Introduction: Navigating the Global Market for electric car axel

As the automotive industry shifts towards sustainability, sourcing electric car axles presents a significant challenge for B2B buyers navigating this evolving landscape. The demand for electric vehicles (EVs) is on the rise, driven by global carbon reduction initiatives and a growing need for efficient transport solutions. However, understanding the intricacies of electric axles—ranging from their types and applications to the intricacies of supplier vetting and cost considerations—can be overwhelming. This guide aims to demystify the electric car axle market, providing a comprehensive overview tailored to international buyers, particularly those in Africa, South America, the Middle East, and Europe, including regions like Brazil and Saudi Arabia.

Within this guide, you will explore the various types of electric axles, their applications in different vehicle segments, and the latest technological advancements that enhance performance and efficiency. Additionally, we will delve into best practices for vetting suppliers, ensuring that you partner with manufacturers who meet your quality and sustainability standards. By equipping you with actionable insights and strategic approaches, this guide empowers you to make informed purchasing decisions that align with your business objectives, ultimately enhancing your fleet’s performance and reducing your carbon footprint.

Understanding electric car axel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Integrated eAxle | Combines motor, power electronics, and transmission in one unit | Passenger vehicles, light trucks | Pros: Compact design, reduced complexity. Cons: Limited customization options. |

| Modular eAxle | Allows for tailored power output and torque specifications | Commercial vehicles, delivery vans | Pros: Flexible configurations, scalable performance. Cons: Potentially higher upfront costs. |

| Dual Motor eAxle | Features two motors for enhanced torque and performance | High-performance vehicles, SUVs | Pros: Improved acceleration, better load handling. Cons: Increased weight may affect efficiency. |

| Fuel Cell eAxle | Uses hydrogen fuel cells for power generation | Heavy-duty trucks, long-range transport | Pros: Zero emissions, longer range. Cons: Infrastructure for hydrogen is still developing. |

| Switched Reluctance eAxle | Utilizes switched reluctance motors for cost-effective solutions | Budget-friendly EVs, urban mobility | Pros: Low cost, simple design. Cons: Lower efficiency and torque compared to other motors. |

What are the Characteristics of Integrated eAxles?

Integrated eAxles are designed to combine the electric motor, power electronics, and transmission into a single compact unit. This design minimizes the complexity of the powertrain, making it an attractive option for passenger vehicles and light trucks. For B2B buyers, the main consideration is the balance between compactness and performance. While they offer ease of installation and reduced costs, the trade-off may be limited customization options, which could affect specific operational needs.

How Do Modular eAxles Offer Flexibility?

Modular eAxles are highly adaptable, allowing manufacturers to customize power output and torque to fit various commercial applications, including delivery vans and larger commercial vehicles. Their flexible configurations enable businesses to scale performance according to their operational requirements. However, the initial investment may be higher than traditional systems, which is an essential factor for budget-conscious buyers.

Why Choose Dual Motor eAxles for Performance?

Dual Motor eAxles are engineered to provide enhanced torque and performance by integrating two motors into a single axle. This design is particularly beneficial for high-performance vehicles and SUVs that require quick acceleration and robust load handling. B2B buyers should consider the added weight of this system, which might impact overall vehicle efficiency, but the performance benefits often outweigh this drawback for specific applications.

What Makes Fuel Cell eAxles a Sustainable Choice?

Fuel Cell eAxles utilize hydrogen fuel cells to generate power, making them an eco-friendly alternative for heavy-duty trucks and long-range transport. They offer the advantage of zero emissions and a longer range compared to battery-only systems. However, buyers must consider the current lack of widespread hydrogen infrastructure, which may limit the practicality of this technology in certain regions.

Are Switched Reluctance eAxles Suitable for Budget-Conscious Buyers?

Switched Reluctance eAxles feature a straightforward design that makes them a cost-effective option for budget-friendly electric vehicles and urban mobility solutions. While they are less efficient and have lower torque compared to more advanced motor types, their simplicity and low cost make them appealing for manufacturers looking to keep production expenses down. B2B buyers should weigh these factors against their performance needs and operational goals.

Key Industrial Applications of electric car axel

| Industry/Sector | Specific Application of electric car axel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Transportation | Last-mile delivery electric vehicles (EVs) | Reduced operational costs, lower emissions, and improved efficiency | Compatibility with existing fleet, charging infrastructure, and total cost of ownership |

| Public Transportation | Electric buses and urban transit systems | Enhanced sustainability, lower maintenance costs, and improved passenger comfort | Compliance with local regulations, range requirements, and integration with existing infrastructure |

| Automotive Manufacturing | Production of electric and hybrid vehicles | Competitive advantage in the EV market and adherence to environmental standards | Supplier reliability, technological compatibility, and scalability of production |

| Mining & Heavy Equipment | Electric-powered mining vehicles | Lower fuel costs, reduced emissions, and enhanced operational efficiency | Robustness for heavy-duty applications, availability of spare parts, and local service support |

| Agriculture | Electric tractors and farm machinery | Decreased fuel costs, reduced noise pollution, and improved sustainability | Power requirements for specific tasks, compatibility with existing equipment, and local support services |

How is Electric Car Axle Used in Logistics & Transportation?

