Introduction: Navigating the Global Market for 4kw electric car

In today’s rapidly evolving transportation landscape, sourcing a reliable 4kW electric car presents a unique challenge for international B2B buyers. As global demand for sustainable and efficient vehicles rises, businesses must navigate a complex market filled with diverse models, specifications, and regulatory requirements. This comprehensive guide aims to equip decision-makers with essential insights into the 4kW electric car segment, covering various types, applications, and the intricacies of supplier vetting.

By exploring factors such as performance capabilities, charging infrastructure, and cost implications, this guide empowers B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe—including key markets like Brazil and Nigeria—to make informed purchasing decisions. Understanding the nuances of the 4kW electric vehicle market is crucial not only for enhancing fleet sustainability but also for leveraging financial incentives and regulatory advantages available in different territories.

Through detailed analysis and actionable recommendations, this guide serves as a valuable resource, helping businesses transition towards greener transportation solutions while maximizing operational efficiency and cost-effectiveness. Whether you are looking to upgrade existing fleets or invest in new electric vehicle technologies, this guide provides the knowledge necessary to navigate the global market effectively.

Understanding 4kw electric car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Low-Speed Electric Vehicles (LSEVs) | Typically limited to 45 km/h, require no driving license, designed for urban environments | Urban transport, local deliveries | Pros: Cost-effective, easy to operate. Cons: Limited speed and range. |

| Electric Mini Trucks | Designed for short-haul deliveries, often enclosed, suitable for urban logistics | E-commerce, municipal services | Pros: High payload capacity, environmentally friendly. Cons: Limited to urban areas. |

| Electric Passenger Cars | Compact design, suitable for personal or shared transport, often includes advanced tech | Ride-sharing, corporate fleets | Pros: Versatile, can integrate with apps. Cons: Higher initial investment. |

| Off-Grid Compatible Electric Cars | Compatible with solar and off-grid charging systems, designed for remote areas | Rural transport, emergency services | Pros: Sustainability, independence from grid. Cons: Initial setup cost for solar systems. |

| Electric Tricycles | Three-wheeled design, often more stable, ideal for short distances | Tourism, local commuting | Pros: Maneuverable, cost-effective. Cons: Limited cargo space. |

What Are Low-Speed Electric Vehicles (LSEVs) and Their B2B Relevance?

Low-Speed Electric Vehicles (LSEVs) are primarily designed for urban settings where speeds are capped at 45 km/h. These vehicles often do not require a driving license, making them accessible for a broader range of users. B2B applications include urban transport services and local deliveries, particularly in densely populated areas. Their affordability and ease of operation are attractive to businesses looking to reduce transportation costs, although their limited speed may restrict use in fast-paced environments.

How Do Electric Mini Trucks Serve Urban Logistics?

Electric Mini Trucks are tailored for short-haul deliveries, featuring an enclosed design that protects cargo and enhances security. These vehicles are particularly suited for urban logistics, where they can navigate congested streets and deliver goods efficiently. Businesses in e-commerce and municipal services benefit from their high payload capacity and zero emissions, promoting sustainable practices. However, their operational range is generally limited to urban areas, which may constrain logistics strategies for companies with wider delivery networks.

What Advantages Do Electric Passenger Cars Offer for Corporate Fleets?

Electric Passenger Cars are compact and designed for both personal and shared transport. These vehicles often come equipped with advanced technology, including connectivity features that facilitate fleet management. They are ideal for ride-sharing services and corporate fleets, enabling businesses to provide eco-friendly transportation options. While they offer versatility and the potential for integration with mobile applications, the higher initial investment may pose a barrier for some businesses.

Why Are Off-Grid Compatible Electric Cars Important for Rural Areas?

Off-Grid Compatible Electric Cars are specifically designed to work with solar and off-grid charging systems, making them ideal for remote locations. These vehicles are essential for rural transport and emergency services, providing mobility where traditional infrastructure may be lacking. Their sustainability and independence from the electrical grid can significantly lower operational costs over time. However, businesses must consider the initial investment required for solar system setups, which can be substantial.

How Do Electric Tricycles Fit into Local Commuting Solutions?

Electric Tricycles, characterized by their three-wheeled design, offer enhanced stability and are particularly effective for short-distance travel. They are popular in tourism and local commuting sectors, providing an eco-friendly alternative to traditional vehicles. Their maneuverability and cost-effectiveness make them appealing for businesses looking to operate within urban settings. However, the limited cargo space may restrict their use for businesses requiring larger transportation capacities.

