configuration and a power range typically between 350 to 450 horsepower. These trucks are primarily used in construction and mining sectors due to their ability to handle substantial loads and navigate varying terrains. When considering a purchase, buyers should assess the truck’s load capacity and maintenance requirements, as higher loads can lead to increased wear and tear.

How Do Heavy-Duty 6×4 Trucks Stand Out?

Heavy-duty 6×4 trucks are designed for more demanding applications, featuring enhanced suspension systems and horsepower exceeding 500 HP. They are particularly suitable for heavy construction and quarrying operations where durability and performance are critical. Buyers should evaluate the truck’s initial investment against its long-term durability and operational efficiency, as these trucks often provide better cost-effectiveness over time despite a higher upfront cost.

What Makes Multi-Functional Dump Trucks Versatile?

Multi-functional dump trucks are equipped with hydraulic systems and can accommodate various body types, making them ideal for waste management and recycling operations. Their adaptability allows businesses to efficiently switch between tasks, optimizing resource use. However, buyers should consider the complexity of these trucks, as it may lead to higher repair and maintenance costs, impacting overall operational budgets.

Why Choose Tipper 6×4 Dump Trucks?

Tipper 6×4 dump trucks come with specialized mechanisms for efficient unloading, making them a popular choice for material transport and demolition projects. Their design reduces the need for manual unloading, thereby enhancing productivity on job sites. However, buyers should be aware that the specific functionality may limit their use to particular applications, which could affect versatility in fleet operations.

What Are the Benefits of Euro 3 Compliant Trucks?

Euro 3 compliant trucks are designed to meet stringent emissions standards, making them suitable for urban construction and roadworks. Their environmentally friendly design appeals to businesses looking to enhance their sustainability profile while complying with local regulations. Buyers should consider the availability of these models in their region, as they may face limitations in supply compared to other types, potentially impacting procurement strategies.

Key Industrial Applications of 6×4 Euro 3 Dump Truck

| Industry/Sector | Specific Application of 6×4 Euro 3 Dump Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Material transportation on site | Efficiently moves heavy materials, reducing downtime | Ensure compliance with local emissions standards |

| Mining | Hauling ore and waste | Increases productivity by transporting large loads quickly | Assess durability and maintenance support |

| Agriculture | Transporting soil and fertilizers | Enhances crop yield by ensuring timely delivery of inputs | Evaluate payload capacity and off-road capabilities |

| Waste Management | Collecting and transporting waste | Streamlines waste disposal processes, improving operational efficiency | Check for body design and unloading mechanisms |

| Infrastructure Development | Moving construction debris | Supports timely project completion, minimizing delays | Consider versatility for various terrain types |

How is the 6×4 Euro 3 Dump Truck Used in the Construction Industry?

In the construction sector, the 6×4 Euro 3 dump truck plays a crucial role in transporting materials such as sand, gravel, and concrete. Its robust build and significant payload capacity enable it to efficiently handle heavy loads, which helps minimize downtime on construction sites. For international buyers, particularly in regions like Africa and South America, ensuring compliance with local emissions regulations is essential, as well as considering the truck’s adaptability to varying terrain.

What Role Does the 6×4 Euro 3 Dump Truck Play in Mining Operations?

The mining industry relies heavily on the 6×4 Euro 3 dump truck for hauling ore and waste materials from extraction sites to processing facilities. Its powerful engine and sturdy design allow for quick transportation of large quantities, which is vital for maintaining productivity. Buyers should focus on the truck’s durability and the availability of maintenance support, especially in remote mining locations, to ensure operational efficiency.

How is the 6×4 Euro 3 Dump Truck Beneficial for Agricultural Operations?

In agriculture, the 6×4 Euro 3 dump truck is commonly used to transport soil, fertilizers, and other agricultural inputs. Its capacity to carry substantial payloads enables farmers to enhance their crop yield by ensuring timely deliveries of essential materials. Buyers in regions such as the Middle East should evaluate the truck’s payload capacity and off-road capabilities to navigate diverse farming landscapes effectively.

How Does the 6×4 Euro 3 Dump Truck Support Waste Management?

The waste management sector utilizes the 6×4 Euro 3 dump truck for collecting and transporting waste materials. This application streamlines waste disposal processes, significantly improving operational efficiency. Businesses should consider the truck’s body design and unloading mechanisms to ensure they meet specific waste management needs, particularly in urban environments where space may be limited.

What is the Importance of the 6×4 Euro 3 Dump Truck in Infrastructure Development?

In infrastructure development, the 6×4 Euro 3 dump truck is essential for moving construction debris and materials, supporting timely project completion. Its ability to navigate various terrain types is crucial for projects in regions with challenging landscapes. Buyers should assess the truck’s versatility and performance in different conditions to ensure it meets the demands of infrastructure projects across diverse geographical areas.

