Introduction: Navigating the Global Market for electric car motor

In the rapidly evolving landscape of electric vehicle technology, sourcing the right electric car motor is a pivotal challenge for international B2B buyers. With diverse motor types such as induction, permanent magnet, and synchronous motors, understanding their unique applications and performance characteristics is essential for making informed decisions. This comprehensive guide serves as a valuable resource, covering not only the various types of electric car motors but also key considerations such as supplier vetting, pricing strategies, and integration with existing systems.

For businesses operating in regions like Africa, South America, the Middle East, and Europe—where the electric vehicle market is gaining momentum—this guide empowers buyers to navigate the complexities of sourcing electric car motors. By providing insights into the latest technologies, performance metrics, and cost implications, this resource enables companies to align their procurement strategies with their operational needs and sustainability goals.

Moreover, as global demand for electric vehicles continues to rise, understanding the intricacies of motor selection becomes crucial for maintaining a competitive edge. Whether you are a manufacturer, a fleet operator, or an automotive parts distributor, this guide will equip you with the knowledge necessary to make strategic purchasing decisions, ensuring you select the most suitable electric car motor for your business objectives.

Understanding electric car motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Induction Motor | Asynchronous design, relies on induced current; robust and cost-effective. | Commercial vehicles, industrial applications | Pros: Low manufacturing cost, durable. Cons: Lower efficiency at low speeds. |

| Permanent Magnet Motor | Synchronous design with embedded magnets; high efficiency at low speeds. | Passenger vehicles, performance EVs | Pros: High torque, compact size. Cons: Higher manufacturing costs, thermal management issues. |

| Brushless DC Motor | Uses electronic commutation; quiet operation and high efficiency. | E-bikes, scooters, small vehicles | Pros: High efficiency, low maintenance. Cons: More complex control systems needed. |

| Switched Reluctance Motor | Simple design with no permanent magnets; relies on magnetic reluctance. | Heavy-duty applications, mining vehicles | Pros: Robust, low-cost materials. Cons: Higher torque ripple, complex control. |

| Dual Motor Systems | Combines multiple motors for enhanced performance; often used in high-performance EVs. | Luxury and high-performance vehicles | Pros: Improved traction and efficiency. Cons: Increased complexity and cost. |

What Are the Characteristics of Induction Motors for Electric Vehicles?

Induction motors are widely used in various electric vehicle applications due to their robustness and cost-effectiveness. They operate asynchronously, meaning the rotor speed lags behind the magnetic field, which induces current and creates torque. This type of motor is particularly suitable for commercial vehicles and industrial applications where durability is paramount. B2B buyers should consider the lower manufacturing costs and the motor’s ability to handle high loads, although they may experience reduced efficiency at lower speeds.

How Do Permanent Magnet Motors Enhance Electric Vehicle Performance?

Permanent magnet motors are known for their high efficiency and compact design, making them ideal for passenger vehicles and performance electric vehicles. These synchronous motors utilize embedded magnets, which allow them to provide significant torque at low speeds. For B2B buyers, the main considerations include the higher manufacturing costs associated with the magnets and the need for effective thermal management to prevent overheating during operation.

What Advantages Do Brushless DC Motors Offer for Small Electric Vehicles?

Brushless DC motors are favored for their quiet operation and high efficiency, making them suitable for smaller electric vehicles like e-bikes and scooters. They utilize electronic commutation instead of brushes, leading to lower maintenance requirements and longer lifespans. B2B buyers should weigh the benefits of high efficiency against the more complex control systems required to operate these motors effectively.

Why Are Switched Reluctance Motors Gaining Popularity in Heavy-Duty Applications?

Switched reluctance motors are characterized by their simple design and reliance on magnetic reluctance rather than permanent magnets. This makes them a cost-effective choice for heavy-duty applications, such as mining vehicles. While they offer the advantage of using low-cost materials, B2B buyers must consider the higher torque ripple and the complexity of control systems necessary for optimal performance.

What Are the Benefits and Challenges of Dual Motor Systems?

Dual motor systems combine multiple motors to enhance performance and traction, particularly in luxury and high-performance electric vehicles. This approach allows for improved efficiency and better handling in various driving conditions. B2B buyers should evaluate the benefits of increased performance against the potential challenges of complexity and higher costs associated with dual motor setups.

Key Industrial Applications of electric car motor

| Industry/Sector | Specific Application of Electric Car Motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Production of electric vehicles | Streamlined assembly processes and reduced emissions | Compatibility with existing systems and regulatory compliance |

| Public Transportation | Electric buses and trams | Lower operational costs and improved air quality | Battery integration and charging infrastructure compatibility |

| Logistics & Delivery | Electric delivery vans and trucks | Enhanced fuel efficiency and reduced maintenance costs | Range requirements and payload capacity |

| Agriculture | Electric farm machinery (tractors, harvesters) | Increased productivity and lower fuel costs | Durability under varying environmental conditions |

| Renewable Energy | Electric vehicles as mobile energy storage units | Enhanced energy management and grid stability | Inverter and battery integration capabilities |

How Are Electric Car Motors Used in Automotive Manufacturing?

