Introduction: Navigating the Global Market for 6×4 Tractor Truck Diesel Tractor Truck

The demand for 6×4 tractor trucks, particularly diesel models, is surging in diverse global markets, presenting a unique challenge for B2B buyers seeking reliable and efficient transportation solutions. Sourcing the right 6×4 tractor truck can significantly impact operational efficiency, logistics costs, and overall business performance. This comprehensive guide is designed to address the complexities of the global market, providing valuable insights into various types of 6×4 tractor trucks, their applications, and critical factors to consider when making purchasing decisions.

Within this guide, international buyers from regions such as Africa, South America, the Middle East, and Europe will find essential information on supplier vetting processes, cost considerations, and the latest technological advancements in tractor truck models. We will explore the nuances of different brands, specifications, and maintenance requirements, empowering buyers to navigate the marketplace confidently.

By leveraging this guide, businesses can make informed choices that align with their operational needs, ensuring they select the best 6×4 tractor truck for their specific applications. From understanding emission standards to assessing fuel efficiency and horsepower, this resource aims to equip B2B buyers with the knowledge necessary to optimize their fleet and achieve sustainable growth.

Understanding 6×4 Tractor Truck Diesel Tractor Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Truck Tractors | High horsepower (up to 750 HP), robust build, air suspension | Long-haul freight, heavy cargo transport | Pros: Powerful, durable, suited for heavy loads. Cons: Higher fuel consumption, initial cost. |

| Medium-Duty Truck Tractors | Moderate horsepower (270-550 HP), versatile configurations | Regional distribution, construction | Pros: Balanced power and efficiency, versatile. Cons: Limited heavy-load capability compared to heavy-duty. |

| Off-Road Truck Tractors | Enhanced traction, reinforced chassis, specialized tires | Mining, agriculture, rough terrain transport | Pros: Superior off-road performance, durable. Cons: Can be more expensive, limited on-road efficiency. |

| Eco-Friendly Diesel Tractors | Advanced emission controls, hybrid options | Urban logistics, environmentally conscious transport | Pros: Lower emissions, fuel-efficient. Cons: Higher upfront costs, technology learning curve. |

| Multi-Purpose Truck Tractors | Configurable for various attachments, diverse engine options | Versatile applications in logistics, agriculture | Pros: Adaptability, cost-effective for varied uses. Cons: May lack specialization in a single area. |

What Are the Characteristics of Heavy-Duty Truck Tractors?

Heavy-duty truck tractors are designed to handle the most demanding transport tasks, featuring engines that can deliver up to 750 HP. Their robust construction and air suspension systems provide stability and comfort over long distances. These trucks are particularly suited for long-haul freight and heavy cargo transport, making them ideal for businesses in industries such as logistics and construction. However, they typically come with higher fuel consumption rates and initial costs, which are crucial considerations for budget-conscious buyers.

Why Choose Medium-Duty Truck Tractors for Regional Distribution?

Medium-duty truck tractors strike a balance between power and efficiency, with horsepower ranging from 270 to 550 HP. They are versatile enough to serve in regional distribution and construction applications, where moderate loads are common. Their adaptability makes them a popular choice among businesses looking to optimize their fleet for various tasks. However, while they provide good fuel economy, their capacity may not meet the demands of heavy-load transport, which is a consideration for potential buyers.

What Features Make Off-Road Truck Tractors Stand Out?

Off-road truck tractors are built for rugged terrains, featuring enhanced traction and reinforced chassis designs. These trucks are essential in sectors like mining and agriculture, where they can navigate challenging environments effectively. Their durability and specialized tires make them a reliable choice for transporting goods in rough conditions. However, they often come at a premium price and may not perform as efficiently on paved roads, which buyers should keep in mind.

How Do Eco-Friendly Diesel Tractors Benefit Businesses?

Eco-friendly diesel tractors incorporate advanced emission control technologies and may include hybrid options, making them suitable for urban logistics. As businesses increasingly prioritize sustainability, these tractors offer a way to reduce environmental impact while maintaining operational efficiency. While they provide lower emissions and better fuel efficiency, the initial investment can be higher, and companies may face a learning curve in adapting to new technologies.

What Are the Advantages of Multi-Purpose Truck Tractors?

Multi-purpose truck tractors are designed for versatility, allowing businesses to configure them for various attachments and applications. This adaptability makes them ideal for a range of industries, from logistics to agriculture. Their diverse engine options help cater to different operational needs, providing a cost-effective solution for companies with varied transport requirements. However, the lack of specialization may mean that they do not excel in any single area, which could be a drawback for some buyers.

Key Industrial Applications of 6×4 Tractor Truck Diesel Tractor Truck

| Industry/Sector | Specific Application of 6×4 Tractor Truck Diesel Tractor Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Long-haul freight transport | Efficient transportation of goods over long distances | Reliability of the truck, fuel efficiency, and payload capacity |

| Construction | Heavy equipment towing and site transport | Facilitates movement of construction materials and machinery | Durability, power, and compatibility with various trailers |

| Agriculture | Transporting agricultural products and machinery | Streamlines the supply chain for agricultural goods | Terrain adaptability, load capacity, and engine power |

| Mining | Hauling materials and equipment in mining operations | Enhances productivity by moving heavy loads efficiently | Robust design, fuel consumption, and maintenance support |

| Oil and Gas | Transporting drilling equipment and supplies | Ensures timely delivery of critical equipment | Compliance with safety standards, engine performance, and reliability |

How is the 6×4 Tractor Truck Diesel Tractor Truck Used in Logistics and Transportation?

In the logistics and transportation industry, the 6×4 tractor truck is primarily utilized for long-haul freight transport. These trucks are designed to handle substantial loads, making them ideal for delivering goods across vast distances. They solve the problem of inefficiency and high operational costs associated with smaller vehicles. International buyers, especially in regions like Africa and South America, should consider sourcing trucks with high fuel efficiency and robust payload capacities to optimize their logistics operations.

What Role Does the 6×4 Tractor Truck Play in Construction?