3 Common User Pain Points for ‘6×4 Euro 3 Dump Truck’ & Their Solutions

Scenario 1: Difficulty in Meeting Regulatory Compliance for Euro 3 Emissions Standards

The Problem: B2B buyers, particularly in regions like Europe and South America, often face challenges in ensuring that their 6×4 Euro 3 dump trucks comply with stringent emissions regulations. Non-compliance can lead to hefty fines and restrictions on operational capabilities, affecting profitability. This is especially critical in urban areas where environmental regulations are increasingly enforced, and companies risk losing contracts if their fleets do not meet legal requirements.

The Solution: To mitigate this issue, buyers should prioritize sourcing trucks from reputable manufacturers that provide clear documentation on emissions compliance. When evaluating potential purchases, verify that the dump trucks come with necessary certifications and emissions data. Additionally, consider investing in retrofit technologies that can enhance emissions performance if you are acquiring older models. This proactive approach not only ensures compliance but can also improve the overall efficiency of the fleet, leading to long-term savings and better market positioning.

Scenario 2: Challenges in Spare Parts Availability and Maintenance

The Problem: Maintaining a fleet of 6×4 Euro 3 dump trucks can be daunting due to inconsistent availability of spare parts. Buyers often encounter delays when trying to source essential components, leading to extended downtimes and increased operational costs. This issue is exacerbated in regions where local suppliers may not stock parts for specific truck brands, making repairs a logistical nightmare.

The Solution: To alleviate this pain point, buyers should establish relationships with multiple suppliers, ensuring a steady pipeline of spare parts for their specific truck models. It’s beneficial to conduct a thorough assessment of local and international suppliers who specialize in Euro 3 dump trucks. Additionally, investing in a maintenance management system can help track the condition of parts, schedule preventative maintenance, and identify which components may require preemptive replacement. This systematic approach minimizes downtime and keeps operational costs in check.

Scenario 3: Inefficiencies in Load Capacity and Payload Management

The Problem: Many B2B buyers struggle with optimizing the load capacity of their 6×4 Euro 3 dump trucks. Overloading can lead to compliance issues, increased wear and tear, and potential legal ramifications. Conversely, underloading means lost revenue opportunities, particularly in construction and mining operations where maximizing payload is essential for profitability.

The Solution: Implementing a robust load management system is crucial for buyers to balance their operations effectively. This can include digital weighing systems installed on the trucks that provide real-time feedback on load weight before departure. Additionally, training drivers on best practices for load distribution and weight management can enhance performance and compliance. By establishing clear operational guidelines and utilizing technology for monitoring, companies can maximize their payload while adhering to legal weight limits, thus optimizing both efficiency and profitability.

By addressing these common pain points with actionable solutions, B2B buyers can enhance the performance and reliability of their 6×4 Euro 3 dump truck fleets, ensuring they remain competitive in their respective markets.

Strategic Material Selection Guide for 6×4 Euro 3 Dump Truck

What Materials Are Commonly Used in 6×4 Euro 3 Dump Trucks?

When selecting materials for the construction of a 6×4 Euro 3 dump truck, it is essential to consider various factors, including performance, durability, cost, and suitability for specific applications. Here, we analyze four common materials used in these vehicles: steel, aluminum, composite materials, and rubber.

How Does Steel Contribute to the Performance of Dump Trucks?

Steel is the most widely used material in the construction of dump trucks, particularly for the chassis and body. Its key properties include high tensile strength and excellent durability, which allow it to withstand heavy loads and harsh operating conditions. Steel also offers good corrosion resistance when treated with appropriate coatings, making it suitable for various environments, including humid or saline conditions often found in coastal regions.

Pros: Steel is relatively low-cost compared to other materials and offers exceptional strength and durability. It is also easily sourced and can be fabricated into complex shapes, making it suitable for various truck designs.

Cons: The main drawbacks of steel are its weight and susceptibility to corrosion if not properly maintained. This can lead to increased fuel consumption and higher maintenance costs over time.

For international buyers, particularly in regions like Africa and the Middle East, compliance with local standards for steel quality (such as ASTM or DIN) is essential. Buyers should also consider the availability of maintenance services to address corrosion issues.

What Role Does Aluminum Play in Dump Truck Design?

Aluminum is increasingly being used in the construction of dump trucks, particularly for components like the body and certain structural elements. Its key properties include lightweight characteristics and resistance to corrosion, making it an attractive option for enhancing fuel efficiency.

Pros: The primary advantage of aluminum is its lightweight nature, which can significantly reduce the overall weight of the dump truck, leading to improved fuel efficiency and payload capacity. Additionally, aluminum’s corrosion resistance extends the life of the vehicle body.

Cons: However, aluminum is generally more expensive than steel and may not offer the same level of strength under extreme conditions. It can also be more challenging to weld and fabricate, requiring specialized skills and equipment.

International buyers should be aware of the specific aluminum grades used in truck manufacturing and ensure compliance with relevant standards. Understanding the local market’s acceptance of aluminum components is crucial, especially in regions where steel is traditionally favored.

