Introduction: Navigating the Global Market for 3 wheel electric cargo bike

In today’s rapidly evolving logistics landscape, the challenge of sourcing reliable and efficient transportation solutions is paramount. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, the three-wheel electric cargo bike presents a unique opportunity to enhance urban delivery systems while reducing carbon footprints. This guide delves into the nuances of the global market for three-wheel electric cargo bikes, equipping decision-makers with the knowledge needed to navigate this burgeoning sector effectively.

Throughout this comprehensive guide, we will explore various types of electric cargo bikes, their diverse applications in different industries, and the key factors to consider when vetting suppliers. Buyers will gain insights into cost structures, maintenance requirements, and the latest technological advancements that enhance performance and safety. By addressing these critical aspects, the guide empowers businesses to make informed purchasing decisions that align with their operational needs and sustainability goals.

As demand for innovative and environmentally friendly transport solutions continues to grow, understanding the intricacies of the three-wheel electric cargo bike market will be essential for companies looking to stay ahead of the competition. With this guide, B2B buyers can confidently navigate the complexities of sourcing and integrating these vehicles into their logistics strategies, driving efficiency and sustainability in their operations.

Understanding 3 wheel electric cargo bike Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Family Cargo E-Bikes | Spacious seating for multiple passengers, safety features | Family transport, childcare services | Pros: Safe for children, high capacity. Cons: Higher price point. |

| Utility Cargo Bikes | Designed for heavy loads, robust construction | Delivery services, logistics | Pros: High payload capacity, durable. Cons: Heavier, may require more maintenance. |

| Delivery Cargo E-Bikes | Streamlined design for efficient urban deliveries | E-commerce, food delivery | Pros: Maneuverable, optimized for short trips. Cons: Limited passenger capacity. |

| Adventure Cargo Bikes | Off-road capabilities, rugged design | Outdoor tours, recreational transport | Pros: Versatile for various terrains. Cons: Less focus on passenger comfort. |

| Customizable Cargo E-Bikes | Modular design for tailored configurations | Specialized delivery, niche markets | Pros: Flexible for specific needs. Cons: Potentially longer lead times for customization. |

What Are the Key Characteristics of Family Cargo E-Bikes?

Family cargo e-bikes are designed with safety and comfort as priorities, featuring spacious seating for multiple children and robust safety features such as seatbelts and padded interiors. They often include weather protection like rain covers, making them suitable for family outings and errands. B2B buyers in childcare services or family-oriented businesses will find these bikes ideal for transporting children safely while promoting eco-friendly transportation.

How Do Utility Cargo Bikes Differ from Other Variants?

Utility cargo bikes emphasize heavy-duty construction and high payload capacities, making them suitable for transporting goods in urban environments. They typically feature reinforced frames and larger cargo areas. Businesses in logistics and delivery will benefit from their durability and reliability, though buyers should consider the potential for increased maintenance due to the heavy use.

Why Are Delivery Cargo E-Bikes Gaining Popularity?

Delivery cargo e-bikes are optimized for urban logistics, designed to navigate through traffic efficiently while carrying goods. Their compact size and lightweight design make them perfect for last-mile deliveries in congested areas. E-commerce and food delivery businesses will find these bikes valuable for improving operational efficiency, although they may sacrifice passenger capacity for cargo space.

What Makes Adventure Cargo Bikes a Unique Choice?

Adventure cargo bikes are built for versatility, often featuring rugged frames and off-road capabilities. They are ideal for businesses offering outdoor tours or recreational activities, allowing for the transport of gear and passengers across various terrains. While they provide unique opportunities for adventure-based services, buyers should weigh the trade-off between comfort and durability.

How Do Customizable Cargo E-Bikes Serve Niche Markets?

Customizable cargo e-bikes offer modular designs that allow businesses to tailor configurations according to specific needs, such as specialized delivery or unique cargo requirements. This flexibility can be a significant advantage for niche markets looking for tailored solutions. However, buyers should be aware of potentially longer lead times and increased costs associated with customization.

Key Industrial Applications of 3 wheel electric cargo bike

| Industry/Sector | Specific Application of 3 wheel electric cargo bike | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Retail | Last-mile delivery for groceries and small packages | Efficient transport reduces delivery times and operational costs | Consider battery range, cargo capacity, and local terrain adaptability |

| Tourism & Recreation | Family-friendly tours and activities | Enhances customer experience and promotes eco-friendly tourism | Look for safety features, comfort, and storage for equipment |

| Healthcare & Community Services | Transporting medical supplies and personnel | Timely delivery improves service efficiency in urban settings | Ensure reliability, speed, and compliance with health regulations |

| Food & Beverage | Mobile food vending and catering services | Expands business reach and reduces overhead costs | Assess weight capacity, ease of maneuverability, and weather protection |

| Education & Childcare | School runs and transporting children for activities | Provides a safe and fun mode of transport, fostering community ties | Evaluate seating capacity, safety features, and local assembly options |

How is the 3 Wheel Electric Cargo Bike Used in E-commerce & Retail?

In the e-commerce and retail sectors, 3 wheel electric cargo bikes serve as an effective solution for last-mile delivery. They enable businesses to transport groceries and small packages efficiently, particularly in urban environments where traffic congestion is common. By utilizing these bikes, companies can reduce delivery times and operational costs, making them a valuable asset. Buyers should consider the battery range and cargo capacity, ensuring the bike can handle the required load while navigating local terrain.

