Introduction: Navigating the Global Market for camioneta elctrica de alta velocidad

In an era where sustainability and efficiency are paramount, sourcing high-speed electric trucks (camioneta eléctrica de alta velocidad) presents a formidable challenge for international B2B buyers. As businesses across Africa, South America, the Middle East, and Europe seek to modernize their fleets, understanding the complexities of this market is essential. This guide delves into the diverse types of high-speed electric trucks available, their applications across various industries, and the critical factors to consider when vetting suppliers.

From evaluating specifications such as towing capacity and battery range to assessing the latest technological advancements and charging infrastructure, this comprehensive resource equips decision-makers with the knowledge necessary to make informed purchasing decisions. Additionally, we explore cost considerations and financing options, helping businesses navigate potential budget constraints while maximizing value.

By leveraging the insights provided in this guide, B2B buyers can confidently engage with manufacturers and suppliers, ensuring that their investments align with both operational needs and environmental goals. As the global market for electric vehicles continues to evolve, staying ahead of trends and understanding the nuances of sourcing high-speed electric trucks will empower businesses to thrive in a competitive landscape.

Understanding camioneta elctrica de alta velocidad Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Size Electric Pickup | High towing capacity, spacious cargo area, long range | Construction, logistics, agriculture | Pros: Excellent utility; Cons: Higher purchase price. |

| Compact Electric Pickup | Maneuverable size, efficient battery use, lower cost | Urban deliveries, small businesses | Pros: Cost-effective; Cons: Limited cargo capacity. |

| Luxury Electric Pickup | Premium features, advanced technology, high performance | Executive transport, high-end logistics | Pros: Exceptional comfort; Cons: Maintenance costs can be high. |

| Off-Road Electric Pickup | Enhanced suspension, rugged design, terrain adaptability | Mining, outdoor services | Pros: Superior off-road capability; Cons: Heavier weight affects efficiency. |

| Utility Electric Pickup | Versatile configurations, customizable features, fleet-ready | Municipal services, utility companies | Pros: Highly adaptable; Cons: May lack some performance metrics of full-size models. |

What Are the Characteristics of Full-Size Electric Pickups?

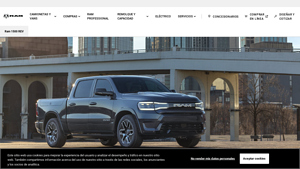

Full-size electric pickups, such as the Ram 1500 REV and Chevy Silverado EV, are designed for heavy-duty applications. They typically offer impressive towing capacities, spacious cargo areas, and extended driving ranges, making them ideal for industries like construction and logistics. B2B buyers should consider the total cost of ownership, including potential savings on fuel and maintenance, as well as the upfront investment.

How Do Compact Electric Pickups Fit into Urban Applications?

Compact electric pickups are designed for urban environments, offering a smaller footprint and greater maneuverability. They are particularly useful for businesses engaged in last-mile delivery or those with limited parking space. The lower cost of these vehicles can be appealing for small businesses, although buyers should evaluate the trade-off of reduced cargo capacity compared to full-size models.

What Makes Luxury Electric Pickups Attractive for B2B Buyers?

Luxury electric pickups combine performance with premium features, catering to businesses that prioritize comfort and advanced technology. These vehicles are often used for executive transport or high-end logistics. While they provide an exceptional driving experience, potential buyers should be aware of the higher maintenance costs associated with luxury vehicles and assess their specific needs against the benefits offered.

How Do Off-Road Electric Pickups Serve Specialized Industries?

Off-road electric pickups are engineered for rugged terrain and demanding environments, making them suitable for industries such as mining and outdoor services. With enhanced suspension systems and durable designs, they excel in challenging conditions. B2B buyers must consider the weight and efficiency trade-offs, as these vehicles may consume more energy compared to their on-road counterparts.

What Are the Benefits of Utility Electric Pickups for Municipal Services?

Utility electric pickups are versatile vehicles designed for various applications, including municipal services and utility companies. Their customizable features allow businesses to tailor them for specific tasks, such as transporting tools and equipment. While they offer adaptability, buyers should evaluate their performance metrics against full-size models to ensure they meet operational demands effectively.

