Introduction: Navigating the Global Market for electric vehicle with air conditioner

Navigating the global market for electric vehicles equipped with air conditioning presents unique challenges for international B2B buyers. As industries pivot towards sustainable transport solutions, the demand for electric vehicles (EVs) with efficient air conditioning systems becomes critical. Buyers must consider various factors such as energy efficiency, climate adaptability, and technological advancements in air conditioning. This guide is designed to provide comprehensive insights into the types of electric vehicles available, their applications across different sectors, and effective supplier vetting strategies to ensure quality and reliability.

With a focus on markets in Africa, South America, the Middle East, and Europe—including key players like Saudi Arabia and Germany—this guide empowers B2B buyers to make informed purchasing decisions. It delves into the operational mechanics of air conditioning in electric vehicles, exploring how these systems maintain comfort and safety while optimizing energy consumption. Furthermore, it addresses cost considerations, potential return on investment, and the evolving landscape of EV technology.

By leveraging this detailed guide, buyers will gain the knowledge necessary to navigate the complexities of sourcing electric vehicles with air conditioning systems that meet their specific needs, ensuring they remain competitive in an ever-evolving global market.

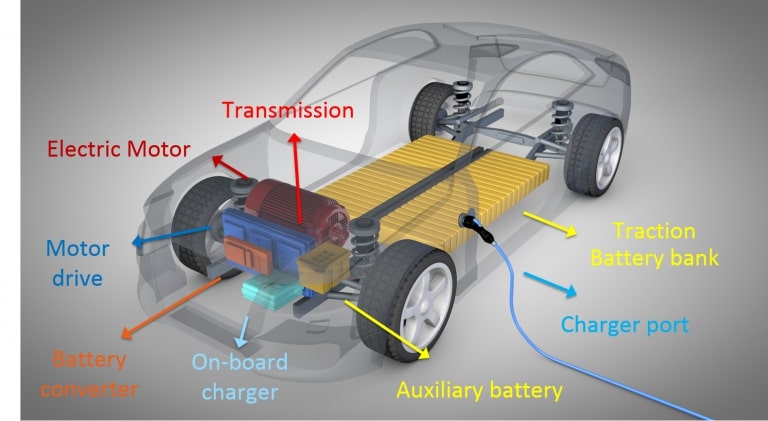

Understanding electric vehicle with air conditioner Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Electric Vehicle | Utilizes a basic electric heater and compressor for air conditioning | Fleet vehicles, urban transport | Pros: Cost-effective, widely available. Cons: Limited range in extreme temperatures. |

| Heat Pump Electric Vehicle | Employs a heat pump for efficient heating and cooling | Luxury electric vehicles, long-distance travel | Pros: Energy-efficient, better range. Cons: Higher initial investment, less effective in extreme cold. |

| Hybrid Electric Vehicle | Combines electric and internal combustion engine systems | Commercial delivery, mixed-use transport | Pros: Versatile, extended range. Cons: Complexity in maintenance, reliance on fuel. |

| Battery Electric Vehicle | Features advanced thermal management systems | High-performance applications, EV startups | Pros: Optimized for performance, innovative tech. Cons: Higher costs, limited availability. |

| Compact Electric Vehicle | Smaller size with simplified HVAC systems | Urban commuting, ride-sharing services | Pros: Lower operational costs, easy maneuverability. Cons: Limited cabin space, reduced comfort in extreme weather. |

What Are the Key Characteristics of Standard Electric Vehicles?

Standard Electric Vehicles (SEVs) typically utilize a conventional electric heater and air conditioning compressor system. These vehicles are designed for urban environments, making them suitable for fleet vehicles and city transport applications. While they are generally cost-effective and widely available, B2B buyers should be aware that their range can diminish significantly in extreme temperatures, which may affect operational efficiency.

How Do Heat Pump Electric Vehicles Enhance Energy Efficiency?

Heat Pump Electric Vehicles (HPEVs) use a heat pump system, which allows them to efficiently manage both heating and cooling. This technology makes them ideal for luxury electric vehicles and those intended for long-distance travel. B2B buyers should consider the initial investment, as HPEVs tend to be more expensive upfront. However, their energy efficiency can lead to lower operational costs and extended range, especially in moderate climates.

What Makes Hybrid Electric Vehicles Versatile for Commercial Use?

Hybrid Electric Vehicles (HEVs) combine electric and internal combustion engine systems, offering versatility for various commercial applications such as delivery services and mixed-use transport. They provide an extended driving range, making them suitable for longer trips. However, their complexity can lead to higher maintenance costs and reliance on fuel. B2B buyers should evaluate the balance between operational costs and the flexibility offered by HEVs.

Why Are Battery Electric Vehicles Ideal for High-Performance Applications?

Battery Electric Vehicles (BEVs) are engineered with advanced thermal management systems, optimizing performance for high-demand applications. They are particularly attractive to EV startups and companies focused on innovation. While BEVs come with higher upfront costs, their cutting-edge technology can result in superior performance and efficiency. B2B buyers should weigh the benefits of performance against the investment required.

What Are the Advantages of Compact Electric Vehicles for Urban Mobility?

Compact Electric Vehicles (CEVs) are designed for urban commuting and ride-sharing services, featuring simplified HVAC systems to reduce complexity and costs. They are easy to maneuver in crowded city environments and have lower operational costs, making them appealing for businesses focused on urban transport solutions. However, buyers should note the limited cabin space and potential comfort issues in extreme weather conditions when considering CEVs for their fleets.