Key Industrial Applications of 4kw electric car

| Industry/Sector | Specific Application of 4kw Electric Car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Urban Transportation | Last-mile delivery services using 4kw electric cars | Reduced operational costs and enhanced delivery speed | Availability of charging infrastructure and local regulations |

| Tourism and Leisure | Electric vehicles for guided tours in urban areas | Eco-friendly transport options attracting tourists | Durability and comfort features tailored for passenger use |

| Agriculture | Utility vehicles for farm transport and logistics | Efficient transport of goods, reducing fuel costs | Robust design for rugged terrains and battery capacity |

| Healthcare | Patient transport in urban settings | Reliable and cost-effective patient transport | Compliance with healthcare regulations and reliability of service |

| Logistics and Supply Chain | Fleet vehicles for distribution centers | Improved sustainability and lower carbon footprint | Fleet management systems and maintenance support availability |

How is the 4kw Electric Car Used in Urban Transportation?

In urban transportation, 4kw electric cars are increasingly utilized for last-mile delivery services. These vehicles provide a cost-effective solution for businesses looking to reduce fuel expenses while ensuring timely deliveries. By leveraging 4kw electric cars, companies can navigate congested city streets more efficiently. International buyers, particularly from regions like Africa and South America, should consider local charging infrastructure and regulatory compliance when sourcing these vehicles.

What Role Does the 4kw Electric Car Play in Tourism and Leisure?

In the tourism sector, 4kw electric cars are often employed for guided tours, offering an eco-friendly mode of transportation that appeals to environmentally conscious travelers. These vehicles enhance the tourist experience by providing quiet, clean rides through urban areas. Buyers in Europe and the Middle East must focus on the vehicle’s durability and comfort features to ensure a pleasant experience for tourists while adhering to local tourism regulations.

How Can 4kw Electric Cars Benefit Agriculture?

In agriculture, 4kw electric cars serve as utility vehicles for transporting goods across farms. They help farmers reduce fuel costs and improve operational efficiency, particularly in rural areas where traditional fuel sources may be limited. Buyers from regions like Brazil and Nigeria should prioritize vehicles with robust designs capable of handling rugged terrains, along with adequate battery capacity for extended use.

What Advantages Do 4kw Electric Cars Offer in Healthcare?

The healthcare sector leverages 4kw electric cars for patient transport, particularly in urban settings where traffic congestion can delay traditional vehicles. These electric cars provide a reliable and cost-effective means of transporting patients, ensuring timely access to medical facilities. International B2B buyers must ensure compliance with healthcare regulations and focus on the reliability of these vehicles to maintain high service standards.

How Do 4kw Electric Cars Enhance Logistics and Supply Chains?

In logistics and supply chain operations, 4kw electric cars can replace traditional fleet vehicles, contributing to sustainability goals while lowering the carbon footprint. These vehicles are ideal for short-distance deliveries and can be integrated into existing fleet management systems. Buyers should consider the availability of maintenance support and the ability to track vehicle performance when sourcing these electric cars for logistics applications.

3 Common User Pain Points for ‘4kw electric car’ & Their Solutions

Scenario 1: Inadequate Charging Infrastructure for 4kW Electric Cars

The Problem: Many B2B buyers, particularly in emerging markets such as Africa and South America, face significant challenges regarding the availability of charging infrastructure suitable for 4kW electric vehicles. This inadequacy can lead to operational inefficiencies, where businesses cannot fully utilize their electric car fleets due to limited charging points. Additionally, the lack of reliable charging stations can deter potential customers from adopting electric vehicles, as they fear being stranded with insufficient battery life.

The Solution: To mitigate this issue, businesses should strategically partner with local governments and private sector stakeholders to invest in establishing a robust charging network. Conducting a feasibility study can help identify high-traffic areas where charging stations would be most beneficial. Moreover, companies can consider investing in mobile charging solutions or solar-powered charging stations, which can be particularly effective in regions with abundant sunlight. By integrating these solutions into their operations, businesses can enhance their service offerings and encourage the adoption of 4kW electric vehicles among their clientele.

Scenario 2: Limited Vehicle Range Causing Operational Constraints

The Problem: A common concern among B2B buyers is the limited range of 4kW electric cars, which can restrict their operational capabilities. In sectors such as logistics and transportation, where long-distance travel is often required, the fear of running out of battery can hinder the decision to switch from traditional fuel-powered vehicles to electric alternatives. This limitation can lead to increased operational costs and reduced competitiveness in the market.

The Solution: To address range anxiety, companies should evaluate the specific range requirements of their operations before purchasing 4kW electric cars. Implementing a mixed fleet strategy can also be beneficial, where electric vehicles are used for shorter trips and traditional vehicles for longer distances. Additionally, investing in advanced battery technology and energy management systems can optimize the vehicle’s performance and extend its range. Businesses should also explore partnerships with battery swap services to facilitate quick battery changes, thereby minimizing downtime and enhancing operational efficiency.

Scenario 3: High Initial Investment and Maintenance Costs

The Problem: The initial capital expenditure associated with acquiring 4kW electric cars can be a significant hurdle for many businesses, particularly in developing regions. Coupled with concerns about maintenance and the potential need for specialized repairs, this financial burden can lead to hesitation in adopting electric vehicles. B2B buyers may worry about the return on investment, especially if they are accustomed to lower upfront costs associated with traditional vehicles.