In the automotive manufacturing sector, electric car motors are pivotal in the production of electric vehicles (EVs). These motors facilitate a more efficient assembly process by integrating seamlessly with other components, reducing the overall carbon footprint during production. For international buyers, particularly in regions like Africa and South America, sourcing motors that comply with local regulations and can withstand diverse environmental conditions is crucial. Additionally, manufacturers must consider the compatibility of these motors with existing automotive systems.

What Role Do Electric Car Motors Play in Public Transportation?

Electric car motors are extensively used in public transportation systems, particularly in electric buses and trams. These motors contribute to significant reductions in operational costs through lower energy consumption and maintenance needs. Moreover, they help enhance air quality in urban areas by eliminating exhaust emissions. For buyers in Europe, such as Germany, understanding the local infrastructure for charging stations and the operational range of these vehicles is essential for successful implementation.

How Are Electric Car Motors Transforming Logistics and Delivery?

In the logistics and delivery sector, electric car motors power delivery vans and trucks, providing businesses with a means to achieve enhanced fuel efficiency and reduced maintenance costs. The ability to use electric motors allows companies to meet sustainability goals while cutting operational expenses. International buyers must evaluate the range and payload capacity of electric vehicles to ensure they meet specific delivery requirements, particularly in vast regions like South America.

Why Are Electric Car Motors Important in Agriculture?

Electric car motors are increasingly being utilized in agricultural machinery, such as tractors and harvesters. These motors boost productivity by enabling quieter, cleaner operations while significantly lowering fuel costs. For agricultural businesses, particularly in the Middle East and Africa, it is essential to consider the durability and performance of these motors under various environmental conditions, including heat and dust, to ensure reliability and longevity.

How Do Electric Car Motors Enhance Renewable Energy Systems?

Electric car motors serve as mobile energy storage units in renewable energy systems, allowing electric vehicles to feed excess energy back into the grid. This capability enhances energy management and contributes to grid stability, making it a valuable application in regions with growing renewable energy sectors. For European buyers, especially in countries like Germany, understanding inverter and battery integration capabilities is critical for maximizing the benefits of this technology.

3 Common User Pain Points for ‘electric car motor’ & Their Solutions

Scenario 1: Understanding the Compatibility of Electric Car Motors with Existing Systems

The Problem: Many B2B buyers face the challenge of ensuring that the electric car motor they choose is compatible with their existing vehicle systems. This can be particularly difficult for businesses involved in electric vehicle (EV) conversions or retrofitting older vehicles. Without comprehensive compatibility, they risk incurring additional costs and delays due to the need for modifications or replacements of other components, such as batteries, controllers, or drivetrains.

The Solution: To navigate this issue effectively, buyers should conduct a thorough analysis of the entire vehicle architecture before selecting an electric motor. Collaborate with manufacturers who provide detailed technical specifications and compatibility data for their products. It’s essential to engage in discussions about the specific requirements of the vehicle, including the desired performance metrics and the operational environment. Furthermore, consider utilizing simulation software to model how different motors will interact with the existing systems. This proactive approach can help identify potential issues early in the design process, allowing for smoother integration and reduced costs.

Scenario 2: Managing Supply Chain and Availability of Electric Car Motors

The Problem: Sourcing electric car motors can be a daunting task for B2B buyers, especially in regions with limited access to suppliers or where demand often exceeds supply. Unpredictable lead times and fluctuating availability can disrupt production schedules, leading to project delays and potential losses. This is particularly pressing in markets across Africa and South America, where supply chain issues are more pronounced.

The Solution: To mitigate these challenges, buyers should establish strong relationships with multiple suppliers to create a more resilient supply chain. Diversifying the supplier base not only enhances reliability but also provides leverage in negotiations. Moreover, implementing a just-in-time inventory system can help manage stock levels more effectively and reduce holding costs. Regularly reviewing market trends and maintaining open lines of communication with suppliers can also provide insights into upcoming shortages or new products. This proactive management of the supply chain can significantly enhance operational efficiency and ensure timely project completion.

Scenario 3: Overcoming Performance and Efficiency Concerns in Electric Car Motors

The Problem: Buyers often express concerns regarding the performance and efficiency of electric car motors, particularly when transitioning from traditional internal combustion engines. They may worry about the torque delivery, acceleration, and overall energy efficiency of electric motors, which can significantly impact the driving experience and operational costs. These concerns are heightened in regions where electric vehicles are still gaining acceptance and where performance benchmarks are critical for market competitiveness.

The Solution: To address performance and efficiency concerns, buyers should prioritize motors that have been rigorously tested and validated in real-world applications. Request case studies or performance metrics from suppliers that demonstrate how their motors perform under various conditions. Additionally, consider investing in advanced motor technologies such as synchronous permanent magnet motors, which typically offer higher efficiency and better torque characteristics. Collaborating with engineering teams to optimize the integration of the motor with the vehicle’s power management systems can further enhance performance. Ongoing performance monitoring and adjustments post-installation can ensure that the electric vehicle meets the expected operational standards, thus boosting buyer confidence in electric motor technology.

By addressing these common pain points, B2B buyers can navigate the complexities of integrating electric car motors into their operations more effectively, leading to enhanced productivity and market competitiveness.

Strategic Material Selection Guide for electric car motor

What Are the Key Materials Used in Electric Car Motors?