In construction, 6×4 tractor trucks are essential for towing heavy equipment and transporting materials to and from job sites. Their powerful engines and durable designs enable them to navigate rough terrains often found on construction sites. By utilizing these trucks, construction companies can enhance their operational efficiency and reduce downtime. Buyers in this sector should focus on the truck’s durability, power, and compatibility with various trailers to ensure smooth operations.

How is the 6×4 Tractor Truck Beneficial for Agriculture?

The agricultural sector leverages 6×4 tractor trucks to transport products and machinery, facilitating a streamlined supply chain. These trucks help in moving harvested crops and heavy farming equipment, addressing challenges related to logistics in rural areas. Buyers need to consider the truck’s adaptability to different terrains and its load capacity, particularly in regions with varying road conditions, such as rural Africa or South America.

What Applications Does the 6×4 Tractor Truck Have in Mining?

In mining operations, 6×4 tractor trucks are crucial for hauling materials and equipment. Their robust construction allows them to transport heavy loads efficiently, significantly enhancing productivity. Companies in the mining sector must prioritize sourcing trucks with reliable fuel consumption and strong performance to minimize operational disruptions and ensure compliance with safety regulations.

How is the 6×4 Tractor Truck Used in the Oil and Gas Industry?

The oil and gas industry uses 6×4 tractor trucks for transporting drilling equipment and supplies to remote locations. These trucks play a vital role in ensuring that critical equipment arrives on time, which is essential for maintaining project timelines. Buyers in this sector should focus on trucks that meet safety standards and offer high engine performance to navigate challenging environments while ensuring reliability in operations.

3 Common User Pain Points for ‘6×4 Tractor Truck Diesel Tractor Truck’ & Their Solutions

Scenario 1: Overcoming Fuel Efficiency Concerns in 6×4 Tractor Trucks

The Problem: B2B buyers, particularly in regions like Africa and South America, often face the challenge of high fuel costs, which can significantly impact their bottom line. Diesel prices fluctuate, and when operating heavy machinery like 6×4 tractor trucks, inefficiencies in fuel consumption can lead to substantial financial losses. Buyers may also struggle to find models that optimize fuel efficiency while meeting their transportation needs, especially in rugged terrains common in these regions.

The Solution: To mitigate fuel efficiency concerns, buyers should prioritize sourcing 6×4 tractor trucks that feature advanced fuel management systems. Look for models equipped with intelligent fuel-saving technologies, such as those from CAMC or Volvo, which have been designed to optimize fuel consumption through better engine performance and adaptive driving modes. Additionally, consider investing in regular maintenance services that ensure the vehicle operates at peak efficiency, including checking tire pressure, ensuring proper engine tuning, and replacing air filters. Educating drivers on efficient driving techniques—such as maintaining steady speeds and minimizing idling—can also contribute to improved fuel economy.

Scenario 2: Navigating Maintenance and Downtime Challenges

The Problem: B2B buyers are often concerned about the reliability of 6×4 tractor trucks and the potential for unexpected breakdowns, which can lead to costly downtime. In industries reliant on timely deliveries, such as logistics and construction, any delay can result in lost contracts and diminished customer trust. Buyers may find it challenging to identify the right suppliers who provide not only the trucks but also reliable parts and service support.

The Solution: To address maintenance and downtime issues, buyers should opt for reputable manufacturers known for the durability and reliability of their 6×4 tractor trucks, such as Mercedes-Benz or Scania. When selecting a truck, inquire about the availability of spare parts and after-sales service in your region. Establishing a partnership with a local dealer who can provide prompt service and access to quality replacement parts is crucial. Implementing a proactive maintenance schedule, including regular inspections and servicing, will further reduce the risk of unexpected breakdowns. Consider utilizing telematics systems to monitor vehicle performance and maintenance needs in real-time, allowing for timely interventions before minor issues escalate into major problems.

Scenario 3: Ensuring Compliance with Emission Standards

The Problem: As global regulations around emissions tighten, B2B buyers face the challenge of ensuring that their 6×4 tractor trucks comply with the latest environmental standards, particularly in Europe and parts of the Middle East. Non-compliance can lead to hefty fines and restrictions on operational capabilities, making it essential for buyers to stay informed about the specific emission regulations in their operating regions.

The Solution: Buyers should prioritize sourcing 6×4 tractor trucks that meet or exceed the latest emission standards, such as Euro 6, which is increasingly becoming the benchmark in many markets. When evaluating options, buyers should not only consider the upfront cost but also the long-term savings associated with compliance, including lower fuel taxes and fewer penalties. Engaging with manufacturers that provide transparent information about their vehicles’ emissions profiles, like DAF and MAN, will help ensure compliance. Additionally, buyers can leverage government incentives for low-emission vehicles, which can offset some of the initial investment costs. Staying updated on local regulations and establishing a relationship with regulatory bodies will also aid in maintaining compliance and avoiding potential disruptions to business operations.

Strategic Material Selection Guide for 6×4 Tractor Truck Diesel Tractor Truck

What Are the Common Materials Used in 6×4 Tractor Truck Diesel Tractor Truck Manufacturing?

When selecting materials for 6×4 tractor trucks, several factors influence performance, durability, and cost. This guide analyzes four common materials used in their construction: steel, aluminum, composites, and rubber. Each material has distinct properties, advantages, and disadvantages that can significantly impact the operational efficiency of these vehicles.

How Does Steel Perform in 6×4 Tractor Truck Applications?

Steel is the most widely used material in the manufacturing of truck chassis and structural components due to its exceptional strength and durability. It typically exhibits high temperature and pressure ratings, making it suitable for heavy-duty applications. Steel’s corrosion resistance can be enhanced through galvanization or coatings, which is essential for trucks operating in diverse climates.

Pros: Steel offers superior strength and impact resistance, making it ideal for heavy loads and rugged terrains. It is also relatively cost-effective and widely available.

Cons: The main drawback is its weight, which can affect fuel efficiency. Additionally, untreated steel is prone to corrosion, necessitating additional treatment processes.

