Introduction: Navigating the Global Market for cargo Trucks Spare Parts

In the competitive landscape of the global cargo trucks spare parts market, sourcing the right components is a critical challenge for international B2B buyers. Whether you’re operating in Africa, South America, the Middle East, or Europe, the task of finding reliable suppliers who offer quality parts at competitive prices can be daunting. This guide aims to demystify the complexities of sourcing cargo trucks spare parts by providing a comprehensive overview of the types of parts available, their applications, and crucial supplier vetting processes.

From essential components like brakes and lighting systems to specialized parts for cargo trucks, understanding the nuances of each category is vital for making informed purchasing decisions. Additionally, we delve into cost considerations, helping buyers navigate budget constraints while ensuring quality and reliability.

By equipping B2B buyers with actionable insights and practical tips, this guide empowers decision-makers to confidently approach their sourcing needs. With a focus on fostering strong supplier relationships and optimizing procurement strategies, you’ll be better positioned to enhance your fleet’s performance and reduce downtime. Explore this guide to unlock the potential of your cargo truck operations, ensuring that you have the right parts when you need them the most.

Understanding cargo Trucks Spare Parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Engine Components | Includes parts like pistons, valves, and gaskets. | Fleet maintenance, repair shops | Pros: Essential for vehicle performance; Cons: High cost and complex installation. |

| Electrical Systems | Comprises wiring harnesses, batteries, and lighting. | Logistics companies, delivery services | Pros: Vital for safety and functionality; Cons: Vulnerable to wear and require regular checks. |

| Chassis and Suspension | Encompasses springs, shock absorbers, and axles. | Construction, transportation sectors | Pros: Enhances vehicle stability; Cons: Installation may require specialized knowledge. |

| Body and Exterior Parts | Includes doors, panels, and bumpers. | Custom builds, repair facilities | Pros: Affects aesthetics and aerodynamics; Cons: Can be costly for high-quality materials. |

| Braking Systems | Features brake pads, rotors, and hydraulic components. | Freight carriers, emergency services | Pros: Critical for safety; Cons: Frequent replacement needed, impacting operational costs. |

What Are the Key Characteristics of Engine Components in Cargo Trucks?

Engine components are fundamental to the operation of cargo trucks, encompassing critical elements such as pistons, valves, and gaskets. These parts ensure optimal engine performance, fuel efficiency, and compliance with emission standards. B2B buyers should consider the compatibility of these components with specific engine models and the overall lifecycle costs associated with maintenance and replacement. Investing in high-quality engine parts can lead to significant long-term savings and improved vehicle reliability.

Why Are Electrical Systems Crucial for Cargo Truck Operations?

Electrical systems in cargo trucks include wiring harnesses, batteries, and lighting systems that are essential for safe and efficient operation. These components are crucial for powering various systems, including navigation and safety features. For B2B buyers, understanding the durability and warranty of electrical parts is vital, as these systems can be prone to wear and tear. Regular maintenance and timely replacements can prevent costly downtimes and enhance the overall safety of cargo transportation.

How Do Chassis and Suspension Parts Impact Cargo Truck Performance?

Chassis and suspension parts, such as springs, shock absorbers, and axles, are crucial for maintaining vehicle stability and handling. These components directly affect the ride quality and load-bearing capacity of cargo trucks, making them essential for industries like construction and transportation. B2B buyers should evaluate the specific requirements of their operations and consider factors such as load capacity and terrain when selecting these parts. Proper installation and maintenance of chassis components can significantly enhance vehicle longevity and operational efficiency.

What Role Do Body and Exterior Parts Play in Cargo Truck Functionality?

Body and exterior parts, including doors, panels, and bumpers, not only contribute to the aesthetic appeal of cargo trucks but also influence their aerodynamics and overall functionality. For businesses involved in custom builds or repairs, selecting high-quality body parts is crucial. Buyers should consider the material durability and fitment to ensure seamless integration with existing structures. While these components can represent a higher upfront cost, investing in quality can lead to reduced maintenance needs and improved vehicle performance over time.

Why Are Braking Systems Essential for Cargo Truck Safety?

Braking systems are a critical safety component in cargo trucks, consisting of brake pads, rotors, and hydraulic parts. The reliability of these systems is paramount for preventing accidents and ensuring compliance with safety regulations. B2B buyers must prioritize the quality and performance of braking components, as frequent replacements can lead to increased operational costs. Regular inspections and timely upgrades of braking systems are essential for maintaining fleet safety and minimizing liability risks associated with cargo transportation.

Key Industrial Applications of cargo Trucks Spare Parts

| Industry/Sector | Specific Application of cargo Trucks Spare Parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Transportation | Replacement parts for delivery trucks | Minimizes downtime and ensures timely deliveries | Quality assurance, compatibility with existing fleet |

| Food & Beverage | Parts for refrigerated cargo trucks | Maintains product quality during transportation | Temperature control features, regulatory compliance |

| Construction | Heavy-duty parts for dump trucks | Enhances operational efficiency on job sites | Durability, load capacity, and local availability |

| Waste Management | Components for garbage trucks | Increases reliability and reduces operational costs | Availability of specialized parts and service support |

| Agriculture | Spare parts for agricultural transport vehicles | Supports timely harvest and distribution of products | Adaptability to varied terrains and environmental conditions |

How Are Cargo Truck Spare Parts Utilized in Logistics & Transportation?

