Introduction: Navigating the Global Market for enclosed electric tricycle

In an increasingly interconnected world, sourcing enclosed electric tricycles presents a unique challenge for international B2B buyers. As businesses strive for sustainable transportation solutions that combine utility and efficiency, the demand for these innovative vehicles is on the rise. Enclosed electric tricycles not only offer a cost-effective alternative to traditional vehicles but also cater to diverse applications—from urban commuting and delivery services to recreational use. This guide aims to provide a comprehensive overview of the market, exploring various types of enclosed electric tricycles, their applications, and essential factors to consider when vetting suppliers.

Understanding the nuances of this growing sector is critical for making informed purchasing decisions. From evaluating product specifications and performance metrics to analyzing cost structures and potential return on investment, this guide equips B2B buyers from Africa, South America, the Middle East, and Europe—specifically in regions like Germany and Brazil—with the knowledge needed to navigate the complexities of the market. By focusing on actionable insights and practical advice, this resource empowers businesses to identify reliable suppliers, compare offerings, and ultimately select the best enclosed electric tricycles to meet their operational needs.

Whether you are looking to enhance your fleet, reduce carbon emissions, or improve transportation efficiency, this guide serves as your roadmap in the evolving landscape of enclosed electric mobility.

Understanding enclosed electric tricycle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Micro Enclosed Trike | Compact size, motorcycle classification, low operational costs | Delivery services, personal utility | Pros: Affordable, low maintenance; Cons: Limited range compared to larger models. |

| Semi-Enclosed Velomobile | Lightweight design, pedal assist, weather protection | Urban commuting, eco-friendly transport | Pros: Compact, bike-lane friendly; Cons: Less protection than fully enclosed models. |

| Cargo Enclosed Trike | Enhanced cargo capacity, robust design, stability | Logistics, last-mile delivery | Pros: High payload capacity; Cons: Heavier, may require more space for parking. |

| Fully Enclosed Trike | Complete weather protection, enhanced safety features | Public transport, shared mobility | Pros: Maximum comfort and safety; Cons: Higher initial investment and maintenance costs. |

| Adaptive Mobility Trike | Customizable for disabled users, hand controls | Accessibility transportation | Pros: Inclusive design; Cons: May have longer lead times for customization. |

What are the Key Characteristics of Micro Enclosed Trikes?

Micro enclosed trikes, such as the ZEV T3-1, offer a compact footprint with motorcycle-like utility. Designed for maximum hauling ability, they can accommodate up to three adults while being street-legal in many regions. Their low operational costs make them ideal for delivery services and personal utility applications. B2B buyers should consider the affordability and low maintenance needs, alongside the limited range compared to larger models.

How Do Semi-Enclosed Velomobiles Stand Out?

Semi-enclosed velomobiles, like the Veemo, combine the efficiency of e-bikes with the comfort of a car. Their lightweight and compact design is perfect for urban commuting, allowing for easy navigation through traffic and bike lanes. The weather-resistant features provide additional comfort, making them suitable for year-round use. B2B buyers may find value in their eco-friendliness, though they may sacrifice some protection compared to fully enclosed options.

What Makes Cargo Enclosed Trikes Ideal for Logistics?

Cargo enclosed trikes are specifically designed to handle heavier loads, making them a robust solution for logistics and last-mile delivery. Their stability and enhanced cargo capacity set them apart in the market. B2B buyers should evaluate their need for higher payload capabilities against the increased weight and space requirements for parking. These trikes offer a practical solution for businesses focused on efficient urban logistics.

Why Choose a Fully Enclosed Trike for Public Transport?

Fully enclosed trikes provide complete weather protection and enhanced safety features, making them suitable for public transport or shared mobility solutions. Their design prioritizes passenger comfort, which can be a significant selling point for businesses in the transport sector. However, the higher initial investment and maintenance costs may deter some buyers. Those prioritizing safety and comfort will find these trikes worthwhile.

How Do Adaptive Mobility Trikes Cater to Diverse Needs?

Adaptive mobility trikes are designed to accommodate users with disabilities, featuring customizable options and hand controls for ease of use. This inclusivity makes them vital for accessibility-focused transportation solutions. B2B buyers should consider the potential for longer lead times due to customization needs but will benefit from the growing market demand for accessible transport options.

Key Industrial Applications of enclosed electric tricycle

| Industry/Sector | Specific Application of enclosed electric tricycle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Delivery and Logistics | Last-mile delivery solutions for e-commerce and local businesses | Cost-effective transportation with reduced carbon footprint | Battery life, payload capacity, and local regulations for vehicle use |

| Urban Mobility | Personal commuting in urban areas | Efficient navigation through traffic and reduced parking needs | Size, weight, and compliance with local traffic laws |

| Tourism and Recreation | Guided tours and leisure activities in tourist areas | Unique experience for tourists and reduced environmental impact | Comfort features, safety standards, and range for longer tours |

| Healthcare and Mobility | Patient transport and mobility assistance for healthcare facilities | Increased accessibility for patients and reduced operational costs | Customization options for disabled users and safety certifications |

| Agricultural Transport | Transporting goods and supplies within farms | Enhances efficiency in logistics and reduces reliance on fossil fuels | Terrain adaptability, payload capacity, and durability in rough conditions |

How Can Enclosed Electric Tricycles Enhance Last-Mile Delivery Solutions?