Key Industrial Applications of camioneta elctrica de alta velocidad

| Industry/Sector | Specific Application of camioneta electrica de alta velocidad | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Last-mile delivery and urban transport | Reduced operational costs and lower emissions | Battery range, charging infrastructure, payload capacity |

| Construction | Site transportation and equipment hauling | Increased efficiency and reduced fuel costs | Durability, towing capacity, and off-road capabilities |

| Agriculture | Transport of goods and equipment in rural areas | Enhanced mobility and sustainability in operations | Terrain compatibility, battery life, and load capacity |

| Public Services | Emergency response and utility services | Quick deployment and reduced environmental impact | Reliability, maintenance support, and charging solutions |

| Tourism and Recreation | Shuttle services and adventure tourism | Improved customer experience and eco-friendly operations | Comfort features, range, and adaptability to various terrains |

How Can the Logistics and Transportation Sector Leverage High-Speed Electric Trucks?

In logistics and transportation, high-speed electric trucks are increasingly used for last-mile delivery and urban transport. These vehicles offer a significant reduction in operational costs due to lower energy consumption and maintenance requirements compared to traditional diesel trucks. Additionally, they contribute to lowering emissions, aligning with sustainability goals. Buyers in this sector should consider battery range and the availability of charging infrastructure to ensure efficient operations in urban environments.

What Role Do High-Speed Electric Trucks Play in the Construction Industry?

In the construction industry, high-speed electric trucks serve as essential vehicles for site transportation and equipment hauling. Their ability to carry heavy loads while providing quick access to various locations on-site enhances operational efficiency. Furthermore, the reduced fuel costs associated with electric trucks can lead to significant savings over time. Buyers should prioritize durability, towing capacity, and off-road capabilities to meet the rigorous demands of construction environments.

How Can Agriculture Benefit from High-Speed Electric Trucks?

High-speed electric trucks are transforming agricultural operations by facilitating the transport of goods and equipment in rural areas. These trucks provide enhanced mobility, allowing farmers to navigate challenging terrains with ease. The sustainability aspect of electric trucks also resonates well with agricultural practices aimed at reducing carbon footprints. Buyers need to assess terrain compatibility, battery life, and load capacity to ensure these vehicles can meet specific agricultural needs.

Why Are High-Speed Electric Trucks Important for Public Services?

Public services, including emergency response and utility services, benefit from high-speed electric trucks due to their quick deployment capabilities and reduced environmental impact. These vehicles can swiftly navigate urban settings, providing essential services without contributing to air pollution. When sourcing electric trucks for public services, reliability, maintenance support, and efficient charging solutions are critical considerations to ensure continuous operation.

How Do High-Speed Electric Trucks Enhance the Tourism and Recreation Industry?

In the tourism and recreation sector, high-speed electric trucks are utilized for shuttle services and adventure tourism activities. They provide an eco-friendly transportation option that enhances the overall customer experience. By integrating electric trucks into their operations, businesses can promote sustainability while offering comfortable and efficient travel solutions. Buyers should focus on comfort features, range, and the vehicle’s adaptability to various terrains to meet diverse tourist needs.

3 Common User Pain Points for ‘camioneta elctrica de alta velocidad’ & Their Solutions

Scenario 1: Insufficient Charging Infrastructure for Fleets

The Problem: For B2B buyers considering the adoption of high-speed electric trucks, a significant challenge is the lack of adequate charging infrastructure. This issue is particularly pronounced in regions such as Africa and South America, where the electrical grid may not support the rapid charging requirements of high-performance electric vehicles. Buyers are concerned about the operational downtime of their fleets, which can lead to increased costs and logistical headaches.