What Role Does the 3 Wheel Electric Cargo Bike Play in Tourism & Recreation?

In the tourism and recreation industries, 3 wheel electric cargo bikes enhance customer experiences by offering family-friendly tours and activities. These bikes allow families to explore local attractions together, transforming mundane transport into enjoyable adventures. The eco-friendly aspect appeals to environmentally conscious tourists, promoting sustainable travel. Key considerations for buyers include safety features, comfort, and adequate storage for equipment like picnic gear or safety kits.

How Can Healthcare & Community Services Benefit from 3 Wheel Electric Cargo Bikes?

Healthcare and community services leverage 3 wheel electric cargo bikes for transporting medical supplies and personnel efficiently. Their ability to navigate congested urban areas ensures timely deliveries, which is crucial for healthcare providers. This reliability improves service efficiency, particularly in densely populated regions. Buyers must assess the bikes’ reliability, speed, and compliance with health regulations to ensure they meet the specific needs of their operations.

In What Ways Do Food & Beverage Businesses Utilize 3 Wheel Electric Cargo Bikes?

Food and beverage businesses use 3 wheel electric cargo bikes for mobile food vending and catering services. These bikes allow vendors to reach a broader customer base while minimizing overhead costs associated with traditional food trucks. The convenience of transporting food and beverages directly to customers enhances service delivery. When sourcing these bikes, businesses should evaluate weight capacity, ease of maneuverability, and weather protection to ensure optimal performance.

How Are 3 Wheel Electric Cargo Bikes Applied in Education & Childcare?

In the education and childcare sectors, 3 wheel electric cargo bikes provide a safe and enjoyable mode of transport for school runs and activities. They enable caregivers to transport children securely, fostering a sense of community among families. The bikes’ design can accommodate multiple children, making them an efficient alternative to traditional vehicles. Buyers should evaluate seating capacity, safety features, and local assembly options to ensure compliance with local regulations and standards.

3 Common User Pain Points for ‘3 wheel electric cargo bike’ & Their Solutions

Scenario 1: Navigating Limited Cargo Capacity Challenges

The Problem:

For businesses in logistics and delivery services, cargo capacity is a crucial factor when selecting a transportation solution. Many B2B buyers find that traditional cargo bikes, including three-wheel electric models, struggle to meet the demands of larger loads. This limitation can hinder operational efficiency, forcing companies to make multiple trips or invest in additional vehicles, leading to increased costs and time delays.

The Solution:

When sourcing a three-wheel electric cargo bike, prioritize models with higher cargo capacities, such as those that can carry over 450 lbs. Look for features like adjustable storage compartments or customizable cargo areas that can adapt to various business needs. Additionally, consider bikes that offer modular designs, allowing for the attachment of extra storage units or racks. This flexibility enables businesses to maximize their transport capabilities while minimizing the need for multiple vehicles. Conduct a thorough analysis of your typical load requirements and choose a model that exceeds those needs to ensure you can accommodate growth without frequent upgrades.

Scenario 2: Ensuring Safety and Stability During Transportation

The Problem:

Safety is a significant concern for businesses that utilize three-wheel electric cargo bikes, especially when transporting precious cargo such as children or fragile goods. B2B buyers often worry about the stability of the bike during transit, particularly in urban environments with uneven surfaces or heavy traffic. If the bike is not designed with proper safety features, it can lead to accidents or damage, resulting in financial loss and reputational damage.

The Solution:

Select electric cargo bikes that are built with stability-enhancing features, such as a low center of gravity, wider wheelbase, and robust braking systems. Look for models that come equipped with safety certifications, ensuring they meet industry standards for performance and safety. For instance, bikes with hydraulic disc brakes provide better stopping power, essential for navigating busy streets. Additionally, inquire about integrated safety features like seatbelts and protective enclosures, which can secure passengers or cargo during transport. Conduct regular maintenance checks to ensure all safety systems function correctly, and train your staff on safe riding practices to enhance operational safety.

Scenario 3: Overcoming Range Anxiety in Urban Deliveries

The Problem:

Range anxiety is a common issue faced by B2B buyers considering three-wheel electric cargo bikes, particularly for businesses involved in urban deliveries. Concerns about battery life and the bike’s ability to cover necessary distances without frequent recharges can complicate logistics planning. This anxiety can deter businesses from fully transitioning to electric solutions, impacting their overall sustainability goals.

The Solution:

To alleviate range anxiety, select electric cargo bikes that offer long-lasting battery options, ideally with a range of 30 miles or more on a single charge. Evaluate the battery specifications, such as watt-hours and amp-hours, to gauge their efficiency under load. Furthermore, consider models that allow for quick battery swaps or have the option to connect to charging stations at key delivery points. Establish a charging strategy that includes designated charging times during off-peak hours to ensure that bikes are ready for daily operations. By integrating smart route planning tools that optimize delivery paths based on battery life, businesses can enhance their operational efficiency while minimizing range concerns.

Strategic Material Selection Guide for 3 wheel electric cargo bike

What Are the Key Materials Used in 3 Wheel Electric Cargo Bikes?