In the logistics sector, enclosed electric tricycles serve as an innovative solution for last-mile delivery, especially in urban environments. They provide a compact and agile alternative to traditional delivery vehicles, allowing businesses to navigate congested streets efficiently while minimizing their carbon footprint. With a payload capacity that can accommodate packages up to 225 kg, they can handle various delivery needs. For international buyers, understanding local regulations regarding vehicle use and ensuring sufficient battery life for operational demands are crucial factors when sourcing these vehicles.

What Benefits Do Enclosed Electric Tricycles Offer for Urban Commuting?

In urban mobility, enclosed electric tricycles are becoming popular for personal commuting. They offer a unique blend of safety and comfort, allowing users to bypass traffic while enjoying weather protection. Their compact design makes them ideal for navigating narrow streets and crowded city environments, addressing common issues like parking scarcity. When sourcing, buyers should consider the vehicle’s size, weight, and compliance with local traffic laws to ensure seamless integration into urban transport systems.

How Do Enclosed Electric Tricycles Enhance Tourism Experiences?

Tourism and recreation industries can leverage enclosed electric tricycles for guided tours and leisure activities. These vehicles provide a unique and eco-friendly way for tourists to explore destinations, enhancing their overall experience while promoting sustainability. The enclosed design offers comfort and protection from the elements, which is particularly appealing in varying weather conditions. Buyers in this sector should focus on comfort features, safety standards, and the vehicle’s range to ensure a satisfying experience for tourists.

In What Ways Can Healthcare Facilities Benefit from Enclosed Electric Tricycles?

Healthcare facilities can utilize enclosed electric tricycles for patient transport and mobility assistance, increasing accessibility for individuals with mobility challenges. These vehicles offer a cost-effective means of transporting patients within healthcare campuses or to nearby facilities. When sourcing, it’s essential to consider customization options for disabled users and ensure that the vehicles meet safety certifications to protect vulnerable populations.

How Are Enclosed Electric Tricycles Useful in Agricultural Transport?

In agriculture, enclosed electric tricycles can be employed to transport goods and supplies across farms, enhancing logistical efficiency. Their eco-friendly operation reduces reliance on fossil fuels, aligning with sustainable farming practices. Buyers should assess the vehicle’s adaptability to various terrains, payload capacity, and durability to withstand the rigors of agricultural environments, ensuring that they meet the specific demands of farm operations.

3 Common User Pain Points for ‘enclosed electric tricycle’ & Their Solutions

Scenario 1: Navigating Regulatory Challenges for Electric Tricycle Usage

The Problem: B2B buyers often face a maze of regulations when introducing enclosed electric tricycles into their fleets. Different countries and regions have varying laws regarding vehicle classifications, licensing requirements, and operational restrictions. For instance, some regions may classify these tricycles as motorcycles, requiring specific licenses or insurance, while others might treat them as bicycles, allowing for easier deployment. This inconsistency can lead to compliance issues, unexpected costs, and delays in getting vehicles on the road.

The Solution: To successfully navigate these regulatory hurdles, it is critical for buyers to conduct thorough research on local laws and regulations. Establishing relationships with local authorities and regulatory bodies can provide insights into current and upcoming changes in vehicle classification and usage laws. Additionally, sourcing enclosed electric tricycles that come with comprehensive documentation regarding their compliance can simplify the approval process. Buyers should also consider consulting with legal experts who specialize in transportation regulations in their target markets. This proactive approach not only ensures compliance but also aids in anticipating potential regulatory changes that could affect operations.

Scenario 2: Addressing Maintenance and Repair Concerns for Electric Tricycles

The Problem: One of the most significant pain points for B2B buyers is the concern about maintenance and repair of enclosed electric tricycles. Given that these vehicles often operate in diverse and sometimes harsh environments, the wear and tear can be significant. Buyers may worry about the availability of spare parts, the technical expertise required for repairs, and the costs associated with prolonged downtime if a vehicle needs maintenance.

The Solution: To mitigate these concerns, buyers should prioritize sourcing electric tricycles from manufacturers that offer robust after-sales support, including comprehensive warranties and readily available spare parts. Establishing a partnership with a reliable service provider or local dealership can facilitate quicker repairs and maintenance, minimizing downtime. Furthermore, investing in training for in-house maintenance staff can empower companies to handle minor repairs, ensuring that vehicles remain operational without significant service interruptions. Regularly scheduled maintenance checks can also preemptively address issues before they escalate, thus extending the lifespan of the tricycles and optimizing operational efficiency.

Scenario 3: Ensuring Battery Performance and Range Reliability

The Problem: Battery performance is a common concern for B2B buyers investing in enclosed electric tricycles. Many buyers fear that limited battery life and range could hinder operational efficiency, especially in regions where charging infrastructure is underdeveloped. Questions arise about how to ensure that the vehicles can handle daily operational demands without frequent recharging, which can disrupt service schedules and customer satisfaction.