In the logistics and transportation sector, cargo trucks are essential for timely deliveries. Spare parts like brake systems, lighting components, and suspension systems are critical for maintaining vehicle performance. Any malfunction can lead to delays, impacting customer satisfaction. Buyers in this sector must prioritize sourcing high-quality, compatible parts that meet specific vehicle models to ensure seamless integration and compliance with local regulations, particularly in diverse markets like Africa and South America.

What Role Do Cargo Truck Spare Parts Play in the Food & Beverage Industry?

Refrigerated cargo trucks are vital for transporting perishable goods. Spare parts such as cooling units, temperature sensors, and insulation materials help maintain the integrity of the products during transit. This is crucial for meeting health and safety standards. International buyers must consider sourcing components that comply with local food safety regulations and are capable of withstanding varying climate conditions, particularly in regions with extreme temperatures.

How Do Spare Parts Impact the Construction Industry?

In the construction industry, cargo trucks, especially dump trucks, are used to transport materials and equipment. Heavy-duty parts such as hydraulic systems, axle components, and tires are essential for ensuring efficient operations on job sites. The reliability of these trucks directly influences project timelines and costs. Buyers should focus on sourcing durable parts that can handle heavy loads and rough terrains, ensuring they are readily available to minimize downtime.

Why Are Spare Parts Essential for Waste Management Operations?

Waste management relies heavily on garbage trucks equipped with specialized components such as compactors, lift systems, and hydraulic cylinders. These parts enhance the reliability of waste collection operations, thus reducing operational costs and improving service delivery. Buyers in this sector should ensure that they source parts that are durable and designed for the specific demands of waste management, including compliance with local environmental regulations.

What is the Importance of Cargo Truck Spare Parts in Agriculture?

Agricultural transport vehicles are crucial for the timely distribution of harvested goods. Spare parts such as trailer hitches, brake systems, and suspension components must be reliable to navigate challenging terrains. The efficiency of these vehicles directly affects productivity and profitability in agriculture. Buyers should seek parts that are adaptable to diverse environmental conditions and ensure compatibility with various vehicle models to support seamless operations.

3 Common User Pain Points for ‘cargo Trucks Spare Parts’ & Their Solutions

Scenario 1: Navigating Delays in Spare Parts Delivery

The Problem:

International B2B buyers often encounter significant delays in receiving cargo truck spare parts due to logistical challenges, customs regulations, and supply chain disruptions. This can lead to prolonged downtime for their fleet, resulting in lost revenue and unsatisfied customers. For companies relying on timely delivery, such delays can severely impact their operational efficiency and reputation in the marketplace.

The Solution:

To mitigate delivery delays, it is essential for B2B buyers to establish strong relationships with reputable suppliers who have proven capabilities in international shipping and logistics. Before placing orders, engage in discussions about their shipping processes, lead times, and experience with customs clearance in your region. Additionally, consider leveraging local distributors or suppliers who can provide the same parts domestically, thereby reducing transit times. Implementing a robust inventory management system can also help track usage rates and predict parts needs, allowing for proactive ordering well in advance of anticipated demands.

Scenario 2: Difficulty in Identifying the Right Spare Parts

The Problem:

One of the most common pain points for B2B buyers is the challenge of accurately identifying the correct spare parts for their specific cargo trucks. The variety of models, parts specifications, and manufacturers can make this a daunting task, leading to incorrect orders that waste time and resources. This issue is particularly pronounced when dealing with older or less common truck models, where part compatibility is not straightforward.

The Solution:

Investing time in comprehensive parts catalogs and utilizing digital tools can significantly improve the accuracy of parts identification. Many suppliers offer online databases where buyers can search by truck model, VIN, or part number. It is advisable to cross-reference these databases with the vehicle’s service manual to ensure compatibility. Furthermore, engaging with technical support teams from suppliers can provide additional guidance. Consider establishing a standard operating procedure (SOP) for parts ordering that includes verification steps and documentation, which will help streamline the identification process and reduce errors.

Scenario 3: Managing Cost and Quality of Spare Parts

The Problem:

B2B buyers often struggle with balancing the cost of spare parts against the quality and reliability of those parts. In regions like Africa and South America, where budget constraints are prevalent, the temptation to opt for cheaper, lower-quality parts can lead to increased maintenance issues and higher long-term costs. This dilemma can compromise the overall performance and safety of cargo trucks.

The Solution:

To effectively manage costs while ensuring quality, buyers should conduct thorough research on suppliers and the parts they offer. Look for suppliers that provide transparent information regarding their manufacturing processes, material quality, and warranty policies. It may be beneficial to invest in original equipment manufacturer (OEM) parts when feasible, as they typically offer better reliability and longevity compared to generic alternatives. Additionally, consider bulk purchasing agreements or long-term contracts with suppliers, which can often result in discounted pricing. Regularly assessing and comparing the total cost of ownership, including maintenance and downtime costs, can also provide insight into the best value options available.