The Solution: To alleviate these financial concerns, businesses should explore financing options such as leasing programs or government grants aimed at promoting electric vehicle adoption. This can help spread the initial costs over time and make the investment more manageable. Additionally, establishing strong relationships with manufacturers and service providers can ensure access to affordable maintenance and parts, reducing long-term operational costs. Implementing comprehensive training programs for staff on electric vehicle maintenance can also enhance in-house capabilities and further decrease reliance on external service providers, ultimately leading to cost savings and improved vehicle longevity.

Strategic Material Selection Guide for 4kw electric car

What Are the Key Materials for a 4kW Electric Car?

When selecting materials for a 4kW electric car, it is crucial to consider their properties, advantages, disadvantages, and compliance with international standards. This analysis focuses on four common materials: aluminum, steel, lithium-ion batteries, and composites.

How Does Aluminum Benefit Electric Car Design?

Aluminum is widely used in electric vehicle (EV) manufacturing due to its excellent strength-to-weight ratio. It typically has a temperature rating suitable for automotive applications, with good corrosion resistance, making it ideal for various components such as the chassis and body panels.

Pros: Aluminum is lightweight, which enhances vehicle efficiency and range. It also offers good thermal conductivity, aiding in battery cooling.

Cons: The primary downside is its higher cost compared to steel and the complexity of manufacturing processes, which may require specialized techniques like welding or extrusion.

Impact on Application: Aluminum’s lightweight nature improves energy efficiency, while its corrosion resistance ensures longevity in diverse environments, particularly in regions with high humidity or salinity.

Considerations for International Buyers: Compliance with standards such as ASTM and EN is essential. Buyers in Africa and South America may also consider local sourcing to reduce costs.

What Role Does Steel Play in Electric Vehicle Construction?

Steel remains a staple in automotive manufacturing, particularly for structural components. It boasts high tensile strength and is readily available, making it a cost-effective choice for parts like the frame and safety structures.

Pros: Steel is durable and can withstand significant stress, providing safety benefits. It is also relatively inexpensive and widely available.

Cons: The primary drawback is its weight, which can negatively affect the vehicle’s range and efficiency. Steel also has lower corrosion resistance compared to aluminum unless treated.

Impact on Application: Steel’s strength is crucial for safety features, but its weight can hinder performance, especially in regions with varying terrain.

Considerations for International Buyers: Compliance with international standards like JIS and ASTM is necessary. Buyers should also consider local regulations regarding material sourcing and environmental impact.

How Do Lithium-Ion Batteries Enhance Electric Vehicle Performance?

Lithium-ion batteries are the heart of electric vehicles, providing the necessary energy storage for a 4kW electric car. They have a high energy density and are capable of rapid charging.

Pros: These batteries offer excellent performance and longevity, with a low self-discharge rate. They are lightweight compared to other battery technologies, enhancing vehicle efficiency.

Cons: The main limitations include high costs and environmental concerns regarding lithium extraction and disposal. Additionally, they require specific management systems to ensure safety and performance.

Impact on Application: Lithium-ion batteries are essential for maximizing range and efficiency, particularly in regions with limited charging infrastructure.

Considerations for International Buyers: Compliance with international safety standards (like IEC and UL) is critical. Buyers should also be aware of local regulations regarding battery disposal and recycling.

What Advantages Do Composites Offer in Electric Car Manufacturing?

Composites, particularly carbon fiber and fiberglass, are increasingly used in electric vehicle construction for components like body panels and interior parts. They offer high strength-to-weight ratios and excellent corrosion resistance.

Pros: Composites are lightweight, which improves vehicle efficiency and performance. They also provide design flexibility and can be molded into complex shapes.

Cons: The manufacturing process can be complex and costly, which may limit their use in mass production.

Impact on Application: The use of composites can significantly enhance vehicle aesthetics and performance, particularly in high-end models.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards like ASTM D3039 for tensile properties. Additionally, understanding local manufacturing capabilities is essential for sourcing.

Summary Table of Material Selection for 4kW Electric Cars

| Material | Typical Use Case for 4kW Electric Car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Chassis and body panels | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | High |

| Steel | Structural components | Durable and cost-effective | Heavier, affecting range | Medium |

| Lithium-Ion | Energy storage | High energy density and efficiency | High cost and environmental concerns | High |

| Composites | Body panels and interiors | Lightweight and design flexibility | Complex and costly manufacturing | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions in sourcing materials for 4kW electric cars tailored to specific regional needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for 4kw electric car

What Are the Key Stages in the Manufacturing Process of a 4kW Electric Car?

The manufacturing process for a 4kW electric car involves several crucial stages that ensure the vehicle is built to high standards of quality and performance.

