Introduction: Navigating the Global Market for electric cars made in india

As global demand for sustainable transportation solutions rises, sourcing electric cars made in India presents both opportunities and challenges for international B2B buyers. With a rapidly expanding electric vehicle (EV) market, India has emerged as a hub for innovative and competitively priced electric cars, making it essential for businesses in regions like Africa, South America, the Middle East, and Europe to understand the landscape. This guide delves into the various types of electric vehicles available, their applications across different sectors, and key considerations for supplier vetting.

International buyers will benefit from insights on cost structures, enabling them to make informed decisions that align with their strategic goals. The guide also highlights the strengths of Indian manufacturers, such as Mahindra and Tata, known for their cutting-edge technology and commitment to quality. By addressing critical factors such as charging infrastructure, warranty options, and after-sales service, this resource equips B2B buyers with the knowledge needed to navigate the complexities of the Indian electric vehicle market confidently.

Ultimately, this comprehensive guide serves as a crucial tool for those looking to capitalize on the burgeoning electric car segment in India, ensuring that businesses can source vehicles that meet their operational needs while contributing to a greener future.

Understanding electric cars made in india Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Compact EVs | Small size, affordable, efficient for urban use | Delivery services, ride-sharing | Pros: Low cost, easy maneuverability. Cons: Limited range, smaller cargo space. |

| SUV EVs | Larger, higher capacity, advanced features | Corporate fleets, family transport | Pros: More space, higher range. Cons: Higher initial investment, larger footprint. |

| Luxury EVs | Premium features, advanced technology | Executive transport, high-end rentals | Pros: Superior comfort and performance. Cons: High maintenance costs, premium pricing. |

| Commercial EVs | Designed for heavy loads and long distances | Logistics, freight transport | Pros: High payload capacity, efficient for long hauls. Cons: Limited availability, higher upfront costs. |

| Two-Wheelers | Compact, lightweight, and economical | Urban commuting, last-mile delivery | Pros: Very low cost, high efficiency. Cons: Limited passenger capacity, less suitable for longer distances. |

What are the Characteristics and Suitability of Compact EVs?

Compact electric vehicles (EVs) are designed for urban environments where space is at a premium. Their small size and affordability make them ideal for businesses focused on delivery services or ride-sharing applications. When considering a compact EV, B2B buyers should evaluate the total cost of ownership, including charging infrastructure and maintenance. These vehicles are perfect for navigating congested city streets, though their limited range and cargo capacity may not meet all business needs.

How Do SUV EVs Serve Corporate Fleets?

SUV EVs offer a balance between space and efficiency, making them suitable for corporate fleets and family transport. With a higher passenger capacity and advanced features, they cater to businesses that require versatility. B2B buyers should consider the vehicle’s range, charging options, and overall comfort. Although they come with a higher initial investment, the long-term savings on fuel and maintenance can be significant, especially for companies prioritizing sustainability.

What Makes Luxury EVs Attractive for Executive Transport?

Luxury electric vehicles are characterized by their premium features and cutting-edge technology, making them an excellent choice for executive transport and high-end rentals. These vehicles provide superior comfort and performance, appealing to businesses looking to impress clients or enhance their brand image. However, B2B buyers must weigh the high maintenance costs and premium pricing against the potential benefits of increased customer satisfaction and loyalty.

Why Are Commercial EVs Essential for Logistics?

Commercial electric vehicles are engineered to handle heavy loads and long distances, making them essential for logistics and freight transport. Their high payload capacity and efficiency can significantly reduce operational costs for businesses in these sectors. Buyers should consider the availability of suitable models and charging infrastructure, as well as the upfront costs. While they may require a larger investment, the potential for long-term savings and reduced emissions makes them a compelling choice for forward-thinking companies.

How Do Two-Wheelers Fit into Last-Mile Delivery Solutions?

Two-wheel electric vehicles are compact, lightweight, and economical, making them ideal for urban commuting and last-mile delivery solutions. Their very low cost and high efficiency appeal to businesses looking to minimize expenses. However, B2B buyers should note the limited passenger capacity and suitability for longer distances. These vehicles are an excellent choice for companies focused on quick, cost-effective deliveries in densely populated areas.

Key Industrial Applications of electric cars made in india

| Industry/Sector | Specific Application of Electric Cars Made in India | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Delivery | Last-Mile Delivery Solutions | Reduced operational costs through lower fuel expenses and maintenance. | Assess vehicle range, charging infrastructure, and payload capacity. |

| Public Transportation | Electric Buses and Taxis | Enhanced urban mobility with reduced emissions, attracting eco-conscious customers. | Evaluate fleet size, charging solutions, and local regulatory compliance. |

| Corporate Fleets | Employee Transportation Services | Improved employee satisfaction and corporate sustainability goals. | Consider vehicle specifications, maintenance support, and total cost of ownership. |

| Tourism and Travel | Electric Rental Vehicles | Attractive eco-friendly options for tourists, enhancing brand image. | Focus on vehicle availability, charging networks, and service agreements. |

| Agriculture and Farming | Utility Vehicles for Farm Operations | Efficient transport of goods and personnel, minimizing carbon footprint. | Look for durability, battery life, and compatibility with local terrain. |

How Can Electric Cars Made in India Benefit the Logistics and Delivery Industry?