The Solution: To effectively mitigate this pain point, B2B buyers should conduct a thorough assessment of the existing charging infrastructure within their operational regions before making a purchase. Engaging with local energy providers can provide insights into upcoming projects aimed at enhancing electric vehicle (EV) charging networks. Moreover, investing in fast-charging stations strategically placed along key routes can ensure that vehicles can recharge quickly and efficiently during breaks. Additionally, buyers can explore partnerships with EV charging solution providers who can offer tailored solutions, including mobile charging units that can be deployed as needed. By taking these proactive steps, companies can ensure that their electric truck fleets remain operational and efficient, ultimately driving down costs and enhancing productivity.

Scenario 2: Concerns About Range Limitations in Remote Areas

The Problem: A common apprehension among B2B buyers is the perceived range limitations of high-speed electric trucks, especially in remote areas where charging stations may be sparse. This concern is particularly relevant for logistics companies operating in regions with vast distances between urban centers, such as in parts of the Middle East and Africa. Buyers fear that running out of charge mid-journey could lead to costly delays and impact service reliability.

The Solution: To address these range-related concerns, buyers should prioritize models with proven extended range capabilities, such as those offering upwards of 350 miles on a single charge. Additionally, implementing route optimization software can help in planning more efficient delivery routes that account for charging station locations and battery consumption. Training drivers on best practices for energy management while driving—such as using regenerative braking and maintaining steady speeds—can also enhance the effective range of electric trucks. Furthermore, buyers might consider investing in backup battery systems or portable chargers that can provide emergency power when needed. By focusing on these strategies, companies can confidently operate their high-speed electric trucks without the constant worry of range limitations.

Scenario 3: Integration with Existing Fleet Management Systems

The Problem: Another pain point for B2B buyers revolves around the integration of high-speed electric trucks into their existing fleet management systems. Many businesses rely on sophisticated software for tracking vehicle performance, maintenance schedules, and fuel efficiency metrics. The introduction of electric vehicles may require significant adjustments to these systems, leading to potential disruptions in operations and increased costs.

The Solution: To streamline the integration process, buyers should select electric truck models that come with compatible telematics and fleet management solutions. Manufacturers that offer robust data integration capabilities can significantly ease the transition. Additionally, buyers should invest in training for their fleet management teams to familiarize them with the new technologies associated with electric vehicles, including battery management systems and charging protocols. Conducting pilot programs with a limited number of electric trucks can also allow businesses to test the integration with their existing systems before a full rollout. By taking a structured approach to integration, companies can minimize disruptions and leverage the full potential of their high-speed electric truck fleets, enhancing operational efficiency and overall performance.

Strategic Material Selection Guide for camioneta elctrica de alta velocidad

What Are the Key Materials for High-Speed Electric Trucks?

When selecting materials for high-speed electric trucks, it is crucial to consider their properties, advantages, disadvantages, and specific implications for international markets. Here, we analyze four common materials: aluminum, high-strength steel, carbon fiber, and thermoplastics.

How Does Aluminum Benefit High-Speed Electric Trucks?

Aluminum is a popular choice for electric truck manufacturers due to its lightweight nature and excellent corrosion resistance. With a density about one-third that of steel, aluminum significantly reduces vehicle weight, enhancing energy efficiency and range. Its thermal conductivity also aids in battery cooling, which is essential for maintaining performance during high-speed operations.

Pros: Aluminum is durable, offers good strength-to-weight ratios, and is relatively easy to fabricate. It can be extruded or cast into complex shapes, making it versatile for various components like chassis and body panels.

Cons: The primary limitation of aluminum is its cost, which is higher than traditional steel. Additionally, while it is resistant to corrosion, it may require protective coatings in harsher environments, which can add to manufacturing complexity.

Impact on Application: Aluminum is compatible with various media, including battery fluids and environmental conditions, making it suitable for diverse climates, particularly in regions like Africa and the Middle East.

Considerations for International Buyers: Compliance with standards such as ASTM and ISO is essential. Buyers should also be aware of the availability of aluminum in local markets, as sourcing can affect overall costs.

What Role Does High-Strength Steel Play in Electric Trucks?

High-strength steel (HSS) is increasingly used in electric trucks for its superior strength and durability. It provides excellent structural integrity while allowing for thinner sections, which contributes to weight savings.

