Introduction: Navigating the Global Market for end Dump Truck

In today’s rapidly evolving global market, sourcing the right end dump truck can be a daunting challenge for international B2B buyers. With diverse applications across industries—from construction to waste management—understanding the specifications, capabilities, and local regulations is crucial. This comprehensive guide addresses the essential considerations for purchasing end dump trucks, including various types available in the market, their specific applications, and tips for effective supplier vetting. Additionally, we delve into cost factors, maintenance requirements, and the implications of international shipping, all tailored to the unique needs of buyers in regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Brazil.

By equipping decision-makers with actionable insights and practical tools, this guide empowers you to make informed purchasing decisions that align with your operational requirements and budget constraints. The complexities of navigating the global market for end dump trucks necessitate a well-rounded understanding of not only the products themselves but also the strategic partnerships that can enhance your supply chain. Whether you are looking for high-capacity models, specialized configurations, or sustainable options, this guide is designed to help you confidently navigate your sourcing journey.

Understanding end Dump Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard End Dump Truck | Raised front end for unloading, versatile design | Construction, aggregate transport | Pros: Quick unloading, versatile; Cons: Limited in tight spaces. |

| Lightweight End Dump Truck | Constructed with AR 450 wear plate, reduced weight | Sand and small aggregate transport | Pros: Enhanced payload capacity; Cons: May not handle heavy materials. |

| Half Round End Dump Truck | Curved design for easier material flow, high-capacity options | Asphalt, gravel, and general material hauling | Pros: Versatile use in various terrains; Cons: More complex design may increase maintenance. |

| Elliptical End Dump Truck | Unique elliptical shape for stability, robust construction | Heavy materials like scrap metal and boulders | Pros: High capacity and durability; Cons: Heavier, may require stronger towing vehicles. |

| Quarter Frame End Dump Truck | Single point suspension, designed for stability during unloading | Urban and rural construction | Pros: Maintains tire contact during dumping; Cons: Limited customization options. |

What are the Characteristics of a Standard End Dump Truck?

The standard end dump truck is characterized by its straightforward design that allows for efficient unloading by raising the front end, causing materials to slide out the back. This type is widely used in construction and aggregate transport due to its maneuverability and availability. When considering this truck, buyers should evaluate the specific unloading conditions and ensure that the truck’s height and capacity match their operational needs.

How Does a Lightweight End Dump Truck Differ from Other Types?

Lightweight end dump trucks are designed with advanced materials such as AR 450 wear plates, which reduce weight without compromising strength. This makes them particularly suitable for transporting sand and smaller aggregates. Buyers should consider the balance between weight and load capacity, as these trucks excel in maximizing payload while being easier to handle on the road.

What Advantages Does a Half Round End Dump Truck Offer?

The half round end dump truck features a curved design that enhances material flow during unloading, making it ideal for asphalt and gravel transport. Its versatility allows it to perform well in both metropolitan areas and rural settings. When purchasing, buyers should assess the truck’s compatibility with the materials they intend to haul, as well as its ability to navigate various terrains.

Why Choose an Elliptical End Dump Truck?

Elliptical end dump trucks are designed for stability and robustness, making them suitable for heavy materials like scrap metal and large boulders. Their unique shape allows for a lower center of gravity, improving handling. Buyers should consider the weight of the materials they plan to transport and ensure that their towing vehicles can accommodate the elliptical truck’s requirements.

What Makes the Quarter Frame End Dump Truck a Good Choice?

The quarter frame end dump truck features a single-point suspension system that ensures all tires maintain contact with the ground during the unloading process. This design minimizes the risk of tipping and enhances safety. Buyers should evaluate their specific needs for stability and load distribution, particularly in urban construction projects where space and maneuverability are critical.

Key Industrial Applications of end Dump Truck

| Industry/Sector | Specific Application of end Dump Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Transporting aggregates (sand, gravel, etc.) | Efficient material handling, reducing operational delays | Load capacity, durability of materials, and hoist type |

| Road Maintenance & Paving | Hauling hot mix asphalt (HMA) for road construction | Quick unloading to maintain project timelines | Compatibility with paving equipment and material temperature control |

| Mining | Transporting ore and minerals from extraction sites | High payload capacity and robust design for rough terrain | Weight limits, axle configuration, and suspension type |

| Agriculture | Moving bulk fertilizers and soil amendments | Streamlined logistics for large-scale farming | Tarp options for weather protection and ease of loading/unloading |

| Waste Management | Hauling construction debris and scrap materials | Efficient waste removal and recycling processes | Customization options for specific waste types and weight capacity |

How is an End Dump Truck Used in Construction?

In the construction industry, end dump trucks are essential for transporting aggregates such as sand, gravel, and crushed stone. Their ability to unload materials efficiently minimizes downtime on job sites, allowing for a faster completion of projects. Buyers in this sector should consider the truck’s load capacity and the durability of materials used in construction. For international buyers, especially in regions like Africa and South America, local road conditions and maintenance availability are critical factors to ensure reliable performance.

What Role Do End Dump Trucks Play in Road Maintenance and Paving?

End dump trucks are widely used in road maintenance and paving projects to haul hot mix asphalt (HMA). Their design allows for quick unloading, which is crucial for maintaining the temperature of the asphalt and ensuring a smooth application. Buyers must ensure compatibility with paving equipment and consider features such as tailgate design to prevent material spillage. For buyers in the Middle East and Europe, understanding local regulations regarding transport vehicles can also influence purchasing decisions.