Strategic Material Selection Guide for cargo Trucks Spare Parts

What Are the Key Materials Used in Cargo Trucks Spare Parts?

When selecting materials for cargo trucks spare parts, it’s essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials: steel, aluminum, plastic, and rubber.

How Does Steel Perform in Cargo Truck Spare Parts?

Steel is a widely used material in cargo truck spare parts due to its exceptional strength and durability. It typically exhibits high temperature and pressure ratings, making it suitable for components like chassis, suspension systems, and engine parts. Steel’s corrosion resistance can be enhanced through galvanization or coating, which is crucial for trucks operating in harsh environments.

Pros: Steel is known for its high tensile strength and cost-effectiveness, making it a popular choice for heavy-duty applications. Its manufacturing processes are well-established, ensuring a consistent supply of high-quality parts.

Cons: However, steel can be heavy, which may affect the overall weight of the vehicle and its fuel efficiency. Additionally, if not properly treated, it is susceptible to rust and corrosion, particularly in humid or saline environments.

For international B2B buyers, compliance with standards such as ASTM A36 or DIN 17100 is critical. Buyers in regions like Africa and South America should also consider local environmental conditions when selecting steel parts.

What Advantages Does Aluminum Offer for Cargo Truck Spare Parts?

Aluminum is another popular material, especially for parts that require a lightweight solution without sacrificing strength. It has good corrosion resistance and performs well in various temperatures, making it ideal for components such as body panels and brackets.

Pros: The primary advantage of aluminum is its lightweight nature, which can significantly improve fuel efficiency. It also offers excellent resistance to corrosion, reducing maintenance costs over time.

Cons: On the downside, aluminum can be more expensive than steel and may not have the same load-bearing capacity. Its manufacturing processes can also be more complex, which could lead to longer lead times for international orders.

B2B buyers should ensure that aluminum parts meet standards like ASTM B221 or JIS H4000. In regions like the Middle East, where high temperatures are common, the thermal properties of aluminum can be particularly beneficial.

How Do Plastics Fit into the Cargo Truck Spare Parts Landscape?

Plastics are increasingly used in cargo truck spare parts due to their versatility and lightweight characteristics. Common applications include interior components, electrical housings, and some exterior parts.

Pros: Plastics offer excellent resistance to moisture, chemicals, and UV light, making them suitable for various environmental conditions. They are also cost-effective and can be molded into complex shapes, allowing for innovative designs.

Cons: However, plastics generally have lower strength compared to metals and may not be suitable for high-stress applications. They can also degrade over time when exposed to extreme temperatures.

International buyers should consider compliance with standards such as ASTM D638 for tensile properties. In markets like Europe, recyclability and environmental impact are increasingly important factors in material selection.

What Role Does Rubber Play in Cargo Truck Spare Parts?

Rubber is primarily used for components that require flexibility and shock absorption, such as seals, gaskets, and suspension bushings. It performs well under varying temperatures and provides excellent resistance to wear and tear.

Pros: The flexibility of rubber allows it to absorb vibrations and impacts, enhancing the comfort and safety of cargo trucks. It is also relatively inexpensive and widely available.

Cons: However, rubber can degrade over time, especially when exposed to ozone, UV light, or extreme temperatures. Its performance can also vary significantly based on the specific type of rubber used.

For international B2B buyers, ensuring that rubber components comply with standards such as ASTM D2000 is crucial. In regions with high temperatures, selecting rubber compounds that can withstand heat is particularly important.

Summary Table of Material Selection for Cargo Trucks Spare Parts

| Material | Typical Use Case for cargo Trucks Spare Parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis, suspension systems, engine parts | High strength and cost-effective | Heavy and susceptible to rust | Medium |

| Aluminum | Body panels, brackets | Lightweight and corrosion-resistant | More expensive and lower load capacity | High |

| Plastic | Interior components, electrical housings | Moisture and chemical resistance | Lower strength and potential degradation | Low |

| Rubber | Seals, gaskets, suspension bushings | Flexibility and shock absorption | Degrades over time and variable performance | Low |

This strategic material selection guide provides valuable insights for B2B buyers in the cargo truck parts market, enabling informed decisions based on performance, cost, and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cargo Trucks Spare Parts

What Are the Main Stages of Manufacturing Cargo Truck Spare Parts?

The manufacturing of cargo truck spare parts involves a series of meticulously planned stages, each critical for ensuring the end product meets industry standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

This initial stage involves sourcing high-quality raw materials that comply with international standards. Common materials include steel, aluminum, and plastics, each selected based on the specific application of the spare part. Suppliers often perform material testing to ensure durability and performance, with certifications like ASTM or ISO 9001 playing a crucial role in material selection. -

Forming:

The forming process encompasses various techniques such as stamping, casting, and machining. Stamping is commonly used for metal parts, where sheets of metal are shaped into desired forms using dies. Casting is employed for complex shapes, allowing for intricate designs that would be difficult to achieve through machining alone. For precision components, CNC machining is utilized to achieve tight tolerances, ensuring that parts fit together seamlessly. -

Assembly:

After forming, the next step is assembly, where individual components are brought together to create the final product. This process may involve welding, riveting, or bolting parts together. Automated assembly lines are increasingly used to enhance efficiency and reduce human error, while skilled technicians oversee the process to ensure quality. -

Finishing:

The finishing stage includes surface treatments like painting, plating, or coating to enhance corrosion resistance and aesthetics. Techniques such as powder coating provide a durable finish, while galvanization protects against rust. This stage is essential for ensuring that parts can withstand harsh environmental conditions, particularly for trucks operating in diverse climates.

