Introduction: Navigating the Global Market for complete brake down electric car

The global market for complete breakdown electric cars presents a unique set of challenges for international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe. As the automotive industry pivots towards sustainability, understanding the intricacies of electric vehicle (EV) systems—especially braking technology—is essential for sourcing reliable and efficient vehicles. This guide delves into the multifaceted landscape of complete breakdown electric cars, covering essential topics such as types of braking systems, their applications, supplier vetting processes, and cost considerations.

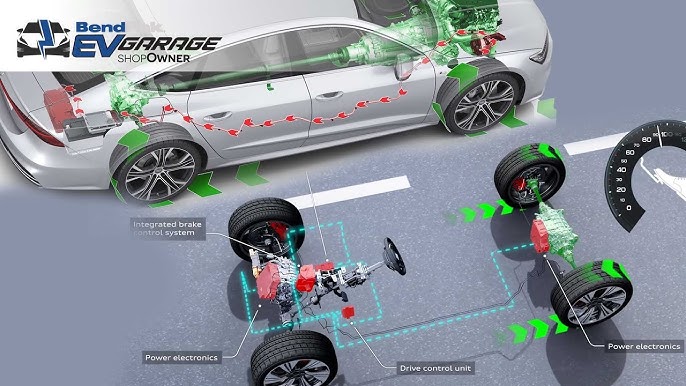

Electric vehicles stand out not only for their environmental benefits but also for their innovative braking technologies, such as regenerative braking, which enhances efficiency and reduces maintenance costs. By exploring these features, buyers can make informed decisions that align with their operational needs and sustainability goals. This comprehensive guide empowers B2B buyers to navigate the complexities of sourcing electric cars, ensuring they understand the technological advancements and market dynamics that influence purchasing decisions.

With a focus on actionable insights and expert recommendations, this resource aims to equip businesses with the knowledge necessary to thrive in the evolving EV landscape. Whether you are looking to enhance your fleet or invest in cutting-edge technology, this guide will serve as your strategic partner in making sound, informed purchasing choices in the global electric vehicle market.

Understanding complete brake down electric car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Battery Electric Vehicles (BEVs) | Fully electric, no internal combustion engine, longer ranges | Fleet management, ride-sharing services | Pros: Lower operating costs; Cons: Longer refueling times compared to petrol vehicles. |

| Plug-in Hybrid Electric Vehicles (PHEVs) | Combines electric and gasoline engines, allows for extended range | Delivery services, public transport | Pros: Flexibility in fuel choice; Cons: More complex maintenance. |

| Fuel Cell Electric Vehicles (FCEVs) | Uses hydrogen fuel cells for power, quick refueling | Heavy-duty transport, long-distance logistics | Pros: Fast refueling; Cons: Limited hydrogen infrastructure. |

| Light Electric Vehicles (LEVs) | Smaller, lightweight, often two or three-wheeled | Urban delivery, last-mile logistics | Pros: Cost-effective for short distances; Cons: Limited range and payload capacity. |

| Autonomous Electric Vehicles (AEVs) | Integrated with self-driving technology, advanced sensors | Logistics, public transport, ride-hailing | Pros: Potential for reduced labor costs; Cons: High initial investment and regulatory hurdles. |

What are Battery Electric Vehicles (BEVs) and Their B2B Suitability?

Battery Electric Vehicles (BEVs) operate solely on electric power, offering significant advantages such as lower operating costs and reduced environmental impact. They are ideal for businesses focused on sustainability, such as fleet management and ride-sharing services, where minimizing fuel costs is essential. Buyers should consider the vehicle’s range and charging infrastructure, as longer refueling times can impact operational efficiency.

How Do Plug-in Hybrid Electric Vehicles (PHEVs) Benefit B2B Operations?

Plug-in Hybrid Electric Vehicles (PHEVs) combine electric and gasoline engines, offering flexibility for businesses that require extended range without the limitations of solely electric vehicles. They are suitable for delivery services and public transport, where varied driving conditions may necessitate a backup fuel source. However, potential buyers should be aware of the more complex maintenance requirements associated with dual powertrains.

Why Choose Fuel Cell Electric Vehicles (FCEVs) for Heavy-Duty Applications?

Fuel Cell Electric Vehicles (FCEVs) utilize hydrogen fuel cells, providing quick refueling capabilities and long ranges, making them suitable for heavy-duty transport and long-distance logistics. Their operational efficiency can significantly benefit businesses in sectors where downtime is costly. However, buyers must consider the current limitations in hydrogen refueling infrastructure, which can affect operational feasibility.

What Advantages Do Light Electric Vehicles (LEVs) Offer for Urban Logistics?

Light Electric Vehicles (LEVs) are compact, lightweight vehicles often used for short-distance travel. They are particularly effective for urban delivery and last-mile logistics, where maneuverability and cost-effectiveness are crucial. While they provide significant savings on fuel and maintenance, potential buyers should evaluate their limited range and payload capacity to ensure they meet business needs.

How Do Autonomous Electric Vehicles (AEVs) Transform Transportation?