Material Preparation

The first stage is material preparation, where raw materials are sourced and inspected for compliance with industry standards. Common materials include high-strength steel for the chassis, lightweight aluminum for body panels, and advanced composites for interior components. This stage also involves evaluating battery materials, which are critical for the electric vehicle’s performance. Suppliers must provide certifications for materials used, ensuring they meet specifications for durability and safety.

Forming and Fabrication

Once materials are prepared, the next step is forming and fabrication. This includes processes such as stamping, welding, and machining. Advanced techniques like laser cutting and CNC machining are often employed to achieve precise dimensions and intricate designs. The forming stage is crucial for creating parts that fit together seamlessly, which is vital for the structural integrity of the vehicle.

Assembly

The assembly stage is where all components come together. This process often follows a lean manufacturing approach to minimize waste and enhance efficiency. Key components, such as the electric drivetrain, battery packs, and control systems, are installed during this phase. Automated assembly lines are common, allowing for consistent quality and speed. Each assembly line should have clear protocols to ensure that every vehicle meets the required specifications.

Finishing

Finally, the finishing stage includes painting, quality checks, and final assembly adjustments. The painting process often involves multiple layers to ensure durability and aesthetic appeal. Final quality checks are performed to ensure the vehicle meets design and performance specifications before it is shipped to customers.

How Is Quality Assurance Implemented in the Manufacturing of 4kW Electric Cars?

Quality assurance (QA) is integral to the manufacturing process of 4kW electric cars, ensuring that every vehicle meets international safety and performance standards.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 play a crucial role in quality assurance. ISO 9001 outlines the requirements for a quality management system (QMS) and helps organizations ensure they meet customer and regulatory requirements consistently. In addition to ISO 9001, certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the components being sourced.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are critical throughout the manufacturing process. These checkpoints typically include:

- Incoming Quality Control (IQC): This phase inspects raw materials and components upon delivery to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify defects or deviations early. This includes checks at various stages of assembly.

- Final Quality Control (FQC): Before the vehicle is dispatched, a thorough inspection ensures that the final product meets all specifications and is free of defects.

What Testing Methods Are Commonly Used?

Common testing methods for electric vehicles include:

- Electrical Testing: Ensuring that the electric drivetrain and battery systems operate correctly and safely.

- Durability Testing: Evaluating how well the vehicle withstands different environmental conditions, including heat, cold, and humidity.

- Crash Testing: Conducting simulations and real-world tests to assess the vehicle’s safety features and compliance with regulations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify a supplier’s quality control processes:

- Supplier Audits: Conducting on-site audits allows buyers to assess the supplier’s manufacturing capabilities and quality management systems directly.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s performance metrics, defect rates, and compliance with international standards.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and adherence to standards.

What Are the Unique Quality Control Challenges for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, may face unique challenges when it comes to quality control:

- Regulatory Compliance: Different countries have varying regulations regarding electric vehicles. Ensuring that suppliers meet these diverse requirements can be complex.

- Cultural Differences: Variations in quality expectations and practices can lead to misunderstandings. Clear communication and established protocols are essential.

- Supply Chain Reliability: Ensuring the consistent quality of components sourced from various countries can be challenging. Establishing strong relationships with suppliers can mitigate these risks.

Conclusion: Ensuring Quality in the Manufacturing of 4kW Electric Cars

In conclusion, the manufacturing processes and quality assurance measures for 4kW electric cars are vital for delivering reliable, safe, and high-performance vehicles. By understanding the key stages of manufacturing and implementing effective quality control measures, B2B buyers can ensure they partner with suppliers who prioritize quality and compliance. This is particularly important in the international market, where standards and regulations may vary significantly. Building strong relationships with suppliers and conducting thorough due diligence will ultimately lead to better outcomes for buyers and manufacturers alike.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘4kw electric car’

This guide serves as a practical checklist for B2B buyers interested in procuring 4kW electric cars, specifically tailored for diverse international markets including Africa, South America, the Middle East, and Europe. By following these steps, businesses can ensure they make informed decisions while sourcing electric vehicles that meet their operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential to ensure that the 4kW electric car meets your operational requirements. Consider factors such as range, battery capacity, maximum speed, and charging time. This clarity helps streamline the selection process and ensures compatibility with your business model.

Step 2: Assess Local Market Regulations

Understanding the regulatory landscape in your target market is crucial. Different regions may have unique licensing, safety, and emissions requirements for electric vehicles. Familiarize yourself with these regulations to avoid potential compliance issues and ensure that your procurement aligns with local laws.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is necessary. Review company profiles, request case studies, and seek references from other buyers in similar industries or regions. Focus on suppliers with proven track records in delivering quality electric vehicles and customer support.

- Tip: Look for suppliers with certifications such as EEC, DOT, or ISO to ensure they meet industry standards.

Step 4: Investigate After-Sales Support and Warranty

A strong after-sales support system is vital for the longevity of your investment. Inquire about the warranty terms, service agreements, and availability of spare parts. Reliable support can significantly reduce downtime and enhance the overall performance of your fleet.

