Introduction: Navigating the Global Market for long range electric cargo bike

In the ever-evolving landscape of urban logistics, sourcing long-range electric cargo bikes presents a unique challenge for international B2B buyers. As cities across Africa, South America, the Middle East, and Europe grapple with congestion and environmental concerns, the demand for efficient and sustainable transportation solutions has surged. This guide aims to provide a comprehensive overview of the long-range electric cargo bike market, exploring various types, applications, and innovative designs that cater to diverse business needs.

From understanding the specifications that determine performance, such as battery capacity and cargo space, to navigating the complexities of supplier vetting and pricing, this guide equips buyers with the knowledge required to make informed purchasing decisions. We delve into the latest trends in electric cargo bike technology, highlighting their versatility for transporting goods, people, and even pets, while maintaining eco-friendliness and efficiency.

By addressing key considerations like regulatory compliance, maintenance, and customization options, this guide empowers businesses to select the right electric cargo bike that aligns with their operational goals. Whether you’re based in Brazil’s bustling urban centers or Germany’s eco-conscious landscapes, understanding the nuances of this market will enable you to leverage electric cargo bikes as a strategic asset in your logistics and transportation strategy.

Understanding long range electric cargo bike Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Long-Range Dual-Battery Cargo Bike | Extended battery life, typically over 60 miles range | Delivery services, logistics | Pros: Enhanced range; Cons: Higher initial cost. |

| Tricycle Cargo Bike | Stable three-wheel design, larger cargo capacity | Family transport, urban deliveries | Pros: Increased stability; Cons: Bulkier and less maneuverable. |

| Folding Electric Cargo Bike | Compact design, easy to store and transport | Small businesses, urban commuting | Pros: Space-saving; Cons: Limited cargo capacity. |

| Heavy-Duty Electric Cargo Bike | High load capacity (up to 450 lbs) | Construction, heavy goods transport | Pros: Robust design; Cons: Heavier and less agile. |

| Electric Cargo Bike with Passengers | Designed for carrying multiple passengers | Family outings, group deliveries | Pros: Versatile usage; Cons: Requires more maintenance. |

What are the Characteristics of Long-Range Dual-Battery Cargo Bikes?

Long-range dual-battery cargo bikes are designed to maximize distance and efficiency, making them ideal for businesses requiring extensive delivery routes. With the capacity to travel over 60 miles on a single charge, they are particularly suitable for logistics companies and delivery services. When purchasing, consider the weight of the cargo, the terrain of the delivery routes, and the bike’s overall power management system.

How Do Tricycle Cargo Bikes Enhance Stability for Businesses?

Tricycle cargo bikes offer a stable three-wheel design that is perfect for transporting heavy loads and passengers. Their larger cargo area is beneficial for family transport or urban deliveries, making them an excellent choice for businesses focused on community services or family-oriented activities. Buyers should assess the bike’s turning radius and overall size to ensure it fits their operational needs.

What Makes Folding Electric Cargo Bikes Ideal for Urban Environments?

Folding electric cargo bikes are designed for urban environments where space is at a premium. Their compact design allows for easy storage and transport, making them ideal for small businesses that require mobility and flexibility. However, potential buyers should be mindful of their limited cargo capacity, which may not suit all business models.

Why Choose Heavy-Duty Electric Cargo Bikes for Robust Applications?

Heavy-duty electric cargo bikes are built to carry substantial loads, often exceeding 450 lbs, making them perfect for construction sites or businesses that handle heavy goods. Their robust design ensures durability and reliability, but buyers must consider the bike’s weight and potential maneuverability issues in tight spaces.

How Can Electric Cargo Bikes with Passengers Serve Diverse Needs?

Electric cargo bikes designed to carry passengers provide versatility for family outings and group deliveries. They accommodate multiple riders while maintaining cargo space, making them an attractive option for businesses focused on eco-friendly transportation solutions. Buyers should evaluate the safety features and seating arrangements to ensure comfort and security for all passengers.

Key Industrial Applications of long range electric cargo bike

| Industry/Sector | Specific Application of long range electric cargo bike | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce and Retail | Last-mile delivery of goods | Reduces delivery times and operational costs | Battery range, load capacity, and durability |

| Food and Beverage | Mobile food delivery services | Enhances customer reach and service flexibility | Temperature control features and cargo space |

| Logistics and Warehousing | Internal transport of goods | Increases efficiency in warehouse operations | Maneuverability, weight capacity, and charging time |

| Tourism and Recreation | Guided tours and family transport | Attracts eco-conscious customers and expands offerings | Comfort, safety features, and customization options |

| Healthcare | Patient transport and medical supply delivery | Improves accessibility and response times | Safety features, load capacity, and battery life |

How Can Long Range Electric Cargo Bikes Enhance E-commerce and Retail Operations?

In the e-commerce and retail sector, long-range electric cargo bikes are revolutionizing last-mile delivery. They enable businesses to transport goods directly to customers’ doorsteps efficiently, reducing delivery times and operational costs. With the ability to navigate urban environments easily, these bikes can access areas that traditional delivery vehicles may find challenging. When sourcing these bikes, businesses should consider battery range, load capacity, and overall durability to ensure they can meet delivery demands.

What Role Do Long Range Electric Cargo Bikes Play in Food and Beverage Delivery?