When selecting materials for 3 wheel electric cargo bikes, it is crucial to consider their properties, advantages, and limitations. The choice of materials directly impacts performance, safety, manufacturing complexity, and compliance with international standards. Below is an analysis of four common materials used in the construction of these bikes.

How Does Aluminum Impact the Performance of Electric Cargo Bikes?

Aluminum is a popular choice for the frame of electric cargo bikes due to its lightweight nature and excellent corrosion resistance. With a density of about 2.7 g/cm³, aluminum provides a good strength-to-weight ratio, making it easier to maneuver while carrying heavy loads. Additionally, aluminum can withstand a wide range of temperatures, making it suitable for various climates.

Pros: Aluminum frames are durable and resistant to rust, which is particularly beneficial in humid or rainy environments. They are also relatively easy to manufacture, allowing for complex designs that enhance aesthetics and functionality.

Cons: However, aluminum can be more expensive than steel, which may be a consideration for budget-conscious buyers. It can also be less impact-resistant than steel, making it susceptible to denting under heavy stress.

International Considerations: Buyers in regions like Africa and South America should ensure that the aluminum used meets international standards such as ASTM B221 for extruded aluminum. Compliance with local regulations regarding material safety and recycling is also essential.

What Role Does Steel Play in the Structure of Cargo Bikes?

Steel is another commonly used material in the construction of 3 wheel electric cargo bikes, particularly for frames and structural components. Known for its high tensile strength, steel provides excellent durability and stability, making it suitable for heavy loads.

Pros: Steel’s robustness allows it to handle significant stress without deforming, which is ideal for cargo bikes that frequently transport heavy items. Additionally, steel is generally less expensive than aluminum, making it a cost-effective option.

Cons: However, steel is heavier than aluminum, which can affect the bike’s maneuverability. It is also prone to rust if not properly treated or coated, which can be a significant drawback in humid or coastal environments.

International Considerations: Buyers should look for steel that complies with standards like ASTM A500 for structural steel tubing. Understanding local corrosion resistance requirements is also vital for buyers in regions with high humidity or salt exposure.

How Does Composite Material Enhance Cargo Bike Design?

Composite materials, such as carbon fiber or fiberglass, are increasingly used in high-end electric cargo bikes. These materials offer a unique combination of lightweight properties and high strength, making them suitable for performance-oriented designs.

Pros: Composites can be molded into complex shapes, allowing for innovative designs that improve aerodynamics and aesthetics. They are also resistant to corrosion and can withstand a variety of environmental conditions.

Cons: The primary drawback is the high cost of composite materials, which can significantly increase the overall price of the bike. Additionally, manufacturing processes for composites can be more complex and require specialized equipment.

International Considerations: B2B buyers should ensure that composite materials meet relevant safety standards, such as ASTM D3039 for composite materials testing. Understanding the local market’s acceptance of composites is also crucial, especially in regions where traditional materials are preferred.

What Advantages Does Plastic Offer for Cargo Bike Components?

Plastics, particularly high-density polyethylene (HDPE) and polypropylene, are commonly used for non-structural components like fenders, cargo boxes, and seat cushions. These materials are lightweight, durable, and resistant to moisture.

Pros: Plastics are generally more affordable than metals and can be produced in various colors and designs, enhancing the bike’s aesthetic appeal. Their resistance to corrosion makes them suitable for outdoor use.

Cons: However, plastics may not provide the same level of strength as metals, which can limit their application in load-bearing components. They can also degrade under prolonged exposure to UV light unless treated.

International Considerations: Buyers should ensure that plastics used comply with standards such as ASTM D638 for tensile properties. Awareness of local recycling regulations for plastics is also essential, particularly in regions focusing on sustainability.

Summary Table of Material Selection for 3 Wheel Electric Cargo Bikes

| Material | Typical Use Case for 3 Wheel Electric Cargo Bike | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame and structural components | Lightweight and corrosion-resistant | Higher cost and less impact resistance | Medium |

| Steel | Frame and structural components | High strength and durability | Heavier and prone to rust | Low |

| Composite | High-end frames and components | Lightweight and strong | High cost and complex manufacturing | High |

| Plastic | Non-structural components (fenders, cargo boxes) | Affordable and moisture-resistant | Limited strength and UV degradation | Low |

This analysis provides a comprehensive overview of material options for 3 wheel electric cargo bikes, helping international B2B buyers make informed decisions based on performance, cost, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for 3 wheel electric cargo bike

What Are the Main Stages in the Manufacturing Process of 3 Wheel Electric Cargo Bikes?

The manufacturing process for three-wheel electric cargo bikes is intricate, involving several key stages that ensure the final product meets the high standards expected by B2B buyers.

Material Preparation: What Materials Are Used?

The first step in manufacturing begins with material preparation. Typically, high-strength steel or aluminum alloys are selected for the frame due to their durability and lightweight properties. Additionally, various plastics and composites are used for components like the cargo box, seat cushions, and fenders. Suppliers must ensure that all materials comply with international standards to guarantee safety and quality.

Forming: How Are Components Shaped?

Once materials are prepared, the forming stage takes place. This involves techniques such as stamping, bending, and welding to create the bike’s frame and body. Advanced methods like hydroforming may be employed to achieve complex shapes with minimal weight. During this phase, precision is crucial; thus, manufacturers often use CNC (Computer Numerical Control) machines to ensure accuracy and repeatability.