Step 5: Request Detailed Quotations

When you shortlist potential suppliers, request detailed quotations that outline the total costs involved. Ensure that the quotations include all potential expenses such as shipping, taxes, and installation fees. This transparency helps in comparing offers effectively and prevents unexpected costs down the line.

Step 6: Conduct a Trial Run

If possible, arrange for a trial run of the electric vehicles. This allows you to assess the performance, comfort, and usability of the cars firsthand. A practical evaluation can provide insights into the suitability of the vehicles for your specific operational context.

Step 7: Plan for Charging Infrastructure

Finally, consider the necessary charging infrastructure to support your electric vehicle fleet. Evaluate options for both on-grid and off-grid charging solutions that align with your business operations. Investing in a robust charging system is essential to maximize vehicle uptime and operational efficiency.

By following this checklist, B2B buyers can navigate the complexities of sourcing 4kW electric cars, ensuring that their procurement process is thorough, compliant, and strategically aligned with their operational goals.

Comprehensive Cost and Pricing Analysis for 4kw electric car Sourcing

What Are the Key Cost Components for Sourcing a 4kW Electric Car?

When sourcing a 4kW electric car, understanding the cost structure is essential for international B2B buyers. The primary cost components include:

-

Materials: The core materials for electric cars encompass batteries, electric motors, chassis, and bodywork. The choice of materials significantly affects the overall cost. For instance, lithium-ion batteries are a major cost driver, and their prices can fluctuate based on global demand and raw material availability.

-

Labor: Labor costs vary widely depending on the manufacturing location. Regions with lower labor costs, such as parts of Asia and some African countries, can offer competitive pricing. However, it’s crucial to balance labor cost with the skill level and efficiency of the workforce.

-

Manufacturing Overhead: This includes costs related to the factory operation, such as utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, leading to more competitive pricing.

-

Tooling: Initial tooling costs for production setups can be substantial, especially for customized electric vehicles. These costs are often amortized over the production run, impacting the unit cost.

-

Quality Control (QC): Ensuring high-quality standards is vital in the automotive industry. Quality assurance measures can add to the cost but are necessary to avoid costly recalls and maintain brand reputation.

-

Logistics: Transportation costs for shipping vehicles from manufacturing facilities to end-users can vary significantly based on distance, mode of transport, and local regulations. Incoterms can influence logistics costs, affecting the final price.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on competition, market demand, and the supplier’s business model.

How Do Price Influencers Affect the Sourcing of 4kW Electric Cars?

Several factors can influence the pricing of 4kW electric cars, particularly for international B2B buyers:

-

Volume/MOQ: Larger orders often lead to better pricing due to economies of scale. Negotiating minimum order quantities (MOQs) can also affect unit costs.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should weigh the benefits of customization against additional expenses.

-

Materials and Quality Certifications: The choice of materials can impact price significantly. High-quality materials and certifications (e.g., ISO, EEC) may increase costs but can enhance the vehicle’s marketability.

-

Supplier Factors: The reputation, reliability, and financial stability of suppliers can influence pricing. Established suppliers may charge a premium for their experience and service quality.

-

Incoterms: Understanding Incoterms is crucial for cost management. They dictate who is responsible for shipping costs, insurance, and tariffs, which can significantly affect the total landed cost.

What Buyer Tips Can Enhance Cost-Efficiency for International B2B Buyers?

B2B buyers should consider several strategies to enhance cost-efficiency when sourcing 4kW electric cars:

-

Negotiate Effectively: Building strong relationships with suppliers can lead to better negotiation outcomes. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, operating costs, and potential resale value. This holistic view can guide better purchasing decisions.

-

Be Aware of Pricing Nuances: Different regions may have varying pricing structures influenced by local regulations, tariffs, and market demand. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these nuances.

-

Consider Payment Terms: Favorable payment terms can improve cash flow management and reduce financial strain. Discuss options such as deferred payments or financing arrangements with suppliers.

-

Stay Updated on Market Trends: The electric vehicle market is dynamic, with technology advancements and regulatory changes affecting pricing. Keeping abreast of these trends can help buyers make informed sourcing decisions.

Disclaimer on Indicative Prices

Pricing for 4kW electric cars can vary significantly based on the aforementioned factors. Therefore, it is crucial for buyers to obtain tailored quotes from suppliers and conduct thorough due diligence to ensure accurate cost assessments.

Alternatives Analysis: Comparing 4kw electric car With Other Solutions

Understanding Alternatives for 4kW Electric Cars

As the demand for sustainable transportation solutions increases, businesses are exploring various alternatives to 4kW electric cars. These alternatives not only provide different functionalities but also cater to diverse operational needs and market conditions. In this analysis, we will compare the 4kW electric car with two viable alternatives: electric scooters and low-speed electric vehicles (LSEVs).