Key Industrial Applications of electric vehicle with air conditioner

| Industry/Sector | Specific Application of Electric Vehicle with Air Conditioner | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric Buses with Air Conditioning | Enhanced passenger comfort and safety, reduced emissions | Compliance with local regulations, energy efficiency, and maintenance support |

| Logistics and Delivery | Electric Delivery Vans with Climate Control | Improved driver comfort, extended operational range, and lower operational costs | Battery capacity, charging infrastructure, and payload capacity |

| Tourism and Hospitality | Electric Tour Vehicles with Air Conditioning | Improved guest experience, sustainable tourism branding | Customization options, battery range, and service availability |

| Agriculture and Farming | Electric Utility Vehicles for Farm Operations | Reduced fuel costs, lower environmental impact, and operational efficiency | Durability, battery life, and adaptability to various terrains |

| Construction and Infrastructure | Electric Construction Vehicles with Climate Control | Enhanced worker comfort, compliance with environmental standards | Robustness, energy efficiency, and integration with existing machinery |

How are Electric Buses with Air Conditioning Transforming Public Transportation?

Electric buses equipped with air conditioning systems are revolutionizing public transportation by ensuring a comfortable travel experience for passengers, particularly in regions with extreme weather conditions. These vehicles not only enhance passenger comfort but also contribute to reduced emissions, aligning with global sustainability goals. For international B2B buyers, especially in regions like the Middle East and Europe, sourcing electric buses requires consideration of compliance with local regulations, energy efficiency ratings, and ongoing maintenance support to ensure operational longevity.

What Role do Electric Delivery Vans Play in Logistics?

In the logistics sector, electric delivery vans fitted with air conditioning systems provide a dual benefit: maintaining a comfortable working environment for drivers and ensuring the integrity of temperature-sensitive goods. This technology is particularly advantageous in hot climates, where driver fatigue can impact delivery efficiency. Buyers in South America and Africa should focus on battery capacity, charging infrastructure availability, and payload capacity when sourcing these vehicles, as these factors directly influence operational efficiency and cost-effectiveness.

How Can Electric Tour Vehicles Enhance the Tourism Experience?

Electric tour vehicles with climate control systems are becoming increasingly popular in the tourism and hospitality industry. They not only improve the guest experience by providing a comfortable environment during tours but also promote sustainable tourism initiatives. For B2B buyers in Europe and South America, customization options for these vehicles, battery range for extended tours, and reliable service availability are critical factors to consider to meet the diverse needs of tourists.

Why are Electric Utility Vehicles Important for Agriculture?

In agriculture, electric utility vehicles equipped with air conditioning systems are gaining traction due to their ability to reduce fuel costs and minimize environmental impact. These vehicles enhance operational efficiency, particularly in hot climates where worker comfort is crucial for productivity. Buyers in Africa and South America should prioritize durability, battery life, and the vehicle’s adaptability to various terrains when sourcing these electric utility vehicles to ensure they can withstand the demands of agricultural operations.

How do Electric Construction Vehicles Improve Work Conditions?

Electric construction vehicles with air conditioning systems are essential for enhancing worker comfort on job sites, particularly in extreme weather conditions. These vehicles help to comply with environmental standards while reducing overall operational costs. B2B buyers in Europe and the Middle East should consider the robustness of the vehicles, energy efficiency, and how well they can integrate with existing machinery when making purchasing decisions to ensure they meet industry requirements.

3 Common User Pain Points for ‘electric vehicle with air conditioner’ & Their Solutions

Scenario 1: Balancing Energy Efficiency and Comfort in Extreme Climates

The Problem: B2B buyers operating electric vehicle (EV) fleets in regions with extreme temperatures, such as the Middle East or northern Europe, face significant challenges. The air conditioning systems in electric vehicles can dramatically affect battery performance and overall energy efficiency. In extreme heat, the demand for cooling can lead to rapid battery depletion, reducing the vehicle’s operational range and increasing downtime for charging. Conversely, in colder climates, heating systems can drain the battery quickly, complicating logistics and route planning. This dual challenge requires careful consideration of both comfort and range.

The Solution: To address these challenges, B2B buyers should consider EV models equipped with advanced thermal management systems, such as heat pumps. These systems are more energy-efficient than traditional electric heaters and can provide heating and cooling without excessive energy consumption. Buyers should also invest in software solutions that optimize route planning based on real-time weather data, ensuring vehicles are used in the most efficient manner possible. Preconditioning features, where vehicles are heated or cooled while still plugged into a charging station, should also be utilized to minimize energy use during travel. By selecting the right EV model and employing smart operational strategies, businesses can enhance both comfort and efficiency in extreme climates.

Scenario 2: Ensuring Robust Performance in Urban Environments

The Problem: Fleet operators in urban settings, particularly in congested cities across Africa and South America, often struggle with the reliability of air conditioning systems in electric vehicles. High traffic volumes and frequent stop-and-go scenarios can lead to overheating issues, especially if the vehicle’s air conditioning is running continuously. This can result in performance degradation and potentially costly repairs. Additionally, the need for frequent stops for charging can complicate the operational logistics of maintaining a comfortable cabin temperature.