In the logistics and transportation sector, electric car axles are critical for last-mile delivery vehicles. By integrating eAxles into electric vans and trucks, companies can achieve significant reductions in operational costs and emissions. This technology not only enhances vehicle efficiency but also supports sustainability initiatives. B2B buyers in this sector should consider the compatibility of eAxles with existing fleet models and the availability of charging infrastructure, especially in regions where electric vehicle adoption is still developing, such as parts of Africa and South America.

What Role Do Electric Car Axles Play in Public Transportation?

Electric car axles are transforming public transportation, particularly in electric buses and urban transit systems. These axles provide high torque and efficiency, enabling buses to operate more sustainably while offering a smoother ride for passengers. The key benefits include lower maintenance costs and compliance with stringent environmental regulations. International buyers must evaluate local regulations, the required range for daily operations, and the integration of eAxles with existing transit infrastructure, especially in rapidly urbanizing regions of the Middle East and Europe.

How Are Electric Car Axles Impacting Automotive Manufacturing?

In automotive manufacturing, the adoption of electric car axles is essential for producing electric and hybrid vehicles. These axles offer a competitive edge by streamlining the powertrain, resulting in lighter and more efficient vehicles. Manufacturers benefit from improved performance metrics and adherence to environmental standards. B2B buyers should focus on supplier reliability, technological compatibility, and the ability to scale production to meet market demand, particularly in regions where electric vehicle markets are expanding, such as Brazil and Saudi Arabia.

What Benefits Do Electric Car Axles Offer in Mining & Heavy Equipment?

Electric car axles are increasingly used in electric-powered mining vehicles, providing substantial benefits such as lower fuel costs and reduced emissions. The durability and efficiency of these axles are crucial for heavy-duty applications in harsh environments. For B2B buyers in the mining sector, it is essential to assess the robustness of the axles, the availability of spare parts, and local service support to ensure uninterrupted operations, particularly in remote locations.

How Can Electric Car Axles Improve Agricultural Machinery?

In agriculture, electric car axles are being integrated into electric tractors and farm machinery, leading to decreased fuel costs and reduced noise pollution. These advancements support sustainable farming practices and enhance operational efficiency. Buyers in this sector should consider the specific power requirements for various agricultural tasks, compatibility with existing equipment, and the availability of local support services to maximize the benefits of eAxles in their operations.

3 Common User Pain Points for ‘electric car axel’ & Their Solutions

Scenario 1: Navigating the High Costs of Electric Axles

The Problem:

B2B buyers often face significant budget constraints when considering the transition to electric vehicles, particularly for fleets that require electric axles (eAxles). The upfront costs associated with these advanced components can be prohibitive, especially for businesses operating in developing regions such as Africa and South America. Companies may worry that the investment in eAxles will not yield a return on investment (ROI) due to high initial outlay and uncertain operational savings.

The Solution:

To mitigate costs, businesses should explore financing options and incentives available for green technology investments. Many governments offer grants or tax incentives for companies transitioning to electric vehicles, which can significantly offset costs. Additionally, buyers should engage with multiple suppliers to compare pricing and negotiate bulk purchase agreements. Investing in modular eAxle systems can also be a cost-effective strategy; these systems allow businesses to tailor specifications according to their specific needs, avoiding overspending on unnecessary features. Finally, conducting a thorough lifecycle cost analysis can help businesses understand the long-term savings associated with reduced fuel and maintenance costs, making the initial investment more palatable.

Scenario 2: Ensuring Compatibility with Existing Vehicle Designs

The Problem:

Another common pain point for B2B buyers is the challenge of integrating electric axles into existing vehicle designs. Many businesses have a fleet of traditional vehicles and may be hesitant to invest in eAxles due to concerns over compatibility with their current powertrains. This is particularly relevant for logistics companies looking to electrify their fleets without incurring excessive retrofitting costs.

The Solution:

To address compatibility concerns, buyers should conduct comprehensive assessments of their current vehicle architectures. It is crucial to collaborate closely with eAxle manufacturers who offer modular and customizable systems. These suppliers can provide detailed specifications and support to ensure that the eAxles can be seamlessly integrated with existing vehicle designs. Additionally, businesses should consider phased implementation; starting with a pilot program using a small number of vehicles can help identify potential issues without overwhelming the entire fleet. This approach allows for adjustments and learning, making the transition smoother and more efficient.

Scenario 3: Managing the Reliability of Electric Axles in Diverse Conditions

The Problem:

B2B buyers often express concerns about the reliability of electric axles under varying operational conditions, especially in regions with challenging terrains or climates, such as the Middle East and South America. The fear of breakdowns or performance issues can hinder the adoption of electric vehicles, as businesses rely heavily on their fleets for consistent performance.

The Solution:

To ensure reliability, buyers should prioritize sourcing eAxles from reputable manufacturers known for their rigorous testing and quality control processes. Understanding the specifications of the eAxle, including its operational range, torque capacity, and temperature tolerance, is critical. Businesses should also invest in training for maintenance staff to ensure proper upkeep and troubleshooting of electric axles. Regular preventive maintenance schedules can help identify potential issues before they escalate into significant problems. Furthermore, buyers should consider eAxles with integrated monitoring systems that provide real-time data on performance metrics, enabling proactive management and enhancing overall reliability in diverse conditions.

Strategic Material Selection Guide for electric car axel

What Are the Key Materials for Electric Car Axles?