How Are End Dump Trucks Beneficial in Mining Operations?

In the mining sector, end dump trucks are vital for transporting ore and minerals from extraction sites to processing plants. Their high payload capacity and robust construction make them ideal for handling heavy loads in challenging terrains. Buyers should focus on the truck’s weight limits, axle configurations, and suspension types to ensure optimal performance in specific mining environments. For international buyers, particularly in Africa, understanding the local infrastructure and logistics capabilities is essential to maximize the utility of these trucks.

How Can End Dump Trucks Streamline Agricultural Operations?

In agriculture, end dump trucks are utilized for moving bulk fertilizers and soil amendments. Their large capacity allows farmers to transport significant quantities of materials, enhancing logistics and operational efficiency on large-scale farms. Buyers should consider options for tarps to protect loads from weather elements and facilitate easier loading and unloading. In regions like South America, where agricultural practices vary widely, adaptability to different crop types and local conditions is key for successful procurement.

What Advantages Do End Dump Trucks Offer in Waste Management?

End dump trucks are increasingly employed in waste management for hauling construction debris and scrap materials. Their efficient unloading capabilities streamline waste removal processes, making them a preferred choice for recycling operations. Buyers should look for customization options that cater to specific waste types and ensure the trucks can handle varying weight capacities. For international buyers in Europe and the Middle East, compliance with environmental regulations and waste management standards is crucial when sourcing these vehicles.

3 Common User Pain Points for ‘end Dump Truck’ & Their Solutions

Scenario 1: Difficulty in Ensuring Material Integrity During Transport

The Problem: B2B buyers often face challenges related to the integrity of materials transported by end dump trucks, particularly in varying weather conditions. For instance, when transporting hot mix asphalt (HMA) or concrete, exposure to rain or excessive heat can alter the material’s properties, leading to issues such as segregation or increased water-cement ratios. This not only affects the quality of the end product but can also lead to costly rework and project delays, impacting the overall profitability and reputation of the contracting company.

The Solution: To mitigate these risks, buyers should consider investing in end dump trucks that come equipped with integral covers or tarps specifically designed for the materials being transported. When selecting a truck, look for models that feature robust, weather-resistant tarps that can effectively shield the load from moisture. Additionally, implementing a routine maintenance schedule for the truck’s tarp system can ensure that it remains functional and reliable throughout its use. For optimal performance, operators should be trained on the best practices for loading and unloading, including ensuring minimal exposure time to the elements. This proactive approach can safeguard the material integrity during transport, ultimately leading to higher quality work and customer satisfaction.

Scenario 2: Challenges with Payload Capacity and Efficiency

The Problem: A common issue faced by B2B buyers of end dump trucks is the need for high payload capacity without compromising efficiency. In regions where the demand for bulk material transport is high, buyers often struggle to find trucks that balance weight limits with volume needs. Overloading can lead to legal issues and increased wear and tear on the truck, while underloading can result in inefficient operations and lost revenue.

The Solution: Buyers should focus on selecting end dump trucks with a high cubic yard capacity that also comply with local weight regulations. For example, consider models that feature lightweight construction materials, such as aluminum or high-strength steel, which can reduce the overall weight of the truck while maximizing payload capacity. Additionally, investing in advanced suspension systems, such as air-ride suspension, can enhance stability and load distribution during transport, allowing for safer handling of heavier loads. Furthermore, implementing a logistics plan that optimizes route selection and load scheduling can significantly improve operational efficiency, reducing both time and costs associated with material transport.

Scenario 3: Inefficiencies and Safety Risks During Unloading

The Problem: Unloading materials can often present significant safety and efficiency challenges for operators of end dump trucks. Poorly designed unloading mechanisms can lead to accidents, such as tipping or spillage, especially when dealing with uneven terrain or heavy loads. These risks not only endanger the safety of the operators and surrounding workers but can also result in material loss and additional cleanup costs.

The Solution: To address these concerns, buyers should prioritize end dump trucks that incorporate advanced unloading systems, such as high-lift tailgates and single-point suspension designs. These features ensure that the truck remains stable during the unloading process and allows for smooth material flow, reducing the risk of accidents. It is also advisable to conduct thorough training sessions for operators on the proper unloading techniques and safety protocols, tailored to the specific materials and site conditions they will encounter. Regular safety audits and maintenance checks on the unloading mechanisms can further enhance safety and operational efficiency, ensuring that the unloading process is both secure and effective.

Strategic Material Selection Guide for end Dump Truck

What Are the Key Materials Used in End Dump Trucks?

Selecting the right materials for end dump trucks is crucial for ensuring durability, performance, and cost-effectiveness. Here, we analyze four common materials used in the construction of end dump trucks, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Steel Perform as a Material for End Dump Trucks?

Steel is the most widely used material in end dump truck construction, particularly in the chassis and body. Its key properties include high tensile strength, excellent impact resistance, and good weldability. Steel can withstand high pressures and temperatures, making it suitable for heavy-duty applications.

Pros: Steel is durable and cost-effective, providing a long service life with proper maintenance. It is also readily available and can be easily fabricated into complex shapes.

