Introduction: Navigating the Global Market for three wheeler car

Navigating the global market for three-wheeler cars presents unique challenges for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Sourcing reliable and cost-effective three-wheeler vehicles, which can serve diverse applications from urban transport to delivery services, is essential for businesses looking to enhance their logistics and mobility solutions. With a plethora of options available, buyers often struggle to identify the best suppliers, understand pricing structures, and assess the quality and performance of these vehicles.

This comprehensive guide serves as an essential resource for B2B buyers seeking to make informed purchasing decisions in the three-wheeler market. It covers various types of three-wheelers, including open-air roadsters and utility models, and delves into their specific applications across different sectors. Additionally, the guide provides insights on supplier vetting processes, cost analysis, and the latest innovations shaping the industry. By equipping buyers with actionable information and strategic insights, this guide empowers businesses to navigate the complexities of the three-wheeler car market effectively. Whether you’re operating in bustling cities like Ho Chi Minh City or navigating the logistics landscape in Lagos, understanding these dynamics will help you make choices that drive success and efficiency in your operations.

Understanding three wheeler car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Conventional Trike | One wheel in front, two in the rear | Recreation, tourism, delivery services | Pros: Stable ride, good for leisure; Cons: Limited cargo space. |

| Reverse Trike | Two wheels in front, one in the rear | Urban commuting, food trucks, rentals | Pros: Enhanced stability, easier to handle; Cons: Higher initial costs. |

| Electric Trike | Battery-powered, eco-friendly design | Short-distance transport, last-mile delivery | Pros: Low operational costs, sustainability; Cons: Range limitations, longer charging times. |

| Cargo Trike | Designed for heavy loads, often with a flatbed | Freight transport, small business deliveries | Pros: High payload capacity; Cons: Less maneuverable in tight spaces. |

| Luxury Trike | High-end materials, advanced technology, customizable | Premium rentals, tourism, personal use | Pros: Enhanced comfort and style; Cons: High maintenance costs. |

What Are the Characteristics of Conventional Trikes?

Conventional trikes typically feature a design with one wheel in front and two in the back, offering a stable riding experience. They are widely used in recreational activities and tourism, making them a popular choice for businesses in these sectors. When considering a purchase, B2B buyers should evaluate the balance between leisure capabilities and the vehicle’s ability to navigate various terrains. The limited cargo space may pose challenges for businesses focused on utility.

How Do Reverse Trikes Stand Out in the Market?

Reverse trikes, with their two front wheels, provide enhanced stability and ease of handling, making them suitable for urban commuting and food service applications. Their design allows for a more comfortable riding position and greater control, appealing to businesses that prioritize safety and accessibility. However, the higher initial costs may deter some buyers, necessitating a careful analysis of potential ROI in urban environments.

What Are the Advantages of Electric Trikes?

Electric trikes are gaining traction due to their eco-friendly design and low operational costs. They are ideal for short-distance transport and last-mile delivery solutions, particularly in urban settings where sustainability is a priority. Businesses should consider the trade-offs, such as range limitations and charging infrastructure, when integrating electric trikes into their fleets, ensuring they meet operational needs without compromising efficiency.

Why Choose Cargo Trikes for Freight Transport?

Cargo trikes are specifically engineered to handle heavy loads, often featuring a flatbed design that enhances their utility for freight transport and deliveries. This type of three-wheeler is particularly beneficial for small businesses that require a reliable means of transporting goods in urban areas. However, buyers should be aware of their limited maneuverability in tight spaces, which may affect delivery efficiency.

What Makes Luxury Trikes a Premium Choice?

Luxury trikes are characterized by high-end materials and advanced technology, catering to businesses that offer premium rentals or tourism experiences. Their customizable features enhance the overall riding experience, making them attractive for clients seeking comfort and style. Despite their appeal, potential buyers must consider the higher maintenance costs associated with luxury vehicles, weighing them against the anticipated market demand.

Key Industrial Applications of three wheeler car

| Industry/Sector | Specific Application of three wheeler car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Delivery | Last-mile delivery services | Cost-effective transport for small packages | Vehicle durability, fuel efficiency, and payload capacity |

| Tourism and Recreation | Sightseeing tours | Unique experience enhancing customer engagement | Customization options and comfort features |

| Agriculture | Transporting goods and produce | Efficient movement of agricultural products | Load capacity and off-road capability |

| Urban Mobility | Public transportation | Affordable and accessible transit solutions | Compliance with local regulations and maintenance support |

| Emergency Services | Quick response vehicles | Rapid deployment in emergencies | Reliability, safety features, and service availability |

How Are Three-Wheeler Cars Used in Logistics and Delivery?

In the logistics sector, three-wheeler cars are increasingly employed for last-mile delivery services, particularly in urban areas with heavy traffic. Their compact size allows them to navigate narrow streets and congested environments effectively. Businesses benefit from reduced operational costs compared to larger delivery vehicles, making them ideal for transporting small packages. International buyers should consider the vehicle’s durability and fuel efficiency, as well as its payload capacity, to ensure it meets the demands of their logistics operations.