Impact on Application: Steel is compatible with various media, including diesel fuel and hydraulic fluids, making it a reliable choice for truck components.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for structural integrity. In regions like Africa and South America, where road conditions can be challenging, the durability of steel is a significant advantage.

What Role Does Aluminum Play in 6×4 Tractor Truck Design?

Aluminum is increasingly used in truck manufacturing due to its lightweight properties and resistance to corrosion. This material is particularly beneficial for components like body panels and fuel tanks, where weight savings can lead to improved fuel efficiency.

Pros: The primary advantage of aluminum is its lightweight nature, which contributes to better fuel economy and payload capacity. It also has excellent corrosion resistance, reducing maintenance costs over time.

Cons: Aluminum is generally more expensive than steel and can be less durable under extreme stress conditions. Its manufacturing processes can also be more complex, requiring specialized techniques.

Impact on Application: Aluminum’s compatibility with various fuels and fluids makes it suitable for truck applications, but care must be taken to avoid galvanic corrosion when used with steel components.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer aluminum for its lightweight benefits, but must consider the higher initial costs. Compliance with standards like JIS for aluminum alloys is also essential.

How Are Composites Changing the Landscape for 6×4 Tractor Trucks?

Composite materials, such as fiberglass and carbon fiber, are gaining traction in the truck industry for their high strength-to-weight ratios. These materials are often used in non-structural components, including interior fittings and aerodynamic enhancements.

Pros: Composites offer significant weight savings and can be engineered for specific performance characteristics, such as impact resistance and thermal stability.

Cons: The primary limitation is the cost, as composites are generally more expensive than traditional materials. Additionally, their manufacturing processes can be complex and time-consuming.

Impact on Application: Composites are compatible with various environmental conditions, but their use is often limited to specific applications where weight savings are critical.

Considerations for International Buyers: Buyers should evaluate the cost-benefit ratio of composites, especially in emerging markets where budget constraints are significant. Compliance with local standards for composites is also crucial.

What Is the Importance of Rubber in 6×4 Tractor Truck Components?

Rubber is essential for various truck components, particularly tires, seals, and suspension parts. Its flexibility and resilience make it ideal for applications where shock absorption and traction are required.

Pros: Rubber provides excellent shock absorption, enhancing ride quality and vehicle stability. It is also widely available and can be produced in various formulations to meet specific performance needs.

Cons: Rubber can degrade over time due to exposure to UV light and ozone, necessitating regular maintenance and replacement.

Impact on Application: Rubber is compatible with diesel fuel and hydraulic fluids, making it suitable for seals and gaskets in diesel engines.

Considerations for International Buyers: Buyers should consider the climate when selecting rubber components, as extreme temperatures can affect performance. Compliance with international tire standards is also critical for safety.

Summary Table of Material Selection for 6×4 Tractor Trucks

| Material | Typical Use Case for 6×4 Tractor Truck Diesel Tractor Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis, structural components | High strength and durability | Heavy weight, corrosion potential | Medium |

| Aluminum | Body panels, fuel tanks | Lightweight, corrosion-resistant | Higher cost, lower stress durability | High |

| Composites | Interior fittings, aerodynamic components | High strength-to-weight ratio | Expensive, complex manufacturing | High |

| Rubber | Tires, seals, suspension parts | Excellent shock absorption | Degradation over time | Medium |

This strategic material selection guide provides essential insights for international B2B buyers looking to optimize their procurement strategies for 6×4 tractor trucks. Understanding the properties and implications of each material can lead to better decision-making and enhanced operational efficiency.

In-depth Look: Manufacturing Processes and Quality Assurance for 6×4 Tractor Truck Diesel Tractor Truck

What are the Main Manufacturing Processes for 6×4 Tractor Truck Diesel Trucks?

The manufacturing of 6×4 tractor trucks involves a series of meticulously planned processes designed to ensure performance, durability, and reliability. These processes can be broadly categorized into material preparation, forming, assembly, and finishing.

How is Material Prepared for 6×4 Tractor Trucks?

Material preparation is the foundational stage in the manufacturing process. High-quality raw materials, such as steel, aluminum, and composite materials, are sourced according to specific standards. Suppliers typically provide certifications that validate the quality of these materials. Advanced software systems are often utilized to ensure precise material requirements are calculated based on design specifications.

Once materials are procured, they undergo initial quality checks (Incoming Quality Control, or IQC) to verify that they meet industry standards and specifications. This step is crucial for preventing defects early in the production process.

What Forming Techniques are Used in Manufacturing?

The forming stage involves transforming raw materials into usable components through techniques such as stamping, casting, and machining. For example, the chassis and body panels of the tractor truck are typically stamped from high-strength steel sheets, while engine components may be cast from aluminum alloys to reduce weight.

Modern manufacturers often employ Computer Numerical Control (CNC) machining for precision parts. This technology allows for high levels of accuracy and repeatability, ensuring that components fit together seamlessly during assembly.

How are Components Assembled in 6×4 Tractor Trucks?

The assembly process is where individual components come together to create the final product. This stage is usually divided into sub-assembly lines focusing on specific parts, such as the engine, transmission, and chassis. Skilled workers and automated systems work in tandem to ensure that each component is fitted correctly and securely.

During assembly, critical checkpoints are established (In-Process Quality Control, or IPQC) to monitor the quality of work at various stages. These checkpoints may involve visual inspections, functional tests, or the use of specialized tools to ensure that components meet specified tolerances.

What Finishing Processes Enhance the Quality of 6×4 Tractor Trucks?

Finishing processes include surface treatment, painting, and final inspections. Surface treatments, such as galvanizing or powder coating, are applied to enhance corrosion resistance and aesthetics. The painting process is often completed in controlled environments to ensure a flawless finish.

Final inspections (Final Quality Control, or FQC) are conducted to ensure that the finished product meets all specifications. This includes checking functionality, safety features, and aesthetic quality. Any discrepancies identified during this phase can lead to rework or rejection of the unit.

What International Quality Standards Should B2B Buyers Consider?

