Introduction: Navigating the Global Market for electric car body

As the global automotive industry transitions towards sustainability, the challenge of sourcing high-quality electric car bodies has become increasingly prominent for international B2B buyers. The demand for electric vehicles (EVs) is surging, yet many businesses grapple with understanding the complexities of the electric car body market, including material specifications, design variations, and supplier credibility. This comprehensive guide aims to demystify the electric car body landscape, offering insights into various types of electric vehicle bodies, their applications, and the materials that optimize performance and sustainability.

Within these pages, buyers will find essential information on vetting suppliers, understanding cost structures, and navigating the logistics of procurement, particularly tailored for emerging markets in Africa, South America, the Middle East, and Europe. By focusing on regions such as Nigeria and Brazil, this guide addresses the unique challenges and opportunities these markets present, empowering businesses to make informed purchasing decisions. With expert insights and actionable strategies, B2B buyers can confidently navigate the evolving global market for electric car bodies, ensuring they select solutions that meet their operational needs while aligning with their sustainability goals.

Understanding electric car body Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| All-Electric Vehicles (BEVs) | No tailpipe emissions, large traction battery, quiet operation | Fleet management, urban transportation | Pros: Lower operating costs, eco-friendly. Cons: Limited range compared to hybrids. |

| Plug-In Hybrid Electric Vehicles (PHEVs) | Combines electric motor with internal combustion engine, rechargeable battery | Logistics, emergency services | Pros: Flexibility in power sources, extended range. Cons: More complex maintenance. |

| Hybrid Electric Vehicles (HEVs) | Primarily gas-powered with electric assist, no plug-in capability | Public transport, rideshare services | Pros: Fuel efficiency, less dependency on charging infrastructure. Cons: Higher emissions than BEVs. |

| Sports Electric Vehicles | Performance-oriented designs with lightweight materials | Luxury markets, high-performance rentals | Pros: Superior speed and handling, brand prestige. Cons: Higher cost, niche market appeal. |

| Commercial Electric Vans | Designed for cargo transport, spacious interiors, robust build | Delivery services, trades, logistics firms | Pros: Cost-effective for last-mile delivery, environmentally friendly. Cons: Potentially higher upfront costs. |

What Are the Key Characteristics of All-Electric Vehicles (BEVs)?

All-Electric Vehicles (BEVs) feature a design that eliminates tailpipe emissions, relying solely on an extensive traction battery that powers an electric motor. This body type is ideal for urban settings where emissions regulations are stringent. B2B buyers should consider the operational cost savings associated with BEVs, as they often have lower maintenance needs compared to traditional vehicles. However, range limitations can be a concern for businesses requiring long-distance travel.

How Do Plug-In Hybrid Electric Vehicles (PHEVs) Combine Power Sources?

PHEVs integrate both an electric motor and an internal combustion engine, allowing them to operate on electric power alone for short distances while seamlessly switching to gasoline for longer trips. This versatility makes them suitable for logistics and emergency services where operational flexibility is crucial. When purchasing PHEVs, businesses should evaluate their typical usage patterns to ensure they benefit from both electric and gas capabilities, although they may incur higher maintenance costs due to the dual systems.

What Are the Benefits of Hybrid Electric Vehicles (HEVs) for B2B Applications?

Hybrid Electric Vehicles (HEVs) primarily utilize gasoline but are equipped with an electric motor to enhance fuel efficiency. This body type is beneficial for public transport and rideshare services where reducing fuel costs is essential. B2B buyers should note that while HEVs offer better fuel economy than traditional vehicles, they still emit some greenhouse gases, making them less attractive for companies focused on sustainability.

Why Are Sports Electric Vehicles Gaining Popularity in Luxury Markets?

Sports Electric Vehicles are designed for high performance, featuring lightweight materials that enhance speed and handling. These vehicles appeal to luxury markets and high-performance rentals, providing a unique driving experience. B2B buyers in these sectors should consider the prestige associated with sports EVs, although the higher cost and niche market may limit their broader application.

What Makes Commercial Electric Vans Suitable for Delivery Services?

Commercial Electric Vans are tailored for cargo transport, offering spacious interiors and robust builds. They are increasingly popular among delivery services and logistics firms due to their cost-effectiveness for last-mile delivery solutions. When considering these vans, B2B buyers should weigh the initial investment against long-term savings on fuel and maintenance, recognizing that the upfront costs may be higher compared to traditional vans.