Autonomous Electric Vehicles (AEVs) integrate self-driving technology, presenting a revolutionary option for logistics and public transport. Their ability to operate without a driver can lead to reduced labor costs and increased efficiency. However, businesses must navigate high initial investments and the evolving regulatory landscape surrounding autonomous technology, making comprehensive market research essential before procurement.

Key Industrial Applications of complete brake down electric car

| Industry/Sector | Specific Application of complete brake down electric car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric taxi services | Reduced operational costs and enhanced efficiency | Availability of charging infrastructure and service support |

| Logistics and Delivery | Last-mile delivery vehicles | Lower fuel costs and reduced maintenance needs | Vehicle range, load capacity, and regulatory compliance |

| Urban Mobility | Car-sharing and ride-hailing services | Increased revenue potential and customer satisfaction | Fleet management capabilities and software integration |

| Mining and Construction | Electric utility vehicles for site operations | Lower emissions and reduced noise pollution | Durability, battery life, and support for rugged terrains |

| Tourism and Leisure | Electric tour buses and shuttles | Enhanced customer experience and eco-friendliness | Comfort features and range for longer routes |

How Can Public Transportation Benefit from Complete Brake Down Electric Cars?

In public transportation, electric taxi services are becoming increasingly popular. They provide a sustainable alternative to traditional taxis, significantly reducing operational costs due to lower fuel expenses and less maintenance. Moreover, the regenerative braking system extends the lifespan of brake components, leading to fewer service interruptions. International buyers, particularly in regions like Africa and South America, should consider the availability of charging infrastructure and robust service support to ensure operational efficiency.

What Advantages Does the Logistics and Delivery Sector Gain from Electric Vehicles?

In logistics, last-mile delivery vehicles utilizing complete brake down electric cars offer substantial benefits. They help reduce fuel costs and maintenance expenses, making operations more profitable. The regenerative braking feature also contributes to energy efficiency, which is crucial for companies aiming to minimize their carbon footprint. Buyers in the Middle East and Europe must evaluate vehicle range and load capacity, as well as compliance with local regulations, to ensure smooth operations.

How Do Urban Mobility Solutions Leverage Electric Cars?

Electric cars are transforming urban mobility through car-sharing and ride-hailing services. These applications not only increase revenue potential but also enhance customer satisfaction by providing eco-friendly transport options. The seamless integration of fleet management software is essential for maximizing efficiency. B2B buyers from regions like Vietnam and Saudi Arabia should focus on the capabilities of these management systems to optimize their operations.

In What Ways Can Mining and Construction Industries Utilize Electric Vehicles?

The mining and construction sectors can adopt electric utility vehicles powered by complete brake down electric cars for site operations. These vehicles offer significant advantages, including lower emissions and reduced noise pollution, which are critical in sensitive environments. The durability and battery life of these vehicles are paramount for rugged terrains. Buyers should ensure that the vehicles can withstand harsh conditions while also providing necessary support and maintenance.

How Can the Tourism Sector Enhance Experiences with Electric Vehicles?

In the tourism and leisure industry, electric tour buses and shuttles can greatly improve customer experiences by offering eco-friendly and quiet transportation options. This shift not only appeals to environmentally conscious travelers but also enhances the overall quality of service. For international buyers, especially in Europe and emerging markets, comfort features and adequate range for longer routes are key considerations for successful integration into their fleets.

3 Common User Pain Points for ‘complete brake down electric car’ & Their Solutions

Scenario 1: Navigating Complex Maintenance Needs for Electric Car Brakes

The Problem: B2B buyers in the automotive sector often face challenges in maintaining electric vehicles (EVs) due to their unique braking systems. Unlike traditional vehicles, electric cars utilize regenerative braking alongside conventional brakes. This dual system can lead to confusion regarding maintenance schedules and requirements. If not properly managed, businesses may encounter increased operational costs from premature brake wear or inefficient braking performance, ultimately affecting their fleet’s reliability and safety.

The Solution: To effectively manage the maintenance of electric car brakes, B2B buyers should implement a robust maintenance protocol that incorporates both regenerative and traditional braking systems. First, invest in training programs for your maintenance staff to ensure they understand the intricacies of electric car braking systems. This includes recognizing when to rely on regenerative braking and how to adjust its settings for optimal performance. Regularly scheduled inspections are crucial; establish a routine that checks both braking systems for wear, with a focus on the regenerative components, as they may be less intuitive to service. Additionally, partnering with suppliers who provide detailed service manuals and training can enhance your team’s confidence in handling EV brake systems.

Scenario 2: Ensuring Efficient Energy Recovery in Urban Driving

The Problem: Businesses operating electric vehicle fleets in urban environments often struggle with maximizing energy efficiency. Stop-and-go traffic can diminish the effectiveness of regenerative braking, leading to increased battery consumption and reduced range. For companies relying on their EVs for deliveries or services, this inefficiency can translate into higher operational costs and logistical challenges.

The Solution: To enhance energy recovery from regenerative braking, B2B buyers should implement a driver training program focused on optimal driving techniques that promote energy efficiency. Educating drivers on how to anticipate stops and use regenerative braking effectively can significantly improve energy recovery. Additionally, consider investing in telematics systems that monitor driving patterns and provide feedback to drivers in real time. This data can help identify areas where driving behavior can be adjusted for better energy recuperation. Furthermore, integrating route planning software that accounts for traffic patterns can help minimize stops and starts, thus maximizing the benefits of regenerative braking.