The Solution: To mitigate these issues, B2B buyers should focus on sourcing electric vehicles with robust cooling systems that are specifically designed for urban environments. Features such as high-capacity battery cooling systems and enhanced airflow designs can prevent overheating even in stop-and-go traffic. Additionally, integrating smart fleet management systems can help monitor vehicle performance and air conditioning usage in real-time. This data can inform proactive maintenance schedules and operational adjustments. Furthermore, considering electric vehicles with fast-charging capabilities will enable fleet operators to minimize downtime while ensuring that the cabin remains comfortable for drivers and passengers alike.

Scenario 3: Managing Maintenance and Repair Costs for Air Conditioning Systems

The Problem: B2B buyers often encounter high maintenance and repair costs associated with air conditioning systems in electric vehicles. As these systems become more complex, understanding the specific needs and potential failures can be challenging. This complexity is further exacerbated by a lack of trained technicians familiar with the latest EV air conditioning technologies. The inability to effectively maintain these systems can lead to prolonged vehicle downtime and increased operational costs.

The Solution: To effectively manage maintenance and repair costs, B2B buyers should prioritize partnerships with OEMs and certified service providers who offer comprehensive training on the latest air conditioning technologies in electric vehicles. Investing in training programs for in-house technicians can also enhance service capabilities and reduce reliance on external repair services. Furthermore, adopting predictive maintenance tools that use data analytics can help identify potential issues before they result in costly repairs. Regular maintenance schedules should be established to ensure that the air conditioning systems operate at optimal efficiency. By focusing on education, partnerships, and predictive analytics, businesses can significantly reduce their maintenance costs and improve the reliability of their electric vehicle fleets.

Strategic Material Selection Guide for electric vehicle with air conditioner

What Materials Are Commonly Used in Electric Vehicle Air Conditioning Systems?

In the context of electric vehicle (EV) air conditioning systems, selecting the right materials is crucial for ensuring performance, durability, and compliance with international standards. Here, we analyze four common materials used in these systems: aluminum, stainless steel, thermoplastics, and copper. Each material has unique properties, advantages, and considerations that can significantly impact the design and functionality of air conditioning systems in electric vehicles.

How Does Aluminum Benefit Electric Vehicle Air Conditioning Systems?

Aluminum is widely used in EV air conditioning systems due to its lightweight and excellent thermal conductivity. It typically has a temperature rating of up to 150°C and is highly resistant to corrosion, especially when anodized. The primary advantage of aluminum is its low weight, which contributes to improved energy efficiency and range in electric vehicles. However, aluminum can be more expensive than other metals and may require more complex manufacturing processes, such as extrusion or die-casting. For international buyers, compliance with standards such as ASTM B209 is essential, and preferences may vary based on regional availability and cost considerations.

What Role Does Stainless Steel Play in Air Conditioning Systems?

Stainless steel is another common material, particularly in components exposed to high pressures and temperatures. It offers excellent corrosion resistance and can withstand temperatures exceeding 200°C, making it suitable for compressor housings and piping. The durability of stainless steel ensures a longer lifespan, which is a significant advantage for B2B buyers looking for reliability. However, its higher cost and weight compared to aluminum can be a drawback, especially for manufacturers focused on minimizing vehicle weight. Buyers from regions with strict environmental regulations, such as Germany, must ensure compliance with standards like DIN EN 10088.

How Do Thermoplastics Enhance Performance in Air Conditioning Systems?

Thermoplastics, such as polyamide and polypropylene, are increasingly used in air conditioning systems due to their lightweight nature and good thermal insulation properties. These materials can withstand temperatures up to 120°C and offer excellent chemical resistance. The primary advantage of thermoplastics is their ease of manufacturing, which allows for complex shapes and lower production costs. However, they may not be as durable as metals and can degrade under extreme conditions. For buyers in Africa and South America, the cost-effectiveness of thermoplastics may be appealing, but they must also consider local climate conditions that could affect material performance.

What Advantages Does Copper Offer for Electric Vehicle Air Conditioning Systems?

Copper is renowned for its exceptional thermal and electrical conductivity, making it an ideal choice for heat exchangers and refrigerant lines in air conditioning systems. It can handle high pressures and temperatures, making it suitable for various components. The primary advantage of copper is its efficiency in heat transfer, which can enhance the overall performance of the air conditioning system. However, copper is heavier and more expensive than aluminum and thermoplastics, which may limit its use in lightweight vehicle designs. Buyers should also be aware of the need for compliance with international standards such as ASTM B280 for copper tubing.

Summary Table of Material Selection for Electric Vehicle Air Conditioning Systems

| Material | Typical Use Case for electric vehicle with air conditioner | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Evaporator and condenser components | Lightweight and good thermal conductivity | Higher manufacturing complexity | Medium |

| Stainless Steel | Compressor housings and high-pressure pipes | Excellent corrosion resistance and durability | Higher cost and weight | High |

| Thermoplastics | Ducting and insulation components | Cost-effective and easy to manufacture | Lower durability under extreme conditions | Low |

| Copper | Heat exchangers and refrigerant lines | Exceptional thermal conductivity | Heavier and more expensive | High |

In conclusion, the selection of materials for electric vehicle air conditioning systems is a critical aspect that affects performance, durability, and compliance with international standards. B2B buyers must carefully consider the specific applications, regional preferences, and cost implications when choosing materials for their products.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle with air conditioner