Long-range electric cargo bikes are increasingly used in the food and beverage industry for mobile delivery services. These bikes allow restaurants and food vendors to extend their reach, delivering meals directly to customers while maintaining freshness. The flexibility offered by electric cargo bikes enhances service options, allowing businesses to cater to a broader audience. Key sourcing considerations include temperature control features and adequate cargo space to accommodate various food items securely.

How Do Long Range Electric Cargo Bikes Improve Logistics and Warehousing Efficiency?

In logistics and warehousing, long-range electric cargo bikes facilitate the internal transport of goods, significantly increasing operational efficiency. They can quickly move items between storage areas, loading docks, and shipping zones, reducing time spent on manual transport methods. This efficiency translates into cost savings and improved workflow. When sourcing, companies should prioritize maneuverability, weight capacity, and charging time to ensure that the bikes fit seamlessly into their existing operations.

Can Long Range Electric Cargo Bikes Enhance Tourism and Recreation Experiences?

Tourism and recreation sectors benefit from the use of long-range electric cargo bikes for guided tours and family transport. These bikes provide an eco-friendly alternative for exploring urban and rural areas, appealing to environmentally conscious travelers. They also offer a fun and engaging way for families to navigate tourist attractions together. Sourcing considerations include comfort, safety features, and customization options to cater to diverse groups and enhance the overall experience.

How Are Long Range Electric Cargo Bikes Used in Healthcare Delivery?

In healthcare, long-range electric cargo bikes are utilized for patient transport and medical supply delivery. They improve accessibility, allowing healthcare providers to reach patients in urban areas quickly and efficiently. Additionally, these bikes can be equipped to transport medical supplies, ensuring timely delivery for critical care. When sourcing, healthcare providers should focus on safety features, load capacity, and battery life to ensure reliability and performance in various scenarios.

3 Common User Pain Points for ‘long range electric cargo bike’ & Their Solutions

Scenario 1: Navigating Range Anxiety for Delivery Fleets

The Problem: One of the most significant challenges B2B buyers face when considering long-range electric cargo bikes is range anxiety. For businesses relying on these bikes for deliveries, the fear of running out of battery during transit can lead to operational delays and customer dissatisfaction. This is especially true in regions with less developed charging infrastructure or where the delivery routes are longer than the bike’s range capability, such as in rural areas of Africa or South America.

The Solution: To address this concern, buyers should prioritize sourcing long-range electric cargo bikes with dual-battery systems. This feature not only extends the operational range significantly—often exceeding 60 miles—but also allows for seamless transitions between batteries. When selecting a model, consider the bike’s compatibility with local charging solutions and ensure it includes a robust battery management system to maximize battery lifespan. Additionally, integrating GPS tracking can help monitor battery levels in real-time, allowing businesses to plan routes efficiently and avoid any unexpected downtime.

Scenario 2: Ensuring Cargo Security During Transit

The Problem: Another pain point for B2B buyers is the secure transportation of goods. Electric cargo bikes often serve multiple functions, from delivering groceries to transporting equipment, which requires adequate cargo security. Businesses may worry about theft or damage during transit, especially in urban environments where the risk is heightened.

The Solution: To mitigate these risks, buyers should look for electric cargo bikes equipped with robust locking mechanisms and secure cargo compartments. Models that offer integrated locking systems can deter theft and provide peace of mind. Additionally, investing in cargo covers or waterproof tarps can protect items from the elements and prying eyes. For businesses that require high-security measures, consider customizing the bike with GPS tracking systems and remote locking features, allowing operators to monitor their cargo’s location and security status at all times.

Scenario 3: Adapting to Varied Load Capacities

The Problem: Different businesses have different cargo needs, and B2B buyers often struggle with selecting a long-range electric cargo bike that can handle various load capacities. For example, a logistics company may require a bike capable of transporting heavy equipment one day and lighter packages the next. This variability can lead to inefficiencies if the chosen bike cannot adapt to the changing demands of the business.

The Solution: To ensure versatility, buyers should seek long-range electric cargo bikes that offer customizable cargo solutions. Look for models with adjustable cargo beds or racks that can accommodate a variety of load sizes and weights. Additionally, consider bikes that allow for modular attachments—such as removable cargo containers or baskets—providing flexibility for different transportation tasks. By investing in a bike with these features, businesses can streamline their operations and avoid the need for multiple vehicles, ultimately saving time and reducing costs. Training staff on how to effectively load and secure different types of cargo can further enhance the bike’s usability across various applications.

Strategic Material Selection Guide for long range electric cargo bike

When selecting materials for long-range electric cargo bikes, it is essential to consider various factors that impact performance, durability, and cost. Here, we analyze four common materials used in the manufacturing of these bikes, focusing on their properties, advantages, limitations, and implications for international B2B buyers.

Which Materials Are Commonly Used in Long-Range Electric Cargo Bikes?

Aluminum Alloy

Key Properties: Aluminum alloys are lightweight yet strong, with excellent corrosion resistance. They can withstand varying temperatures and pressures, making them suitable for diverse climates.

Pros & Cons: Aluminum’s lightweight nature enhances bike performance and efficiency, especially for long-range travel. However, while it offers good durability, it can be more expensive than steel and may require specialized manufacturing techniques, increasing production complexity.