The selection of materials for electric car motors is crucial for optimizing performance, durability, and cost-effectiveness. Below, we analyze four common materials used in electric car motors, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Copper Windings Affect Electric Car Motor Performance?

Copper is widely used for windings in electric motors due to its excellent electrical conductivity and thermal properties. Key properties include high thermal conductivity, which allows for efficient heat dissipation, and low resistivity, ensuring minimal energy loss during operation.

Pros: Copper windings provide high efficiency and reliability, essential for performance-driven applications. They are also relatively easy to manufacture and shape into various configurations.

Cons: The primary disadvantage is cost; copper is more expensive than alternatives like aluminum. Additionally, copper can be susceptible to corrosion if not properly insulated.

Impact on Application: Copper’s high conductivity makes it ideal for applications requiring rapid energy transfer, such as in high-performance electric vehicles. However, its susceptibility to corrosion necessitates protective measures in humid or saline environments, which may be a consideration for buyers in coastal regions.

Why Is Steel a Preferred Material for Motor Stators?

Steel is commonly used for the stator core in electric motors due to its magnetic properties and mechanical strength. Key properties include high permeability, which enhances magnetic flux, and durability under mechanical stress.

Pros: Steel is relatively inexpensive and widely available, making it a cost-effective choice for manufacturers. Its strength contributes to the overall robustness of the motor.

Cons: On the downside, steel is heavier than alternative materials, which can negatively impact the overall weight and efficiency of the vehicle. Additionally, it may require additional processing to reduce eddy current losses.

Impact on Application: Steel’s magnetic properties make it suitable for various electric motor designs, but its weight must be managed, especially in applications where weight savings are critical, such as in electric sports cars.

How Do Permanent Magnets Enhance Motor Efficiency?

Permanent magnets, typically made from rare-earth materials like neodymium, are used in synchronous motors to improve efficiency and performance. Key properties include high magnetic strength and stability at elevated temperatures.

Pros: The use of permanent magnets allows for a more compact motor design and higher torque at lower speeds, enhancing overall efficiency. This is particularly beneficial for electric vehicles that require quick acceleration.

Cons: The main disadvantage is the cost and availability of rare-earth materials, which can fluctuate based on market conditions. Additionally, high temperatures can demagnetize these materials, affecting performance.

Impact on Application: Permanent magnets are ideal for high-performance applications but require careful thermal management. International buyers should consider sourcing strategies to mitigate risks associated with rare-earth supply chains.

What Role Does Aluminum Play in Electric Motor Manufacturing?

Aluminum is increasingly used in electric motors, particularly for rotor construction, due to its lightweight and good conductivity. Key properties include a lower density compared to copper and steel, making it advantageous for weight-sensitive applications.

Pros: The lightweight nature of aluminum contributes to overall vehicle efficiency and performance. It is also less expensive than copper and has good corrosion resistance.

Cons: However, aluminum has lower electrical conductivity than copper, which may lead to higher resistive losses. Its mechanical properties can also be less robust than steel, requiring careful design considerations.

Impact on Application: Aluminum is suitable for applications where weight reduction is critical, such as in compact electric vehicles. Buyers should ensure compliance with local standards regarding material strength and conductivity.

Summary of Material Selection for Electric Car Motors

| Material | Typical Use Case for electric car motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Windings | High electrical conductivity | High cost, corrosion susceptibility | High |

| Steel | Stator cores | Cost-effective, durable | Heavier, potential eddy current losses | Med |

| Permanent Magnets | Synchronous motors | High efficiency, compact design | Cost volatility, thermal sensitivity | High |

| Aluminum | Rotor construction | Lightweight, corrosion-resistant | Lower conductivity, less robust | Med |

This material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions that align with performance requirements and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car motor

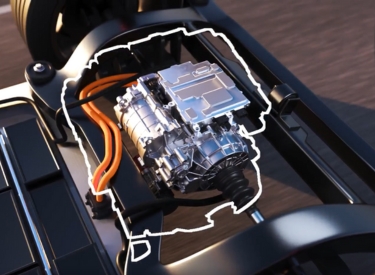

What Are the Main Stages in Electric Car Motor Manufacturing?

The manufacturing of electric car motors is a complex process that involves several key stages, each critical for ensuring the performance and reliability of the final product. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Car Motor Production?

Material preparation is the initial step where raw materials are sourced and processed to meet specific specifications. Common materials for electric motors include high-grade steel for the stator and rotor, copper for the windings, and various composites for insulation. Quality control begins at this stage, as suppliers must provide certifications for material properties, such as conductivity and tensile strength. B2B buyers should ensure that their suppliers adhere to relevant international material standards, such as ASTM or ISO 9001.

What Forming Techniques Are Used in Electric Motor Manufacturing?

Once materials are prepared, the forming stage takes place. This includes processes such as stamping, forging, and machining. The stator and rotor components are typically stamped from sheets of electrical steel, which enhances magnetic properties and reduces losses. Precision machining is essential to achieve tight tolerances, particularly for parts that interact closely, such as the rotor and stator assembly. B2B buyers should inquire about the forming techniques used by suppliers, as these directly affect the motor’s efficiency and longevity.

How Are Electric Car Motors Assembled?