The Solution: To enhance battery performance and reliability, buyers should evaluate the specifications of the electric tricycles, focusing on battery capacity and range capabilities. Opting for vehicles equipped with advanced battery technologies, such as lithium-ion or high-capacity variants, can provide longer operational ranges. Additionally, establishing partnerships with local charging station providers or investing in on-site charging solutions can alleviate concerns about range anxiety. Implementing a strategic charging schedule that aligns with operational needs can also optimize battery usage. Furthermore, educating drivers on best practices for battery care, such as avoiding complete discharges and charging during off-peak hours, can maximize battery lifespan and performance.

Strategic Material Selection Guide for enclosed electric tricycle

What Are the Key Materials Used in Enclosed Electric Tricycles?

When selecting materials for enclosed electric tricycles, manufacturers must consider various factors that impact performance, durability, and cost. Here, we analyze four common materials: steel, aluminum, composite materials, and plastics, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Steel Perform in Enclosed Electric Tricycles?

Steel is a traditional choice for the frame of electric tricycles due to its high strength and durability. It typically offers excellent tensile strength, making it capable of withstanding significant loads and impacts. Steel also has good corrosion resistance when treated with appropriate coatings.

Pros: Steel frames are robust and can be manufactured at a relatively low cost. They also provide excellent crash protection, which is crucial for safety in urban environments.

Cons: The weight of steel can be a disadvantage, affecting the overall efficiency and range of electric vehicles. Additionally, steel can be prone to rust if not properly coated, which may require ongoing maintenance.

Impact on Application: Steel is suitable for applications where structural integrity is paramount, particularly in regions with varying climates.

Considerations for B2B Buyers: Buyers in Africa and South America should ensure that the steel used meets local standards for corrosion resistance, particularly in humid or coastal areas. Compliance with international standards like ASTM can also enhance marketability.

What Are the Benefits of Using Aluminum in Electric Tricycles?

Aluminum is increasingly popular in the design of electric tricycles due to its lightweight nature and resistance to corrosion. It has a lower density than steel, which can significantly reduce the overall weight of the vehicle, enhancing efficiency and range.

Pros: The primary advantage of aluminum is its weight-saving properties, which can improve battery life and performance. Additionally, aluminum does not rust, making it ideal for various environmental conditions.

Cons: Aluminum can be more expensive than steel, and its manufacturing processes can be more complex, requiring specialized techniques such as welding or extrusion.

Impact on Application: Aluminum is particularly suitable for urban environments where weight and efficiency are critical.

Considerations for B2B Buyers: Buyers from Europe, especially Germany, may prefer aluminum due to its recyclability and compliance with stringent environmental regulations. Understanding local manufacturing capabilities and costs is essential for effective procurement.

How Do Composite Materials Enhance Electric Tricycle Design?

Composite materials, such as fiberglass and carbon fiber, are gaining traction in the electric vehicle market. These materials offer high strength-to-weight ratios and excellent corrosion resistance.

Pros: Composites can be molded into complex shapes, allowing for innovative designs. They are also lightweight, which can enhance vehicle performance and energy efficiency.

Cons: The primary drawback is the higher cost associated with composite materials, both in terms of raw materials and manufacturing processes. Additionally, they may require specialized knowledge for repairs.

Impact on Application: Composites are ideal for applications where weight savings and advanced design are priorities.

Considerations for B2B Buyers: Buyers in the Middle East should consider the availability of composite manufacturing facilities and the potential for higher initial investment costs. Compliance with international standards for safety and performance is also critical.

What Role Do Plastics Play in Enclosed Electric Tricycles?

Plastics, particularly engineering plastics, are often used for components such as body panels, dashboards, and interior fittings. They are lightweight, versatile, and can be produced in various colors and finishes.

Pros: Plastics are generally low-cost and can be manufactured quickly. They also provide good insulation and can be designed to be impact-resistant.

Cons: While plastics are resistant to corrosion, they may not offer the same level of structural integrity as metals. Additionally, certain plastics can degrade over time when exposed to UV light.

Impact on Application: Plastics are suitable for non-structural components where weight and cost savings are essential.

Considerations for B2B Buyers: Buyers from South America should assess the local availability of high-quality engineering plastics and ensure compliance with safety standards like ISO and ASTM.

Summary Table of Material Selection for Enclosed Electric Tricycles

| Material | Typical Use Case for enclosed electric tricycle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Heavier weight, prone to rust | Low |

| Aluminum | Frame and lightweight components | Lightweight and corrosion-resistant | Higher cost, complex manufacturing | Medium |

| Composite | Body panels and advanced structural elements | High strength-to-weight ratio | High cost, specialized repairs | High |

| Plastics | Interior fittings and non-structural components | Low-cost and versatile | May degrade over time, less strength | Low |

This strategic material selection guide provides essential insights for international B2B buyers, helping them make informed decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for enclosed electric tricycle

What Are the Main Stages of Manufacturing Enclosed Electric Tricycles?

The manufacturing process for enclosed electric tricycles involves several critical stages that ensure the final product meets safety, performance, and quality standards. Understanding these stages can help B2B buyers assess potential suppliers effectively.

Material Preparation: Which Materials Are Used and Why?