Impact on Application: Aluminum is compatible with various media, including moisture and chemicals, which is vital for bikes used in urban environments. Its corrosion resistance ensures longevity, especially in humid or coastal regions.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from Europe may prefer aluminum due to its lightweight properties, while those in regions with rough terrains, like parts of Africa, might prioritize durability.

Steel

Key Properties: Steel is known for its high tensile strength and durability. It has good fatigue resistance and can handle significant loads, making it ideal for cargo applications.

Pros & Cons: Steel is generally more affordable than aluminum and easier to manufacture, which can lower production costs. However, it is heavier, which may impact the bike’s range and efficiency. Steel is also prone to rust if not properly treated.

Impact on Application: Steel’s robustness makes it suitable for carrying heavy loads, but its weight can be a disadvantage for long-distance travel. Proper coatings can enhance its corrosion resistance.

Considerations for International Buyers: Buyers in South America and Africa may find steel appealing due to cost-effectiveness. However, they should ensure that the steel used meets local standards for strength and corrosion resistance.

Carbon Fiber

Key Properties: Carbon fiber is exceptionally lightweight and has high tensile strength, offering excellent performance in terms of speed and efficiency. It also has good resistance to temperature fluctuations.

Pros & Cons: The primary advantage of carbon fiber is its weight-to-strength ratio, which enhances bike performance. However, it is significantly more expensive than both aluminum and steel and requires specialized manufacturing processes.

Impact on Application: Carbon fiber is ideal for high-performance applications where weight reduction is critical. Its resistance to environmental factors makes it suitable for various climates.

Considerations for International Buyers: While carbon fiber is popular in Europe for high-end bikes, its cost may be prohibitive for buyers in developing regions. Compliance with international standards is essential for ensuring quality and safety.

Plastic Composites

Key Properties: Plastic composites are lightweight and resistant to corrosion, making them suitable for various environmental conditions. They can be molded into complex shapes, allowing for innovative designs.

Pros & Cons: These materials are typically less expensive than metals and can reduce overall bike weight. However, they may not offer the same level of strength and durability as metals, which can limit their application in heavy-duty cargo bikes.

Impact on Application: Plastic composites are ideal for non-load-bearing components, such as fenders and covers. Their resistance to moisture makes them suitable for wet environments.

Considerations for International Buyers: Buyers in the Middle East and Africa may appreciate the cost-effectiveness of plastic composites, but they should ensure that the materials meet local standards for durability and safety.

Summary Table of Material Selection for Long-Range Electric Cargo Bikes

| Material | Typical Use Case for long range electric cargo bike | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | Frame and structural components | Lightweight with good corrosion resistance | Higher cost and manufacturing complexity | High |

| Steel | Frame and cargo racks | Cost-effective and durable | Heavier, prone to rust without treatment | Low |

| Carbon Fiber | High-performance frames | Excellent weight-to-strength ratio | Very high cost and specialized manufacturing | High |

| Plastic Composites | Non-load-bearing components | Lightweight and corrosion-resistant | Limited strength for heavy loads | Medium |

This strategic material selection guide provides critical insights for B2B buyers, helping them make informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for long range electric cargo bike

What Are the Key Stages in the Manufacturing Process of Long-Range Electric Cargo Bikes?

The manufacturing process of long-range electric cargo bikes typically involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential for ensuring that the final product meets the high standards required for performance, safety, and durability.

1. Material Preparation: What Materials Are Used and How Are They Processed?

The first step in manufacturing involves sourcing high-quality materials. Key components include aluminum or steel for the frame, lithium-ion batteries, electric motors, and various plastics for components such as fenders and cargo containers.

- Sourcing and Quality Control: Suppliers must adhere to international standards to ensure the materials are of the highest quality. This may involve certifications such as ISO 9001, which outlines the criteria for an effective quality management system.

- Material Testing: Before production, materials undergo rigorous testing for strength, weight, and durability to ensure they can withstand the demands of heavy cargo and long distances.

2. Forming: How Are the Components Shaped and Prepared?

Once materials are prepared, they move to the forming stage. This stage includes processes such as cutting, welding, and molding.

- Frame Construction: The bike’s frame is typically constructed using advanced welding techniques, which enhance strength while minimizing weight. The use of CNC (Computer Numerical Control) machinery allows for precise cuts and shapes.

- Battery and Motor Integration: The integration of electric motors and batteries is crucial. Manufacturers often use specialized fixtures to ensure components fit perfectly and function optimally.

What Are the Main Assembly Techniques for Long-Range Electric Cargo Bikes?

The assembly phase is where all components come together. This stage is crucial for ensuring that the bike functions correctly and meets safety standards.

- Modular Assembly: Many manufacturers utilize a modular approach, allowing for easier upgrades and repairs. This can be particularly beneficial for B2B buyers looking to customize their fleets.

- Quality Checks During Assembly: Quality Control (QC) checkpoints are established at various stages in the assembly process to catch any defects early. This includes inspections of components before they are installed on the frame.

How Is the Finishing Process Carried Out for Long-Range Electric Cargo Bikes?

The finishing stage involves painting, coating, and final assembly. This stage not only enhances the aesthetic appeal but also adds protective layers to the bike.

- Surface Treatments: Techniques like powder coating are commonly employed to provide durability and resistance to corrosion. This is particularly important for bikes that may be exposed to harsh environmental conditions.