Electric cars manufactured in India are increasingly being utilized for last-mile delivery solutions. These vehicles can significantly reduce operational costs due to lower fuel consumption and reduced maintenance needs compared to traditional vehicles. For international buyers in regions like Africa or South America, understanding the local charging infrastructure and vehicle range is crucial. Additionally, payload capacity must align with delivery requirements to ensure efficiency.

In What Ways Are Electric Cars Transforming Public Transportation?

The introduction of electric buses and taxis in urban areas is transforming public transportation. These vehicles not only reduce greenhouse gas emissions but also cater to a growing base of environmentally conscious consumers. For international buyers, it is essential to assess the local regulatory environment and available charging solutions to support fleet operations. The ability to integrate these vehicles into existing transport systems can enhance urban mobility.

What Advantages Do Electric Cars Offer for Corporate Fleets?

Electric cars are becoming a viable option for corporate fleets, especially for employee transportation services. They can improve employee satisfaction and align with corporate sustainability initiatives. International buyers should consider the specifications of the vehicles, the availability of maintenance support, and the total cost of ownership when sourcing these vehicles for corporate use. This ensures that the investment aligns with long-term business goals.

How Are Electric Rental Vehicles Enhancing Tourism and Travel?

Electric rental vehicles are gaining traction in the tourism sector, providing eco-friendly transportation options for travelers. This not only enhances the travel experience but also boosts the brand image of rental companies committed to sustainability. For international buyers, it is important to evaluate vehicle availability and charging networks in popular tourist destinations. Service agreements can also ensure reliable operations, catering to fluctuating demand.

Can Electric Vehicles Improve Efficiency in Agriculture and Farming?

Electric cars are being adapted for use in agriculture, serving as utility vehicles for transporting goods and personnel. They offer an efficient means of operation while minimizing the carbon footprint associated with traditional farming methods. For buyers in this sector, durability, battery life, and compatibility with local terrain are key considerations. Understanding these factors can help ensure that the vehicles meet the unique demands of agricultural operations.

3 Common User Pain Points for ‘electric cars made in india’ & Their Solutions

Scenario 1: Navigating Limited Charging Infrastructure for Electric Cars

The Problem: One of the most pressing challenges faced by B2B buyers considering electric cars made in India is the limited charging infrastructure, particularly in regions outside major urban centers. Buyers are concerned that insufficient charging stations will hinder their operational efficiency, affecting logistics and delivery timelines. This fear is compounded for companies that operate in less developed areas, where the availability of charging options is even scarcer. As a result, businesses may hesitate to invest in electric vehicles, fearing that their fleet could be rendered non-operational due to charging accessibility issues.

The Solution: To effectively navigate this challenge, B2B buyers should prioritize sourcing electric vehicles from manufacturers that have established partnerships with charging infrastructure providers. This includes brands that offer bundled services, integrating vehicle purchase with charging solutions. Additionally, buyers should conduct a comprehensive analysis of charging station networks in their operational areas, leveraging platforms that provide real-time data on charging station availability. Investing in fleet management software that includes route optimization based on charging station locations can also help mitigate downtime. Furthermore, engaging in discussions with local governments and energy providers can lead to collaborative efforts to enhance charging infrastructure, ensuring that businesses have the support they need for their electric vehicle fleets.

Scenario 2: Concerns About Vehicle Performance and Range

The Problem: Many B2B buyers express concerns regarding the performance and range of electric cars, particularly when compared to traditional internal combustion engine vehicles. Buyers worry about whether electric vehicles can meet the demands of their operations, especially for industries requiring long-haul transportation. The anxiety surrounding range anxiety—where drivers fear running out of battery power—can significantly impact the decision-making process when sourcing electric vehicles.

The Solution: To address these concerns, B2B buyers should focus on electric car models with proven performance metrics and substantial real-world range capabilities. Engaging in pilot programs that allow companies to test vehicles under actual working conditions can provide valuable insights into their performance and reliability. Furthermore, manufacturers should be transparent about the specifications and capabilities of their vehicles, including real-time data on battery life and efficiency in varying conditions. Buyers can also look for vehicles equipped with advanced regenerative braking systems, which can enhance range and performance. By ensuring that the selected vehicles align with their operational needs, buyers can make informed decisions that mitigate performance-related apprehensions.

Scenario 3: Managing Total Cost of Ownership (TCO) for Electric Vehicles

The Problem: Understanding the total cost of ownership (TCO) for electric vehicles can be challenging for B2B buyers. While the initial purchase price may be lower for some models, buyers may be concerned about hidden costs such as maintenance, battery replacement, and energy expenses. This uncertainty can lead to hesitation in committing to electric vehicle investments, especially when trying to present a robust business case to stakeholders.

The Solution: B2B buyers should conduct a thorough TCO analysis before making any purchases. This involves evaluating not only the upfront costs but also long-term expenses related to maintenance, energy consumption, and potential tax incentives or rebates available for electric vehicles. Collaborating with manufacturers that offer transparent pricing models and detailed TCO calculators can provide a clearer financial picture. Additionally, buyers should seek out electric vehicles with long warranties and low maintenance requirements to minimize future costs. Forming partnerships with energy providers can also lead to favorable rates for charging electricity, further reducing operational expenses. By approaching the investment from a holistic financial perspective, B2B buyers can confidently make informed decisions regarding their electric vehicle acquisitions.

Strategic Material Selection Guide for electric cars made in india

What Are the Key Materials Used in Electric Cars Made in India?