Scenario 3: Managing Fleet Performance and Brake Wear

The Problem: Another significant pain point for B2B buyers is managing the performance and longevity of electric vehicle brakes. While regenerative braking can extend the life of traditional brake components, varying driving conditions and load factors can lead to uneven wear. This inconsistency can create unexpected maintenance costs and downtime, impacting overall fleet efficiency.

The Solution: To effectively manage brake wear and maintain fleet performance, B2B buyers should adopt a comprehensive monitoring system that tracks brake usage and performance metrics. Implementing advanced fleet management software that analyzes brake wear patterns can provide insights into when brake components need to be serviced or replaced. Additionally, consider integrating a predictive maintenance model that uses data analytics to forecast potential issues before they arise. This proactive approach can prevent costly downtime and ensure that the fleet operates smoothly. Collaborating with manufacturers to understand specific braking system characteristics for different EV models can also provide valuable insights into best practices for maintenance and optimal performance under various operational conditions.

Strategic Material Selection Guide for complete brake down electric car

What Are the Key Materials for Brake Systems in Electric Vehicles?

When considering the strategic material selection for brake systems in electric vehicles (EVs), several materials stand out due to their unique properties and performance characteristics. This analysis focuses on four primary materials: aluminum alloys, carbon composites, stainless steel, and ceramics. Each material offers distinct advantages and limitations, impacting overall vehicle performance, maintenance, and cost.

How Do Aluminum Alloys Perform in Electric Vehicle Brake Systems?

Aluminum alloys are widely used in the manufacturing of brake components due to their lightweight nature and good strength-to-weight ratio. These alloys typically exhibit excellent corrosion resistance, making them suitable for various environmental conditions. The temperature rating of aluminum alloys can vary, but they generally perform well under moderate thermal loads.

Pros: The primary advantage of aluminum alloys is their lightweight property, which contributes to overall vehicle efficiency and range. They also offer good thermal conductivity, aiding in heat dissipation during braking.

Cons: However, aluminum alloys can be more expensive than traditional materials like cast iron. They may also require more complex manufacturing processes, which can increase production costs.

Impact on Application: Aluminum alloys are particularly effective in applications where weight reduction is critical, such as in electric vehicles, enhancing energy efficiency.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure that the aluminum alloys meet local standards for corrosion resistance, particularly in humid or saline environments.

What Role Do Carbon Composites Play in EV Brake Systems?

Carbon composites are increasingly being utilized for high-performance brake applications in electric vehicles. These materials offer exceptional strength, low weight, and high thermal stability, making them suitable for demanding driving conditions.

Pros: The key advantage of carbon composites is their ability to withstand high temperatures without significant degradation. This property leads to better performance under heavy braking conditions, which is essential for safety.

Cons: On the downside, carbon composites can be significantly more expensive than metals and may require specialized manufacturing techniques, which can complicate the supply chain.

Impact on Application: Carbon composites are particularly advantageous in high-performance EVs where braking efficiency and weight savings are paramount.

Considerations for International Buyers: Buyers should consider the availability of carbon composite materials in their local markets and any associated certifications required for high-performance applications.

How Does Stainless Steel Compare for Brake Components?

Stainless steel is a common choice for brake components due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for various braking applications.

Pros: The primary advantage of stainless steel is its durability and resistance to wear, which translates to longer service life for brake components. Its strength allows for thinner designs, contributing to weight savings.

Cons: The main disadvantage is the higher cost compared to traditional carbon steel and the potential for weight increases, which can affect overall vehicle efficiency.

Impact on Application: Stainless steel is particularly suitable for environments with high humidity or exposure to corrosive elements, ensuring longevity and reliability.

Considerations for International Buyers: Buyers should verify compliance with international standards such as ASTM and DIN, especially in regions with stringent regulations.

Why Are Ceramics Important in Electric Vehicle Brake Systems?

Ceramic materials are known for their high-temperature resistance and low wear rates, making them an excellent choice for brake pads in electric vehicles. They provide consistent performance and reduced brake dust.

Pros: The key advantage of ceramics is their ability to operate effectively at high temperatures, which enhances braking performance and reduces fade.

Cons: However, ceramics can be more brittle than other materials, which may lead to cracking under extreme conditions. They are also generally more expensive.

Impact on Application: Ceramics are particularly beneficial in urban driving conditions where frequent braking occurs, as they maintain performance without generating excessive dust.

Considerations for International Buyers: Buyers should ensure that ceramic brake components meet local performance standards and are compatible with the specific braking systems used in their vehicles.

Summary Table of Material Selection for Electric Vehicle Brake Systems

| Material | Typical Use Case for complete brake down electric car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Brake calipers and components | Lightweight, enhances efficiency | Higher cost, complex manufacturing | Medium |

| Carbon Composites | High-performance brake systems | High strength, thermal stability | Expensive, specialized manufacturing | High |

| Stainless Steel | Brake discs and components | Durable, corrosion-resistant | Heavier, higher cost | Medium |

| Ceramics | Brake pads | High-temperature performance | Brittle, more expensive | High |

This material selection guide provides actionable insights for B2B buyers in diverse international markets, helping them make informed decisions that align with their specific operational requirements and local conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for complete brake down electric car

What Are the Main Stages in the Manufacturing Process of a Complete Breakdown Electric Car?