How Is Quality Assurance Implemented in Cargo Truck Spare Parts Manufacturing?

Quality assurance (QA) is a fundamental aspect of manufacturing cargo truck spare parts, ensuring that each product meets specific standards for safety, reliability, and performance. The QA process typically aligns with international standards such as ISO 9001, as well as industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute).

-

International and Industry-Specific Standards:

Compliance with ISO 9001 indicates a commitment to quality management systems, encompassing all phases of production. CE marking demonstrates that products meet EU safety, health, and environmental protection requirements, while API standards are crucial for parts related to oil and gas applications. -

Quality Control Checkpoints:

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. These typically include:

– Incoming Quality Control (IQC): Inspection of raw materials before production begins, ensuring they meet specifications.

– In-Process Quality Control (IPQC): Ongoing checks during manufacturing to identify defects early, allowing for immediate corrective actions.

– Final Quality Control (FQC): A thorough examination of finished products to confirm they meet all quality standards before shipment. -

Common Testing Methods:

Various testing methods are employed to assess the integrity and functionality of spare parts. These include:

– Mechanical Testing: Evaluates the strength and durability of materials.

– Dimensional Inspection: Ensures that parts conform to specified dimensions and tolerances.

– Non-Destructive Testing (NDT): Techniques like ultrasonic or magnetic particle testing are used to identify internal defects without damaging the parts.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial to ensure reliable procurement. Here are actionable strategies:

-

Supplier Audits:

Conducting on-site audits is one of the most effective ways to assess a supplier’s quality control processes. Buyers should look for evidence of compliance with international standards and the presence of documented quality management systems. -

Quality Reports and Documentation:

Requesting detailed quality reports can provide insights into a supplier’s QC measures. These should include inspection records, test results, and any certifications. Suppliers should be willing to share this information to build trust. -

Third-Party Inspections:

Engaging third-party inspection agencies can offer an unbiased assessment of the manufacturing process and quality control. These agencies can conduct audits and testing on behalf of the buyer, ensuring compliance with standards. -

Certifications and Accreditations:

Buyers should verify any claims of certifications (e.g., ISO, CE, API) by checking with the issuing bodies. This step ensures that the supplier maintains compliance with the necessary quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the complexities of quality control in international trade can present unique challenges for B2B buyers. Understanding these nuances is essential for successful procurement:

-

Cultural Differences in Quality Standards:

Different regions may have varying standards and expectations regarding quality. Buyers should familiarize themselves with local practices and regulations to avoid misunderstandings. -

Language Barriers:

Communication can be hindered by language differences. It’s vital for buyers to ensure that technical specifications and quality requirements are clearly understood by all parties involved. -

Logistical Considerations:

Shipping and customs processes can impact the quality of spare parts. Buyers should be aware of potential delays and ensure that proper handling and storage conditions are maintained throughout transit. -

Warranty and After-Sales Support:

Understanding a supplier’s warranty policies and after-sales support is crucial for long-term partnerships. Buyers should inquire about the process for addressing defects or issues that may arise post-purchase.

By comprehensively understanding the manufacturing processes and quality assurance measures, international B2B buyers can make informed decisions when sourcing cargo truck spare parts, ensuring that they invest in high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cargo Trucks Spare Parts’

In the complex world of logistics and transportation, sourcing spare parts for cargo trucks is a critical operation that can significantly impact efficiency and cost management. This guide provides a structured approach to help B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Identify the make, model, and year of the cargo trucks you are sourcing parts for, as compatibility is essential. Document specific requirements, such as dimensions, materials, and performance standards to ensure that the parts will meet operational demands.

Step 2: Research Potential Suppliers

Begin your search by identifying potential suppliers who specialize in cargo truck spare parts. Utilize online marketplaces, industry forums, and trade shows to gather a list of reputable vendors. Pay attention to their product offerings, customer reviews, and market presence to gauge reliability and experience in the industry.

Step 3: Evaluate Supplier Certifications

Before proceeding with any supplier, verify their certifications and compliance with international standards. Look for certifications such as ISO 9001, which indicates a commitment to quality management. This step helps ensure that the parts you procure will meet safety and performance benchmarks.

Step 4: Request Samples or Prototypes

Once you have narrowed down your list of suppliers, request samples or prototypes of the parts you need. Testing these samples allows you to assess quality, fit, and functionality before placing a bulk order. This is particularly important for critical components that directly affect vehicle performance and safety.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your chosen suppliers regarding pricing, payment terms, and delivery schedules. Ensure that you understand the total cost, including shipping and potential tariffs, to avoid budget overruns. Negotiating favorable terms can lead to long-term partnerships that benefit both parties.