In the evolving landscape of electric vehicle (EV) technology, the selection of materials for electric car axles is critical. The right materials not only enhance performance but also ensure durability, cost-effectiveness, and compliance with international standards. Below, we analyze four common materials used in electric car axles, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Aluminum: A Lightweight Champion

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and good thermal conductivity. It typically withstands temperatures up to 600°C and offers low density, making it an ideal choice for lightweight applications.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which contributes to improved vehicle efficiency and range. However, it can be more expensive than steel and may require additional surface treatments to enhance corrosion resistance, increasing manufacturing complexity.

Impact on Application: Aluminum axles are particularly suitable for applications where weight reduction is a priority, such as in passenger electric vehicles. However, they may not be the best choice for heavy-duty applications due to lower tensile strength compared to steel.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should be aware of compliance with standards such as ASTM and DIN for aluminum alloys. Additionally, the availability of aluminum can vary by region, affecting supply chain logistics.

Steel: The Traditional Workhorse

Key Properties: Steel offers high strength and durability, with temperature ratings typically exceeding 800°C. It is also highly resistant to wear and fatigue, making it suitable for demanding applications.

Pros & Cons: Steel’s strength makes it ideal for heavy-duty vehicles and applications requiring high load-bearing capacity. However, it is heavier than aluminum, which can negatively impact vehicle efficiency. The manufacturing process can also be more complex due to the need for heat treatment.

Impact on Application: Steel axles are commonly used in commercial vehicles and heavy-duty applications where load capacity is critical. Their robustness ensures longevity but may compromise energy efficiency.

Considerations for International Buyers: Buyers should ensure compliance with local and international standards, such as JIS in Japan or ASTM in the U.S. Additionally, fluctuations in steel prices can impact overall project costs.

Composite Materials: The Future of Lightweight Solutions

Key Properties: Composite materials, such as carbon fiber reinforced polymers (CFRP), provide excellent strength-to-weight ratios and corrosion resistance. They can withstand high temperatures and are often tailored for specific performance characteristics.

Pros & Cons: The primary advantage of composites is their lightweight nature, which significantly enhances vehicle performance. However, they are generally more expensive to produce and may require specialized manufacturing processes, which can complicate supply chains.

Impact on Application: Composites are particularly well-suited for high-performance electric vehicles where weight reduction is essential. Their unique properties can also allow for innovative designs that traditional materials cannot achieve.

Considerations for International Buyers: Buyers must consider the availability of composite manufacturing facilities in their regions. Compliance with international standards for composite materials is also crucial, especially in markets with stringent regulations.

Magnesium Alloys: The Lightweight Alternative

Key Properties: Magnesium alloys are among the lightest structural materials, with excellent machinability and good corrosion resistance. They typically perform well at temperatures up to 300°C.

Pros & Cons: The main advantage of magnesium is its low weight, which can significantly improve vehicle efficiency. However, it is more prone to corrosion than aluminum and steel, necessitating protective coatings that can increase costs.

Impact on Application: Magnesium alloys are suitable for applications where weight savings are crucial, such as in sports electric vehicles. However, their lower strength compared to steel limits their use in heavy-duty applications.

Considerations for International Buyers: Buyers should be aware of the specific corrosion protection measures required for magnesium alloys and ensure compliance with relevant standards, especially in regions with high humidity or saline environments.

Summary Table

| Material | Typical Use Case for electric car axel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Passenger electric vehicles | Lightweight, enhances efficiency | Higher cost, requires surface treatment | Medium |

| Steel | Heavy-duty commercial vehicles | High strength and durability | Heavier, complex manufacturing process | Low |

| Composite Materials | High-performance electric vehicles | Excellent strength-to-weight ratio | Expensive, specialized manufacturing | High |

| Magnesium Alloys | Sports electric vehicles | Very lightweight | Prone to corrosion, lower strength | Medium |

This strategic material selection guide provides a comprehensive overview of the materials available for electric car axles, equipping international B2B buyers with the insights needed to make informed decisions that align with their operational goals and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car axel

What Are the Main Stages of the Manufacturing Process for Electric Car Axles?

The manufacturing process for electric car axles (eAxles) is a multi-stage operation that involves meticulous planning and execution to ensure high-quality products. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Car Axles?

Material preparation involves selecting high-grade materials that meet specific performance and durability standards. Common materials include high-strength steel, aluminum alloys, and advanced composites, which provide the necessary strength-to-weight ratios. The preparation stage also includes cutting raw materials to precise dimensions, often using CNC (Computer Numerical Control) machines for accuracy. This stage is crucial for ensuring that the subsequent forming processes yield components that fit together seamlessly.

What Forming Techniques Are Used in eAxle Manufacturing?

The forming stage employs various techniques to shape the prepared materials into components. Techniques such as forging, machining, and stamping are commonly used. Forging is particularly advantageous for creating strong and lightweight parts, while machining allows for the precise shaping of components like gear housings and axle shafts. Advanced stamping techniques can produce complex geometries efficiently, reducing material waste and production time.

How Are Electric Car Axles Assembled?

Once the components are formed, the assembly stage begins. This phase integrates various parts such as the electric motor, transmission, and power electronics into a single unit. Modern assembly lines often utilize robotic automation to enhance precision and speed. The assembly process must consider factors like torque specifications and alignment to ensure optimal performance of the eAxle. Additionally, modular designs allow for customization to meet specific vehicle requirements, making the assembly process adaptable to different applications.