Assembly: What Does the Assembly Process Involve?

The assembly stage is where components come together to form the complete bike. This includes installing the electric motor, battery, braking systems, and wiring. Quality control during this phase is vital to ensure that all parts fit correctly and function as intended. Automated assembly lines may be used to increase efficiency, but skilled labor is also essential for tasks that require a human touch, such as final adjustments and quality checks.

Finishing: How Is the Final Product Prepared?

In the finishing stage, the bikes undergo painting, coating, and quality inspections. This not only enhances the aesthetic appeal but also adds protection against environmental factors. Manufacturers often apply powder coating for durability, which is especially important for cargo bikes used in varying climates. Final inspections are conducted to ensure that the bike meets all design specifications and safety standards.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet the required standards before they reach the market.

What Are the Relevant International Standards for Quality Control?

International standards such as ISO 9001 provide a framework for quality management systems. Compliance with these standards ensures that manufacturers consistently produce high-quality products and improve their processes. Additionally, certifications such as CE (Conformité Européenne) and UL (Underwriters Laboratories) are critical for electric components, ensuring they meet safety and performance standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Materials and components are inspected upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Quality checks are conducted at various stages of production to catch defects early.

-

Final Quality Control (FQC): The completed bikes are thoroughly inspected before shipping to ensure they meet all functional and aesthetic criteria.

What Common Testing Methods Are Used for Electric Cargo Bikes?

Testing methods for electric cargo bikes include stress testing, performance testing, and safety testing. Stress tests help evaluate the structural integrity of the bike under various loads, while performance tests assess the efficiency of the electric motor and battery life. Safety tests, such as brake performance and stability checks, are essential to ensure the bike can handle real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial.

What Steps Can Buyers Take to Ensure Supplier Compliance with Quality Standards?

-

Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes, quality control systems, and compliance with relevant standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including testing results and compliance certifications, to assess the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes and product quality.

What Are the Quality Control Nuances for International Buyers?

International buyers should be aware of regional regulations that may affect product compliance. For example, electric cargo bikes sold in the European market must meet specific CE marking requirements, while products entering the U.S. may require UL certification. Understanding these nuances can help buyers ensure that they are sourcing compliant products, thus minimizing potential legal or logistical challenges.

Conclusion: How Can Quality Assurance Impact Your Purchasing Decisions?

The manufacturing processes and quality assurance measures for three-wheel electric cargo bikes are complex yet essential for ensuring product safety and performance. By understanding these processes, B2B buyers can make informed purchasing decisions, ensuring they select suppliers who prioritize quality, safety, and compliance with international standards. Investing time in verifying these aspects can lead to better product reliability and customer satisfaction in the long run.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘3 wheel electric cargo bike’

Introduction

This guide aims to assist B2B buyers in effectively sourcing three-wheel electric cargo bikes. As demand for eco-friendly transportation solutions grows, understanding the nuances of procurement is essential. This checklist provides actionable steps to ensure you make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, outline the specific requirements for the electric cargo bike you need. Consider factors such as cargo capacity, battery life, motor power, and safety features.

– Cargo Capacity: Determine the weight and volume of items you plan to transport.

– Battery Life: Assess the range needed for your operations to avoid interruptions during deliveries.

Step 2: Research Market Trends and Needs

Understanding current market trends in regions like Africa, South America, the Middle East, and Europe is crucial. Analyze demand for electric cargo bikes in your target market to identify the most suitable models.

– Local Regulations: Check for regulations regarding electric vehicles in your region.

– Consumer Preferences: Investigate what features are most appealing to your customer base, such as eco-friendliness or design.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers to ensure they meet your standards. Request detailed company profiles, client testimonials, and case studies to assess their credibility.

– Certifications: Verify that the bikes comply with international safety standards, such as UL certifications.

– After-Sales Support: Consider suppliers who offer comprehensive after-sales service, including warranty and maintenance options.

Step 4: Compare Pricing and Payment Terms

Gather quotes from multiple suppliers and compare pricing structures. Look beyond the initial cost; consider total cost of ownership, including shipping, assembly, and maintenance.

– Payment Flexibility: Review payment terms to determine if they align with your cash flow needs.

– Bulk Purchase Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

Step 5: Assess Shipping and Delivery Options

Evaluate the logistics of shipping and delivery, particularly if you are sourcing from overseas. Ensure that the supplier can accommodate your timeline and delivery requirements.

– Free Shipping Offers: Look for suppliers who provide free shipping or local assembly to minimize additional costs.

– Tracking Information: Confirm that the supplier offers tracking for shipments to monitor delivery status.

Step 6: Conduct a Trial or Pilot Program

Before committing to a large order, consider conducting a trial with a few units. This allows you to assess the performance and suitability of the cargo bikes in real-world conditions.

– Feedback Collection: Gather feedback from users on aspects like comfort, ease of use, and battery performance.

– Adaptability: Determine how well the bikes can handle varying loads and terrains typical in your market.

Step 7: Finalize the Purchase and Review Contract Terms

Once you have selected a supplier and are satisfied with the trial, finalize your purchase. Carefully review the contract terms to ensure they align with your expectations.

– Warranty and Return Policy: Understand the warranty coverage and return policies in case of defects or dissatisfaction.