How Do Composite Materials Enhance Dump Truck Performance?

Composite materials, such as fiberglass-reinforced plastics, are becoming popular in the manufacture of dump truck bodies and panels. These materials are characterized by their high strength-to-weight ratio and excellent resistance to corrosion and impact.

Pros: Composites are lightweight, which enhances fuel efficiency and payload capacity. They also provide superior resistance to environmental factors, reducing maintenance needs.

Cons: The primary limitation of composite materials is their higher cost and the complexity of manufacturing processes. Additionally, they may not be suitable for all structural applications due to their lower impact resistance compared to metals.

For B2B buyers, particularly in emerging markets, understanding the local acceptance and availability of composite materials is vital. Compliance with international standards for composites can also affect purchasing decisions.

Why is Rubber Essential for Dump Truck Functionality?

Rubber is primarily used in tires and suspension components of dump trucks. Its key properties include excellent elasticity, shock absorption, and resistance to wear.

Pros: Rubber provides superior traction and comfort during operation, which is crucial for off-road conditions commonly encountered in construction and mining applications. It also helps in reducing vibrations, contributing to overall vehicle stability.

Cons: The main disadvantage of rubber is its susceptibility to degradation from UV exposure and extreme temperatures, which can lead to a shorter lifespan compared to metal components.

International buyers should consider the quality of rubber materials used in tires and suspension systems, ensuring they meet local standards for durability and performance. Understanding the climate conditions in their operational regions can also influence the selection of rubber compounds.

Summary Table of Material Selection for 6×4 Euro 3 Dump Trucks

| Material | Typical Use Case for 6×4 Euro 3 Dump Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and body construction | High strength and durability | Heavy and prone to corrosion | Low |

| Aluminum | Body and structural components | Lightweight and corrosion-resistant | Higher cost and fabrication complexity | Medium |

| Composite | Body panels and non-structural elements | Lightweight and low maintenance | Higher cost and lower impact resistance | High |

| Rubber | Tires and suspension components | Excellent traction and shock absorption | Degrades under UV exposure | Medium |

This guide provides essential insights for B2B buyers looking to select the right materials for 6×4 Euro 3 dump trucks, ensuring optimal performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 6×4 Euro 3 Dump Truck

What Are the Key Manufacturing Processes for 6×4 Euro 3 Dump Trucks?

The manufacturing of a 6×4 Euro 3 dump truck involves several critical stages that ensure both efficiency and quality. The process typically includes material preparation, forming, assembly, and finishing. Each stage employs specific techniques aimed at meeting the rigorous demands of heavy-duty vehicles.

How Is Material Prepared for Manufacturing Dump Trucks?

The first step in manufacturing involves sourcing high-quality raw materials such as high-strength steel and aluminum alloys. These materials are selected for their durability and ability to withstand heavy loads. The preparation phase includes cutting, bending, and shaping these materials to meet design specifications. Advanced technologies such as CNC (Computer Numerical Control) machining are commonly employed to ensure precision in the dimensions and forms of components.

What Forming Techniques Are Used in the Production of Dump Trucks?

Once materials are prepared, the forming process begins. This stage often utilizes techniques like stamping, welding, and forging. Stamping is used to create flat components that will later be assembled into the truck’s frame. Welding techniques, including MIG (Metal Inert Gas) and TIG (Tungsten Inert Gas), are crucial for joining various parts, ensuring structural integrity. Forging may be used for creating critical components such as the axles and suspension systems, offering enhanced strength and durability.

How Is the Assembly Process Structured for 6×4 Euro 3 Dump Trucks?

The assembly phase is where the various components come together to form the complete vehicle. This process is typically organized on an assembly line to optimize workflow and reduce production time. Each section of the dump truck, from the chassis to the cab, is assembled in a systematic manner, with teams focused on specific areas such as electrical systems, hydraulic systems, and drivetrains. Quality control checkpoints are integrated at this stage to verify that each assembly meets the required specifications.

What Finishing Processes Are Important for Dump Trucks?

Finishing processes play a vital role in ensuring the durability and aesthetic quality of the dump truck. This includes surface treatments such as powder coating or painting, which protect against corrosion and environmental wear. Additionally, final inspections are conducted to ensure that all components are functioning correctly and that the vehicle meets safety regulations.

How Is Quality Assurance Integrated into the Manufacturing of 6×4 Euro 3 Dump Trucks?

Quality assurance (QA) is essential in the manufacturing process of 6×4 Euro 3 dump trucks. It ensures that every vehicle produced meets international standards and customer expectations. The QA process typically adheres to standards like ISO 9001, which focuses on quality management systems, and industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute).

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control is implemented at multiple stages throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specifications.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects early, allowing for corrective measures.

- Final Quality Control (FQC): This stage includes comprehensive testing of the finished dump truck, ensuring it meets all operational and safety standards.

What Testing Methods Are Commonly Used for 6×4 Euro 3 Dump Trucks?