What Finishing Processes Are Necessary for eAxles?

The finishing stage includes processes that enhance the durability and aesthetics of the eAxles. Surface treatments, such as anodizing or powder coating, are applied to prevent corrosion and improve wear resistance. Additionally, precision balancing and alignment checks are conducted to ensure smooth operation. This stage is critical as it influences the overall performance and lifespan of the eAxle.

What Quality Control Measures Are Essential in eAxle Manufacturing?

Quality assurance is a fundamental aspect of eAxle manufacturing, ensuring that each unit meets international standards and customer expectations. Key quality control measures include adhering to relevant international standards like ISO 9001, which outlines quality management principles, and industry-specific certifications such as CE for European markets and API for certain applications.

Which QC Checkpoints Should Be Implemented?

Quality control checkpoints should be implemented at various stages of the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials for compliance with specifications. Suppliers should provide material certifications to verify quality.

- In-Process Quality Control (IPQC): This involves monitoring the manufacturing process to ensure adherence to specifications. Regular checks during forming, assembly, and finishing help identify defects early.

- Final Quality Control (FQC): The final inspection stage assesses the completed eAxles against performance and dimensional standards. Functional testing, including load testing and performance simulations, ensures that the eAxles meet operational requirements.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to ensure the reliability and performance of eAxles:

- Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and magnetic particle inspection help detect internal flaws without damaging components.

- Performance Testing: This includes dynamic testing to assess torque delivery and efficiency under simulated driving conditions.

- Environmental Testing: Subjecting components to extreme temperatures and humidity levels ensures they can withstand real-world operating conditions.

How Can B2B Buyers Verify Supplier Quality Control?

International B2B buyers must take proactive steps to verify the quality control measures of their suppliers. This can involve:

- Conducting Supplier Audits: Regular audits can assess the manufacturing processes and quality control practices of potential suppliers. Audits should focus on compliance with international standards and the effectiveness of quality management systems.

- Requesting Quality Reports: Buyers should request detailed quality reports that outline testing results, inspection records, and certification status. These reports provide insights into the supplier’s commitment to quality.

- Engaging Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the manufacturing processes and product quality. This is particularly important for buyers from regions with varying quality standards.

What Are the QC and Certification Nuances for International B2B Buyers?

For B2B buyers from Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is critical. Different regions may have specific regulatory requirements that influence the manufacturing and certification processes.

- Regional Compliance: Buyers should ensure that suppliers meet local regulations and standards, such as the European Union’s REACH regulations or specific automotive industry standards.

- Cultural Considerations: In some regions, the emphasis on quality may vary, requiring buyers to conduct thorough due diligence to ensure that suppliers maintain consistent quality standards.

- Supply Chain Transparency: Establishing clear communication channels with suppliers can facilitate transparency regarding quality control processes, making it easier to address any potential issues.

By understanding the manufacturing processes and quality assurance measures related to electric car axles, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality components that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car axel’

In today’s fast-evolving automotive landscape, sourcing electric car axles (eAxles) is crucial for businesses looking to enhance their sustainability and performance. This guide offers a step-by-step checklist to help international B2B buyers effectively procure electric car axles tailored to their operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of any successful procurement process. Consider the vehicle type, weight, desired performance metrics, and compatibility with existing powertrains. Ensure to specify the required motor types, such as permanent magnet synchronous or induction motors, and other features like torque capacity and efficiency ratings.

Step 2: Research Market Trends and Innovations

Stay informed about the latest advancements in eAxle technology. Understanding trends, such as the integration of power electronics and increased efficiency from silicon carbide semiconductors, can help you make informed decisions. This knowledge allows you to identify suppliers who offer cutting-edge products that align with market demands.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your requirements. Request detailed company profiles, including their experience in manufacturing eAxles and any relevant case studies. Check for references from other businesses in similar sectors or regions to gauge reliability and performance.

Step 4: Verify Compliance and Certifications

Ensure that potential suppliers comply with international quality standards and certifications. Look for ISO certifications, as well as adherence to regional standards that may apply in your target markets (such as CE marking in Europe). Compliance not only ensures product quality but also mitigates risks related to safety and regulatory issues.

Step 5: Assess Customization Capabilities

Different applications require tailored solutions. Evaluate whether the supplier can customize eAxles to meet specific requirements, such as power output, torque, and space constraints. This flexibility is essential for optimizing performance in various vehicle types, from passenger cars to commercial trucks.

Step 6: Request Samples and Conduct Testing

Before finalizing your order, request samples of the eAxles for testing. Conduct performance evaluations under real-world conditions to ensure they meet your specifications. Pay attention to factors such as efficiency, durability, and ease of installation, as these will impact the overall performance of your vehicle.

Step 7: Negotiate Terms and Establish a Partnership

Once you have selected a supplier, negotiate the terms of the contract carefully. Discuss pricing, delivery timelines, warranties, and after-sales support. Establishing a strong partnership with your supplier is essential for long-term success, as it can lead to better service, collaborative innovation, and more favorable terms in future transactions.

By following these steps, B2B buyers can confidently navigate the sourcing process for electric car axles, ensuring they select the right products to meet their business needs and contribute to a sustainable future.