– Ongoing Support: Clarify what kind of support the supplier offers post-purchase, including maintenance and parts availability.

By following these steps, B2B buyers can make well-informed decisions when sourcing three-wheel electric cargo bikes, ensuring they meet both operational needs and market demands.

Comprehensive Cost and Pricing Analysis for 3 wheel electric cargo bike Sourcing

What Are the Key Cost Components for Sourcing 3 Wheel Electric Cargo Bikes?

When evaluating the cost structure for 3 wheel electric cargo bikes, several critical components contribute to the overall pricing. These include:

-

Materials: The choice of materials significantly impacts cost. High-quality steel or aluminum frames, durable plastics, and specialized components (like lithium batteries) can elevate the price. Sourcing materials locally or regionally can offer cost benefits, especially for international buyers.

-

Labor: Labor costs vary by region and can be influenced by local wage standards. In regions with lower labor costs, such as parts of Africa and South America, the overall production cost may decrease, which can be beneficial for international buyers.

-

Manufacturing Overhead: This encompasses utilities, rent, equipment depreciation, and other operational expenses. Factories with efficient processes can minimize overhead, leading to competitive pricing.

-

Tooling: The initial setup for manufacturing can be costly, particularly for custom designs. Buyers should inquire about the tooling costs if they require specific modifications or unique features.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability and safety, which can add to the cost. Certifications (like UL or ISO) may also incur additional expenses but enhance marketability.

-

Logistics: Shipping costs are a significant factor, especially for international orders. Costs can vary depending on the Incoterms agreed upon, the shipping method, and destination. Understanding freight options is crucial for cost control.

-

Margin: Suppliers typically add a margin to cover risks and ensure profitability. This margin can vary based on market demand, competition, and supplier reputation.

How Do Price Influencers Affect the Cost of 3 Wheel Electric Cargo Bikes?

Several factors can influence the pricing of 3 wheel electric cargo bikes, making it essential for buyers to understand their implications:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Negotiating MOQs can help secure better pricing, especially for larger distributors or fleet operators.

-

Specifications and Customization: Custom features, such as enhanced cargo capacity or specific color schemes, can increase costs. Buyers should weigh the necessity of these features against their budget.

-

Materials and Quality Certifications: Premium materials and certifications like UL compliance can drive prices up. Buyers should assess the trade-off between cost and quality to ensure they are getting value.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers may charge more for their proven track record and customer service.

-

Incoterms: Understanding shipping terms is vital. For example, choosing EXW (Ex Works) can minimize initial costs, but may lead to higher overall expenses due to increased logistics responsibilities.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing 3 Wheel Electric Cargo Bikes?

To maximize cost-efficiency when sourcing electric cargo bikes, international B2B buyers should consider the following strategies:

-

Negotiate Pricing: Don’t hesitate to negotiate terms with suppliers, especially for larger orders. Building a relationship can lead to better terms and pricing.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operating costs (like electricity), and potential resale value when assessing the overall cost.

-

Understand Pricing Nuances: Different markets have varying pricing structures. For buyers in Africa and South America, understanding local market dynamics can help in making informed decisions. Be aware of currency fluctuations and potential tariffs that could affect pricing.

-

Research Supplier Capabilities: Ensure that suppliers can meet quality and delivery expectations. A slightly higher price may be justified if it guarantees better quality and reliability.

-

Leverage Local Resources: Consider sourcing from local suppliers to reduce shipping costs and lead times. This approach can also support local economies and may simplify logistics.

Disclaimer on Indicative Prices

Prices for 3 wheel electric cargo bikes can fluctuate based on market conditions, supplier negotiations, and customization requests. It is advisable for buyers to conduct thorough research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing 3 wheel electric cargo bike With Other Solutions

Exploring Alternatives to 3 Wheel Electric Cargo Bikes

In the growing landscape of urban logistics and family transport, the 3 wheel electric cargo bike stands out as an innovative solution. However, it’s essential for B2B buyers to evaluate other viable alternatives that may suit their specific operational needs. This section explores two key alternatives: traditional cargo vans and electric scooters, providing a comprehensive comparison to assist in informed decision-making.

| Comparison Aspect | 3 Wheel Electric Cargo Bike | Traditional Cargo Van | Electric Scooter |

|---|---|---|---|

| Performance | Up to 35 miles range, 450 lbs capacity | Varies widely, typically higher payloads | Limited range (15-40 miles), lower payload |

| Cost | $2,999 – $6,499 | $25,000 – $50,000 | $500 – $2,000 |

| Ease of Implementation | Easy to maneuver in urban areas, minimal parking space needed | Requires designated parking, higher operational costs | Highly portable, easy to park |

| Maintenance | Low maintenance; battery and tires require attention | Higher maintenance costs, complex systems | Generally low maintenance, battery replacement needed |

| Best Use Case | Urban family transport, short deliveries | Commercial logistics, larger cargo loads | Quick errands, personal transport |

What Are the Benefits and Drawbacks of Traditional Cargo Vans?

Traditional cargo vans are often the go-to solution for businesses needing to transport goods over longer distances or heavier loads. Their significant payload capacity and versatility make them suitable for commercial logistics, including deliveries and service calls. However, they come with a higher upfront cost, typically ranging from $25,000 to $50,000, along with ongoing expenses related to fuel, insurance, and maintenance. Additionally, navigating tight urban environments can be challenging, and parking can become a logistical headache.

