Introduction: Navigating the Global Market for wheel electric vehicle

In an increasingly electrified world, sourcing the right wheel electric vehicle (WEV) can pose significant challenges for international B2B buyers. The complexities of understanding different technologies, applications, and regional market dynamics can be overwhelming, particularly in diverse markets across Africa, South America, the Middle East, and Europe, including key countries like Saudi Arabia and Germany. This comprehensive guide addresses these challenges head-on, providing a detailed exploration of various types of wheel electric vehicles, their applications, and the latest innovations in in-wheel motor technology.

With a focus on actionable insights, this guide equips buyers with the knowledge needed to make informed purchasing decisions. It covers critical aspects such as supplier vetting processes, cost considerations, and the advantages of in-wheel motors, which enhance efficiency, range, and overall vehicle performance. By delving into market trends and emerging technologies, this resource empowers B2B buyers to navigate the complexities of sourcing wheel electric vehicles, ensuring they can confidently choose solutions that align with their operational needs and sustainability goals.

As the global market for electric mobility continues to expand, understanding these nuances will be key for businesses looking to capitalize on the opportunities presented by this transformative sector.

Understanding wheel electric vehicle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| In-Wheel Hub Motors | Motors integrated into the wheel, reducing drivetrain complexity. | Light commercial vehicles, urban transport solutions. | Pros: Enhanced efficiency, reduced weight. Cons: Increased unsprung mass can affect handling. |

| Solar Electric Vehicles | Equipped with solar panels for supplementary energy. | Eco-friendly transport, fleet vehicles. | Pros: Reduced charging needs, sustainable energy source. Cons: Limited range in low-sun areas. |

| Range-Extended EVs | Combines electric power with a small internal combustion engine for extended range. | Long-haul transport, delivery services. | Pros: Greater range flexibility, reduced range anxiety. Cons: Additional maintenance for combustion engine. |

| Battery Electric Vehicles (BEVs) | Fully powered by batteries with no combustion engine. | Personal and commercial fleets, logistics. | Pros: Zero emissions, lower running costs. Cons: Dependence on charging infrastructure. |

| Hybrid Electric Vehicles (HEVs) | Combines electric motors with traditional engines for improved efficiency. | Taxi services, public transportation. | Pros: Versatile energy use, improved fuel efficiency. Cons: Complexity in maintenance and repairs. |

What Are In-Wheel Hub Motors and Their B2B Applications?

In-wheel hub motors are a revolutionary approach to electric vehicle design, integrating the motor directly into the wheel. This configuration reduces the complexity of traditional drivetrains, leading to lighter vehicles and improved energy efficiency. B2B applications primarily include light commercial vehicles and urban transport solutions, where efficiency and space-saving designs are crucial. Buyers should consider the trade-off of increased unsprung mass, which may impact vehicle handling, versus the benefits of enhanced torque response and reduced mechanical complexity.

How Do Solar Electric Vehicles Enhance Sustainability?

Solar electric vehicles utilize integrated solar panels to harness solar energy, providing an additional power source for the vehicle. This technology is particularly suitable for eco-friendly transport initiatives and fleet vehicles aiming to reduce their carbon footprint. The primary purchasing considerations include the vehicle’s performance in varying sunlight conditions, as limited solar exposure can restrict the vehicle’s range. Buyers benefit from reduced charging frequency, but must weigh this against the potential limitations in regions with less consistent sunlight.

What Are the Benefits of Range-Extended Electric Vehicles?

Range-extended electric vehicles (RE-EVs) combine electric propulsion with a small internal combustion engine, offering the flexibility of extended range. This makes them ideal for long-haul transport and delivery services where range anxiety can be a concern. B2B buyers should consider the balance between the benefits of greater operational range and the added complexity and maintenance requirements of having a combustion engine. This hybrid approach can provide a reliable solution for businesses needing to cover longer distances without frequent charging stops.

Why Choose Battery Electric Vehicles for Fleets?

Battery electric vehicles (BEVs) are fully powered by electric batteries, making them a popular choice for personal and commercial fleets. They offer zero emissions and lower running costs, appealing to businesses focused on sustainability and cost-efficiency. However, B2B buyers must consider the availability and reliability of charging infrastructure, which can impact operational efficiency. The long-term savings on fuel and maintenance can outweigh these initial concerns, especially in regions with robust charging networks.

What Are the Advantages of Hybrid Electric Vehicles?

Hybrid electric vehicles (HEVs) combine electric and traditional internal combustion engines, enhancing fuel efficiency and versatility. They are particularly suitable for taxi services and public transportation, where varied driving conditions demand flexibility. Buyers should assess the complexity of maintenance and repairs, as HEVs require knowledge of both electric and combustion systems. The potential for improved fuel economy and lower emissions makes HEVs an attractive option for businesses looking to optimize their transport solutions while maintaining operational flexibility.

Key Industrial Applications of wheel electric vehicle

| Industry/Sector | Specific Application of wheel electric vehicle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric buses and shuttles | Reduced operational costs and lower emissions | Local regulations, vehicle range, charging infrastructure |

| Logistics and Delivery Services | Last-mile delivery vehicles | Enhanced efficiency and reduced delivery times | Battery capacity, load capacity, urban maneuverability |

| Agriculture | Electric utility vehicles for farming | Cost savings on fuel and maintenance | Terrain adaptability, battery life, service support |

| Construction | Electric construction equipment | Lower emissions and reduced noise pollution | Equipment durability, power requirements, service availability |

| Tourism and Leisure | Electric tour vehicles | Improved customer experience and environmental appeal | Battery range, passenger capacity, local regulations |

How Are Wheel Electric Vehicles Transforming Public Transportation?