Comprehensive Cost and Pricing Analysis for electric car axel Sourcing

What Are the Key Cost Components in Electric Car Axle Sourcing?

When sourcing electric car axles, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts costs. High-quality metals, composites, and advanced electronic components are essential for durability and performance but can be expensive. The integration of silicon carbide semiconductor technology, for instance, enhances efficiency but also raises material costs.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor is often required for assembly, particularly when dealing with advanced technologies such as eAxles, which integrate motors and electronics.

-

Manufacturing Overhead: This includes utilities, facility maintenance, and equipment depreciation. As manufacturers optimize their production lines for electric axles, economies of scale can help reduce these costs over time.

-

Tooling: Initial tooling costs can be substantial, especially for custom or specialized axles. Buyers should consider whether the supplier has the necessary tooling to produce the desired specifications efficiently.

-

Quality Control (QC): Rigorous QC processes are essential to ensure that the axles meet safety and performance standards. This may involve additional costs for testing and certification, particularly in regions with strict regulatory requirements.

-

Logistics: Shipping costs can fluctuate based on distance, mode of transport, and import/export regulations. International buyers should factor in potential tariffs and customs duties, which can add to the total cost.

-

Margin: Suppliers typically include a margin to cover their risks and profit expectations. This margin can vary based on market demand, supplier reputation, and the complexity of the product.

How Do Price Influencers Affect Electric Car Axle Costs?

Several factors can influence pricing in the electric axle market:

-

Volume/MOQ: Larger orders often lead to reduced unit costs due to economies of scale. Establishing a minimum order quantity (MOQ) can help negotiate better pricing.

-

Specifications and Customization: Customized solutions tailored to specific vehicle types or performance requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: The quality and type of materials used in the axle production can influence pricing. Premium materials may enhance performance but also raise costs.

-

Quality and Certifications: Axles that meet international safety and performance standards may carry a premium. Certifications can also impact the overall price, as they often require additional testing and compliance efforts.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while emerging manufacturers might offer competitive pricing to gain market share.

-

Incoterms: Understanding the Incoterms agreed upon in the contract is crucial. They define the responsibilities of the buyer and seller regarding shipping, insurance, and tariffs, which can significantly impact the total cost.

What Buyer Tips Can Enhance Cost Efficiency in Electric Axle Sourcing?

To optimize sourcing decisions, international B2B buyers should consider the following strategies:

-

Negotiation: Engage in discussions with multiple suppliers to understand market rates. Highlighting long-term partnership potential may lead to better pricing and terms.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with maintenance, efficiency, and performance. This holistic view can guide better investment decisions.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, local market conditions, and regulatory environments in target regions. Understanding these factors can help in negotiating favorable terms and avoiding unexpected costs.

-

Leverage Regional Suppliers: In regions such as Africa, South America, and the Middle East, sourcing from local manufacturers may reduce shipping costs and lead times. Additionally, local suppliers may have better insights into regional market dynamics.

Disclaimer on Pricing

Prices for electric car axles can vary widely based on the aforementioned factors. This analysis provides indicative insights, and actual costs may differ based on specific requirements and market conditions. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing electric car axel With Other Solutions

In the rapidly evolving automotive sector, businesses are presented with various options for enhancing vehicle performance and sustainability. When considering electric car axles (eAxles), it’s essential to evaluate alternative technologies that can fulfill similar needs. This analysis compares eAxles with hybrid powertrains and traditional internal combustion engine (ICE) systems, providing insights for B2B buyers navigating their electrification journey.

Comparison Table

| Comparison Aspect | Electric Car Axel | Hybrid Powertrain | Internal Combustion Engine (ICE) |

|---|---|---|---|

| Performance | High torque and efficiency | Moderate to high torque | High power but less efficient |

| Cost | Moderate initial investment | Higher due to complexity | Generally lower upfront costs |

| Ease of Implementation | Requires new infrastructure | Existing infrastructure can be used | Well-established technology |

| Maintenance | Lower due to fewer moving parts | Moderate complexity | Higher due to more components |

| Best Use Case | Urban and short-distance travel | Versatile applications | Long-distance and heavy-duty use |

What Are the Advantages and Disadvantages of Hybrid Powertrains?

Hybrid powertrains combine an internal combustion engine with an electric motor, offering flexibility in fuel usage. They excel in versatility, making them suitable for various vehicle types, from passenger cars to commercial fleets. However, their complexity leads to higher costs and maintenance requirements compared to eAxles. Businesses focused on reducing emissions while retaining some operational familiarity may find hybrids an attractive compromise.

How Do Internal Combustion Engines Compare?

Internal combustion engines remain a widely used technology, particularly for long-haul and heavy-duty applications. They generally have lower upfront costs and established infrastructure, making them easy to implement. However, they fall short in terms of sustainability and efficiency, contributing significantly to carbon emissions. As global regulations tighten, companies relying solely on ICE technology may face increasing operational costs and reputational risks.

How Can B2B Buyers Choose the Right Solution?

Selecting the right technology hinges on a company’s specific operational needs, budget constraints, and sustainability goals. For businesses prioritizing low emissions and high efficiency, electric car axles represent a forward-thinking choice, particularly for urban environments. Conversely, those needing immediate cost-effectiveness and established infrastructure may lean towards hybrid systems or traditional ICEs. Ultimately, a thorough assessment of the business’s goals and the local regulatory landscape will guide the decision-making process, ensuring alignment with future mobility trends and sustainability commitments.