Key Industrial Applications of electric car body

| Industry/Sector | Specific Application of Electric Car Body | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of lightweight electric vehicle bodies | Reduces overall vehicle weight, improving efficiency and range | Sourcing advanced materials like aluminum and high-strength steel |

| Public Transportation | Development of electric buses and shuttles | Lower operational costs and reduced emissions | Compliance with local regulations and standards for public transport |

| Logistics and Delivery | Electric delivery vans and trucks | Enhances sustainability and lowers fuel costs | Customization options for cargo space and battery capacity |

| Renewable Energy Vehicles | Electric utility vehicles for energy companies | Supports green initiatives and reduces carbon footprint | Need for durable and weather-resistant materials |

| Automotive Parts Suppliers | Supply of body components for electric vehicle assembly | Access to a growing market and partnership opportunities | Quality control and certification processes for parts manufacturing |

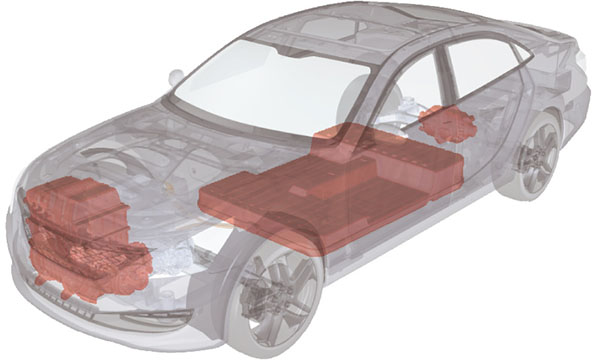

How is Electric Car Body Used in Automotive Manufacturing?

In the automotive manufacturing sector, electric car bodies are produced using lightweight materials such as aluminum and advanced high-strength steels. This application addresses the challenge of vehicle weight, which directly impacts efficiency and range. Buyers from regions like Africa and South America must consider the sourcing of these materials, ensuring they meet local regulations and sustainability goals. The integration of innovative designs can also enhance vehicle performance and consumer appeal.

What Role Do Electric Car Bodies Play in Public Transportation?

Electric car bodies are crucial in the development of electric buses and shuttles, offering a sustainable alternative to traditional diesel-powered vehicles. This transition reduces operational costs and emissions, aligning with global trends towards cleaner public transport solutions. For international buyers, particularly in the Middle East and Europe, it’s vital to ensure that the designs comply with local transport regulations and standards while also providing comfort and safety for passengers.

How Are Electric Car Bodies Transforming Logistics and Delivery?

In the logistics sector, electric delivery vans and trucks are becoming increasingly popular due to their lower operational costs and reduced environmental impact. The electric car body design caters to the need for efficient cargo space while maintaining lightweight characteristics to maximize range. B2B buyers in regions such as Nigeria and Brazil should focus on customization options that meet specific delivery requirements, ensuring that the vehicles can handle diverse cargo types while being cost-effective.

What Benefits Do Electric Car Bodies Offer for Renewable Energy Vehicles?

Electric utility vehicles designed with specialized electric car bodies are essential for energy companies aiming to enhance their sustainability efforts. These vehicles support green initiatives by reducing the carbon footprint associated with traditional fuel-powered utility vehicles. Buyers in Europe and the Middle East should prioritize durable and weather-resistant materials that can withstand harsh operating conditions while ensuring compliance with environmental regulations.

How Can Automotive Parts Suppliers Leverage Electric Car Body Manufacturing?

Automotive parts suppliers have significant opportunities in the electric vehicle market by providing body components for electric vehicle assembly. This application allows suppliers to tap into a growing market driven by the shift towards electric mobility. For international B2B buyers, it is crucial to focus on quality control and certification processes to ensure that parts meet industry standards, thereby fostering trust and reliability in the supply chain.

3 Common User Pain Points for ‘electric car body’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in Electric Car Body Manufacturing

The Problem: B2B buyers in the electric vehicle (EV) sector often face significant challenges related to the supply chain, particularly when sourcing materials for electric car bodies. Global events, such as geopolitical tensions or pandemics, can cause unexpected delays in the delivery of critical components like lightweight metals (aluminum, high-strength steel) and composite materials. This can disrupt production timelines and lead to increased costs, ultimately affecting the bottom line and market competitiveness.

The Solution: To mitigate supply chain risks, B2B buyers should prioritize establishing relationships with multiple suppliers across different geographical regions. This diversification strategy not only ensures a steady flow of materials but also creates a buffer against localized disruptions. Additionally, investing in advanced inventory management systems can help track stock levels in real time, allowing for proactive adjustments to orders based on demand forecasts. Collaborating closely with suppliers to develop a just-in-time manufacturing approach can further enhance responsiveness and reduce excess inventory costs. Engaging in strategic partnerships or consortiums focused on sustainable sourcing can also provide access to alternative materials that meet both environmental and performance standards.

Scenario 2: Addressing Regulatory Compliance for Electric Car Bodies

The Problem: As governments worldwide implement stricter regulations regarding vehicle emissions and safety standards, B2B buyers must ensure that the electric car bodies they source comply with these evolving requirements. This can be particularly daunting in regions with rapidly changing regulatory landscapes, such as the European Union and parts of South America, where failure to comply can result in substantial fines and market entry barriers.

The Solution: B2B buyers should invest in comprehensive regulatory training for their procurement teams to stay informed about the latest standards affecting electric car bodies. Partnering with legal experts who specialize in automotive regulations can provide insights into compliance requirements and help navigate the complexities of international standards. Additionally, establishing a quality assurance program that includes regular audits and certifications of suppliers can ensure that all sourced materials and components meet safety and environmental regulations. Leveraging technology, such as compliance management software, can streamline the monitoring of regulations across different markets, making it easier to maintain compliance without extensive manual processes.