For international B2B buyers, understanding the quality assurance processes in manufacturing is crucial. Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. This certification indicates that the manufacturer has implemented effective processes to ensure quality across all stages of production.

In addition to ISO certifications, industry-specific standards such as the European CE marking and API (American Petroleum Institute) standards for engines may also be relevant. These certifications assure buyers that the products comply with safety, health, and environmental regulations.

How are Quality Control Checkpoints Implemented?

Quality control checkpoints are integral to ensuring that the manufacturing process meets established standards. The checkpoints typically include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival.

- In-Process Quality Control (IPQC): Monitoring production at various stages to catch defects early.

- Final Quality Control (FQC): Conducting thorough inspections of the finished product before shipment.

Common testing methods include dimensional inspections, functional tests, and performance evaluations. Advanced technology, such as automated inspection systems, may be employed to enhance accuracy and efficiency.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international buyers, verifying the quality assurance processes of suppliers is essential. There are several methods to ensure that suppliers maintain high-quality standards:

-

Supplier Audits: Conducting audits of potential suppliers can provide firsthand insight into their manufacturing processes and quality control measures. This may include examining production facilities, quality management systems, and employee training programs.

-

Requesting Quality Reports: Suppliers should provide detailed reports that outline their quality control processes, certifications, and any non-conformance incidents. This transparency is critical for building trust.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s manufacturing and quality control processes. These agencies can conduct inspections at various stages of production, ensuring adherence to specified standards.

What Are the Specific Quality Assurance Nuances for Different Regions?

When dealing with suppliers from different regions, such as Africa, South America, the Middle East, and Europe, buyers should be aware of specific quality assurance nuances. For instance, the regulatory environment and quality standards may vary significantly across these regions.

In Africa and South America, local regulations may not always align with international standards, making it crucial for buyers to conduct thorough due diligence on suppliers. In contrast, European suppliers often have stringent quality standards and certifications that are recognized globally. Understanding these regional differences can help buyers make informed decisions and mitigate risks associated with quality issues.

Conclusion

The manufacturing processes and quality assurance practices for 6×4 tractor trucks play a vital role in ensuring that these vehicles meet the demands of international markets. By understanding the key stages of manufacturing, relevant quality standards, and methods for verifying supplier capabilities, B2B buyers can make informed choices that align with their operational needs and expectations. This knowledge not only enhances the buyer’s confidence but also contributes to building long-term partnerships with reliable suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘6×4 Tractor Truck Diesel Tractor Truck’

When sourcing a 6×4 Diesel Tractor Truck, it’s vital to navigate the complexities of the procurement process with clarity and precision. This guide provides a structured checklist to help B2B buyers make informed decisions, ensuring they secure the right vehicle for their operational needs.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical specifications required for your operations. Consider factors such as horsepower (HP), axle configuration, load capacity, and fuel efficiency. This will help narrow down options and ensure that the trucks you consider meet your operational demands.

- Key Considerations:

- Minimum horsepower requirements based on your typical load.

- Desired fuel type (e.g., diesel) and its associated emissions standards (e.g., Euro 2-6).

- Specific features such as suspension type and transmission.

Step 2: Research Market Trends

Understanding current market trends is crucial for making informed purchasing decisions. Analyze pricing, availability, and popular models within the regions you’re targeting, such as Africa, South America, the Middle East, and Europe.

- Action Points:

- Utilize online marketplaces and industry reports to gauge average pricing.

- Identify reputable manufacturers and models that align with your specifications.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a strong reputation for reliability and quality.

- What to Look For:

- Certifications and compliance with international standards (ISO, CE).

- Availability of after-sales support and warranty options.

- Customer reviews and ratings on platforms like Autoline or local trade forums.

Step 4: Request Quotes and Compare Offers

Once you have a shortlist of potential suppliers, request detailed quotes. Ensure each quote includes comprehensive specifications, pricing, and terms of sale. This will allow for a straightforward comparison of what each supplier offers.

- Comparison Factors:

- Total cost of ownership, including maintenance and operational costs.

- Delivery timelines and logistics capabilities.

- Payment terms and financing options.

Step 5: Conduct a Site Visit (If Possible)

If feasible, visiting the supplier’s facility can provide invaluable insights into their operations. This step allows you to assess the quality of the manufacturing processes and the condition of their inventory.

- Site Visit Checklist:

- Inspect the production line and quality control measures.

- Meet with key personnel to discuss any specific concerns or requirements.

- Review the facility’s compliance with safety and environmental standards.

Step 6: Negotiate Terms and Finalize the Purchase

Once you’ve selected a supplier, engage in negotiations to finalize the purchase terms. Discuss price, delivery schedules, and any additional services such as training or maintenance.

- Negotiation Tips:

- Be clear about your requirements and expectations.

- Consider bulk purchasing discounts if you plan to buy multiple units.

- Ensure all agreements are documented in a contract.

Step 7: Plan for Delivery and Integration

After finalizing the purchase, develop a plan for delivery and integration of the new trucks into your fleet. This includes logistics for transportation and any necessary modifications to meet local regulations.

- Integration Considerations:

- Schedule training sessions for your drivers on the specific models.

- Ensure compliance with local licensing and registration requirements.

- Prepare for any necessary maintenance setup or service contracts.

Following this checklist will enhance your sourcing process, enabling you to select the right 6×4 Diesel Tractor Truck to meet your operational needs efficiently.

Comprehensive Cost and Pricing Analysis for 6×4 Tractor Truck Diesel Tractor Truck Sourcing

What Are the Key Cost Components in Sourcing 6×4 Tractor Trucks?

When considering the acquisition of 6×4 tractor trucks, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: This encompasses the raw materials used in manufacturing, such as steel, aluminum, and other components. High-quality materials typically lead to more durable vehicles, which can affect the initial cost and long-term maintenance expenses.

-

Labor: The cost of skilled labor for assembly, welding, and finishing processes is significant. Labor costs can vary by region, which is a crucial consideration for international buyers.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these overheads, influencing the final price.