Essential Technical Properties and Trade Terminology for electric car axel

What Are the Key Technical Properties of Electric Car Axles?

When assessing electric car axles (eAxles), understanding critical technical specifications is essential for making informed purchasing decisions. Here are some vital properties:

1. Torque Capacity

Torque capacity refers to the maximum torque an eAxle can transmit without failing. This property is crucial for performance, especially in applications requiring rapid acceleration or heavy loads. For B2B buyers, knowing the torque capacity helps ensure that the axle can meet the demands of specific vehicles and operational conditions, thus preventing potential breakdowns or inefficiencies.

2. Power Output

Power output, measured in kilowatts (kW), indicates the amount of power the eAxle can deliver. eAxles typically range from 50 kW to 300 kW, allowing for scalability across various vehicle types. Buyers must consider their vehicle’s requirements to select an axle that can support the desired performance level, particularly in commercial applications where power demands may vary.

3. Efficiency Rating

Efficiency ratings, often expressed as a percentage, indicate how effectively an eAxle converts electrical energy from the battery into mechanical energy for vehicle propulsion. Higher efficiency ratings (up to 96% for some systems) translate into longer ranges and reduced battery capacity requirements. This is a significant factor for businesses looking to optimize their fleet’s operational costs and environmental impact.

4. Integration Level

The integration level pertains to how many components (motor, transmission, power electronics) are housed within the axle unit. A high integration level simplifies installation and reduces overall vehicle weight. This is essential for B2B buyers focused on cost-effectiveness and ease of deployment, especially in markets with varying infrastructure capabilities.

5. Material Grade

The material grade used in the construction of eAxles affects durability and weight. Common materials include high-strength steel and lightweight alloys. Understanding material specifications can help buyers ensure that they are investing in axles that will withstand the rigors of their intended applications, thereby enhancing the vehicle’s lifespan and performance.

Which Trade Terminology Should B2B Buyers Understand?

In addition to technical properties, familiarity with industry terminology is vital for effective communication and negotiation. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, partnering with reputable OEMs can ensure access to high-quality components that meet industry standards, which is critical for maintaining vehicle performance and safety.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory effectively and negotiate pricing. This term can significantly impact budgeting, especially for businesses looking to scale their electric vehicle fleets.

3. RFQ (Request for Quotation)

An RFQ is a standard business process to invite suppliers to bid on specific products or services. Buyers should prepare detailed RFQs to ensure they receive competitive pricing and suitable specifications that meet their operational needs.

4. Incoterms

Incoterms (International Commercial Terms) are a set of rules that define responsibilities of sellers and buyers in international transactions. Familiarity with these terms helps businesses understand shipping costs, risks, and responsibilities, ensuring smoother international procurement processes.

5. Duty Cycle

Duty cycle refers to the operational time a vehicle is expected to perform under load. Understanding duty cycles is critical for B2B buyers to select eAxles that can handle specific operational requirements, ensuring efficiency and reliability in various applications.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions regarding electric car axles, ultimately leading to improved operational efficiency and cost-effectiveness in their fleet management.

Navigating Market Dynamics and Sourcing Trends in the electric car axel Sector

What Are the Key Market Drivers and Trends Influencing the Electric Car Axle Sector?

The electric car axle (eAxle) sector is witnessing a transformative shift driven by a confluence of global factors. Governments across the globe are pushing for stringent emissions regulations, incentivizing electric vehicle (EV) adoption. This regulatory environment is particularly pronounced in Europe, where the European Union has committed to significantly reducing carbon emissions by 2030. In contrast, emerging markets in Africa and South America are increasingly recognizing the potential of electric mobility to address urban pollution and energy dependency.

Current B2B sourcing trends indicate a growing preference for modular, integrated solutions like the eAxle, which combine electric motors, power electronics, and transmissions into a single unit. This shift not only enhances efficiency and performance—achieving efficiencies of up to 96%—but also simplifies logistics and reduces costs for manufacturers. Furthermore, advancements in semiconductor technologies, particularly silicon carbide, are enabling higher power densities and improved vehicle performance.

International buyers are also increasingly looking for scalable solutions that can be customized to meet regional demands, particularly in markets like Brazil and Saudi Arabia, where vehicle requirements differ significantly. The rise of hybrid vehicles as a transitional solution to full electrification is another trend that resonates across diverse markets, offering a more accessible entry point for businesses exploring electric mobility.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing for Electric Car Axles?

Sustainability is becoming a pivotal criterion for B2B buyers in the electric car axle sector. The environmental impact of sourcing materials—especially in lithium-ion battery production—cannot be overlooked. Buyers are urged to engage with suppliers who demonstrate transparency in their sourcing practices, ensuring that materials are obtained responsibly and ethically. This includes assessing the supply chain for potential environmental and social impacts, particularly concerning mining practices in regions rich in lithium and cobalt.

Moreover, the importance of ethical supply chains is amplified by consumer demand for transparency and corporate responsibility. Buyers are increasingly seeking suppliers with recognized ‘green’ certifications, such as ISO 14001, which denotes effective environmental management systems, or those using recycled materials in their products. This not only enhances brand reputation but also aligns with the growing corporate focus on sustainability.

