Introduction: Navigating the Global Market for electric cars price

In an era where sustainability and innovation are at the forefront of the automotive industry, navigating the global market for electric cars price poses significant challenges for international B2B buyers. With varying pricing structures across regions, understanding the total cost of ownership—including purchase price, maintenance, and charging infrastructure—becomes critical for companies in Africa, South America, the Middle East, and Europe, such as Brazil and Nigeria. This guide addresses these complexities by offering a comprehensive overview of electric vehicle pricing, helping businesses make informed sourcing decisions.

Within this resource, we delve into various types of electric vehicles, from affordable sedans to premium SUVs, and their applications across different sectors. Additionally, we provide insights into supplier vetting processes, ensuring that businesses can identify reliable manufacturers and distributors. By exploring factors that influence electric vehicle prices, such as battery technology, range, and local market conditions, this guide empowers buyers to navigate their purchasing strategies effectively.

Our aim is to equip B2B buyers with the knowledge and tools needed to maximize their investments in electric vehicles. By understanding the nuances of pricing and the broader market landscape, companies can better align their procurement strategies with sustainability goals while capitalizing on the growing demand for electric mobility.

Understanding electric cars price Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Budget Electric Vehicles | MSRP under $50,000, basic features, limited range | Fleet services, small businesses | Pros: Affordable entry point; Cons: Limited range and features. |

| Mid-Range Electric Vehicles | MSRP between $50,000 and $70,000, enhanced features | Corporate fleets, employee incentives | Pros: Better range and features; Cons: Higher initial investment. |

| Luxury Electric Vehicles | MSRP over $70,000, advanced technology, premium features | Executive transport, high-end services | Pros: Superior range and performance; Cons: High cost and maintenance. |

| Used Electric Vehicles | Pre-owned models, varying price points, potential for significant savings | Cost-conscious businesses, startups | Pros: Lower purchase price; Cons: Potential for higher repair costs. |

| Commercial Electric Vehicles | Designed for business use, larger capacity, specialized features | Delivery services, logistics companies | Pros: Tailored for specific business needs; Cons: Higher upfront costs and limited availability. |

What Are the Characteristics of Budget Electric Vehicles?

Budget electric vehicles (BEVs) typically have a manufacturer’s suggested retail price (MSRP) under $50,000. These models often feature essential functionalities and a limited driving range, making them suitable for urban commuting and short-distance travel. B2B buyers such as small businesses or fleet services can benefit from the lower acquisition costs. However, the trade-off includes a reduced range and fewer technological features, which may not meet the needs of businesses requiring extensive travel.

How Do Mid-Range Electric Vehicles Stand Out?

Mid-range electric vehicles fall within the $50,000 to $70,000 price bracket and offer a balance between affordability and advanced features. These vehicles often come equipped with better battery technology, providing enhanced range and comfort. They are ideal for corporate fleets and businesses looking to incentivize employees with greener transportation options. While they provide a more comfortable ride and additional features, the higher initial investment may be a consideration for budget-conscious companies.

What Defines Luxury Electric Vehicles?

Luxury electric vehicles are characterized by their premium pricing, generally exceeding $70,000, and advanced technology features. These models often come equipped with high-performance capabilities, extended ranges, and luxurious interiors, making them suitable for executive transport or high-end service industries. While they offer superior performance and status, the significant upfront costs and ongoing maintenance expenses can be a barrier for some businesses.

Why Consider Used Electric Vehicles for B2B Purchases?

Used electric vehicles offer a cost-effective alternative for businesses looking to integrate EVs into their fleets without the hefty price tag of new models. These vehicles come at various price points and can provide substantial savings. However, B2B buyers should be aware of the potential for higher repair costs and limited warranties associated with pre-owned models. Careful inspection and consideration of the vehicle’s history are crucial before making a purchase.

What Are the Benefits of Commercial Electric Vehicles?

Commercial electric vehicles are specifically designed for business applications, featuring larger capacities and specialized functionalities suited for logistics and delivery services. These vehicles often entail higher upfront costs but can lead to significant long-term savings through lower operational expenses, such as fuel and maintenance. B2B buyers in sectors like logistics should weigh the benefits of tailored features against the investment required, as these vehicles can significantly enhance operational efficiency.

Key Industrial Applications of electric cars price

| Industry/Sector | Specific Application of Electric Cars Price | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Delivery | Fleet Electrification | Reduced operational costs through lower fuel expenses and maintenance; enhanced sustainability profile. | Evaluate total cost of ownership, charging infrastructure, and vehicle range to meet delivery demands. |

| Public Transportation | Electric Bus Services | Lower emissions and operational costs, improved public health, and a modernized fleet appeal. | Consider government incentives, vehicle lifespan, and compatibility with existing infrastructure. |

| Corporate Fleets | Employee Transportation Programs | Cost savings on fuel and maintenance, improved employee satisfaction, and corporate sustainability goals. | Assess employee needs, vehicle availability, and financing options for bulk purchases. |

| Car Rentals & Sharing | Electric Vehicle Rental Services | Attraction of eco-conscious customers, reduced fuel costs, and potential for premium pricing. | Analyze local market demand, charging station availability, and partnerships with EV manufacturers. |

| Agriculture | Electric Utility Vehicles | Enhanced operational efficiency with lower running costs and reduced environmental impact. | Look for ruggedness, battery life, and the ability to operate in diverse terrains for agricultural needs. |

How Can Electric Cars Price Impact the Logistics and Delivery Sector?

