Introduction: Navigating the Global Market for electric car lithium mini

As the global demand for sustainable transportation surges, the market for electric car lithium batteries has become a focal point for B2B buyers seeking innovative solutions. However, sourcing electric car lithium mini models presents unique challenges, from navigating fluctuating supply chains to ensuring compliance with international regulations. This guide serves as a comprehensive resource, delving into the various types of electric car lithium mini options available, their applications in diverse sectors, and the intricacies of supplier vetting.

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe—including key markets like Saudi Arabia and Vietnam—will find valuable insights into cost considerations, financing options, and potential savings associated with electric vehicles. The guide empowers businesses to make informed purchasing decisions by providing a robust framework for evaluating suppliers and understanding the evolving landscape of electric vehicle technology.

With a focus on actionable strategies and market trends, this guide not only addresses the current challenges but also equips B2B buyers with the knowledge necessary to leverage the opportunities within the electric car lithium mini market. By the end of this resource, you will be well-positioned to navigate the complexities of sourcing, ensuring your organization stays ahead in the competitive landscape of sustainable transportation solutions.

Understanding electric car lithium mini Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| MINI Electric Hardtop | Compact design, fully electric, sporty performance | Urban fleet services, car-sharing programs | Pros: Lower operational costs, tax incentives. Cons: Limited cargo space. |

| MINI Countryman SE | Plug-in hybrid, spacious interior, versatile for families | Corporate fleets, rental services | Pros: Flexibility of electric and gasoline options. Cons: Higher initial cost. |

| MINI Electric Convertible | Open-top design, electric drivetrain, unique driving experience | Luxury rental services, event transportation | Pros: Attractive for tourists, unique selling point. Cons: Limited range compared to sedans. |

| MINI Cooper SE | Standard electric model, known for agility and handling | Delivery services, urban commuting | Pros: Excellent maneuverability, low maintenance. Cons: Smaller battery capacity. |

| MINI Countryman PHEV | Combines electric and gasoline, larger battery and range | Long-distance corporate travel, family use | Pros: Extended range, suitable for diverse needs. Cons: Complexity in maintenance. |

What are the characteristics of the MINI Electric Hardtop?

The MINI Electric Hardtop is characterized by its compact design and fully electric drivetrain, providing a sporty driving experience akin to its gasoline counterparts. Ideal for urban fleet services and car-sharing programs, this model offers significant operational cost savings due to lower energy consumption and reduced maintenance needs. B2B buyers should consider the vehicle’s limited cargo space, which may not suit all operational requirements.

How does the MINI Countryman SE cater to business needs?

The MINI Countryman SE is a plug-in hybrid that combines electric and gasoline power, making it versatile for various business applications. Its spacious interior is well-suited for corporate fleets or rental services that prioritize passenger comfort. While it offers the flexibility of switching between power sources, B2B buyers should be aware of the higher initial investment compared to fully electric models.

What makes the MINI Electric Convertible a unique option for businesses?

The MINI Electric Convertible stands out with its open-top design, providing a unique driving experience that appeals to luxury rental services and event transportation. Its electric drivetrain ensures eco-friendliness while attracting tourists seeking memorable experiences. However, potential buyers should consider its limited range, which may not be ideal for longer trips.

What advantages does the MINI Cooper SE offer for urban commuting?

The MINI Cooper SE is a standard electric model known for its agility and handling, making it an excellent choice for delivery services and urban commuting. Its compact size allows for easy navigation in crowded city environments, and its low maintenance costs are attractive for businesses. However, B2B buyers should note that its smaller battery capacity may limit longer trips without charging.

Why is the MINI Countryman PHEV suitable for diverse business operations?

The MINI Countryman PHEV combines electric and gasoline power, making it suitable for long-distance corporate travel and family use. Its larger battery offers extended range capabilities, appealing to businesses that require flexibility in their transportation needs. However, the complexity of maintenance with hybrid systems may require additional consideration for B2B buyers focusing on operational efficiency.

Key Industrial Applications of electric car lithium mini

| Industry/Sector | Specific Application of electric car lithium mini | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Integration into city car-sharing services | Reduces operational costs and enhances sustainability | Local regulations, charging infrastructure availability |

| Corporate Fleets | Employee commuting solutions | Lower fuel and maintenance costs, improved employee satisfaction | Battery performance, warranty terms, charging options |

| Tourism and Hospitality | Eco-friendly transport for guests | Attracts eco-conscious travelers, enhances brand image | Vehicle availability, service support, local charging stations |

| Logistics and Delivery | Last-mile delivery solutions | Increased efficiency and reduced carbon footprint | Range capabilities, load capacity, regional support |

| Urban Mobility Solutions | Development of electric mini-taxis | Competitive pricing and reduced environmental impact | Fleet management software, driver training programs |

How Can Electric Car Lithium Mini Transform Public Transportation Services?