The first step in the manufacturing process is material preparation. Manufacturers typically use high-strength steel or aluminum for the frame to ensure durability while keeping the vehicle lightweight. Advanced composite materials may also be employed for body panels to provide weather resistance and reduce overall weight.

During this phase, materials undergo rigorous inspections to verify they meet specifications. This includes checking for any imperfections or inconsistencies that could affect the structural integrity of the tricycle.

Forming: How Are Components Shaped and Assembled?

The forming stage involves cutting, bending, and welding the raw materials to create the vehicle’s frame and body. Techniques such as CNC machining and laser cutting are commonly used for precision.

Welding, whether MIG or TIG, is critical for ensuring strong joints that can withstand stress and strain during operation. Manufacturers may use robotic welding systems to improve efficiency and consistency.

After the frame is formed, components such as the battery housing, electric motor mounts, and suspension systems are integrated into the structure. This stage is crucial for achieving the necessary balance and weight distribution for safe operation.

Assembly: What Steps Are Taken to Bring Everything Together?

Assembly is where all components come together to form the finished product. This process often involves multiple workstations, where specialized teams install electrical systems, brakes, and other mechanical parts.

Quality control checkpoints are integrated throughout the assembly line. For example, after the electrical systems are installed, a functional test is performed to ensure everything operates correctly.

Additionally, ergonomic considerations are taken into account during assembly to ensure comfort for users, especially in urban environments where these tricycles are often used.

Finishing: How Is the Final Product Prepared for Market?

The finishing stage includes painting, applying decals, and adding any optional features like storage compartments or upgraded seating. This is often where manufacturers also ensure that the vehicle meets aesthetic standards, as appearance can significantly impact marketability.

Final inspections are critical in this phase. They verify that the tricycle not only looks good but also meets all operational and safety standards before it is shipped to buyers.

What Are the Key Quality Assurance Practices for Enclosed Electric Tricycles?

Quality assurance (QA) is vital in the manufacturing of enclosed electric tricycles, ensuring that products are safe, reliable, and compliant with international standards. For B2B buyers, understanding these practices can aid in supplier selection.

Which International Standards Should B2B Buyers Consider?

Manufacturers of enclosed electric tricycles often adhere to various international standards, such as ISO 9001 for quality management systems. Compliance with this standard indicates that a manufacturer has a systematic approach to managing quality, which is crucial for ensuring consistent product quality.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) for the European market and UL (Underwriters Laboratories) for North America are essential. These certifications ensure that products meet safety and performance standards required in their respective markets.

What Are the Common Quality Control Checkpoints?

Quality control checkpoints throughout the manufacturing process include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards. Any defective materials are returned to suppliers.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checkpoints assess the quality of components and assemblies. This could include dimensional checks and functional tests of electrical systems.

-

Final Quality Control (FQC): Once assembly is complete, the entire vehicle undergoes a comprehensive inspection. This includes safety features, operational tests, and aesthetic evaluations.

What Testing Methods Are Commonly Employed?

Testing methods for enclosed electric tricycles can vary widely but typically include:

-

Performance Testing: Assessing the range, speed, and handling under different conditions to ensure the vehicle meets advertised specifications.

-

Safety Testing: Evaluating the effectiveness of safety features such as brakes, lights, and structural integrity through crash tests or simulations.

-

Durability Testing: Subjecting the vehicle to extreme conditions to ensure it can withstand environmental factors like rain, snow, and heat.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control practices is essential. This can be achieved through various methods:

-

Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing processes, quality control practices, and overall facility conditions. This can reveal much about the supplier’s commitment to quality.

-

Quality Reports: Requesting detailed quality reports from suppliers can provide insight into their performance metrics, including defect rates and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control processes. These inspectors can verify compliance with necessary standards and provide documentation for peace of mind.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating quality control nuances can be particularly challenging for international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe.

Understanding regional standards and regulations is crucial. For instance, products sold in Europe must comply with CE marking regulations, while North American products may need UL certification. Buyers should also be aware of local market demands and preferences, which can influence design and functionality.

Establishing a solid communication channel with suppliers can aid in addressing any quality concerns that arise during the production process. This includes setting clear expectations regarding quality standards and timelines.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for enclosed electric tricycles is essential for B2B buyers. By focusing on material preparation, forming, assembly, and finishing, alongside robust quality control measures, buyers can make informed decisions and choose reliable suppliers that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘enclosed electric tricycle’

The following guide serves as a comprehensive checklist for B2B buyers interested in procuring enclosed electric tricycles. This step-by-step process will help ensure you make informed decisions that align with your business needs and regional requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for identifying the right enclosed electric tricycle. Consider factors such as maximum payload capacity, range, and power output. For instance, if your operations require transporting goods or passengers over longer distances, prioritize models with higher range and payload capabilities.

Step 2: Research Regulatory Compliance

Understanding local regulations regarding electric vehicles is essential. Different regions may have varying laws regarding vehicle classifications, licensing, and safety standards. Ensure the tricycles you consider meet these regulations to avoid legal complications and ensure safe operation.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is vital to thoroughly vet potential suppliers. Request detailed company profiles, product specifications, and case studies from businesses in similar sectors. Look for suppliers with a proven track record in your region, as they are more likely to understand local market dynamics and compliance requirements.