Pros: HSS is cost-effective compared to aluminum and offers excellent resistance to deformation and impact. Its availability is widespread, making it a practical choice for manufacturers.

Cons: While HSS is strong, it is heavier than aluminum, which can negatively impact energy efficiency and range. Additionally, the welding and fabrication processes can be more complex, requiring specialized techniques.

Impact on Application: HSS is particularly effective in load-bearing components and safety structures, ensuring that the truck can withstand harsh conditions and impacts.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as DIN and JIS, especially in regions like Europe and South America, where safety regulations are stringent.

How Does Carbon Fiber Enhance Performance in Electric Trucks?

Carbon fiber is known for its exceptional strength-to-weight ratio and stiffness, making it an attractive option for high-performance electric trucks. Its lightweight nature contributes to improved acceleration and handling.

Pros: Carbon fiber is highly durable and resistant to fatigue, making it ideal for components that undergo repeated stress. Its aesthetic appeal also allows for innovative design possibilities.

Cons: The primary drawback is its high cost and manufacturing complexity. Carbon fiber components often require specialized processes, which can lead to longer production times.

Impact on Application: Carbon fiber is particularly suitable for aerodynamic components and body panels, enhancing the vehicle’s overall efficiency.

Considerations for International Buyers: Due to its cost, carbon fiber may be less accessible in emerging markets like Nigeria or Vietnam. Buyers should evaluate the long-term benefits versus initial investment.

What Advantages Do Thermoplastics Offer for Electric Trucks?

Thermoplastics are increasingly utilized in electric trucks for non-structural components due to their lightweight and moldability. They can be used in interior panels, exterior trims, and battery housings.

Pros: These materials are cost-effective and can be produced in large volumes. They also offer good impact resistance and can be recycled, aligning with sustainability goals.

Cons: Thermoplastics may not provide the same level of strength as metals or carbon fiber, limiting their use in critical structural applications. Additionally, they can be sensitive to temperature variations.

Impact on Application: Thermoplastics are suitable for various environmental conditions, making them ideal for diverse markets, including Africa and South America.

Considerations for International Buyers: Buyers should consider local recycling capabilities and the availability of thermoplastics that meet international standards.

Summary Table of Material Selection for High-Speed Electric Trucks

| Material | Typical Use Case for camioneta elctrica de alta velocidad | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Chassis, body panels | Lightweight, corrosion-resistant | Higher cost, requires coatings | High |

| High-Strength Steel | Load-bearing components, safety structures | Cost-effective, strong | Heavier, complex fabrication | Medium |

| Carbon Fiber | Aerodynamic components, body panels | Exceptional strength-to-weight ratio | High cost, complex manufacturing | High |

| Thermoplastics | Interior panels, exterior trims | Cost-effective, recyclable | Limited strength, temperature sensitivity | Low |

This strategic material selection guide provides valuable insights for B2B buyers in the electric truck market, enabling informed decisions that align with performance, cost, and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for camioneta elctrica de alta velocidad

What Are the Key Stages in the Manufacturing Process of High-Speed Electric Trucks?

The manufacturing process for high-speed electric trucks, or “camioneta eléctrica de alta velocidad,” is complex and involves several critical stages, each designed to ensure efficiency and product integrity. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The journey begins with the selection of high-quality materials. Manufacturers typically use lightweight materials such as aluminum and high-strength steel for the chassis to enhance performance and range. Additionally, advanced composites may be employed for body panels to reduce weight while maintaining durability. Suppliers must ensure that all materials meet stringent quality standards, which can be verified through certifications and test reports.

-

Forming: This stage involves shaping the prepared materials into the required components. Techniques such as stamping, extrusion, and molding are commonly utilized. For instance, the body panels may be stamped from sheets of aluminum, while the battery casings could be molded from durable plastics. Precision is crucial here, as any deviations can impact the vehicle’s aerodynamics and structural integrity.