What Role Do Three-Wheeler Cars Play in Tourism and Recreation?

In the tourism sector, three-wheeler cars serve as an attractive option for sightseeing tours, offering a unique and engaging experience for visitors. These vehicles can be customized with branding and comfort features to enhance the overall tourist experience. For B2B buyers in the tourism industry, the ability to personalize the vehicle is crucial, as it allows them to reflect their brand identity while providing comfort to passengers. Buyers should also evaluate maintenance and support services to ensure the longevity of their fleet.

How Are Three-Wheeler Cars Beneficial to Agriculture?

Three-wheeler cars find significant utility in the agriculture sector, primarily for transporting goods and produce from farms to markets. Their design is well-suited for carrying heavy loads across varied terrains, making them invaluable in rural areas. Businesses benefit from their efficiency in moving agricultural products quickly and cost-effectively. Buyers in this sector should prioritize load capacity and off-road capability when sourcing three-wheeler cars, ensuring they can handle the demands of agricultural logistics.

Why Are Three-Wheeler Cars Important for Urban Mobility?

Three-wheeler cars are increasingly recognized as a solution for public transportation in urban areas, providing affordable and accessible transit options. Their ability to maneuver through congested streets makes them ideal for city commuting, addressing the challenges of traffic and limited parking. For B2B buyers in the public transport sector, compliance with local regulations is essential, as is the availability of maintenance support to ensure vehicle reliability. Buyers should also consider the vehicle’s comfort features to enhance the passenger experience.

How Do Three-Wheeler Cars Support Emergency Services?

Three-wheeler cars can be adapted for use as quick response vehicles in emergency services, enabling rapid deployment in critical situations. Their agility allows them to navigate through traffic and reach locations that larger vehicles may struggle to access. Businesses in the emergency sector benefit from the reliability and safety features of these vehicles, which are crucial during emergencies. When sourcing three-wheelers for this application, buyers should focus on the vehicle’s reliability and available safety features to ensure optimal performance in high-pressure scenarios.

3 Common User Pain Points for ‘three wheeler car’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Three-Wheeler Vehicles

The Problem: B2B buyers often face significant challenges in understanding and navigating the regulatory landscape surrounding three-wheeler vehicles. Different regions have unique licensing requirements, safety regulations, and environmental standards that must be adhered to. For instance, in parts of Africa and South America, the regulations may differ vastly from those in Europe or the Middle East. This complexity can lead to costly delays, fines, or even the inability to operate legally if vehicles do not meet the necessary standards.

The Solution: To effectively overcome regulatory challenges, B2B buyers should engage with local authorities and industry associations early in the procurement process. Conducting thorough market research to understand the specific regulatory requirements in the target market is crucial. Buyers can also partner with local distributors who have a deep understanding of the legal landscape. Additionally, investing in compliance management software can help track changes in regulations and ensure that all vehicles are compliant with local laws. This proactive approach not only minimizes risks but also fosters strong relationships with regulatory bodies, which can be beneficial for future operations.

Scenario 2: Ensuring Maintenance and After-Sales Support for Three-Wheelers

The Problem: A common pain point for B2B buyers of three-wheeler vehicles is ensuring reliable maintenance and after-sales support. Many buyers may find that the vehicles require specialized parts and service that are not readily available in their regions, leading to prolonged downtimes and increased operational costs. This issue can be particularly pronounced in remote areas where access to qualified mechanics and parts suppliers is limited.

The Solution: To mitigate maintenance challenges, buyers should thoroughly evaluate the manufacturer’s network of dealers and service centers before purchasing three-wheeler vehicles. Opting for manufacturers with a robust global presence and a well-established supply chain can ensure easier access to parts and trained technicians. Additionally, buyers should consider service contracts that include regular maintenance checks and emergency support to keep their fleets operational. Training programs for local mechanics on servicing these vehicles can also be beneficial, enabling quicker turnaround times for repairs and reducing dependency on distant service centers.

Scenario 3: Customization and Adaptability to Diverse Market Needs

The Problem: B2B buyers often struggle with the need for customization in three-wheeler vehicles to cater to diverse market needs. For instance, buyers in urban environments may require vehicles optimized for maneuverability and fuel efficiency, while those in rural areas may prioritize durability and cargo capacity. The inability to adapt vehicles to specific local demands can result in lost sales opportunities and diminished customer satisfaction.

The Solution: Buyers should prioritize manufacturers that offer extensive customization options for their three-wheeler vehicles. Engaging in discussions with manufacturers to understand their capabilities for modifying vehicle specifications—such as load capacity, engine type, and features—can help ensure the vehicles meet local demands. Additionally, conducting market surveys to gather insights on customer preferences can guide buyers in making informed decisions about necessary customizations. By tailoring the vehicles to meet specific regional needs, buyers can enhance their market competitiveness and improve customer retention.