The electric vehicle (EV) industry in India is rapidly evolving, with manufacturers focusing on innovative materials to enhance performance, safety, and sustainability. Understanding the properties, advantages, and limitations of these materials is crucial for international B2B buyers looking to invest in electric cars. Here, we analyze four common materials used in electric cars made in India.

How Does Aluminum Benefit Electric Vehicle Manufacturing?

Aluminum is widely used in electric vehicles due to its lightweight properties, which contribute to improved energy efficiency and range. Its excellent corrosion resistance makes it suitable for various environmental conditions, particularly in humid or coastal regions. However, while aluminum offers durability, its higher manufacturing costs compared to steel can be a drawback for budget-conscious manufacturers.

For international buyers, compliance with standards such as ASTM B209 for aluminum sheet and plate can influence sourcing decisions. Additionally, the lightweight nature of aluminum aligns well with the growing demand for fuel-efficient vehicles in markets like Europe and the Middle East, where regulatory pressures are increasing.

What Role Does Steel Play in Electric Cars?

Steel remains a primary material in electric vehicle construction, particularly for structural components. Its high strength and durability make it ideal for safety-critical applications, such as the chassis and body. However, traditional steel can be heavier than alternatives like aluminum, potentially impacting the vehicle’s range.

The cost-effectiveness of steel is a significant advantage, especially for manufacturers aiming to keep production costs low. International buyers should consider compliance with standards like ASTM A36 for structural steel, ensuring that the materials meet the necessary safety and performance criteria in their regions.

Why Is Composite Material Important for Electric Vehicles?

Composite materials, particularly carbon fiber and fiberglass, are increasingly used in electric vehicles for components such as body panels and interior parts. These materials offer high strength-to-weight ratios, enhancing performance while reducing overall vehicle weight. However, the manufacturing complexity and higher costs associated with composites can limit their widespread adoption.

For B2B buyers, understanding the specific requirements for composite materials, including compliance with ISO 9001 for quality management, is essential. Markets in Africa and South America may have different preferences regarding material sustainability, making it crucial to align product offerings with local expectations.

How Does Lithium-Ion Battery Technology Influence Material Selection?

Lithium-ion batteries are at the heart of electric vehicles, and the materials used in their construction significantly impact performance and safety. Key materials include lithium, cobalt, and nickel, which are crucial for battery efficiency and longevity. However, sourcing these materials responsibly is a challenge, given environmental concerns and geopolitical factors.

International buyers must be aware of compliance with standards such as IEC 62133 for battery safety, particularly in regions like Europe, where regulations are stringent. The growing emphasis on sustainable sourcing practices is also a consideration for markets in the Middle East and Africa, where environmental impact is increasingly scrutinized.

Summary Table of Strategic Material Selection

| Material | Typical Use Case for electric cars made in india | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body panels, frames | Lightweight, corrosion-resistant | Higher manufacturing costs | Medium |

| Steel | Chassis, structural components | Cost-effective, high strength | Heavier than alternatives | Low |

| Composite | Body panels, interior parts | High strength-to-weight ratio | Manufacturing complexity and cost | High |

| Lithium-Ion | Battery packs | High energy density, efficiency | Sourcing challenges, environmental impact | High |

This strategic material selection guide provides valuable insights for international B2B buyers interested in electric cars made in India. By understanding the properties, advantages, and limitations of these materials, buyers can make informed decisions that align with their market needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cars made in india

What Are the Main Stages in the Manufacturing Process of Electric Cars Made in India?

The manufacturing process of electric cars in India is a complex and highly regulated sequence of stages designed to ensure quality and efficiency. The main stages typically include material preparation, forming, assembly, and finishing. Each stage incorporates advanced techniques that align with global standards to ensure the production of high-quality vehicles.

How is Material Prepared for Electric Car Manufacturing?

Material preparation is the first crucial step in the manufacturing process. It involves sourcing high-quality raw materials such as aluminum, steel, and advanced composites, which are essential for the lightweight and robust structure of electric vehicles (EVs). The selection of battery materials, including lithium and cobalt, also takes place during this stage. Manufacturers often employ just-in-time (JIT) inventory systems to minimize waste and ensure that materials are available when needed, enhancing efficiency.

What Techniques are Used in the Forming Stage of Electric Car Production?

The forming stage includes various techniques such as stamping, welding, and molding to shape the vehicle’s components. Advanced robotics and automation are frequently used to ensure precision and consistency. For instance, laser welding techniques are popular for joining components, offering superior strength while reducing the risk of distortion. Manufacturers also utilize computer numerical control (CNC) machines for precision cutting and shaping, which is critical for producing intricate battery enclosures and vehicle frames.

How is the Assembly of Electric Cars Conducted?

During the assembly stage, the vehicle’s components are brought together on an assembly line. This process is highly structured, often following the principles of lean manufacturing to reduce waste and optimize productivity. Quality control checkpoints are integrated into the assembly line, allowing for real-time monitoring and adjustments. Key components such as the electric motor, battery packs, and electronic control units are installed at this stage, requiring specialized knowledge and skills from the workforce.

What Finishing Techniques are Applied in Electric Car Manufacturing?

Finishing is the final stage of the manufacturing process, where the vehicle undergoes painting, detailing, and installation of interior components. Advanced painting techniques, such as robotic spray painting, ensure a uniform finish while minimizing environmental impact. Manufacturers also focus on aesthetic aspects, integrating human-centered design principles that enhance the user experience. This stage may also include the installation of advanced driver assistance systems (ADAS) and infotainment technologies, which are becoming increasingly important in modern electric vehicles.