The manufacturing process of a complete breakdown electric car involves several critical stages that ensure the vehicle meets both performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Car Manufacturing?

Material preparation is the first step in the manufacturing process. It involves sourcing high-quality raw materials such as aluminum for the body, steel for the chassis, and advanced composites for lightweight components. Suppliers must adhere to international standards such as ISO 9001 to ensure quality. The materials undergo rigorous testing for strength, durability, and weight to optimize performance and efficiency.

What Techniques Are Used in the Forming Stage of Electric Car Production?

Once materials are prepared, the forming stage takes place. This stage includes processes like stamping, casting, and extrusion. For example, the body panels of an electric car are typically stamped from sheets of aluminum, which provides a lightweight yet sturdy structure. Advanced techniques like hydroforming may be used for complex shapes. The goal is to create components that not only fit together seamlessly but also contribute to the vehicle’s aerodynamics and overall efficiency.

How Is the Assembly of Electric Cars Conducted?

The assembly stage is where individual components come together to form the complete vehicle. This process often employs automation and robotics to enhance precision and speed. Key components such as the electric motor, battery pack, and braking systems—including both traditional and regenerative braking systems—are integrated during this phase.

Assembly lines are designed to facilitate easy access to components, ensuring that each part is installed correctly. Quality control personnel monitor the assembly process to detect any issues early, which can minimize rework and reduce costs.

What Finishing Techniques Are Used for Electric Cars?

The finishing stage involves painting, coating, and final inspections. The vehicle’s exterior is typically treated with anti-corrosive coatings to enhance durability. Advanced painting techniques, such as electrostatic painting, ensure an even application and high-quality finish.

Final inspections at this stage are critical. They may include visual checks for paint defects, alignment of body panels, and functional tests of electrical systems. Each vehicle undergoes a comprehensive quality assurance process to ensure that it meets all regulatory standards and customer expectations before leaving the factory.

What Are the International and Industry-Specific Quality Assurance Standards for Electric Cars?

Quality assurance in electric car manufacturing is governed by various international standards, such as ISO 9001, which focuses on quality management systems. For electric vehicles, additional industry-specific certifications may be required, such as CE marking in Europe, which indicates compliance with health, safety, and environmental protection standards.

In regions like Africa and South America, understanding local compliance requirements is crucial. Manufacturers must also consider certification from recognized authorities, such as the American National Standards Institute (ANSI) or the International Electrotechnical Commission (IEC), which can facilitate smoother market entry.

What Are the Key Quality Control Checkpoints in Electric Car Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with specific checkpoints designed to catch defects and ensure compliance with standards.

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of materials received from suppliers. It includes testing for strength, weight, and compatibility with existing components.

-

In-Process Quality Control (IPQC): During the assembly phase, IPQC involves monitoring each assembly step to ensure that components are installed correctly and function as intended. This may include real-time testing of electrical systems.

-

Final Quality Control (FQC): The final checkpoint occurs after assembly and finishing. It encompasses a comprehensive inspection, including functional tests of all vehicle systems, to ensure that the car is ready for delivery.

What Common Testing Methods Are Used in Electric Car Quality Assurance?

Testing methods in electric vehicle manufacturing can vary based on the component being evaluated. Common methods include:

-

Functional Testing: Verifying that all electronic systems, including the regenerative braking and battery management systems, operate correctly.

-

Durability Testing: Subjecting components to stress tests to simulate real-world conditions, ensuring longevity and reliability.

-

Safety Testing: Conducting crash tests and examining electrical safety to comply with regulatory standards.

These methods not only ensure the vehicle’s performance but also provide assurance to B2B buyers regarding safety and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying a supplier’s quality control processes is essential for ensuring product reliability. Buyers can conduct supplier audits, examining their manufacturing processes and quality assurance measures. Requesting quality assurance reports that detail testing methods and results can provide insight into the supplier’s commitment to quality.

Additionally, third-party inspections can be beneficial. These independent evaluations can offer an unbiased assessment of a supplier’s adherence to international standards and industry-specific certifications.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing electric vehicles. Understanding regional certifications, such as the Gulf Cooperation Council (GCC) standards in the Middle East or the European Union’s type approval processes, is vital. Buyers should ensure that suppliers can meet these local requirements while maintaining compliance with international standards.

Furthermore, cultural differences in business practices may influence communication and expectations regarding quality assurance. Establishing clear agreements on quality standards and inspection processes can help mitigate misunderstandings and foster strong supplier relationships.