-

Assembly: Once components are formed, they move to the assembly line. This is a highly automated process where robotic systems often play a vital role in enhancing efficiency and accuracy. Key components, including the electric powertrain, battery packs, and interior features, are integrated during this phase. Manufacturers often adopt modular assembly techniques, allowing for greater flexibility and easier updates to vehicle designs in response to market demands.

-

Finishing: The final stage involves painting, surface treatments, and quality checks. A multi-layer painting process not only enhances aesthetic appeal but also provides corrosion resistance. Additionally, manufacturers might employ advanced coatings that improve battery efficiency by managing heat dissipation. This stage is crucial for ensuring that the truck meets both aesthetic and functional requirements before it reaches the market.

How Is Quality Assurance Implemented in Electric Truck Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that every vehicle meets international standards and customer expectations. The QA process involves several international and industry-specific standards, along with various checkpoints throughout the production cycle.

-

International Standards: Compliance with standards such as ISO 9001 for quality management systems is essential. This certification indicates that a manufacturer has established a systematic approach to managing quality across all processes. Additionally, CE marking may be required for vehicles sold in Europe, indicating compliance with safety, health, and environmental protection standards.

-

Industry-Specific Standards: Electric vehicles must also adhere to specific standards related to battery safety and performance, such as those set by the American National Standards Institute (ANSI) or the Society of Automotive Engineers (SAE). These standards govern aspects such as battery testing protocols and vehicle crashworthiness.

-

Quality Control Checkpoints: Implementing a robust quality control system typically involves three key checkpoints:

– Incoming Quality Control (IQC): This step involves inspecting raw materials upon delivery to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify and rectify issues early. This can involve monitoring critical parameters such as torque specifications during assembly.

– Final Quality Control (FQC): Before a vehicle leaves the factory, it undergoes comprehensive testing, including performance and safety checks. This phase often includes simulated road tests to assess various functionalities.

What Testing Methods Are Commonly Used in Electric Truck Production?

To ensure quality and safety, a variety of testing methods are employed throughout the manufacturing process. These include:

- Functional Testing: Verifying that all systems (electrical, mechanical, and software) perform as intended. This might include testing the battery management system and electric drive unit.

- Environmental Testing: Assessing the vehicle’s performance under extreme conditions, such as high temperatures or humidity, to ensure reliability in diverse climates, particularly relevant for markets in Africa and the Middle East.

- Durability Testing: Simulating years of wear and tear to ensure longevity. This often includes road simulations and vibration testing.

- Safety Testing: Conducting crash tests to evaluate the vehicle’s structural integrity and occupant protection in the event of an accident.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are several strategies:

-

Audits: Conducting on-site audits of manufacturing facilities can provide insights into the operational capabilities and quality practices of potential suppliers. During audits, buyers should assess the adherence to international standards and internal quality processes.

-

Quality Reports: Requesting detailed quality assurance reports can help buyers understand a supplier’s performance history. These reports should include data on defect rates, testing results, and compliance with relevant standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control practices. These services often include pre-shipment inspections, which can verify that products meet specified requirements before they are dispatched.

What Are the Quality Control Nuances for International B2B Buyers?

When dealing with international suppliers, particularly in emerging markets, buyers must be aware of several nuances in quality control:

-

Understanding Local Standards: Different countries may have varying standards and regulations. Buyers should ensure that their suppliers are compliant with both local and international standards to avoid legal and operational issues.

-

Cultural Differences: Quality perceptions may vary by region. Establishing clear communication and expectations regarding quality requirements is vital to avoid misunderstandings.

-

Logistical Considerations: The logistics of shipping and customs can impact the quality of products. B2B buyers should consider how products are handled and stored during transit to maintain quality integrity.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when selecting suppliers for high-speed electric trucks, ensuring they receive products that meet their quality and performance expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘camioneta elctrica de alta velocidad’

To assist B2B buyers in sourcing high-speed electric trucks, this guide provides a comprehensive checklist to ensure informed decision-making and successful procurement. This structured approach will help buyers navigate the complexities of sourcing while focusing on key specifications and supplier evaluations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring the selected truck meets operational needs. Consider factors such as payload capacity, range, towing capabilities, and charging times. Document these specifications to communicate effectively with potential suppliers and to compare different models accurately.