What Quality Assurance Standards Are Applicable to Electric Cars Made in India?

Quality assurance (QA) is a pivotal component of the manufacturing process for electric cars in India. Manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system (QMS). Compliance with these standards is essential for ensuring that products meet customer and regulatory requirements consistently.

How Do International Standards Like ISO 9001 Enhance Quality Control?

ISO 9001 certification indicates that a manufacturer has established a robust QMS that emphasizes continuous improvement and customer satisfaction. This standard requires organizations to monitor and measure their processes, ensuring that they can identify areas for improvement. For international B2B buyers, verification of a supplier’s ISO certification can provide assurance of their commitment to quality.

What Specific Quality Control Checkpoints Are Implemented?

Quality control is integrated at several checkpoints throughout the manufacturing process, including Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC involves inspecting materials and components upon arrival to ensure they meet specified standards before being used in production.

- IPQC monitors the manufacturing process itself, checking for defects and ensuring that assembly techniques are followed correctly.

- FQC is the final inspection stage, where completed vehicles undergo rigorous testing to ensure they meet all performance and safety standards before being delivered to customers.

What Testing Methods Are Commonly Used in Electric Car Manufacturing?

Various testing methods are employed to ensure the quality and reliability of electric vehicles. Common tests include:

- Functional Testing: Ensures that all electrical and mechanical systems operate as intended.

- Safety Testing: Evaluates the vehicle’s performance in crash scenarios, checking compliance with global safety standards.

- Battery Testing: Assesses the battery’s capacity, charge cycles, and thermal management to ensure optimal performance and longevity.

- Durability Testing: Simulates real-world conditions to evaluate how the vehicle holds up over time.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers seeking electric vehicles manufactured in India should take proactive steps to verify supplier quality control measures. Here are some actionable strategies:

- Conduct Supplier Audits: Regular audits can provide insights into a supplier’s manufacturing processes, quality control measures, and compliance with international standards.

- Request Quality Reports: Suppliers should provide documentation detailing their quality control processes, including results from IQC, IPQC, and FQC inspections.

- Engage Third-Party Inspectors: Utilizing independent third-party inspection services can offer an unbiased assessment of a supplier’s quality assurance practices.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing electric cars from India, international B2B buyers should be aware of certain nuances in quality control that may affect their purchasing decisions. These include:

- Regulatory Compliance: Understanding the specific regulatory requirements in their home markets, such as CE marking in Europe or local safety standards in African and South American countries, is essential.

- Cultural Differences: Different countries may have varying approaches to quality assurance and customer service. It’s important to establish clear communication channels and expectations with suppliers.

- Market-Specific Modifications: Some manufacturers may need to adapt their vehicles to meet local market needs, which could impact quality. Buyers should ensure that these modifications do not compromise safety or performance.

Conclusion

The manufacturing processes and quality assurance protocols for electric cars made in India are structured to meet both domestic and international standards. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with reputable suppliers who prioritize quality and compliance. This knowledge is essential for navigating the evolving landscape of electric vehicle manufacturing and securing high-quality products for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cars made in india’

Introduction

This guide serves as a practical checklist for international B2B buyers interested in procuring electric cars manufactured in India. With the rapid growth of the electric vehicle (EV) sector in India, understanding the sourcing process is crucial for making informed decisions. This checklist outlines essential steps to ensure successful procurement while maximizing value and minimizing risk.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in the sourcing process. Identify the key features you require in an electric vehicle, such as battery capacity, range, charging time, and safety standards. This clarity will help you communicate effectively with potential suppliers and ensure that the vehicles meet your operational needs.

Step 2: Research the Market Landscape

Understanding the electric vehicle market in India is vital for informed decision-making. Investigate leading manufacturers, emerging players, and their product offerings. Pay attention to market trends, consumer preferences, and technological advancements to identify potential partners that align with your business objectives.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a proven track record in delivering quality electric vehicles, including certifications and compliance with international standards.

- Key Considerations:

- Supplier reputation in the market

- Customer reviews and feedback

- Industry certifications (e.g., ISO, quality standards)

Step 4: Assess Pricing and Payment Terms

Pricing structures can vary significantly among manufacturers. Compare costs not just for the vehicles but also for associated services such as warranties, maintenance, and support. Understanding payment terms, including financing options, can provide flexibility and influence your overall budget.

- Important Factors:

- Total cost of ownership (TCO)

- Availability of leasing options

- Currency fluctuations if dealing with international suppliers

Step 5: Verify Compliance with Regulations

Ensure that the electric vehicles comply with both Indian and international regulations. This includes safety standards, emissions norms, and import/export regulations. Compliance is crucial for avoiding legal issues and ensuring that the vehicles are suitable for your target market.

Step 6: Conduct Site Visits and Inspections

Whenever possible, conduct site visits to the manufacturing facilities. This allows you to assess production capabilities, quality control processes, and overall operational efficiency. Engaging in face-to-face discussions with the management can provide deeper insights into their commitment to quality and customer service.

Step 7: Establish After-Sales Support and Warranty Terms

After-sales support is a critical factor in the procurement process. Ensure that the supplier offers comprehensive support services, including maintenance, spare parts availability, and warranty terms. This can significantly impact the long-term success of your investment in electric vehicles.