Scenario 3: Overcoming Design Limitations in Electric Car Body Development

The Problem: Many B2B buyers encounter challenges when integrating innovative designs for electric car bodies that leverage advanced materials and technologies. Traditional design practices may not fully exploit the unique properties of lightweight composites or high-strength steels, leading to suboptimal performance and aesthetics. This limitation can hinder the competitive edge needed in the rapidly evolving EV market, particularly in regions like Africa and the Middle East, where consumer preferences are shifting toward modern, stylish vehicles.

The Solution: To overcome design limitations, B2B buyers should adopt a collaborative approach that involves cross-functional teams, including engineers, designers, and material scientists. Utilizing computer-aided design (CAD) software that supports simulations can help visualize the impact of different materials and designs early in the development process. Engaging with suppliers who specialize in advanced materials can provide insights into the latest innovations and best practices for integrating these materials into electric car bodies. Furthermore, investing in rapid prototyping technologies, such as 3D printing, allows for the quick iteration of designs, enabling buyers to test and refine body shapes efficiently before mass production. This iterative approach fosters creativity and ensures that the final product aligns with market demands and consumer expectations.

Strategic Material Selection Guide for electric car body

What Are the Key Materials Used in Electric Car Body Construction?

The selection of materials for electric car bodies is crucial for optimizing performance, safety, and sustainability. Here, we analyze four common materials—aluminum, high-strength steel, carbon fiber, and composite materials—highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Benefit Electric Car Body Design?

Aluminum is widely used in electric vehicle (EV) bodies due to its lightweight nature and excellent corrosion resistance. Key properties include a density that is about one-third that of steel, which significantly reduces the overall weight of the vehicle, enhancing energy efficiency and range. Aluminum also exhibits good thermal conductivity and is recyclable, aligning with sustainability goals.

Pros: Its lightweight characteristic improves vehicle performance and efficiency. Additionally, aluminum is easier to mold into complex shapes, which can enhance aerodynamics.

Cons: The primary drawback is the cost, as aluminum can be more expensive than traditional steel. Manufacturing complexity can also increase due to the need for specialized welding techniques.

Impact on Application: Aluminum is particularly suitable for electric vehicles that require a lightweight structure to maximize battery efficiency. However, it may not be as effective in high-impact scenarios compared to some steels.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local availability and cost fluctuations. Compliance with standards such as ASTM for aluminum alloys is essential for ensuring quality and safety.

What Role Does High-Strength Steel Play in Electric Car Bodies?

High-strength steel (HSS) is another popular choice for electric car bodies, known for its superior strength-to-weight ratio. Key properties include excellent tensile strength and impact resistance, making it suitable for safety-critical components.

Pros: HSS provides durability and structural integrity, which is vital for crash safety. It is also more cost-effective compared to aluminum, making it attractive for budget-conscious manufacturers.

Cons: The heavier weight of HSS can negatively impact energy efficiency and range. Additionally, the manufacturing process can be more complex due to the need for advanced forming techniques.

Impact on Application: HSS is ideal for areas requiring high strength, such as the passenger compartment and safety structures. However, it may limit overall vehicle weight reduction strategies.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as DIN or JIS for steel grades. The availability of HSS in local markets can vary, impacting lead times and costs.

How Does Carbon Fiber Enhance Electric Car Body Performance?

Carbon fiber is increasingly being considered for high-performance electric vehicles due to its exceptional strength and lightweight properties. Key properties include high tensile strength, low density, and excellent fatigue resistance.

Pros: The primary advantage of carbon fiber is its lightweight nature, which significantly improves vehicle performance and efficiency. It also offers superior resistance to corrosion and can be molded into complex shapes.

Cons: The main limitation is the high cost of production, making it less accessible for mass-market vehicles. Additionally, the manufacturing process can be complex and time-consuming.

Impact on Application: Carbon fiber is particularly beneficial for performance-focused EVs, where weight savings directly translate to enhanced speed and range. However, it may not be suitable for all applications due to cost constraints.

Considerations for International Buyers: Buyers should be aware of the technological capabilities of local suppliers, as carbon fiber production requires specialized equipment. Compliance with international standards is also crucial for ensuring quality.

What Are the Advantages of Using Composite Materials in Electric Car Bodies?

Composite materials, which combine two or more constituents, are gaining traction in electric vehicle manufacturing. Key properties include tailored mechanical properties and lightweight characteristics.

Pros: Composites can be engineered to provide specific performance characteristics, such as enhanced impact resistance or thermal stability. They are also lightweight, contributing to overall vehicle efficiency.

Cons: The primary disadvantage is the complexity of manufacturing and potential difficulties in recycling. Additionally, composites can be more expensive than traditional materials.

Impact on Application: Composites are particularly useful in non-structural components or areas where weight reduction is critical without compromising safety.

Considerations for International Buyers: Buyers should evaluate the local infrastructure for composite manufacturing and recycling. Compliance with relevant standards is essential for ensuring product quality.