How Do Electric Scooters Compare in Urban Transport?

Electric scooters have gained popularity as a cost-effective and portable alternative for short-distance travel. They are lightweight and easy to park, making them ideal for quick errands in crowded urban areas. Prices can be quite low, ranging from $500 to $2,000, which appeals to budget-conscious buyers. However, electric scooters generally offer a limited range and lower payload capacity compared to 3 wheel electric cargo bikes. They are not well-suited for transporting children or larger cargo, which may limit their utility for family-oriented or comprehensive delivery solutions.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the best transportation solution, B2B buyers should consider their specific use cases, budget constraints, and operational requirements. The 3 wheel electric cargo bike is particularly effective for urban family transport and light deliveries, offering a balance of performance, cost, and ease of use. In contrast, traditional cargo vans serve well in commercial logistics but come with higher costs and maintenance needs. Electric scooters provide a budget-friendly option for personal or small-scale transport but lack the capacity for larger loads. Understanding these differences will enable businesses to make informed choices that align with their operational goals and customer expectations.

Essential Technical Properties and Trade Terminology for 3 wheel electric cargo bike

What Are the Key Technical Properties of a 3 Wheel Electric Cargo Bike?

When evaluating 3 wheel electric cargo bikes, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

1. Payload Capacity

The payload capacity indicates how much weight the bike can safely carry, typically measured in pounds or kilograms. For example, many models can support between 450 lbs (204 kg) and 600 lbs (272 kg). This specification is vital for businesses that plan to transport goods or passengers, ensuring they choose a model that meets their operational requirements without compromising safety or performance.

2. Range Per Charge

The range per charge refers to the distance the bike can travel on a single battery charge, often expressed in miles or kilometers. Ranges typically vary from 20 to 35 miles (32 to 56 km) depending on the load and terrain. A longer range is essential for businesses that need to conduct deliveries or transport goods over greater distances, as it reduces the frequency of recharging and enhances efficiency.

3. Motor Power

Motor power, usually measured in watts (W), affects the bike’s performance, especially when carrying heavy loads or navigating inclines. Common specifications include motors ranging from 350W to 500W. A more powerful motor ensures better acceleration and climbing ability, which is critical for urban environments where steep streets may be encountered.

4. Battery Specifications

Battery specifications, including voltage (V) and amp-hour (Ah) ratings, determine the energy capacity and efficiency of the bike. For instance, a 48V 12Ah lithium battery provides a balance between weight and performance. Understanding battery specifications helps businesses assess the bike’s operational longevity and charging needs, which can impact logistics and overall cost.

5. Braking System

The type of braking system used (e.g., hydraulic disc brakes) is essential for safety, especially when transporting heavy loads. Effective braking systems enhance stopping power and control, which are critical in busy urban settings. A reliable braking system reduces the risk of accidents, ensuring safer operations for cargo transport.

What Common Trade Terms Should B2B Buyers Know When Purchasing a 3 Wheel Electric Cargo Bike?

Familiarity with industry-specific terminology can streamline the purchasing process and facilitate negotiations. Here are several key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand name. In the context of electric cargo bikes, understanding OEM relationships can help buyers ensure they are sourcing quality components from reputable manufacturers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it impacts inventory management and cost efficiency. Knowing the MOQ helps businesses plan their purchases according to their operational needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For buyers of electric cargo bikes, issuing an RFQ can help in comparing different suppliers’ offerings, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers when negotiating shipping costs, delivery responsibilities, and risk management during transport.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This is crucial for businesses needing timely deliveries to maintain operations. Knowing lead times allows buyers to plan their logistics effectively, minimizing disruptions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when selecting 3 wheel electric cargo bikes, ensuring they choose models that meet their business needs while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the 3 wheel electric cargo bike Sector

What are the Key Trends Shaping the 3 Wheel Electric Cargo Bike Market?

The 3 wheel electric cargo bike sector is experiencing rapid growth, driven by urbanization, the demand for sustainable transportation solutions, and the need for efficient last-mile delivery services. In regions like Africa and South America, where infrastructure may be lacking, these bikes offer a versatile alternative to traditional vehicles, allowing businesses to navigate congested urban areas effectively. The increasing focus on green logistics is also propelling interest in electric cargo bikes, as they offer a low-emission solution for transporting goods and people.

Emerging technologies, such as advanced battery systems and IoT integration, are enhancing the functionality of these bikes. Innovations like smart displays, GPS tracking, and performance analytics are becoming essential features for B2B buyers looking to optimize their operations. Additionally, the trend towards customization—where businesses can tailor bikes to meet specific logistical needs—is gaining traction, particularly among small to medium-sized enterprises (SMEs) that require adaptable solutions.

The market dynamics are also influenced by regulatory frameworks promoting eco-friendly transportation. Countries in Europe, for instance, are incentivizing the adoption of electric vehicles, including cargo bikes, through subsidies and tax benefits. This trend is likely to expand as governments globally aim to reduce carbon footprints and improve urban mobility.

How is Sustainability and Ethical Sourcing Addressed in the 3 Wheel Electric Cargo Bike Sector?