In the public transportation sector, electric buses and shuttles powered by wheel electric vehicles are becoming essential. They offer a sustainable alternative to traditional diesel buses, significantly reducing operational costs and emissions. For international buyers, especially in regions like Europe and the Middle East, it’s crucial to consider local regulations regarding emissions and noise. Additionally, evaluating the vehicle’s range and the availability of charging infrastructure will be vital for successful integration into existing transit systems.

What Role Do Wheel Electric Vehicles Play in Logistics and Delivery Services?

In logistics, last-mile delivery vehicles equipped with wheel electric technology enhance efficiency and reduce delivery times. These vehicles can navigate urban environments more effectively than traditional trucks, thanks to their compact design and agility. Buyers from Africa and South America should prioritize battery capacity and load capacity to ensure that these vehicles meet their operational demands. Furthermore, understanding local urban regulations can help optimize routing and compliance.

How Are Wheel Electric Vehicles Benefiting Agriculture?

Electric utility vehicles designed for agricultural applications are gaining traction due to their ability to lower fuel and maintenance costs. These vehicles can perform various tasks, from transporting goods around farms to operating equipment. Buyers in the agricultural sector must consider terrain adaptability and battery life, particularly in regions with diverse landscapes. Access to service support and repair facilities is also essential for minimizing downtime.

In What Ways Are Wheel Electric Vehicles Enhancing Construction Operations?

In construction, electric equipment powered by wheel electric vehicles is transforming project sites by reducing emissions and noise pollution. This is particularly beneficial in urban areas where regulations are stringent. Buyers should focus on the durability of equipment and its power requirements to ensure it can handle demanding construction tasks. Additionally, understanding the availability of service and parts can enhance operational reliability and efficiency.

How Do Wheel Electric Vehicles Elevate the Tourism and Leisure Industry?

Electric tour vehicles are reshaping the tourism and leisure industry by offering eco-friendly transportation options that enhance customer experiences. These vehicles attract environmentally conscious tourists and can operate in areas with strict emissions regulations. For international buyers, especially in tourist-heavy regions, evaluating battery range and passenger capacity is critical. Additionally, compliance with local regulations will ensure smooth operations in diverse markets.

3 Common User Pain Points for ‘wheel electric vehicle’ & Their Solutions

Scenario 1: Navigating Regulatory Compliance for Electric Vehicles

The Problem: B2B buyers in regions like Europe and the Middle East often face complex regulatory landscapes when sourcing wheel electric vehicles (WEVs). Compliance with local laws regarding emissions, safety standards, and vehicle specifications can be overwhelming. Additionally, the rapid pace of technological advancements in electric mobility means that regulations can change frequently, leaving businesses uncertain about which models meet compliance requirements.

The Solution: To navigate regulatory compliance effectively, B2B buyers should engage with local automotive associations and regulatory bodies early in the sourcing process. Conduct thorough research on the specific regulations that apply to WEVs in their target market. Collaborating with suppliers who have a proven track record of compliance can also streamline the process. Buyers should request documentation detailing the vehicle’s compliance status and seek suppliers who offer models designed with the latest regulations in mind. Implementing a compliance checklist tailored to specific regional requirements will help ensure that all vehicles sourced meet necessary standards, thus minimizing the risk of costly delays or penalties.

Scenario 2: Addressing Concerns Over Maintenance and Durability of In-Wheel Motors

The Problem: One of the major concerns for B2B buyers is the maintenance and long-term durability of in-wheel motors used in wheel electric vehicles. Many potential buyers worry about the increased unsprung weight affecting vehicle handling and the potential for damage from road conditions. This is especially relevant in markets with less developed infrastructure where potholes and uneven surfaces are common.

The Solution: To mitigate these concerns, buyers should focus on sourcing WEVs that come with robust warranties and established service networks. When evaluating suppliers, it is essential to inquire about the materials used in the construction of the in-wheel motors and their testing processes under real-world conditions. Partnering with manufacturers that provide comprehensive maintenance training for technicians can also enhance the longevity of the vehicles. Additionally, buyers should consider implementing a regular maintenance schedule that includes inspections of the in-wheel motors to catch any wear and tear early, thereby extending the operational lifespan of the vehicles.

Scenario 3: Optimizing Fleet Management and Range Anxiety

The Problem: Many businesses looking to integrate wheel electric vehicles into their fleet face the challenge of range anxiety—concerns about how far the vehicles can travel on a single charge. This is particularly relevant for companies operating in vast regions or those requiring vehicles to cover long distances without frequent charging opportunities. Additionally, optimizing fleet management becomes challenging when integrating new electric models that may have different charging needs.

The Solution: To address range anxiety, B2B buyers should conduct a thorough analysis of their operational routes to understand the charging infrastructure available in their areas of operation. Investing in a fleet management system that incorporates real-time data on vehicle range and charging station availability can help alleviate concerns. Buyers should also consider WEVs with extended ranges or those equipped with fast-charging capabilities to ensure minimal downtime. Collaborating with energy providers to establish charging stations at strategic locations can further enhance fleet efficiency. Additionally, educating drivers on energy-efficient driving practices can maximize the range of electric vehicles, ensuring that operations run smoothly without unexpected interruptions.

Strategic Material Selection Guide for wheel electric vehicle

What Are the Key Materials for Wheel Electric Vehicles?

In the rapidly evolving market of wheel electric vehicles (EVs), material selection plays a crucial role in determining performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the construction of wheel electric vehicles, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Benefit Wheel Electric Vehicle Design?