Cons: However, steel is susceptible to corrosion, especially in humid or saline environments, which can lead to increased maintenance costs. Additionally, it is heavier than alternative materials, potentially affecting fuel efficiency.

Impact on Application: Steel’s compatibility with various media types, including aggregates and construction materials, makes it versatile. However, it may require protective coatings or treatments to enhance corrosion resistance.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local standards such as ASTM or DIN for steel quality. Corrosion resistance is particularly important in coastal areas.

What Role Does Aluminum Play in End Dump Truck Construction?

Aluminum is increasingly popular for end dump truck bodies due to its lightweight properties. It has excellent corrosion resistance and can handle a range of temperatures without losing structural integrity.

Pros: The primary advantage of aluminum is its weight savings, which can improve fuel efficiency and payload capacity. It also resists rust and corrosion, leading to lower maintenance costs over time.

Cons: On the downside, aluminum is generally more expensive than steel and may not provide the same level of impact resistance. It can be more challenging to weld and fabricate due to its different thermal properties.

Impact on Application: Aluminum is suitable for transporting lighter materials, such as aggregates and sand. However, it may not be ideal for heavy-duty applications involving dense materials like boulders.

Considerations for International Buyers: Buyers in Europe and the Middle East may prefer aluminum for its corrosion resistance in high-humidity environments. Compliance with specific aluminum grades and standards is essential.

How Does High-Strength Steel Compare for End Dump Trucks?

High-strength steel (HSS) is a specialized material used in high-performance end dump trucks. It offers enhanced strength-to-weight ratios, allowing for thinner sections without compromising durability.

Pros: HSS provides significant weight savings while maintaining structural integrity, which can lead to improved fuel efficiency and payload capacity. It also offers excellent resistance to deformation under heavy loads.

Cons: The main disadvantage is the higher cost associated with high-strength steel compared to standard steel. Additionally, it may require specialized welding techniques, increasing manufacturing complexity.

Impact on Application: HSS is ideal for heavy-duty applications where high load-bearing capacity is required. It is particularly effective in environments where trucks frequently encounter rough terrains.

Considerations for International Buyers: Compliance with international standards such as JIS or ASTM is critical, especially for buyers in regions with stringent regulations. Understanding the specific grades of HSS available in local markets is also important.

What About Composite Materials for End Dump Trucks?

Composite materials, such as fiberglass-reinforced plastics, are emerging in end dump truck design, particularly for lightweight applications. They offer good resistance to corrosion and can be molded into complex shapes.

Pros: Composites are lightweight, reducing overall vehicle weight and improving fuel efficiency. They also provide excellent corrosion resistance, leading to lower maintenance costs.

Cons: However, composites can be expensive and may not provide the same structural strength as metals. They can also be more challenging to repair if damaged.

Impact on Application: Composites are suitable for transporting non-abrasive materials and can be effective in specialized applications. However, they may not be suitable for heavy-duty use.

Considerations for International Buyers: Buyers should consider the availability and cost of composite materials in their region. Understanding local regulations regarding composite use in heavy vehicles is also essential.

Summary Table of Material Selection for End Dump Trucks

| Material | Typical Use Case for end Dump Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and body | Durable and cost-effective | Susceptible to corrosion | Medium |

| Aluminum | Lightweight applications | Lightweight and corrosion-resistant | Higher cost and fabrication complexity | High |

| High-Strength Steel | Heavy-duty applications | Excellent strength-to-weight ratio | Higher cost and welding complexity | High |

| Composite Materials | Specialized lightweight applications | Lightweight and corrosion-resistant | Expensive and lower structural strength | High |

This analysis provides an overview of the materials used in end dump trucks, equipping international B2B buyers with the insights needed to make informed purchasing decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for end Dump Truck

What Are the Main Stages in the Manufacturing Process of End Dump Trucks?

The manufacturing process of end dump trucks involves several critical stages, each designed to ensure the final product meets rigorous performance and safety standards. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The initial step involves selecting high-quality materials that can withstand heavy loads and harsh operating conditions. Common materials include high-strength steel, such as AR 450 wear plates, which are essential for the truck’s bed and structural components. These materials are then cut and shaped to the required dimensions using advanced CNC machines, ensuring precision and consistency. -

Forming:

Forming techniques, such as welding and bending, are employed to create the truck’s structural components. Robotic welding systems are often used to ensure uniformity and strength in joints, particularly in critical areas like the chassis and hoist assembly. This stage may also include the fabrication of the bed and tailgate, which must be designed to facilitate smooth unloading. -

Assembly:

In this stage, the individual components are assembled into a complete truck. This includes attaching the axles, suspension systems, and hoisting mechanisms. The assembly process typically follows a standardized workflow to maintain efficiency and quality. Workers utilize jigs and fixtures to align components accurately, reducing the risk of errors. -

Finishing:

The final stage involves applying protective coatings and paints that enhance durability and aesthetics. High-gloss, UV-protectant, and rust-inhibiting paints are commonly used to ensure longevity. This stage also includes installing electrical systems, such as LED lighting, which enhance safety during operation.

How Is Quality Assurance Implemented During the Manufacturing of End Dump Trucks?

Quality assurance (QA) is a fundamental aspect of manufacturing end dump trucks, aimed at ensuring that the final product meets international standards and customer expectations.

-

What International Standards Govern End Dump Truck Quality?