Assembly is a critical phase where all components come together. This process often employs automated systems to ensure consistency and reduce human error. Key assembly techniques include winding the copper wire around the stator, inserting the rotor, and securing the components within the motor housing. Quality checkpoints during assembly, known as In-Process Quality Control (IPQC), are crucial to catch any defects early. Buyers should request details on assembly line practices, including worker training and automation levels, to gauge the reliability of the manufacturing process.

What Finishing Processes Enhance Electric Motor Quality?

Finishing processes improve the motor’s performance and durability. This includes surface treatments like coating and insulation, which protect against corrosion and electrical shorts. Balancing the rotor is also vital to minimize vibrations during operation. Final quality checks, known as Final Quality Control (FQC), involve testing the assembled motors for electrical performance, thermal characteristics, and noise levels. Buyers can benefit from understanding the specific finishing techniques and tests performed to ensure high-quality outcomes.

What Quality Assurance Standards Are Relevant to Electric Motor Manufacturing?

Quality assurance in electric motor manufacturing is governed by various international and industry-specific standards. ISO 9001 is a widely recognized standard focusing on quality management systems, ensuring that manufacturers consistently meet customer requirements. For electric motors, additional certifications may be required, such as CE marking for compliance with European safety standards or API certifications for specific applications.

How Are Quality Control Checkpoints Implemented?

Effective quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This stage verifies the quality of raw materials before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues in real time.

- Final Quality Control (FQC): This stage includes comprehensive testing of finished motors to ensure they meet performance specifications.

B2B buyers should ask suppliers for their quality control protocols and any relevant documentation that demonstrates compliance with established standards.

What Testing Methods Are Commonly Used in Electric Motor Quality Assurance?

Testing methods for electric motors include various techniques designed to assess performance, safety, and durability. Common tests involve:

- Electrical Testing: Checking for proper voltage, current, and resistance to ensure optimal performance.

- Thermal Testing: Evaluating how the motor handles heat under load conditions.

- Vibration Testing: Measuring vibrations to ensure the motor operates smoothly and quietly.

B2B buyers should consider suppliers that provide detailed test reports and certifications to verify the reliability of their electric motors.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are effective strategies:

- Conduct Audits: Regular audits of suppliers can help assess compliance with quality standards and manufacturing practices.

- Request Documentation: Ask for quality control reports, including IQC, IPQC, and FQC results, to gain insights into the supplier’s processes.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an objective assessment of a supplier’s capabilities and adherence to quality standards.

What Are the Nuances of Quality Certification for International B2B Buyers?

International buyers must navigate various nuances when it comes to quality certification. Different regions may have specific compliance requirements. For example, European buyers often prioritize CE certification, while buyers in Brazil may require INMETRO certification for electrical products. Understanding these regional standards can help B2B buyers make informed decisions when selecting suppliers.

In summary, the manufacturing processes and quality assurance for electric car motors are intricate and multi-faceted. By focusing on each stage of production and understanding the quality control measures in place, B2B buyers can ensure they partner with manufacturers capable of delivering high-quality, reliable electric motors tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car motor’

When sourcing electric car motors, it’s essential to follow a systematic approach to ensure you select the right components for your specific needs. This guide provides a step-by-step checklist designed for B2B buyers, particularly those operating in emerging markets across Africa, South America, the Middle East, and Europe. By adhering to these steps, you can streamline the procurement process and enhance the performance of your electric vehicle projects.

Step 1: Define Your Technical Specifications

Before you start contacting suppliers, clearly outline the technical requirements of the electric motor you need. Consider factors such as power output, efficiency ratings, voltage requirements, and torque characteristics. Defining these specifications helps narrow down your options and ensures compatibility with other components in your vehicle system.

Step 2: Research Motor Types and Technologies

Understanding the different types of electric motors—such as induction, permanent magnet, and brushless motors—is crucial. Each type has unique characteristics that affect performance and efficiency. For instance, permanent magnet motors are typically more efficient at low speeds but may have limitations at high speeds. Researching these technologies enables you to make informed decisions that align with your vehicle’s design and usage.

Step 3: Evaluate Potential Suppliers

Vet suppliers thoroughly to ensure they meet your quality and service expectations. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers who have a solid track record in manufacturing electric motors and can provide certifications to demonstrate compliance with international standards.

- Check for Certifications: Ensure suppliers have relevant quality certifications, such as ISO 9001, to guarantee their manufacturing processes meet industry standards.

- Assess Experience: Consider the supplier’s experience in supplying electric motors to your specific market or industry.

Step 4: Request Samples and Test Performance

Before making a bulk order, request samples of the electric motors you are considering. Testing these samples allows you to evaluate their performance under real-world conditions and ensures they meet your specifications. Pay attention to factors such as heat generation, efficiency at various speeds, and noise levels during operation.

Step 5: Consider Supply Chain Logistics

Evaluate the logistics of sourcing electric motors, including shipping times, costs, and potential import/export regulations that could affect delivery. Ensure that your chosen supplier can provide timely delivery and support for any after-sales service or technical assistance you may need.

- Assess Local Regulations: Be aware of any local regulations regarding the importation of electric vehicle components, as these can impact your overall project timeline and costs.

Step 6: Negotiate Terms and Pricing

Once you have identified potential suppliers and tested the motors, negotiate the terms of purchase, including pricing, payment terms, and warranty conditions. Establishing clear terms can help prevent misunderstandings and ensure a smooth transaction process.