Step 6: Review Logistics and Shipping Options

Consider the logistics of transporting the parts from the supplier to your location. Evaluate shipping methods, transit times, and costs. It is essential to coordinate these details to minimize downtime and ensure that your cargo trucks are operational as quickly as possible.

Step 7: Establish a Follow-Up and Quality Assurance Process

After the parts are delivered, implement a system for quality assurance and follow-up. Inspect the parts upon arrival to confirm they meet your specifications and standards. Establishing a feedback loop with your supplier can foster continuous improvement and strengthen your business relationship.

By following these steps, you can streamline the sourcing process for cargo truck spare parts, ensuring that your operations remain efficient and cost-effective. Each step is designed to mitigate risks and enhance the quality of your procurement, ultimately leading to better service delivery and customer satisfaction.

Comprehensive Cost and Pricing Analysis for cargo Trucks Spare Parts Sourcing

What Are the Key Cost Components in Sourcing Cargo Truck Spare Parts?

When sourcing cargo truck spare parts, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality and type of materials directly impact the price. High-grade materials may increase upfront costs but can enhance durability and reduce maintenance expenses over time.

-

Labor: Labor costs encompass the wages of workers involved in the manufacturing process. Skilled labor often results in higher quality parts, which can justify the investment.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these overhead costs.

-

Tooling: The cost of specialized tools and machinery used in production can be significant, particularly for custom parts. Buyers should consider whether standard parts can meet their needs to avoid these costs.

-

Quality Control (QC): Ensuring that parts meet specifications through rigorous QC processes can add to the cost. However, this investment is crucial for minimizing defects and ensuring reliability.

-

Logistics: Transportation and handling costs vary based on the distance from the supplier and the shipping method chosen. Understanding these logistics is vital for budgeting accurately.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on competition, demand, and supplier relationships.

How Do Price Influencers Affect Cargo Truck Spare Parts Costs?

Several factors influence the pricing of cargo truck spare parts, and understanding these can aid in negotiating better deals:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often result in discounts, making it advantageous for businesses to consolidate purchases when possible.

-

Specifications/Customization: Custom parts tailored to specific vehicle models or performance requirements can increase costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials: As mentioned, the choice of materials plays a crucial role. Premium materials may lead to higher costs but can yield lower long-term operational costs.

-

Quality and Certifications: Parts that meet industry standards or certifications typically command higher prices. Investing in certified parts can enhance reliability and safety, making them worth the additional cost.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven quality, while lesser-known suppliers might offer lower prices but with increased risk.

-

Incoterms: Understanding international shipping terms is essential for cost management. Different Incoterms can affect who bears the responsibility for shipping costs and risks, impacting the overall price.

What Buyer Tips Can Help Optimize Costs in Sourcing Spare Parts?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following tips to optimize costs:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Building relationships can lead to better terms and discounts.

-

Cost-Efficiency: Assess the total cost of ownership rather than just the purchase price. Consider maintenance, downtime, and replacement frequency when evaluating parts.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, tariffs, and import duties that can affect the final price. Local regulations may also impact sourcing decisions.

-

Supplier Diversification: Don’t rely solely on one supplier. Exploring multiple sources can lead to better pricing and reduced risk in the supply chain.

-

Research and Comparison: Conduct thorough market research and compare prices among suppliers. This will provide a clearer picture of the market and help in making informed decisions.

Disclaimer on Indicative Prices

Prices for cargo truck spare parts can vary significantly based on numerous factors, including market demand, regional pricing strategies, and supplier terms. It is advisable to request quotes from multiple suppliers to ensure competitive pricing and to verify the latest market conditions before making any purchasing decisions.

Alternatives Analysis: Comparing cargo Trucks Spare Parts With Other Solutions

Understanding Alternatives in Cargo Truck Maintenance Solutions

In the competitive landscape of cargo truck operations, selecting the right maintenance solution is crucial for efficiency and profitability. While traditional cargo truck spare parts remain a staple for repairs and enhancements, alternative solutions are emerging that can offer comparable or even superior benefits. This analysis compares cargo truck spare parts with two viable alternatives: aftermarket parts and fleet maintenance software.

Comparison Table

| Comparison Aspect | Cargo Trucks Spare Parts | Aftermarket Parts | Fleet Maintenance Software |

|---|---|---|---|

| Performance | High reliability; OEM standards | Variable quality; dependent on supplier | Optimizes maintenance schedules; enhances fleet performance |

| Cost | Moderate to high; OEM pricing | Generally lower; varies widely | Subscription-based; potential cost savings through efficiency |

| Ease of Implementation | Direct replacement; straightforward | May require additional research | Requires training and integration |

| Maintenance | Regular inspections needed; physical inventory | Similar to OEM; quality checks necessary | Automated alerts and tracking; reduces manual oversight |

| Best Use Case | Direct replacements for specific models | Cost-effective for budget-conscious operators | Ideal for managing large fleets with complex maintenance needs |

In-Depth Analysis of Alternatives

What are Aftermarket Parts and Their Benefits?

Aftermarket parts are alternative components produced by third-party manufacturers. They often come at a lower cost than OEM parts, making them appealing for budget-conscious operators. The primary advantage of aftermarket parts is their affordability, which can lead to significant savings, especially for fleets that require frequent replacements. However, quality can be inconsistent, and some parts may not meet the same standards as OEM components, potentially affecting long-term vehicle performance.