Summary Table of Material Selection for Electric Car Bodies

| Material | Typical Use Case for electric car body | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body panels, chassis | Lightweight, corrosion-resistant | Higher cost, complex manufacturing | High |

| High-Strength Steel | Structural components | Durable, cost-effective | Heavier, complex forming processes | Medium |

| Carbon Fiber | High-performance vehicles | Exceptional strength-to-weight ratio | Very high cost, complex production | High |

| Composite Materials | Non-structural components | Tailored properties, lightweight | Manufacturing complexity, recycling issues | Medium to High |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, aiding in informed decision-making for electric car body construction.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car body

What Are the Key Manufacturing Stages for Electric Car Bodies?

Manufacturing electric car bodies involves several critical stages that ensure both functionality and aesthetic appeal. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Car Body Manufacturing?

Material preparation is the first step in the manufacturing process. Manufacturers select high-strength materials such as aluminum and advanced high-strength steels for their lightweight and durable characteristics. These materials are often pre-treated to enhance corrosion resistance and improve weldability.

In addition, manufacturers utilize advanced composite materials for specific components to further reduce weight without compromising strength. This preparation phase may also involve cutting materials into specific shapes and sizes, which is crucial for optimizing the subsequent forming process.

What Techniques Are Used in Forming Electric Car Bodies?

The forming stage is where the prepared materials are shaped into the desired body components. Common techniques include stamping, extrusion, and molding. Stamping is widely used for creating large panels, such as doors and hoods, while extrusion is more suited for producing long, continuous shapes like frame components.

Molding techniques, particularly for composite materials, allow for complex shapes that can enhance aerodynamics and aesthetics. Additionally, advanced technologies like 3D printing are increasingly being integrated into this phase, enabling rapid prototyping and customization.

How Are Electric Car Bodies Assembled?

Once formed, the various components are brought together in the assembly stage. This process often employs robotic automation to ensure precision and efficiency. Robots are utilized for welding, fastening, and attaching components, reducing human error and increasing production speed.

Moreover, assembly lines are designed for flexibility, allowing manufacturers to accommodate different models and specifications. This adaptability is particularly important in the electric vehicle market, which is characterized by rapid innovation and changing consumer preferences.

What Finishing Processes Are Applied to Electric Car Bodies?

Finishing processes add the final touches to electric car bodies, enhancing both appearance and durability. Surface treatments such as painting, coating, and polishing are common, with manufacturers often using environmentally friendly materials to align with sustainability goals.

Quality control in this stage is crucial, as the finishing not only affects the aesthetic appeal but also the vehicle’s resistance to environmental factors. Manufacturers often use automated inspection systems to detect defects in paint quality and surface finishes.

What Quality Assurance Standards Are Relevant for Electric Car Body Manufacturing?

Quality assurance is vital in maintaining the integrity of electric car bodies. International standards such as ISO 9001 provide a framework for quality management systems, ensuring consistent product quality and customer satisfaction.

In addition to ISO standards, industry-specific certifications like CE marking in Europe and API certification for certain components may also apply. These certifications assure buyers that the products meet safety, health, and environmental protection standards.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control checkpoints are implemented at various stages of the manufacturing process to ensure compliance with established standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This occurs when raw materials arrive at the facility. Inspectors verify that materials meet specified standards before they are used in production.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves monitoring critical parameters and processes to ensure that components are being produced correctly.

-

Final Quality Control (FQC): This final inspection assesses the completed electric car body for any defects or non-conformance with specifications. Any issues identified at this stage can be rectified before the product is shipped.

What Common Testing Methods Are Used in Quality Assurance for Electric Car Bodies?

Manufacturers employ a range of testing methods to verify the quality of electric car bodies. Common methods include:

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspections are used to detect internal flaws without damaging the components.

-

Dimensional Inspection: This involves measuring the dimensions of parts and assemblies to ensure they conform to design specifications.

-

Environmental Testing: Electric car bodies may undergo tests simulating extreme conditions, such as temperature fluctuations and exposure to moisture, to assess their durability and performance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers need to ensure that their suppliers maintain rigorous quality control processes. Here are several strategies to verify supplier QC:

-

Conduct Audits: Buyers can perform on-site audits of suppliers to assess their manufacturing processes and quality management systems. This allows for direct evaluation of adherence to standards and practices.

-

Request Quality Reports: Suppliers should provide documentation of quality control measures, including inspection reports, testing results, and certifications. These documents offer insight into the supplier’s commitment to quality.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of supplier quality. These organizations can verify compliance with international standards and provide certifications that enhance buyer confidence.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must navigate various QC and certification nuances. Differences in regulatory requirements, testing standards, and certification processes can complicate procurement.

It is essential for buyers to understand the specific quality standards applicable in their target markets. For instance, European markets may require CE marking, while other regions may have different local regulations. Establishing clear communication with suppliers regarding these requirements can mitigate compliance risks and ensure that products meet local standards.

Additionally, considering the logistics of shipping and customs can impact the quality assurance process. Buyers should ensure that their suppliers are well-versed in international shipping regulations and can provide appropriate documentation for smooth customs clearance.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make informed decisions when sourcing electric car bodies, ensuring they partner with suppliers that uphold high standards of quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car body’

Introduction

Sourcing an electric car body is a critical component for manufacturers looking to enter or expand in the electric vehicle (EV) market. This guide outlines actionable steps to help B2B buyers effectively procure electric car bodies that meet their specifications and market demands. By following this checklist, you can ensure that you select the right materials, suppliers, and technologies that align with your business objectives.