As the market evolves, buyers should also consider the lifecycle impact of eAxles, from production through to end-of-life recycling. Collaborating with suppliers who prioritize circular economy principles can further bolster sustainability efforts, ensuring that electric car axles contribute positively to the overall environmental goals of their organizations.

What Are the Significant Milestones in the Evolution of Electric Car Axles?

The evolution of electric car axles has been marked by several key milestones that have shaped the current landscape. Initially, traditional axles served merely as support structures for vehicles, transferring power from the engine to the wheels. However, with the advent of electric vehicles in the early 2000s, the integration of electric motors with axles began to gain traction, leading to the development of hybrid systems.

By the 2010s, advancements in battery technology and electric motor efficiency catalyzed the emergence of eAxles as a compact, integrated solution for electric and hybrid vehicles. The introduction of silicon carbide semiconductors further enhanced performance, enabling eAxles to achieve higher efficiency rates and lower operational costs. Today, eAxles are not only a critical component of electric vehicles but are also seen as a key enabler for the shift towards sustainable transport solutions globally.

In summary, as the electric car axle sector continues to evolve, B2B buyers must stay informed about market dynamics, prioritize sustainable practices, and appreciate the historical context of the technologies they are sourcing. This comprehensive understanding will empower them to make informed decisions that align with their business objectives and environmental commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car axel

-

How do I choose the right electric car axle for my fleet?

Selecting the appropriate electric car axle requires a thorough understanding of your fleet’s specific needs, including vehicle type, weight, and usage conditions. Assess the axle’s performance specifications, such as torque capacity and efficiency ratings. Consider the compatibility with your existing powertrain and the flexibility for future upgrades. Additionally, evaluate the supplier’s reputation and experience in the market, especially in regions like Africa or South America, where local conditions may vary significantly. -

What is the best electric axle for heavy-duty vehicles?

For heavy-duty vehicles, look for electric axles with high torque capacity and robust performance metrics. Axles designed for commercial applications often feature modular designs that can accommodate additional power requirements. Brands that utilize advanced technologies like silicon carbide semiconductors can offer improved efficiency and performance. Always verify the axle’s ability to handle the specific load and duty cycle of your operations, and consult with suppliers about their customization options to meet your unique requirements. -

What are the advantages of using eAxles in electric vehicles?

eAxles combine multiple components—electric motor, power electronics, and transmission—into a single unit, enhancing efficiency and reducing complexity. This integration can lead to significant weight savings and improved space utilization, allowing for more streamlined vehicle designs. Additionally, eAxles often provide higher performance metrics, such as torque and acceleration, which are essential for modern electric vehicles. These advantages make eAxles a cost-effective solution for both hybrid and fully electric vehicle applications. -

What factors should I consider when vetting suppliers for electric axles?

When vetting suppliers, consider their industry experience, production capabilities, and quality assurance processes. Review their track record in delivering products to your region, as familiarity with local regulations and conditions can be crucial. Request samples and performance data to evaluate the quality of their products. It’s also beneficial to check customer testimonials and case studies to understand their reliability and customer service levels. Lastly, ensure they can provide technical support and after-sales service. -

What is the minimum order quantity (MOQ) for electric axles?

The minimum order quantity for electric axles can vary widely depending on the manufacturer and your specific requirements. Some suppliers may offer flexible MOQs for first-time buyers or smaller businesses, while others may require larger orders to ensure cost-effectiveness. It’s advisable to communicate your needs directly with potential suppliers to negotiate MOQs that align with your budget and operational needs. Also, consider the potential for future orders to establish a longer-term partnership. -

What payment terms are typically offered by suppliers of electric axles?

Payment terms can differ significantly among suppliers and depend on factors such as order size, business relationship, and regional practices. Common options include upfront payments, partial payments with the balance upon delivery, or extended payment terms for established customers. Always clarify the terms before finalizing the order, and consider using secure payment methods to protect your investment. Negotiating favorable terms can help manage cash flow, especially for larger purchases. -

How do I ensure quality assurance for electric axles?

To ensure quality assurance, request detailed specifications and performance testing results from your supplier. Inquire about their manufacturing processes and quality control measures, including certifications like ISO 9001. It may be beneficial to conduct factory visits or audits to assess their operations firsthand. Additionally, consider implementing a third-party inspection service to verify product quality before shipment, especially if you are importing axles from overseas. -

What logistics considerations should I be aware of when importing electric axles?