Common testing methods for quality assurance in dump trucks include:

- Load Testing: Simulating real-world conditions to assess the vehicle’s load-bearing capacity.

- Functional Testing: Verifying that all systems, such as hydraulics and electrical components, operate as intended.

- Durability Testing: Subjecting the truck to extreme conditions to evaluate its longevity and reliability.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies:

- Supplier Audits: Conducting on-site audits to review manufacturing practices and quality control measures. This allows buyers to assess compliance with international standards and company policies.

- Requesting Quality Reports: Buyers should ask for detailed quality assurance reports, including data from IQC, IPQC, and FQC processes.

- Third-Party Inspections: Utilizing independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control systems.

What Are the Specific Quality Control Nuances for International Buyers?

International buyers should be aware of various nuances in quality control specific to their regions. For instance, the certification requirements might vary significantly between countries. In some regions, adherence to local regulations may also be essential, necessitating additional certifications. Buyers should familiarize themselves with these standards to ensure compliance and quality.

Furthermore, language barriers and differences in business practices can pose challenges. Therefore, establishing clear communication channels with suppliers is vital to ensure that quality expectations are understood and met throughout the manufacturing process.

Conclusion

Understanding the manufacturing processes and quality assurance measures for 6×4 Euro 3 dump trucks is essential for B2B buyers. By familiarizing themselves with the stages of production, quality control checkpoints, and verification methods, buyers can make informed decisions that align with their operational needs and standards. This knowledge not only aids in selecting reliable suppliers but also contributes to the overall success of procurement strategies in the heavy-duty vehicle market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6×4 Euro 3 Dump Truck’

The procurement of a 6×4 Euro 3 dump truck requires careful planning and execution to ensure that you make an informed decision. This guide offers a practical checklist to help international B2B buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Begin by outlining the technical requirements for the dump truck. Consider factors such as load capacity, engine power, and axle configuration. A well-defined specification helps ensure that the truck meets the operational demands of your projects.

- Load Capacity: Determine how much material the truck needs to transport.

- Engine Power: A minimum of 385 HP is common; assess if this meets your performance needs.

- Axle Configuration: The 6×4 configuration is standard; confirm that it aligns with your operational requirements.

Step 2: Research Available Models

Explore various models available in the market, such as those from brands like Howo, MAN, and Volvo. Understanding the models will allow you to compare performance, price, and features effectively.

- Market Comparison: Look at performance metrics and user reviews for different brands.

- Regional Availability: Ensure that the models you consider are readily available in your region.

Step 3: Evaluate Potential Suppliers

Before committing, vet suppliers thoroughly to ensure reliability and quality. Request company profiles, case studies, and references from buyers in similar industries or regions.

- Supplier Background: Check how long the supplier has been in business and their market reputation.

- Customer Testimonials: Seek feedback from previous customers to gauge satisfaction levels.

Step 4: Verify Compliance with Regulations

Ensure that the dump trucks comply with local and international regulations, including emissions standards. This is particularly important in regions with strict environmental regulations.

- Emissions Compliance: Confirm that the Euro 3 standard meets your local requirements.

- Documentation: Request all necessary certifications and compliance documents from the supplier.

Step 5: Inspect the Equipment

Arrange for a physical inspection of the truck before purchase. This is crucial to identify any potential issues that could affect performance and safety.

- Condition Assessment: Check for wear and tear, particularly in critical areas such as the engine and chassis.

- Test Drive: If possible, conduct a test drive to evaluate handling and performance under load.

Step 6: Negotiate Pricing and Terms

Once you have identified a suitable supplier, negotiate the pricing and payment terms. This step is essential to ensure that you are getting the best value for your investment.

- Price Comparison: Use your research to benchmark pricing against similar models.

- Payment Terms: Discuss payment options, warranties, and after-sales support to avoid future disputes.

Step 7: Finalize the Purchase Agreement

After agreeing on terms, finalize the purchase agreement. Ensure that all details are clearly outlined, including delivery schedules and warranty information.

- Contract Clarity: Review the contract to confirm that all terms are mutually agreed upon.

- Delivery Timeline: Establish a clear timeline for delivery and any contingencies for delays.

By following this checklist, you can approach the procurement of a 6×4 Euro 3 dump truck with confidence, ensuring that you make informed decisions that align with your operational needs and compliance requirements.

Comprehensive Cost and Pricing Analysis for 6×4 Euro 3 Dump Truck Sourcing

What Are the Key Cost Components in Sourcing a 6×4 Euro 3 Dump Truck?

When considering the procurement of a 6×4 Euro 3 dump truck, it’s essential to understand the various cost components that contribute to the final pricing. The primary cost elements include:

-

Materials: The cost of raw materials such as steel, aluminum, and plastics significantly affects the price. High-quality materials enhance durability and performance but can increase the overall cost.

-

Labor: Labor costs vary by region and influence the manufacturing process. Skilled labor may command higher wages but can also improve the quality of the finished product.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help in controlling these costs.