In the logistics and delivery sector, the price of electric cars plays a critical role in fleet electrification. Businesses can significantly reduce operational costs by transitioning to electric vehicles (EVs), as they incur lower fuel expenses and require less maintenance compared to traditional combustion engine vehicles. Additionally, adopting EVs enhances a company’s sustainability profile, which can be a key differentiator in a competitive market. International buyers should consider the total cost of ownership, including charging infrastructure and vehicle range, to ensure that these electric solutions meet their delivery demands effectively.

What Are the Benefits of Electric Bus Services in Public Transportation?

For public transportation, electric bus services offer substantial benefits, including lower emissions and reduced operational costs. These advantages contribute to improved public health and a modernized fleet that appeals to environmentally conscious commuters. Additionally, many governments provide incentives for transitioning to electric buses, making them a financially viable option. When sourcing electric buses, buyers should consider factors like vehicle lifespan, compatibility with existing infrastructure, and the potential for government subsidies to maximize their investment.

How Do Corporate Fleets Benefit from Electric Cars?

Corporate fleets can leverage the price of electric cars for employee transportation programs, achieving cost savings on fuel and maintenance while enhancing employee satisfaction. As businesses increasingly focus on sustainability, the adoption of EVs aligns with corporate social responsibility goals. International B2B buyers should assess the specific needs of their workforce, the availability of suitable vehicles, and financing options for bulk purchases to ensure a smooth transition to electric fleets.

What Opportunities Exist in Electric Vehicle Rental Services?

The car rental and sharing industry can capitalize on the growing demand for electric vehicles by integrating them into their fleets. The price of electric cars allows rental companies to attract eco-conscious customers while benefiting from reduced fuel costs. Moreover, the potential for premium pricing on electric rentals can enhance profitability. Buyers should analyze local market demand, the availability of charging stations, and potential partnerships with EV manufacturers to create a robust rental offering.

How Can Electric Utility Vehicles Transform Agriculture?

In agriculture, electric utility vehicles provide enhanced operational efficiency with lower running costs and a reduced environmental impact. These vehicles are particularly beneficial for tasks such as transporting equipment and supplies across diverse terrains. When sourcing electric utility vehicles, agricultural buyers should prioritize ruggedness, battery life, and the ability to operate effectively in various conditions to ensure they meet the unique demands of farming operations.

3 Common User Pain Points for ‘electric cars price’ & Their Solutions

Scenario 1: Budget Constraints in Emerging Markets

The Problem: B2B buyers in regions such as Africa and South America often face significant budget constraints when considering electric vehicle (EV) purchases. The initial price of electric cars can be substantially higher than traditional vehicles, making it difficult for businesses to justify the investment, especially in markets where economic conditions fluctuate. Additionally, the lack of local financing options and the high cost of importing EVs can deter potential buyers from making a purchase.

The Solution: To navigate these financial challenges, businesses should explore partnerships with local banks or financial institutions that offer tailored financing solutions for EV purchases. Additionally, buyers can leverage government incentives or subsidies aimed at promoting electric mobility, which can significantly reduce the upfront costs. Conducting a thorough cost-benefit analysis that includes potential long-term savings on fuel and maintenance can also help in making a compelling case for the investment. Engaging with local dealers to negotiate bulk purchase discounts or exploring used electric vehicles as a more affordable alternative can further ease the financial burden.

Scenario 2: Navigating Price Variability Across Different Markets

The Problem: Electric car pricing can vary widely across different regions due to factors such as import tariffs, local taxes, and market demand. For B2B buyers operating in multiple countries, this price variability can complicate procurement strategies, making it challenging to establish a consistent budget and plan for fleet expansion. Moreover, fluctuating exchange rates can further exacerbate these pricing issues, leading to unexpected costs.

The Solution: To effectively manage price variability, B2B buyers should establish a centralized procurement strategy that includes comprehensive market research across the regions they operate in. Utilizing data analytics tools to monitor pricing trends and currency fluctuations can provide valuable insights. Additionally, developing relationships with multiple suppliers can create competitive pricing opportunities. Buyers can also consider negotiating long-term contracts with manufacturers, which may offer fixed pricing over a certain period, thereby mitigating the risk of sudden price increases.

Scenario 3: Understanding Total Cost of Ownership

The Problem: Many B2B buyers focus solely on the initial purchase price of electric vehicles without fully understanding the total cost of ownership (TCO). This oversight can lead to unexpected expenses down the line, such as higher charging costs, maintenance, and insurance. In regions where charging infrastructure is underdeveloped, the costs associated with setting up charging stations can also be a significant concern.

The Solution: To address this issue, buyers should conduct a thorough TCO analysis that encompasses not only the purchase price but also operational costs, including charging, maintenance, insurance, and resale value. Engaging with EV manufacturers or third-party consultants to obtain detailed forecasts on these costs can provide a clearer picture. Additionally, businesses should explore partnerships with charging network providers to ensure access to affordable and reliable charging solutions. Utilizing software tools that allow for real-time monitoring of charging costs and vehicle performance can also help in managing expenses and optimizing fleet operations.

Strategic Material Selection Guide for electric cars price

What are the Key Materials Affecting Electric Car Pricing?

When considering the price of electric cars, the selection of materials plays a crucial role in determining both manufacturing costs and the overall performance of the vehicle. Below, we analyze four common materials used in electric vehicles (EVs) and their implications for B2B buyers, particularly in international markets such as Africa, South America, the Middle East, and Europe.

How Does Aluminum Influence Electric Car Pricing?

Aluminum is widely used in electric vehicles due to its lightweight properties, which contribute to improved energy efficiency and range. Key properties of aluminum include excellent corrosion resistance and a high strength-to-weight ratio, making it suitable for various vehicle components such as frames and body panels.