In the public transportation sector, electric car lithium minis can be integrated into city car-sharing services. This application helps cities reduce their carbon footprint while providing residents and visitors with convenient transportation options. By utilizing electric vehicles, cities can lower operational costs associated with fuel and maintenance, making it a financially viable option. For international buyers, understanding local regulations regarding electric vehicle usage and the availability of charging infrastructure is crucial for successful implementation.

What Are the Benefits of Using Electric Cars in Corporate Fleets?

For corporate fleets, electric car lithium minis serve as a sustainable commuting solution for employees. Companies can benefit from significantly lower fuel and maintenance costs, which enhances overall operational efficiency. Additionally, offering electric vehicles can improve employee satisfaction by promoting a green corporate image. Buyers in this sector should consider battery performance, warranty terms, and various charging options to ensure the vehicles meet their specific needs.

How Can Electric Car Lithium Mini Enhance Guest Experiences in Tourism and Hospitality?

In the tourism and hospitality industry, electric car lithium minis can provide eco-friendly transportation options for guests. This application not only attracts eco-conscious travelers but also enhances the brand image of hotels and resorts committed to sustainability. To successfully implement this solution, businesses should focus on vehicle availability, service support, and the proximity of local charging stations to ensure seamless guest experiences.

What Role Do Electric Cars Play in Logistics and Delivery Services?

Electric car lithium minis can significantly improve last-mile delivery solutions in logistics and delivery services. By adopting these vehicles, companies can increase operational efficiency while reducing their carbon footprint. This is particularly beneficial in urban areas where emissions regulations are becoming more stringent. Buyers should pay attention to the range capabilities of the vehicles, load capacity, and the availability of regional support to optimize their logistics operations.

How Can Electric Mini-Taxis Contribute to Urban Mobility Solutions?

Electric mini-taxis represent a forward-thinking approach to urban mobility solutions. By deploying electric car lithium minis as taxis, operators can offer competitive pricing while simultaneously reducing environmental impact. This application is particularly relevant in densely populated areas where air quality is a concern. Key considerations for buyers include fleet management software and driver training programs to ensure the effective operation of electric vehicles in urban settings.

3 Common User Pain Points for ‘electric car lithium mini’ & Their Solutions

Scenario 1: Challenges in Charging Infrastructure for Electric Car Lithium Mini

The Problem: B2B buyers in regions like Africa and South America often face significant challenges regarding the availability and reliability of charging infrastructure for electric vehicles, including the electric car lithium mini. Many potential users are hesitant to invest in electric vehicles due to fears of being stranded with an uncharged battery, especially in urban areas where charging stations are sparse or non-existent. This concern is compounded by the varying levels of development and investment in EV infrastructure across different countries.

The Solution: To address this challenge, B2B buyers should consider partnering with local governments and private companies to invest in the expansion of charging networks. By engaging in collaborative efforts, businesses can help advocate for the installation of more charging stations in strategic locations, such as commercial centers, highways, and residential areas. Additionally, buyers should explore the feasibility of installing Level 2 chargers at their facilities to support their own fleet of electric cars. Investing in mobile charging solutions or establishing partnerships with existing charging networks can also alleviate the fear of running out of battery. It’s crucial to conduct a comprehensive assessment of current charging infrastructure in the target market and work towards filling those gaps through partnerships and investments.

Scenario 2: Misunderstanding Cost Savings of Electric Vehicles

The Problem: Many B2B buyers are initially attracted to electric vehicles like the electric car lithium mini due to the anticipated cost savings compared to traditional gasoline vehicles. However, there is often a lack of understanding regarding the total cost of ownership, including maintenance, insurance, and potential tax incentives. This can lead to miscalculations and hesitance in making the switch, especially when buyers are focused solely on the upfront costs without considering long-term savings.

The Solution: To overcome this issue, businesses should conduct a thorough analysis of the total cost of ownership for electric vehicles versus conventional vehicles. This analysis should include not only the purchase price but also factors such as fuel savings, reduced maintenance costs (e.g., no oil changes), insurance premiums, and potential government incentives. B2B buyers can use online calculators and tools to simulate these costs based on their specific use cases and local energy prices. Additionally, collaborating with financial advisors or EV specialists can help in accurately projecting savings over time. Providing education and resources to stakeholders within the organization can also foster a better understanding of the economic benefits of transitioning to electric vehicles.

Scenario 3: Concerns about Vehicle Performance and Range Anxiety

The Problem: In markets where the electric car lithium mini is being introduced, B2B buyers often express concerns about performance and range. There is a pervasive belief that electric vehicles cannot match the performance of traditional vehicles, particularly in terms of acceleration, range, and load capacity. This skepticism can hinder the adoption of electric cars for fleet use, especially in industries that rely on quick transport and long-distance travel.

The Solution: To alleviate these concerns, businesses should focus on educating their teams about the advancements in electric vehicle technology. Highlighting the performance specifications of the electric car lithium mini, such as rapid acceleration times and efficient energy use, can help dispel myths. Moreover, buyers should consider conducting pilot programs that allow potential users to experience the vehicle’s performance first-hand. This could include test-driving vehicles under various conditions to demonstrate their capabilities. Additionally, offering comprehensive training on optimizing range through driving techniques, such as regenerative braking and preconditioning, can empower drivers to maximize performance. By showcasing the practical benefits and real-world capabilities of electric vehicles, businesses can foster a more positive perception and encourage adoption within their operations.