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It typically withstands temperatures up to 150°C and pressures that are suitable for most EV applications.

Pros & Cons: The lightweight nature of aluminum contributes to improved vehicle efficiency and range. However, while it is relatively easy to manufacture, the cost can be higher compared to traditional steel. Additionally, aluminum may require specialized welding techniques that can complicate manufacturing processes.

Impact on Application: Aluminum is compatible with various media, including moisture and road salts, making it suitable for diverse climates. Its corrosion resistance is particularly beneficial in regions with high humidity or saline environments, such as coastal areas in Africa or the Middle East.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is essential. Buyers in Europe may prefer aluminum due to its lightweight properties, while those in regions like South America may weigh cost against performance.

What Role Does Steel Play in Wheel Electric Vehicles?

Key Properties: Steel offers high tensile strength and durability, with temperature ratings often exceeding 200°C. It is less resistant to corrosion compared to aluminum but can be treated for enhanced longevity.

Pros & Cons: Steel is generally more affordable and easier to source, making it a popular choice for mass production. However, its heavier weight can negatively impact the overall efficiency of the vehicle, leading to reduced range.

Impact on Application: Steel’s robustness makes it suitable for high-stress applications, but its susceptibility to rust necessitates protective coatings, especially in humid environments.

Considerations for International Buyers: Buyers in regions like Germany may prefer high-strength steel that meets stringent safety regulations, while those in Africa may focus on cost and availability.

How Does Carbon Fiber Enhance Performance in Wheel Electric Vehicles?

Key Properties: Carbon fiber is renowned for its exceptional strength-to-weight ratio and stiffness, with temperature resistance often exceeding 300°C. It is also highly resistant to corrosion and fatigue.

Pros & Cons: The lightweight nature of carbon fiber significantly enhances vehicle performance and efficiency. However, the manufacturing process is complex and costly, which can limit its use to high-end models or specialized applications.

Impact on Application: Carbon fiber’s compatibility with various environmental conditions makes it ideal for high-performance EVs. Its durability ensures long-term reliability, which is crucial for international markets.

Considerations for International Buyers: Buyers in Europe and the Middle East may be more inclined to invest in carbon fiber due to its performance benefits, while cost-sensitive markets in South America may prioritize more economical materials.

What Are the Advantages of Using Composite Materials in Wheel Electric Vehicles?

Key Properties: Composite materials combine polymers with fibers (like glass or carbon) to create lightweight, durable structures. They can withstand a wide range of temperatures and exhibit excellent corrosion resistance.

Pros & Cons: Composites are highly customizable, allowing for tailored properties to suit specific applications. However, they can be more expensive and complex to manufacture, which may deter some manufacturers.

Impact on Application: Composites are particularly effective in environments where weight reduction is critical, such as in urban electric vehicles. Their resistance to environmental factors enhances their longevity.

Considerations for International Buyers: Compliance with international standards is crucial, and buyers should assess the availability of composite materials in their respective regions. Markets in Africa may require education on the benefits and applications of composites.

Summary of Material Selection for Wheel Electric Vehicles

| Material | Typical Use Case for wheel electric vehicle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Wheel rims and structural components | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | High |

| Steel | Chassis and structural supports | High strength and affordability | Heavier, impacting efficiency | Low |

| Carbon Fiber | High-performance components | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

| Composite | Body panels and interior components | Customizable and lightweight | Expensive and complex to manufacture | Med |

This strategic material selection guide aims to provide B2B buyers with actionable insights into the various materials suitable for wheel electric vehicles, enabling informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for wheel electric vehicle

What Are the Key Stages in the Manufacturing Process of Wheel Electric Vehicles?

The manufacturing of wheel electric vehicles (WEVs) involves several critical stages, each designed to ensure precision and efficiency. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Is the Right Material Chosen for WEVs?

The first stage in the manufacturing process involves selecting high-quality materials that meet the stringent requirements of WEVs. Common materials include lightweight metals such as aluminum and advanced composites that enhance performance while reducing weight. Suppliers must ensure that these materials comply with international standards to guarantee durability and safety. This stage often requires extensive testing of raw materials to confirm their specifications and performance characteristics.

What Forming Techniques Are Used in WEV Manufacturing?

Once materials are prepared, the next step is forming them into the required shapes. This can involve several techniques, including:

- Stamping: Used for creating body panels and structural components.

- Injection Molding: Often employed for non-structural components made of plastics.

- Casting: Utilized for producing complex shapes, particularly in motor housings or wheel assemblies.

Each technique is selected based on the specific requirements of the component, such as strength, weight, and production volume.

How Is the Assembly Process Structured for Wheel Electric Vehicles?

The assembly stage is where individual components are brought together to create the final product. This process can vary depending on the design and complexity of the vehicle but typically involves:

- Sub-Assembly: Components such as motors, batteries, and electronics are assembled into sub-units before final assembly.

- Main Assembly Line: The sub-units are integrated into the vehicle chassis. Advanced robotics and automation are increasingly used to enhance precision and reduce assembly time.

Efficient assembly processes are crucial for meeting production targets and ensuring consistent quality across units.

What Finishing Techniques Are Employed in WEV Production?

Finishing is the final stage of manufacturing and involves surface treatments and quality checks to enhance aesthetics and protect against corrosion. Techniques such as painting, anodizing, or powder coating are commonly used. Each finishing method must be compatible with the materials used and designed to withstand environmental challenges, particularly for vehicles intended for diverse climates found in markets across Africa, South America, and the Middle East.