- Final Assembly: After painting, the bikes undergo final assembly, including the installation of accessories such as racks, lights, and safety features.

What Quality Assurance Practices Are Relevant for Long-Range Electric Cargo Bikes?

Quality assurance (QA) is an integral part of the manufacturing process for long-range electric cargo bikes. Ensuring that products meet international standards and customer expectations is crucial for B2B buyers.

1. Which International Standards Should Buyers Look For?

Compliance with international standards is vital for ensuring product safety and reliability. Key certifications include:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: Required for products sold in the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Certification: In some regions, especially in industries where bikes are used for commercial purposes, an API (American Petroleum Institute) certification may be relevant.

2. What Are the Key QC Checkpoints in the Manufacturing Process?

Quality Control is typically segmented into several checkpoints:

- Incoming Quality Control (IQC): Raw materials and components are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, random inspections are conducted to check for defects or issues that may arise during production.

- Final Quality Control (FQC): After assembly, each bike undergoes a comprehensive inspection to verify that it meets all specifications and safety standards.

What Common Testing Methods Are Used in Quality Assurance for Electric Cargo Bikes?

Testing is a critical aspect of quality assurance, ensuring that the bikes perform as expected under various conditions.

- Load Testing: Bikes are subjected to load testing to simulate real-world usage. This helps ensure that the frame, tires, and cargo area can handle the specified weight limits.

- Electrical Testing: Components such as batteries and motors undergo electrical testing to verify their performance and safety.

- Field Testing: Some manufacturers conduct field tests in various environments to assess the bike’s performance in real-world conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential.

- Supplier Audits: Conducting audits of potential suppliers can provide insight into their manufacturing processes and quality assurance measures.

- Requesting Quality Reports: Buyers should ask for documentation related to quality checks and testing results. This may include IQC, IPQC, and FQC reports.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of a supplier’s quality control practices and compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing long-range electric cargo bikes internationally, buyers must be aware of specific nuances:

- Regulatory Compliance: Different regions have varying regulations regarding electric vehicles. Understanding local laws in the target market is essential.

- Cultural Considerations: Communication styles and business practices can differ significantly across regions. Establishing a strong relationship with suppliers can facilitate smoother transactions and better quality assurance.

In summary, understanding the manufacturing processes and quality assurance practices for long-range electric cargo bikes is crucial for B2B buyers. By focusing on the key stages of manufacturing and the relevant quality standards, buyers can make informed decisions that align with their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘long range electric cargo bike’

Introduction

This guide provides a practical checklist for B2B buyers looking to procure long-range electric cargo bikes. As these bikes gain popularity for their eco-friendly transport solutions, understanding the procurement process is essential for ensuring that you select the right model for your needs. This step-by-step approach will help you navigate the complexities of sourcing while maximizing your investment.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial before you start evaluating options. Consider factors such as battery capacity, range, load capacity, and motor power. These specifications will guide your search and ensure you select a bike that meets your operational requirements.

- Battery Capacity: Look for bikes that offer a sufficient range for your intended use, ideally exceeding 35 miles per charge.

- Load Capacity: Ensure the bike can handle the weight you plan to transport, factoring in additional cargo or passengers.

Step 2: Research Market Trends and Regulations

Understanding the latest market trends and regulatory requirements in your target regions can inform your purchasing decision. Regulations may dictate speed limits, safety features, and battery disposal requirements, which can vary significantly between countries.

- Local Regulations: Familiarize yourself with e-bike classifications in your region, as this can affect where and how you can use the bikes.

- Market Trends: Investigate popular models and features that are gaining traction in your market segment to ensure your choice aligns with consumer preferences.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. This step will help you mitigate risks associated with product quality and supplier reliability. Request detailed company profiles, case studies, and references from other businesses in your industry.

- Supplier Reliability: Look for suppliers with a solid track record of delivering quality products and customer service.

- Product Certifications: Ensure that the bikes meet international safety and quality standards, such as CE marking or ISO certifications.

Step 4: Request Product Samples

Whenever possible, request samples or demonstrations of the bikes you’re considering. This hands-on approach allows you to assess the quality, comfort, and usability of the bikes firsthand.

- Testing Performance: Evaluate aspects like handling, stability under load, and ease of use.

- Assess Customization Options: Inquire about available customization options that could cater to your specific needs.

Step 5: Analyze Pricing Structures

Understanding the pricing structure is vital to ensure you are making a sound financial investment. Look beyond the initial purchase price to consider warranty terms, maintenance costs, and potential discounts for bulk orders.

- Total Cost of Ownership: Factor in long-term costs such as battery replacements and servicing.

- Bulk Order Discounts: Inquire about pricing tiers for larger orders, which can significantly reduce your overall expenditure.

Step 6: Confirm After-Sales Support and Warranty

A reliable after-sales support system and warranty are essential for long-term satisfaction. Confirm that the supplier offers comprehensive support, including maintenance services, spare parts availability, and warranty terms.

- Warranty Length: Ensure the warranty covers a reasonable period, ideally two years or more.

- Maintenance Services: Check if the supplier provides ongoing maintenance support or training for your staff.

Step 7: Finalize Purchase Agreement

Once you have completed your due diligence, it’s time to finalize your purchase agreement. Ensure that all terms and conditions are clearly outlined, including delivery timelines and payment terms.