How Does Fleet Maintenance Software Enhance Operations?

Fleet maintenance software is a digital solution that streamlines maintenance management. This technology allows fleet operators to track vehicle performance, schedule maintenance, and manage spare parts inventory more efficiently. The primary benefits include reduced downtime and improved vehicle reliability, as automated alerts can prevent issues before they escalate. However, the initial investment in software and the need for staff training can be barriers for some businesses, particularly smaller operations.

Making the Right Choice for Your Cargo Truck Maintenance Needs

When considering the best solution for cargo truck maintenance, B2B buyers should evaluate their specific operational requirements, budget constraints, and long-term goals. Cargo truck spare parts are ideal for those prioritizing reliability and direct replacements, particularly in industries where downtime can be costly. Conversely, aftermarket parts offer an economical option but require careful supplier evaluation to ensure quality. For companies managing larger fleets, fleet maintenance software presents a strategic advantage by enhancing operational efficiency and enabling proactive maintenance strategies.

Ultimately, the decision should align with the company’s operational scale, financial strategy, and performance expectations, ensuring that the chosen solution supports both immediate needs and long-term growth.

Essential Technical Properties and Trade Terminology for cargo Trucks Spare Parts

What Are the Essential Technical Properties of Cargo Truck Spare Parts?

When sourcing spare parts for cargo trucks, understanding critical technical properties is essential for ensuring reliability, durability, and performance. Here are some key specifications to consider:

1. Material Grade

Material grade refers to the quality and composition of the materials used in manufacturing truck parts, such as steel, aluminum, or plastic. High-grade materials typically offer better strength, corrosion resistance, and longevity. For B2B buyers, selecting parts made from appropriate material grades is vital for reducing maintenance costs and ensuring safety.

2. Tolerance

Tolerance defines the permissible limit of variation in a physical dimension of a part. Precision in manufacturing parts with exact tolerances is crucial for proper fit and function. In cargo trucks, parts that do not meet specified tolerances can lead to mechanical failures or performance issues, which can be costly for businesses.

3. Load Capacity

Load capacity indicates the maximum weight that a component can support safely. This specification is particularly important for structural parts like axles and suspension systems. Ensuring that spare parts meet or exceed load capacity requirements helps prevent premature wear and enhances the overall safety of cargo trucks.

4. Compatibility

Compatibility refers to how well a spare part fits with existing components of a cargo truck. It is essential for buyers to verify that parts are compatible with the specific make and model of their vehicles. This avoids costly errors and downtime due to incorrect parts being installed.

5. Finish and Coating

The finish and coating of a part can significantly affect its resistance to environmental factors such as moisture, dirt, and chemicals. Parts with high-quality finishes are less likely to rust or corrode, extending their service life. For international buyers, understanding the appropriate coatings can help in choosing parts suitable for specific climates.

6. Certification Standards

Parts may come with various certifications, such as ISO or SAE standards, indicating that they have met specific quality and safety benchmarks. Certifications provide assurance regarding the reliability and performance of spare parts. B2B buyers should prioritize certified components to mitigate risks associated with substandard products.

What Are Common Trade Terms Used in Cargo Truck Spare Parts?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to parts made by the original manufacturer of the vehicle or its components. These parts are often preferred for their guaranteed compatibility and quality. Buyers should consider OEM parts when seeking replacements to maintain vehicle performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it can affect inventory management and cash flow. Buyers should negotiate MOQs that align with their purchasing capabilities.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to obtain pricing and terms for specific products. This process allows buyers to compare offers from different vendors, ensuring they get the best deal. A well-structured RFQ can streamline procurement processes and enhance decision-making.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, including shipping and delivery. Familiarity with these terms is essential for B2B buyers to understand their obligations and costs associated with shipping spare parts across borders.

5. Warranty

A warranty is a manufacturer’s promise regarding the repair or replacement of a part if it fails within a certain period. Knowing the warranty terms can help buyers make informed decisions and minimize risks associated with defective parts.

6. Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times is crucial for B2B buyers to effectively manage inventory and avoid disruptions in operations. Long lead times can impact business performance, making it essential to choose suppliers with reliable delivery schedules.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions that enhance their operational efficiency and reduce costs in the long run.

Navigating Market Dynamics and Sourcing Trends in the cargo Trucks Spare Parts Sector

What Are the Key Market Dynamics and Trends Affecting Cargo Truck Spare Parts?

The cargo truck spare parts market is witnessing transformative changes driven by several global factors. Increased demand for logistics and transportation, particularly in emerging economies in Africa, South America, the Middle East, and Europe, has created a robust market for spare parts. As e-commerce continues to expand, the need for cargo trucks equipped with reliable components is paramount. Furthermore, advancements in technology are reshaping sourcing trends. Digital platforms and e-commerce solutions are facilitating real-time inventory management and order fulfillment, enabling international B2B buyers to streamline their procurement processes.