Strategic Material Selection Guide for three wheeler car

What Are the Key Materials Used in Three Wheeler Cars?

When selecting materials for three-wheeler cars, it’s essential to consider various factors that affect performance, durability, and cost. Below are some common materials used in the manufacturing of three-wheeler vehicles, analyzed from a B2B perspective.

How Does Steel Perform in Three Wheeler Car Manufacturing?

Steel is a traditional choice for automotive applications due to its strength and versatility. Key properties include high tensile strength and excellent impact resistance, which are crucial for vehicle safety. Steel also offers good weldability, making it easier to manufacture complex shapes. However, its susceptibility to corrosion can be a drawback, particularly in humid or coastal environments.

Pros: Steel is durable and cost-effective, making it suitable for structural components and chassis. Its availability and familiarity in manufacturing processes also simplify sourcing and production.

Cons: The weight of steel can negatively impact fuel efficiency, and it requires protective coatings to prevent rust, which adds to manufacturing complexity.

For international B2B buyers, compliance with standards such as ASTM A36 is vital, especially in regions like Africa and South America, where environmental conditions may accelerate corrosion.

What Role Does Aluminum Play in Three Wheeler Cars?

Aluminum is increasingly favored for its lightweight properties, which enhance fuel efficiency and handling. It has a high strength-to-weight ratio and excellent corrosion resistance, making it suitable for various components, including body panels and frames.

Pros: The reduced weight of aluminum contributes to better performance and lower fuel consumption. Its resistance to corrosion minimizes maintenance costs over time.

Cons: Aluminum can be more expensive than steel, and its manufacturing processes may require specialized equipment, increasing initial setup costs.

International buyers should consider compliance with standards like ASTM B221 for aluminum extrusions and be aware of regional preferences for lightweight materials, particularly in markets focused on sustainability, such as Europe.

Why Is Plastic Becoming Popular in Three Wheeler Vehicle Design?

Plastics, particularly engineering-grade polymers, are gaining traction in three-wheeler design due to their versatility and lightweight nature. Key properties include resistance to corrosion and the ability to mold into complex shapes.

Pros: Plastics are often less expensive than metals and can be produced in various colors without the need for additional coatings. They also contribute to weight reduction, enhancing fuel efficiency.

Cons: While plastics are durable, they may not withstand high temperatures as well as metals, which can limit their application in areas exposed to engine heat.

For buyers in regions like the Middle East, where high temperatures can be a concern, selecting heat-resistant plastics compliant with standards like ISO 1043 is crucial.

How Does Composite Material Benefit Three Wheeler Cars?

Composite materials, such as carbon fiber and fiberglass, offer exceptional strength and weight advantages. They are particularly useful for high-performance applications where reducing weight is critical.

Pros: Composites provide excellent fatigue resistance and can be tailored for specific performance characteristics, making them ideal for high-end models.

Cons: The cost of composite materials is significantly higher than metals and plastics, which can restrict their use to premium models or specific applications.

B2B buyers should be aware of the need for compliance with industry standards like ASTM D3039 for composite materials and consider the market’s willingness to pay for high-performance vehicles in regions like Europe and South America.

Summary Table of Material Selection for Three Wheeler Cars

| Material | Typical Use Case for three wheeler car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Body panels and frames | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | High |

| Plastic | Interior components and body parts | Cost-effective and versatile | Limited heat resistance | Low |

| Composite | High-performance parts | Exceptional strength-to-weight ratio | Very high cost | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions that align with regional market demands and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for three wheeler car

What Are the Main Stages in the Manufacturing Process of Three-Wheeler Cars?

The manufacturing process of three-wheeler cars involves several key stages that ensure both efficiency and quality. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

Material Preparation: What Materials Are Used and How Are They Processed?

The first stage involves selecting and preparing materials, primarily steel, aluminum, and composite materials. Steel is commonly used for the chassis due to its strength and durability, while aluminum is favored for components that require weight reduction. Composite materials may be used in body panels for improved aesthetics and reduced weight.

In this stage, raw materials undergo cutting, machining, and treatment processes such as galvanization or powder coating to enhance corrosion resistance and surface finish. Suppliers should demonstrate expertise in sourcing high-quality materials that meet international standards, which is critical for long-lasting performance.

Forming: How Are Components Shaped and Manufactured?

The forming stage includes processes such as stamping, bending, and welding. Stamping is used for creating body panels and structural components, while bending shapes the steel and aluminum into specific designs.

Welding techniques, including MIG and TIG welding, are employed to join components securely. Advanced technologies like laser cutting and CNC machining are increasingly used for precision and efficiency. Buyers should look for suppliers that invest in modern equipment and skilled labor to ensure high-quality manufacturing.

Assembly: What Is the Process for Bringing Components Together?

Assembly is a critical phase where all prepared components are brought together. This stage often employs both manual and automated processes. The assembly line must be optimized for efficiency, ensuring that each component is installed correctly and in the right sequence.