Strategic Material Selection Guide for electric car lithium mini

What Are the Key Materials Used in Electric Car Lithium MINIs?

When selecting materials for electric vehicles, particularly for the lithium battery systems in MINI electric cars, several factors come into play. Here, we analyze four common materials: lithium-ion, aluminum, steel, and plastics, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Lithium-Ion Perform in Electric Car Applications?

Key Properties: Lithium-ion batteries are known for their high energy density, lightweight nature, and ability to operate efficiently across a wide temperature range. They typically have a voltage rating of 3.6 to 3.7 volts per cell, allowing for compact designs.

Pros & Cons: The primary advantage of lithium-ion is its superior energy density, which allows for longer driving ranges. However, they can be expensive to manufacture and require complex battery management systems to ensure safety and longevity. Additionally, they are sensitive to temperature extremes, which can affect performance.

Impact on Application: Lithium-ion batteries are essential for providing the energy needed for electric propulsion. Their compatibility with various charging infrastructures is crucial for usability in diverse markets.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local climate conditions, as extreme temperatures can impact battery performance. Compliance with international standards such as IEC 62133 for safety is also critical.

What Role Does Aluminum Play in Electric Vehicle Design?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity. It can withstand high temperatures, making it suitable for various components in electric vehicles.

Pros & Cons: The lightweight nature of aluminum helps improve vehicle efficiency and range. However, it can be more expensive than traditional steel and may require specialized welding techniques, increasing manufacturing complexity.

Impact on Application: Aluminum is often used in the chassis and body panels of electric vehicles, contributing to overall vehicle weight reduction and enhancing performance.

Considerations for International Buyers: Buyers in Europe may prefer aluminum for its recyclability and compliance with environmental regulations. Understanding local supply chains for aluminum sourcing can also influence cost and availability.

Why Is Steel Still Relevant in Electric Car Manufacturing?

Key Properties: Steel is known for its strength, durability, and cost-effectiveness. It has excellent structural integrity and can resist high pressures and temperatures.

Pros & Cons: While steel is less expensive than aluminum, it is heavier, which can negatively impact the vehicle’s range. However, advancements in high-strength steel have improved its performance in electric vehicle applications.

Impact on Application: Steel is commonly used in the structural components of electric vehicles, providing safety and durability.

Considerations for International Buyers: Buyers from the Middle East and Africa should be aware of local steel standards and certifications, such as ASTM A992 for structural steel, to ensure compliance and quality.

How Do Plastics Contribute to Electric Vehicle Performance?

Key Properties: Plastics are lightweight, corrosion-resistant, and can be molded into complex shapes. They have varying temperature ratings depending on the type, with some engineered plastics able to withstand high temperatures.

Pros & Cons: The versatility of plastics allows for innovative designs and weight reduction. However, they may not offer the same durability as metals and can degrade under UV exposure unless treated.

Impact on Application: Plastics are used in various interior and exterior components, including dashboards, battery casings, and insulation materials.

Considerations for International Buyers: Buyers should consider the environmental impact of plastic use, especially in regions with stringent regulations on plastic waste. Compliance with standards such as ISO 14001 for environmental management can enhance marketability.

Summary Table of Material Selection for Electric Car Lithium MINIs

| Material | Typical Use Case for electric car lithium mini | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium-Ion | Battery systems | High energy density, lightweight | Expensive, temperature-sensitive | High |

| Aluminum | Chassis and body panels | Lightweight, corrosion-resistant | Higher cost, requires specialized manufacturing | Med |

| Steel | Structural components | Strong, durable, cost-effective | Heavier, can impact range | Low |

| Plastics | Interior/exterior components | Versatile, lightweight, moldable | Less durable, UV degradation risk | Med |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in electric car lithium MINIs, enabling informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car lithium mini

What Are the Main Stages of Manufacturing Electric Car Lithium MINIs?

The manufacturing process for electric car lithium MINIs involves several critical stages, each designed to ensure the highest quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials essential for electric vehicles (EVs). Lithium-ion batteries, which are a significant component of electric cars, require specific types of lithium, cobalt, and nickel. Manufacturers often engage in rigorous supplier assessments to ensure that these raw materials meet international quality standards and ethical sourcing requirements.

-

Forming: During the forming stage, the prepared materials undergo various processes to create battery cells and modules. Techniques such as stamping, injection molding, and die-casting are commonly used to shape components. In the case of lithium-ion batteries, the electrodes are coated with active materials and assembled into cells, ensuring optimal energy density and performance.

-

Assembly: The assembly stage is where the individual components come together to form the complete vehicle. This includes integrating the battery pack, electric drive systems, and the vehicle chassis. Automated assembly lines often play a pivotal role in enhancing precision and efficiency. Robotics are widely employed to minimize human error, particularly in tasks that require high levels of accuracy, such as soldering and wiring.