How Is Quality Assurance Implemented in the Production of Wheel Electric Vehicles?

Quality assurance (QA) is essential in the manufacturing of WEVs, ensuring that products meet both safety and performance standards. International and industry-specific standards guide the QA process.

Which International Standards Are Relevant for WEV Quality Control?

Manufacturers often adhere to ISO 9001, which provides a framework for quality management systems. Compliance with this standard helps ensure that processes are consistent and continuously improved. Additionally, for markets in Europe, adherence to CE marking standards is crucial, indicating compliance with health, safety, and environmental protection standards.

What Are the Key Quality Control Checkpoints in WEV Manufacturing?

Quality control is typically segmented into several checkpoints:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected to verify that they meet specifications before being used in production.

- In-Process Quality Control (IPQC): This involves monitoring the manufacturing process at various stages to identify any defects or deviations from standards in real-time.

- Final Quality Control (FQC): The finished vehicles undergo rigorous testing to ensure they meet all performance and safety standards before delivery.

These checkpoints help minimize defects and ensure a high-quality end product.

What Common Testing Methods Are Used to Ensure Quality in WEVs?

Various testing methods are employed to assess the performance and safety of WEVs, including:

- Durability Testing: Simulating real-world conditions to evaluate how components withstand stress and wear over time.

- Safety Testing: Conducting crash tests and electrical safety assessments to meet regulatory requirements.

- Performance Testing: Evaluating range, charging efficiency, and handling characteristics under various conditions.

Each of these tests must be documented, providing a traceable record that can be reviewed by B2B buyers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, verifying the quality control practices of suppliers is critical. Here are some actionable steps buyers can take:

What Audit Processes Should Be Implemented for Supplier Verification?

Buyers should conduct regular audits of potential suppliers to assess their compliance with quality standards. This can include:

- On-Site Audits: Visiting manufacturing facilities to evaluate processes and quality control systems.

- Documentation Review: Analyzing quality management documentation, including certifications and previous audit reports.

How Can Reports and Third-Party Inspections Enhance Quality Assurance?

Requesting detailed quality assurance reports from suppliers can provide insights into their testing protocols and quality outcomes. Additionally, engaging third-party inspection services can offer an unbiased evaluation of a supplier’s capabilities, ensuring that they meet the required standards.

What Unique Quality Control Nuances Should International Buyers Consider?

When engaging with suppliers in different regions, international buyers should be aware of specific quality control nuances. For instance:

- Regulatory Differences: Different markets may have varying regulatory requirements. Understanding these can help avoid compliance issues.

- Cultural Expectations: Engaging with suppliers across cultures may require adapting communication and negotiation styles to establish trust and clarity regarding quality expectations.

By understanding these nuances, B2B buyers can foster successful partnerships that prioritize quality and performance in wheel electric vehicles, ultimately leading to better market outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wheel electric vehicle’

In the rapidly evolving market for wheel electric vehicles (EVs), international B2B buyers must navigate a complex landscape of technological innovations, supplier options, and regulatory requirements. This guide provides a step-by-step checklist to streamline the sourcing process, ensuring you make informed decisions that align with your business goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing strategy. Determine the type of wheel electric vehicle you need—consider factors such as size, range, battery capacity, and motor technology (e.g., in-wheel hub motors). Specificity in these areas will help potential suppliers tailor their offerings to meet your exact requirements.

Step 2: Research the Market Landscape

Understanding the current market landscape is crucial for identifying potential suppliers and technologies. Analyze trends in wheel electric vehicle design, such as advancements in hub motor technology, and the growing demand for sustainable transportation solutions. This knowledge will empower you to choose suppliers that are not only innovative but also aligned with market demands.

Step 3: Evaluate Potential Suppliers

Before committing, it’s essential to thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with proven expertise in wheel electric vehicle manufacturing and a track record of delivering high-quality products on time.

- Consider their technological capabilities: Are they using the latest innovations in hub motor technology?

- Assess their production capacity: Can they meet your order volume within your timeline?

Step 4: Verify Compliance and Certifications

Ensure that your selected suppliers comply with relevant industry standards and regulations. Request documentation of certifications such as ISO 9001 for quality management and any specific electric vehicle safety standards applicable in your region. Compliance not only assures product quality but also mitigates risks associated with legal liabilities.

Step 5: Analyze Cost Structures and Financing Options

Understanding the cost structure of potential suppliers is vital for effective budgeting. Review pricing models, including upfront costs, maintenance expenses, and financing options such as leasing or installment plans. A comprehensive cost analysis will help you select a supplier that offers the best value without compromising on quality.

Step 6: Request Prototypes or Samples

Before finalizing your procurement decision, request prototypes or samples of the wheel electric vehicles. This step allows you to assess the design, performance, and reliability of the vehicles firsthand. Conduct thorough testing to ensure they meet your specified requirements and standards.

Step 7: Establish a Clear Communication Plan

Effective communication is key to a successful partnership with your chosen supplier. Establish a clear communication plan that outlines points of contact, reporting structures, and feedback mechanisms. Regular updates and open lines of communication will help address any issues promptly and foster a collaborative relationship.

By following this checklist, B2B buyers can confidently navigate the sourcing process for wheel electric vehicles, ensuring they align with both technological advancements and market demands while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for wheel electric vehicle Sourcing

What Are the Key Cost Components in Sourcing Wheel Electric Vehicles?

When sourcing wheel electric vehicles (EVs), understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The choice of materials significantly impacts the overall cost. High-performance materials for battery packs, motors, and lightweight composites can drive up expenses but improve efficiency and longevity. For instance, sourcing advanced lithium-ion batteries or in-wheel motors can increase upfront costs but yield better performance and range.