-

Tooling: Investment in tooling and machinery is crucial for producing trucks to specific standards. Custom tooling for specialized designs may lead to higher upfront costs but can be offset by increased efficiency in production.

-

Quality Control (QC): Quality assurance processes ensure that trucks meet safety and performance standards. Investing in rigorous QC can reduce warranty claims and enhance customer satisfaction, though it may increase initial costs.

-

Logistics: Transportation costs for delivering the trucks to buyers can vary widely based on distance, shipping method, and local regulations. Efficient logistics management can help in reducing these expenses.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the typical margins in the industry can aid in negotiation.

How Do Price Influencers Affect the Cost of 6×4 Euro 3 Dump Trucks?

Several factors can influence the pricing of 6×4 Euro 3 dump trucks, particularly for international buyers:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often attract discounts, while smaller orders may incur higher per-unit costs.

-

Specifications and Customization: Custom features or specifications can lead to additional costs. Buyers should consider their specific needs against the potential for higher pricing due to customizations.

-

Materials and Quality Certifications: The choice of materials and any associated certifications (like ISO standards) can impact costs. High-quality materials or certifications may come at a premium but can offer better longevity and performance.

-

Supplier Factors: The supplier’s reputation, location, and financial stability can influence pricing. Established suppliers may offer more reliability but at a higher cost, while newer or less established suppliers might provide lower prices at the risk of quality or service.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) that govern shipping and delivery responsibilities can help in calculating total costs. Incoterms define who pays for shipping, insurance, and tariffs, which can significantly affect the final price.

What Are Effective Buyer Tips for Sourcing 6×4 Euro 3 Dump Trucks Internationally?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, navigating the procurement process can be complex. Here are some actionable tips:

-

Negotiate Wisely: Leverage your understanding of cost structures and price influencers to negotiate better terms. Don’t hesitate to ask for discounts based on volume or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Evaluate the long-term costs associated with operating the dump truck, including fuel efficiency, maintenance, and potential resale value, rather than focusing solely on the purchase price.

-

Research Market Prices: Familiarize yourself with current market prices and comparable models to ensure you are getting a fair deal. Tools like online marketplaces and auction sites can provide valuable insights.

-

Assess Supplier Reliability: Look for suppliers with positive reviews and proven track records in delivering quality products. This can reduce risks associated with quality and service.

-

Understand Local Regulations: Be aware of any local regulations regarding emissions and vehicle standards, especially when importing trucks. Compliance can prevent costly fines and ensure smoother operations.

Disclaimer on Indicative Prices

The prices indicated in this analysis are for reference purposes and may vary based on market conditions, supplier negotiations, and additional customization. Always consult with multiple suppliers to get the most accurate and competitive pricing tailored to your specific requirements.

Alternatives Analysis: Comparing 6×4 Euro 3 Dump Truck With Other Solutions

Exploring Alternatives to the 6×4 Euro 3 Dump Truck

In the competitive landscape of heavy-duty transportation, businesses often seek alternatives to the traditional 6×4 Euro 3 Dump Truck. These alternatives can vary in performance, cost, and utility, making it essential for B2B buyers to evaluate their options comprehensively. This analysis will compare the 6×4 Euro 3 Dump Truck with two viable alternatives: the 8×4 Euro 3 Dump Truck and the 6×4 Electric Dump Truck.

| Comparison Aspect | 6×4 Euro 3 Dump Truck | 8×4 Euro 3 Dump Truck | 6×4 Electric Dump Truck |

|---|---|---|---|

| Performance | 385 HP, 20,000 kg load capacity | 480 HP, 25,000 kg load capacity | 300 HP, 15,000 kg load capacity |

| Cost | $18,000 | $25,000 | $40,000 |

| Ease of Implementation | Moderate | Moderate | High (charging infrastructure required) |

| Maintenance | Moderate | Higher (more components) | Lower (fewer moving parts) |

| Best Use Case | General construction | Heavy-duty applications | Urban construction, eco-friendly projects |

In-Depth Analysis of Alternatives

1. 8×4 Euro 3 Dump Truck

The 8×4 Euro 3 Dump Truck offers superior performance, boasting a higher horsepower and load capacity compared to the 6×4 model. This makes it an ideal choice for heavy-duty applications where transporting large amounts of material is essential. However, the increased power and capacity come with a higher cost and greater fuel consumption. Additionally, the complexity of its mechanics can lead to higher maintenance requirements, which may deter some buyers focused on operational efficiency.

2. 6×4 Electric Dump Truck

The 6×4 Electric Dump Truck presents a modern solution for businesses looking to minimize their carbon footprint. While it has lower horsepower and load capacity than the traditional 6×4 Euro 3 Dump Truck, it compensates with reduced maintenance costs due to fewer moving parts. However, the initial investment is higher, and the need for charging infrastructure can complicate implementation, especially in regions where electric resources are limited. This alternative is best suited for urban construction projects where environmental concerns are prioritized.