Comparison Table

| Comparison Aspect | 4kW Electric Car | Electric Scooter | Low-Speed Electric Vehicle (LSEV) |

|---|---|---|---|

| Performance | Up to 45 km/h, suitable for short commutes | Up to 30-40 km/h, ideal for urban travel | Up to 45 km/h, designed for short distances |

| Cost | Moderate initial investment; lower running costs | Lower purchase price, affordable maintenance | Moderate investment, varies by model |

| Ease of Implementation | Requires charging infrastructure and space | Minimal infrastructure, easy to park | Requires charging stations but often fits in smaller spaces |

| Maintenance | Moderate; battery and electrical components need upkeep | Low; fewer moving parts | Moderate; similar to cars but simpler mechanics |

| Best Use Case | Short to medium commutes, urban environments | Urban commuting, last-mile delivery | Short-distance travel, urban areas, and recreational use |

Detailed Breakdown of Alternatives

What are the advantages and disadvantages of using electric scooters?

Electric scooters are an excellent alternative for businesses focusing on urban commuting and last-mile delivery. They are cost-effective, with a lower initial investment and minimal maintenance costs. Their compact design allows for easy parking and maneuverability in congested areas. However, their performance is limited to shorter distances, and they may not be suitable for transporting multiple passengers or heavy loads. Additionally, weather conditions can significantly affect their usability, making them less reliable in adverse climates.

How do low-speed electric vehicles (LSEVs) compare to 4kW electric cars?

Low-speed electric vehicles (LSEVs) are designed for short-distance travel, much like the 4kW electric car. They offer a similar top speed of up to 45 km/h and are ideal for urban settings. LSEVs are often more affordable and can accommodate more passengers compared to scooters. However, they may require more substantial charging infrastructure than scooters and can have higher operational costs due to battery maintenance. Their size also requires more space for parking, which can be a drawback in densely populated areas.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right solution, B2B buyers should assess their specific operational needs, budget constraints, and the infrastructure available in their target markets. The 4kW electric car is a strong contender for businesses needing a reliable vehicle for short to medium commutes, while electric scooters can be advantageous for urban, cost-sensitive operations. Low-speed electric vehicles serve as a middle ground, offering versatility for short-distance travel with more passenger capacity. By carefully evaluating these alternatives, businesses can make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for 4kw electric car

What Are the Essential Technical Properties of a 4kW Electric Car?

When considering the procurement of a 4kW electric car, understanding its technical properties is crucial for making informed purchasing decisions. Here are several key specifications that B2B buyers should be familiar with:

-

Power Output (kW)

The power output of 4kW indicates the maximum energy the vehicle can draw from its battery to drive the electric motor. This specification is essential for understanding the car’s performance capabilities, particularly in urban settings where low-speed vehicles are common. In regions like Africa and South America, where road conditions may vary, knowing the power output helps in evaluating the vehicle’s suitability for local driving conditions. -

Battery Capacity (kWh)

Battery capacity, typically measured in kilowatt-hours (kWh), defines how much energy the battery can store. A larger capacity allows for longer driving ranges between charges, which is critical for fleet operators. B2B buyers should assess the trade-off between vehicle weight and battery size, especially in emerging markets where infrastructure for charging may be limited. -

Charging Time (hours)

This specification indicates how long it takes to fully charge the vehicle’s battery. Shorter charging times can enhance operational efficiency, especially for businesses that rely on quick turnaround times. Understanding the charging capabilities is vital for fleet management, particularly in regions with limited charging infrastructure. -

Vehicle Weight (kg)

The weight of the vehicle affects its efficiency, handling, and overall performance. Lighter vehicles generally consume less energy, which can lead to lower operational costs. Buyers should consider the weight in relation to the vehicle’s intended use, especially in environments where road conditions may be challenging. -

Range (km)

The range of an electric vehicle is the distance it can travel on a single charge. This is a critical factor for businesses that need to plan logistics and transportation. In markets with less-developed charging infrastructure, a longer range can significantly reduce operational constraints and enhance reliability. -

Speed Limit (km/h)

The speed limit, often capped at around 45 km/h for low-speed electric cars, is a regulatory specification that defines where the vehicle can operate legally. Understanding this limit is crucial for compliance with local laws and regulations, particularly in urban areas where low-speed vehicles are increasingly popular.

What Trade Terms Should B2B Buyers Know for 4kW Electric Cars?

Navigating the procurement of electric vehicles involves familiarity with specific industry jargon. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, understanding the role of OEMs is crucial for ensuring quality and compatibility of components in the electric car supply chain. -

MOQ (Minimum Order Quantity)

This term refers to the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ helps businesses budget and plan their inventory effectively, especially when entering new markets or establishing fleet operations. -

RFQ (Request for Quotation)

An RFQ is a document that solicits pricing and terms from suppliers. This is a critical step in the procurement process, allowing businesses to compare costs and negotiate better terms with manufacturers or distributors of electric vehicles. -

Incoterms (International Commercial Terms)

These are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to clarify shipping, insurance, and risk management, particularly when importing electric vehicles from global suppliers. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to the delivery of the product. For businesses, understanding lead times is vital for effective inventory management and operational planning, especially in industries where demand can fluctuate. -

Warranty Period

This term indicates the duration for which the manufacturer guarantees the vehicle’s performance and quality. A robust warranty is an important factor for B2B buyers, as it reflects the manufacturer’s confidence in their product and provides peace of mind regarding maintenance and repairs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and market conditions.