Step 2: Conduct Market Research

Understanding the market landscape is essential for identifying potential suppliers and available models. Research various manufacturers and their offerings, focusing on features, pricing, and customer reviews. Utilize industry reports and forums to gather insights about performance and reliability from current users.

Step 3: Evaluate Potential Suppliers

Before making a commitment, vet suppliers thoroughly to ensure they can meet your requirements. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. Pay attention to their reputation, production capacity, and customer service responsiveness.

Step 4: Verify Compliance and Certifications

Confirm that the vehicles meet regional regulations and safety standards. Look for certifications such as ISO, EPA, or local equivalents, which indicate adherence to quality and environmental regulations. This step is crucial to avoid legal complications and ensure the vehicle’s reliability and efficiency.

Step 5: Assess After-Sales Support and Warranty

Inquire about the after-sales support provided by the supplier, including maintenance services, spare parts availability, and warranty terms. A robust support system is vital for minimizing downtime and ensuring the longevity of your investment. Consider the length and coverage of the warranty as indicators of supplier confidence in their product.

Step 6: Request Test Drives and Demonstrations

Whenever possible, arrange for test drives or demonstrations of the electric trucks you are considering. This hands-on experience will help evaluate the vehicle’s performance, comfort, and technological features. Take note of how the truck handles under load, its acceleration, and the ease of use of its electronic systems.

Step 7: Negotiate Terms and Conditions

Once you have identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Be prepared to discuss bulk purchase discounts or financing options that may be available. Clear agreements on terms can prevent misunderstandings and ensure a smooth procurement process.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing high-speed electric trucks, ensuring a well-informed and strategic approach to their procurement needs.

Comprehensive Cost and Pricing Analysis for camioneta elctrica de alta velocidad Sourcing

What Are the Key Cost Components in Sourcing High-Speed Electric Trucks?

When sourcing high-speed electric trucks (camioneta eléctrica de alta velocidad), understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The cost of materials, such as advanced batteries, electric motors, and lightweight body components, can significantly impact the overall price. High-quality materials often lead to higher upfront costs but can enhance durability and performance, resulting in lower maintenance costs over time.

-

Labor: Skilled labor is essential for the manufacturing of electric trucks. Labor costs can vary widely based on the region and the complexity of the assembly process. In countries with higher labor costs, manufacturers may focus on automation to mitigate expenses.

-

Manufacturing Overhead: This includes utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce overhead costs, which can be crucial for keeping prices competitive.

-

Tooling: The initial investment in tooling and molds can be substantial, especially for custom designs. Buyers should consider whether the supplier has the necessary capabilities to produce the desired specifications without incurring excessive tooling costs.

-

Quality Control: Ensuring the vehicle meets safety and performance standards involves rigorous testing and inspections. This adds to the overall cost but is essential for maintaining product integrity and gaining customer trust.

-

Logistics: Shipping costs can vary depending on the destination and the Incoterms agreed upon. Buyers in Africa, South America, the Middle East, and Europe should factor in import duties and transportation fees when calculating total costs.

-

Margin: Manufacturers typically apply a margin to cover their costs and generate profit. Understanding the typical margins in the industry can provide insights into negotiating better pricing.

How Do Price Influencers Affect the Cost of High-Speed Electric Trucks?

Several factors influence pricing, making it essential for buyers to be aware of these variables:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Negotiating for bulk discounts can significantly reduce overall expenses.

-

Specifications and Customization: Custom features can increase costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Material Quality and Certifications: Higher quality materials may come at a premium but can lead to better performance and longer life cycles. Certifications for safety and environmental standards can also affect pricing.

-

Supplier Factors: The reputation and reliability of the supplier can impact costs. Established suppliers may charge more for their assurance of quality and timely delivery.

-

Incoterms: Understanding shipping terms is vital. FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can alter the total landed cost, influencing overall pricing strategies.