Sustainability is at the forefront of the electric cargo bike industry, with manufacturers increasingly prioritizing environmentally friendly practices. The production of 3 wheel electric cargo bikes often involves the use of sustainable materials, such as recycled aluminum and responsibly sourced wood for cargo areas. This not only reduces the environmental impact but also appeals to consumers who prioritize eco-conscious products.

Moreover, ethical sourcing is becoming crucial for B2B buyers. Companies are under pressure to ensure that their supply chains are transparent and adhere to ethical labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade certifications are gaining importance, as buyers seek assurance that their purchases contribute to positive social and environmental outcomes.

The push for sustainability is also reflected in the lifecycle management of electric cargo bikes. Manufacturers are adopting practices that facilitate recycling and reusing components, thereby minimizing waste. By investing in sustainable solutions, businesses not only meet regulatory requirements but also enhance their brand reputation and appeal to a growing base of eco-conscious consumers.

What is the Brief Evolution of the 3 Wheel Electric Cargo Bike?

The 3 wheel electric cargo bike has evolved significantly over the past few decades. Initially, these vehicles were primarily utilized in niche markets, such as agriculture and small-scale logistics. However, as urbanization accelerated and environmental concerns became more pressing, the demand for electric cargo bikes surged.

In recent years, advancements in battery technology and electric motor efficiency have made these bikes more accessible and practical for everyday use. As a result, they have transitioned from being merely a utility vehicle to a preferred mode of transportation for families and businesses alike. The integration of smart technology has further enhanced their appeal, positioning them as a modern solution for urban mobility challenges.

In summary, the 3 wheel electric cargo bike market is poised for continued growth, driven by sustainability trends, technological advancements, and evolving consumer preferences. For international B2B buyers, understanding these dynamics is essential for making informed sourcing decisions that align with both operational needs and environmental goals.

Frequently Asked Questions (FAQs) for B2B Buyers of 3 wheel electric cargo bike

-

How do I choose the right supplier for 3 wheel electric cargo bikes?

Selecting the right supplier involves thorough research and vetting. Start by assessing the supplier’s reputation, certifications, and experience in manufacturing electric cargo bikes. Look for reviews from other B2B buyers and request references. Ensure the supplier complies with international safety standards and regulations specific to your target market, whether in Africa, South America, the Middle East, or Europe. Additionally, consider their production capacity, lead times, and after-sales support, as these factors will significantly influence your business operations. -

What are the typical minimum order quantities (MOQs) for electric cargo bikes?

MOQs can vary widely depending on the supplier and the specific model of the electric cargo bike. Generally, you might encounter MOQs ranging from 10 to 50 units for standard models, while custom-designed bikes may require higher quantities. It’s essential to discuss your needs directly with potential suppliers to negotiate suitable MOQs that align with your business strategy. Keep in mind that larger orders can often lead to better pricing and more favorable payment terms. -

What payment terms should I expect when purchasing electric cargo bikes?

Payment terms vary by supplier and can include options like full payment upfront, a deposit with the balance due upon shipment, or credit terms for established buyers. Typical arrangements include a 30% deposit and 70% upon delivery. It’s crucial to negotiate terms that provide security for both parties, especially for large orders. Always review the supplier’s payment policies and consider using secure payment methods to mitigate risks associated with international transactions. -

How can I ensure the quality of the electric cargo bikes I’m purchasing?

To guarantee quality, request samples before making a bulk purchase. Conduct a thorough inspection of the sample bikes, focusing on materials, craftsmanship, and functionality. Additionally, inquire about the supplier’s quality assurance processes, including certifications and testing procedures. Consider conducting third-party inspections during production and before shipment to ensure the bikes meet your specifications and international safety standards. -

What logistics considerations should I be aware of when importing electric cargo bikes?

Logistics play a critical role in the timely delivery of your electric cargo bikes. Ensure you understand shipping options, including air and sea freight, and evaluate their respective costs and transit times. Be aware of customs regulations and tariffs in your destination country to avoid unexpected fees. Collaborating with a logistics partner familiar with international shipping can streamline the process and help navigate potential challenges. -

Can I customize the electric cargo bikes for my market?

Most suppliers offer customization options to cater to specific market needs. Customizations may include branding, color choices, cargo configurations, and additional features like safety enhancements or special cargo compartments. Discuss your requirements with potential suppliers early in the negotiation process to understand the extent of customization available and any associated costs or MOQs. -

What are the typical warranty terms for electric cargo bikes?

Warranty terms can vary significantly by manufacturer but typically range from one to three years. A comprehensive warranty should cover defects in materials and workmanship, including components like the motor and battery. Always request detailed warranty information before finalizing your order, as this will help you assess the long-term reliability of your investment and the supplier’s commitment to quality. -

How do I address after-sales service and support for electric cargo bikes?