-

Labor: Labor costs vary by region. Countries with lower labor costs, such as those in parts of Africa and South America, may offer competitive pricing, but this must be balanced against skill levels and workforce availability. Skilled labor is essential for complex assembly processes, particularly for innovations like in-wheel motor technology.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and administrative costs. Efficient production processes and advanced manufacturing technologies can help reduce overhead, impacting the overall pricing.

-

Tooling: The initial investment in tooling for custom components or designs can be substantial. However, the cost can be amortized over larger production runs, making it essential for buyers to consider minimum order quantities (MOQs) when negotiating.

-

Quality Control (QC): Ensuring that the EVs meet stringent quality standards is vital, especially for markets in Europe and the Middle East, where compliance with regulations is strict. Investing in comprehensive QC processes can add to initial costs but can prevent expensive recalls and reputation damage.

-

Logistics: The cost of transporting materials and finished vehicles can vary significantly based on location and shipping methods. Buyers should consider the impact of logistics on total cost and look for suppliers with efficient distribution networks.

-

Margin: Suppliers typically include a margin in their pricing to ensure profitability. Understanding the competitive landscape can help buyers gauge acceptable margins and negotiate effectively.

How Do Price Influencers Affect the Sourcing of Wheel Electric Vehicles?

Several factors influence the pricing of wheel electric vehicles, including volume or MOQ, specifications and customization, material choices, quality certifications, supplier capabilities, and Incoterms.

-

Volume/MOQ: Higher order volumes often lead to lower unit costs due to economies of scale. Buyers should negotiate MOQs that align with their production needs while maximizing cost efficiency.

-

Specifications and Customization: Custom features or advanced specifications can lead to increased costs. Buyers should clearly define their requirements upfront to avoid unexpected expenses during production.

-

Material Selection: The choice of materials not only affects performance but also pricing. Buyers should balance cost with the quality and performance characteristics of materials used in the EVs.

-

Quality and Certifications: Compliance with international quality standards can add to the cost but is essential for market acceptance. Buyers in regions with stringent regulations must ensure their suppliers can meet these requirements.

-

Supplier Factors: The reputation, reliability, and production capacity of suppliers play a significant role in pricing. Establishing long-term partnerships with reputable suppliers can lead to better pricing and service.

-

Incoterms: Understanding shipping terms is vital for calculating total costs. Different Incoterms can affect the buyer’s responsibilities for shipping, insurance, and customs duties, impacting overall expenditure.

What Negotiation Strategies Can Enhance Cost-Efficiency in Sourcing Wheel Electric Vehicles?

For international B2B buyers, particularly in diverse markets like Africa, South America, the Middle East, and Europe, negotiation is key to achieving cost efficiency. Here are several strategies:

-

Leverage Volume Discounts: Buyers should consider consolidating orders to meet MOQs and negotiate for volume discounts. This can significantly lower per-unit costs.

-

Clarify Specifications Early: Clearly defining vehicle specifications during the negotiation phase can prevent costly changes later in the process. This ensures that suppliers provide accurate pricing from the start.

-

Explore Total Cost of Ownership (TCO): Evaluating TCO, which includes operational costs, maintenance, and resale value, can provide a more comprehensive view of the investment. This approach can justify higher initial costs for vehicles with lower long-term operational expenses.

-

Factor in Regional Variations: When sourcing from different regions, understanding local market conditions, currency fluctuations, and regulatory landscapes can provide leverage in negotiations.

-

Build Long-Term Relationships: Establishing strong partnerships with suppliers can lead to better pricing, priority service, and collaboration on future projects.

What Should International Buyers Consider Regarding Pricing Nuances?

International buyers must navigate various pricing nuances, including currency exchange rates, geopolitical factors, and local market conditions.

-

Currency Exchange Rates: Fluctuations in currency can impact pricing, especially for buyers purchasing from foreign suppliers. It’s advisable to negotiate contracts in stable currencies or consider hedging strategies.

-

Geopolitical Factors: Political stability in supplier countries can affect pricing and supply chain reliability. Buyers should assess the geopolitical landscape to mitigate risks.

-

Local Market Conditions: Understanding local demand and competition can provide insights into fair pricing. Buyers should conduct market research to inform their negotiation strategies.

Disclaimer: Prices provided in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific project requirements. Always seek detailed quotes and conduct thorough due diligence.

Alternatives Analysis: Comparing wheel electric vehicle With Other Solutions

Introduction: Understanding Alternatives to Wheel Electric Vehicles

As the demand for sustainable transportation solutions grows, businesses must evaluate various technologies to identify the most suitable for their operational needs. Wheel electric vehicles (WEVs) represent a significant advancement in electric mobility, but several alternative solutions also exist, each with unique benefits and drawbacks. Understanding these alternatives can aid B2B buyers in making informed decisions that align with their objectives.