Step 7: Plan for Future Needs

As the electric vehicle market evolves, consider suppliers who can accommodate future advancements in technology or changes in your project requirements. Building a long-term relationship with a reliable supplier can provide you with the flexibility to adapt to market changes and technological innovations.

By following this checklist, B2B buyers can make informed decisions when sourcing electric car motors, ultimately leading to successful project outcomes and enhanced vehicle performance.

Comprehensive Cost and Pricing Analysis for electric car motor Sourcing

What Are the Key Cost Components in Electric Car Motor Sourcing?

When sourcing electric car motors, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, such as copper for windings, rare-earth elements for permanent magnets, and aluminum for casings, can significantly impact pricing. Fluctuations in the market for these materials may lead to price variations.

-

Labor: Labor costs will vary depending on the region of manufacturing. Skilled labor, particularly for assembly and quality control, is essential for ensuring the reliability and performance of electric motors.

-

Manufacturing Overhead: This includes costs related to facility operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overheads, influencing the final price.

-

Tooling: Initial setup costs for molds and tooling can be substantial, particularly for custom motor designs. These costs are typically amortized over the production volume, making them less significant for larger orders.

-

Quality Control (QC): Implementing robust QC processes ensures that motors meet required specifications and certifications, which can add to production costs but ultimately protects against costly recalls or failures.

-

Logistics: Shipping costs can vary widely based on the size and weight of motors, as well as the distance to the destination. Understanding Incoterms can help buyers manage these costs effectively.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market conditions, competition, and the supplier’s positioning strategy.

How Do Price Influencers Affect Electric Car Motor Costs?

Several factors can influence the final pricing of electric car motors, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders typically attract lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to maximize cost-efficiency.

-

Specifications and Customization: Custom motors tailored to specific applications may incur additional costs due to unique design requirements. It’s essential to balance the need for customization with budget constraints.

-

Materials Quality and Certifications: Motors that meet higher quality standards or certifications (like ISO or UL) may command higher prices but often provide better performance and reliability, which can reduce long-term operational costs.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Well-established suppliers may offer premium pricing due to their track record, while newer suppliers may compete on cost.

-

Incoterms: Understanding shipping terms and responsibilities can help avoid unexpected costs. For example, choosing DDP (Delivered Duty Paid) may seem convenient but could lead to higher upfront costs.

What Are the Best Negotiation Tips for B2B Buyers?

To achieve favorable pricing in electric car motor sourcing, B2B buyers should consider the following strategies:

-

Conduct Market Research: Understanding current market trends and pricing benchmarks will empower buyers during negotiations.

-

Leverage Volume Discounts: Commit to larger orders if feasible, as this can significantly reduce per-unit costs.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the long-term operational costs, including maintenance, energy efficiency, and potential downtime.

-

Build Relationships: Establishing a long-term partnership with suppliers can lead to better pricing and favorable terms over time.

-

Be Prepared to Walk Away: If a deal does not meet your financial or operational requirements, be willing to explore other suppliers.

What Pricing Nuances Should International Buyers Be Aware Of?

International B2B buyers, especially from Africa, South America, the Middle East, and Europe, should keep several nuances in mind:

-

Currency Fluctuations: Exchange rates can affect the cost of imports. Consider negotiating contracts in stable currencies to mitigate risks.

-

Tariffs and Duties: Be aware of any import tariffs that may apply, as these can significantly increase the total cost.

-

Cultural Differences: Understanding local business practices and negotiation styles can enhance communication and lead to better outcomes.

Disclaimer on Indicative Prices

Prices for electric car motors can vary widely based on specifications, supplier, and market conditions. Therefore, it is essential for buyers to conduct thorough due diligence and obtain quotes tailored to their specific requirements before making purchasing decisions.

Alternatives Analysis: Comparing electric car motor With Other Solutions

Understanding Alternative Solutions to Electric Car Motors

As the automotive industry shifts towards electrification, understanding the various technologies available is crucial for B2B buyers. Electric car motors are a popular choice for electric vehicle (EV) propulsion, but several alternative solutions also exist. This analysis compares electric car motors to other viable technologies, helping buyers make informed decisions based on performance, cost, and specific use cases.

Comparison Table

| Comparison Aspect | Electric Car Motor | Hydrogen Fuel Cell | Internal Combustion Engine (ICE) |

|---|---|---|---|

| Performance | High torque and efficiency, good for various vehicle types | Moderate torque, best for larger vehicles | High torque, proven performance, but less efficient |

| Cost | Higher initial cost, but lower operating costs | High production and infrastructure costs | Lower initial cost, higher fuel and maintenance costs |

| Ease of Implementation | Requires specialized knowledge for integration | Complex infrastructure for refueling | Widely understood technology, easier to implement |

| Maintenance | Low maintenance due to fewer moving parts | Moderate, requires specific components | Higher maintenance due to more moving parts |

| Best Use Case | Urban and suburban electric vehicles | Long-range transport and heavy-duty vehicles | Traditional vehicles, high-performance applications |

Detailed Breakdown of Alternatives

Hydrogen Fuel Cells

Hydrogen fuel cells convert hydrogen into electricity to power electric motors. They offer a moderate performance suitable for larger vehicles, making them ideal for long-range transport, especially in regions where infrastructure supports hydrogen refueling. However, the initial costs and the need for extensive refueling infrastructure can be significant barriers. While they produce zero emissions, the production of hydrogen can still have environmental impacts, depending on the source.