Choosing the Right Solution for Your Needs

Selecting the appropriate truck for your operations depends on various factors, including the nature of your projects, budget constraints, and environmental considerations. If your business requires heavy hauling capabilities, the 8×4 Euro 3 Dump Truck is a strong contender, offering power and capacity at a price. Conversely, if sustainability is a priority and your operations are primarily urban, the 6×4 Electric Dump Truck could align better with your goals, despite its higher upfront costs. Ultimately, a thorough assessment of your operational needs and financial parameters will guide you in making the most informed decision for your fleet.

Essential Technical Properties and Trade Terminology for 6×4 Euro 3 Dump Truck

What Are the Key Technical Properties of a 6×4 Euro 3 Dump Truck?

When considering a 6×4 Euro 3 dump truck, several technical specifications play a pivotal role in its performance and suitability for various applications. Here are some essential properties to understand:

-

Engine Power (HP)

– Defined as the measure of the engine’s output, typically ranging from 385 to 480 HP for Euro 3 dump trucks. Higher horsepower indicates better performance in heavy-load conditions, essential for construction and mining operations.

– B2B Importance: Selecting the right horsepower is crucial for meeting project demands and ensuring operational efficiency, especially in rugged terrains. -

Axle Configuration (6×4)

– This configuration indicates that the truck has six wheels, with four being driven. It provides a balance between load capacity and maneuverability, making it ideal for transporting heavy materials.

– B2B Importance: Understanding axle configurations helps businesses choose vehicles that can effectively handle specific loads and road conditions, enhancing safety and efficiency. -

Load Capacity (kg or tons)

– Load capacity generally varies but can be around 20,000 kg (approximately 22 tons) for a 6×4 dump truck. This metric reflects the maximum weight the truck can safely carry, including the weight of the vehicle itself.

– B2B Importance: Knowing the load capacity is critical for businesses to comply with local regulations and ensure that transportation operations are both safe and profitable. -

Fuel Type and Efficiency

– Most 6×4 Euro 3 dump trucks operate on diesel, which provides the necessary power while adhering to Euro 3 emission standards. Fuel efficiency can vary, impacting overall operational costs.

– B2B Importance: Fuel consumption directly affects operating expenses, making it vital for companies to consider efficiency when budgeting for fleet operations. -

Suspension System

– The suspension system (spring/spring or air/spring) affects ride quality and load stability. A robust suspension system helps maintain vehicle control, especially when loaded.

– B2B Importance: A suitable suspension system minimizes wear and tear on the vehicle and enhances driver comfort, which can lead to increased productivity. -

Body Type and Unloading Mechanism

– The body type (e.g., tipper) and unloading mechanism (e.g., rear or side unloading) determine how materials are loaded and unloaded. This affects efficiency and the types of materials that can be transported.

– B2B Importance: Understanding body types and unloading methods allows businesses to select trucks that fit their operational workflows, improving efficiency in material handling.

What Are the Common Trade Terminology and Acronyms Used in the Dump Truck Industry?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

– Refers to the company that manufactures the original product. In the context of dump trucks, it indicates the brand responsible for the vehicle’s design and production.

– B2B Importance: Understanding OEM helps buyers assess product quality and reliability, as reputable manufacturers often provide better support and warranty options. -

MOQ (Minimum Order Quantity)

– This term defines the smallest quantity of a product that a supplier is willing to sell. For dump trucks, MOQs can vary based on supplier policies.

– B2B Importance: Knowing the MOQ is crucial for buyers to plan their procurement strategies effectively and manage inventory costs. -

RFQ (Request for Quotation)

– An RFQ is a document that potential buyers send to suppliers to solicit price quotes for specific quantities of products. This is a standard practice in B2B purchasing.

– B2B Importance: An RFQ allows companies to compare prices and terms from multiple suppliers, fostering competitive bidding and potentially better pricing. -

Incoterms (International Commercial Terms)

– These are standardized terms published by the International Chamber of Commerce that define the responsibilities of buyers and sellers in international trade. Common terms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight).

– B2B Importance: Understanding Incoterms is vital for clarifying shipping responsibilities, costs, and risks, which can prevent disputes and ensure smooth transactions. -

Lead Time

– The period between the initiation of an order and its delivery. In the context of dump trucks, this can include manufacturing and shipping times.

– B2B Importance: Knowing the lead time helps businesses plan projects and manage cash flow effectively, ensuring that equipment is available when needed. -

Warranty

– A warranty is a promise from the manufacturer or seller regarding the condition of the vehicle and the terms of repair or replacement in case of defects.

– B2B Importance: A solid warranty can provide peace of mind for buyers, ensuring that they are protected against unexpected repair costs and enhancing the overall value of the purchase.

By understanding these technical properties and trade terminologies, businesses can make informed decisions when purchasing 6×4 Euro 3 dump trucks, ultimately enhancing operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the 6×4 Euro 3 Dump Truck Sector

What Are the Key Market Drivers for 6×4 Euro 3 Dump Trucks?