Pros: The primary advantages of aluminum include its durability and resistance to corrosion, which enhance the vehicle’s lifespan. Additionally, its lightweight nature helps reduce energy consumption, positively impacting the overall cost of ownership.

Cons: However, aluminum can be more expensive than traditional steel, and its manufacturing process is complex, requiring specialized equipment. This can lead to higher initial costs for manufacturers, which may be passed on to the consumer.

Impact on Application: Aluminum’s compatibility with various media, including battery systems, makes it an ideal choice for EVs. However, international buyers should consider local recycling capabilities, as aluminum can be costly to recycle in some regions.

What Role Does Steel Play in Electric Vehicle Manufacturing?

Steel remains a staple in vehicle manufacturing, including electric cars, due to its strength and versatility. High-strength steel variants are often used to enhance safety and structural integrity.

Pros: Steel is relatively low-cost compared to aluminum and offers excellent durability and crash resistance. It is also widely available and can be easily sourced, making it a practical choice for manufacturers.

Cons: On the downside, steel is heavier than aluminum, which can negatively impact the vehicle’s range and efficiency. Additionally, it is more susceptible to corrosion unless treated, which can add to maintenance costs over time.

Impact on Application: Steel’s compatibility with various coatings and treatments allows for effective use in different environments, but international buyers must ensure compliance with local standards regarding emissions and recyclability.

How Do Composites Affect Electric Car Pricing and Performance?

Composite materials, such as carbon fiber and fiberglass, are increasingly used in electric vehicles to reduce weight while maintaining strength. These materials are particularly beneficial in performance-oriented EVs.

Pros: Composites offer significant weight savings, which can enhance performance and efficiency. They also provide excellent corrosion resistance and can be molded into complex shapes, allowing for innovative designs.

Cons: The primary drawback is the high cost of composite materials and the complexity of their manufacturing processes. This can lead to increased production costs, which may be reflected in the final price of the vehicle.

Impact on Application: Composites are often used in high-performance applications, but buyers in emerging markets should consider the availability of repair facilities and the potential for higher insurance costs due to the materials’ specialized nature.

What is the Importance of Lithium in Electric Vehicle Battery Systems?

Lithium is a critical component in the batteries that power electric vehicles. Its properties allow for high energy density and lightweight solutions, which are essential for maximizing range.

Pros: Lithium batteries provide a long cycle life and high efficiency, making them ideal for electric vehicles. The lightweight nature of lithium contributes to overall vehicle performance.

Cons: However, lithium is subject to market volatility, which can affect battery costs. Additionally, the extraction and processing of lithium raise environmental concerns, particularly in regions with strict regulations.

Impact on Application: International buyers must be aware of the sourcing practices and regulations surrounding lithium, as compliance with environmental standards is increasingly scrutinized in global markets.

Summary Table of Material Considerations

| Material | Typical Use Case for electric cars price | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Vehicle frames, body panels | Lightweight, corrosion-resistant | Higher cost, complex manufacturing | High |

| Steel | Structural components | Low-cost, durable | Heavier, corrosion susceptibility | Low |

| Composites | Performance parts, body panels | Weight savings, design flexibility | High cost, complex manufacturing | High |

| Lithium | Battery systems | High energy density, lightweight | Market volatility, environmental concerns | Medium |

This guide provides valuable insights for B2B buyers navigating the complexities of material selection in electric vehicles, particularly in diverse international markets. Understanding these materials’ properties, advantages, and limitations can help inform strategic purchasing decisions that align with both performance goals and cost considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cars price

What Are the Main Stages of Electric Car Manufacturing?

The manufacturing of electric vehicles (EVs) involves a series of meticulously planned stages that ensure quality and efficiency. Understanding these stages is crucial for B2B buyers looking to source electric cars.

-

Material Preparation: The manufacturing process begins with the selection and preparation of materials. Key components include lightweight metals like aluminum for the chassis, high-strength steel for safety, and advanced composites for body panels. Battery cells, often made from lithium-ion technology, are also sourced and prepared during this stage.

-

Forming: This stage involves shaping the prepared materials into their final forms. Techniques such as stamping, forging, and extrusion are commonly used. For example, the body panels may be stamped from sheets of aluminum or steel, while the battery enclosures are often extruded to ensure strength and durability. Advanced robotics are increasingly employed to enhance precision and reduce waste during this phase.

-

Assembly: The assembly process is where the vehicle components come together. This includes integrating the battery pack, electric motors, and electronic control systems into the chassis. Automated assembly lines are prevalent, utilizing robotics to ensure consistency and speed. Quality checks are integrated into the assembly line to catch any defects early, significantly reducing rework costs.

-

Finishing: The final stage includes painting, detailing, and installing interior components. This phase not only enhances the aesthetic appeal of the vehicle but also involves several quality control checks. For example, paint thickness is measured to ensure durability against environmental factors.

What Quality Control Measures Are Essential for Electric Cars?

Quality assurance (QA) is a critical aspect of electric vehicle manufacturing, ensuring that every unit meets safety and performance standards. B2B buyers must be aware of the relevant international and industry-specific standards that govern this process.

-

International Standards: ISO 9001 is a widely recognized quality management standard that outlines requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer adheres to best practices in quality control and continuous improvement. Other relevant standards include ISO 26262 for automotive functional safety and ISO 14001 for environmental management.

-

Industry-Specific Certifications: In addition to general ISO standards, certain industry-specific certifications such as CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for components related to energy sources are vital. These certifications assure buyers that the products meet stringent safety and performance criteria.