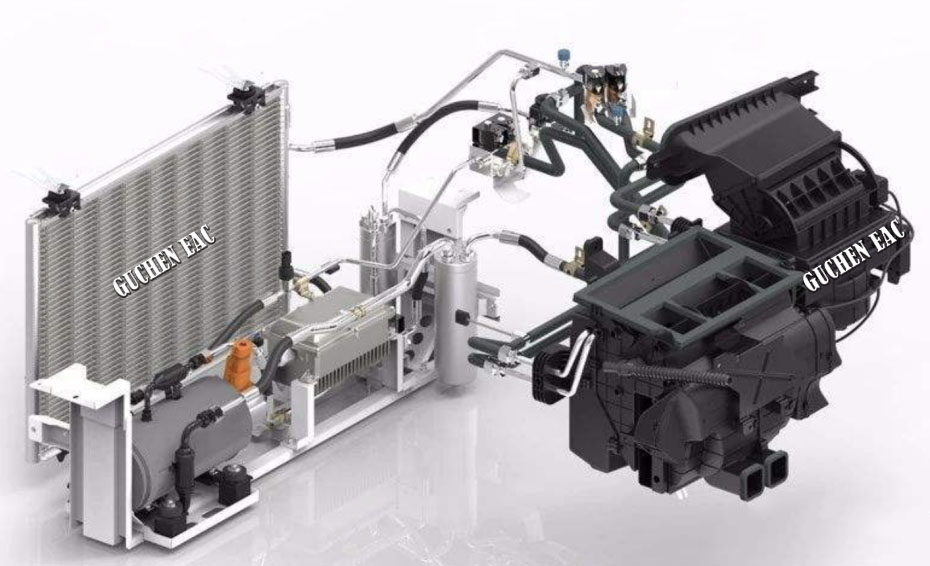

What Are the Main Stages in the Manufacturing Process for Electric Vehicles with Air Conditioning Systems?

The manufacturing process for electric vehicles (EVs) equipped with air conditioning systems involves several critical stages, each requiring meticulous attention to detail and adherence to quality standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Components Sourced and Prepared?

The first stage in manufacturing involves sourcing high-quality materials, including metals for the chassis, plastics for interior components, and specialized materials for the air conditioning system. Suppliers must be vetted to ensure compliance with international standards such as ISO 9001, which focuses on quality management systems.

Once sourced, materials undergo preparation, which may include cutting, machining, and surface treatments. For instance, components like the refrigerant lines and compressor housing require precise fabrication to ensure optimal performance and reliability. This stage also includes quality control checks to verify material specifications and eliminate defects before moving forward.

What Key Techniques Are Used in Forming Components?

The forming stage involves transforming raw materials into specific shapes that are crucial for the vehicle’s functionality. Advanced techniques such as stamping, injection molding, and CNC machining are commonly employed. For example, the air conditioning system components, like the evaporator and condenser, are often produced using injection molding due to its efficiency and ability to create complex geometries.

In this stage, manufacturers also focus on the integration of the air conditioning system into the vehicle’s design. Engineers work closely with production teams to ensure that the placement of components facilitates effective airflow and thermal management, which is vital for both comfort and energy efficiency.

How Does the Assembly Process Ensure Quality and Performance?

The assembly stage is where individual components come together to form the complete vehicle. This process is typically divided into sub-assemblies, such as the electrical system, HVAC (heating, ventilation, and air conditioning), and drivetrain. Each sub-assembly undergoes rigorous testing to ensure compatibility and functionality.

Quality control checkpoints, such as In-Process Quality Control (IPQC), are established to monitor the assembly line. These checkpoints may include visual inspections, functional tests, and measurements to confirm that components fit together correctly and perform as intended. The integration of automated systems can enhance precision and reduce human error during assembly.

What Finishing Techniques Are Applied to Ensure a High-Quality Product?

The finishing stage encompasses various processes aimed at enhancing the vehicle’s aesthetics and durability. This includes painting, coating, and surface treatments designed to protect against corrosion and wear. For electric vehicles, special attention is paid to insulating materials and thermal management solutions that ensure efficient operation of the air conditioning system.

Final inspections are conducted to ensure that all components meet the required specifications. This stage may also include aesthetic checks for paint quality and interior finishes, ensuring that the vehicle meets customer expectations in terms of appearance and performance.

What International Standards and Quality Assurance Practices Are Essential for EV Manufacturers?

Quality assurance is paramount in the manufacturing of electric vehicles with air conditioning systems, especially for B2B buyers in diverse international markets. Compliance with international standards such as ISO 9001 ensures a consistent quality management framework across all manufacturing processes.

Which Industry-Specific Standards Should Buyers Be Aware Of?

In addition to general quality standards, industry-specific certifications are crucial. For instance, CE marking is required for products sold in Europe, indicating compliance with health, safety, and environmental protection standards. Similarly, API certifications may be relevant for components that involve lubricants or fluids.

What Are the Key Quality Control Checkpoints Throughout the Manufacturing Process?

Quality control checkpoints are established at various stages of the manufacturing process to ensure product integrity. These checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival at the manufacturing facility to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, this involves monitoring production activities and conducting tests to identify issues early.

- Final Quality Control (FQC): At this stage, the complete vehicle undergoes comprehensive testing, including performance assessments of the air conditioning system, to ensure it operates effectively and meets all safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential to mitigate risks and ensure product reliability.

What Methods Can Buyers Use to Conduct Supplier Audits?

Conducting regular audits is one effective method for verifying quality control practices. Buyers can request access to quality management system documentation, including audit reports and corrective action plans. Additionally, on-site audits can provide firsthand insight into manufacturing processes and quality assurance practices.

How Can Third-Party Inspections Enhance Confidence in Supplier Quality?