After-sales service is crucial for maintaining customer satisfaction and product longevity. When negotiating with suppliers, inquire about their support policies, including repair services, replacement parts availability, and customer service channels. Consider establishing a partnership with local service providers to facilitate maintenance and repairs in your region. Clear communication about service expectations will enhance your operational efficiency and build trust with your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 3 Wheel Electric Cargo Bike Manufacturers & Suppliers List

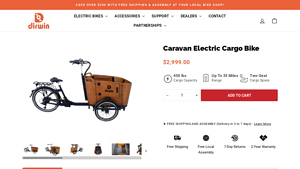

1. Dirwin – Caravan Electric Cargo Bike

Domain: dirwinbike.com

Registered: 2021 (4 years)

Introduction: {“name”:”Caravan Electric Cargo Bike”,”price”:”$2,999.00″,”cargo_capacity”:”450 lbs”,”range”:”Up to 35 Miles”,”features”:[“Two-Seat Cargo Space”,”Finely Crafted Polished Wood”,”Cushioned Seats With Seatbelts”,”20+ Cubic Feet Cargo Container”,”Tricycle Style Extra Stability”,”Water-proof rain cover”,”Durable rear rack”,”Soft floor liner”],”motor_power”:”350W”,”battery”:”16Ah lithium battery”,”pedal…

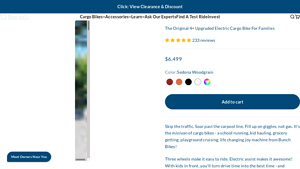

2. Bunch Bike – The Original 4+ Upgraded Electric Cargo Bike

Domain: bunchbike.com

Registered: 2018 (7 years)

Introduction: Product Name: The Original 4+ Upgraded Electric Cargo Bike for Families

Sale Price: $6,499

Regular Price: $4,965

Color Options: Sedona Woodgrain, Honey Woodgrain, Cool Black, Sleek White, Custom Design

Weight: 168 lbs

Max Recommended Rider Weight: 250 lbs

Max Loading Capacity of Cargo Area: 400 lbs

Max Total Loading Capacity of Bike: 600 lbs

Range Per Charge: 20-30 miles

Maximum Speed: 20 mph

Batt…

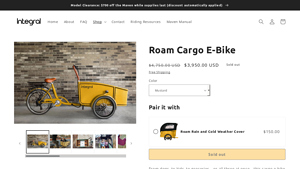

3. Integral Electrics – Roam Cargo E-Bike

Domain: integralelectrics.com

Registered: 2018 (7 years)

Introduction: {“name”: “Roam Cargo E-Bike”, “regular_price”: “$4,750.00 USD”, “sale_price”: “$3,950.00 USD”, “discount”: “$700 off”, “shipping”: “Free Shipping”, “color”: “Mustard”, “cargo_capacity”: “440 lbs (200 kgs)”, “range”: “25-35 miles”, “motor”: “500W Bafang hub drive motor”, “battery”: “48V 624Wh Li-Ion battery”, “charging_time”: “4-6 hours”, “dimensions”: {“required_parking_space”: “3 ft. wide and 8 f…

4. Worksman – Heavy Duty Industrial Trikes

Domain: worksmancycles.com

Registered: 1997 (28 years)

Introduction: Worksman Mover(TM) Industrial Tricycle M2626-3CB: Global standard in heavy duty industrial trikes, 26 inch wheels, THREE SPEED coaster brake, optional cargo basket and rear fenders, price: $1,159.00. Worksman Front Loader – Super Delivery Trike – Model SUD: Industrial Front Load Tricycle with 42″ x 23″ x 24″ front cabinet, super heavy duty, price: $1,899.00. Worksman Adaptable Industrial Tricycle …

5. Specialized – Globe Haul ST

Domain: bicycling.com

Registered: 1999 (26 years)

Introduction: Best Overall: Specialized Globe Haul ST – Price: €2,500, Tires: 20 x 3.5 in., Weight: 77 lbs., Cargo Capacity: 419 lbs. Pros: One of the smallest cargo bike footprints, Excellent battery life and power delivery, Strong brakes. Cons: Lack of suspension can mean a harsh ride on rough roads, Can only carry one kiddo.

Best Value: Aventon Abound – Price: $1,999 (Now $1,599), Tires: 20 x 2.4 in., Weigh…

6. Babboe – Pro Trike

Domain: babboepro.com

Registered: 2020 (5 years)

Introduction: Babboe Pro Trike: A stable cargo bike with a great price/quality ratio. Features include: 3 wheels, 300 litres box capacity, practical lid for easy access, smart design for easy partitioning, padlock for security, option for custom decals for advertising. Variants: Babboe Pro Trike (non-electric) and Babboe Pro Trike-E (electric). Specifications: Box load capacity of 100 kg, hub gear for both mode…

Strategic Sourcing Conclusion and Outlook for 3 wheel electric cargo bike

As the demand for sustainable urban transport solutions grows, the strategic sourcing of three-wheel electric cargo bikes presents a compelling opportunity for international B2B buyers. These innovative vehicles not only offer impressive cargo capacities—up to 450 lbs—but also ensure safety and comfort for passengers, making them ideal for family use and commercial applications alike. The integration of powerful motors and long-lasting batteries enhances their functionality, enabling businesses to optimize last-mile delivery and reduce transportation costs.

Investing in high-quality electric cargo bikes can lead to significant long-term savings and a reduced carbon footprint, aligning with global sustainability goals. As markets in Africa, South America, the Middle East, and Europe continue to evolve, sourcing from reliable manufacturers will be crucial to ensure product quality and after-sales support.

Looking ahead, the landscape for electric cargo bikes is poised for growth, driven by urbanization and changing consumer preferences. B2B buyers are encouraged to explore partnerships with reputable suppliers to stay ahead of the curve and capitalize on this transformative shift in mobility solutions. Embrace the opportunity to enhance your fleet and contribute to a greener future today.