- Review Contractual Terms: Pay close attention to clauses regarding returns, damages, and liabilities.

- Negotiate Terms: Don’t hesitate to negotiate terms that align with your budget and operational needs.

Following this structured checklist will help ensure that you make informed decisions when procuring long-range electric cargo bikes, ultimately enhancing your operational efficiency and sustainability efforts.

Comprehensive Cost and Pricing Analysis for long range electric cargo bike Sourcing

What Are the Key Cost Components in Sourcing Long-Range Electric Cargo Bikes?

When considering the sourcing of long-range electric cargo bikes, it is crucial to understand the various cost components that contribute to the final price. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. High-quality aluminum or steel frames, durable batteries, and reliable motors are essential for performance and longevity. Suppliers may offer different grades of materials, which can alter pricing substantially.

-

Labor: Labor costs can vary based on the region of production. Countries with lower labor costs may provide more competitive pricing, but it’s essential to assess the skill level of the workforce to ensure quality. Skilled labor often results in better craftsmanship and durability.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help lower these costs, which can then be passed on to the buyer as a more competitive price.

-

Tooling: The initial setup for production can require significant investment in tooling, especially for customized designs. Buyers should factor in these costs when assessing the overall pricing structure.

-

Quality Control (QC): Implementing robust QC measures is crucial to ensure the bikes meet safety standards and performance expectations. This can increase initial costs but can save money in the long run by reducing returns and warranty claims.

-

Logistics: Transportation costs for shipping the bikes to the end market can vary widely. Factors such as distance, shipping method, and Incoterms can influence these costs. Understanding the logistics involved can help buyers negotiate better terms.

-

Margin: Suppliers typically mark up prices to achieve a profit margin, which can vary based on market conditions and competition. Buyers should be aware of typical margins in the industry to identify fair pricing.

How Do Price Influencers Affect Long-Range Electric Cargo Bike Costs?

Several factors can influence the pricing of long-range electric cargo bikes, particularly for international buyers.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their demand forecasts to optimize pricing.

-

Specifications and Customization: Customization can increase costs due to additional design and manufacturing processes. Buyers should clearly define their specifications to avoid unnecessary expenses.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can significantly affect pricing. Bikes that meet international safety standards may come at a premium but can enhance marketability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their credibility and service levels, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the overall cost structure.

What Are Essential Buyer Tips for Long-Range Electric Cargo Bikes?

For international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, understanding pricing nuances is essential to making informed purchasing decisions.

-

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders. Many suppliers are open to negotiations, particularly if you can guarantee consistent orders.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes maintenance, operational costs, and potential resale value. A higher initial investment may be justified by lower long-term costs.

-

Pricing Nuances: Be aware of currency fluctuations, import duties, and taxes that can affect the final price. Additionally, understanding local market trends can provide leverage in negotiations.

-

Quality Over Price: While it may be tempting to choose the lowest-priced option, prioritize quality and durability to ensure customer satisfaction and reduce future costs associated with repairs or replacements.

-

Due Diligence: Conduct thorough research on potential suppliers, including reviews and references. This can help mitigate risks associated with quality and delivery timelines.

By understanding these cost components, price influencers, and actionable buyer tips, B2B buyers can navigate the complex landscape of sourcing long-range electric cargo bikes effectively.

Alternatives Analysis: Comparing long range electric cargo bike With Other Solutions

The increasing demand for sustainable transportation solutions has led businesses to explore various alternatives to long-range electric cargo bikes. Each option has its unique benefits and drawbacks, making it essential for B2B buyers to carefully evaluate their specific needs and operational contexts. This analysis compares long-range electric cargo bikes with traditional delivery vans and cargo tricycles, offering insights to help businesses make informed decisions.

Comparison Table

| Comparison Aspect | Long Range Electric Cargo Bike | Traditional Delivery Van | Cargo Tricycle |

|---|---|---|---|

| Performance | Up to 35 miles range, 20 mph speed | Typically higher payload, longer range | 20-30 miles range, lower speed |

| Cost | $1,399 – $1,999 | $25,000 – $60,000 | $1,500 – $3,000 |

| Ease of Implementation | Quick setup; minimal training | Requires fleet management and licensing | Moderate setup; some training needed |

| Maintenance | Low maintenance; battery checks | Higher maintenance costs; regular servicing required | Low maintenance; simple mechanics |

| Best Use Case | Urban deliveries, eco-conscious businesses | Long-distance logistics, large cargo loads | Family transport, local deliveries |

In-Depth Analysis of Alternatives

Traditional Delivery Van

Traditional delivery vans are a long-standing solution for transporting goods. They offer significant cargo capacity and longer ranges compared to electric cargo bikes. However, the high purchase and maintenance costs can be prohibitive for small and medium-sized enterprises. Additionally, vans contribute to urban congestion and pollution, which may contradict sustainability goals. They are best suited for businesses needing to transport large volumes over longer distances, but they come with regulatory burdens such as licensing and insurance.

Cargo Tricycle

Cargo tricycles provide a stable and versatile option for transporting goods and passengers. With a lower price point than electric cargo bikes and vans, they are accessible to many businesses. Their performance is generally adequate for local deliveries and family transport, but they may struggle with speed and range compared to electric cargo bikes. While they require less maintenance than traditional vehicles, their design can limit cargo capacity and comfort. They are ideal for businesses focused on family-oriented services or local deliveries in urban areas.