Engaging third-party inspection services can further enhance confidence in supplier quality. These independent organizations can conduct thorough assessments and provide unbiased reports on the manufacturer’s adherence to international standards and industry-specific certifications. This can be particularly valuable for buyers in regions with stringent regulatory requirements.

What Are the Nuances of Quality Control and Certification for International Buyers?

Navigating quality control and certification nuances can be complex for international buyers. Each region may have specific regulations and standards that manufacturers must meet. For instance, compliance with European Union regulations may differ significantly from those in the Middle East or South America.

How Should Buyers Approach Regional Differences in Quality Standards?

Buyers should conduct thorough research on the regulatory requirements of their target markets. Engaging local experts or consultants can provide valuable insights into the necessary certifications and quality standards. Additionally, establishing clear communication with suppliers about quality expectations can help ensure compliance with both international and regional standards.

Conclusion: Why Is Understanding Manufacturing Processes and Quality Assurance Critical for B2B Buyers?

Understanding the manufacturing processes and quality assurance practices for electric vehicles with air conditioning systems is crucial for B2B buyers. It empowers them to make informed decisions when selecting suppliers, ensuring that they receive high-quality products that meet international standards. By prioritizing quality and compliance, buyers can mitigate risks and enhance their operational efficiency in a competitive marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle with air conditioner’

This guide aims to assist B2B buyers in effectively sourcing electric vehicles equipped with air conditioning systems. As the demand for electric vehicles (EVs) continues to rise globally, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of these vehicles is essential for making informed purchasing decisions. The following checklist outlines critical steps to consider when procuring EVs with air conditioning.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as vehicle range, battery capacity, air conditioning type (traditional or heat pump), and overall energy efficiency. These specifications will guide your selection and ensure the vehicles meet your operational needs.

Step 2: Research Compliance and Standards

Verify that the electric vehicles comply with local and international safety and environmental regulations. Different markets have specific standards regarding emissions, safety features, and energy efficiency. Understanding these requirements can prevent costly compliance issues and facilitate smoother import processes.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, including their manufacturing capabilities and experience in producing electric vehicles with air conditioning systems. Look for case studies or references from other businesses in similar sectors to assess reliability and product quality.

– Sub-bullets:

– Check for industry certifications (e.g., ISO).

– Review customer feedback and testimonials.

Step 4: Assess Air Conditioning Technology

Examine the air conditioning systems offered in the vehicles. Determine whether they use traditional electric heaters or advanced heat pump technology, as this can significantly impact energy efficiency and performance in varying climates. Understanding the technology will help you select vehicles that can operate effectively in the specific weather conditions of your target markets.

Step 5: Consider After-Sales Support and Warranty

Ensure that the supplier provides comprehensive after-sales support and a robust warranty. Effective support is vital for addressing any issues that may arise post-purchase, such as system malfunctions or maintenance needs. A strong warranty can also safeguard your investment against unforeseen repairs.

Step 6: Review Total Cost of Ownership (TCO)

Calculate the total cost of ownership, which includes initial purchase price, maintenance costs, energy consumption, and potential tax incentives. A thorough TCO analysis will provide a clearer picture of the long-term financial implications of your investment, helping you make a more informed decision.

Step 7: Plan for Charging Infrastructure

Evaluate the availability and accessibility of charging infrastructure in your operational area. Understanding the charging options will help you assess the practicality of integrating EVs into your fleet. Consider partnerships with charging station providers to facilitate easier access to charging points for your vehicles.

By following this structured checklist, B2B buyers can navigate the complexities of sourcing electric vehicles with air conditioning systems, ensuring that they make well-informed and strategic purchasing decisions.

Comprehensive Cost and Pricing Analysis for electric vehicle with air conditioner Sourcing

What Are the Key Cost Components for Sourcing Electric Vehicles with Air Conditioning?

When sourcing electric vehicles (EVs) equipped with air conditioning systems, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of materials constitutes a significant portion of the overall expense. This includes the cost of batteries, electric motors, refrigerants, and components specific to the air conditioning system, such as compressors and heat pumps. The choice of materials can greatly impact both performance and cost.

-

Labor: Labor costs vary depending on the region and the complexity of the assembly process. Skilled labor for electric vehicle manufacturing can be higher due to the technical expertise required for both EV assembly and the integration of air conditioning systems.

-

Manufacturing Overhead: This encompasses indirect costs related to production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help in minimizing overhead costs.

-

Tooling: Initial tooling costs can be substantial, especially for specialized machinery required for assembling electric vehicles. These costs are often amortized over the production volume.

-

Quality Control (QC): Ensuring the reliability and safety of EVs is paramount. Investments in quality control processes and certifications can add to the costs but are essential for compliance and customer satisfaction.

-

Logistics: Transportation costs for components and finished vehicles must be considered, especially for international shipments. Factors like distance, mode of transport, and tariffs will influence logistics costs.

-

Margin: The profit margin varies by supplier and market dynamics. Buyers should be aware that higher-quality components or advanced technologies may result in higher margins.

How Do Price Influencers Affect the Cost of Electric Vehicles with Air Conditioning?

Several factors can influence the pricing of electric vehicles with air conditioning systems:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes typically lead to lower per-unit costs due to economies of scale. Buyers should assess their needs and negotiate accordingly.

-

Specifications and Customization: Custom features or enhanced specifications can significantly raise costs. Buyers should weigh the benefits of customization against the associated costs.