Internal Combustion Engine (ICE)

ICE technology has been the backbone of the automotive industry for over a century. It delivers high torque and is well-understood by manufacturers and mechanics alike. The initial investment for ICE vehicles is typically lower compared to electric car motors and fuel cells. However, they are less efficient and have higher operating costs due to fuel prices and maintenance needs. ICE vehicles are best suited for traditional applications and high-performance scenarios but face increasing regulatory pressures regarding emissions.

Conclusion: How to Choose the Right Solution for Your Needs

For B2B buyers in the automotive sector, the decision between electric car motors, hydrogen fuel cells, and internal combustion engines should be informed by specific operational needs, cost considerations, and performance requirements. Electric car motors are ideal for urban applications where efficiency and low maintenance are prioritized. Hydrogen fuel cells present a compelling option for industries focused on long-range transport, while internal combustion engines may still serve traditional markets where infrastructure and familiarity with technology prevail. By assessing these factors, buyers can align their choice with both current capabilities and future sustainability goals.

Essential Technical Properties and Trade Terminology for electric car motor

What Are the Key Technical Properties of Electric Car Motors?

When selecting electric car motors, B2B buyers must understand several critical technical properties that significantly impact performance, efficiency, and compatibility with existing systems. Here are essential specifications to consider:

1. Motor Type

Electric motors can be categorized into three main types: Induction, Permanent Magnet, and Synchronous Motors. Each type has unique characteristics affecting efficiency, torque, and cooling requirements. For example, permanent magnet motors are generally more efficient at low speeds but can suffer from overheating at high speeds.

2. Power Rating (kW)

The power rating indicates the motor’s output capability, measured in kilowatts (kW). This specification is crucial for determining the motor’s performance in different applications, such as passenger vehicles versus heavy-duty trucks. A higher power rating typically translates to better acceleration and load-carrying capacity, making it a vital consideration for buyers.

3. Torque (Nm)

Torque, measured in Newton-meters (Nm), reflects the motor’s ability to generate rotational force. It is essential for understanding how well a vehicle can start and maintain speed, especially when carrying heavy loads. B2B buyers should prioritize motors with sufficient torque ratings for their specific application needs, as inadequate torque can affect overall vehicle performance.

4. Voltage Rating (V)

The voltage rating indicates the electrical input required for the motor to function optimally. Common voltage ratings for electric car motors range from 72V to 800V. Selecting the correct voltage is critical for ensuring compatibility with the vehicle’s battery system, as mismatched voltage can lead to inefficiencies or equipment failure.

5. Efficiency Rating (%)

Efficiency ratings measure how effectively a motor converts electrical energy into mechanical energy. Higher efficiency ratings are crucial for maximizing the vehicle’s range and reducing energy costs. B2B buyers should look for motors with high efficiency ratings, particularly for commercial applications where operational costs are a significant concern.

6. Cooling Method

The cooling method—air-cooled or liquid-cooled—affects the motor’s ability to maintain performance under load. Liquid cooling is generally more effective for high-performance applications, while air cooling may suffice for smaller or less demanding vehicles. Understanding the cooling requirements helps buyers ensure that the motor will perform reliably under expected conditions.

What Are Common Trade Terms in the Electric Motor Industry?

Familiarity with industry jargon is vital for B2B buyers to navigate the electric motor market effectively. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source components for electric vehicle production or conversion.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is important for budgeting and inventory management, as it affects purchasing decisions, especially for startups or smaller enterprises.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price bids from suppliers for specific products or services. Submitting an RFQ can help B2B buyers compare costs and evaluate potential suppliers, making it an essential step in procurement processes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers regarding shipping costs, risks, and delivery. Familiarity with Incoterms is critical for B2B buyers involved in international transactions, as they determine liability and ownership during transit.

5. Regenerative Braking

This term refers to the process in electric vehicles where the electric motor acts as a generator during braking, converting kinetic energy back into stored energy in the battery. Understanding regenerative braking is vital for buyers focused on efficiency and range optimization.

6. BMS (Battery Management System)

A BMS is crucial for monitoring and managing battery performance, ensuring safety, and optimizing lifespan. Buyers should consider the compatibility of the motor with various BMS technologies to enhance overall vehicle efficiency.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing electric car motors, ultimately leading to more successful procurement strategies and product development.

Navigating Market Dynamics and Sourcing Trends in the electric car motor Sector

What Are the Current Market Dynamics and Key Trends in the Electric Car Motor Sector?

The electric car motor sector is undergoing significant transformation driven by the global shift toward electrification in transportation. Key factors propelling this change include government regulations aimed at reducing carbon emissions, increasing consumer demand for sustainable transportation options, and advancements in battery technology. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Brazil) are increasingly prioritizing electric vehicle (EV) components, particularly electric motors, to meet the growing market demand.