Quality control checkpoints are integrated into the assembly process to catch any defects early. Suppliers should have a well-defined assembly process that adheres to best practices, ensuring that the final product meets design specifications and safety standards.

Finishing: What Techniques Are Used to Enhance the Final Product?

The finishing stage enhances the vehicle’s aesthetics and protects against environmental factors. This includes painting, applying decals, and final inspections. The paint process often involves automated spray booths and curing ovens to ensure a uniform finish.

Finishing touches also involve installing interior components, such as seating and dashboard systems, which are often customized according to buyer specifications. Suppliers should have quality assurance measures in place to ensure that the finishing meets both aesthetic and functional requirements.

How Is Quality Assurance Implemented in Three-Wheeler Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that the final product meets specific quality standards. For B2B buyers, understanding the QA processes of potential suppliers is essential for minimizing risks and ensuring product reliability.

What Are the Relevant International Standards for Quality Assurance?

International standards such as ISO 9001 are fundamental for quality management systems across manufacturing sectors, including three-wheelers. This standard emphasizes continuous improvement, customer satisfaction, and process efficiency.

In addition, industry-specific certifications such as CE marking in Europe or API standards for parts related to performance and safety are crucial. Buyers should verify that suppliers hold these certifications, indicating adherence to recognized quality standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure product integrity. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This phase checks the quality of raw materials before they enter production. Suppliers should conduct rigorous testing to ensure materials meet specifications.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC ensures that each stage meets predefined standards. This includes monitoring welding techniques and assembly accuracy.

-

Final Quality Control (FQC): The final inspection before shipment, FQC verifies that the finished product meets all quality standards, including functionality, safety, and aesthetics.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed to ensure the quality and performance of three-wheeler cars:

-

Destructive Testing: This involves testing components to failure to understand their limits. It is often used for materials used in critical structural areas.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspections assess material integrity without causing damage.

-

Functional Testing: This includes road tests and simulations to ensure the vehicle performs as intended under various conditions.

B2B buyers should inquire about the testing methodologies used by suppliers and request access to test reports to ensure compliance with industry standards.

How Can B2B Buyers Verify Supplier Quality Control?

Verifying a supplier’s quality control processes is vital for ensuring that products meet the required standards. Buyers can take several steps:

-

Conduct Audits: Regular audits can help buyers assess a supplier’s adherence to quality standards and identify areas for improvement. This may include reviewing production processes, quality documentation, and compliance with international standards.

-

Request Quality Reports: Buyers should request detailed quality reports that outline the testing methods, results, and any corrective actions taken. This transparency can help build trust and confidence in the supplier’s capabilities.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes and the final product’s compliance with specifications.

What Are the Quality Control Nuances for International Buyers?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, several nuances must be considered:

-

Regulatory Compliance: Buyers must be aware of the specific regulatory requirements in their target markets, which can differ significantly. Understanding local regulations regarding safety, emissions, and import standards is crucial.

-

Cultural and Operational Differences: Different regions may have varying practices and standards for quality control. Buyers should consider these differences when evaluating suppliers to ensure compatibility with their expectations.

-

Logistics and Supply Chain Management: Effective quality assurance also involves managing logistics and supply chain challenges, ensuring that products are delivered on time and in accordance with quality standards.

By comprehensively understanding the manufacturing processes and quality assurance protocols for three-wheeler cars, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful partnerships and reliable products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘three wheeler car’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers interested in procuring three-wheeler cars. With the increasing popularity of these vehicles in various international markets, it is essential to follow a structured approach to ensure that you select the right model and supplier that meets your business needs.

1. Define Your Technical Specifications

Before you begin sourcing, clearly outline the technical specifications that your three-wheeler car must meet. Consider factors such as engine capacity, load capacity, fuel efficiency, and safety features. Understanding your requirements will streamline the selection process and help you compare different models effectively.

2. Identify Your Target Market

Determine the specific markets you plan to target with your three-wheeler vehicles. Each region may have unique preferences and regulatory requirements. For instance, markets in Africa may prioritize durability and fuel efficiency, while European buyers might focus on advanced safety features and environmental compliance. Tailoring your selection to these preferences will enhance market acceptance.

3. Conduct Market Research

Engage in thorough market research to identify potential suppliers and their offerings. Review industry reports, trade publications, and online resources to gather insights on leading manufacturers and emerging players in the three-wheeler sector. This research will help you understand pricing trends, technological advancements, and consumer preferences.

4. ✅ Verify Supplier Certifications

Ensure that your potential suppliers possess the necessary certifications and compliance with international standards. Certifications such as ISO 9001 for quality management and ISO 14001 for environmental management are crucial indicators of a supplier’s reliability. Verify their adherence to local regulations in the regions where you intend to operate.

5. Evaluate Potential Suppliers

Before making a commitment, it is essential to conduct a thorough evaluation of potential suppliers. Request detailed company profiles, including their manufacturing capabilities, production capacity, and quality control processes. Additionally, seek case studies and references from other buyers in similar industries or regions to gauge their reliability and performance.