Conclusion: Ensuring Quality in Electric Car Manufacturing for B2B Buyers

Manufacturing electric vehicles is a complex process that requires meticulous attention to detail across various stages, from material preparation to final quality control. For B2B buyers, understanding these processes, the relevant quality standards, and how to verify supplier compliance is essential for making informed purchasing decisions. By prioritizing quality assurance in their procurement strategies, buyers can ensure that they are investing in reliable and efficient electric vehicles that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘complete brake down electric car’

Introduction

This sourcing guide provides a structured checklist for B2B buyers interested in procuring complete brake systems for electric vehicles (EVs). As the market for electric cars expands, understanding the nuances of electric vehicle braking systems—including traditional and regenerative braking—is essential for making informed purchasing decisions. This checklist will help you navigate the complexities of sourcing high-quality braking components that enhance vehicle performance, safety, and efficiency.

Step 1: Understand Your Technical Requirements

Identify the specific technical specifications needed for the brake systems of electric vehicles. This includes understanding the integration of regenerative braking technology, compatibility with existing vehicle systems, and performance metrics such as stopping distance and heat dissipation. Tailor your requirements based on the types of EV models you plan to support.

- Key Considerations:

- Assess the braking needs based on vehicle weight and design.

- Consider regulatory compliance for safety standards in your target markets.

Step 2: Research Supplier Capabilities

Conduct thorough research on potential suppliers to ensure they can meet your technical requirements. Look for suppliers with a proven track record in manufacturing braking systems for electric vehicles, particularly those that specialize in regenerative braking technologies.

- Key Considerations:

- Evaluate their production capacity and technological expertise.

- Investigate past projects and client testimonials to gauge reliability.

Step 3: Verify Supplier Certifications

It’s crucial to verify that suppliers hold relevant certifications and adhere to international quality standards. This not only assures the quality of the braking systems but also indicates their commitment to safety and environmental regulations.

- Key Considerations:

- Look for ISO certifications and compliance with regional automotive standards.

- Ensure they have quality control processes in place for their products.

Step 4: Request Product Samples

Before finalizing your procurement, request samples of the braking systems. Testing samples allows you to assess the performance and compatibility of the components with your vehicles.

- Key Considerations:

- Conduct thorough testing under various driving conditions.

- Evaluate the durability and effectiveness of both traditional and regenerative braking functions.

Step 5: Evaluate After-Sales Support

Assess the level of after-sales support offered by potential suppliers. Effective support can significantly impact your operations, especially regarding maintenance and troubleshooting of braking systems.

- Key Considerations:

- Inquire about warranty terms and availability of replacement parts.

- Determine the responsiveness and expertise of their customer service team.

Step 6: Analyze Cost and Payment Terms

Evaluate the pricing structure of different suppliers and understand their payment terms. While cost is important, consider the total cost of ownership, including installation, maintenance, and the potential for long-term savings through reduced brake wear.

- Key Considerations:

- Compare quotes and ensure they include all necessary components and services.

- Look for flexible payment options that suit your cash flow needs.

Step 7: Establish Long-Term Partnerships

Consider forming long-term partnerships with suppliers who demonstrate reliability and innovation in braking technologies. Such relationships can lead to better pricing, priority support, and access to new technologies as they develop.

- Key Considerations:

- Discuss opportunities for collaboration on future projects or product developments.

- Evaluate their willingness to invest in joint ventures or co-development initiatives.

By following this checklist, B2B buyers can confidently navigate the procurement process for complete brake systems in electric vehicles, ensuring they make informed decisions that align with their operational needs and market demands.

Comprehensive Cost and Pricing Analysis for complete brake down electric car Sourcing

What Are the Key Cost Components for Sourcing a Complete Breakdown Electric Car?

When sourcing a complete breakdown electric car, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of materials encompasses batteries, electric motors, and braking systems, which are crucial for EV performance. High-quality materials can significantly increase the overall cost but will enhance durability and efficiency. Buyers should consider sourcing from suppliers that offer sustainable and certified materials, as this can also affect the long-term value of the vehicle.

-

Labor: Labor costs vary significantly depending on the region of manufacturing. Skilled labor is essential for assembling electric vehicles, particularly for components like regenerative braking systems that require specialized knowledge. Regions with a strong workforce in automotive engineering, such as Europe, may have higher labor costs, but they often ensure superior quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can reduce overhead, allowing for competitive pricing. Buyers should inquire about the manufacturer’s production capacity and efficiency metrics.

-

Tooling: The initial investment in tooling can be substantial, particularly for custom specifications. Buyers should evaluate whether the tooling costs are included in the quoted price or if they will be charged separately. Customization can drive up costs, but it may lead to a product that better meets market demands.

-

Quality Control (QC): Robust QC processes are vital for ensuring that every vehicle meets safety and performance standards. Investing in quality assurance can prevent costly recalls and enhance brand reputation. Buyers should ask about the QC protocols of potential suppliers.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transport, and volume. International buyers need to consider the logistics costs associated with importing electric vehicles, including tariffs and taxes. Efficient logistics management can mitigate unexpected expenses.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely. Buyers should seek transparency regarding how margins are calculated and be prepared to negotiate to achieve a more favorable deal.

How Do Price Influencers Impact the Sourcing of Electric Cars?

Several factors influence pricing in the sourcing of complete breakdown electric cars, including volume/MOQ, specifications/customization, material quality, supplier factors, and Incoterms.