Emerging trends highlight a focus on efficiency and performance. As electric motors become more sophisticated, manufacturers are innovating with various designs, such as permanent magnet synchronous motors (PMSMs) and induction motors, to enhance torque and efficiency. Additionally, the integration of smart technologies, including IoT-enabled motors, is facilitating predictive maintenance and optimizing performance metrics. B2B buyers should keep an eye on these technological advancements to ensure they source cutting-edge products that align with market demands.

Another notable trend is the localization of supply chains. Many companies are shifting towards regional sourcing to mitigate risks associated with global supply disruptions, particularly evident during the COVID-19 pandemic. This shift allows international buyers to engage more effectively with local suppliers, fostering partnerships that can enhance reliability and responsiveness to market changes.

How Important Is Sustainability and Ethical Sourcing in the Electric Car Motor Sector?

Sustainability and ethical sourcing are increasingly critical in the electric car motor sector, reflecting broader trends in global manufacturing and consumer preferences. The environmental impact of sourcing materials, particularly rare earth elements used in permanent magnets, has raised concerns among stakeholders. Buyers should prioritize suppliers that demonstrate a commitment to sustainable practices, such as responsible mining operations and minimized carbon footprints.

Ethical supply chains are essential for maintaining brand reputation and meeting regulatory requirements. Companies that adhere to sustainability standards often benefit from ‘green’ certifications, which can enhance their marketability and appeal to environmentally conscious consumers. B2B buyers should seek out manufacturers who incorporate recyclable materials and environmentally friendly processes in their motor production.

Furthermore, the importance of transparency in the supply chain cannot be overstated. Buyers should engage with suppliers who provide detailed information about their sourcing practices and the environmental impact of their operations. Collaborating with suppliers committed to sustainable practices not only fosters long-term partnerships but also contributes to the overall health of the planet, aligning with the values of modern consumers and regulatory bodies.

What Is the Brief Evolution and History of Electric Car Motors Relevant to B2B Buyers?

The evolution of electric car motors dates back to the 19th century, when pioneers like Thomas Davenport created the first small-scale electric motor. However, it wasn’t until the late 20th century that significant advancements occurred, leading to the modern electric motors used in today’s vehicles. The introduction of lithium-ion battery technology in the early 2000s marked a turning point, enabling electric motors to deliver higher efficiency and performance.

In recent years, the growth of the EV market has accelerated rapidly, driven by government incentives and technological advancements. The shift from internal combustion engines to electric drivetrains necessitated a reevaluation of motor design, efficiency, and production methods. This historical context is vital for B2B buyers, as understanding the trajectory of electric motor technology can inform sourcing decisions and highlight potential opportunities for collaboration with manufacturers who are at the forefront of innovation.

By staying abreast of market dynamics, sustainability practices, and the historical evolution of electric motors, international B2B buyers can make informed decisions that align with both current trends and future developments in the electric vehicle sector.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car motor

-

How do I choose the right electric car motor for my application?

Selecting the appropriate electric car motor requires considering several factors, including the vehicle’s intended use, required power output, and compatibility with existing systems. Assess the vehicle’s weight, desired range, and performance specifications. Additionally, consider the motor types—induction, permanent magnet, or synchronous—and their efficiency ratings at varying speeds. Collaborating with suppliers who provide detailed technical specifications and have experience in your specific market can ensure a better fit for your needs. -

What are the key specifications to look for in an electric motor?

When sourcing an electric motor, focus on specifications such as power rating (measured in kilowatts), torque output, efficiency percentage, and operational voltage. Additionally, evaluate the motor’s thermal management capabilities, size, and weight, as these will impact installation and performance. Checking for certifications and compliance with international standards can also enhance reliability and safety in different markets. -

What is the typical lead time for electric car motor orders?

Lead times for electric car motors can vary significantly based on factors like supplier location, motor customization, and order volume. Generally, standard motors may take 4-6 weeks for delivery, while custom designs can extend this timeframe to several months. It’s essential to communicate with suppliers early in the procurement process to establish realistic timelines and ensure timely delivery to meet project deadlines. -

What are the minimum order quantities (MOQ) for electric car motors?

Minimum order quantities for electric car motors depend on the manufacturer and the type of motor requested. Some suppliers may have an MOQ of one unit for standard products, while custom motors typically require larger orders to justify production costs. Engage with multiple suppliers to find those who can accommodate your needs, especially if you are a smaller business or a startup. -

How can I ensure the quality of the electric motors I am purchasing?

To ensure quality, select suppliers with a proven track record and relevant certifications such as ISO 9001. Request samples and conduct performance testing to evaluate the motor’s efficiency and reliability. Additionally, inquire about the supplier’s quality assurance processes, including testing protocols and warranty offerings, to safeguard your investment and minimize the risk of defects. -

What payment terms should I expect when purchasing electric car motors?

Payment terms can vary widely among suppliers, but typical arrangements include upfront payments, partial payments upon order confirmation, or payment upon delivery. Ensure to negotiate terms that align with your cash flow needs. In international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks associated with cross-border trade. -

What factors should I consider regarding logistics and shipping for electric car motors?

When planning logistics, consider the motor’s size, weight, and packaging requirements to ensure safe transport. Evaluate potential shipping methods, such as air freight for faster delivery or sea freight for cost savings. Additionally, factor in customs regulations and import duties in your destination country, as these can significantly affect total costs and delivery times. -

How do I vet suppliers for electric car motors in international markets?