Comparison Table

| Comparison Aspect | Wheel Electric Vehicle | In-Wheel Hub Motors | Solar-Powered Vehicles |

|---|---|---|---|

| Performance | High torque response and efficiency | Enhanced handling with torque vectoring | Limited range based on sunlight availability |

| Cost | Moderate initial investment; lower running costs | Potentially higher initial costs due to technology | Varies widely; often lower operational costs |

| Ease of Implementation | Requires integration into existing vehicle designs | Complex integration into traditional platforms | Easier for new designs; retrofitting can be challenging |

| Maintenance | Standard EV maintenance; fewer moving parts | Specialized maintenance may be needed | Regular solar panel maintenance; battery replacement |

| Best Use Case | Urban environments, cargo transport | Performance vehicles, off-road applications | Areas with high solar exposure and limited charging infrastructure |

Detailed Breakdown of Alternatives

In-Wheel Hub Motors

In-wheel hub motors offer a compelling alternative to traditional electric vehicle designs. By integrating the electric motor directly into the wheel, this technology minimizes energy loss associated with conventional drivetrains. The advantages include improved handling and efficiency, as well as the potential for advanced features like torque vectoring, which enhances vehicle stability and traction. However, the complexity of integration into existing vehicle platforms can pose challenges, particularly for manufacturers looking to retrofit older models.

Solar-Powered Vehicles

Solar-powered vehicles, such as those developed by companies like Aptera, utilize solar panels to harness sunlight, providing a unique eco-friendly transportation solution. These vehicles can achieve a degree of energy independence, allowing for off-grid travel in sunny climates. While they are generally lower in operational costs, their performance is heavily dependent on weather conditions, which can limit usability in regions with inconsistent sunlight. Additionally, the initial investment may vary widely based on the technology and design chosen.

Conclusion: Making the Right Choice for Your Business

Choosing the right transportation solution depends on a variety of factors, including operational requirements, cost considerations, and the specific environment in which the vehicle will be used. Wheel electric vehicles stand out for their performance and efficiency, making them ideal for urban logistics and short-distance travel. In contrast, in-wheel hub motors provide advanced handling characteristics for performance-focused applications, while solar-powered vehicles offer sustainability in regions with ample sunlight. B2B buyers should assess these alternatives based on their unique business needs, evaluating factors like initial investment, maintenance requirements, and overall efficiency to make the most informed decision.

Essential Technical Properties and Trade Terminology for wheel electric vehicle

What Are the Key Technical Properties of Wheel Electric Vehicles?

When considering wheel electric vehicles (WEVs), several technical properties are crucial for B2B buyers to understand. These specifications not only influence the vehicle’s performance but also impact manufacturing costs, operational efficiency, and overall design flexibility.

-

In-Wheel Motor Technology

In-wheel motors, also known as hub motors, are integrated directly into the wheel assembly. This design reduces drivetrain complexity and enhances efficiency by minimizing energy loss typically associated with traditional drivetrains. For B2B buyers, adopting vehicles with in-wheel motors can lead to lower manufacturing costs and improved vehicle performance, making them a competitive choice in the market. -

Torque Vectoring Capability

Torque vectoring refers to the ability to distribute power to individual wheels based on driving conditions. This feature enhances traction and stability, particularly in challenging terrains or adverse weather. For businesses, investing in vehicles with this capability can lead to safer operations and improved driver satisfaction, which is essential for fleet management. -

Material Grade and Weight Specifications

The materials used in the construction of wheel electric vehicles, such as aluminum alloys or advanced composites, directly affect weight, durability, and performance. Lighter materials can improve range and efficiency, while stronger materials enhance safety. Understanding material grades is vital for B2B buyers to ensure they select vehicles that meet specific operational demands without compromising quality. -

Battery Capacity and Efficiency

Battery specifications, including capacity (measured in kWh) and efficiency (measured in Wh/km), determine how far a vehicle can travel on a single charge. A higher capacity allows for longer ranges, which is crucial for businesses that require extensive travel. B2B buyers must evaluate battery performance to ensure it aligns with their operational needs and reduces downtime. -

Charging Time and Infrastructure Compatibility

The time required to charge a vehicle and its compatibility with existing charging infrastructure are critical factors. Fast-charging capabilities can significantly reduce operational downtime, while compatibility ensures seamless integration into a company’s logistics network. For B2B decision-makers, understanding these aspects helps in planning and optimizing fleet operations.

What Are Common Trade Terminology and Jargon in the Wheel Electric Vehicle Industry?

Navigating the wheel electric vehicle market requires familiarity with specific trade terms that are commonly used among manufacturers and suppliers.

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of WEVs, OEMs are essential for sourcing high-quality components that meet industry standards. Understanding OEM relationships can help B2B buyers ensure they are partnering with reliable suppliers. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is critical for B2B buyers, as it can affect inventory management and initial investment costs. Knowing the MOQ helps businesses plan their purchasing strategy effectively. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for specific products or services. This process is vital for obtaining competitive pricing and ensuring that all potential suppliers are evaluated fairly. B2B buyers should utilize RFQs to facilitate transparent negotiations. -

Incoterms

Incoterms are international commercial terms that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms is essential for B2B buyers to understand shipping costs, risks, and logistics management in international trade. -

TCO (Total Cost of Ownership)

TCO refers to the overall cost of owning a vehicle, including purchase price, maintenance, fuel, insurance, and depreciation. For B2B buyers, calculating TCO is crucial for making informed purchasing decisions that align with budget constraints and long-term financial planning.

Understanding these technical properties and trade terminology equips B2B buyers with the insights needed to make informed decisions in the evolving market of wheel electric vehicles, ultimately enhancing operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the wheel electric vehicle Sector

What Are the Current Market Dynamics and Key Trends in the Wheel Electric Vehicle Sector?

The wheel electric vehicle (WEV) sector is witnessing unprecedented growth driven by a confluence of technological advancements, regulatory support, and shifting consumer preferences. Global demand for sustainable transportation solutions is accelerating, particularly in regions such as Africa, South America, the Middle East, and Europe. For international B2B buyers, understanding these dynamics is crucial.