6. Request Samples and Conduct Test Drives

Once you have shortlisted potential suppliers, request samples or arrange for test drives of the three-wheeler cars. This step allows you to assess the quality of the vehicle firsthand, including performance, comfort, and handling. Take note of any specific features that may enhance usability for your target market.

7. Negotiate Terms and Conditions

Finally, engage in negotiations with your selected supplier to finalize the purchase terms and conditions. Discuss pricing, payment terms, delivery schedules, and after-sales support. A clear agreement will help prevent misunderstandings and ensure a smooth procurement process.

By following this structured checklist, B2B buyers can make informed decisions when sourcing three-wheeler cars, ultimately leading to successful procurement and satisfied end-users.

Comprehensive Cost and Pricing Analysis for three wheeler car Sourcing

What Are the Key Cost Components in Sourcing Three-Wheeler Cars?

When sourcing three-wheeler cars, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The quality and type of materials used significantly impact the overall cost. High-strength steel and lightweight composites are common in three-wheeler production, influencing both durability and weight.

-

Labor: Labor costs vary by region. Countries with lower labor costs can provide a competitive advantage, but it’s essential to consider the skill level and training of the workforce.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Initial tooling costs can be high, particularly for customized designs. However, these costs can be amortized over larger production volumes.

-

Quality Control (QC): Implementing robust QC measures is vital to ensure product reliability. While this may add to initial costs, it prevents costly recalls and enhances brand reputation.

-

Logistics: Transportation and warehousing costs can fluctuate based on distance and mode of transport. Incoterms will also affect the logistics costs, influencing who bears the responsibility for shipping and handling.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the acceptable margin for your industry will help in negotiations.

How Do Price Influencers Affect the Cost of Three-Wheeler Cars?

Several factors can influence the pricing of three-wheeler cars:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower unit prices due to economies of scale. Negotiating favorable terms for higher volumes can significantly reduce costs.

-

Specifications and Customization: Customized vehicles or those with enhanced specifications (like advanced safety features or luxury finishes) will command higher prices. Buyers must balance the desire for customization with budget constraints.

-

Materials: The choice of materials not only affects performance but also pricing. Premium materials will increase costs, while standard options may provide cost savings.

-

Quality Certifications: Vehicles that meet stringent quality standards (like ISO certifications) may have higher initial costs but offer long-term savings through reduced maintenance and improved resale value.

-

Supplier Factors: The reliability, reputation, and location of suppliers can affect both pricing and delivery times. Building relationships with reputable suppliers can lead to better pricing and support.

-

Incoterms: Understanding Incoterms is crucial for determining who is responsible for shipping costs and risks. This can significantly impact the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices for Three-Wheeler Cars?

B2B buyers should consider the following strategies to enhance cost-efficiency when sourcing three-wheeler cars:

-

Negotiate Terms: Always negotiate payment terms, delivery schedules, and pricing. Flexibility in payment terms can provide cash flow benefits.

-

Assess Total Cost of Ownership (TCO): Consider not just the purchase price but also the long-term costs associated with maintenance, fuel efficiency, and potential resale value. A higher initial investment may lead to lower TCO.

-

Understand Pricing Nuances for International Sourcing: Be aware of regional differences in pricing, including tariffs, taxes, and shipping costs. For example, sourcing from Southeast Asia may offer cost advantages due to lower labor costs, but shipping to Africa or Europe may offset some savings.

-

Leverage Local Insights: Engage with local partners or agents who understand the market dynamics, regulations, and cultural nuances. This can lead to better supplier negotiations and more informed decision-making.

-

Request Samples and Prototypes: Before committing to large orders, request samples to assess quality. This can prevent costly mistakes and ensure that the product meets your specifications.

Disclaimer on Indicative Prices

While the prices of three-wheeler cars can vary widely based on the factors mentioned above, it is essential to approach pricing with a flexible mindset. The figures may fluctuate based on market conditions, supplier negotiations, and specific requirements. Always consult with multiple suppliers to obtain a comprehensive understanding of current market pricing.

Alternatives Analysis: Comparing three wheeler car With Other Solutions

Exploring Alternatives to Three Wheeler Cars for B2B Buyers

In the ever-evolving landscape of transportation solutions, three-wheeler cars present a unique offering, particularly for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe. However, understanding alternatives can help businesses make informed decisions that align with their operational needs. This analysis compares three-wheeler cars with two viable alternatives: electric scooters and conventional four-wheeled vehicles.

| Comparison Aspect | Three Wheeler Car | Electric Scooter | Conventional Four-Wheeler |

|---|---|---|---|

| Performance | Moderate speed and power; suitable for urban commuting | Lower speed, limited range; ideal for short distances | High speed, robust power; versatile for various terrains |

| Cost | Mid-range initial investment; higher than scooters but lower than cars | Low initial cost; minimal operating expenses | High initial purchase price; higher maintenance and fuel costs |

| Ease of Implementation | Requires specific licensing; relatively easy to operate | No special license in many areas; easy to learn | Requires a driver’s license; more complex operation |

| Maintenance | Moderate maintenance; parts may be less accessible | Minimal maintenance; fewer mechanical parts | Higher maintenance; more parts and systems to manage |

| Best Use Case | Urban commuting and delivery services | Short-distance travel in urban areas | Long-distance travel, family transport, and larger cargo needs |

What Are the Benefits and Drawbacks of Electric Scooters?