Step 1: Define Your Technical Specifications

Before beginning your search for suppliers, it’s essential to establish clear technical specifications for the electric car body. This includes dimensions, weight, materials (such as advanced high-strength steels or aluminum), and design features specific to electric vehicles. Understanding these requirements will guide your supplier discussions and ensure that the bodies you source are compatible with your overall vehicle design.

Step 2: Research Material Requirements for Electric Car Bodies

Electric vehicle bodies often require different materials compared to traditional vehicles to optimize weight and performance. Focus on lightweight materials like aluminum and specialized steels that enhance energy efficiency and safety. Look for suppliers that provide detailed material certifications and performance data, as these will be crucial for meeting regulatory standards and consumer expectations.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they can meet your specifications and quality standards. Request company profiles, case studies, and references from buyers in similar industries or regions. Assess their production capabilities, technology partnerships, and experience in manufacturing electric car bodies to ensure they can deliver on your requirements.

- Key Questions to Consider:

- What is their experience with electric vehicle components?

- Can they provide examples of past projects or client testimonials?

Step 4: Verify Compliance with Industry Standards

Compliance with local and international automotive regulations is non-negotiable. Ensure that your potential suppliers adhere to relevant standards such as ISO/TS 16949 for automotive quality management systems and any specific regulations pertaining to electric vehicles. This not only mitigates risk but also enhances your product’s credibility in the marketplace.

Step 5: Request Prototypes and Samples

Before finalizing a supplier, request prototypes or samples of the electric car body. This allows you to assess quality, fit, and design before committing to larger orders. Evaluate these samples against your specifications, and consider conducting stress tests to ensure they meet performance standards.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate the terms of your contract carefully. This includes pricing, lead times, payment terms, and warranty conditions. Establish clear expectations for quality control processes and penalties for non-compliance to protect your investment and ensure a smooth supply chain.

Step 7: Plan for Ongoing Supplier Relationships

After procurement, maintain a proactive relationship with your supplier. Regular communication regarding production updates, quality feedback, and market trends will foster collaboration and innovation. This relationship can also provide insights into new technologies and materials that could enhance your electric vehicle offerings in the future.

By following this checklist, B2B buyers can streamline their sourcing process for electric car bodies, ensuring they select the best suppliers to meet their needs in an increasingly competitive market.

Comprehensive Cost and Pricing Analysis for electric car body Sourcing

When considering sourcing electric car bodies, it is crucial for B2B buyers to understand the multifaceted cost structure and the various factors influencing pricing. This knowledge enables informed decision-making and strategic negotiations.

What Are the Key Cost Components in Electric Car Body Sourcing?

-

Materials: The primary materials used in electric car bodies include high-strength steels and lightweight aluminum. These materials not only contribute to the vehicle’s performance but also impact production costs significantly. For instance, advanced high-strength steels may carry a premium compared to traditional materials, but they offer enhanced safety and weight reduction benefits.

-

Labor: Labor costs can vary widely based on the region and the complexity of the body design. Skilled labor is essential for processes such as welding, assembly, and finishing. Countries with a robust automotive manufacturing sector, like Germany or Japan, may have higher labor costs but also offer superior craftsmanship.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Efficient manufacturing processes can help mitigate these costs, making it essential to choose suppliers with optimized operations.

-

Tooling: Custom tooling for electric vehicle bodies can be a significant upfront investment. The type and complexity of the body design dictate the tooling costs. Buyers should consider these costs in their budgeting, especially when opting for bespoke designs.

-

Quality Control (QC): Ensuring that the bodies meet safety and performance standards requires a robust QC process. This adds to the overall cost but is critical for maintaining quality and compliance with international standards.

-

Logistics: Shipping and handling costs can vary based on the distance from the manufacturer to the buyer, as well as the mode of transport. For international buyers, understanding Incoterms is vital to avoid unexpected costs.

-

Margin: Supplier profit margins can vary based on market conditions and demand. Understanding these margins can provide insights into the pricing structure and help in negotiation discussions.

What Influences Pricing in Electric Car Body Sourcing?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often result in lower per-unit costs due to economies of scale. Buyers should assess their production needs and consider negotiating for better rates based on anticipated volumes.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should clearly define their specifications upfront to avoid unexpected costs later in the process.

-

Material Quality and Certifications: Premium materials and certifications (such as ISO standards) can enhance the product’s reliability but may also increase costs. Buyers should weigh the benefits of these investments against their budget constraints.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding the terms of shipping and liability is crucial, particularly for international transactions. Incoterms dictate who is responsible for costs and risks at various stages of the shipping process.

What Tips Can Help Buyers Achieve Cost Efficiency?

-

Negotiate Terms: Engage suppliers in discussions about pricing, MOQs, and delivery terms. Having a clear understanding of your requirements can strengthen your negotiating position.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as maintenance, warranty, and potential resale value. This comprehensive view can inform better sourcing decisions.