- Check for Certifications: Ensure the supplier has relevant certifications such as CE, UL, or ISO, which indicate adherence to quality and safety standards.

Step 4: Analyze Product Features

Different models come with varying features that can significantly impact usability and maintenance costs. Assess features such as weather protection, safety enhancements (like disc brakes and seat belts), and ease of maintenance. For instance, models with lightweight construction may offer better maneuverability in urban settings.

Step 5: Request Demonstrations and Test Rides

Whenever possible, arrange for product demonstrations or test rides. This hands-on experience allows you to evaluate the vehicle’s performance, comfort, and suitability for your intended use. Pay attention to aspects such as driving ease, stability, and any unique features that might enhance the user experience.

Step 6: Consider After-Sales Support and Maintenance

Evaluate the after-sales support provided by the supplier, including warranty terms and availability of replacement parts. A robust support system can significantly reduce downtime and maintenance costs. Inquire about the supplier’s responsiveness to service requests and the availability of technical support.

Step 7: Review Financial Considerations

Finally, carefully analyze the total cost of ownership, including purchase price, maintenance, and operational costs. Compare financing options and potential subsidies available for electric vehicles in your region. Understanding these financial aspects will help you make a cost-effective decision that aligns with your budget.

By following this checklist, B2B buyers can confidently navigate the procurement process for enclosed electric tricycles, ensuring that they select a vehicle that meets their operational needs while complying with local regulations.

Comprehensive Cost and Pricing Analysis for enclosed electric tricycle Sourcing

What Are the Key Cost Components in Sourcing Enclosed Electric Tricycles?

When sourcing enclosed electric tricycles, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margins.

-

Materials: The choice of materials significantly impacts the cost. Lightweight yet durable materials such as aluminum and high-strength steel are commonly used, which can lead to higher upfront costs but lower operational costs due to enhanced efficiency and longevity. Battery technologies, such as lithium or silicate, also vary in price and lifespan, influencing the overall cost.

-

Labor: Labor costs can vary significantly based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can come at the expense of quality if not managed correctly. Skilled labor is essential for assembly, particularly for electric and mechanical systems, which may require higher wages.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient production processes and technology can help reduce overhead costs, thus lowering the final product price.

-

Tooling: The initial investment in tooling can be substantial, especially for custom designs or large production runs. Buyers should consider the tooling costs when negotiating pricing, as these expenses are often amortized over the production volume.

-

Quality Control (QC): Implementing stringent QC measures ensures product reliability and compliance with safety standards. While this adds to the cost, it can prevent expensive recalls or reputational damage, making it a worthwhile investment.

-

Logistics: Transporting tricycles from manufacturing sites to buyers involves shipping, customs, and handling fees. These costs vary by location and can significantly affect the total cost, particularly for international shipments.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s market positioning and the competitive landscape.

How Do Price Influencers Impact the Cost of Enclosed Electric Tricycles?

Several factors can influence pricing when sourcing enclosed electric tricycles:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQ) that align with their needs.

-

Specifications and Customization: Custom features, such as enhanced safety equipment or specific battery configurations, can increase costs. Buyers should be clear about their requirements to avoid unexpected expenses.

-

Materials: The choice of materials not only affects durability but also the cost. High-quality materials may incur higher initial costs but can lead to lower total ownership costs due to reduced maintenance and longer lifespan.

-

Quality and Certifications: Products that meet international safety and quality certifications may command higher prices but provide peace of mind and market acceptance, particularly in regions with stringent regulations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer better service but at a premium, while emerging suppliers might provide lower prices with varying levels of reliability.

-

Incoterms: Understanding the shipping terms and conditions is essential. Incoterms define the responsibilities of buyers and sellers in international shipping, impacting logistics costs and risk management.

What Buyer Tips Can Help Optimize Costs When Sourcing Enclosed Electric Tricycles?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several strategies can optimize costs:

-

Negotiate Effectively: Establish clear communication with suppliers to negotiate better terms. Discuss volume discounts, payment terms, and the potential for long-term partnerships to secure favorable pricing.

-

Focus on Total Cost of Ownership: Evaluate not only the purchase price but also maintenance, operational costs, and resale value. A higher initial cost may be justified by lower long-term expenses.

-

Understand Pricing Nuances: Be aware of market trends, currency fluctuations, and regional demand that can affect pricing. This understanding can help in timing purchases and negotiating contracts.

-

Consider Local Regulations: Familiarize yourself with local regulations regarding electric vehicles, as compliance can affect operational costs and market entry strategies.

-

Request Samples: Before committing to large orders, request samples to assess quality and performance. This can help avoid costly mistakes and ensure the product meets your specifications.

Disclaimer

Prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and obtain multiple quotes to ensure competitive pricing.