Emerging trends include the rise of just-in-time (JIT) sourcing, where businesses prioritize efficiency and cost-effectiveness by acquiring parts as needed rather than maintaining large inventories. This approach minimizes holding costs and enhances cash flow. Additionally, the integration of data analytics and artificial intelligence in supply chain management is allowing companies to predict demand more accurately, making it easier for buyers to source the right parts at the right time. The increasing focus on aftermarket services is also significant, as companies look to enhance the lifespan of their vehicles through preventive maintenance and timely replacement of worn-out parts.

How Is Sustainability and Ethical Sourcing Impacting the Cargo Truck Spare Parts Industry?

Sustainability and ethical sourcing are becoming increasingly critical in the cargo truck spare parts sector. The environmental impact of manufacturing and disposing of spare parts is prompting companies to adopt more sustainable practices. This includes sourcing materials that minimize ecological footprints, such as recycled metals and biodegradable plastics. Buyers are increasingly seeking suppliers who demonstrate a commitment to sustainable practices, which can enhance their brand reputation and customer loyalty.

Moreover, ethical supply chains are essential for ensuring that components are produced under fair labor conditions. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are becoming benchmarks for evaluating suppliers. Companies that prioritize these certifications not only mitigate risks related to compliance but also position themselves as leaders in corporate social responsibility. As international buyers become more discerning, they are likely to favor suppliers who align with their values regarding sustainability and ethical practices.

What Is the Evolution of the Cargo Truck Spare Parts Market?

The cargo truck spare parts market has evolved significantly over the decades, driven by technological advancements and changing consumer needs. Initially dominated by local suppliers, the market has expanded to include global players, enabling a more diverse range of products and services. The introduction of standardized parts has facilitated easier sourcing and replacement, benefiting fleet operators who require consistent quality across their vehicles.

In recent years, the rise of e-commerce and digital marketplaces has transformed how buyers interact with suppliers. This shift has led to increased transparency in pricing and availability, allowing buyers to make informed decisions quickly. As the market continues to grow, the emphasis on innovation and sustainability will likely shape its future, with B2B buyers increasingly prioritizing suppliers that can meet their operational, ethical, and environmental standards.

Frequently Asked Questions (FAQs) for B2B Buyers of cargo Trucks Spare Parts

-

How do I solve supply chain issues when sourcing cargo truck spare parts?

Supply chain disruptions can occur due to various factors such as geopolitical tensions, logistics challenges, or supplier reliability. To mitigate these issues, consider diversifying your supplier base by sourcing from multiple regions. Establish strong communication channels with suppliers to receive timely updates on stock availability and shipping timelines. Additionally, investing in local warehousing can help maintain inventory levels and reduce lead times, ensuring that you can meet your operational demands without significant delays. -

What is the best way to vet suppliers for cargo truck spare parts?

When vetting suppliers, start by evaluating their industry reputation, customer reviews, and experience in the market. Request certifications and quality assurance documents to ensure they comply with international standards. Additionally, consider visiting their facilities if possible or using third-party inspection services to assess their manufacturing capabilities. Establishing a trial order can also help evaluate their service and product quality before committing to larger purchases. -

What customization options are available for cargo truck spare parts?

Many suppliers offer customization for cargo truck spare parts to meet specific operational needs. This may include modifications in size, material, or functionality. When considering customization, clearly communicate your requirements and expectations to the supplier. Ensure they have the capacity and expertise to deliver tailored solutions and request prototypes or samples to validate the modifications before bulk orders. -

What are the typical minimum order quantities (MOQ) for cargo truck spare parts?

Minimum order quantities can vary significantly based on the type of part and the supplier’s policies. Generally, suppliers may have MOQs ranging from a few units to several hundred. It’s advisable to discuss your needs with the supplier upfront, as some may be flexible with MOQs, especially for first-time buyers or larger contracts. Establishing a long-term relationship can also lead to more favorable terms in the future. -

What payment terms should I expect when purchasing cargo truck spare parts internationally?

Payment terms can differ widely among suppliers and regions. Common options include upfront payment, partial payment upon order confirmation, and balance upon delivery. For international transactions, using secure payment methods such as letters of credit or escrow services can provide additional protection. Always negotiate terms that align with your cash flow needs while ensuring the supplier is comfortable with the arrangements. -

How can I ensure quality assurance for cargo truck spare parts?

To guarantee quality, engage suppliers who adhere to recognized quality management systems, such as ISO 9001. Request detailed product specifications and quality control processes before placing an order. Implementing a robust inspection protocol upon receipt of parts, including random sampling and testing, can help identify any discrepancies early. Additionally, maintaining an open line of communication with your supplier regarding quality expectations is vital for long-term success. -

What logistics considerations should I keep in mind when sourcing spare parts?

Logistics plays a crucial role in the timely delivery of cargo truck spare parts. Consider factors such as shipping methods (air, sea, or land), transit times, and customs regulations in both the exporting and importing countries. Collaborate with reliable freight forwarders who have experience in handling automotive parts to navigate these complexities. Additionally, planning for potential delays by incorporating buffer times into your supply chain can help mitigate risks. -

How do I handle returns or exchanges for defective cargo truck spare parts?