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs. Establishing a Minimum Order Quantity (MOQ) can also affect pricing. Buyers should consider their market demand when negotiating order sizes.

-

Specifications/Customization: Custom features can significantly affect the final price. It’s crucial for buyers to clearly define their requirements to avoid unexpected costs later. Customization should align with market needs to maximize ROI.

-

Materials and Quality/Certifications: The choice of materials directly impacts both cost and vehicle performance. Buyers should prioritize suppliers with relevant certifications, as these can indicate a commitment to quality and sustainability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with a strong track record may offer better warranties and support, which can justify higher costs.

-

Incoterms: Understanding Incoterms is essential for managing shipping responsibilities and costs. Buyers should clarify who bears the costs and risks at each stage of transportation to avoid surprises.

What Are the Best Negotiation and Cost-Efficiency Strategies for International Buyers?

To maximize cost-efficiency, international B2B buyers should adopt several strategies:

-

Negotiate Terms: Be prepared to negotiate not only on price but also on payment terms, delivery timelines, and warranty conditions. Establishing a good relationship with suppliers can lead to more favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Consider all costs associated with the vehicle, including maintenance, energy consumption, and potential resale value. A lower initial price may not always lead to better long-term savings.

-

Understand Pricing Nuances: Different regions may have varying pricing structures due to labor, materials, and market conditions. Buyers should conduct thorough market research to understand these nuances before making a decision.

-

Stay Informed on Market Trends: Keeping abreast of technological advancements and market shifts can provide leverage during negotiations. Being informed allows buyers to make strategic decisions that align with future market demands.

Disclaimer

The prices and insights provided are indicative and subject to change based on market conditions, currency fluctuations, and supplier negotiations. Buyers should conduct their due diligence to obtain the most accurate and relevant information for their specific sourcing needs.

Alternatives Analysis: Comparing complete brake down electric car With Other Solutions

The increasing demand for sustainable transportation solutions has led to the exploration of various technologies in the electric vehicle (EV) market. Among these, the complete brake down electric car stands out due to its unique braking system that combines traditional and regenerative braking methods. However, businesses looking to invest in electric vehicles should also consider alternative solutions that may offer similar benefits. Below, we compare the complete brake down electric car with two viable alternatives: hybrid electric vehicles (HEVs) and conventional internal combustion engine (ICE) vehicles.

| Comparison Aspect | Complete Brake Down Electric Car | Hybrid Electric Vehicle (HEV) | Conventional Internal Combustion Engine Vehicle (ICE) |

|---|---|---|---|

| Performance | High efficiency with regenerative braking, extending range by up to 30% | Good fuel efficiency, but less than EVs; moderate regenerative capabilities | Limited efficiency, reliant on fuel; lower overall performance |

| Cost | Higher initial investment; lower long-term maintenance costs | Moderate initial cost; better fuel economy reduces operational costs | Lower initial cost; high fuel and maintenance expenses |

| Ease of Implementation | Requires charging infrastructure; may have longer charging times | More versatile; can operate on fuel or electric power | Widely available infrastructure; no special requirements |

| Maintenance | Low maintenance due to reduced brake wear; regular inspections needed | Moderate maintenance; brake wear is less than ICE but more than EVs | High maintenance; regular brake replacements and engine care required |

| Best Use Case | Ideal for urban environments with charging stations; long-range travel options | Suitable for diverse driving conditions, including rural areas | Best for regions with limited charging infrastructure or high fuel availability |

What are the Pros and Cons of Hybrid Electric Vehicles (HEVs)?

Hybrid electric vehicles combine a traditional combustion engine with an electric motor, allowing for improved fuel efficiency compared to conventional vehicles. The regenerative braking system in HEVs captures energy during braking, enhancing efficiency. However, HEVs still rely on gasoline, which can limit their environmental benefits. They also require more maintenance than pure electric vehicles due to the complexity of having both an engine and electric components.

How do Conventional Internal Combustion Engine Vehicles Compare?

Conventional ICE vehicles are widely available and have lower initial costs, making them accessible for many businesses. Their established infrastructure for refueling is a significant advantage, especially in regions lacking charging stations. However, they come with high operational costs due to fuel consumption and maintenance needs. Additionally, they do not offer the environmental benefits associated with electric vehicles, making them less sustainable in the long term.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right vehicle solution, B2B buyers must consider their specific operational needs and environmental goals. The complete brake down electric car offers significant advantages in efficiency and maintenance, particularly in urban settings with robust charging infrastructure. Conversely, hybrid vehicles provide versatility for varied driving conditions but still rely on fossil fuels. Conventional ICE vehicles may be the most cost-effective in the short term but carry long-term costs and environmental concerns. Ultimately, the decision should align with the company’s sustainability objectives, budget constraints, and operational demands.

Essential Technical Properties and Trade Terminology for complete brake down electric car

What Are the Key Technical Properties of a Complete Brake System for Electric Cars?

When evaluating the technical specifications of electric car brake systems, several critical properties come into play. Understanding these properties is vital for B2B buyers, especially those looking to source components or negotiate contracts.