Key international standards, such as ISO 9001, guide the quality management processes in manufacturing. These standards emphasize a systematic approach to quality assurance, focusing on continuous improvement and customer satisfaction. Additionally, region-specific certifications like CE (for Europe) and API (for the oil and gas sector) may be relevant, depending on the intended use of the trucks. -

What Are the Key Quality Control Checkpoints?

The quality control process typically involves several checkpoints, including:

- Incoming Quality Control (IQC): This ensures that materials meet specified standards before they enter the production process. Suppliers must provide certification and test reports for materials used in manufacturing.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, inspections are conducted to ensure that each stage meets quality standards. This includes checking weld integrity and component alignment during assembly.

- Final Quality Control (FQC): Once the truck is assembled, a comprehensive inspection is performed to assess overall performance, safety features, and compliance with specifications. This may include dynamic testing of the hoist and tailgate mechanisms.

- What Common Testing Methods Are Used?

Various testing methods are utilized to verify the quality and performance of end dump trucks, including:

- Load Testing: Assessing the truck’s ability to carry and unload maximum loads safely.

- Structural Integrity Testing: Utilizing non-destructive testing (NDT) methods such as ultrasonic and magnetic particle inspections to identify any flaws in welds or materials.

- Operational Testing: Evaluating the functionality of hydraulic systems, brakes, and electrical components to ensure they operate as intended.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

-

Conducting Supplier Audits:

Regular audits allow buyers to assess the manufacturing facility’s adherence to quality standards. This includes reviewing documentation, inspecting manufacturing processes, and interviewing staff about their quality assurance practices. -

Requesting Quality Reports and Certifications:

Buyers should ask suppliers for documentation, including ISO certifications, test reports, and compliance documents. These materials provide insight into the supplier’s commitment to quality and adherence to international standards. -

Engaging Third-Party Inspection Services:

Utilizing independent inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality control processes. These inspections can be conducted at various stages of production, from material sourcing to final assembly.

What Are the Quality Control Nuances for International Buyers?

When sourcing end dump trucks from international suppliers, buyers must be aware of several nuances in quality control that can affect their purchasing decisions:

-

Understanding Regional Regulations:

Different regions may have specific regulations regarding vehicle safety, emissions, and operational standards. Buyers must ensure that the trucks comply with local regulations in their target markets, which may differ significantly from the supplier’s home country. -

Evaluating Supply Chain Transparency:

Buyers should assess the transparency of the supplier’s supply chain, including sourcing practices for raw materials. Sustainable sourcing and ethical manufacturing practices are increasingly important in global procurement. -

Consideration of After-Sales Support and Warranty Policies:

Quality assurance does not end with the delivery of the truck. Buyers should inquire about after-sales support, maintenance services, and warranty policies. A robust after-sales program can significantly affect the long-term performance and reliability of the purchased equipment.

In conclusion, understanding the manufacturing processes and quality assurance practices associated with end dump trucks is essential for B2B buyers. By focusing on these elements, buyers can make informed decisions that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘end Dump Truck’

To assist international B2B buyers in navigating the procurement of end dump trucks, this guide provides a structured checklist to ensure informed purchasing decisions. By following these steps, buyers can maximize their investment and secure vehicles that meet their operational needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the end dump truck based on your operational needs. Consider factors such as capacity, dimensions, and materials to be transported. For example, if you plan to haul heavy materials like scrap metal, ensure the truck is equipped with a robust AR 450 wear plate for durability.

Step 2: Assess Load Capacity Requirements

Evaluate the load capacity you need for your operations. End dump trucks come in various capacities, typically ranging from 25 to 39.5 cubic yards. Ensure that the truck you choose can handle the maximum load you intend to transport, as this will affect efficiency and operational costs.

Step 3: Research and Verify Supplier Credentials

Conduct thorough research on potential suppliers. Look for certifications and industry affiliations that demonstrate a commitment to quality and safety standards. Additionally, check for customer reviews and testimonials, particularly from businesses in your region or industry, to gauge reliability.

Step 4: Request Detailed Product Specifications

When engaging with suppliers, request comprehensive product specifications for the end dump trucks. This should include information on materials, axle configurations, suspension types, and any optional features such as tarp systems or lift axles. Understanding these specifications helps ensure the truck meets your specific operational requirements.

Step 5: Evaluate After-Sales Support and Warranty

Inquire about the after-sales support and warranty options provided by the supplier. A strong warranty can protect your investment, while robust after-sales service ensures that any issues can be resolved quickly. Evaluate the supplier’s commitment to customer service and support for maintenance and repairs.

Step 6: Consider Customization Options

Explore customization options available for the end dump trucks. Depending on your business needs, you may require specific features such as custom lengths, side heights, or specialized hoist systems. Customization can enhance the truck’s efficiency and suitability for your operational tasks.

Step 7: Negotiate Pricing and Payment Terms

Finally, negotiate pricing and payment terms with your chosen supplier. Be prepared to discuss bulk purchase discounts or financing options that can ease cash flow. Establish clear terms regarding delivery timelines, installation, and any additional costs to avoid surprises later in the procurement process.

By following this checklist, B2B buyers can make informed decisions when sourcing end dump trucks, ultimately enhancing their operational efficiency and productivity.