-

Tooling: Investment in tooling is essential for producing high-quality parts. This cost can be amortized over production volume, impacting the unit price for lower volumes.

-

Quality Control (QC): Rigorous QC processes ensure that trucks meet safety and performance standards. Effective quality management can prevent costly recalls or repairs, thereby affecting the total cost of ownership.

-

Logistics: Transportation costs from the manufacturer to the buyer’s location can be substantial, especially for international shipments. Factors such as shipping mode, distance, and customs duties will influence these costs.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, brand reputation, and competition.

How Do Price Influencers Affect the Cost of 6×4 Tractor Trucks?

Several factors influence the pricing of 6×4 tractor trucks beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk often leads to price reductions. Buyers should assess their needs to determine the most cost-effective order size.

-

Specifications and Customization: Trucks with specialized features or custom specifications may incur higher costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials and Quality Certifications: Trucks built with premium materials or that comply with stringent quality standards (e.g., Euro 6 emission standards) typically command higher prices. However, these investments can lead to lower maintenance costs and better resale value.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with strong track records may charge more but can provide better service and support.

-

Incoterms: Understanding the terms of sale is crucial for international buyers. Incoterms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and import duties, which can significantly impact overall costs.

What Negotiation Tips Can Help Buyers Secure Better Pricing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to significant cost savings:

-

Research Market Prices: Understanding the average market prices for specific models helps in negotiating better deals. Utilize online platforms and trade shows to gather information.

-

Leverage Volume Orders: When possible, place larger orders to negotiate discounts. Suppliers are often willing to lower prices for bulk purchases.

-

Request Multiple Quotes: Obtaining quotes from different suppliers provides leverage in negotiations. This allows buyers to compare pricing and service offerings.

-

Focus on Total Cost of Ownership (TCO): Highlight the long-term savings associated with quality trucks. A higher initial investment may result in lower maintenance and fuel costs over time.

-

Be Flexible with Payment Terms: Offering to pay upfront or negotiating favorable payment terms can sometimes lead to better pricing.

What Should Buyers Keep in Mind Regarding Pricing Nuances?

International buyers must be aware of specific pricing nuances that can impact their purchase decisions:

-

Currency Fluctuations: Exchange rates can influence the final cost when dealing with foreign suppliers. Consider locking in rates or using forward contracts to mitigate risks.

-

Import Duties and Taxes: Ensure to account for additional costs such as tariffs, taxes, and customs fees when calculating the total cost of acquisition.

-

After-Sales Support and Warranty: Evaluate the after-sales support and warranty offered by suppliers. A robust warranty can save costs on repairs and replacements in the long run.

Disclaimer

The prices mentioned in various listings can fluctuate based on market conditions, regional availability, and specific buyer requirements. It is advisable for buyers to conduct thorough due diligence and consult with multiple sources to obtain the most accurate pricing information.

Alternatives Analysis: Comparing 6×4 Tractor Truck Diesel Tractor Truck With Other Solutions

Introduction to Alternatives for 6×4 Tractor Truck Diesel Solutions

In the competitive landscape of heavy-duty transportation, selecting the right truck is crucial for efficiency and cost-effectiveness. The 6×4 Tractor Truck Diesel is a popular choice due to its robust performance and reliability. However, buyers should consider viable alternatives that may better suit their specific operational needs. This analysis compares the 6×4 Tractor Truck Diesel with two alternative solutions: the 4×2 Tractor Truck and the Electric Truck. Each option has its unique strengths and weaknesses, which can influence a buyer’s decision.

Comparison Table

| Comparison Aspect | 6X4 Tractor Truck Diesel Tractor Truck | 4×2 Tractor Truck | Electric Truck |

|---|---|---|---|

| Performance | High torque and power, suitable for heavy loads | Moderate power, good for lighter loads | Instant torque, ideal for city driving |

| Cost | Higher initial investment; operational costs vary | Lower purchase price; moderate operational costs | High initial cost; low operational costs |

| Ease of Implementation | Requires specific training and maintenance | Easier to operate and maintain | Requires charging infrastructure and training |

| Maintenance | Regular maintenance needed; parts widely available | Lower maintenance frequency | Minimal maintenance; specialized service required |

| Best Use Case | Long-haul transportation and heavy-duty tasks | Regional transport and light hauling | Urban logistics and short-haul transport |

Detailed Breakdown of Alternatives

4×2 Tractor Truck

The 4×2 Tractor Truck presents a cost-effective alternative for businesses that do not require the heavy-duty capabilities of a 6×4 model. It is ideal for regional transport and light hauling, making it suitable for less demanding routes. The lower purchase price and moderate operational costs make it appealing for budget-conscious buyers. However, its performance may not suffice for heavy loads, limiting its utility in more rigorous applications. Maintenance is generally less frequent, which can reduce downtime and operational disruptions.

Electric Truck

Electric Trucks represent a growing trend in the transportation industry, particularly in urban settings where emissions regulations are stringent. These vehicles offer instant torque and are well-suited for city driving and short-haul transport. While they come with a high initial investment, operational costs are significantly lower due to reduced fuel expenses and minimal maintenance requirements. However, the need for charging infrastructure can pose challenges, especially in regions with limited access to electric charging stations. Buyers must also consider the training required for staff to operate and maintain these advanced vehicles.

Conclusion: How to Choose the Right Solution for Your Needs

Selecting the appropriate truck solution requires careful consideration of your operational requirements, budget, and future growth plans. The 6×4 Tractor Truck Diesel is an excellent choice for heavy-duty applications, while the 4×2 Tractor Truck offers a more economical option for lighter loads. On the other hand, Electric Trucks present an environmentally friendly alternative for urban logistics. Buyers should evaluate their specific use cases, including load capacity, route distances, and available maintenance support, to determine which solution aligns best with their business goals. By making an informed decision, B2B buyers can enhance their operational efficiency and ensure long-term success in their transportation endeavors.

Essential Technical Properties and Trade Terminology for 6×4 Tractor Truck Diesel Tractor Truck

What Are the Key Technical Properties of a 6×4 Tractor Truck Diesel Tractor Truck?