One of the most significant trends is the integration of in-wheel motor technology, which enhances vehicle efficiency and design flexibility. This innovation allows for reduced drivetrain complexity, thereby minimizing energy losses and improving overall vehicle performance. Companies like Protean Electric and Vanderhall Motor Works are at the forefront of this technology, offering solutions that cater to diverse market needs.

Additionally, the rise of electric vehicles (EVs) is being supported by stringent emission regulations and government incentives aimed at promoting sustainable transportation. For instance, European countries are implementing aggressive targets for EV adoption, which could lead to increased sourcing opportunities for B2B buyers in the automotive supply chain. Moreover, the proliferation of solar-powered vehicles, as seen with Aptera Motors, showcases the potential for alternative energy sources to revolutionize the market.

In terms of sourcing trends, B2B buyers are increasingly looking for suppliers that offer modular and scalable solutions, which can adapt to varying vehicle designs and performance requirements. This flexibility is essential for manufacturers aiming to stay competitive in a rapidly evolving market.

How Can Sustainability and Ethical Sourcing Impact the Wheel Electric Vehicle Sector?

Sustainability is not just a buzzword in the wheel electric vehicle sector; it is a fundamental aspect shaping market dynamics. The environmental impact of manufacturing processes, materials sourcing, and end-of-life vehicle management is under scrutiny from consumers and regulators alike. For B2B buyers, prioritizing suppliers that adhere to sustainable practices can enhance brand reputation and customer loyalty.

Ethical sourcing of materials, particularly for batteries and electric components, is critical. The extraction of minerals like lithium and cobalt has raised concerns about labor practices and environmental degradation. Buyers should seek partnerships with companies that are committed to ethical sourcing and transparent supply chains. Certifications such as ISO 14001 (Environmental Management) and adherence to the OECD Due Diligence Guidance for Responsible Supply Chains are indicators of a supplier’s commitment to sustainability.

Moreover, the use of ‘green’ materials in vehicle production—such as recycled metals and sustainable composites—can significantly reduce the carbon footprint of the manufacturing process. B2B buyers should engage with suppliers that prioritize eco-friendly materials, as this not only aligns with global sustainability goals but can also lead to cost savings in the long run.

What Has Been the Evolution of Wheel Electric Vehicle Technology?

The evolution of wheel electric vehicle technology has been marked by significant milestones that have shaped its current landscape. Initially, electric vehicles relied heavily on traditional drivetrain configurations, which limited design flexibility and efficiency. However, the advent of in-wheel motor technology has revolutionized this paradigm.

By integrating motors directly into the wheel hub, manufacturers have reduced the complexity of vehicle designs while improving performance metrics such as acceleration and handling. This innovation has paved the way for more versatile vehicle platforms, enabling the production of a wider range of electric vehicles tailored to diverse market needs.

As the market continues to mature, the ongoing focus on sustainability and technological innovation will likely drive further advancements in wheel electric vehicle technology, creating new opportunities for B2B buyers looking to invest in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of wheel electric vehicle

-

How do I choose the right supplier for wheel electric vehicles?

Choosing the right supplier involves assessing their experience, product quality, and reputation in the market. Look for suppliers with a proven track record in electric vehicle manufacturing and positive client testimonials. It’s beneficial to request samples and certifications to ensure compliance with international standards. Additionally, consider their ability to provide after-sales support and service, as this can significantly impact your operations in the long run. -

What is the best payment method for sourcing wheel electric vehicles internationally?

The best payment method depends on your relationship with the supplier and the transaction size. Common options include letters of credit, bank transfers, and PayPal. Letters of credit offer security for both parties, while bank transfers can be more straightforward for established relationships. Always ensure that your payment method aligns with your risk management strategy and consider using escrow services for larger orders to safeguard your investment. -

What are the minimum order quantities (MOQs) for wheel electric vehicles?

MOQs can vary significantly based on the supplier and the type of vehicle you are ordering. Typically, manufacturers may set MOQs to ensure cost-effectiveness in production. It is essential to discuss your needs upfront; some suppliers may be flexible with MOQs for first-time buyers or long-term partnerships. Always negotiate terms that suit your business model while considering your budget and market demand. -

How can I customize wheel electric vehicles to meet my specific needs?

Customization options often depend on the supplier’s capabilities. Discuss your requirements regarding design, features, and specifications early in the negotiation process. Many manufacturers offer modular designs that allow for various configurations and features, such as different battery capacities or technology integrations. Ensure that any customization aligns with regulatory requirements in your target market. -

What quality assurance measures should I expect from suppliers?

Reputable suppliers should have robust quality assurance protocols, including ISO certifications, regular inspections, and testing procedures. Ask about their quality control processes and request documentation of compliance with international standards. It’s also beneficial to inquire about warranty terms and after-sales support, as these factors contribute to the overall reliability of the vehicles you are sourcing. -

What logistics considerations should I keep in mind when importing wheel electric vehicles?

Logistics play a crucial role in the successful importation of wheel electric vehicles. Consider shipping methods, transit times, and customs clearance processes specific to your region. Partnering with a logistics provider experienced in automotive imports can streamline the process. Additionally, ensure that you understand the import duties and taxes applicable in your country to avoid unexpected costs. -

How do I ensure compliance with international regulations when sourcing wheel electric vehicles?

Compliance with international regulations is essential to avoid legal issues and ensure market entry. Research the specific regulations in your target market, including safety, emissions, and import standards. Engage with legal experts or consultants who specialize in automotive regulations to guide you through the process. Additionally, request compliance documentation from your suppliers to verify that their products meet the necessary standards. -

What are the emerging trends in wheel electric vehicle technology that I should be aware of?