How to Choose the Right Solution for Your Business Needs

When deciding between long-range electric cargo bikes and their alternatives, consider your specific operational requirements. If your business model prioritizes sustainability and urban mobility, electric cargo bikes offer an eco-friendly solution with lower operational costs. On the other hand, if you require substantial cargo capacity and longer distances, a traditional delivery van may be more appropriate despite its higher costs. Meanwhile, cargo tricycles can serve as an excellent middle ground for local deliveries and family transport, balancing affordability with functionality. Ultimately, understanding your business’s unique needs will guide you in selecting the most suitable transportation solution.

Essential Technical Properties and Trade Terminology for long range electric cargo bike

What Are the Key Technical Properties of Long Range Electric Cargo Bikes?

When evaluating long range electric cargo bikes for B2B purchasing, understanding the following technical specifications is crucial for ensuring performance, safety, and suitability for specific applications.

1. Motor Power (Wattage)

The motor power, typically measured in watts (W), is a key determinant of the bike’s performance. Most long-range electric cargo bikes feature motors ranging from 350W to 750W. A more powerful motor allows for better performance on inclines and when carrying heavy loads. For B2B buyers, selecting the appropriate wattage ensures that the bike meets the operational demands of their logistics or transportation needs.

2. Battery Capacity (Ah)

Battery capacity, measured in amp-hours (Ah), indicates how much energy the battery can store. For long-range electric cargo bikes, a higher Ah rating translates to longer distances per charge, often ranging from 20 to 100 miles. This is particularly important for businesses that rely on consistent and extended use throughout the day, as it minimizes downtime for recharging.

3. Payload Capacity (lbs)

Payload capacity refers to the maximum weight the bike can safely carry, which is typically between 300 to 600 lbs for cargo bikes. Understanding payload capacity is vital for B2B buyers as it directly impacts the bike’s usability in transporting goods, equipment, or passengers. Ensuring that the bike can handle the required load without compromising safety or performance is essential.

4. Frame Material and Design

The material and design of the bike frame significantly affect durability and weight. Common materials include aluminum and steel, each offering different benefits in terms of weight and strength. A well-designed frame that balances sturdiness with lightweight properties can enhance handling and maneuverability, making it easier for businesses to navigate urban environments.

5. Range (Miles)

The range indicates the maximum distance the bike can travel on a single charge, which is crucial for operational efficiency. Long-range electric cargo bikes typically offer a range of 35 to 100 miles. For businesses, understanding the range helps in planning routes and ensuring that the bikes can complete their daily tasks without requiring frequent recharges.

What Are Common Trade Terms Related to Long Range Electric Cargo Bikes?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of electric cargo bikes, OEM relationships can influence the quality and reliability of components such as motors and batteries. Understanding OEM partnerships helps buyers assess the bike’s overall quality.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. For B2B buyers, knowing the MOQ is critical for budgeting and inventory management. It allows businesses to plan their purchases according to their operational needs without overcommitting financially.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and other details for specific products. This term is crucial for B2B buyers as it initiates the procurement process and allows for comparison between different suppliers to secure the best deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms helps B2B buyers navigate logistics and reduce risks associated with international transactions.

5. TCO (Total Cost of Ownership)

TCO refers to the comprehensive assessment of all costs associated with purchasing and operating a product over its lifetime. For long-range electric cargo bikes, TCO includes the initial purchase price, maintenance, insurance, and energy costs. This metric is vital for businesses to evaluate the long-term financial impact of their investment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational goals and financial strategies.

Navigating Market Dynamics and Sourcing Trends in the long range electric cargo bike Sector

What Are the Current Market Dynamics and Key Trends for Long Range Electric Cargo Bikes?

The long range electric cargo bike market is experiencing significant growth driven by various global factors. Urbanization is increasing, leading to heightened demand for sustainable transport solutions. In regions such as Africa and South America, the need for efficient and eco-friendly logistics solutions is becoming critical, particularly as cities grapple with congestion and pollution. In Europe, countries like Germany are pushing for greener initiatives, which include promoting electric vehicles for urban transport, further fueling the demand for electric cargo bikes.

Emerging technology trends are reshaping the market landscape. Innovations in battery technology, such as lithium-ion and solid-state batteries, are enhancing the range and efficiency of electric cargo bikes. These advancements enable bikes to cover longer distances with heavier loads, meeting the needs of businesses that require reliable logistics solutions. Furthermore, the integration of smart technology, such as GPS tracking and IoT connectivity, is becoming standard, allowing businesses to optimize their supply chains and improve operational efficiency.

For international B2B buyers, understanding regional dynamics is crucial. In Africa and South America, cost-effective sourcing and local partnerships can facilitate market entry and customer engagement. In contrast, European buyers may focus more on compliance with stringent environmental regulations and quality certifications. Engaging with local distributors and understanding the regional preferences will play a pivotal role in successful sourcing strategies.

How Can Sustainability and Ethical Sourcing Impact B2B Purchasing Decisions for Long Range Electric Cargo Bikes?