- What to Look For:

- Duration and coverage of warranty

- Availability of service centers

- Responsiveness to customer inquiries

By following this checklist, B2B buyers can navigate the complexities of sourcing electric cars made in India, ensuring they make informed and strategic decisions that align with their business goals.

Comprehensive Cost and Pricing Analysis for electric cars made in india Sourcing

What Are the Key Cost Components in Electric Car Manufacturing in India?

When sourcing electric cars made in India, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, including lithium for batteries, steel for chassis, and various electronic components, significantly influences the final price. Prices can fluctuate based on global supply chain dynamics and availability.

-

Labor: Skilled labor is essential for manufacturing electric vehicles (EVs). India’s labor costs are relatively lower compared to many Western countries, but the complexity of EV technology requires trained personnel, which can increase costs.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, such as utilities, facility maintenance, and administrative expenses. Overhead can vary depending on the manufacturer’s scale and efficiency.

-

Tooling: The initial investment in tooling and machinery is substantial, particularly for specialized components unique to electric vehicles. This is a critical factor for manufacturers aiming to meet specific quality standards.

-

Quality Control (QC): Ensuring that vehicles meet safety and performance standards involves rigorous testing and quality assurance processes. The costs associated with QC can vary based on the certifications required for different markets.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, are significant, especially for international buyers. Understanding the logistics involved is essential for accurately calculating total costs.

-

Margin: Manufacturers typically build a profit margin into their pricing, which can vary based on brand positioning, market demand, and competitive landscape.

How Do Price Influencers Affect the Cost of Electric Cars in India?

Several factors can influence the pricing of electric vehicles, including:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes can lead to discounts, making it essential for buyers to negotiate favorable terms based on their purchasing capacity.

-

Specifications and Customization: Custom features can significantly impact pricing. Buyers should clearly outline their requirements to avoid unexpected costs.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or safety standards) can increase costs but are often necessary for international markets.

-

Supplier Factors: The reputation and reliability of suppliers play a role in pricing. Established manufacturers may charge a premium for their proven track record.

-

Incoterms: Understanding Incoterms is crucial for determining who bears the cost and risk at each stage of the supply chain. This can affect the total landed cost of the vehicle.

What Are Some Buyer Tips for Sourcing Electric Cars from India?

When engaging in B2B transactions for electric cars in India, consider the following tips:

-

Negotiation: Leverage your position as a bulk buyer to negotiate better terms. Discuss payment terms, delivery schedules, and warranty conditions to maximize value.

-

Cost-Efficiency: Analyze the total cost of ownership (TCO), which includes not only the purchase price but also maintenance, insurance, and potential resale value. This approach helps in making informed purchasing decisions.

-

Pricing Nuances for International Buyers: Be aware of additional costs such as tariffs, taxes, and compliance fees when importing vehicles. Understanding local regulations in your target market can prevent unexpected expenses.

-

Quality Assurance: Prioritize manufacturers who can provide robust QC processes and certifications. This ensures that the vehicles meet the necessary standards for safety and performance.

Disclaimer on Indicative Prices

Prices for electric cars made in India can fluctuate based on market conditions, specifications, and other variables. It is advisable for international buyers to obtain detailed quotes and conduct thorough due diligence before making purchasing decisions.

Alternatives Analysis: Comparing electric cars made in india With Other Solutions

Understanding the Alternatives in Electric Vehicle Solutions

As the demand for sustainable transportation solutions increases, B2B buyers must evaluate various alternatives to electric cars made in India. This analysis will compare Indian electric vehicles (EVs) with two viable alternatives: hybrid vehicles and hydrogen fuel cell vehicles. Each option has its own strengths and weaknesses, making it essential for businesses to understand the distinctions in performance, cost, ease of implementation, maintenance, and optimal use cases.

| Comparison Aspect | Electric Cars Made In India | Hybrid Vehicles | Hydrogen Fuel Cell Vehicles |

|---|---|---|---|

| Performance | High torque, instant power | Moderate power, less efficient | High efficiency, quick refueling |

| Cost | INR 6.24 Lakh – 75.00 Lakh | INR 10 Lakh – 30 Lakh | INR 40 Lakh – 1 Crore |

| Ease of Implementation | Increasing charging infrastructure | Established fuel infrastructure | Limited refueling stations |

| Maintenance | Low maintenance costs | Moderate maintenance | Higher maintenance costs |

| Best Use Case | Urban commuting and logistics | Mixed-use, urban and rural | Long-distance travel, fleet use |

What Are the Pros and Cons of Electric Cars Made in India?

Electric cars produced in India, such as the Tata Nexon EV and Mahindra BE 6, offer a range of performance benefits, including high torque and instant power delivery. They are particularly well-suited for urban commuting and logistics, where short travel distances and frequent stops are common. The cost of these vehicles ranges from INR 6.24 Lakh to INR 75.00 Lakh, making them accessible to various segments of the market. Additionally, the maintenance costs are generally low, thanks to fewer moving parts compared to traditional internal combustion engines. However, the effectiveness of these vehicles is heavily reliant on the availability of charging infrastructure, which is still developing in many regions.

How Do Hybrid Vehicles Compare?

Hybrid vehicles serve as a middle ground between traditional gasoline engines and fully electric models. They combine internal combustion engines with electric propulsion, offering better fuel efficiency than conventional cars but less efficiency than electric vehicles. The cost of hybrids typically ranges from INR 10 Lakh to INR 30 Lakh. One advantage of hybrids is their established fuel infrastructure, making them easier to implement in areas with limited EV charging stations. However, they require moderate maintenance and may not be as environmentally friendly as fully electric options, given their reliance on fossil fuels.