-

Materials: The choice of high-quality or specialized materials can lead to increased prices. Buyers should consider the long-term benefits of investing in quality components.

-

Quality and Certifications: Compliance with international standards can impact costs. Suppliers with certifications may charge a premium, but this often results in higher quality and reliability.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more but offer better warranties and service.

-

Incoterms: Understanding Incoterms is crucial for international transactions. They define responsibilities between buyers and suppliers, impacting overall costs, including shipping and customs duties.

What Are the Best Buyer Tips for Negotiating Costs?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can yield significant savings:

-

Negotiate on Volume: Leverage larger orders to negotiate better pricing. Suppliers are often willing to provide discounts for bulk purchases.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the initial purchase price but also the TCO, which includes maintenance, energy efficiency, and resale value.

-

Understand Pricing Nuances: Be aware of regional pricing differences, currency fluctuations, and trade agreements that may impact costs.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of costs to identify areas for potential savings.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing and terms in the long run.

What Should Buyers Keep in Mind Regarding Pricing?

Buyers should approach pricing discussions with a clear understanding of their needs and market conditions. Prices can vary widely based on specifications, supplier capabilities, and regional economic factors. It is advisable to seek multiple quotes and perform due diligence on suppliers to ensure the best value.

Disclaimer: Prices and costs mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific requirements. Always consult with suppliers for the most accurate pricing information.

Alternatives Analysis: Comparing electric vehicle with air conditioner With Other Solutions

Introduction to Alternatives for Electric Vehicles with Air Conditioning

In the rapidly evolving automotive landscape, electric vehicles (EVs) equipped with air conditioning systems are gaining traction as a sustainable transportation solution. However, various alternatives exist that also aim to provide effective climate control and energy efficiency. This analysis will compare electric vehicles with air conditioning against two viable alternatives: traditional internal combustion engine vehicles with HVAC systems and hybrid electric vehicles (HEVs). By evaluating these options, international B2B buyers can make informed decisions based on performance, cost, ease of implementation, and maintenance.

Comparison Table

| Comparison Aspect | Electric Vehicle With Air Conditioner | Traditional Internal Combustion Engine (ICE) | Hybrid Electric Vehicle (HEV) |

|---|---|---|---|

| Performance | High efficiency, instant torque | Moderate performance, dependent on fuel type | Balanced performance, good fuel economy |

| Cost | Higher initial investment, lower operating costs | Lower initial cost, higher fuel and maintenance costs | Moderate initial investment, good fuel savings |

| Ease of Implementation | Requires charging infrastructure | Widely available refueling infrastructure | Requires both charging and refueling infrastructure |

| Maintenance | Lower maintenance needs, fewer moving parts | Higher maintenance due to complex engine systems | Moderate maintenance; both electric and combustion components |

| Best Use Case | Urban commuting, eco-conscious buyers | Long-distance travel, lower upfront costs | Versatile use, city and highway driving |

Detailed Breakdown of Alternatives

Traditional Internal Combustion Engine (ICE) Vehicles

Traditional ICE vehicles utilize gasoline or diesel engines, coupled with HVAC systems for climate control. Their performance is generally reliable, especially for long-distance travel, as refueling stations are widely available. However, they incur higher fuel costs and maintenance due to complex engine systems and emissions regulations. While upfront costs are lower than EVs, the long-term operational expenses can be significant, especially with fluctuating fuel prices and environmental fees.

Hybrid Electric Vehicles (HEVs)

HEVs combine a conventional engine with an electric motor, allowing for enhanced fuel efficiency and reduced emissions. They offer a balanced performance that suits both urban and highway driving. The dual power sources help to alleviate range anxiety often associated with pure EVs, as they can switch to gasoline when the battery is depleted. However, the complexity of having both systems can lead to moderate maintenance needs and costs. While HEVs present a middle ground in terms of initial investment, they still require both charging and refueling infrastructures, which may not be as readily available in all markets.

Conclusion: Choosing the Right Solution for Specific Needs

When selecting the ideal vehicle solution, B2B buyers should carefully consider their operational requirements, budget constraints, and environmental goals. Electric vehicles with air conditioning systems excel in energy efficiency and lower long-term costs, making them suitable for businesses focused on sustainability. Conversely, traditional ICE vehicles may appeal to those prioritizing initial affordability and extensive refueling options. Hybrid electric vehicles offer a flexible solution for companies needing a balance of both worlds. Ultimately, the best choice will depend on the specific use case, regional infrastructure, and company values regarding environmental responsibility.

Essential Technical Properties and Trade Terminology for electric vehicle with air conditioner

What Are the Key Technical Properties of Electric Vehicles with Air Conditioning?

When considering electric vehicles (EVs) equipped with air conditioning systems, several critical technical properties must be evaluated. These specifications not only influence the performance and efficiency of the vehicle but also affect its marketability and suitability for different regions.

1. Refrigerant Type

The choice of refrigerant in an EV’s air conditioning system is vital. Common refrigerants include R134a and R1234yf, with the latter being more environmentally friendly due to its lower global warming potential. B2B buyers should consider refrigerant type for compliance with regional environmental regulations and its implications for vehicle efficiency and maintenance.

2. Cooling Capacity (BTU/h)

Cooling capacity, measured in British Thermal Units per hour (BTU/h), indicates how effectively the air conditioning system can cool the cabin. A higher cooling capacity is essential for regions with extreme temperatures, ensuring passenger comfort. B2B buyers need to assess this specification to determine whether the vehicle can meet the climatic challenges in their target markets.