Sustainability is not just a trend; it is becoming a fundamental principle for businesses worldwide. The long range electric cargo bike sector is no exception, as companies and consumers alike are increasingly prioritizing environmentally friendly practices. The environmental impact of traditional logistics methods—characterized by high carbon emissions and resource depletion—has prompted a shift towards electric cargo bikes as a cleaner alternative.

Ethical sourcing is equally important. Businesses sourcing electric cargo bikes must consider the entire supply chain, ensuring that materials are sourced responsibly and that manufacturers adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and Fair Trade standards can serve as indicators of a manufacturer’s commitment to sustainability and ethical practices. Buyers looking for long range electric cargo bikes should prioritize suppliers that demonstrate transparency in their sourcing processes and product lifecycle.

In addition to ethical considerations, sustainable materials—like recycled aluminum and eco-friendly composites—are increasingly favored. These materials not only reduce the environmental footprint but can also enhance the durability and performance of electric cargo bikes. As sustainability becomes a key purchasing criterion, buyers must evaluate potential suppliers on their commitment to green practices.

What Is the Evolution of the Long Range Electric Cargo Bike Market?

The long range electric cargo bike market has evolved significantly over the past decade. Initially, these bikes were viewed primarily as niche products, often associated with urban delivery services or recreational use. However, as cities worldwide have recognized the need for sustainable transport solutions, demand has surged. Technological advancements have played a crucial role in this evolution, with improvements in battery life, motor efficiency, and design aesthetics making electric cargo bikes more appealing to a broader audience.

Today, electric cargo bikes are not only seen as a solution for urban logistics but also as versatile vehicles for family transport and personal use. The introduction of dual-battery systems has further enhanced their appeal, allowing for longer trips without the worry of running out of power. As the market continues to expand, international buyers must stay informed about ongoing developments to leverage the opportunities that arise in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of long range electric cargo bike

-

How do I choose the right long-range electric cargo bike for my business needs?

When selecting a long-range electric cargo bike, consider factors such as cargo capacity, range, and battery specifications. Evaluate the types of goods you will transport to determine the required weight capacity. Additionally, assess the terrain and distance of your deliveries to select a bike that offers sufficient range and power. Look for customization options that align with your business branding and operational requirements. Finally, request test rides and seek feedback from current users to ensure the bike meets your expectations. -

What is the typical range of long-range electric cargo bikes?

Long-range electric cargo bikes generally offer a range between 30 to 70 miles on a single charge, depending on the model and battery capacity. For businesses requiring longer distances, consider bikes with dual-battery systems, which can extend the range significantly. Additionally, factors such as load weight, terrain, and riding conditions can influence the effective range. Always consult the manufacturer’s specifications to find a model that meets your operational needs. -

What are the key features to look for in a long-range electric cargo bike?

Key features to consider include motor power (typically between 250W to 750W), battery capacity (measured in Ah), and load capacity. Look for bikes with robust frames, adjustable seating, and integrated storage options for versatility. Safety features such as quality brakes, lights, and reflectors are crucial for urban environments. Additionally, consider the bike’s ease of maintenance and the availability of replacement parts to minimize downtime in your operations. -

What are the payment terms typically offered for bulk purchases of electric cargo bikes?

Payment terms can vary by supplier, but many offer options such as net 30, net 60, or net 90 days for bulk orders. Some suppliers may require a deposit upfront, with the balance due upon delivery or after a specified period. It’s advisable to negotiate terms that align with your cash flow and operational needs. Ensure to clarify any additional costs, such as shipping or customs duties, which may affect the total purchase price. -

What is the minimum order quantity (MOQ) for long-range electric cargo bikes?

MOQs can vary significantly among manufacturers and depend on the bike model. Typically, MOQs range from 5 to 50 units, with some suppliers offering lower quantities for first-time buyers or trial orders. Always inquire about the potential for flexibility in MOQs, especially if you’re testing the market or seeking a specific model. Establishing a strong relationship with your supplier may also provide opportunities for better terms over time. -

How can I ensure the quality of long-range electric cargo bikes before purchasing?

To ensure quality, request detailed product specifications and certifications from potential suppliers. Ask for samples or arrange for test rides to assess performance and durability. Inquire about the manufacturing process, quality control measures, and warranty terms. It’s also beneficial to read reviews and feedback from other B2B buyers. Establishing a relationship with suppliers who have a proven track record in quality assurance will further enhance your confidence in the product. -

What logistics considerations should I keep in mind when importing electric cargo bikes?

When importing electric cargo bikes, consider shipping methods, customs regulations, and delivery timelines. Choose a logistics partner experienced in handling bulky items and familiar with the regulations in your destination country. Ensure that all necessary documentation, such as import permits and customs declarations, is prepared in advance to avoid delays. Additionally, factor in potential tariffs and taxes that may apply to your shipment, which can impact overall costs. -

How do I vet suppliers for long-range electric cargo bikes?