Alternatives Analysis: Comparing enclosed electric tricycle With Other Solutions

Introduction to Alternatives for Enclosed Electric Tricycles

As the demand for sustainable and efficient urban transportation grows, businesses are exploring various mobility solutions. Enclosed electric tricycles (EETs) offer a unique blend of safety, comfort, and eco-friendliness. However, several alternative solutions can also meet similar transportation needs, each with its own advantages and drawbacks. This analysis compares enclosed electric tricycles with traditional scooters and cargo bicycles, providing insights for B2B buyers considering their options.

| Comparison Aspect | Enclosed Electric Tricycle | Traditional Scooter | Cargo Bicycle |

|---|---|---|---|

| Performance | Speed: Up to 35 mph; Range: 45 miles | Speed: Up to 30 mph; Range: 40-70 miles | Speed: Up to 15 mph; Range: 20-40 miles |

| Cost | MSRP: $8,400 – $9,880 | MSRP: $2,500 – $4,500 | MSRP: $1,000 – $3,000 |

| Ease of Implementation | Requires minimal infrastructure; street legal | Minimal infrastructure; requires helmet in some regions | Requires bike lanes; less regulation |

| Maintenance | Moderate; battery replacement every 2-4 years | Low; typically requires basic servicing | Low; minimal moving parts |

| Best Use Case | Urban commuting, delivery services | Personal commuting, short trips | Cargo transport, family use |

Detailed Breakdown of Alternatives

Traditional Scooters

Traditional scooters are a popular alternative for urban transportation, particularly in densely populated areas. They are generally more affordable than enclosed electric tricycles, with prices ranging from $2,500 to $4,500. Their ease of use and minimal infrastructure requirements make them appealing for quick trips. However, they often lack weather protection and can be less stable in adverse conditions, necessitating the use of helmets in many regions. While they are suitable for personal commuting, their limited cargo capacity makes them less ideal for delivery services.

Cargo Bicycles

Cargo bicycles are another viable alternative, especially for businesses focused on transporting goods or families. Priced between $1,000 and $3,000, they offer a low-cost solution with minimal maintenance needs. Cargo bicycles can navigate bike lanes easily and have a smaller environmental footprint. However, they typically have lower speeds and ranges compared to enclosed electric tricycles, making them less suitable for longer commutes. Additionally, they may require physical effort, which could be a disadvantage for some users.

Conclusion: Choosing the Right Solution for Your Business

When selecting the right transportation solution, B2B buyers must consider specific operational needs, including performance, cost, and intended use cases. Enclosed electric tricycles offer a balance of speed, safety, and cargo capacity, making them ideal for urban commuting and delivery services. Traditional scooters provide a more economical option for personal transport, while cargo bicycles excel in family and goods transport. Ultimately, the decision should align with the buyer’s unique operational requirements, regulatory environment, and long-term sustainability goals.

Essential Technical Properties and Trade Terminology for enclosed electric tricycle

What Are the Key Technical Properties of Enclosed Electric Tricycles?

When considering an investment in enclosed electric tricycles, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some essential properties that B2B buyers should focus on:

-

Battery Capacity (kWh)

This refers to the amount of energy stored in the battery, typically measured in kilowatt-hours (kWh). A higher capacity indicates a longer range, allowing for extended use between charges. For example, a battery capacity of 4.1 kWh can provide a range of approximately 45 miles at 25 mph. This is particularly important for businesses that require reliable transportation solutions for deliveries or commuting. -

Payload Capacity (kg)

The payload capacity indicates how much weight the tricycle can safely carry, including passengers and cargo. For instance, a tricycle with a maximum payload of 225 kg (496 lbs) offers versatility for various applications, from personal transport to goods delivery. Understanding this metric helps businesses assess whether the vehicle meets their operational needs without compromising safety. -

Vehicle Weight (kg)

The empty weight of the vehicle affects its efficiency, handling, and energy consumption. A lighter vehicle often translates to better range and speed. For example, an enclosed electric tricycle weighing 390 kg (863 lbs) can offer a balance between stability and energy efficiency. Buyers should consider the vehicle’s weight in relation to its intended use and performance requirements. -

Top Speed (km/h)

The maximum speed of the vehicle is a critical factor, especially in urban environments. A top speed of 32 km/h (20 mph) allows for safe yet efficient travel in city traffic. Buyers need to ensure that the speed aligns with local regulations and their operational requirements, such as delivery timelines. -

Motor Power (kW)

Motor power is an essential specification that affects acceleration, hill-climbing ability, and overall performance. For instance, a motor rated at 4 kW provides sufficient power for various terrains and load conditions. Understanding motor specifications helps businesses evaluate the vehicle’s capability to meet their specific demands.

What Trade Terms Should B2B Buyers Know When Acquiring Enclosed Electric Tricycles?

Familiarity with industry-specific terminology can streamline the purchasing process and enhance communication with suppliers. Here are some common terms relevant to B2B transactions:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electric tricycles, OEMs can provide critical components like batteries or electric motors, enabling buyers to ensure quality and compatibility. -

MOQ (Minimum Order Quantity)

The MOQ is the smallest number of units a supplier is willing to sell. Understanding the MOQ is essential for budget planning and inventory management. For businesses looking to purchase multiple tricycles, knowing the MOQ helps in negotiating favorable terms and costs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. Crafting a precise RFQ can lead to better pricing and terms, allowing buyers to compare offers effectively. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, particularly regarding shipping and delivery. Familiarity with these terms helps businesses understand their obligations and liabilities, reducing the risk of misunderstandings in cross-border transactions. -

Lead Time

This term refers to the time taken from placing an order to the delivery of the product. Knowing the lead time for enclosed electric tricycles is vital for planning and operational efficiency, especially for businesses that rely on timely deliveries. -

Warranty Period

This defines the duration during which the manufacturer is responsible for repairing or replacing defective parts. Understanding warranty terms is crucial for assessing long-term costs and ensuring product reliability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, negotiate effectively, and ultimately select the right enclosed electric tricycle for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the enclosed electric tricycle Sector

What Are the Current Market Dynamics and Key Trends in the Enclosed Electric Tricycle Sector?