-

Research Pricing Nuances for International Markets: Different regions may have varying pricing structures due to local manufacturing capabilities, tariffs, and import duties. Understanding these nuances is especially important for buyers in Africa, South America, the Middle East, and Europe.

-

Seek Multiple Quotes: Obtaining quotes from multiple suppliers can provide a broader perspective on market pricing and help identify the best value for your needs.

Disclaimer

Prices and cost structures are indicative and can fluctuate based on market conditions, supplier negotiations, and specific project requirements. It is advisable to conduct thorough market research and engage with suppliers directly for the most accurate and current pricing information.

Alternatives Analysis: Comparing electric car body With Other Solutions

Introduction to Alternatives in Electric Car Body Solutions

As the electric vehicle (EV) market continues to expand, understanding the various body construction methods is crucial for B2B buyers. The electric car body is a specialized solution designed to optimize performance, efficiency, and sustainability. However, several alternative methods and technologies are emerging that may also meet the needs of businesses looking to invest in electric vehicles. This analysis will compare the electric car body against two notable alternatives: aluminum body construction and composite materials.

Comparison Table

| Comparison Aspect | Electric Car Body | Aluminum Body Construction | Composite Materials |

|---|---|---|---|

| Performance | High strength-to-weight ratio; optimized aerodynamics | Good weight reduction; effective thermal management | Excellent strength and flexibility; tailored properties |

| Cost | Generally higher due to advanced materials and technology | Moderate; cost-effective for mass production | Higher initial investment; cost varies by type |

| Ease of Implementation | Requires specialized manufacturing processes | Well-established; easier integration | Requires advanced manufacturing techniques |

| Maintenance | Low maintenance; corrosion-resistant | Moderate; susceptible to dents and corrosion | Low maintenance; resistant to environmental factors |

| Best Use Case | High-performance, bespoke EVs for luxury markets | Mainstream EV production; cost-sensitive applications | High-performance applications requiring tailored properties |

Detailed Breakdown of Alternatives

Aluminum Body Construction

Aluminum bodies are widely used in the automotive industry due to their favorable weight-to-strength ratio. This construction method allows for significant weight savings, which can enhance the range and efficiency of electric vehicles. Additionally, aluminum offers effective thermal management, crucial for battery performance. However, while aluminum is cost-effective for mass production, it may be susceptible to corrosion and dents, requiring periodic maintenance. This makes aluminum a suitable option for mainstream EV production where cost sensitivity is a priority.

Composite Materials

Composite materials, such as carbon fiber reinforced plastics, provide excellent strength and flexibility, allowing for tailored properties in vehicle design. They can significantly reduce weight, leading to improved performance and range. Composites are also resistant to environmental factors, resulting in lower maintenance needs. However, the initial investment in composite materials can be higher, and their manufacturing processes may require specialized techniques. This makes composites ideal for high-performance applications or luxury vehicles where performance and aesthetics are paramount.

Conclusion: Choosing the Right Electric Car Body Solution

For B2B buyers evaluating electric car body solutions, the decision will largely depend on specific business needs and target markets. If the focus is on performance and luxury, investing in an electric car body or composite materials may yield the best results despite higher costs. Conversely, for businesses targeting mass-market production, aluminum body construction offers a balance of performance and cost-effectiveness. Ultimately, understanding the nuances of each alternative will empower buyers to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for electric car body

What Are the Key Technical Properties of Electric Car Bodies?

Understanding the technical properties of electric car bodies is crucial for B2B buyers, particularly when considering materials and designs that influence performance, safety, and sustainability. Here are several key specifications:

-

Material Grade

Electric car bodies commonly utilize advanced materials such as high-strength steel, aluminum alloys, and composite materials. For instance, grades like 6082 aluminum are favored for their lightweight properties, which enhance vehicle efficiency and range. Choosing the right material grade is vital for reducing weight while maintaining structural integrity, thereby optimizing performance and safety. -

Tensile Strength

This property measures a material’s ability to withstand pulling forces without breaking. Electric vehicles (EVs) require bodies that can endure significant stress, especially in crash scenarios. Materials with high tensile strength contribute to passenger safety and longevity of the vehicle, making this a critical factor in material selection for manufacturers. -

Thermal Conductivity

With electric vehicles relying heavily on battery systems, thermal management becomes essential. Materials with appropriate thermal conductivity can help dissipate heat generated during battery operation, ensuring optimal performance and preventing overheating. This characteristic is crucial for maintaining the battery’s lifespan and efficiency. -

Corrosion Resistance

Electric car bodies are often exposed to various environmental conditions, making corrosion resistance a vital property. Materials like stainless steel or treated aluminum can prolong the vehicle’s life and reduce maintenance costs. This is particularly important for markets in humid or coastal regions, where corrosion can significantly impact vehicle longevity. -

Manufacturing Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In electric vehicle manufacturing, tight tolerances are necessary to ensure proper fit and function of components, especially in the assembly of battery systems and electric motors. High precision in manufacturing reduces the risk of operational issues and enhances overall vehicle reliability. -

Weight Distribution

Proper weight distribution is critical in electric car design, affecting handling, stability, and performance. The placement of battery packs and the choice of materials must ensure an even weight distribution, contributing to improved driving dynamics and safety. B2B buyers should consider how weight distribution impacts vehicle performance when selecting body designs.