Comprehensive Cost and Pricing Analysis for end Dump Truck Sourcing

What Are the Key Cost Components in End Dump Truck Manufacturing?

When analyzing the cost structure for end dump trucks, several key components contribute to the overall pricing. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Materials are a significant cost driver, especially with high-strength materials such as AR 450 wear plates used for the tub and other structural components. The choice of materials directly impacts durability and performance, which are critical in demanding environments.

Labor costs encompass both skilled and unskilled labor involved in assembly and welding, as well as any specialized workers required for quality checks and equipment operation.

Manufacturing overhead includes utilities, depreciation on machinery, and facility costs. These indirect costs can vary significantly based on the location and efficiency of the production facility.

Tooling costs arise from the need for specialized equipment to produce custom or high-spec models. This is particularly relevant when dealing with customized designs that cater to specific regional needs or regulatory requirements.

Quality control is essential for ensuring that the end dump trucks meet international standards and certifications. This process, while adding to costs, is crucial for maintaining reliability and safety.

Logistics costs involve transportation from the manufacturing site to the buyer’s location, which can vary based on distance and the complexity of the supply chain. Finally, the profit margin is influenced by market demand, competition, and the perceived value of the product.

What Influences End Dump Truck Pricing?

Several factors can influence the pricing of end dump trucks. Volume and minimum order quantities (MOQ) play a critical role; larger orders typically attract discounts. Buyers must consider their needs carefully, as purchasing in bulk can lead to significant cost savings.

Specifications and customization also affect pricing. Standard models may be less expensive than customized units that require additional engineering or materials. Buyers should clearly define their specifications to avoid unexpected costs.

The quality of materials used and the certifications obtained can further influence pricing. Higher quality materials and certifications can lead to a higher upfront cost but can result in lower maintenance and operational costs over the truck’s lifespan.

Supplier factors such as reputation, reliability, and history of service can impact pricing. Established suppliers with a track record may charge a premium but can offer better warranties and support.

Incoterms should also be carefully reviewed as they dictate the responsibilities of buyers and sellers in terms of shipping and risk management. Understanding these terms can help buyers negotiate better deals and avoid unforeseen costs.

How Can Buyers Negotiate Effectively for End Dump Trucks?

Effective negotiation strategies are vital for securing the best deals on end dump trucks. Buyers should prepare by conducting thorough market research to understand prevailing prices and competitor offerings.

Cost-efficiency can be enhanced by considering the Total Cost of Ownership (TCO), which includes purchase price, maintenance, fuel efficiency, and resale value. A lower initial purchase price may not always represent the best value if the truck incurs high operating costs over time.

Buyers should also leverage their purchasing power by negotiating for volume discounts or exploring financing options that could ease cash flow constraints.

Finally, it is essential to understand the pricing nuances specific to international buyers. Factors such as currency fluctuations, import duties, and local regulations can significantly impact the final cost. Buyers from regions like Africa, South America, the Middle East, and Europe must consider these aspects in their procurement strategies to ensure they make informed decisions.

What Should Buyers Keep in Mind Regarding Pricing Disclaimers?

When sourcing end dump trucks, it is crucial to recognize that pricing can vary widely based on the aforementioned factors. Therefore, buyers should seek indicative prices and request detailed quotes that reflect their specific requirements.

It is advisable to obtain multiple quotes from different suppliers to gauge the market and avoid overpaying. Always clarify what is included in the price, such as warranties, service agreements, and delivery terms, to avoid any unexpected costs down the line.

By being informed and strategic, buyers can navigate the complexities of end dump truck sourcing and secure favorable terms that align with their operational needs.

Alternatives Analysis: Comparing end Dump Truck With Other Solutions

Exploring Alternative Solutions to End Dump Trucks in Transportation

When evaluating the best transportation solution for construction materials and aggregates, it’s crucial to consider alternatives to end dump trucks. While end dump trucks are widely used for their efficiency and versatility, other solutions may better suit specific operational needs and budget constraints. Below, we compare end dump trucks with two viable alternatives: Side Dump Trucks and Bottom Dump Trailers.

Comparison Table

| Comparison Aspect | End Dump Truck | Side Dump Truck | Bottom Dump Trailer |

|---|---|---|---|

| Performance | High unloading speed; versatile | Excellent for tight spaces; reduces spillage | Good for bulk materials; stable unloading |

| Cost | Moderate to high initial investment | Generally higher due to complexity | Moderate initial cost, lower than side dump |

| Ease of Implementation | Easy to integrate into existing fleets | Requires training for operators | Simple operation; minimal training needed |

| Maintenance | Lower due to fewer moving parts | Higher due to more complex design | Moderate; accessible components |

| Best Use Case | Large construction sites; bulk material transport | Urban settings; precise unloading | High-capacity material transport; quarries |

Detailed Breakdown of Alternatives

What are the Advantages and Disadvantages of Side Dump Trucks?

Side dump trucks are designed to unload materials sideways rather than from the back. This feature allows for efficient unloading in tight spaces, making them ideal for urban construction projects. They minimize the risk of spillage, as materials can be deposited directly into a designated area. However, side dump trucks tend to be more expensive due to their complex design and require specialized training for operators to handle their unique unloading mechanism effectively.

How Do Bottom Dump Trailers Compare to End Dump Trucks?