The market for 6×4 Euro 3 dump trucks is significantly influenced by several global drivers, including infrastructure development, urbanization, and increasing demand for efficient transportation solutions. In emerging economies like Nigeria and Brazil, government initiatives aimed at improving road networks and construction capabilities are propelling the demand for heavy-duty vehicles. In regions like the Middle East, massive investments in infrastructure projects, such as stadiums and highways, further enhance the market potential.

In terms of technology, the rise of digital platforms for sourcing and procurement is reshaping how B2B buyers engage with suppliers. Online marketplaces and auction sites allow international buyers to access a broader range of options, compare prices, and evaluate product specifications efficiently. Additionally, advancements in telematics are making it easier for operators to monitor vehicle performance, which is critical for optimizing fleet management and operational efficiency.

Emerging trends also include a shift towards used vehicles as companies look to balance cost with quality. The availability of Euro 3 compliant vehicles at competitive prices offers an attractive solution for businesses prioritizing both budget constraints and regulatory compliance. As sustainability becomes a focal point in procurement strategies, buyers are increasingly interested in vehicles that meet environmental standards without sacrificing performance.

How Can Sustainability and Ethical Sourcing Impact the 6×4 Euro 3 Dump Truck Market?

Sustainability is becoming a key consideration in the procurement of 6×4 Euro 3 dump trucks, particularly as global awareness of environmental issues rises. The environmental impact of heavy-duty vehicles, including emissions and fuel consumption, is prompting buyers to seek options that align with sustainable practices. As a result, manufacturers are being pushed to improve their production processes and utilize more eco-friendly materials.

Ethical sourcing is equally important in this context. Buyers are increasingly focused on the integrity of their supply chains, which includes understanding where materials are sourced and how they are produced. Certifications such as ISO 14001 for environmental management or adherence to the United Nations Global Compact principles can enhance a company’s reputation and demonstrate commitment to ethical practices.

Moreover, the integration of ‘green’ technologies, such as energy-efficient engines and alternative fuel options, is gaining traction. These advancements not only help reduce the carbon footprint of operations but can also lead to long-term cost savings through improved fuel efficiency and lower maintenance costs.

What Is the Evolution of the 6×4 Euro 3 Dump Truck?

The 6×4 Euro 3 dump truck has evolved significantly since its introduction, reflecting advancements in engineering and regulatory standards. Initially, the Euro 3 standard was implemented to reduce harmful emissions from diesel vehicles, leading manufacturers to innovate around engine efficiency and exhaust treatment technologies.

In the early 2000s, the adoption of Euro 3 regulations marked a pivotal shift in the heavy-duty vehicle market, especially in Europe. This prompted manufacturers to enhance their designs, focusing on fuel efficiency and reliability. Over time, as environmental concerns intensified, the industry began transitioning toward newer standards, such as Euro 5 and Euro 6. However, the 6×4 Euro 3 dump truck remains relevant, especially in markets where cost-effectiveness and compliance with existing regulations are critical.

Today, these trucks are recognized not only for their robustness and versatility in construction and mining applications but also as a practical solution for businesses in developing markets. As international B2B buyers navigate the complexities of sourcing, understanding the historical context of these vehicles can inform better purchasing decisions and strategic planning for future investments.

Frequently Asked Questions (FAQs) for B2B Buyers of 6×4 Euro 3 Dump Truck

1. How do I choose the right 6×4 Euro 3 Dump Truck for my business needs?

Choosing the right 6×4 Euro 3 Dump Truck involves assessing your specific operational requirements, such as load capacity, engine power, and terrain conditions. Look for trucks with a minimum of 385HP, as this power level can efficiently handle heavy loads. Additionally, consider features like fuel efficiency and maintenance history. It’s also beneficial to compare different brands, such as Howo or MAN, to find models that align with your budget and performance expectations. Engaging with suppliers who provide detailed specifications and support can further aid in making an informed decision.

2. What are the typical payment terms for purchasing a 6×4 Euro 3 Dump Truck?

Payment terms can vary widely among suppliers, but common options include a deposit of 20-30% upfront with the balance due upon delivery or acceptance of the vehicle. Some suppliers may offer flexible financing options or letters of credit for larger orders. It’s crucial to clarify all terms before finalizing the purchase, including any applicable taxes, shipping fees, and warranties. Additionally, understanding the currency exchange implications for international transactions can prevent unexpected costs.

3. What customization options are available for the 6×4 Euro 3 Dump Truck?

Many manufacturers offer customization options for the 6×4 Euro 3 Dump Truck, allowing buyers to tailor features to their specific operational needs. Common modifications include adjusting the dump bed size, adding hydraulic systems for enhanced lifting capabilities, or incorporating specialized body designs for specific materials (e.g., gravel, sand). Discussing your requirements with the supplier can help identify available options, ensuring the truck meets your operational demands effectively.