The enclosed electric tricycle market is gaining momentum globally, driven by urbanization, the rise of eco-conscious consumerism, and the need for efficient transportation solutions. This sector is particularly appealing to international B2B buyers in regions like Africa, South America, the Middle East, and Europe, where urban congestion and environmental concerns are prevalent. The demand for enclosed electric tricycles is fueled by their compact size, low operational costs, and versatility for both personal and commercial use. In regions like Germany and Brazil, regulatory incentives for electric vehicles further enhance market attractiveness.

Emerging technologies are reshaping the sourcing landscape. Manufacturers are increasingly adopting advanced battery technologies, such as lithium-ion and silicate batteries, to enhance performance and reduce lifecycle costs. Additionally, the integration of smart technologies, such as connectivity features and user-friendly interfaces, is becoming a key differentiator among competitors. B2B buyers are also focusing on sourcing vehicles with modular designs that allow for customization and adaptability to local market needs.

How Are Sustainability and Ethical Sourcing Influencing B2B Purchasing Decisions?

Sustainability is at the forefront of the enclosed electric tricycle sector. B2B buyers are increasingly prioritizing products that minimize environmental impact, prompting manufacturers to adopt eco-friendly practices and materials. This includes using sustainable manufacturing processes, selecting recyclable materials, and ensuring energy-efficient production methods.

Moreover, ethical sourcing is becoming essential for businesses that wish to enhance their brand reputation and meet consumer expectations. Certifications such as ISO 14001 for environmental management and adherence to fair labor practices are critical for establishing credibility in the market. Buyers are looking for partners who can demonstrate transparency in their supply chains, ensuring that their products are not only green but also ethically produced.

How Has the Enclosed Electric Tricycle Sector Evolved Over Time?

The evolution of the enclosed electric tricycle can be traced back to the growing need for alternative transportation solutions that offer both efficiency and sustainability. Initially conceptualized as a niche product, advancements in battery technology and electric propulsion systems have transformed these vehicles into viable options for urban commuting and logistics.

As cities grapple with pollution and traffic congestion, the demand for enclosed electric tricycles has surged, making them a key player in the electric vehicle market. Manufacturers are continually innovating, incorporating features that enhance safety, comfort, and usability, thereby broadening their appeal to a wider audience. This trend is particularly pronounced in regions like Europe, where regulatory frameworks support the adoption of green technologies, solidifying the enclosed electric tricycle’s place in the future of urban mobility.

By understanding these dynamics, B2B buyers can make informed purchasing decisions that align with their sustainability goals while capitalizing on the growing demand for innovative transportation solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of enclosed electric tricycle

-

How do I choose the right enclosed electric tricycle for my business needs?

Selecting the appropriate enclosed electric tricycle requires evaluating several factors, including payload capacity, range, and speed. Assess your operational requirements, such as the typical distance covered and the number of passengers or cargo. For urban environments, prioritize models that comply with local regulations and can navigate bike lanes. Additionally, consider the vehicle’s maintenance costs and battery type, as these will impact long-term operational expenses. Conducting a thorough market comparison will help identify the best fit for your specific use case. -

What are the key features to look for in an enclosed electric tricycle?

When sourcing an enclosed electric tricycle, focus on safety features such as seat belts, hydraulic brakes, and a robust frame construction. Evaluate the vehicle’s weatherproofing to ensure rider comfort in diverse climates. Battery capacity and charging time are critical for operational efficiency, as well as the vehicle’s range to minimize downtime. Consider the ease of maintenance, including the availability of spare parts and service support. A model with user-friendly controls will also enhance accessibility for a wider range of operators. -

What are the typical payment terms when sourcing electric tricycles internationally?

Payment terms can vary significantly among suppliers, but common practices include a deposit upon order confirmation (typically 30-50%) followed by the balance before shipment. Some suppliers may offer letters of credit or payment upon delivery, depending on the buyer-supplier relationship and country regulations. It’s essential to clarify these terms upfront to avoid misunderstandings. Always ensure that the terms are documented in the purchase agreement, including any conditions for refunds or returns. -

How can I vet suppliers of enclosed electric tricycles?

To effectively vet suppliers, begin by researching their reputation in the industry through online reviews, testimonials, and case studies. Request references from previous clients to gauge their satisfaction with the product and service quality. Assess the supplier’s production capabilities, quality assurance processes, and compliance with international safety standards. A site visit or virtual tour can also provide insight into their operations. Lastly, ensure they have reliable after-sales support and warranty policies. -

What is the minimum order quantity (MOQ) for electric tricycles?