-

Finishing: The final stage involves quality checks and the application of finishing touches, such as painting and installing interior components. This stage also includes system diagnostics to ensure all electronic systems function correctly. The focus on aesthetics and performance is crucial, as the electric vehicle market is competitive and consumers expect both innovation and visual appeal.

How Is Quality Assurance Ensured in Electric Car Lithium MINIs?

Quality assurance (QA) is paramount in the manufacturing of electric car lithium MINIs, as it directly impacts safety, performance, and customer satisfaction. Key quality assurance practices include adherence to international standards, multiple quality checkpoints, and rigorous testing methods.

-

International Standards: Manufacturers typically comply with ISO 9001, an internationally recognized standard for quality management systems. This standard emphasizes continuous improvement and customer satisfaction. Additionally, compliance with industry-specific standards such as CE marking for electrical safety and API standards for performance can be critical for market acceptance, especially in regions like Europe and the Middle East.

-

Quality Control Checkpoints: The quality control process is structured into several checkpoints:

– Incoming Quality Control (IQC): This checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections are conducted to monitor production quality, identify defects, and implement corrective actions in real-time.

– Final Quality Control (FQC): Before the vehicles are shipped, a comprehensive inspection is performed to ensure that all specifications are met. This includes functional testing of electrical systems, battery performance assessments, and visual inspections for cosmetic defects. -

Common Testing Methods: Various testing methods are employed to verify product quality. These include:

– Electrical Testing: To measure battery capacity, voltage, and overall performance.

– Thermal Testing: Ensures that battery systems can operate effectively under different temperature conditions.

– Durability Testing: Involves simulating real-world driving conditions to assess vehicle performance over time.

What Steps Can B2B Buyers Take to Verify Supplier Quality Control?

B2B buyers must adopt a proactive approach to verify the quality control practices of their suppliers. Several steps can be taken to ensure that the manufacturing processes align with their quality expectations.

-

Conduct Supplier Audits: Regular audits are an effective way to assess a supplier’s adherence to quality standards. Buyers should evaluate the supplier’s manufacturing processes, quality management systems, and compliance with international standards during these audits.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their quality assurance practices, inspection results, and any corrective actions taken in response to defects. Reviewing these documents can provide insights into the supplier’s commitment to quality.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can add an additional layer of assurance. These independent entities can conduct thorough evaluations of manufacturing processes and product quality, offering unbiased reports.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control in the electric car lithium market is essential.

-

Regional Compliance Requirements: Different regions have unique regulatory requirements. For example, electric vehicles sold in Europe must comply with the European Union’s stringent safety and environmental standards. Buyers should ensure that their suppliers are familiar with and compliant with these regulations.

-

Cultural Considerations: Cultural differences can influence quality perceptions and practices. Buyers should be aware of these differences and establish clear communication channels to address quality expectations effectively.

-

Logistical Challenges: The global nature of supply chains can introduce logistical challenges that impact quality. Buyers should assess the supplier’s ability to manage these challenges, including transportation, storage conditions, and handling of materials.

-

Sustainability and Ethical Sourcing: Increasingly, B2B buyers are prioritizing sustainability in their purchasing decisions. Suppliers who demonstrate commitment to ethical sourcing of materials and environmentally friendly manufacturing processes can enhance their appeal in international markets.

Conclusion

The manufacturing processes and quality assurance practices for electric car lithium MINIs are critical for ensuring high-performance vehicles that meet the demands of modern consumers. By understanding these processes, B2B buyers can make informed decisions, mitigate risks, and foster partnerships with manufacturers that prioritize quality and innovation. As the electric vehicle market continues to evolve, maintaining a focus on quality assurance will be essential for success in this competitive landscape.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car lithium mini’

Introduction

This guide serves as a practical checklist for B2B buyers interested in procuring electric car lithium MINI vehicles. With the growing demand for electric vehicles (EVs) globally, particularly in emerging markets, it is essential to navigate the sourcing process efficiently. This checklist will help you make informed decisions, ensuring that you select the right models, suppliers, and terms that align with your business goals.

1. Identify Your Business Needs

Clearly define the purpose and requirements for your electric car procurement. Consider factors such as the intended use (e.g., fleet, rentals, or corporate transportation), expected range, and charging capabilities. Understanding your specific needs will guide you in selecting the most suitable MINI electric models.

2. Research Market Trends and Regulations

Stay updated on market trends and regional regulations affecting electric vehicle adoption. Different countries have varying incentives, tax benefits, and infrastructure developments for EVs. Researching these aspects will help you anticipate changes in demand and compliance requirements.

- Look for:

- Government incentives for electric vehicle purchases.

- Infrastructure developments, such as charging stations.

3. Define Your Technical Specifications

Establish clear technical specifications for the electric vehicles you intend to procure. Key specifications include battery capacity, charging time, and range per charge. These details are crucial for ensuring that the vehicles meet your operational requirements.

- Key Metrics to Consider:

- Battery life and warranty (e.g., 8 years/100,000 miles).

- Charging options (e.g., Level 2, DC fast charging).

4. Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your quality and service expectations. Request company profiles, product catalogs, and references from other businesses that have procured from them. It’s essential to assess not just their products but also their customer service and support capabilities.

- What to Assess:

- Supplier certifications and compliance with international standards.

- Previous customer reviews and case studies.

5. Analyze Total Cost of Ownership (TCO)

Calculate the total cost of ownership for the electric MINI vehicles you are considering. This should include initial purchase costs, maintenance, energy consumption, and potential resale value. Understanding TCO will help you make a more financially sound decision.

- Factors to Include:

- Estimated fuel savings over time.

- Maintenance requirements and costs compared to traditional vehicles.

6. Negotiate Terms and Conditions

Once you’ve shortlisted suppliers, initiate negotiations on pricing, delivery timelines, and warranty terms. Clear communication about your expectations and requirements can lead to better terms and foster a stronger supplier relationship.

- Key Negotiation Points:

- Volume discounts for bulk purchases.

- Warranty coverage and service agreements.

7. Plan for Charging Infrastructure

Consider the charging infrastructure needed for your fleet of electric MINI vehicles. Evaluate options for home charging setups or partnerships with local charging networks. Proper planning will ensure that your operations run smoothly and that vehicles are always ready for use.

- Infrastructure Considerations:

- Availability of charging stations in your operational areas.

- Installation of home charging units for overnight charging.

By following this checklist, B2B buyers can navigate the complexities of sourcing electric car lithium MINI vehicles more effectively, ensuring a successful procurement process that aligns with their business objectives.

Comprehensive Cost and Pricing Analysis for electric car lithium mini Sourcing

What Are the Key Cost Components for Sourcing Electric Car Lithium MINI?

When sourcing electric car lithium MINIs, understanding the cost structure is essential. The primary cost components include:

-

Materials: The lithium-ion batteries are the most significant material cost, accounting for a substantial portion of the overall expense. Other materials include the vehicle chassis, electric motor, and electronic components. The fluctuation in raw material prices, particularly lithium, cobalt, and nickel, can impact overall costs.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor for assembly and quality assurance is crucial, particularly in regions with high labor costs.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, making it vital to consider production scale.

-

Tooling: Initial tooling costs for specialized equipment can be significant, especially for custom designs. Investing in high-quality tooling can reduce long-term costs by increasing efficiency and reducing defect rates.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that the vehicles meet safety and performance standards. This adds to costs but is necessary to maintain brand reputation and compliance.

-

Logistics: Transportation and warehousing costs can vary greatly depending on the distance from the manufacturing facility to the buyer’s location. Effective logistics management can minimize these costs.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and risks. Understanding the market dynamics can help in negotiating better margins.

How Do Price Influencers Affect the Sourcing of Electric Car Lithium MINIs?

Several factors can influence the pricing of electric car lithium MINIs:

-

Volume/MOQ: Higher order volumes can lead to lower per-unit costs due to economies of scale. Suppliers often provide discounts for larger orders, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Customized vehicles can incur additional costs due to unique design requirements or specifications. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: The choice of materials directly impacts pricing. Premium materials may offer better performance but at a higher cost. Evaluating the balance between cost and quality is crucial.

-

Quality and Certifications: Compliance with international quality standards can affect pricing. Suppliers with higher certifications may charge more but offer better reliability and safety.

-

Supplier Factors: The supplier’s reputation, location, and financial stability can influence pricing. Established suppliers may charge a premium, but they often provide better service and reliability.

-

Incoterms: The terms of delivery (Incoterms) significantly affect the overall cost. Understanding who bears the transportation costs and risks is crucial for accurate budgeting.

What Are the Best Buyer Tips for Negotiating Costs?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

-

Negotiate Terms: Always negotiate pricing and payment terms. Long-term contracts can provide leverage for better rates.

-

Focus on Total Cost of Ownership (TCO): Consider not just the purchase price but also the total cost of ownership, including maintenance, charging infrastructure, and potential tax incentives.

-

Understand Pricing Nuances: Be aware of regional pricing differences and potential hidden costs, such as tariffs or import duties that may apply when sourcing internationally.

-

Build Relationships with Suppliers: Establishing strong relationships with suppliers can lead to better pricing and service. Regular communication can also aid in resolving any issues that arise.

Conclusion

While sourcing electric car lithium MINIs, a comprehensive understanding of cost components, price influencers, and effective negotiation strategies is essential. By considering these factors, international buyers can make informed decisions that optimize their sourcing processes and enhance their overall profitability. Always remember that indicative prices can vary based on market conditions, so continuous market monitoring is recommended.