3. Power Consumption (kW)

The power consumption of the air conditioning system, usually expressed in kilowatts (kW), is crucial for understanding its impact on the vehicle’s battery range. A lower power consumption translates to less battery drain, enhancing the vehicle’s overall efficiency. Buyers should evaluate this to ensure that the vehicle can operate effectively without significantly compromising range.

4. Heat Pump Technology

Heat pumps are increasingly used in electric vehicles to provide both heating and cooling. They offer greater energy efficiency compared to traditional resistive heating systems, particularly in moderate climates. Understanding the advantages and limitations of heat pump technology can help B2B buyers select vehicles that align with their operational needs and environmental goals.

5. System Integration

The integration of the air conditioning system with the vehicle’s overall energy management system is critical. This integration affects how the vehicle balances power distribution between driving and climate control, especially in varying temperatures. Buyers should inquire about the integration strategies employed by manufacturers to optimize performance and energy efficiency.

6. Noise Level (dB)

The noise level of the air conditioning system, measured in decibels (dB), impacts passenger comfort and vehicle appeal. A quieter system enhances the driving experience, making it an essential consideration for B2B buyers focusing on consumer satisfaction and market competitiveness.

What Are Common Trade Terms in the Electric Vehicle Industry?

Understanding industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common terms relevant to electric vehicles with air conditioning:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of EVs, OEMs are crucial as they dictate the quality and specifications of components, including air conditioning systems. B2B buyers should prioritize partnerships with reputable OEMs to ensure reliability.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers, as it affects inventory management and cash flow. Negotiating favorable MOQ terms can help companies optimize their procurement processes.

3. RFQ (Request for Quotation)

An RFQ is a business document used to invite suppliers to bid on specific products or services. In the EV industry, an RFQ can help buyers obtain competitive pricing for components like air conditioning systems. A well-structured RFQ ensures that all necessary specifications are clearly communicated, leading to better supplier responses.

4. Incoterms

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms is essential for B2B buyers to understand shipping costs, risks, and logistics involved in acquiring electric vehicles and components.

5. TCO (Total Cost of Ownership)

TCO refers to the comprehensive assessment of costs associated with a product over its entire lifecycle. For electric vehicles, TCO includes purchase price, maintenance, energy consumption, and resale value. B2B buyers should conduct a TCO analysis to make informed purchasing decisions.

By grasping these technical properties and trade terminologies, B2B buyers can navigate the electric vehicle market more effectively, ensuring they choose products that meet their operational requirements and market conditions.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle with air conditioner Sector

What Are the Key Trends Driving the Electric Vehicle with Air Conditioner Market?

The electric vehicle (EV) market is experiencing transformative growth, driven by a confluence of environmental regulations, technological advancements, and changing consumer preferences. Key markets in Africa, South America, the Middle East, and Europe are witnessing a surge in demand for electric vehicles equipped with efficient air conditioning systems. This trend is underpinned by a global shift towards decarbonization, with governments implementing stringent emissions targets and incentives for EV adoption.

Emerging technologies, such as heat pump systems and advanced refrigerants, are becoming critical in enhancing the energy efficiency of air conditioning units in electric vehicles. These innovations not only improve passenger comfort but also mitigate the impact on battery range—a crucial consideration for B2B buyers aiming to meet consumer expectations. Additionally, the integration of smart technologies, including AI-driven climate control, is revolutionizing how air conditioning systems function, optimizing energy consumption based on real-time data.

For international B2B buyers, particularly in regions like Saudi Arabia and Germany, understanding these trends is essential. Buyers should focus on sourcing components that align with sustainability goals while ensuring compliance with local regulations. As competition intensifies, suppliers who can offer advanced, energy-efficient air conditioning solutions will have a distinct advantage in the marketplace.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Electric Vehicle Sector?

Sustainability has emerged as a critical criterion for B2B buyers in the electric vehicle sector, especially when it comes to sourcing air conditioning systems. The environmental impact of manufacturing and operating these components cannot be overstated. Buyers must prioritize suppliers that adhere to ethical sourcing practices and demonstrate a commitment to reducing their carbon footprint.

This includes evaluating the lifecycle of materials used in air conditioning systems, from refrigerants to structural components. Opting for ‘green’ certifications, such as ISO 14001 or LEED, can serve as a benchmark for assessing suppliers’ environmental credentials. Additionally, buyers should consider the use of alternative refrigerants that have lower global warming potential, thus aligning with international efforts to phase out harmful substances.

Moreover, transparency in the supply chain is paramount. Buyers should seek partners who can provide detailed reports on their sourcing practices, ensuring that materials are obtained responsibly and ethically. This not only enhances brand reputation but also mitigates risks associated with regulatory compliance and consumer backlash against unsustainable practices.

How Has the Air Conditioning Technology in Electric Vehicles Evolved Over Time?

The evolution of air conditioning technology in electric vehicles reflects broader advancements in automotive engineering and sustainability. Initially, EV air conditioning systems mirrored those in traditional combustion vehicles, relying on mechanical compressors powered by the engine. However, as electric vehicles gained traction, manufacturers began to innovate, leading to the introduction of electric-driven compressors and heat pump systems.