Electric scooters are an increasingly popular alternative for urban transport. Their low initial cost and minimal maintenance requirements make them attractive, particularly for short-distance travel. They can navigate crowded city streets efficiently and are easy to park. However, their limited range and speed may not meet the needs of businesses requiring more robust transportation solutions. Furthermore, depending on local regulations, the need for dedicated lanes and charging stations can be a logistical challenge.

How Do Conventional Four-Wheelers Compare?

Conventional four-wheeled vehicles offer high performance and versatility, making them suitable for a wide range of applications, from personal transportation to logistics. Their robust power enables them to handle various terrains, making them a reliable choice for long-distance travel. However, the higher initial investment and ongoing maintenance costs can be prohibitive for some businesses. Additionally, operating a four-wheeler typically requires a driver’s license and more extensive training, which may not be feasible for all organizations.

Conclusion: Which Transportation Solution Is Right for Your Business?

When deciding between a three-wheeler car and its alternatives, B2B buyers should carefully consider their specific operational needs, budget constraints, and the intended use case. Three-wheeler cars may be ideal for urban settings where maneuverability and cost-efficiency are priorities. However, electric scooters could be the right fit for short-range needs, while conventional four-wheelers may serve better for long-distance travel and heavier cargo. Ultimately, the choice will depend on balancing performance, cost, and practicality to align with the company’s logistics and transportation strategy.

Essential Technical Properties and Trade Terminology for three wheeler car

What Are the Key Technical Properties of Three-Wheeler Cars?

When considering the purchase of three-wheeler cars, international B2B buyers must pay attention to several critical technical specifications that can significantly impact performance, safety, and operational efficiency. Here are some essential properties to consider:

-

Engine Capacity and Power Output

The engine capacity, often measured in liters (L), indicates the volume of the engine’s cylinders. For instance, many three-wheelers feature engines ranging from 600cc to 1,200cc. The power output, typically expressed in horsepower (HP), affects acceleration and overall performance. A three-wheeler with a higher engine capacity and power output can handle varied terrains and carry heavier loads, making it suitable for diverse applications. -

Material Grade and Construction

The material used in the chassis and bodywork, such as high-strength steel or aluminum alloys, plays a crucial role in the vehicle’s durability and weight. High-grade materials enhance safety and longevity, while lightweight materials can improve fuel efficiency. Buyers should evaluate the material specifications to ensure they align with their operational needs and environmental conditions. -

Load Capacity

The load capacity, often measured in kilograms (kg), indicates how much weight the vehicle can safely carry. This specification is vital for businesses that rely on three-wheelers for transporting goods or passengers. Understanding the load capacity helps buyers select a model that meets their logistical requirements without compromising safety or performance. -

Turning Radius and Maneuverability

The turning radius is a critical specification that defines how tight a vehicle can turn. A smaller turning radius enhances maneuverability, making it easier to navigate urban environments or tight spaces. This property is particularly important for businesses operating in congested areas where efficient movement is necessary. -

Braking System

The type of braking system—whether hydraulic, disc, or drum—affects both safety and maintenance. Advanced braking systems offer better control and shorter stopping distances, which are essential for passenger safety and cargo protection. Buyers should assess the braking technology employed in the three-wheeler to ensure it meets safety standards and operational demands.

What Are Common Trade Terms in the Three-Wheeler Car Industry?

Understanding industry jargon is crucial for effective communication and negotiation in the B2B marketplace. Here are several common terms that buyers should familiarize themselves with:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of three-wheelers, OEMs supply components like engines and chassis that meet specific industry standards. Collaborating with reputable OEMs ensures quality and compatibility, which is essential for performance and safety. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units that a supplier is willing to sell. This term is crucial for B2B buyers who need to understand purchasing requirements to optimize inventory and manage costs. Knowing the MOQ can help buyers plan their orders effectively, especially when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. This process allows buyers to compare offers from different manufacturers, ensuring they receive competitive pricing and favorable terms. An RFQ is an essential tool for budget management and supplier selection. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Familiarity with these terms is essential for B2B buyers to understand shipping costs, risks, and delivery obligations, facilitating smoother transactions across borders. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. This term is critical for inventory management and planning, as longer lead times can affect operational efficiency. Understanding lead times helps buyers anticipate delivery schedules and adjust their logistics accordingly.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing three-wheeler cars, ensuring they meet their specific needs and market demands.

Navigating Market Dynamics and Sourcing Trends in the three wheeler car Sector

What Are the Key Drivers and Trends in the Three-Wheeler Car Market?