Navigating Market Dynamics and Sourcing Trends in the 4kw electric car Sector

What Are the Key Market Trends Influencing the 4kW Electric Car Sector?

The 4kW electric car market is experiencing significant growth driven by various global factors. First, the increasing demand for eco-friendly transportation solutions is fostering interest in low-speed electric vehicles (LSEVs), particularly in regions where traditional automotive infrastructure is lacking. Countries in Africa, South America, and parts of the Middle East are prioritizing sustainable transport options to combat urban congestion and pollution, making the 4kW segment particularly appealing. Additionally, advancements in battery technology and electric vehicle (EV) components are lowering production costs, facilitating greater market entry for international suppliers.

Emerging trends include the integration of smart technology in electric vehicles, such as real-time data tracking for performance and energy consumption. B2B buyers are increasingly looking for suppliers who can offer innovative features like regenerative braking systems and enhanced charging capabilities. There is also a noticeable shift toward modular vehicle designs that allow for easier customization and scalability, providing an avenue for businesses to cater to diverse consumer needs.

Furthermore, the rise of off-grid charging solutions is becoming a focal point, especially in regions with unreliable electrical infrastructure. This trend is influencing sourcing strategies, pushing international buyers to seek out suppliers who can provide comprehensive solutions encompassing both vehicles and supporting infrastructure.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the 4kW Electric Car Sector?

Sustainability is a paramount concern for B2B buyers in the 4kW electric car sector. The environmental impact of sourcing materials and manufacturing processes can significantly affect a company’s reputation and compliance with global regulations. Buyers should prioritize suppliers that adhere to sustainable practices and can provide documentation of their environmental impact, such as carbon footprints and waste management strategies.

Ethical sourcing is equally critical, particularly in regions with complex supply chains. Buyers should seek out manufacturers that support fair labor practices and are transparent about their sourcing materials, especially concerning lithium and cobalt used in batteries. Certifications like ISO 14001 for environmental management systems or adherence to the Responsible Business Alliance (RBA) standards can serve as indicators of a supplier’s commitment to ethical practices.

Moreover, green certifications for materials used in manufacturing, such as recycled or sustainably sourced components, can enhance product appeal. Buyers should leverage these certifications in marketing to attract environmentally conscious consumers, thereby differentiating their offerings in a competitive marketplace.

What Is the Brief Evolution and History of the 4kW Electric Car Market?

The evolution of the 4kW electric car market can be traced back to the early 21st century, when increasing awareness of climate change and the depletion of fossil fuels spurred innovation in electric vehicle technology. Initially, electric cars were seen as impractical due to limited range and high costs. However, as battery technology advanced and production processes became more efficient, manufacturers began to introduce more affordable models, including low-speed electric vehicles (LSEVs) that cater to urban commuting needs.

By the late 2010s, the 4kW segment gained traction due to regulatory support for electric vehicles across various nations and growing consumer interest in sustainable transport solutions. Today, the sector is characterized by a diverse range of offerings, from compact passenger vehicles to utility models, appealing to both individual consumers and businesses. The market continues to evolve, reflecting advancements in technology and shifts in consumer preferences toward greener alternatives.

Frequently Asked Questions (FAQs) for B2B Buyers of 4kw electric car

-

How do I ensure the quality of a 4kW electric car before purchase?

To ensure the quality of a 4kW electric car, it’s crucial to conduct thorough supplier vetting. Request certifications such as EEC (European Economic Community) or DOT (Department of Transportation) compliance, which indicate adherence to safety and performance standards. Additionally, ask for product samples or arrange factory visits to inspect manufacturing processes. Engage in quality assurance checks, including third-party inspections, to assess the vehicle’s components and performance metrics before finalizing the purchase. -

What is the best way to verify a supplier’s credibility for electric vehicles?

Verifying a supplier’s credibility involves multiple steps. Start by checking their company registration, certifications, and industry reputation through online reviews and testimonials. Use platforms like Alibaba or Global Sources, which provide buyer feedback. Conduct direct communication to assess responsiveness and professionalism. Furthermore, consider requesting references from previous clients, especially those from your region, to gain insights into their experience with the supplier. -

What customization options are available for 4kW electric cars?

Customization options for 4kW electric cars can vary by manufacturer. Common modifications include color selection, interior features, battery capacity upgrades, and additional safety or tech features. Discuss your specific requirements with the supplier and inquire about the lead time for custom orders. Ensure that any customizations comply with local regulations in your market, as this can affect the vehicle’s certification and usability. -

What is the minimum order quantity (MOQ) for purchasing 4kW electric cars?