-

Quality Control Checkpoints: Effective QC involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Checks the quality of raw materials and components as they arrive at the factory.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process to identify and rectify issues in real-time.

– Final Quality Control (FQC): A comprehensive review of the completed vehicle before it leaves the factory, ensuring it meets all specifications and safety standards.

What Testing Methods Are Commonly Used in Electric Vehicle Production?

Testing is an integral part of the manufacturing process, ensuring that electric vehicles perform optimally and are safe for consumers. B2B buyers should be familiar with the various testing methods employed by manufacturers.

-

Performance Testing: This includes evaluating the vehicle’s acceleration, braking, and handling under various conditions. Manufacturers often use dynamometers and test tracks to simulate real-world driving scenarios.

-

Battery Testing: Battery performance is critical for EVs. Manufacturers conduct cycle testing to determine the battery’s lifespan, capacity retention, and thermal stability. This testing ensures that the battery can withstand various environmental conditions and usage patterns.

-

Safety Testing: Compliance with safety standards is paramount. Crash tests are conducted to evaluate the vehicle’s structural integrity and occupant protection in the event of a collision. Additionally, electromagnetic compatibility (EMC) testing ensures that electronic components do not interfere with each other.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with local regulations.

-

Conducting Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control measures. An audit should assess adherence to international standards, equipment calibration, and employee training programs.

-

Reviewing Quality Reports: Manufacturers should provide detailed quality reports that outline their QC processes, testing results, and any corrective actions taken in response to defects. These documents are crucial for understanding the manufacturer’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. These inspectors can verify compliance with international standards and provide an additional layer of assurance.

What Are the Quality Control Nuances for International Buyers?

When sourcing electric vehicles, B2B buyers from regions like Africa, South America, the Middle East, and Europe should be aware of specific quality control nuances.

-

Local Regulations: Each region may have unique regulations that manufacturers must comply with. Understanding these regulations is critical for ensuring that the vehicles meet local standards, which may differ from international norms.

-

Cultural Considerations: Cultural differences can impact communication and expectations regarding quality. B2B buyers should establish clear communication channels with suppliers to ensure mutual understanding of quality requirements.

-

Logistical Challenges: International shipping can introduce risks such as damage during transit. Buyers should consider supplier practices regarding packaging and handling to mitigate these risks.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for electric vehicles is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring that they procure vehicles that meet both their standards and those of their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cars price’

The purpose of this guide is to equip B2B buyers with a practical checklist for sourcing electric cars, focusing on price considerations. As the electric vehicle (EV) market continues to expand globally, especially in regions like Africa, South America, the Middle East, and Europe, understanding pricing strategies and market dynamics is crucial for informed purchasing decisions.

Step 1: Define Your Budget Range

Establishing a clear budget is essential to streamline your sourcing process. Determine a price range that aligns with your organization’s financial capabilities and project needs. Consider not only the purchase price but also potential costs for maintenance, charging infrastructure, and any applicable import tariffs.

Step 2: Identify the Types of Electric Vehicles Needed

Different projects may require specific types of electric vehicles, such as sedans, SUVs, or commercial vans. Define the intended use cases—whether for transportation, logistics, or corporate fleets. This clarity will help you focus on vehicles that meet your operational needs while remaining within budget.

Step 3: Research Available Models and Pricing

Conduct thorough research on the electric vehicles available in your defined budget. Utilize resources like automotive rankings and expert reviews to identify models that provide the best value. Pay attention to specifications such as range, charging time, and warranty options, as these factors can significantly impact total cost of ownership.

Step 4: Evaluate Supplier Credibility

Before finalizing a purchase, assess the credibility of potential suppliers. Request documentation that outlines their experience in supplying electric vehicles, including client testimonials and case studies. Verify their certifications and affiliations with recognized automotive organizations to ensure they meet industry standards.

Step 5: Analyze Total Cost of Ownership (TCO)

Understanding the total cost of ownership is critical for long-term financial planning. Factor in aspects such as insurance, maintenance, charging costs, and depreciation. Comparing TCO across different models will provide insights into which vehicles will offer the best return on investment over time.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted potential suppliers, initiate negotiations to secure favorable terms. Discuss payment plans, warranty provisions, and after-sales support. Ensure that the agreement includes clear terms regarding delivery schedules and any potential penalties for delays, which is crucial for maintaining operational efficiency.

Step 7: Plan for Infrastructure and Training

Consider the infrastructure required to support electric vehicle operations. Assess whether your organization has the necessary charging stations and maintenance facilities. Additionally, plan for staff training on the use and maintenance of electric vehicles to ensure smooth integration into your existing fleet.

By following this checklist, B2B buyers can systematically approach the procurement of electric vehicles, ensuring they make informed decisions that align with their operational needs and budget constraints.

Comprehensive Cost and Pricing Analysis for electric cars price Sourcing

What Are the Key Cost Components in Electric Car Pricing?

When analyzing the pricing of electric vehicles (EVs), it is essential to understand the primary cost components that contribute to the final price. These include:

-

Materials: The cost of raw materials is a significant factor, particularly for battery production, which involves lithium, cobalt, and nickel. The volatility in the prices of these materials can directly impact the overall cost of the vehicle.

-

Labor: Labor costs vary by region and can influence pricing significantly. In countries with higher labor costs, such as those in Europe, the final price of EVs may be higher compared to manufacturing in regions with lower labor costs, such as parts of Africa or South America.

-

Manufacturing Overhead: This includes costs related to facilities, equipment, and utilities. Efficient manufacturing processes can help reduce these overhead costs and thereby lower vehicle prices.