Bottom dump trailers utilize a unique design that allows for unloading through a bottom gate. This method provides stability during unloading, reducing the risk of tipping, which can be a concern with end dump trucks. They are particularly effective for transporting bulk materials such as gravel and asphalt, making them suitable for quarry operations. The initial investment for bottom dump trailers is generally lower than for side dump trucks, although they may require more maintenance due to their operational components.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate transportation solution, B2B buyers should assess their specific operational requirements, including the types of materials being transported, site conditions, and budget constraints. End dump trucks are ideal for large-scale projects where speed and versatility are paramount. In contrast, side dump trucks are better suited for urban environments where precision is crucial. Bottom dump trailers offer a balanced solution for high-capacity needs, particularly in quarry settings. By analyzing these factors, businesses can make informed decisions that align with their logistical goals and operational efficiencies.

Essential Technical Properties and Trade Terminology for end Dump Truck

What Are the Key Technical Properties of End Dump Trucks?

Understanding the technical specifications of end dump trucks is essential for B2B buyers to ensure they select the right equipment for their operational needs. Here are some critical specifications that should be considered:

-

Material Grade

End dump trucks are often constructed from high-strength steel, such as AR 450 wear plate. This material is crucial for durability and resistance to abrasion, especially when transporting heavy materials like gravel or scrap metal. The higher the grade, the longer the truck will last, reducing maintenance costs over time. -

Hoist System

The hoist system, typically a multi-stage hydraulic lift, determines how effectively the truck can raise its bed to discharge materials. A common configuration is an 8-inch, 5-stage inverted trunnion mount. Understanding the hoist specifications is vital because it affects the truck’s unloading speed and efficiency, which directly impacts operational productivity. -

Suspension Type

Suspension plays a significant role in the truck’s stability and load distribution. A 50,000 lb air ride suspension system is often employed to keep all tires on the ground during the dumping process, which minimizes the risk of tipping. A well-designed suspension system enhances safety and allows for smoother transport on various terrains. -

Capacity

The volume capacity of end dump trucks is generally expressed in cubic yards, with standard models ranging from 31.5 to 39.5 cubic yards. Knowing the capacity helps buyers assess how many trips will be required for specific jobs, influencing operational efficiency and cost-effectiveness. -

Axle Configuration

Most end dump trucks utilize a 25,000 lb axle configuration. Understanding the axle setup is essential for weight distribution and compliance with local regulations. It directly affects the truck’s load-bearing capabilities and overall performance on the road. -

Tire Specifications

Tire specifications, such as the 11R x 24.5 radial tires commonly used, are important for traction and durability. The right tire choice ensures better handling and safety, especially when carrying heavy loads or traveling on rough surfaces.

What Are Common Trade Terms Related to End Dump Trucks?

Familiarizing oneself with industry jargon can facilitate smoother transactions and negotiations. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM is the company that manufactures the original product. In the context of end dump trucks, knowing the OEM can help buyers understand the quality, warranty, and service support associated with their purchase. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQ is crucial for buyers to determine if a supplier’s terms align with their purchasing strategy, especially for fleet purchases. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. In the end dump truck market, submitting an RFQ can help buyers compare costs and make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers, especially when importing end dump trucks from overseas. -

Payload Capacity

This term refers to the maximum weight an end dump truck can safely transport. Understanding payload capacity is vital for compliance with local regulations and for ensuring operational efficiency during transport. -

Warranty Period

The warranty period is the timeframe during which the manufacturer will repair or replace defective parts. Knowing the warranty period can help buyers assess the long-term value and reliability of their investment in end dump trucks.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that their investments in end dump trucks align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the end Dump Truck Sector

What Are the Key Trends Shaping the End Dump Truck Market?

The global end dump truck market is witnessing a surge driven by infrastructure development, urbanization, and demand for efficient transport solutions. In regions like Africa and South America, governments are investing heavily in road construction and maintenance, which directly boosts demand for end dump trucks. The Middle East is also experiencing growth, particularly in construction projects linked to events like Expo 2020 in Dubai, while European markets are focusing on modernization and fleet upgrades to meet stricter environmental regulations.

Emerging technologies are reshaping sourcing trends in the sector. The adoption of telematics and fleet management systems is becoming prevalent, allowing buyers to optimize operations through real-time data analytics. These systems help in reducing operational costs and improving efficiency. Additionally, the trend towards customization is gaining momentum, as international buyers seek specific configurations suited to diverse terrains and material handling needs, such as lightweight designs for sand transport or reinforced models for heavy-duty applications.

Moreover, sustainability is becoming a central theme in procurement decisions. Buyers are increasingly prioritizing manufacturers that offer greener alternatives, including those utilizing recycled materials in their production processes. The market dynamics indicate a shift toward integrated supply chains that emphasize transparency and reliability, enabling B2B buyers to ensure they source from reputable manufacturers who meet international quality standards.

How Can Sustainability and Ethical Sourcing Be Integrated into B2B Procurement for End Dump Trucks?

Sustainability is no longer a buzzword but a necessity in the end dump truck sector. Environmental impacts from manufacturing and operating these vehicles can be significant, including emissions and resource consumption. Thus, B2B buyers are encouraged to seek out manufacturers who employ sustainable practices, such as using eco-friendly materials and minimizing waste during production.