Alternatives Analysis: Comparing electric car lithium mini With Other Solutions

When considering the transition to electric mobility, businesses often evaluate multiple alternatives to find the solution that best fits their operational needs and sustainability goals. This analysis compares the ‘Electric Car Lithium Mini’ with other viable technologies, providing a comprehensive view for B2B buyers in various markets.

| Comparison Aspect | Electric Car Lithium Mini | Alternative 1: Plug-in Hybrid Electric Vehicle (PHEV) | Alternative 2: Traditional Gasoline Vehicle |

|---|---|---|---|

| Performance | Quick acceleration, good range (up to 212 miles) | Moderate range (typically 20-50 miles on electric) + gasoline backup | High range, quick refueling, but less efficient |

| Cost | Higher upfront cost, lower running costs due to fuel savings and tax incentives | Moderate upfront cost; savings on fuel but higher than pure EV | Lower upfront cost, higher ongoing fuel and maintenance costs |

| Ease of Implementation | Requires charging infrastructure; home charging is convenient | Flexible charging options; can utilize existing gas stations | No new infrastructure needed; familiar refueling process |

| Maintenance | Lower maintenance costs (no oil changes, fewer moving parts) | Moderate maintenance (combination of electric and combustion maintenance) | Higher maintenance costs due to engine components |

| Best Use Case | Ideal for urban environments and daily commutes | Suitable for mixed driving patterns; longer trips with less range anxiety | Best for long-distance travel in areas with limited EV infrastructure |

What Are the Advantages and Disadvantages of Plug-in Hybrid Electric Vehicles (PHEVs)?

Plug-in Hybrid Electric Vehicles combine a traditional gasoline engine with an electric motor. This dual system allows for flexibility in driving, especially in regions with limited charging infrastructure. The primary advantage of PHEVs is their extended range and the ability to switch to gasoline when the electric charge is depleted, making them a practical choice for businesses that require versatility. However, they come with higher maintenance costs than fully electric vehicles and may not achieve the same level of fuel savings as electric-only models.

How Do Traditional Gasoline Vehicles Compare to Electric Car Lithium Mini?

Traditional gasoline vehicles are often less expensive upfront and easier to refuel, making them a familiar choice for many businesses. They perform well for long-distance travel due to their extensive refueling infrastructure and quick refueling times. However, they incur higher ongoing costs for fuel and maintenance. Additionally, they do not offer the same environmental benefits or potential tax incentives associated with electric vehicles, which may be a crucial consideration for businesses focused on sustainability.

Conclusion: Which Solution is Right for Your Business Needs?

When evaluating the ‘Electric Car Lithium Mini’ against alternatives like PHEVs and traditional gasoline vehicles, B2B buyers must consider their specific operational requirements, including performance needs, budget constraints, and environmental goals. If your business prioritizes sustainability and is situated in an urban environment with charging infrastructure, the Electric Car Lithium Mini may be the best choice. Conversely, if flexibility and range are critical, a PHEV could serve well, while traditional gasoline vehicles may be suitable for businesses in remote areas with limited electric options. Ultimately, understanding the nuances of each solution will empower buyers to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for electric car lithium mini

What Are the Key Technical Properties of Electric Car Lithium Batteries?

-

Battery Capacity (kWh)

Battery capacity, measured in kilowatt-hours (kWh), indicates how much energy the battery can store. For electric vehicles (EVs) like the MINI Electric, a larger capacity translates to a longer driving range. This is crucial for B2B buyers as it directly impacts the vehicle’s usability and customer satisfaction, especially in regions where charging infrastructure may be less developed. -

Power Output (kW)

Power output reflects the maximum power the battery can deliver at any given moment, measured in kilowatts (kW). A higher power output enables quicker acceleration and enhances the overall driving experience. For businesses, understanding power output is essential when assessing the performance capabilities of electric vehicles to meet operational needs. -

Charging Time (hours)

Charging time indicates how long it takes to recharge the battery fully. Different charging levels (Level 1, Level 2, and DC Fast Charging) offer various charging speeds, affecting downtime for fleet operations. Knowing the charging times allows B2B buyers to plan and optimize usage, ensuring vehicles are available when needed. -

Cycle Life (number of cycles)

Cycle life refers to the number of complete charge and discharge cycles a battery can undergo before its capacity significantly degrades. A longer cycle life reduces replacement costs and ensures a more sustainable investment. Businesses must evaluate this property to forecast long-term operational expenses related to battery maintenance and replacement. -

Temperature Range (°C)

The operational temperature range of a lithium battery indicates the environmental conditions under which the battery can function effectively. Extreme temperatures can affect performance and longevity. Understanding this range is vital for B2B buyers operating in diverse climates, ensuring that vehicles perform reliably across different conditions.

What Are Common Trade Terms Related to Electric Car Lithium Batteries?

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of electric vehicles, OEMs supply batteries, motors, and other essential components. Understanding OEM relationships can help B2B buyers ensure they are sourcing high-quality, reliable parts for their electric vehicle offerings. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For electric car components, MOQs can significantly impact purchasing decisions, especially for smaller businesses. Knowing the MOQ helps buyers manage inventory and cash flow effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. B2B buyers often use RFQs to gauge market prices and supplier capabilities for electric vehicle components, enabling informed decision-making during procurement. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding Incoterms is essential for B2B transactions involving electric vehicles, as they clarify costs, risks, and logistics responsibilities, ensuring smoother international trade. -

Lifecycle Assessment (LCA)

LCA is a method for assessing the environmental impacts associated with all the stages of a product’s life, from raw material extraction to disposal. For electric vehicles, LCA can help businesses understand the sustainability of their products, an increasingly important factor for consumers and regulators alike.