What About Hydrogen Fuel Cell Vehicles?

Hydrogen fuel cell vehicles represent another alternative, utilizing hydrogen to generate electricity for propulsion. They offer high efficiency and rapid refueling, making them ideal for long-distance travel and fleet operations. However, the cost of these vehicles is significantly higher, ranging from INR 40 Lakh to 1 Crore. The primary drawback is the limited availability of hydrogen refueling stations, which poses challenges for widespread adoption. Additionally, maintenance costs can be higher due to the complexity of fuel cell technology.

How Should B2B Buyers Decide on the Right Solution?

For B2B buyers, the choice between electric cars made in India, hybrid vehicles, and hydrogen fuel cell vehicles hinges on specific operational needs and regional infrastructure. Buyers focusing on urban commuting may find electric cars most suitable due to their lower operating costs and performance in short-range scenarios. Conversely, businesses requiring versatility and established refueling options might prefer hybrids. Finally, companies engaged in long-haul logistics may benefit from hydrogen fuel cells, provided they can access the necessary refueling infrastructure. By carefully assessing these factors, businesses can select the most effective transportation solution that aligns with their sustainability goals and operational requirements.

Essential Technical Properties and Trade Terminology for electric cars made in india

What Are the Essential Technical Properties of Electric Cars Made in India?

Electric vehicles (EVs) produced in India offer a variety of specifications critical for international B2B buyers. Understanding these properties is essential for making informed purchasing decisions and ensuring compatibility with local markets.

1. Battery Capacity (kWh)

The battery capacity, measured in kilowatt-hours (kWh), indicates how much energy the battery can store. For instance, many Indian EVs feature batteries ranging from 20 kWh to over 70 kWh. A larger capacity generally translates to a longer driving range, which is a vital consideration for fleet operators and consumers alike. Understanding battery capacity helps buyers assess the vehicle’s suitability for specific use cases, such as urban commuting or long-distance travel.

2. Motor Power (bhp)

Motor power, expressed in brake horsepower (bhp), determines the vehicle’s performance characteristics, including acceleration and top speed. EVs in India typically range from 70 bhp to over 300 bhp. This metric is crucial for businesses that require vehicles capable of carrying heavy loads or navigating challenging terrains. Higher power ratings often correlate with better performance, making it essential for buyers to match motor power with their operational needs.

3. Charging Time (Hours)

Charging time refers to the duration required to fully charge the vehicle’s battery. In India, charging times can vary significantly based on the charger type, ranging from as little as 30 minutes for fast chargers to several hours for standard home chargers. This property is particularly important for fleet managers and businesses that rely on quick turnaround times to maximize vehicle utilization.

4. Driving Range (Kilometers)

The driving range is the maximum distance an EV can travel on a single charge, typically measured in kilometers. Indian electric cars often boast ranges from 150 km to over 500 km, depending on battery capacity and vehicle design. Understanding the driving range is critical for international buyers to ensure that the vehicles meet the daily operational requirements without frequent recharging.

5. Regenerative Braking System

A regenerative braking system captures energy during braking and redirects it to recharge the battery. This feature not only improves overall energy efficiency but also extends the vehicle’s driving range. Buyers should consider this technology as it contributes to reduced operating costs and enhances the sustainability profile of their fleet.

6. Safety Standards and Ratings

Safety standards are crucial for any vehicle, especially in markets with varying regulations. Indian EV manufacturers often comply with international safety standards like Global NCAP ratings. Understanding these ratings is essential for B2B buyers to ensure that the vehicles meet safety expectations in their respective markets.

What Are the Common Trade Terms in the Electric Vehicle Industry?

Navigating the electric vehicle market requires familiarity with specific trade terminology that can impact purchasing decisions and negotiations.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are sold under another brand’s name. In the context of electric vehicles, this term often refers to manufacturers who produce the vehicles themselves or the components used within them. Understanding OEM relationships is crucial for buyers looking for reliability and quality assurance in their purchases.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is vital for international buyers as it affects inventory management and cash flow. Knowing the MOQ helps companies plan their purchases effectively, especially when entering new markets or launching new products.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and terms for specific products or services. This term is essential for B2B buyers as it initiates the procurement process and helps in comparing different suppliers’ offerings. Crafting a clear RFQ can lead to better pricing and service agreements.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers. Understanding Incoterms is crucial for international transactions, as they dictate who bears the costs and risks at various stages of shipping and delivery. Familiarity with these terms can help mitigate misunderstandings and enhance contract negotiations.

5. TCO (Total Cost of Ownership)

TCO refers to the comprehensive assessment of all costs associated with purchasing and operating a vehicle over its entire lifecycle. This includes purchase price, financing, maintenance, fuel (or electricity), and resale value. Buyers should consider TCO to understand the long-term financial implications of their electric vehicle investments.

6. CPO (Certified Pre-Owned)

CPO vehicles are used cars that have been inspected, refurbished, and certified by the manufacturer or a third party. This term is increasingly relevant in the EV market as more consumers seek affordable options. B2B buyers can benefit from CPO programs as they often come with warranties and assurances of quality, making them a viable option for fleet expansions.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing electric vehicles made in India, ensuring compatibility with their operational needs and market requirements.