Ethical sourcing is crucial, particularly in developing markets. Buyers should prioritize suppliers that demonstrate a commitment to fair labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a manufacturer’s dedication to sustainability and ethical practices.

Additionally, selecting end dump trucks constructed from recyclable materials or those with lower emissions can significantly reduce the ecological footprint. Features such as energy-efficient designs and options for alternative fuels should be considered when sourcing. This not only aligns with global sustainability goals but can also enhance a company’s reputation, making it more attractive to environmentally conscious clients and partners.

What Is the Evolution of End Dump Trucks in the B2B Landscape?

The evolution of end dump trucks has been marked by significant technological advancements and shifts in market demand. Initially, these trucks were primarily manual and mechanically simple, serving basic hauling needs. Over the decades, innovations such as hydraulic systems have transformed the efficiency and usability of end dump trucks, allowing for quicker loading and unloading processes.

In the late 20th century, the introduction of lightweight materials and advanced manufacturing techniques enabled manufacturers to produce more durable and fuel-efficient models, catering to the growing demand for sustainable transport solutions. Today, the integration of telematics and automation is redefining operational efficiency, making end dump trucks an indispensable asset for construction and mining industries worldwide.

As international markets evolve, B2B buyers are encouraged to stay informed about these trends and leverage advancements to enhance their procurement strategies and operational capabilities.

Frequently Asked Questions (FAQs) for B2B Buyers of end Dump Truck

-

How do I ensure the end dump truck I purchase meets international standards?

To ensure compliance with international standards, buyers should verify that the end dump truck adheres to local and international regulations, such as safety and environmental standards. Request documentation proving compliance, such as CE certification for Europe or DOT compliance for the U.S. Additionally, consider conducting a third-party inspection to validate quality and safety before purchase. Engaging with reputable suppliers who have a proven track record in international markets can also help mitigate risks associated with non-compliance. -

What is the best capacity for an end dump truck for construction projects?

The optimal capacity for an end dump truck varies based on project requirements. For standard construction tasks, trucks with capacities ranging from 15 to 30 cubic yards are commonly preferred. However, larger projects may benefit from trucks with capacities exceeding 30 cubic yards, enabling fewer trips and reducing transportation costs. Assess the volume of material to be transported and the project timeline to determine the most suitable capacity that aligns with your operational needs. -

What customization options should I consider when sourcing an end dump truck?

Customization options for end dump trucks can significantly impact their efficiency and suitability for specific tasks. Key considerations include bed size, hoist type, suspension system, and materials used in construction. Optional features like tarps, lift axles, and specialized tailgate designs can enhance functionality. Ensure to communicate your specific operational requirements to suppliers to explore available customization options that can optimize performance and durability for your applications. -

How do I vet suppliers when purchasing end dump trucks internationally?

Vetting suppliers is crucial for ensuring a reliable partnership. Start by checking the supplier’s reputation through reviews, testimonials, and case studies. Request references from previous clients, especially those in your region, to gauge their experience. Additionally, verify the supplier’s certifications, production capabilities, and after-sales support. Engaging in direct communication and possibly arranging factory visits can provide deeper insights into their operational standards and product quality. -

What are the typical minimum order quantities (MOQs) for end dump trucks?

Minimum order quantities for end dump trucks can vary widely depending on the manufacturer and the specific model. Generally, MOQs range from one unit for specialized or custom orders to several units for standard models. It is advisable to discuss your needs with potential suppliers to negotiate favorable terms. Keep in mind that larger orders may yield better pricing and terms, so consider consolidating orders with other buyers if feasible. -

What payment terms are commonly offered by international suppliers for end dump trucks?

Payment terms can vary significantly among suppliers, but common practices include a deposit (often 30-50%) upon order confirmation, with the balance due prior to shipment or upon delivery. Some suppliers may offer flexible financing options or letters of credit for larger purchases. It’s essential to establish clear payment terms upfront to avoid misunderstandings. Always ensure that payment methods are secure and traceable to protect your investment. -

How can I ensure quality assurance (QA) for my end dump truck purchase?

To ensure quality assurance, request detailed specifications and quality control processes from the supplier. Many reputable manufacturers perform rigorous testing and inspections throughout the production process. In addition, consider including quality assurance clauses in your purchase agreement, which may involve third-party inspections before shipment. Establishing a clear communication channel with the supplier for updates on production status can also help in managing expectations and quality standards. -

What logistics considerations should I keep in mind when importing end dump trucks?

Logistics play a critical role in the successful import of end dump trucks. Factors to consider include shipping methods (e.g., container shipping vs. roll-on/roll-off), customs clearance processes, and associated tariffs and duties. It is advisable to work with logistics providers who specialize in heavy equipment to navigate the complexities of international shipping. Additionally, ensure that all necessary documentation, such as bills of lading and import permits, is prepared in advance to avoid delays upon arrival.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 End Dump Truck Manufacturers & Suppliers List

1. Construction Trailer Specialists – Rock Master™ Quarter Frame End Dump Trailer

Domain: constructiontrailerspecialists.com

Registered: 2003 (22 years)