The MOQ for enclosed electric tricycles can vary by manufacturer, typically ranging from a single unit to several dozen. Factors influencing MOQ include production capabilities, inventory levels, and the specific model requested. Some suppliers may offer flexibility for first-time buyers or sample orders. It’s advisable to communicate your needs directly with potential suppliers to negotiate terms that align with your business requirements while ensuring they can meet your operational demands. -

What logistics considerations should I keep in mind when importing electric tricycles?

When importing enclosed electric tricycles, consider shipping methods, customs regulations, and potential import duties. Air freight is faster but more expensive, while sea freight offers cost savings at the expense of longer transit times. Verify that the supplier provides all necessary documentation for customs clearance, including invoices, packing lists, and compliance certificates. Establish a reliable logistics partner familiar with international shipping to navigate these complexities and ensure timely delivery. -

How do I ensure quality assurance for enclosed electric tricycles?

To ensure quality assurance, require suppliers to provide detailed specifications and certifications for their products. Conduct pre-shipment inspections to verify that the tricycles meet the agreed-upon standards. Implement a quality control process that includes testing the vehicles upon delivery to confirm functionality and safety features. Consider establishing a long-term partnership with a supplier that has a proven track record of quality, ensuring that they maintain high standards throughout the production process. -

What customization options are available for electric tricycles?

Customization options for enclosed electric tricycles may include modifications to size, color, and additional features such as cargo racks, enhanced lighting, or upgraded battery systems. Many manufacturers offer tailored solutions to meet specific business needs, whether for delivery services or passenger transport. Engage with suppliers early in the sourcing process to discuss your requirements, as this will allow them to provide you with options that align with your operational goals and regulatory compliance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Enclosed Electric Tricycle Manufacturers & Suppliers List

1. ZEV – Micro Vehicle

Domain: zelectricvehicle.com

Registered: 2008 (17 years)

Introduction: This company, ZEV – Micro Vehicle, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Veemo – Enclosed Electric Tricycle

Domain: veemo.ca

Registered: 2014 (11 years)

Introduction: Veemo is an enclosed electric tricycle designed for urban commuting and all-weather use. Key features include:

– Max Speed: 32 KM/H (20MPH)

– Range: 30 – 100 KM (19 – 62 miles)

– Payload Capacity: 159 KG (350 lbs)

– Weight: 61 KG (135 lbs)

– Max Power: 750W / 500W / 250W (software limited based on location)

– Dimensions: 200 cm long x 89 cm wide x 150 cm high (79 in x 35 in x 59 in)

– Batte…

3. Aixam – Fully Enclosed Chinese Trikes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Fully enclosed Chinese trikes, potential registration issues in the US, availability in EU countries with small vehicle licenses, brands like Aixam, Microcar, and Ligier mentioned, concerns about reliability and maintenance, speed limitations discussed (e.g., 25/45 kph or 15/27 mph), rollover risks highlighted.

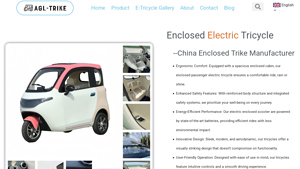

4. AGL-TRIKE – Enclosed Electric Tricycle

Domain: agl-trike.com

Registered: 2023 (2 years)

Introduction: Enclosed Electric Tricycle – AGL-TRIKE: Ergonomic Comfort with spacious cabin for comfortable rides; Enhanced Safety Features with reinforced body structure; Energy-Efficient Performance powered by advanced batteries; Innovative Design that is sleek and aerodynamic; User-Friendly Operation with intuitive controls; Adaptable Seating options for personal and professional needs. Maximum speed: 25 to …

5. Cozy Trikes – Electric Recumbent Handcycle ERH-900 Deluxe

Domain: cozytrikes.com

Registered: 2010 (15 years)

Introduction: 1. Electric Recumbent Handcycle ERH-900 Deluxe: Advanced handcycle from the USA. 2. HD Professional Motorized Folding Electric Wheelchairs: Airline approved, accommodates up to 400 lbs, suitable for indoor and outdoor use. 3. Fat Tire Folding Electric Recumbent Tricycle: Comfortable ride with lumbar support, reclined position. 4. LuxuryTon X-1000: 4-wheel electric mobility scooter with optional ro…

Strategic Sourcing Conclusion and Outlook for enclosed electric tricycle

As the demand for sustainable and efficient transportation solutions continues to rise globally, the enclosed electric tricycle presents a compelling opportunity for B2B buyers across diverse markets. Key takeaways highlight the vehicle’s versatility, cost-effectiveness, and eco-friendliness, making it an ideal choice for urban commuting, delivery services, and personal use. Strategic sourcing of these innovative vehicles can significantly enhance operational efficiency while aligning with environmental goals.

Investing in enclosed electric tricycles not only meets the growing consumer demand for sustainable transportation but also positions businesses to capitalize on emerging markets in Africa, South America, the Middle East, and Europe. These regions are increasingly prioritizing green technologies, paving the way for electric vehicles to thrive.

Looking ahead, B2B buyers should consider engaging with reputable manufacturers and suppliers to secure competitive pricing and reliable support. By embracing this transformative mode of transport, businesses can contribute to a cleaner environment and enhance their brand reputation. Now is the time to act—explore partnerships that will propel your organization into the future of sustainable mobility.