What Are Common Trade Terms Used in the Electric Car Body Industry?

Familiarity with industry jargon is essential for effective communication and decision-making in the B2B environment. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. In the electric vehicle sector, OEMs design and produce electric car bodies, playing a crucial role in the supply chain. Understanding OEM capabilities is essential for buyers looking to collaborate on custom projects. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers, as it affects inventory management and procurement strategies. Knowing the MOQ helps companies plan their purchases and manage cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. In the context of electric car bodies, issuing an RFQ can help buyers compare costs and evaluate suppliers based on pricing and capabilities, ensuring informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized international shipping terms that define the responsibilities of buyers and sellers in the delivery of goods. Understanding Incoterms is crucial for B2B transactions involving electric car bodies, as they clarify who is responsible for shipping costs, insurance, and liability during transport. -

EV (Electric Vehicle)

This term refers to any vehicle that is powered entirely or partially by electricity. For B2B buyers, understanding the different types of EVs (like BEVs and PHEVs) is essential for selecting the right components and materials that meet specific performance and regulatory standards. -

Sustainability Standards

These are criteria that manufacturers must meet to ensure environmentally friendly production practices. For B2B buyers, being aware of sustainability standards is increasingly important as consumers and regulators demand more eco-friendly vehicles. Compliance with these standards can also enhance brand reputation and marketability.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing electric car bodies, ultimately enhancing their business operations and product offerings.

Navigating Market Dynamics and Sourcing Trends in the electric car body Sector

What Are the Current Market Dynamics and Key Trends in the Electric Car Body Sector?

The electric vehicle (EV) market is experiencing transformative growth, driven by increasing consumer demand, regulatory pressures for sustainability, and technological advancements. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should note several key trends shaping the electric car body sector. Firstly, lightweight materials such as aluminum and advanced high-strength steels are becoming standard in EV body designs. These materials not only enhance performance by reducing weight but also improve energy efficiency, crucial for maximizing battery range.

Secondly, there is a notable shift towards modular designs that allow for greater customization and adaptability. This trend facilitates the rapid prototyping and scaling of production, aligning with the bespoke needs of emerging markets. Buyers should also be aware of the growing importance of digital manufacturing technologies, such as 3D printing, which enable more efficient production processes and reduced lead times. As electric vehicles continue to evolve, the integration of smart technologies—like embedded sensors for vehicle diagnostics—into body designs is becoming increasingly prevalent, providing additional opportunities for differentiation in a competitive market.

Furthermore, the global supply chain landscape is shifting, with an emphasis on local sourcing to mitigate risks associated with geopolitical tensions and supply chain disruptions. For B2B buyers, this means that establishing relationships with local suppliers can enhance reliability and responsiveness in the sourcing process.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Electric Car Body Sector?

Sustainability has emerged as a pivotal factor in the electric car body sector, influencing both manufacturing processes and procurement strategies. The environmental impact of sourcing materials for electric vehicles cannot be overstated. Buyers must prioritize suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials or adopting energy-efficient manufacturing methods. This not only reduces the carbon footprint associated with production but also aligns with the growing consumer preference for environmentally responsible products.

In addition, ethical sourcing is becoming increasingly important in the global marketplace. B2B buyers should seek suppliers who can provide transparency in their supply chains, ensuring that materials are obtained responsibly and without exploitation. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

Moreover, the adoption of ‘green’ materials—such as bioplastics and natural fiber composites—can enhance the marketability of electric vehicles. These materials not only appeal to environmentally conscious consumers but also comply with stringent regulations on emissions and waste. By focusing on sustainability and ethical sourcing, B2B buyers can not only enhance their brand reputation but also contribute to a more sustainable future for the automotive industry.

What Has Been the Evolution of the Electric Car Body Sector?

The evolution of the electric car body sector is closely tied to advancements in automotive technology and changing consumer expectations. Initially, electric vehicles were seen as less powerful and less desirable than their gasoline counterparts. However, as battery technology improved, so did the performance and appeal of electric vehicles.

The shift towards electric mobility gained momentum in the early 2000s, spurred by environmental concerns and government incentives. As manufacturers began to invest in electric vehicle technology, the design of electric car bodies evolved to embrace lightweight materials and aerodynamic shapes, improving efficiency and range. Today’s electric car bodies are often designed with modularity in mind, allowing for easier updates and maintenance, and reflecting a growing trend towards personalization and consumer choice.

This historical context is critical for B2B buyers as it highlights the importance of innovation and adaptability in sourcing decisions. Understanding the trajectory of the electric car body sector can inform strategic partnerships and investment opportunities in a rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car body

-

How do I ensure the quality of electric car bodies from suppliers?

To ensure the quality of electric car bodies, establish stringent quality assurance protocols. Conduct thorough supplier audits, focusing on their manufacturing processes, materials used, and compliance with international standards. Request samples to assess craftsmanship and durability. Additionally, consider certifications such as ISO 9001 or IATF 16949, which demonstrate adherence to quality management systems. Engaging third-party inspection services can provide unbiased assessments before finalizing orders. -

What are the key materials used in electric car body construction?