4. How can I verify the credibility of suppliers for 6×4 Euro 3 Dump Trucks?

To ensure a reliable supplier, start by researching their reputation through reviews and testimonials from previous buyers. Check for certifications and industry affiliations that demonstrate compliance with international standards. Request references and consider visiting their facilities if possible. Additionally, engaging with suppliers who provide clear documentation on vehicle history, maintenance records, and warranty options can further validate their credibility.

5. What are the logistics considerations when importing a 6×4 Euro 3 Dump Truck?

Logistics for importing a 6×4 Euro 3 Dump Truck involve several factors, including shipping methods, customs clearance, and local regulations. Determine whether you’ll use container shipping or roll-on/roll-off services based on cost and safety. Familiarize yourself with the import duties and taxes applicable in your country, and ensure compliance with local environmental regulations regarding Euro 3 standards. Partnering with a logistics provider experienced in heavy equipment can streamline the process and mitigate potential delays.

6. What is the average lead time for delivery of a 6×4 Euro 3 Dump Truck?

The average lead time for delivery can vary based on the supplier’s location, stock availability, and customization requests. Generally, expect a lead time ranging from 15 to 60 days. If you are ordering a customized truck, factor in additional time for modifications. It is advisable to confirm these timelines with your supplier upfront to align your operational schedules accordingly.

7. How do I assess the quality assurance practices of suppliers?

To assess quality assurance practices, inquire about the supplier’s manufacturing processes, including quality control measures at various production stages. Request documentation of certifications like ISO standards, which indicate adherence to quality management systems. Additionally, ask for information on warranty terms and after-sales support, as reputable suppliers should offer robust service and maintenance options post-purchase to ensure the longevity of the truck.

8. What are common issues to expect with a used 6×4 Euro 3 Dump Truck?

When purchasing a used 6×4 Euro 3 Dump Truck, potential issues may include wear and tear on critical components like the engine, transmission, and hydraulic systems. It’s essential to conduct a thorough inspection and obtain a detailed maintenance history. Common problems can also arise from poor previous usage or lack of maintenance, which may lead to performance inefficiencies. Engaging a trusted mechanic for a pre-purchase inspection can help identify any underlying issues before finalizing the transaction.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 6X4 Euro 3 Dump Truck Manufacturers & Suppliers List

1. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

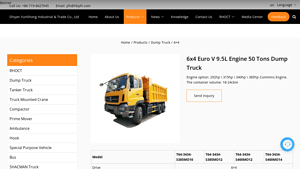

2. HBYLH – 6×4 Euro V Dump Truck

Domain: hbylh.com

Registered: 2011 (14 years)

Introduction: {“Model”:”6×4 Euro V 9.5L Engine 50 Tons Dump Truck”,”Engine Options”:”292hp, 315hp, 340hp, 385hp Cummins Engine”,”Container Volume”:”18-24cbm”,”Drive”:”6×4″,”GVW/GCW (kg)”:”33500/50000″,”Cab Type”:”L-Sleeper”,”Suspension”:”Front fixed rear hydraulic suspension”,”Air Conditioner”:”Electric air conditioning”,”Engine Model”:”ISL9.5-385E51A, ISL9.5-400E51A”,”Emission Standard”:”Euro II – Euro V”,”Rat…

3. China Truck – ZZ3257V3847B1 6×4 Model

Domain: chinatruck.cc

Registered: 2007 (18 years)

Introduction: Model: ZZ3257V3847B1

Drive Type: 6×4

Engine: WP10.380E22

Horse Power: 380hp

Emission Standard: Euro 2

Displacement: 10L

Gearbox: HW19709XST+HW50

Frame: Double (8+8/300)

Front Axle: VGD95

Rear Axle: MCX16ZG

Fuel Tank: 380L

Tyre: 315/80R22

Cab: HW76

Box Body: Customized

Strategic Sourcing Conclusion and Outlook for 6×4 Euro 3 Dump Truck

In the competitive landscape of heavy-duty vehicles, the strategic sourcing of 6×4 Euro 3 dump trucks presents significant advantages for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. These trucks are characterized by their robust performance, high payload capacity, and compliance with environmental standards, making them suitable for diverse applications, from construction to mining.

Investing in 6×4 Euro 3 dump trucks not only enhances operational efficiency but also ensures compliance with increasingly stringent emission regulations. Buyers should prioritize reputable suppliers who offer vehicles with proven reliability and service support to mitigate risks associated with procurement. The current market trends indicate a steady demand for these vehicles, driven by infrastructure development projects and urbanization in emerging markets.

Looking ahead, B2B buyers are encouraged to explore partnerships with manufacturers that emphasize quality, after-sales service, and technological advancements. By strategically sourcing 6×4 Euro 3 dump trucks, businesses can position themselves for growth and capitalize on future opportunities in the ever-evolving transportation sector. Embrace this opportunity to enhance your fleet and drive your business forward.