Vetting suppliers involves researching their reputation, production capabilities, and compliance with international standards. Utilize platforms like Alibaba or ThomasNet to find reviews and ratings. Conduct site visits if possible, or request third-party audits to assess manufacturing practices. Networking within industry associations can also provide insights into reliable suppliers, ensuring you make informed purchasing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Electric Car Motor Manufacturers & Suppliers List

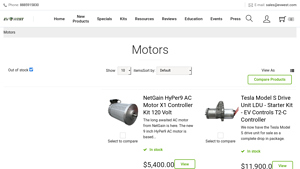

1. EV West – NetGain HyPer9 AC Motor X1 Controller Kit

Domain: evwest.com

Registered: 2010 (15 years)

Introduction: {“products”:[{“name”:”NetGain HyPer9 AC Motor X1 Controller Kit 120 Volt”,”price”:”$5,400.00″,”status”:”In stock”},{“name”:”Tesla Model S Drive Unit LDU – Starter Kit – EV Controls T2-C Controller”,”price”:”$11,900.00″,”status”:”In stock”},{“name”:”Curtis 1238-7601 HPEVS AC-50 Brushless AC Motor – 96 Volt – MOTOR ONLY”,”price”:”$2,400.00″,”status”:”In stock”},{“name”:”NetGain HyPer9 HV AC Motor X1…

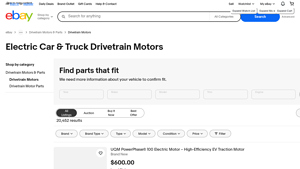

2. Mercedes-Benz – Genuine OE Drive Unit 190-270-31-00

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Electric Car & Truck Drivetrain Motors for sale on eBay. Key products include: 1. Genuine Mercedes-Benz OE Drive Unit 190-270-31-00 priced at $961.70. 2. Danfoss UQM SPM250-130-2 EV Vehicle Motor with KDS E560 Gearbox, Heavy Duty 24V 4.5 HP Electric Motor. 3. Hybrid Starter Generator Motor LISLE 81220 priced at $16.74. 4. Auto-Loc AUTLAD08 Heavy Duty 12 V 8″ Adjustable Linear Actuator Electric Mot…

3. Electric Motor Engineering – Three-Phase Induction Motors

Domain: electricmotorengineering.com

Registered: 2017 (8 years)

Introduction: A three-phase, four-pole induction motor is made of two main parts: a stator and a rotor. The stator consists of three parts: a stator core, conducting wire, and frame. The stator core is made of insulated steel rings laminated together, with slots for the conducting wire to form stator coils. The motor operates by receiving electrical energy from the car’s battery, which energizes the coils in th…

4. Renault Group – Electric Car Motors

Domain: renaultgroup.com

Registered: 2005 (20 years)

Introduction: Electric car motors operate by converting electrical energy from the battery into mechanical energy to drive the vehicle. The main types of motors used are Alternating Current (AC) motors, specifically asynchronous (induction) and synchronous motors. Asynchronous motors are known for high power output, while synchronous motors provide high torque at low speeds and are compact. Electric motors requ…

5. Mazda – 2025 CX-70, 2026 CX-90, 2025 CX-30, 2025 CX-50

Domain: mazdausa.com

Registered: 1995 (30 years)

Introduction: 2025 Mazda CX-70: Starting At $40,445, Combined 25 MPG, Seating 5 Passengers; 2026 Mazda CX-90: Starting At $38,800, Combined 25 MPG, Seating up to 8 Passengers; 2025 Mazda CX-30: Starting At $25,195, Combined 29 MPG, Seating 5 Passengers; 2025 Mazda CX-50: Starting At $30,500, Combined 28 MPG, Seating 5 Passengers; 2025 Mazda CX-5: Starting At $29,050, Combined 28 MPG, Seating 5 Passengers; 2025 …

Strategic Sourcing Conclusion and Outlook for electric car motor

What Are the Key Takeaways for B2B Buyers in the Electric Car Motor Market?

In summary, strategic sourcing of electric car motors is critical for businesses aiming to capitalize on the rapidly growing electric vehicle market. The choice of motor—whether induction, permanent magnet, or current-excited—directly influences the efficiency, performance, and overall cost-effectiveness of electric vehicles. B2B buyers should prioritize suppliers that offer robust support, including integration with battery systems and comprehensive after-sales service. By leveraging data and insights on motor technology advancements, companies can enhance their competitive edge.

How Can B2B Buyers Prepare for Future Trends in Electric Car Motors?

The future of electric car motors is poised for innovation, particularly with the emergence of multi-speed transmissions and advancements in motor efficiency. International buyers, especially from Africa, South America, the Middle East, and Europe, should stay informed about these trends to make educated procurement decisions. Engaging with manufacturers that are at the forefront of technological advancements will be crucial in ensuring sustainability and performance in electric vehicle offerings.

What Actions Should B2B Buyers Take Now?

As the industry evolves, now is the time for B2B buyers to reassess their sourcing strategies. Consider forming partnerships with reliable manufacturers that prioritize quality and innovation. By aligning procurement practices with emerging technologies, businesses can not only meet current demands but also position themselves for future growth in the electric vehicle market. Take action today to secure your place in this dynamic landscape.