Electric car bodies primarily utilize lightweight materials to enhance efficiency and range. Common materials include advanced high-strength steels, aluminum alloys, and composite materials. These materials help reduce overall vehicle weight, which is crucial for maximizing battery performance. Understanding the properties of each material will aid in selecting the best options for specific vehicle designs, balancing strength, weight, and cost. -

What customization options are available for electric car bodies?

Customization options for electric car bodies vary by supplier but often include modifications in design, materials, and finishes. Many manufacturers allow for bespoke features such as unique color schemes, interior layouts, and additional safety or performance enhancements. When discussing customization, clearly outline your requirements and expectations to ensure the final product aligns with your brand identity and market needs. -

What is the minimum order quantity (MOQ) for electric car bodies?

The minimum order quantity (MOQ) for electric car bodies can differ significantly among manufacturers and depends on factors such as production capacity and material availability. Typically, MOQs can range from a few units for smaller suppliers to hundreds for larger manufacturers. It’s essential to communicate your needs upfront and negotiate terms that accommodate your production plans, especially if you’re entering new markets. -

What payment terms should I expect when sourcing electric car bodies?

Payment terms for electric car body orders usually involve a combination of upfront deposits and payment upon delivery. Common practices include a 30% deposit when placing an order, with the remaining balance due before shipping. It’s advisable to negotiate terms that align with your cash flow requirements. Additionally, consider using secure payment methods and establishing clear contractual agreements to protect both parties. -

How can I assess the reliability of a supplier for electric car bodies?

To assess supplier reliability, conduct comprehensive background checks, including reviews of their financial stability, production history, and client testimonials. Request references from previous B2B clients and evaluate their experience in producing electric car bodies specifically. Participating in industry trade shows can also provide insights into a supplier’s reputation and capabilities, helping you make informed decisions. -

What logistics considerations should I keep in mind for importing electric car bodies?

Logistics considerations for importing electric car bodies include understanding shipping routes, customs regulations, and potential tariffs. Engage with freight forwarders experienced in automotive components to streamline the shipping process. Ensure that your supplier provides the necessary documentation for customs clearance, such as certificates of origin and compliance. Planning for potential delays and establishing contingency strategies will also help mitigate risks in the supply chain. -

What international trade regulations should I be aware of when sourcing electric car bodies?

When sourcing electric car bodies internationally, be aware of regulations regarding import/export tariffs, safety standards, and environmental compliance. Different regions may have specific regulations for electric vehicles, including battery disposal and recycling requirements. Familiarize yourself with trade agreements between your country and the supplier’s country to leverage potential benefits. Consulting with legal experts in international trade can also provide valuable guidance to navigate complex regulations effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 Electric Car Body Manufacturers & Suppliers List

1. RBW – Roadster

Domain: rbwevcars.com

Registered: 2019 (6 years)

Introduction: Model: RBW Roadster

0-60 mph: 8.9 seconds

Top Speed: 87 mph

Range: 160 miles (260 km)

Battery: Six Turntide Lithium-ion batteries (up to seven as an optional extra)

Power Output: 70 kW

Charging: 3.5 kW

Recharging Time: 8 hours

Dimensions: Length 12 ft 8 1/2 in (3.8 m), Width 4 ft 11 15/16 in (152.3 cm), Height 4 ft 1 3/8 in (125.4 cm), Ground Clearance 5 in (12.7 cm) min

Gross Vehicle Weight: 1300…

2. National Material – Electric Vehicle Construction Materials

Domain: nationalmaterial.com

Registered: 1999 (26 years)

Introduction: Materials commonly used in electric vehicle construction include:

– Aluminum: Lightweight, durable, corrosion-resistant, 100% recyclable, and cost-effective.

– Steel: Used for chassis, body panels, and structural members due to strength and durability.

– Carbon fiber: Lightweight and high-strength components like battery enclosures, body panels, and wheels.

– Plastics: Used for interior trim, …

Strategic Sourcing Conclusion and Outlook for electric car body

As the electric vehicle market continues to evolve, the strategic sourcing of electric car bodies presents significant opportunities for international B2B buyers. The shift towards sustainable mobility solutions necessitates a keen focus on materials that enhance vehicle performance while reducing environmental impact. Key takeaways include the importance of lightweight materials such as advanced high-strength steel and aluminum, which play a critical role in improving efficiency and range.

Investing in strategic partnerships with suppliers that prioritize innovation and sustainability can set businesses apart in a competitive landscape. Furthermore, understanding regional supply chain dynamics is essential, particularly for buyers in Africa, South America, the Middle East, and Europe, where local market conditions and consumer preferences can vary significantly.

Looking ahead, the demand for electric vehicles is projected to surge, driven by regulatory changes and consumer awareness. Now is the time for B2B buyers to evaluate their sourcing strategies, align with forward-thinking manufacturers, and leverage technological advancements in electric car body design. By doing so, they can not only meet the growing demand but also contribute to a greener future. Engage with suppliers who share your vision for sustainability and innovation to stay ahead in this transformative industry.