-

Tooling: Investment in tooling for production is crucial, particularly for customized or specialized vehicles. The amortization of these costs over production volume can affect pricing strategies.

-

Quality Control (QC): Ensuring high-quality standards often involves additional costs, but it is critical for maintaining brand reputation and customer satisfaction, particularly in competitive markets.

-

Logistics: Transportation and distribution costs can vary significantly based on the location of production and the destination market. These costs are particularly relevant for international buyers who must account for shipping, customs duties, and local taxes.

-

Margin: Manufacturers typically build in a profit margin that reflects their business strategy and market positioning. This margin can vary significantly between brands and models.

How Do Price Influencers Affect Electric Vehicle Sourcing?

Several factors influence the pricing of electric vehicles, particularly for B2B buyers seeking to source these vehicles internationally:

-

Volume and Minimum Order Quantity (MOQ): Buying in bulk can lead to lower per-unit costs, making it essential for businesses to negotiate favorable terms based on their purchasing volume.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should evaluate whether the added features justify the price increase.

-

Materials: The choice of materials can affect both cost and performance. For instance, opting for advanced battery technologies may increase upfront costs but improve efficiency and range.

-

Quality and Certifications: Vehicles that meet higher quality standards or possess certain certifications may command a premium. Buyers should consider the long-term value these certifications provide.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer better warranties or service options, justifying a higher price.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for international transactions. They define the responsibilities of buyers and sellers and can impact overall costs.

What Are the Best Negotiation Tips for International B2B Buyers?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Leverage Total Cost of Ownership (TCO): When negotiating, consider not just the purchase price but the total cost of ownership, including maintenance, warranty, and operational costs.

-

Research Market Prices: Knowledge of current market prices and competitor offerings can empower buyers during negotiations.

-

Build Relationships with Suppliers: Establishing strong relationships can facilitate better terms and pricing, as suppliers may be more willing to negotiate with trusted partners.

-

Consider Local Partnerships: Collaborating with local distributors or partners can provide insights into market conditions and help negotiate better deals.

Why Is Understanding Pricing Nuances Important for International Buyers?

Understanding the nuances of pricing is particularly crucial for international buyers, as factors such as currency fluctuations, import duties, and regional economic conditions can significantly affect the final cost. Therefore, it is advisable for buyers to conduct thorough market research and possibly consult local experts to navigate these complexities effectively.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and other factors. Buyers are encouraged to conduct their own research and seek multiple quotes to ensure they receive competitive pricing.

Alternatives Analysis: Comparing electric cars price With Other Solutions

Exploring Alternatives to Electric Cars: A Comparative Analysis

In the evolving landscape of transportation, electric vehicles (EVs) are often viewed as the future of sustainable mobility. However, for international B2B buyers—especially in regions like Africa, South America, the Middle East, and Europe—it’s crucial to consider viable alternatives that may fit specific operational needs. This section explores the price of electric cars in comparison to other solutions, including hybrid vehicles and traditional internal combustion engine (ICE) vehicles.

Comparison Table

| Comparison Aspect | Electric Cars Price | Hybrid Vehicles Price | Traditional ICE Vehicles Price |

|---|---|---|---|

| Performance | High torque, silent operation; ranges vary (149-512 miles) | Moderate performance; better fuel economy than ICE | High performance; extensive range and quick refueling |

| Cost | Starting at ~$29,635; federal/state incentives available | Starting at ~$25,000; lower operating costs | Starting at ~$20,000; lower initial cost but higher fuel expenses |

| Ease of Implementation | Requires charging infrastructure; may need home charging units | Minimal changes to existing infrastructure; compatible with gasoline stations | Established infrastructure; readily available fueling options |

| Maintenance | Generally lower maintenance; fewer moving parts | Moderate maintenance; still reliant on gasoline engine | Higher maintenance; more moving parts and engine complexity |

| Best Use Case | Urban settings with charging access; environmentally conscious operations | Versatile; good for mixed driving conditions; lower emissions | Long-distance travel; areas with limited charging infrastructure |

Detailed Breakdown of Alternatives

1. Hybrid Vehicles

Hybrid vehicles combine an internal combustion engine with an electric motor, offering an efficient solution for businesses that may not be ready to transition fully to electric. The initial cost is generally lower than that of electric cars, and they provide better fuel economy than traditional vehicles, making them a financially attractive option for companies operating in diverse environments. However, they still rely on gasoline and may have higher maintenance costs than EVs due to their complex powertrains.

2. Traditional Internal Combustion Engine (ICE) Vehicles

ICE vehicles remain the most common mode of transport worldwide. Their initial purchase price is often lower compared to electric and hybrid vehicles, and they provide extensive fueling infrastructure, making them convenient for long-distance travel or in regions where charging stations are scarce. However, they have higher operating costs related to fuel consumption and maintenance, as well as environmental impacts due to emissions. This makes them less favorable for businesses focusing on sustainability.

Conclusion: How to Choose the Right Solution for Your Needs

When considering the transition to electric vehicles or alternatives, B2B buyers must evaluate their specific operational needs, budget constraints, and long-term sustainability goals. Electric cars offer significant benefits in performance and maintenance, particularly in urban settings with adequate charging infrastructure. However, hybrid vehicles present a balanced option for businesses seeking efficiency without the need for extensive changes to existing fueling systems. Traditional ICE vehicles, while economical in the short term, may not align with sustainability objectives. Ultimately, the right choice will depend on the unique circumstances of each business, including geographic considerations, operational range, and financial strategy.

Essential Technical Properties and Trade Terminology for electric cars price

What Are the Key Technical Properties of Electric Cars That Affect Their Pricing?