When considering the acquisition of a 6×4 tractor truck, it’s crucial to understand its technical specifications. These properties impact performance, fuel efficiency, and overall operational cost, which are vital for B2B buyers making investment decisions.

1. Horsepower (HP)

Horsepower indicates the engine’s power output, which affects the truck’s ability to haul heavy loads. Typical ratings for 6×4 tractor trucks range from 270 to 750 HP. Higher horsepower allows for better performance on challenging terrains and during heavy-duty applications, making it a critical factor for logistics companies operating in diverse environments.

2. Axle Configuration

The “6×4” designation refers to the axle configuration, meaning six wheels with four powered by the engine. This setup enhances traction and load distribution, which is particularly important for transporting heavy freight. Understanding axle configuration helps buyers match the truck’s capabilities with their operational needs, especially when considering road conditions in different regions.

3. Emission Standards

Emission standards, such as Euro 2 to Euro 6, dictate the allowable limits of exhaust emissions. Compliance with these standards is not only essential for regulatory reasons but also impacts fuel efficiency and operational costs. Buyers should prioritize trucks that meet higher emission standards to ensure sustainability and compliance in their respective markets.

4. Suspension Type

Suspension systems, such as spring/spring or air/air, directly influence ride comfort and load stability. Air suspension systems offer better shock absorption, which is advantageous for long-distance hauls on uneven surfaces. The choice of suspension affects maintenance costs and the overall longevity of the vehicle, making it a key consideration for fleet operators.

5. Fuel Tank Capacity

Fuel tank capacity typically ranges from 400 to 500 liters. A larger capacity allows for longer distances between refueling, which is crucial for maximizing operational efficiency. For companies operating in regions with limited fuel stations, investing in vehicles with substantial fuel tank capacities can lead to significant cost savings and improved productivity.

What Are Common Trade Terms Related to 6×4 Tractor Trucks?

Understanding trade terminology is essential for smooth transactions and clear communication between buyers and manufacturers or suppliers.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of tractor trucks, OEM parts are often preferred for their guaranteed compatibility and quality, providing peace of mind for fleet managers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to ensure they meet the supplier’s requirements while also managing inventory effectively. This term is particularly relevant for B2B buyers looking to procure multiple units for fleet expansion.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. This process allows buyers to compare costs and terms from various suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for international transactions, as they clarify who bears the risk and costs at different stages of the shipping process.

5. TCO (Total Cost of Ownership)

TCO encompasses all costs associated with acquiring and operating a vehicle over its lifespan, including purchase price, maintenance, fuel, and insurance. Buyers should conduct a TCO analysis to understand the long-term financial implications of their investment in 6×4 tractor trucks.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and financial goals, ultimately enhancing their logistics and transportation capabilities.

Navigating Market Dynamics and Sourcing Trends in the 6×4 Tractor Truck Diesel Tractor Truck Sector

What Are the Current Market Dynamics and Key Trends in the 6×4 Tractor Truck Diesel Sector?

The 6×4 tractor truck diesel market is experiencing significant growth driven by the increasing demand for efficient logistics and transportation solutions across various regions, particularly in Africa, South America, the Middle East, and Europe. As economies in these areas expand, the need for robust freight capabilities becomes crucial. Key trends include the integration of advanced technologies such as telematics and fleet management software, which enhance operational efficiency and reduce costs. Buyers are increasingly looking for trucks that offer not only power and reliability but also connectivity features that enable real-time monitoring and data analysis.

Another emerging trend is the shift towards more fuel-efficient and environmentally friendly models. With rising fuel prices and stringent emission regulations, buyers are prioritizing vehicles that comply with Euro 6 standards or equivalent, which offer improved fuel economy and lower emissions. Additionally, manufacturers are investing in the development of hybrid and electric variants of 6×4 trucks, catering to a growing market segment that values sustainability.

International B2B buyers must also navigate a complex supply chain landscape marked by fluctuating material costs and supply disruptions. Diversifying sourcing strategies and establishing partnerships with reliable suppliers can mitigate risks and enhance procurement efficiency. Furthermore, understanding local market conditions, including regulatory frameworks and consumer preferences, is vital for making informed purchasing decisions.

How Is Sustainability and Ethical Sourcing Shaping the 6×4 Tractor Truck Sector?

Sustainability has become a focal point in the procurement strategies of B2B buyers in the 6×4 tractor truck diesel sector. The environmental impact of diesel vehicles is under scrutiny, prompting manufacturers to adopt more sustainable practices. This includes the use of recycled materials in truck production and the implementation of efficient waste management systems within manufacturing facilities.

Ethical sourcing is equally important. Buyers are increasingly seeking suppliers that adhere to ethical labor practices and environmental standards. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability. Moreover, as consumers become more environmentally conscious, companies that prioritize sustainable practices can enhance their brand reputation and customer loyalty.

Incorporating green technologies, such as advanced fuel management systems and energy-efficient engines, is also gaining traction. These innovations not only reduce the carbon footprint of 6×4 trucks but also lead to significant cost savings in fuel and maintenance. Buyers should consider the long-term benefits of investing in sustainable technologies, as they contribute to operational efficiency and compliance with future regulations.

What Is the Evolution and Historical Context of the 6×4 Tractor Truck Diesel Sector?

The 6×4 tractor truck has a rich history dating back to the early 20th century, evolving from basic vehicles into sophisticated machines integral to the modern logistics ecosystem. Initially designed for heavy-duty applications, advancements in engineering and technology have transformed these trucks into versatile vehicles capable of handling diverse transportation needs.

In the post-World War II era, the global economy saw a surge in demand for efficient freight transport, leading to innovations in design, powertrain technology, and safety features. The introduction of diesel engines significantly improved fuel efficiency and reliability, establishing the diesel 6×4 tractor truck as a preferred choice for long-haul transportation.