Introduction: {‘End_Dumps’: [{‘model’: ‘Rock Master™ Quarter Frame End Dump Trailer’, ‘dimensions’: {‘length’: “24′”, ‘width’: ‘102″‘, ‘side_height’: ’48″‘}, ‘lighting’: ‘Standard LED Lighting’, ‘king_pin_height’: ’18” / 49″‘, ‘color_options’: [‘White’, ‘Black’, ‘Grey’], ‘hoist’: ‘8″, 5 Stage, Inverted Trunnion Mount’, ‘tub’: ‘1/4″ AR 450 Wear Plate’, ‘nose_gate’: ‘3/16″ AR 450 Wear Plate’, ‘axles’: ‘25,000lb. …

2. Truxas – End Dump Trailers

Domain: truxassales.com

Registered: 2014 (11 years)

Introduction: Truxas – Construction Truck Specialist’s End Dump Trailers, Frameless End Dump Trailers, Vacuum Tank Trailers, Dumping Pup Trailers, Dumping Wagons, Roll-Off Trailers, Dumping Equipment Trailers, Interchangeable Body, Trailer Chassis, All Inventory, New Truck Body Parts, New Truck Parts, New Trailer Parts, Used Truck Parts.

3. The Truckers Report – End Dump Trucking Insights

Domain: thetruckersreport.com

Registered: 2003 (22 years)

Introduction: End dump trucking involves hauling products to construction sites, often requiring advanced driving skills due to soft and uneven ground. Drivers may encounter situations where they need to back up long distances on narrow paths, and they must be vigilant about clearance issues to avoid damaging the truck or surrounding property. Weather conditions can complicate the job, with challenges such as l…

4. Maxim Inc – End Dump Trailers

Domain: maximinc.com

Registered: 1998 (27 years)

Introduction: End Dump Trailers: Commonly used in construction and agriculture, range from 26 to 40 ft, tandem or tridem axle configurations. Pros: Higher sides for heavier loads, durable, versatile, rapid unloading, can handle various materials. Cons: Least stable when unloading, harder to maneuver, requires skilled operation, needs sealed tailgate for semi-liquid materials. Recommended brands: Arne’s Manufact…

5. Mactrailer – MVP™ Dump Trailer

Domain: mactrailer.com

Registered: 2000 (25 years)

Introduction: {“Dump_Trailers”: [{“Model”: “MVP™ Dump Trailer”, “Overview”: “Lightweight and strong, for ultimate performance. Features a second side panel to hide dents.”, “Material”: “Aluminum”}, {“Model”: “Sheet & Post Dump Trailer”, “Overview”: “Increase your payload and profits with strength and durability.”, “Material”: “Aluminum”}, {“Model”: “Half Round Dump Trailer”, “Overview”: “Lightweight, durable tr…

6. End Dump Trailers – VANTAGE TRAILERS

Domain: commercialtrucktrader.com

Registered: 2004 (21 years)

Introduction: Used End Dump Trailers for Sale – Commercial Truck Trader

Key Product Details:

– Top Makes: VANTAGE TRAILERS (88), MAC TRAILER MFG (26), EAST (15), FRUEHAUF (14), TRAVIS TRAILER (13), CPS (10), CLEMENT (10), MATE (7), BRAZOS TRAILERS (3), Other Makes include CMC (3), CONSTRUCTION TRAILER SPECIALIST (5), DRAGON (3), HILBILT (4), MAC-LANDER (5), PALMER (4), RANCO (6), RAVENS (4), RELIANCE (4), TRAI…

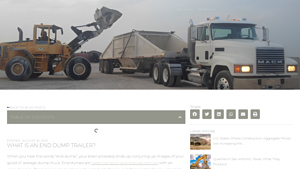

7. WeTruckItAll – End Dump Trailers

Domain: wetruckitall.com

Introduction: End Dumps available in Los Angeles, California. Fleet consists of new End Dump trailers with a legal limit of 80,000 GVW. Trailers range from 34-38 ft, allowing for larger payloads compared to competitors’ 30-32 ft trailers (75,000 GVW). Average payload is 23 tons and 12 CY. Services include on-time pickups and deliveries with well-maintained vehicles and dedicated drivers. Open 7 days a week, inc…

8. Twisted Nail – End Dump Trailers

Domain: twistednail.com

Registered: 2005 (20 years)

Introduction: End Dump Trailers are waste transport and disposal vehicles with an open-top box that unloads from the back. They come in two main materials: aluminum and steel, each with its pros and cons. Aluminum trailers are lighter, rust-resistant, and cost-effective over time but can be costly upfront and require special treatments. Steel trailers are strong, durable, and cheaper upfront but are heavier and…

Strategic Sourcing Conclusion and Outlook for end Dump Truck

As the demand for end dump trucks grows across diverse markets, strategic sourcing becomes essential for international buyers. Understanding the specifications, capabilities, and operational efficiencies of end dump trucks can significantly impact procurement decisions. Key insights highlight the versatility of these trucks in transporting various materials, making them indispensable in construction, mining, and infrastructure projects. Additionally, the availability of custom features and enhancements allows for tailored solutions that meet specific operational needs.

For B2B buyers in regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to cost savings, improved supply chain efficiency, and enhanced project outcomes. By focusing on quality, durability, and technological advancements, companies can ensure they are investing in equipment that not only meets current demands but also adapts to future challenges.

Looking ahead, the end dump truck market is poised for innovation, driven by advancements in materials and technology. Now is the time to engage with trusted suppliers and explore options that align with your operational goals. Make informed decisions today to secure your competitive advantage in the evolving landscape of construction and transportation.