Staying informed about emerging trends can give you a competitive edge. Key trends include the integration of in-wheel motor technology, which enhances efficiency and reduces weight, and advancements in battery technology for longer ranges. Additionally, the use of sustainable materials and solar integration is gaining traction. Monitoring these trends can help you make informed purchasing decisions and position your offerings effectively in the market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Wheel Electric Vehicle Manufacturers & Suppliers List

1. Aptera – Solar Electric Vehicle

Domain: aptera.us

Registered: 2019 (6 years)

Introduction: Aptera is a solar electric vehicle designed to be highly efficient, requiring no charging for most daily use. Key specifications include:

– Integrated solar cells generating approximately 700 watts

– Up to 40 miles of free solar-powered driving per day

– 400 miles of range per full charge

– Acceleration from 0-60 mph in less than 6 seconds

The vehicle is currently in testing and validation, a…

2. Protean Solutions – ProteanDrive

Domain: proteanelectric.com

Registered: 2009 (16 years)

Introduction: Protean Solutions specializes in in-wheel motor technology for passenger cars, light commercial vehicles, and connected & autonomous vehicles. Their key product, ProteanDrive, features integrated power electronics and digital control, allowing for direct drive without gears. Benefits include improved torque response, enhanced handling, faster acceleration, reduced charging frequency, and greater r…

3. ElectraMeccanica – Solo; Arcimoto – Vehicles

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: ElectraMeccanica Solo: Price – $18,500; Issues – Recalled all vehicles due to battery/drive issues; Status – Company operations moving to Arizona, planning a four-wheeler (E4). Arcimoto: Vehicles available, but facing bankruptcy; Lacks doors, which may affect practicality in various weather conditions. Owner feedback indicates it is a fun vehicle with some shortcomings, but offers benefits like HO…

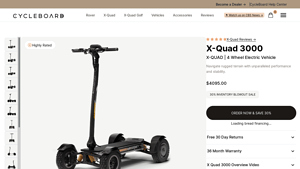

4. CycleBoard – X-Quad 3000 All-terrain Electric Vehicle

Domain: cycleboard.com

Registered: 2005 (20 years)

Introduction: {“name”: “X-Quad 3000 All-terrain 4 wheeled Electric Vehicle”, “price”: “$4095.00”, “top_speed”: “27 MPH”, “motor_power”: “3000w (Dual 1500W Motors)”, “range”: “50 miles+ per charge”, “hill_climbing”: “Inclines up to 30%”, “warranty”: “36-month warranty”, “features”: [{“suspension”: “4-wheel independent double wishbone suspension”}, {“lighting”: “Integrated front lights and rear taillight/brake li…

5. Wheels – Electric Vehicle Solutions

Domain: wheels.com

Registered: 1994 (31 years)

Introduction: Electric Vehicle Solutions: Wheels offers a comprehensive suite of electric vehicle (EV) solutions aimed at enhancing client and driver experiences. Key personnel involved in EV initiatives include John Ciarlone (Director of Product Development), Suresh Rajapakse (Chief Client Officer), Paige Arnold (EV Specialist), Bart Garbicz (EV Implementation Specialist II), Sara Sweeney (Senior Product Manag…

6. BMW – 2025 iX

Domain: cars.usnews.com

Registered: 1995 (30 years)

Introduction: [{‘model’: ‘2025 BMW iX’, ‘price’: ‘$87,250’, ‘overall_score’: ‘8.9/10’, ‘battery’: ‘111.5-kWh’, ‘horsepower’: ‘516 or 610’, ‘features’: [‘12.3-inch digital instrument cluster’, ‘heated steering wheel’, ‘quad-zone automatic climate control’]}, {‘model’: ‘2025 Rivian R1S’, ‘price’: ‘$75,900’, ‘overall_score’: ‘8.9/10’, ‘horsepower’: ‘533 (Dual-Motor) or 1,025 (Quad-Motor)’, ‘features’: [‘vegan leat…

7. Nissan – In-Wheel Motor Technology

Domain: nissan-global.com

Registered: 2000 (25 years)

Introduction: The in-wheel motor is a type of electric vehicle (EV) drive system that places motors adjacent to each wheel, allowing for direct power to the wheels. This design enhances accelerator responsiveness and aligns the vehicle’s behavior with the driver’s steering input, resulting in a more intuitive driving experience. Unlike conventional EVs that use a single motor and drive shaft, the in-wheel motor…

Strategic Sourcing Conclusion and Outlook for wheel electric vehicle

How Can Strategic Sourcing Enhance Your Wheel Electric Vehicle Initiatives?

The evolution of wheel electric vehicle technology presents significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By strategically sourcing in-wheel motor technologies, businesses can capitalize on the enhanced efficiency, reduced manufacturing complexity, and improved vehicle design flexibility these innovations offer. The integration of hub motors not only optimizes vehicle performance but also aligns with global sustainability goals, making it a compelling choice for forward-thinking companies.

Investing in strategic sourcing practices allows organizations to build strong partnerships with suppliers of cutting-edge technologies, ensuring access to the latest advancements while mitigating risks associated with supply chain disruptions. As the electric vehicle market continues to expand, staying ahead of trends will be crucial for maintaining a competitive edge.

Looking forward, the demand for efficient, innovative electric vehicles is set to grow exponentially. Now is the time for B2B buyers to explore partnerships that can enhance their product offerings and meet the evolving needs of consumers. Embrace the future of mobility and take actionable steps today to secure your position in the rapidly advancing electric vehicle landscape.