When importing electric axles, consider logistics factors such as shipping methods, customs regulations, and lead times. Evaluate the reliability of freight forwarders and their experience with handling automotive components. Be aware of any import duties or taxes that may apply in your region, as these can affect overall costs. Planning for potential delays in transit and ensuring proper documentation can also help facilitate smooth customs clearance and delivery of your axles.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Electric Car Axel Manufacturers & Suppliers List

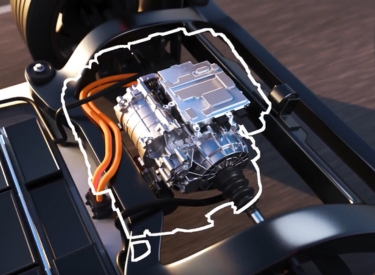

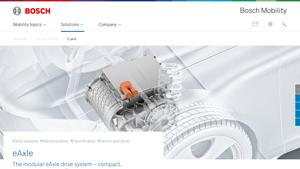

1. Bosch – eAxle Electric Drive Module

Domain: bosch-mobility.com

Registered: 2011 (14 years)

Introduction: eAxle Electric Drive Module, Electric motors for commercial vehicles, Global brushless blower (GBB), Global Blower Motor (GBM), IP modules, MEMS sensors, Integrated circuits, Engineering services (Bosch Engineering GmbH), Proving grounds, Engineering test center, Safety system services, ABS module, Antilock braking system, Brake boosting and brake-force distribution, Brake-by-wire, Electronic stab…

2. Rawsuns – Electric Axle Solutions

Domain: rawsuns.com

Registered: 2018 (7 years)

Introduction: Electric Axle for electric vehicles, designed for high efficiency and performance. Features include a compact design, lightweight construction, and integrated electric motor. Suitable for various applications including passenger vehicles and commercial transport. Offers customizable options for different torque and power requirements.

3. Reddit – EV Axle Swap Kits Discussion

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Discussion on the potential for developing EV axle swap kits, focusing on an axle with an integrated motor that could be scaled for various vehicles with solid rear axles. The idea includes offering different widths and diameters for axles. Concerns about the motor being in an unsprung position and the demand for such kits were raised. Mention of existing products like Magna’s e-Beam for trucks an…

4. Garrett – 3-in-1 E-Powertrain

Domain: garrettmotion.com

Registered: 2018 (7 years)

Introduction: High Power Density 3-in-1 E-Axle for Electric Vehicles. The Garrett 3-in-1 E-Powertrain integrates advanced e-motor, inverter, and transmission technologies into one compact package. It offers a power output range suitable for passenger and light commercial vehicles, achieving up to 3% increased range. The E-Axle is compact and lightweight, with a 40% reduction in weight and size compared to indus…

5. Scout EV – EBeam Rear Axle

Domain: scoutevforum.com

Registered: 2022 (3 years)

Introduction: Electric Solid Rear Axle (EBeam Rear Axle) used in Scout EV’s Terra pickup and Traveler SUV. The electric motor is mounted directly onto the solid axle, which is a unique feature for EVs. The design includes a removable pan at the front of the axle and an oil cooler. The rear suspension consists of a solid axle with two lower links, a Panhard rod, an anti-roll bar, and upper links, similar to desi…

6. Rotontek – Electric Drive Axles

Domain: rotontek.com

Registered: 2016 (9 years)

Introduction: Electric Drive Axles are essential components of electric vehicles that convert electrical energy from the vehicle’s battery into mechanical energy via an electric motor. Key features include:

– **Energy Efficiency**: High energy efficiency due to direct conversion of electrical energy into mechanical energy, use of single-speed transmissions, and regenerative braking.

– **Performance Capabilities…

7. Spicer Electrified – eS4500r e-Axle

Domain: dana.com

Registered: 1993 (32 years)

Introduction: {“product_name”: “eS4500r e-Axle”, “brand”: “Spicer Electrified”, “application”: “light-duty; SUV, truck, and commercial vehicle applications”, “maximum_GVW”: “1.9T”, “maximum_GAWR”: “1.1T”, “rated_rpm”: “14,000 rpm”, “peak_power”: “180 kW”, “maximum_output_torque”: “4,500 Nm”, “reduction_ratios”: [14.88, 11.83, 10.86, 9.13, 7.71], “differential_type”: “Open differential”, “differential_size”: “M1…

8. Diyelectric Car – eAxle Prototype

Domain: diyelectriccar.com

Registered: 2006 (19 years)

Introduction: eAxle project based on a Model 3 drive unit and a Dana 44; 280hp; weight of 325 lbs; designed for versatility; prototype features inverter on chassis side with dynamic junction of 3 phase wires; clearance details forthcoming.

Strategic Sourcing Conclusion and Outlook for electric car axel

What Are the Key Insights for B2B Buyers in Electric Car Axles?

In the evolving landscape of electric vehicle (EV) technology, strategic sourcing of electric axles (eAxles) has emerged as a critical factor for international B2B buyers. The integration of eAxles enhances vehicle efficiency, reduces complexity, and supports cost-effective solutions tailored to diverse vehicle applications, from passenger cars to commercial fleets. As global demand for sustainable transport solutions rises, the ability to source high-performance eAxles can provide a competitive edge in markets across Africa, South America, the Middle East, and Europe.

Why Is Strategic Sourcing Essential for Your Business?

Investing in strategic sourcing not only streamlines procurement processes but also ensures access to advanced technologies that promote sustainability and compliance with environmental regulations. This is especially vital as regions like Brazil and Saudi Arabia are increasingly prioritizing green initiatives. By aligning with manufacturers that offer modular and scalable eAxle solutions, businesses can optimize their supply chains and enhance operational efficiency.

What Should You Consider Moving Forward?

As the electric vehicle market continues to grow, now is the time for B2B buyers to engage with suppliers who can offer innovative, reliable, and adaptable eAxle systems. Consider exploring partnerships that not only meet your current needs but also align with your long-term sustainability goals. Embrace the transition towards electrification and secure your position in the future of mobility.