By grasping these technical properties and industry terms, B2B buyers can make more informed purchasing decisions, ensuring that they invest in electric vehicles that meet their operational needs and align with market trends.

Navigating Market Dynamics and Sourcing Trends in the electric car lithium mini Sector

What Are the Current Market Dynamics and Key Trends in the Electric Car Lithium Mini Sector?

The electric vehicle (EV) market is witnessing transformative growth, driven by increasing environmental concerns, government regulations, and advancements in battery technology. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The global push for carbon neutrality and the transition to sustainable transportation has intensified demand for electric vehicles, including electric mini cars.

Key trends include the rise of compact electric models that cater to urban mobility needs, where space is limited, and fuel prices are high. Additionally, the development of fast-charging infrastructure is becoming a priority, enabling quicker turnaround times for fleet operators and individual users. Emerging technologies such as vehicle-to-grid (V2G) systems are gaining traction, allowing electric vehicles to not only consume energy but also supply it back to the grid, further enhancing their economic viability.

Sourcing trends are shifting towards localizing supply chains to mitigate risks associated with global logistics disruptions. This trend is particularly relevant for lithium battery sourcing, where securing partnerships with local suppliers can enhance sustainability and reduce transportation costs. B2B buyers should focus on suppliers who offer innovative financing solutions and comprehensive support services, such as maintenance programs and charging infrastructure, to maximize the benefits of electric vehicle adoption.

How Can Sustainability and Ethical Sourcing Enhance B2B Opportunities in the Electric Car Lithium Mini Sector?

Sustainability is no longer just a buzzword; it has become a fundamental aspect of business strategy for B2B buyers in the electric vehicle sector. The environmental impact of lithium mining and battery production has raised concerns, prompting buyers to prioritize ethical sourcing practices. Engaging with suppliers who adhere to strict environmental standards and utilize sustainable practices can significantly enhance brand reputation and customer loyalty.

Incorporating ‘green’ certifications into the supply chain is essential for B2B buyers. Certifications such as ISO 14001 for environmental management and the Responsible Minerals Initiative (RMI) for ethical sourcing can bolster credibility and ensure compliance with international regulations. Additionally, sourcing materials from suppliers who emphasize recycled components or innovative battery technologies can reduce overall environmental footprints.

Investing in ethical supply chains not only mitigates environmental risks but also aligns with consumer expectations for corporate responsibility. By prioritizing sustainability, B2B buyers can tap into new market opportunities, enhance their competitive edge, and drive long-term profitability while contributing to global sustainability goals.

What Is the Brief Evolution of Electric Cars and Lithium Mini Vehicles in the B2B Context?

The evolution of electric vehicles, particularly in the mini segment, has been marked by technological advancements and changing consumer preferences. Initially, electric cars faced skepticism due to limited range and performance. However, significant improvements in battery technology have led to enhanced driving ranges and reduced charging times, making electric mini cars a viable option for urban drivers.

The introduction of compact electric models has allowed manufacturers to cater to a growing market of environmentally conscious consumers and businesses looking for cost-effective transportation solutions. B2B buyers are increasingly recognizing the value of electric mini vehicles as part of their fleets, driven by lower operating costs and minimal maintenance needs compared to traditional gasoline vehicles.

Today, as the global focus shifts towards sustainable transportation, electric mini cars are positioned as key players in the automotive landscape. This evolution presents a unique opportunity for B2B buyers to invest in innovative technologies and sustainable practices that align with their business goals and environmental commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car lithium mini

-

How do I determine the right electric car lithium mini for my business needs?

To find the best electric car lithium mini for your business, consider factors like driving range, charging options, maintenance costs, and suitability for your operations. Assess your specific use case—whether for deliveries, employee transport, or client services. Analyze the vehicle’s features and warranties to ensure they align with your operational requirements. It’s also wise to evaluate potential suppliers for their reputation and service offerings, ensuring they can meet your business’s unique needs. -

What are the key benefits of sourcing electric car lithium minis from international suppliers?

Sourcing electric car lithium minis from international suppliers can provide access to innovative technologies, competitive pricing, and diverse product offerings. International suppliers often benefit from economies of scale, allowing them to offer more favorable terms. Additionally, you may find suppliers with expertise in local markets, facilitating smoother logistics and compliance with regional regulations. Engaging with international partners can also enhance your supply chain resilience and increase access to emerging EV technologies. -

What are typical minimum order quantities (MOQs) for electric car lithium minis?

Minimum order quantities (MOQs) for electric car lithium minis can vary significantly by supplier and region. Generally, larger manufacturers may offer flexible MOQs starting from a few units, while smaller suppliers may require higher minimums to justify production costs. It’s crucial to negotiate MOQs based on your business needs and to discuss potential bulk purchase discounts. Understanding the supplier’s production capabilities can also help you determine the best approach to fulfilling your order requirements. -

How can I vet suppliers when sourcing electric car lithium minis?