These advancements allow for improved energy efficiency, enabling air conditioning systems to operate without significantly draining the vehicle’s battery. The heat pump technology, in particular, has revolutionized the heating and cooling capabilities of EVs, allowing for effective climate control while enhancing overall energy management. As a result, the integration of advanced air conditioning systems is no longer just a luxury but a necessity for modern electric vehicles, positioning B2B buyers to invest in suppliers who can deliver cutting-edge solutions that meet both consumer demands and regulatory standards.

In conclusion, navigating the dynamic landscape of electric vehicles with air conditioning systems requires a keen understanding of market trends, sustainability practices, and technological evolution. By focusing on these areas, international B2B buyers can make informed sourcing decisions that contribute to both their bottom line and the broader goals of environmental stewardship.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle with air conditioner

-

1. How do I ensure the air conditioning system in an electric vehicle meets my regional climate needs?

To ensure that the air conditioning system of an electric vehicle (EV) is suitable for your regional climate, consider the vehicle’s cooling and heating capabilities. For warmer climates, focus on systems that effectively cool the cabin and have robust filtration to handle dust and allergens. In colder regions, opt for models with efficient heating solutions, such as heat pumps, which consume less energy. Additionally, verify that the manufacturer provides specifications on performance in extreme temperatures, and consider the availability of service support in your area. -

2. What is the best air conditioning system for electric vehicles used in hot climates?

For electric vehicles operating in hot climates, a high-efficiency air conditioning system is essential. Look for models equipped with a heat pump, which can provide both cooling and heating while using less energy. Systems with variable-speed compressors are also beneficial as they can adjust cooling output based on demand, enhancing efficiency. Additionally, ensure the vehicle has good insulation and tinted windows to minimize heat ingress, which can reduce the overall load on the air conditioning system. -

3. How can I vet suppliers of electric vehicles with air conditioning systems?

When vetting suppliers for electric vehicles, prioritize those with a proven track record in the automotive industry. Check for certifications, such as ISO standards, which indicate quality management. Evaluate customer reviews and request case studies or references from other businesses. Additionally, inquire about their manufacturing processes, supply chain transparency, and after-sales support. A reliable supplier should also provide detailed technical specifications and customization options to meet your specific needs. -

4. What are the typical minimum order quantities (MOQ) for electric vehicles with air conditioning?

Minimum order quantities (MOQ) for electric vehicles can vary significantly based on the manufacturer and the model. Generally, established manufacturers may have higher MOQs due to production costs and logistics. MOQs can range from a few units for niche or custom models to hundreds for standard commercial vehicles. It’s advisable to discuss your requirements with potential suppliers to negotiate MOQs that align with your business needs while considering potential future demand. -

5. What payment terms should I expect when sourcing electric vehicles internationally?

When sourcing electric vehicles internationally, payment terms can vary widely among suppliers. Common terms include a deposit (often 30% to 50%) upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers may offer financing options or letters of credit for larger orders. Always clarify terms upfront and consider using escrow services for added security in transactions. Ensure that the payment method chosen aligns with your cash flow needs and risk management strategy. -

6. How do I ensure quality assurance (QA) for electric vehicles with air conditioning systems?

To ensure quality assurance for electric vehicles, request detailed quality control processes from the manufacturer. Ask about their inspection protocols at various stages of production, including the air conditioning system’s performance. It’s beneficial to seek third-party certifications and reports on product testing. Additionally, consider performing independent inspections before shipment and establish clear agreements on warranties and after-sales service to address any potential issues post-delivery. -

7. What logistics considerations should I keep in mind when importing electric vehicles?

When importing electric vehicles, consider logistics factors such as shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder experienced in handling automotive shipments to streamline the process. Ensure compliance with local regulations regarding vehicle emissions and safety standards. Additionally, factor in the time required for customs clearance and the availability of local charging infrastructure, as these can affect delivery timelines and operational readiness. -

8. How can I customize the air conditioning system in electric vehicles to suit my business needs?

Customization options for air conditioning systems in electric vehicles typically include modifications to capacity, efficiency, and user controls. Discuss specific requirements with potential suppliers, such as enhanced filtration for dust-heavy environments or tailored climate control features for different passenger needs. Manufacturers may also offer options for integrating advanced technologies like smart climate control systems or remote pre-conditioning features. Ensure that any modifications comply with safety standards and do not compromise the vehicle’s overall performance.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

A Look at Electric Vehicle With Air Conditioner Manufacturers & Suppliers

We are currently compiling a detailed list of top electric vehicle with air conditioner suppliers. Please check back later.

Strategic Sourcing Conclusion and Outlook for electric vehicle with air conditioner

Why Is Strategic Sourcing Essential for Electric Vehicles with Air Conditioning?

In the rapidly evolving electric vehicle (EV) market, strategic sourcing of air conditioning systems has become paramount. Understanding the unique operational dynamics of EV air conditioning—such as the reliance on battery power and the integration of advanced technologies like heat pumps—enables international buyers to make informed procurement decisions. This not only enhances vehicle performance and comfort but also aligns with broader sustainability goals.

Investing in high-quality air conditioning solutions can significantly improve energy efficiency, thereby extending the driving range and reducing operational costs. Buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with suppliers that demonstrate innovation and reliability. As the demand for electric vehicles grows, sourcing components that meet these needs will be crucial for maintaining competitive advantage.

Looking ahead, the potential for growth in the electric vehicle sector is immense. By prioritizing strategic sourcing now, companies can position themselves to capitalize on future advancements in technology and consumer demand. Engage with trusted suppliers today to ensure that your offerings remain at the forefront of this electric vehicle revolution.