1. Material Grade

Electric car brakes typically utilize advanced materials such as carbon-ceramic composites or high-performance alloys. The choice of material impacts durability, heat resistance, and weight, which directly affect braking efficiency and vehicle performance. Buyers should prioritize suppliers who adhere to strict material standards to ensure longevity and safety in electric vehicle applications.

2. Friction Coefficient

This specification indicates the effectiveness of the brake pads in generating friction against the brake discs. A higher friction coefficient translates to better stopping power, which is crucial for safety in electric vehicles. Buyers must assess the friction characteristics of brake components to ensure they meet the performance requirements of their specific EV models.

3. Tolerance Levels

Precision in manufacturing tolerances is essential for brake components, as even minor deviations can lead to performance issues or premature wear. Tolerance levels are typically defined in microns and are crucial for ensuring the proper fit and function of brake systems. B2B buyers should confirm that suppliers can maintain stringent tolerances to guarantee quality and reliability.

4. Thermal Conductivity

Electric car brakes experience significant heat during operation, especially in regenerative braking scenarios. High thermal conductivity materials can dissipate heat more effectively, reducing the risk of brake fade and ensuring consistent performance. Evaluating the thermal properties of brake components is essential for maintaining safety and efficiency in electric vehicles.

5. Wear Rate

The wear rate of brake pads and discs directly impacts maintenance costs and vehicle downtime. Electric vehicles benefit from regenerative braking, which reduces wear on traditional brake components. B2B buyers should look for manufacturers that provide wear rate data to estimate lifecycle costs and plan for maintenance schedules accordingly.

6. Weight

The overall weight of brake components affects the vehicle’s efficiency and range. Lighter materials can improve performance but must not compromise safety. Buyers should seek suppliers that offer lightweight options without sacrificing strength and durability.

What Are Common Trade Terms Related to Electric Car Brake Systems?

In the B2B landscape of electric car components, familiarity with industry jargon is critical for effective communication and negotiation.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electric cars, OEMs supply critical components like brake systems to vehicle manufacturers. Understanding the role of OEMs helps buyers ensure they are sourcing high-quality, reliable parts.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell in a single order. This term is vital for B2B buyers to understand as it affects inventory management and cash flow. Knowing the MOQ helps companies plan purchases according to demand and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. In the electric vehicle sector, an RFQ for brake components should detail specifications, quantities, and delivery timelines. Properly crafting an RFQ can lead to better pricing and terms.

4. Incoterms

International Commercial Terms (Incoterms) are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers dealing with global suppliers to understand shipping costs, risks, and insurance responsibilities.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. In the electric vehicle industry, understanding lead times for brake components is essential for production planning and inventory management. Buyers should negotiate lead times to align with their manufacturing schedules.

6. Compatibility

This term refers to the ability of brake components to work seamlessly with different electric vehicle models. Compatibility is crucial for B2B buyers to ensure that the parts they source will fit and function correctly within their specific applications, minimizing the risk of costly errors.

By grasping these technical properties and trade terms, B2B buyers in the electric vehicle sector can make informed decisions, optimize their supply chains, and improve overall operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the complete brake down electric car Sector

What Are the Key Drivers Influencing the Electric Car Brake Market?

The electric vehicle (EV) sector is experiencing robust growth, driven by increasing environmental awareness, government regulations promoting sustainable transport, and advancements in battery technology. This surge is particularly evident in regions like Africa, South America, the Middle East, and Europe, where international B2B buyers are seeking innovative solutions to meet the rising demand for electric vehicles. As a result, the market for electric car brakes is evolving, with a focus on enhanced safety, efficiency, and reduced maintenance costs.

Emerging trends in sourcing include the integration of regenerative braking systems, which not only improve energy efficiency but also prolong the lifespan of traditional braking components. This dual-system approach is becoming a standard feature in many EV models, offering significant advantages such as energy recuperation, which can contribute up to 30% of an electric vehicle’s energy needs. Furthermore, advancements in smart technologies are enabling manufacturers to provide more customizable braking solutions, catering to various driving conditions and preferences.

International B2B buyers must also be aware of the competitive landscape, as traditional automotive suppliers pivot to meet the demands of the electric vehicle market. Collaborations between technology firms and automotive manufacturers are on the rise, providing opportunities for innovative sourcing strategies and partnerships that can enhance product offerings.

How Can Sustainability and Ethical Sourcing Enhance Your B2B Strategy in the Electric Car Sector?

Sustainability is a crucial consideration for B2B buyers in the electric car brake market. The environmental impact of manufacturing processes, from raw material extraction to product lifecycle management, is increasingly scrutinized. Buyers should prioritize suppliers who implement sustainable practices and maintain transparency in their supply chains. This includes using recycled materials and minimizing carbon footprints throughout production.

Ethical sourcing is also paramount. Buyers should seek suppliers that adhere to international labor standards and support fair labor practices. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to sustainability and ethical practices.

The demand for ‘green’ certifications is on the rise, as consumers and businesses alike prefer products that are environmentally friendly. Suppliers offering materials with verified sustainability credentials will not only align with global sustainability goals but also enhance the brand reputation of B2B buyers, making them more competitive in a rapidly evolving marketplace.

What Is the Historical Context of Electric Car Brakes?