To effectively vet suppliers for electric car lithium minis, start by researching their industry reputation, certifications, and customer reviews. Request references from previous clients and assess their experience in international trade. Evaluate their production capabilities, quality assurance processes, and adherence to safety standards. Additionally, consider visiting their facilities if feasible or conducting virtual audits to ensure they meet your quality and operational expectations. -

What payment terms should I expect when purchasing electric car lithium minis?

Payment terms can vary widely based on the supplier and the specifics of your agreement. Common terms include upfront payment, partial payments upon order confirmation, or payment on delivery. It’s advisable to negotiate terms that align with your cash flow while ensuring supplier commitment. Consider using secure payment methods that offer protection for both parties, such as letters of credit or escrow services, to mitigate financial risks in international transactions. -

What logistics considerations should I keep in mind when importing electric car lithium minis?

When importing electric car lithium minis, consider shipping methods, customs regulations, and tariffs applicable to your region. Engage with logistics partners experienced in handling automotive imports to ensure compliance and timely delivery. Plan for potential delays related to customs clearance and be aware of any specific import documentation required for electric vehicles. Additionally, consider warehousing options if you need to store the vehicles before distribution. -

How can I ensure quality assurance (QA) for electric car lithium minis?

To ensure quality assurance for electric car lithium minis, establish clear quality standards and expectations with your supplier before placing an order. Request detailed product specifications and quality certifications. Implement a robust inspection process upon delivery, including thorough vehicle inspections and test drives to verify performance. Consider engaging third-party quality control services to conduct inspections at the supplier’s facility or during shipping, ensuring compliance with your quality standards. -

What customization options are available for electric car lithium minis?

Customization options for electric car lithium minis may include modifications to design, features, and technology integrations based on your business needs. Common customization requests involve branding, interior configurations, and specific technology packages such as advanced navigation or fleet management systems. Discuss your requirements with potential suppliers early in the sourcing process to understand what customization options are feasible and the associated costs, ensuring that the final product aligns with your operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Electric Car Lithium Mini Manufacturers & Suppliers List

1. Reddit – Lithium Recycling and EV Safety

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Lithium Recycling and EV Safety, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Mini E – Battery Pack Details

Domain: minievforum.com

Registered: 2016 (9 years)

Introduction: This company, Mini E – Battery Pack Details, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. AEVA – Portable EV Battery Pack

Domain: forums.aeva.asn.au

Introduction: Portable battery pack for charging electric cars in remote locations. Key features include: 1. Standard plug for compatibility with various electric vehicles. 2. Requires a VAN or pick-up for transport and storage. 3. Example battery capacity: 16.7 kWh (Smart Electric Drive). 4. Estimated weight and size depend on the charge delivered. 5. Charging efficiency considerations (e.g., 80% efficiency). …

4. MINI – All-Electric Models

Domain: newcountrymini.com

Registered: 2002 (23 years)

Introduction: Available all-electric MINI models include the MINI Electric Hardtop 2 Door and the MINI Countryman SE ALL4. The estimated range of the 2024 Electric Hardtop 2 Door is 114 miles, while the estimated range of the 2025 MINI Countryman SE ALL4 is 212 miles. All-electric MINIs provide instant torque and linear acceleration, maintaining the fun-to-drive performance with a lower center of gravity for gr…

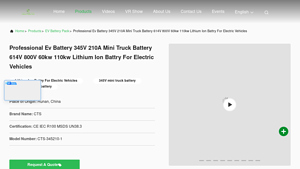

5. CTS Battery – Professional EV Battery

Domain: ctsbattery.com

Registered: 2018 (7 years)

Introduction: {“product_name”: “Professional EV Battery”,”voltage”: “345V”,”current”: “210A”,”application”: “Mini Truck”,”voltage_range”: “614V-800V”,”power”: “60kW-110kW”,”battery_type”: “Lithium-ion”}

Strategic Sourcing Conclusion and Outlook for electric car lithium mini

As the electric vehicle (EV) market continues to expand, strategic sourcing of electric car lithium components, particularly for models like the MINI Electric, becomes crucial for international B2B buyers. By focusing on reliable suppliers and establishing strong partnerships, businesses can ensure access to high-quality lithium-ion batteries, which are essential for optimizing performance and sustainability. The cost savings associated with electric vehicles, coupled with decreasing maintenance requirements, present a compelling case for investment in this sector.

Moreover, as governments worldwide implement incentives to promote EV adoption, now is an opportune moment for buyers in Africa, South America, the Middle East, and Europe to capitalize on these trends. By leveraging strategic sourcing, companies can not only enhance their operational efficiencies but also align with global sustainability goals.

Looking ahead, the demand for electric vehicles will likely surge, driven by consumer preferences and regulatory frameworks. International B2B buyers are encouraged to proactively engage with suppliers and invest in the lithium supply chain to secure their positions in this evolving market. Embrace the electric future now—make informed sourcing decisions that will drive your business forward.