Navigating Market Dynamics and Sourcing Trends in the electric cars made in india Sector

What Are the Current Market Dynamics and Key Trends in the Electric Cars Made in India Sector?

The Indian electric vehicle (EV) market is rapidly evolving, influenced by global trends and local dynamics. As international buyers from Africa, South America, the Middle East, and Europe consider sourcing electric vehicles from India, several key drivers are shaping this landscape. First, the push for sustainable transportation solutions is being driven by government incentives, such as subsidies and tax exemptions, aimed at increasing EV adoption. Additionally, technological advancements in battery production and charging infrastructure are addressing previous barriers to entry, making electric cars more accessible and appealing to consumers.

Emerging B2B sourcing trends include partnerships with local manufacturers who can provide competitive pricing and innovative designs tailored to regional markets. For instance, companies like Mahindra and Tata are leading the charge with a diverse range of models that cater to different segments, from budget-friendly options to premium vehicles. Furthermore, the focus on fleet electrification is gaining traction among businesses, particularly in urban settings where government regulations are tightening around emissions. International buyers should consider these dynamics as they explore sourcing opportunities in India.

How Is Sustainability and Ethical Sourcing Impacting the Electric Cars Made in India Sector?

Sustainability is becoming a cornerstone of the electric vehicle industry, and this is particularly relevant for B2B buyers looking to align with environmentally responsible practices. The production of electric cars in India is increasingly focused on minimizing environmental impact, from sourcing raw materials to manufacturing processes. Ethical sourcing of materials, such as lithium and cobalt used in batteries, is critical. Buyers should prioritize suppliers who adhere to sustainable practices, ensuring that materials are sourced responsibly and do not contribute to environmental degradation.

Moreover, certifications such as ISO 14001 for environmental management systems and adherence to fair labor practices are becoming essential in the procurement process. Companies that provide ‘green’ certifications or utilize recyclable materials in their vehicle production can offer added value to international buyers, enhancing their brand image in markets that prioritize sustainability. As the global demand for electric vehicles continues to rise, aligning with manufacturers committed to sustainability will not only fulfill regulatory requirements but also resonate with environmentally conscious consumers.

What Is the Brief Evolution and History of Electric Cars Made in India?

The electric vehicle sector in India has witnessed a significant transformation over the past decade. Initially, the market was characterized by limited offerings and high costs, with early adopters primarily focused on two-wheeler electric vehicles. However, government initiatives, such as the Faster Adoption and Manufacturing of Hybrid and Electric Vehicles (FAME) scheme, have catalyzed growth, encouraging investment in EV infrastructure and manufacturing capabilities.

As a result, major automotive players like Tata Motors and Mahindra have expanded their portfolios to include a range of electric cars, catering to diverse consumer preferences. The introduction of models like the Tata Nexon EV and Mahindra BE 6 signifies a shift towards more affordable and practical electric options. This evolution reflects not only technological advancements but also a broader societal shift towards sustainable transportation solutions, positioning India as a key player in the global electric vehicle market. For international buyers, understanding this historical context can provide valuable insights into the current landscape and future opportunities within the Indian EV sector.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cars made in india

-

1. How do I evaluate the quality of electric cars made in India?

To assess the quality of electric cars from India, consider the manufacturer’s reputation, certifications, and customer reviews. Look for compliance with international safety standards and quality assurance processes. Engage in direct discussions with suppliers to understand their production methods and quality control measures. Additionally, request samples or arrange for test drives to evaluate performance and build quality firsthand. It may also be beneficial to involve third-party inspection services to verify compliance with your specifications. -

2. What are the key features to look for in electric cars for B2B purchases?

When sourcing electric cars for B2B purposes, prioritize features such as range, charging time, battery life, and warranty terms. Evaluate the vehicle’s payload capacity and performance metrics relevant to your business needs. Additionally, consider advanced safety features and connectivity options, as these can enhance operational efficiency. Customization options may also be important, allowing you to tailor vehicles to specific applications within your business context. -

3. What is the typical minimum order quantity (MOQ) for electric cars made in India?

The MOQ for electric cars can vary significantly based on the manufacturer and model. Generally, established manufacturers may set an MOQ ranging from 10 to 50 units for bulk orders. However, some manufacturers may accommodate smaller orders, especially if you are willing to pay a premium. It’s essential to discuss your specific needs with suppliers to negotiate favorable terms that align with your purchasing strategy. -

4. How can I ensure reliable logistics and delivery for my electric car order?

To guarantee reliable logistics, partner with manufacturers that have established supply chains and distribution networks. Discuss delivery timelines upfront and consider factors such as port locations and shipping methods. It may also be beneficial to engage a freight forwarder who specializes in automotive logistics to navigate customs and ensure timely delivery. Establish clear communication with your supplier regarding tracking shipments and handling potential delays. -

5. What payment terms should I expect when purchasing electric cars from India?

Payment terms for electric car purchases can vary widely. Typically, manufacturers may require an upfront deposit (20-30%) with the balance due upon delivery or before shipment. Some may offer financing options or extended payment plans for bulk orders. It’s crucial to clarify payment terms in advance, including any potential penalties for late payments or discounts for early settlements, to avoid misunderstandings during the transaction. -

6. How do I verify the credibility of electric car suppliers in India?

To verify supplier credibility, conduct thorough research by checking their business licenses, certifications, and industry reputation. Look for reviews and feedback from previous international clients. Utilize platforms such as LinkedIn to connect with industry professionals and gather insights. Additionally, consider requesting references or case studies demonstrating the supplier’s experience in international transactions and compliance with export regulations. -