The development of electric car brakes has evolved significantly over the years. Initially, electric vehicles relied solely on traditional braking systems, which utilized friction to slow down vehicles. However, as technology advanced, the introduction of regenerative braking systems transformed the landscape. This innovation allowed electric vehicles to recover kinetic energy during braking, enhancing efficiency and extending the range of EVs.

The integration of regenerative braking into electric vehicles became more prevalent in the early 2000s, coinciding with the broader adoption of electric vehicles worldwide. Manufacturers began to recognize the dual benefits of improved energy efficiency and reduced wear on conventional braking components. Today, regenerative braking is a standard feature in nearly all electric vehicle models, demonstrating the industry’s shift toward more sustainable and efficient technologies.

As B2B buyers navigate this evolving market, understanding the historical context of electric car brakes can provide valuable insights into future innovations and trends that will shape the electric vehicle landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of complete brake down electric car

-

How do I evaluate the quality of a complete breakdown electric car?

To evaluate the quality of a complete breakdown electric car, consider factors such as the manufacturer’s reputation, certifications, and warranty terms. Request detailed specifications, including battery life, regenerative braking efficiency, and safety features. Additionally, conduct a thorough inspection of the vehicle’s braking system, including both traditional and regenerative components. Test-driving the vehicle can also provide insights into its performance and handling, ensuring it meets your operational needs. -

What is the best electric vehicle for fleet operations?

The best electric vehicle for fleet operations depends on your specific requirements, including range, load capacity, and cost-efficiency. Models like the Tesla Model 3, Nissan Leaf, and Ford E-Transit are popular due to their reliability, range, and advanced features like regenerative braking. Assess your fleet’s operational demands, including the average distance traveled and the types of terrain, to determine which vehicle aligns best with your needs. -

How can I customize electric cars for my business needs?

Customization options for electric cars often include modifications to battery capacity, interior configurations, and tech integrations such as telematics systems. Engage with manufacturers or suppliers who offer bespoke solutions tailored to your business. Discuss your specific requirements upfront, including branding elements, safety features, and any operational adaptations needed for your markets in Africa, South America, the Middle East, and Europe. -

What are the minimum order quantities (MOQs) when sourcing electric vehicles?

Minimum order quantities (MOQs) can vary significantly based on the manufacturer and the specific model of the electric vehicle. Some manufacturers may require a MOQ of 10-20 units, while others may offer flexibility for smaller orders. It’s essential to communicate your needs clearly with potential suppliers to negotiate terms that suit your business model and market entry strategy. -

What payment terms should I expect when purchasing electric vehicles?

Payment terms for electric vehicle purchases typically include options such as full upfront payment, installment plans, or financing arrangements. Many manufacturers may offer favorable terms for bulk purchases, including discounts or deferred payment options. Always clarify the payment structure, including any deposits required, timelines for payment, and penalties for late payments to avoid future disputes. -

How do I vet suppliers for electric vehicles?

To vet suppliers for electric vehicles, start by researching their history, customer reviews, and industry certifications. Request references from previous clients and assess their responsiveness and customer service. Additionally, evaluate their production capabilities, compliance with international standards, and after-sales support. Conducting site visits can also provide valuable insights into their operational integrity and manufacturing processes. -

What logistics considerations should I keep in mind when importing electric vehicles?

When importing electric vehicles, consider shipping methods, customs regulations, and potential tariffs that may apply to your target markets. Collaborate with logistics partners who have experience in handling automotive shipments to ensure compliance with local regulations. Plan for transportation from the port to your facility and factor in lead times for delivery to avoid operational disruptions. -

What quality assurance measures are recommended for electric vehicles?

Implementing quality assurance measures for electric vehicles involves routine inspections and testing of both components and systems. Establish a quality control checklist that includes checks for battery performance, braking systems, and overall vehicle integrity. Regularly review supplier performance and maintain open communication to address any issues promptly, ensuring that all vehicles meet your operational standards and regulatory requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

A Look at Complete Brake Down Electric Car Manufacturers & Suppliers

We are currently compiling a detailed list of top complete brake down electric car suppliers. Please check back later.

Strategic Sourcing Conclusion and Outlook for complete brake down electric car

In the rapidly evolving landscape of electric vehicles (EVs), strategic sourcing is paramount for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. Understanding the unique braking systems in electric cars—specifically the synergy between traditional and regenerative braking—can significantly influence purchasing decisions and operational efficiencies. Regenerative braking not only enhances energy efficiency, potentially increasing vehicle range by up to 30%, but also reduces maintenance costs due to less wear on brake components.

For businesses looking to invest in electric vehicles, sourcing high-quality, reliable components that support these advanced braking technologies is crucial. The long-term benefits of reduced operational costs and improved vehicle performance make strategic sourcing a key factor in achieving competitive advantage in the EV market.

As we look ahead, the demand for electric vehicles is expected to rise, driven by sustainability initiatives and technological advancements. International B2B buyers are encouraged to engage with suppliers who prioritize innovation and quality in their offerings. By doing so, businesses can position themselves at the forefront of the electric vehicle revolution, paving the way for a sustainable and profitable future.