The minimum order quantity (MOQ) for 4kW electric cars typically depends on the manufacturer and the specific model. Many suppliers may have an MOQ ranging from 5 to 50 units, especially for international orders. Discuss your purchasing plans with potential suppliers to negotiate favorable terms. If your order is below the MOQ, consider group purchasing with other businesses to meet the requirement. -

What payment terms should I expect when sourcing 4kW electric cars?

Payment terms can vary widely among suppliers. Common arrangements include a 30% deposit upon order confirmation, followed by the balance due before shipment. Some suppliers may offer letter of credit options or installment payments for larger orders. Always clarify payment methods accepted (e.g., bank transfer, PayPal) and ensure that terms are documented in a formal agreement. This helps mitigate risks and ensures transparency in transactions. -

How can I manage logistics for importing 4kW electric cars?

Managing logistics for importing 4kW electric cars involves several key steps. First, research and select a reliable freight forwarder with experience in handling vehicle shipments. Consider shipping methods (e.g., containerized vs. roll-on/roll-off) based on cost and time efficiency. Ensure all necessary customs documentation is prepared in advance to avoid delays. Additionally, familiarize yourself with import regulations and tariffs in your country to ensure compliance and budget accordingly. -

What are the common challenges faced when sourcing electric vehicles internationally?

Common challenges when sourcing electric vehicles internationally include regulatory compliance, currency fluctuations, and shipping delays. Different countries have varying standards for vehicle emissions and safety, which can affect importability. Additionally, fluctuating exchange rates can impact overall costs. To mitigate these risks, conduct thorough market research and establish strong relationships with suppliers who understand your local market’s requirements. -

What are the key features to look for in a 4kW electric car?

When evaluating a 4kW electric car, key features to consider include battery life, charging speed, range, and safety ratings. Look for vehicles equipped with advanced battery management systems for longevity and efficiency. Additionally, assess the car’s design and comfort, especially if intended for passenger use. Review warranty options and after-sales service offered by the supplier to ensure long-term support and maintenance for your investment.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 2 4Kw Electric Car Manufacturers & Suppliers List

1. KERID – 48V 4KW Mini 4 Seater Electric Car

Domain: electric-sightseeingcar.com

Registered: 2018 (7 years)

Introduction: {“Product Name”: “48V 4KW Mini 4 Seater Electric Car”, “Brand Name”: “KERID”, “Model Number”: “KRD-D4”, “Certification”: [“ISO9001”, “CE”], “Passenger Capacity”: 4, “Max Speed”: “30 km/h”, “Range (loaded)”: “80-100 km”, “Climbing Ability (loaded)”: “0.15-0.30”, “Braking Distance”: “≤4 m”, “Min Turning Radius”: “4 m”, “Min Clearance”: “135 mm”, “Recharge Time”: “8~10 h”, “Dimensions (L×W×H)”: “3300…

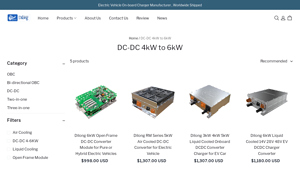

2. Dilong – 4KW to 6KW Electric Vehicle DC-DC Converter

Domain: powerdilong.com

Registered: 2021 (4 years)

Introduction: 4KW to 6KW Electric Vehicle DC-DC Converter

– Manufacturer: Dilong Charger

– Product Types:

– Open Frame DC-DC Converter Module for Pure or Hybrid Electric Vehicles

– Air Cooled DC-DC Converter for Electric Vehicle

– Liquid Cooled Onboard DCDC Converter Charger for EV Car

– Liquid Cooled 14V 28V 48V EV DCDC Charger Converter

– Air-cooled On-board HV to LV 14V 28V 48V DC DC Converter for…

Strategic Sourcing Conclusion and Outlook for 4kw electric car

As the electric vehicle market continues to evolve, the strategic sourcing of 4kW electric cars presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. These vehicles, with their low-speed capabilities and minimal licensing requirements, cater to diverse consumer needs, making them an appealing option for various applications, including urban commuting and last-mile delivery.

Understanding the nuances of sourcing, from raw material procurement to quality management, is crucial for establishing partnerships with reliable manufacturers. Buyers should prioritize suppliers that adhere to international standards and demonstrate a commitment to sustainability. This will not only enhance product quality but also align with global environmental goals.

Looking ahead, the demand for electric vehicles is poised to increase as governments implement stricter emissions regulations and consumers seek greener alternatives. To capitalize on this trend, B2B buyers are encouraged to engage in proactive sourcing strategies, leveraging data analytics to forecast market demands and optimize supply chain efficiencies. By investing in 4kW electric cars today, businesses can position themselves at the forefront of the automotive revolution, driving growth and innovation in their respective markets.