7. Can I customize electric cars for my specific business needs?

Most manufacturers in India offer customization options, allowing you to tailor vehicles to meet specific business requirements. This may include modifications to seating capacity, battery configurations, or additional technology features. Engage with suppliers early in the negotiation process to discuss your customization needs and any associated costs. Be prepared to provide detailed specifications to ensure that the final product aligns with your operational goals. -

8. What after-sales support can I expect when purchasing electric cars from Indian manufacturers?

After-sales support is crucial for maintaining vehicle performance and addressing any issues post-purchase. Most reputable manufacturers provide comprehensive warranties, maintenance services, and access to spare parts. Inquire about their customer service policies, including response times for service requests and availability of technical support. Establishing a clear after-sales service agreement will help ensure a smooth ownership experience and minimize downtime for your fleet.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Electric Cars Made In India Manufacturers & Suppliers List

1. VinFast – VF 8 ECO

Domain: vinfastauto.us

Registered: 2020 (5 years)

Introduction: VinFast offers several electric vehicle models with the following key details:

1. **VF 8 ECO**:

– Passenger Capacity: 5

– Estimated Range: 280 miles (WLTP)

– Lease: $279/month for 24 months

– MSRP: $41,100

– Cash due at signing: $279 first month’s payment, $695 acquisition fee

– Purchase option at lease end: $22,605 + $350 fee

– Financing: 0% APR for 84 months + $7,50…

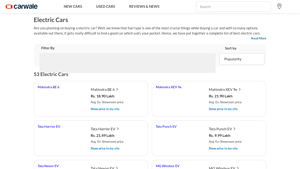

2. CarWale – Electric Cars Overview

Domain: carwale.com

Registered: 2005 (20 years)

Introduction: {“electric_cars”: [{“model”: “Mahindra BE 6”, “price”: “Rs. 18.90 Lakh”}, {“model”: “Mahindra XEV 9e”, “price”: “Rs. 21.90 Lakh”}, {“model”: “Tata Harrier EV”, “price”: “Rs. 21.49 Lakh”}, {“model”: “Tata Punch EV”, “price”: “Rs. 9.99 Lakh”}, {“model”: “Tata Nexon EV”, “price”: “Rs. 12.49 Lakh”}, {“model”: “MG Windsor EV”, “price”: “Rs. 12.00 Lakh”}, {“model”: “Tata Tiago EV”, “price”: “Rs. 7.99 La…

3. Tata Motors – Nexon Electric SUV

Domain: reuters.com

Registered: 1993 (32 years)

Introduction: Tata Motors plans to have 10 electric models in its portfolio over the next 3-4 years, with EVs making up 25% of total car sales by 2025. The latest model is a new version of the Nexon electric SUV with a starting price of 1.5 million rupees ($18,000). Mahindra and Mahindra expects electric models to make up 20%-30% of SUV sales by March 2027 and sells an electric version of the XUV 400 SUV. Hyund…

4. General Motors – EV Lineup; MG Motor India – Intelligent CUV; Greaves Electric Mobility – e-Scooters

Domain: builtin.com

Registered: 1999 (26 years)

Introduction: General Motors: EV lineup includes sedans, pickup trucks, delivery vehicles; operates manufacturing facilities in India. MG Motor India: Offers electric SUVs, CUVs; MG Windsor EV is India’s first intelligent CUV with battery-as-a-service (BAAS). Greaves Electric Mobility: Manufactures e-scooters, e-rickshaws, e-three wheelers; focuses on energy-efficient travel. Piaggio Vehicles: Offers three-whee…

5. Tata Motors – Electric Vehicles

Domain: tatamotors.com

Registered: 2002 (23 years)

Introduction: Tata Motors is the largest player in India’s electric vehicle (EV) market, having produced 150,000 EVs and driven over 2.8 billion kilometers. Key models include Punch.ev, Nexon.ev, and XPRES-T, which is noted as the number one electric SUV. The company focuses on performance, reliability, and technology, offering multiple body styles and options for long-range travel. Their EVs are designed for c…

6. Reddit – $10,000 Electric Cars in India

Strategic Sourcing Conclusion and Outlook for electric cars made in india

In the rapidly evolving landscape of electric vehicles (EVs) in India, strategic sourcing emerges as a pivotal element for international B2B buyers seeking to capitalize on this burgeoning market. With leading manufacturers like Mahindra and Tata setting competitive pricing and innovative designs, opportunities abound for buyers looking to diversify their EV portfolios. The Indian electric car market, characterized by a blend of affordability and advanced technology, presents a unique proposition for global businesses aiming to meet the rising demand for sustainable transportation.

By engaging in strategic sourcing, buyers can leverage India’s robust manufacturing capabilities and favorable government policies designed to promote electric mobility. This approach not only ensures cost efficiency but also aligns with the growing global emphasis on sustainability. Moreover, as the market matures, partnerships with Indian manufacturers can provide access to cutting-edge technology and enhanced supply chain resilience.

Looking ahead, international buyers should act now to explore the vast potential of electric vehicles made in India. By establishing strong sourcing relationships, businesses can position themselves at the forefront of the electric mobility revolution, tapping into new markets across Africa, South America, the Middle East, and Europe. Embrace this opportunity to drive forward your sustainability goals and enhance your competitive edge in the global EV landscape.