The three-wheeler car market is experiencing robust growth, driven by several global trends. Urbanization, particularly in developing regions such as Africa, South America, and parts of Asia, is leading to increased demand for affordable and efficient transportation solutions. As cities become more congested, three-wheelers are favored for their maneuverability and lower operational costs compared to traditional four-wheeled vehicles. Additionally, advancements in technology are influencing sourcing trends, with electric three-wheelers gaining traction. These vehicles not only reduce emissions but also align with the growing consumer preference for sustainable options.

International B2B buyers are increasingly seeking manufacturers that incorporate smart technology into their vehicles, such as GPS tracking, connectivity features, and enhanced safety systems. This trend is particularly pronounced in regions like Europe, where regulatory standards for vehicle emissions and safety are stringent. Emerging markets are also witnessing a rise in customization options, with buyers looking for vehicles that can be tailored to specific business needs, whether for transportation, logistics, or tourism.

How Can Sustainability and Ethical Sourcing Impact B2B Decisions in the Three-Wheeler Car Sector?

Sustainability is becoming a cornerstone of business strategy for international buyers in the three-wheeler car sector. The environmental impact of traditional fossil fuel vehicles is prompting a shift towards electric and hybrid models, which present lower carbon footprints. B2B buyers are increasingly prioritizing suppliers who adhere to ethical sourcing practices. This includes ensuring that raw materials are obtained from responsible sources and that manufacturing processes minimize waste and energy consumption.

Certifications such as ISO 14001 (Environmental Management) and adherence to local and international environmental regulations can serve as important indicators of a supplier’s commitment to sustainability. Buyers are also interested in exploring the use of recycled materials and innovative manufacturing techniques that reduce the environmental impact. By focusing on suppliers who emphasize sustainability, businesses can enhance their brand reputation and appeal to environmentally-conscious consumers.

What Is the Evolution of the Three-Wheeler Car Market and Its Importance to B2B Buyers?

The three-wheeler car market has evolved significantly over the past few decades. Initially designed for basic transportation, these vehicles have transformed into sophisticated options featuring advanced technology, enhanced safety, and improved performance. The introduction of electric three-wheelers marks a pivotal moment in this evolution, aligning with global sustainability goals.

For B2B buyers, understanding this evolution is crucial. It highlights the importance of investing in modern vehicles that not only meet current market demands but are also future-proofed against regulatory changes and consumer preferences. The trend towards customization and technological integration further emphasizes the need for buyers to partner with manufacturers who are at the forefront of innovation. As the market continues to evolve, staying informed about these changes will be essential for making strategic sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of three wheeler car

-

How do I choose the right three-wheeler car for my business needs?

Choosing the right three-wheeler car involves assessing your specific business requirements, such as load capacity, passenger needs, and operational environment. Consider factors like fuel efficiency, maintenance costs, and local regulations. Evaluate various models based on their specifications, performance, and customization options to ensure they align with your operational goals. Engage with suppliers to understand product offerings and seek recommendations based on your intended use. -

What are the key features to look for in a three-wheeler car?

When sourcing a three-wheeler car, key features to consider include engine performance, safety specifications, cargo space, and comfort for passengers. Additional elements like customizable accessories, fuel efficiency, and ease of maintenance should also be evaluated. Look for vehicles that offer advanced technology such as connectivity features or navigation systems, as these can enhance the overall driving experience and operational efficiency. -

What is the typical lead time for ordering three-wheeler cars from suppliers?

Lead times for ordering three-wheeler cars can vary significantly based on factors such as the supplier’s location, manufacturing capabilities, and current demand. Generally, expect a lead time ranging from a few weeks to several months. It’s advisable to communicate with your supplier early in the process to obtain an estimated timeline and to account for potential delays due to logistics or regulatory approvals. -

What are the minimum order quantities (MOQs) for three-wheeler cars?

Minimum order quantities (MOQs) for three-wheeler cars often depend on the manufacturer and the type of vehicle. Some suppliers may require a minimum of 5 to 10 units to qualify for bulk pricing, while others might allow smaller orders. Discuss your purchasing plans with potential suppliers to understand their MOQ policies and explore options for scaling orders based on your business growth. -

How can I ensure quality assurance when sourcing three-wheeler cars?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. Conduct thorough due diligence by reviewing the supplier’s production processes, quality control measures, and previous customer feedback. Additionally, consider arranging for an independent inspection of the vehicles before shipment to verify compliance with your quality standards and local regulations. -

What payment terms should I expect when purchasing three-wheeler cars?

Payment terms can vary widely among suppliers, but common practices include a deposit (often 30-50%) upon order confirmation, followed by the balance upon delivery or before shipment. Some suppliers may offer financing options or payment plans. Always clarify payment terms upfront and ensure they align with your cash flow management strategy to avoid disruptions in your procurement process. -

What logistics considerations should I keep in mind when importing three-wheeler cars?