When evaluating electric cars for B2B procurement, several technical properties are critical in determining their price and overall value. Understanding these specifications can help buyers make informed decisions that align with their operational needs.

1. Battery Capacity (kWh)

Battery capacity, measured in kilowatt-hours (kWh), is a primary determinant of an electric vehicle’s (EV) range and performance. A higher capacity indicates a longer range per charge, which is crucial for businesses that require extensive travel without frequent recharging. For instance, electric vehicles like the 2025 Chevrolet Equinox EV offer a range of up to 319 miles, making them suitable for logistics and transportation companies.

2. Charging Time

Charging time varies depending on the vehicle’s battery and the charging infrastructure used. Typically, Level 1 chargers take the longest, while Level 3 (DC fast chargers) can significantly reduce downtime. Understanding charging time is essential for businesses that operate on tight schedules, as longer charging times can lead to inefficiencies in fleet operations.

3. Motor Power (kW)

The power of the electric motor, measured in kilowatts (kW), affects the vehicle’s acceleration and towing capacity. For example, a vehicle with a higher kW rating will generally provide better performance and efficiency, which can be a deciding factor for businesses that need robust vehicles for transporting goods or heavy equipment.

4. Range (Miles)

The estimated driving range on a single charge is a vital specification for any electric vehicle. This property influences not only the vehicle’s usability but also its appeal to businesses that rely on long-distance travel. Vehicles like the 2025 Hyundai Ioniq 6, with a range of up to 342 miles, can minimize the need for multiple charging stops, thereby enhancing productivity.

5. Cargo Space

The amount of cargo space available in an electric vehicle can significantly impact its utility for commercial use. Buyers should assess cargo capacity in conjunction with the vehicle’s dimensions and layout to ensure it meets their logistical requirements. For example, electric SUVs like the Nissan Ariya are designed to offer ample cargo space, making them suitable for deliveries and transporting equipment.

What Are the Common Trade Terms in the Electric Vehicle Industry?

Familiarity with industry terminology is essential for B2B buyers to navigate negotiations and contracts effectively. Here are some common terms related to electric car pricing and procurement.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products that are sold under another company’s brand. In the electric vehicle sector, this term is often used to refer to the manufacturers of electric vehicles themselves. Understanding OEM relationships can be vital for buyers looking to establish partnerships or procure vehicles directly from manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers as it affects pricing negotiations. Understanding the MOQ can help businesses plan their purchases and manage inventory effectively, especially when considering electric vehicle fleets.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers requesting pricing information for specific products or services. In the context of electric vehicles, an RFQ can help businesses compare costs and specifications from multiple suppliers, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers in global transactions. Familiarity with Incoterms is crucial for B2B buyers involved in international procurement of electric vehicles, as these terms govern shipping, insurance, and liability.

5. TCO (Total Cost of Ownership)

TCO encompasses all costs associated with owning and operating a vehicle over its lifetime, including purchase price, maintenance, fuel, insurance, and depreciation. Understanding TCO is essential for B2B buyers to evaluate the long-term financial impact of electric vehicles compared to traditional combustion engine vehicles.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions regarding electric vehicle acquisitions, aligning their purchases with both operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the electric cars price Sector

What Are the Current Market Dynamics Influencing Electric Car Prices?

The electric vehicle (EV) market is witnessing transformative dynamics that impact pricing, particularly for international B2B buyers in regions like Africa, South America, the Middle East, and Europe. Key drivers include technological advancements, increased production capacities, and evolving consumer preferences towards sustainable mobility. The global push for greener transportation solutions is causing manufacturers to invest heavily in research and development, leading to a wider variety of models at competitive price points. For instance, vehicles like the 2025 Nissan Leaf and Hyundai Kona Electric are positioned under $50,000, appealing to cost-sensitive markets.

Emerging trends also highlight the growing importance of battery technology, which significantly influences pricing. As battery costs decline, manufacturers can offer more affordable models with enhanced range and features. Moreover, the shift toward direct-to-consumer sales channels is reshaping traditional dealership models, allowing for more transparent pricing structures. In regions like Brazil and Nigeria, where affordability is paramount, B2B buyers should focus on sourcing strategies that prioritize value without compromising quality. Additionally, understanding local market dynamics, such as import tariffs and government incentives for EV adoption, can provide crucial insights for effective sourcing.

How Is Sustainability Shaping Ethical Sourcing in the Electric Car Sector?

Sustainability has become a cornerstone of the electric vehicle industry, significantly influencing sourcing strategies for B2B buyers. The environmental impact of sourcing materials for EVs—particularly lithium, cobalt, and nickel—has raised awareness about the importance of ethical supply chains. Buyers are increasingly scrutinizing suppliers to ensure they adhere to sustainability standards, thereby minimizing ecological footprints and supporting responsible mining practices.

Ethical sourcing is further underscored by the demand for ‘green’ certifications and materials in the automotive supply chain. Certifications such as ISO 14001 and adherence to the Responsible Cobalt Initiative are becoming essential benchmarks for suppliers aiming to attract B2B buyers. Companies that prioritize sustainability not only enhance their brand reputation but also position themselves favorably in a market where consumers are increasingly eco-conscious. B2B buyers must therefore align their sourcing strategies with suppliers committed to sustainable practices, ensuring that their procurement processes contribute positively to environmental goals.

What Is the Historical Context Behind Electric Car Pricing Trends?

The evolution of electric car pricing can be traced back to the early 2000s when EVs were considered niche products with limited range and high costs. Initial models, such as the Tesla Roadster, showcased the potential of electric propulsion but were priced beyond the reach of average consumers. However, as technology advanced, production efficiencies improved, and consumer interest grew, the market began to shift.