To vet suppliers, conduct thorough research on their background, reputation, and customer reviews. Request references from previous clients and check their standing with trade organizations or business bureaus. Assess their production capabilities and quality control processes through factory visits or virtual assessments. Ensure that they comply with international safety and environmental standards. Building a relationship with suppliers who demonstrate transparency and reliability will enhance your purchasing experience and reduce risks.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Long Range Electric Cargo Bike Manufacturers & Suppliers List

1. Lectric eBikes – XPedition2 & XP4

Domain: lectricebikes.com

Registered: 2018 (7 years)

Introduction: Electric Cargo eBikes from Lectric eBikes are designed with an integrated rear rack for carrying heavy loads and accommodating two or more people. Key models include the XPedition2 and XP4, with features such as:

– Motor Wattage: 500W nominal, 1092W peak or 750W nominal, 1310W peak

– Range: Up to 50, 60, 70, 85, 120, or 170 miles depending on the model

– Payload Capacity: Ranges from 330 lbs to…

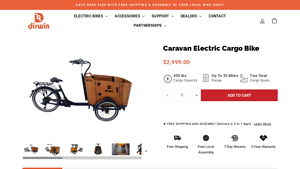

2. Dirwin – Caravan Electric Cargo Bike

Domain: dirwinbike.com

Registered: 2021 (4 years)

Introduction: {“name”:”Caravan Electric Cargo Bike”,”price”:”$2,999.00″,”cargo_capacity”:”450 lbs”,”range”:”Up to 35 Miles”,”features”:[“Two-Seat Cargo Space”,”Finely Crafted Polished Wood”,”Cushioned Seats With Seatbelts”,”20+ Cubic Feet Cargo Container”,”Tricycle Style Extra Stability”,”Water-proof rain cover”,”Durable rear rack”,”Soft floor liner”],”motor_power”:”350W”,”battery”:”16Ah lithium battery”,”pedal…

3. Specialized – Globe Haul ST

Domain: bicycling.com

Registered: 1999 (26 years)

Introduction: Best Overall: Specialized Globe Haul ST – Price: €2,500, Tires: 20 x 3.5 in., Weight: 77 lbs., Cargo Capacity: 419 lbs. Pros: One of the smallest cargo bike footprints, Excellent battery life and power delivery, Strong brakes. Cons: Lack of suspension can mean a harsh ride on rough roads, Can only carry one kiddo.

Best Value: Aventon Abound – Price: $1,999 (Now $1,599), Tires: 20 x 2.4 in., Weigh…

4. Lectric – XPedition 2.0

Domain: electricbikereport.com

Registered: 2010 (15 years)

Introduction: Best Electric Cargo Bikes 2025: 1. Lectric XPedition 2.0 – Price: $1399 (base model), $1699 (mid-tier), $1999 (top-tier); Battery: 624-Wh (base), 840-Wh (top); Motor: 750W rear hub, 1310W peak output, 85 Nm torque; Payload: 450 lbs, Cargo rack capacity: 300 lbs; Features: torque sensor, suspension fork, turn signals, color display, adjustable stem. 2. Aventon Abound LR – Features: sturdy step-thru…

5. Aventon – Abound SR & LR Ebikes

Domain: aventon.com

Registered: 2012 (13 years)

Introduction: NEW Abound SR Ebike: Compact cargo bike with added security features. 4G/GPS Theft Deterrence, 750w Motor, Carry a Single Passenger, Up to 60 miles Average Range, $1,899. NEW Abound LR Ebike: Carry More, Ride More, 4G/GPS Theft Deterrence, 750w Motor, Carry Up To 2 Passengers, $1,999, $400 OFF Abound Ebike, Multifaceted cargo ebike with endless possibilities, 750w Motor, Up to 50 Mile Range, Class…

6. Cargo eBike – 30 MPH City Rider

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Cargo eBike that can go over 30 MPH on throttle and has a range of over 50 miles. Designed for city riding with the capability to carry 10-20 lbs of load. Intended use includes grocery hauling with a delivery box installed in the rear and occasionally carrying cardboard boxes up to 4 feet wide. Requires a rear rack for strapping down cargo. User expresses interest in hacks to remove speed limiters…

7. Rad Power Bikes – RadWagon™ 5

Domain: radpowerbikes.com

Registered: 2015 (10 years)

Introduction: Electric Cargo & Utility Bikes: Designed for carrying kids, gear, or groceries. Options include long-tail cargo bikes for up to two passengers and moped-style utility ebikes with multiple gear-storage options. Key models include: 1. RadWagon™ 5: For riders 4’11”-6’3″, 28 mph, 60+ miles range, 750W motor, 375 lb payload, priced at $2,399. 2. RadRunner™ Max: For riders 4’11”-6’2″, 28 mph, 60+ miles …

Strategic Sourcing Conclusion and Outlook for long range electric cargo bike

The growing demand for long-range electric cargo bikes presents a unique opportunity for international B2B buyers to enhance their logistics and transportation capabilities. Key takeaways include the importance of evaluating suppliers based on product specifications, such as weight capacity and battery life, which are crucial for effective cargo management. Additionally, consider the adaptability of models to local market needs, ensuring that they align with the specific demands of regions across Africa, South America, the Middle East, and Europe.

Strategic sourcing in this sector is vital, as it allows businesses to secure high-quality products while optimizing costs. Collaborating with manufacturers that offer customization options can further enhance the utility and efficiency of these bikes, catering to diverse operational requirements.

As the electric cargo bike market continues to evolve, investing in these sustainable transportation solutions will not only improve operational efficiency but also contribute to environmental goals. We encourage B2B buyers to explore partnerships with reputable suppliers and consider how integrating long-range electric cargo bikes can position their businesses favorably in a competitive landscape. Embrace this shift towards eco-friendly logistics and lead the charge in transforming urban mobility.