Today, the sector is characterized by continuous innovation, with manufacturers focusing on enhancing performance, fuel efficiency, and driver comfort. As the market shifts towards sustainability, the development of electric and hybrid models marks the next chapter in the evolution of the 6×4 tractor truck, aligning with the growing emphasis on reducing environmental impact while meeting the demands of modern logistics.

Frequently Asked Questions (FAQs) for B2B Buyers of 6×4 Tractor Truck Diesel Tractor Truck

-

1. How do I choose the right 6×4 tractor truck for my business needs?

When selecting a 6×4 tractor truck, consider factors such as payload capacity, engine power, fuel efficiency, and compliance with local emission standards. Additionally, evaluate the terrain and distance of your typical routes; trucks with robust engines and higher torque are suitable for hilly or rugged areas. Analyze the total cost of ownership, including maintenance and fuel costs, to ensure it aligns with your budget. Lastly, consider any specific features that may enhance driver comfort and safety, such as advanced suspension systems and ergonomic cab designs. -

2. What are the common financing options available for purchasing 6×4 tractor trucks?

B2B buyers typically have several financing options, including bank loans, leasing agreements, and vendor financing. Bank loans can provide competitive interest rates, while leasing may lower upfront costs and allow for easier upgrades. Vendor financing, offered directly by manufacturers or dealers, can include flexible payment terms and may not require a large down payment. It’s crucial to assess the total cost of each option, including interest rates and fees, to determine which financing method best suits your cash flow and investment strategy. -

3. How can I verify the credibility of a supplier when sourcing 6×4 tractor trucks?

To verify a supplier’s credibility, conduct thorough due diligence that includes checking their business licenses, certifications, and customer reviews. Request references from previous clients and seek testimonials about their experiences. It’s also advisable to visit the supplier’s facilities, if possible, to assess their production capabilities and quality control processes. Additionally, use platforms like Alibaba or Global Sources to check their ratings and feedback from other buyers. Engaging a third-party inspection service can provide an unbiased evaluation of the supplier’s products before finalizing a purchase. -

4. What customization options are typically available for 6×4 tractor trucks?

Most manufacturers offer a range of customization options for 6×4 tractor trucks, including engine upgrades, transmission choices, and cab configurations. You can often select features such as fuel-efficient engines, advanced safety systems, and enhanced suspension for specific driving conditions. Custom paint jobs and branding can also be arranged. It’s essential to discuss your specific requirements with the supplier to ensure that the modifications align with your operational needs and comply with local regulations. -

5. What is the minimum order quantity (MOQ) for 6×4 tractor trucks?

The minimum order quantity for 6×4 tractor trucks varies by supplier and can depend on factors such as production capacity and the specific model requested. Generally, suppliers might set an MOQ of one unit for custom orders, while bulk purchases could require a minimum of five to ten units. Always confirm the MOQ with your supplier before proceeding, as larger orders may lead to discounts or better financing terms. Negotiating the MOQ can also be beneficial, especially if you have a long-term purchasing plan. -

6. What payment terms should I expect when sourcing 6×4 tractor trucks internationally?

Payment terms for international purchases of 6×4 tractor trucks often include options such as letters of credit, advance payments, and installment plans. Letters of credit provide security for both parties, ensuring the seller gets paid upon meeting agreed conditions, while buyers can avoid full upfront payments. Some suppliers may offer flexible installment options, allowing you to spread payments over time. Always clarify payment terms in your contract, including currency, payment methods, and any potential penalties for late payments to avoid misunderstandings. -

7. How can I ensure quality assurance (QA) for my 6×4 tractor truck purchase?

To ensure quality assurance, work with suppliers who adhere to international quality standards such as ISO certification. Request to see their quality control processes, including inspections at different production stages. It’s also advisable to have a third-party inspection agency conduct a thorough check before shipment. Establish clear quality expectations in your purchase agreement, including warranty terms and conditions for returns or repairs. Regular communication with the supplier during the manufacturing process can help address any potential issues early on. -

8. What logistics considerations should I keep in mind when importing 6×4 tractor trucks?

When importing 6×4 tractor trucks, consider logistics aspects such as shipping methods, customs clearance, and delivery timelines. Choose between container shipping or roll-on/roll-off (RoRo) based on cost and convenience. Ensure that all shipping documents, including invoices and customs declarations, are accurate to avoid delays. Familiarize yourself with local import regulations and tariffs to anticipate additional costs. Partnering with a reliable freight forwarder can streamline the logistics process, ensuring timely and efficient delivery of your trucks to the desired location.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 6X4 Tractor Truck Diesel Tractor Truck Manufacturers & Suppliers List

1. Truck Tractor 6×4 – Used Trucks for Sale

Domain: autoline.com

Registered: 1997 (28 years)

Introduction: Truck tractor 6×4 for sale, used truck tractor 6×4. Various brands available including Astra, Beiben, DAF, Dongfeng, FAW, Fiat, Ford, Foton, Freightliner, Hyundai, IVECO, MAN, Mercedes-Benz, Peterbilt, Renault, Scania, Volvo, and more. Features include different axle configurations (6×4), engine power ranging from 371 HP to 750 HP, Euro emission standards from Euro 1 to Euro 6, and various fuel ty…

2. CAMC – 6X4 Tractor Truck

Domain: camcexport.com

Registered: 2021 (4 years)

Introduction: {“Product Name”:”CAMC 6X4 Tractor Truck”,”Condition”:”New”,”Steering”:”Right/left”,”Horsepower”:”270-550hp”,”Driving Form”:”6×4″,”Emission Standard”:”Euro 2″,”Market Segment”:”Express transportation”,”Fuel Type”:”Diesel”,”Overall Dimensions”:”6960*2495*3850mm”,”Engine Capacity”:”> 8L”,”Cylinders”:”6″,”Transmission Type”:”Manual”,”Gear Box Brand”:”CAMC”,”Maximum Torque (Nm)”:”2000-2500Nm”,”Forward …

3. FAW – JH6 6X4 Tractor Trailer Truck

Domain: mining-dumptruck.com

Registered: 2018 (7 years)