Establish clear return and exchange policies with your supplier before making a purchase. Most reputable suppliers will have procedures in place for handling defective parts, which may include return shipping arrangements and replacement processes. Document any issues with the parts thoroughly, including photos and descriptions, to facilitate a smoother claims process. Understanding the warranty terms and conditions associated with your purchase is also essential for managing potential returns effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Cargo Trucks Spare Parts Manufacturers & Suppliers List

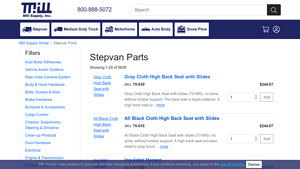

1. Mill Supply – Stepvan Parts

Domain: millsupply.com

Registered: 1996 (29 years)

Introduction: Stepvan Parts available at Mill Supply include:

1. Gray Cloth High Back Seat with Slides – SKU: 70-030, Price: $244.07

2. All Black Cloth High Back Seat with Slides – SKU: 70-035, Price: $244.07

3. Insulator Hanger – SKU: 57-433, Price: $16.50 (Sale Price: $14.52)

4. Complete Wiper Linkage and Motor Assembly – SKU: 49-188, Price: $286.95

5. Sending Unit with Lock Ring – SKU: 81-975, Price: $146.6…

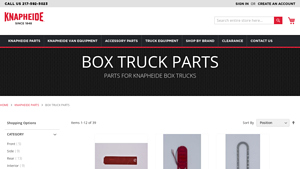

2. Knapheide – Box Truck Parts

Domain: parts.knapheide.com

Registered: 1998 (27 years)

Introduction: Box Truck Parts include various items such as Red Reflector Tape ($11.99), Stop/Turn/Tail/Backup Light for Box Truck ($49.99), Chrome Trim Ring for Stop/Turn/Tail/Backup Light ($9.99), Box Van Grab Handle Aluminum 18″ ($11.99), Box Van Recessed Rope Ring ($7.99), Box Van Solid Aluminum Rivet 3/16″ x 3/8″ ($1.99), Box Van Wire Harness ($69.99), Box Van Corner Cap, Curb Side ($84.99), Box Van Corner…

3. Cargo Heavy Duty – Affordable Truck Parts

Domain: cargohd.com

Registered: 2006 (19 years)

Introduction: Cargo Heavy Duty offers a large inventory of affordable heavy-duty truck parts in Kalamazoo and Coopersville, Michigan. The available parts include brake parts, suspension parts, truck body parts, starters and alternators, landing gears, and clutches. All parts come with a No Questions Asked warranty. Cargo Heavy Duty is an HDA Truck Pride affiliate and provides quality parts to fit various budget…

4. LMC Truck – Truck & SUV Parts

Domain: lmctruck.com

Registered: 1997 (28 years)

Introduction: LMC Truck offers a wide range of truck and SUV parts and accessories for Chevrolet, GMC, Ford, and Dodge vehicles. They have over 30,000 parts in stock and ship most orders within 24-48 business hours. Their product categories include: New Products, Accessories (such as Apparel, Bed & Tailgate Accessories, Bug Deflectors, Fender Flares, Garage Accessories, etc.), Body Components (including Grille …

5. TRP – Heavy Duty Truck Parts

Domain: trpparts.com

Registered: 2007 (18 years)

Introduction: Heavy Duty Truck Parts for Class 8 Trucks. TRP Parts offers a range of products for various regions including the United States, Mexico, Canada, South America, Puerto Rico, Europe, and the United Kingdom. The site provides options to buy online, sign up for a TRP Performance Membership for exclusive rewards, and access to a parts locator app. Users can search for parts by keyword, part number, or …

6. AmericanTrucks – Aftermarket Truck Parts & Accessories

Domain: americantrucks.com

Registered: 1998 (27 years)

Introduction: Aftermarket Truck Parts & Accessories from AmericanTrucks. Free 1 to 3-Day Delivery on Orders $149+. Customer service available M-F 8:30A-11P ET, Sat-Sun 8:30A-9P ET. Vehicle selection for custom shopping experience includes popular models like Ford F-150, F-250, F-350, Ranger, Chevy Silverado (1500, 2500, 3500), Tahoe, Colorado, Ram (1500, 2500, 3500), Dakota, GMC Sierra (1500, 2500, 3500), Yukon…

Strategic Sourcing Conclusion and Outlook for cargo Trucks Spare Parts

In the ever-evolving landscape of cargo truck spare parts, strategic sourcing emerges as a critical component for businesses aiming to optimize operational efficiency and reduce costs. By leveraging reliable suppliers, international B2B buyers can ensure a steady flow of quality components essential for maintaining their fleets. Key takeaways include the importance of assessing supplier reliability, understanding regional market dynamics, and prioritizing parts that enhance vehicle performance and safety.

As emerging markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality spare parts will only increase. B2B buyers should focus on building long-term partnerships with reputable suppliers who offer a wide range of products—from basic components to specialized parts tailored for specific vehicles.

Looking ahead, embracing digital platforms for sourcing and inventory management can significantly streamline procurement processes. This proactive approach not only mitigates supply chain disruptions but also positions businesses to respond swiftly to market changes. Now is the time for international buyers to capitalize on these opportunities and invest in strategic sourcing initiatives that will drive their success in the cargo truck sector.