By the mid-2010s, the introduction of more affordable models, like the Nissan Leaf, marked a significant turning point. This democratization of EVs spurred competition among manufacturers, leading to further reductions in prices and enhancements in performance. Today, electric cars are not only more affordable but also feature diverse options, catering to a wider audience. This historical context is essential for B2B buyers as it highlights the rapid evolution of the market and informs sourcing decisions based on trends and consumer expectations. Understanding this trajectory can guide buyers in anticipating future pricing dynamics and aligning their strategies accordingly.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cars price

-

1. How do I determine the total cost of purchasing electric cars?

To accurately determine the total cost of purchasing electric cars, consider several factors beyond the manufacturer’s suggested retail price (MSRP). Include taxes, import duties, shipping fees, and any additional costs such as registration and insurance. Depending on your location, local incentives or subsidies for electric vehicles may also apply, which can significantly lower the overall cost. It’s advisable to request detailed pricing breakdowns from suppliers to ensure you understand the complete financial commitment. -

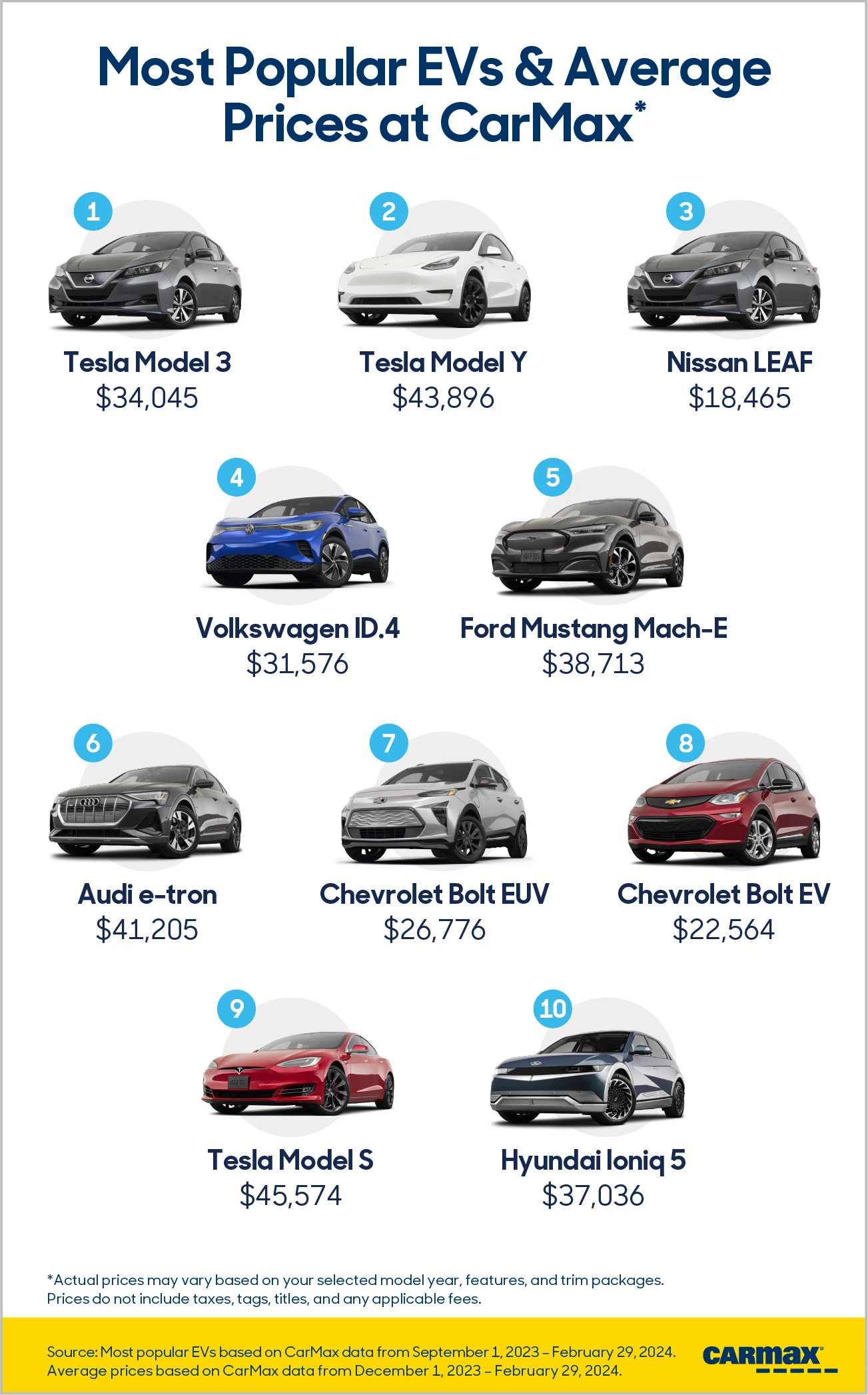

2. What are the most affordable electric vehicles available for international buyers?

Affordability in electric vehicles varies by model and market. For international buyers, models like the 2025 Nissan Leaf and 2025 Hyundai Kona Electric are among the more budget-friendly options, generally starting below $35,000. However, consider local market conditions, availability, and potential tariffs that could affect pricing. Researching local dealerships or manufacturers that offer competitive pricing can lead to better deals, especially in regions like Africa and South America. -