When importing three-wheeler cars, logistics considerations include shipping methods, customs clearance procedures, and local transportation arrangements. Evaluate the costs associated with different shipping options (e.g., container shipping vs. roll-on/roll-off) and understand the documentation required for customs. Partnering with experienced logistics providers can streamline the process and help mitigate potential delays or compliance issues. -

How can I customize three-wheeler cars to meet my brand’s requirements?

Customization options for three-wheeler cars can include exterior branding, interior configurations, and performance enhancements. Discuss your specific branding needs with suppliers who offer personalization services, such as custom paint jobs, decals, or modified interiors. Some manufacturers may provide a range of accessories to enhance functionality, so be sure to explore these options to create vehicles that align with your business identity and operational requirements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Three Wheeler Car Manufacturers & Suppliers List

1. Polaris – Slingshot Series

Domain: slingshot.polaris.com

Registered: 1992 (33 years)

Introduction: Slingshot S: Starting at $24,999 US MSRP. Slingshot SL: Starting at $28,299 US MSRP. Slingshot SLR: Starting at $31,399 US MSRP. Slingshot R: Starting at $34,999 US MSRP. Slingshot 10: Starting at $38,999 US MSRP. All prices are subject to change and exclude destination and handling fees, tax, title, license, and registration. Dealer prices may vary. Each model offers unique features: S is customi…

2. Can-Am – On-Road 3-Wheel Vehicles

Domain: can-am.brp.com

Registered: 1995 (30 years)

Introduction: Can-Am On-Road 3-Wheel Vehicles include models such as CAN-AM Ryker, CAN-AM Spyder F3, and CAN-AM Spyder RT. Promotions include savings of up to $2,500 on select 2024 Spyder models. New 2026 3-wheel vehicles are on the way with fresh colorways, new wheels, and accessories. The vehicles feature a Y-architecture design for stability and comfort, with thousands of customization options available. Rid…

3. Polaris – Slingshot & Morgan – Super 3

Domain: cars.usnews.com

Registered: 1995 (30 years)

Introduction: 1. Polaris Slingshot: Pricing ranges from $21,999 to $38,149; 178 horsepower, 120 lb-ft torque; features include LED headlights, cruise control, proximity keyless entry, optional Apple CarPlay and infotainment system.

2. Morgan Super 3: Starts around $54,000; top speed of 130 mph; 0-62 mph in 7 seconds; open-air design with side blades for air flow and luggage.

3. Campagna T-Rex RR: Starts at $6…

4. BSA – Three-Wheeler & Dymaxion

Domain: classicandsportscar.com

Registered: 1997 (28 years)

Introduction: 1. 1929-1936 BSA Three-Wheeler: Competed with Morgan Three-Wheeler, transitioned to four-wheeled cars in 1936, produced prototypes in 1960, never reached production. 2. 1933 Dymaxion: Designed by Buckminster Fuller, seats 11, top speed 90mph, 30mpg, 20ft long, rear-wheel steering, only 3 prototypes made. 3. 1933-1937 Goliath F400: Based on Goliath Pionier, 396cc air-cooled engine, top speed 30mph,…

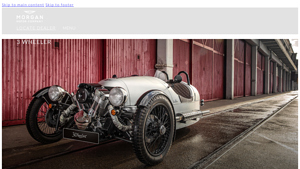

5. Morgan – 3 Wheeler

Domain: morgan-motor.com

Registered: 2015 (10 years)

Introduction: Model: Morgan 3 Wheeler

Production Period: 2011 – Summer 2021

Limited Editions: 33 P101 limited editions

Engine: S&S 1998cc V twin

Gearbox: Mazda 5-speed manual

Max Power: 82 bhp @ 5250rpm

Max Torque: 140Nm @ 3250rpm

Acceleration: 0–62 mph (100 kph) in 6.0 seconds

Top Speed: 115mph (185kph)

Combined MPG: CO2 215g / km

Dry Weight: 525 kg

Heritage: British motoring heritage, associated with Albert B…

Strategic Sourcing Conclusion and Outlook for three wheeler car

The strategic sourcing of three-wheeler cars presents a unique opportunity for international B2B buyers, especially in emerging markets across Africa, South America, the Middle East, and Europe. As demand for versatile, cost-effective, and eco-friendly transportation options rises, sourcing partners that offer innovative designs, customization capabilities, and robust performance will be invaluable. The emphasis on personalization, as seen with brands like Polaris and Can-Am, highlights the importance of catering to local tastes and preferences while ensuring compliance with regional regulations.

Investing in strategic sourcing not only enhances supply chain efficiency but also fosters relationships that can lead to competitive advantages in the marketplace. Buyers should consider factors such as reliability, performance, and after-sales support when evaluating potential suppliers.

Looking ahead, the three-wheeler market is poised for growth, driven by technological advancements and a shift toward sustainable mobility solutions. International buyers are encouraged to engage with manufacturers that prioritize innovation and customer experience. By doing so, they can secure a foothold in a dynamic market that promises significant returns. Embrace the future of transportation—partner with the right suppliers and capitalize on the opportunities within the three-wheeler segment.