Introduction: {“Model”:”FAW JH6 6X4 Tractor Trailer Truck”,”Top Speed”:”115 km/h”,”Engine Type”:”Diesel, 6-cylinder inline, 4-stroke, water-cooled, turbocharged intercooler, direct injection”,”Displacement”:”12.52L”,”Horsepower”:”500 HP”,”Torque”:”2300 N·m”,”Maximum Torque Speed”:”1000-1400 rpm”,”Rated Speed”:”1800 rpm”,”Dimensions”:{“Length”:”6165 mm”,”Width”:”2495 mm”,”Height”:”3910 mm”},”Wheelbase”:”3400+135…

4. HOWO – 6X4 Tractor Truck

Domain: sunskytrailer.com

Registered: 2016 (9 years)

Introduction: {“Model”:”HOWO 6X4 Tractor Truck”,”Engine”:”336 HP Euro II Engine”,”Lead Time”:”30 working days”,”Product Origin”:”China”,”Brand”:”HOWO”,”Shipping Port”:”Any port in China”,”Payment Terms”:”T/T, L/C at sight”,”Price”:”$34500/unit”,”Market Price”:”$36500″,”Price Range”:”10-30/33500$”,”Color”:”White”,”Features”:[“Widely used in transportation and delivery of bulk cargo such as coal, mineral, iron po…

5. Sany – UAE 6×4 Diesel Heavy Tractor Truck

Domain: sanyglobal.com

Registered: 2015 (10 years)

Introduction: {“Model”:”UAE 6×4 Diesel Heavy Tractor Truck”,”Curb Weight”:”10.5 T”,”Gross Combination Weight”:”80-110 T”,”Wheel Base”:”3225+1400; 3300+1400 mm”,”Engine Power”:”517-525 HP”,”Engine Maximum Net Torque”:”2200-2550 Nm”,”Transmission”:”12-16 Forward gears, 2 Reverse gears”,”Emission Standard”:”Euro V”,”Fuel Type”:”Diesel”,”Fuel Tank Capacity”:”400-800 L”,”Front Axle Load”:”7.5-9.5 T”,”Rear Axle Load”…

6. ISUZU – 6×4 Truck Head

Domain: spv-vehicle.com

Registered: 2014 (11 years)

Introduction: {“Model”:”ISUZU 6×4 Truck Head”,”Engine Power”:”350 HP (257 KW)”,”Drive Type”:”6×4, left hand drive”,”Overall Dimensions”:”7100 * 2500 * 3100 mm”,”GVW/Kerb Weight”:”25,000 kg / 8,200 kg”,”Cab Capacity”:”3 persons allowed with 1 sleeper”,”Air Conditioner”:”Yes”,”Engine Brand”:”ISUZU”,”Fuel Type”:”Diesel”,”Displacement”:”9839 ml”,”Emission Standard”:”Euro IV”,”Transmission”:”9-speed forward, 1 rever…

7. IronPlanet – Truck Tractors & Semi Trucks

Domain: ironplanet.com

Registered: 1999 (26 years)

Introduction: Truck Tractors & Semi Trucks for Sale at IronPlanet. Truck Tractors, also known as semi-trucks and on-highway trucks, are available in various models including day cab and sleeper cab options. Top manufacturers include Freightliner, International, Kenworth, Peterbilt, and Volvo. Popular types include S/A Day Cab Truck Tractor, S/A Sleeper Truck Tractor, T/A Day Cab Truck Tractor, T/A Sleeper Truck…

8. Commercial Truck Trader – 6×4 Trucks for Sale

Domain: commercialtrucktrader.com

Registered: 2004 (21 years)

Introduction: 6×4 Trucks for Sale – Key Makes: FREIGHTLINER (6,542), INTERNATIONAL (2,478), KENWORTH (2,443), VOLVO (1,603), PETERBILT (1,359), MACK (907), WESTERN STAR (288), FORD (100). Truck Types Available: Conventional – Day Cab (7,540), Conventional – Sleeper Truck (6,203), Tractor (4,290), Dump Truck (486), Cab Chassis (464), Flatbed Truck (281), Reefer/Refrigerated Truck (167), Dry Van Trailer (156), Bo…

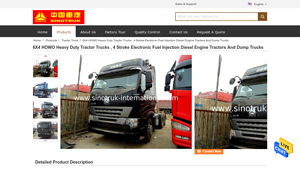

9. Sinotruk – 6X4 HOWO Heavy Duty Tractor Truck

Domain: sinotruk-international.com

Registered: 2015 (10 years)

Introduction: Product Name: 6X4 HOWO Heavy Duty Tractor Truck

Model: ZZ4257N3247N1B

Drive Type: LHD 6X4

Engine: D12.38, 380HP (Euro II), 6 cylinder in-line, water cooling, turbo-charging & inter-cooling, 4 stroke electronic fuel injection diesel engine

Displacement: 11.596L

Cabin: A7-P (with one sleeper, air-conditioner, and new-style seat)

Transmission: HW19712 (12 forwards & 2 reverses)

Front Axle: 1×HF9 (9 T…

Strategic Sourcing Conclusion and Outlook for 6×4 Tractor Truck Diesel Tractor Truck

In conclusion, the strategic sourcing of 6×4 diesel tractor trucks presents a multitude of opportunities for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. The diversity of models available—from high-powered Mercedes-Benz and Volvo trucks to cost-effective alternatives from Chinese manufacturers like CAMC—ensures that businesses can find solutions tailored to their operational needs and budget constraints.

Key takeaways include the importance of evaluating factors such as fuel efficiency, maintenance costs, and technological advancements in sourcing decisions. Buyers should prioritize suppliers that offer robust after-sales support and transparent pricing structures to enhance the value derived from their investments.

As the logistics and transportation sectors continue to evolve, staying ahead of market trends and embracing innovations will be crucial. By strategically sourcing 6×4 tractor trucks, businesses can enhance their operational efficiency and competitiveness. We encourage potential buyers to explore diverse sourcing options and leverage partnerships that align with their strategic goals, ensuring they are well-equipped for the challenges and opportunities ahead.