3. What customization options are available for electric vehicles?

Customization options for electric vehicles can include features such as battery size, color, interior finishes, and technology packages. Many manufacturers offer modular designs that allow for variations in range and performance to meet specific business needs. When sourcing electric cars, inquire with suppliers about the extent of customization they offer and any associated costs. This can ensure that the vehicles align with your operational requirements and brand identity. -

4. What are the minimum order quantities (MOQ) for electric vehicles?

Minimum order quantities for electric vehicles can vary significantly depending on the manufacturer and market. Some manufacturers may have an MOQ of one vehicle, particularly for direct sales to businesses, while others might require bulk orders for better pricing. When negotiating with suppliers, clarify the MOQ to align with your purchasing strategy and budget. It’s also beneficial to discuss potential discounts for larger orders, as many suppliers are willing to accommodate bulk buyers. -

5. How can I vet suppliers of electric vehicles for international trade?

Vetting suppliers for electric vehicles involves assessing their reputation, certifications, and compliance with international standards. Begin by checking for industry certifications like ISO and quality assurance processes. Request references from other B2B clients and review their previous export experience, particularly in your region. Additionally, utilize platforms such as Alibaba or TradeKey to find verified suppliers and read reviews. Ensuring they have a solid track record can mitigate risks associated with international transactions. -

6. What payment terms should I expect when purchasing electric vehicles?

Payment terms for electric vehicles can vary widely among suppliers. Common arrangements include upfront payments, partial payments with financing options, or letters of credit for international purchases. It’s crucial to discuss these terms early in negotiations to avoid misunderstandings. Additionally, consider the implications of currency exchange rates and transaction fees if dealing with international suppliers. Establishing clear payment terms can protect both parties and streamline the purchasing process. -

7. What quality assurance measures should I look for in electric vehicles?

Quality assurance measures in electric vehicles are vital for ensuring reliability and performance. Look for suppliers that implement rigorous testing protocols during manufacturing, including safety and performance assessments. Certifications such as ISO 9001 for quality management systems can indicate adherence to high standards. Request detailed documentation on the vehicle’s testing results and any warranty or service agreements, as these can provide insights into the manufacturer’s commitment to quality. -

8. How do logistics and shipping work for importing electric vehicles?

Logistics for importing electric vehicles involve several key steps, including selecting a shipping method, customs clearance, and delivery to your location. Most companies utilize container shipping for bulk orders or Ro-Ro (roll-on/roll-off) services for individual vehicles. Ensure that your supplier provides assistance with documentation required for customs clearance. Additionally, consider the lead time for shipping and any potential tariffs or taxes that may apply upon arrival. Effective logistics planning can help streamline the process and reduce delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Electric Cars Price Manufacturers & Suppliers List

1. Hyundai – IONIQ 6 & IONIQ 9

Domain: hyundaiusa.com

Registered: 1997 (28 years)

Introduction: Hyundai offers a range of electric vehicles (EVs) including the 2025 IONIQ 6 and the 2026 IONIQ 9. The 2025 IONIQ 6 has an EPA-estimated driving range of up to 342 miles for the SE RWD trim, with other trims offering ranges between 240 to 316 miles. The 2026 IONIQ 9 is a three-row electric SUV with an EPA-estimated range of up to 335 miles and starts at $58,955 MSRP. It features ultra-fast chargin…

2. Chase – Electric Vehicle Financing

Domain: autofinance.chase.com

Registered: 1995 (30 years)

Introduction: Electric vehicles (EVs) and plug-in hybrid vehicles (PHEVs) have a wide range of price tags, from $30,000 to over $100,000, with an average transaction price of $55,614 for new EVs as of January 2025. The federal government offers a rebate of up to $7,500 for fully electric cars and eligible plug-in hybrids, contingent on final assembly in North America. Home charging systems are recommended to be…

3. Cars.com – Electric Vehicle Overview

Domain: cars.com

Registered: 1998 (27 years)

Introduction: [{“model”:”Nissan Leaf”,”starting_price”:”$29,280″,”epa_estimated_range”:”149-212 miles”},{“model”:”Fiat 500e”,”starting_price”:”$32,495″,”epa_estimated_range”:”141-149 miles”},{“model”:”Hyundai Kona Electric”,”starting_price”:”$34,470″,”epa_estimated_range”:”200-261 miles”},{“model”:”Chevrolet Equinox EV”,”starting_price”:”$34,995″,”epa_estimated_range”:”307-319 miles”},{“model”:”Toyota bZ4X”,”st…

Strategic Sourcing Conclusion and Outlook for electric cars price

What Are the Key Takeaways for B2B Buyers in the Electric Vehicle Market?

As the electric vehicle (EV) market continues to evolve, strategic sourcing becomes essential for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. Analyzing the current landscape reveals a range of affordable EV options under $50,000, including models like the 2025 Nissan Leaf and Hyundai Kona Electric, which offer competitive pricing and various features. Understanding local market dynamics, including import duties and incentives, can enhance purchasing strategies.

Investing in electric vehicles not only aligns with global sustainability goals but also offers long-term cost savings in fuel and maintenance. The demand for EVs is projected to rise significantly, driven by increasing environmental regulations and consumer preference for greener options. B2B buyers are encouraged to leverage this trend by establishing partnerships with reliable manufacturers and suppliers to secure the best pricing and availability.

How Can B2B Buyers Prepare for Future Trends in Electric Vehicle Pricing?

Looking ahead, international B2B buyers should remain agile, adapting to shifts in technology and pricing structures. Engaging in proactive sourcing and maintaining close relationships with suppliers will be crucial in navigating the evolving landscape. By staying informed about market trends and technological advancements, businesses can position themselves to capitalize on emerging opportunities in the electric vehicle sector.