What Are the Best Negotiation Tips for International B2B Buyers?

For B2B buyers, particularly from developing regions, leveraging negotiation strategies can yield better pricing:

-

Do Your Research: Understand market prices and the cost structure of electric trucks. This knowledge empowers buyers during negotiations.

-

Emphasize Long-Term Relationships: Suppliers value long-term contracts and repeat business. Highlighting potential future orders can motivate suppliers to offer better rates.

-

Explore Total Cost of Ownership (TCO): Buyers should consider the TCO, which includes purchase price, operating costs, maintenance, and resale value. A higher initial investment may be justified if it results in lower operating costs.

-

Be Flexible with Specifications: If possible, being open to alternative specifications or models can facilitate better pricing.

-

Cultural Sensitivity: Understanding cultural norms in negotiations can foster better relationships and more favorable outcomes.

Conclusion: What Should Buyers Remember About Pricing Nuances?

In summary, while the initial price of high-speed electric trucks is essential, buyers should look beyond the sticker price to understand the total cost implications and the value offered. As prices can vary significantly based on the factors outlined, it’s crucial to approach sourcing strategically, ensuring that both cost and quality align with business goals.

Disclaimer: Prices mentioned are indicative and can fluctuate based on market conditions, exchange rates, and specific buyer-supplier negotiations. Always consult with suppliers for the most accurate pricing.

Alternatives Analysis: Comparing camioneta elctrica de alta velocidad With Other Solutions

Exploring Alternatives to High-Speed Electric Trucks

In the rapidly evolving landscape of commercial transportation, high-speed electric trucks (camioneta eléctrica de alta velocidad) represent a significant shift toward sustainability and efficiency. However, businesses must evaluate various alternatives to determine the best solution for their specific operational needs. This analysis compares high-speed electric trucks with traditional diesel trucks and hybrid electric trucks, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Camioneta Eléctrica De Alta Velocidad | Traditional Diesel Truck | Hybrid Electric Truck |

|---|---|---|---|

| Performance | High torque, quick acceleration, up to 500 miles range | Moderate torque, slower acceleration, up to 700 miles range | Good torque, moderate acceleration, up to 600 miles range |

| Cost | Higher initial investment; lower operational costs | Lower initial cost; higher fuel and maintenance costs | Moderate initial cost; better fuel efficiency than diesel |

| Ease of Implementation | Requires charging infrastructure; incentives available | Established infrastructure; minimal adaptation needed | Requires some charging infrastructure; easier transition than full electric |

| Maintenance | Lower maintenance costs due to fewer moving parts | Higher maintenance costs; engine and transmission issues | Moderate maintenance; both electric and combustion components |

| Best Use Case | Urban deliveries, short-haul transport | Long-distance transport, heavy loads | Mixed-use applications, urban and highway |

Understanding the Pros and Cons of Each Alternative

Traditional Diesel Truck

Diesel trucks have been the backbone of the transportation industry for decades, offering a combination of power and range that is hard to match. They typically come at a lower initial purchase price, making them attractive for businesses on a tight budget. However, they incur higher operational costs due to fuel expenses and maintenance needs. Diesel engines require regular servicing, and fluctuating fuel prices can impact overall costs. Additionally, environmental regulations are increasingly stringent, which could lead to future compliance costs.

Hybrid Electric Truck

Hybrid electric trucks blend traditional combustion engines with electric power, providing an intermediate solution for businesses looking to transition to greener alternatives. They often have better fuel efficiency than their diesel counterparts, resulting in lower fuel costs. This option is more flexible, as it can operate without the need for extensive charging infrastructure. However, hybrid systems can be more complex, leading to moderate maintenance requirements. While they may offer a good compromise, the technology is still evolving, and some businesses may prefer fully electric solutions for sustainability goals.

Making the Right Choice for Your Business

Choosing the right transportation solution hinges on understanding your specific operational needs, budget constraints, and long-term sustainability goals. High-speed electric trucks offer exceptional performance and lower operational costs, making them ideal for urban environments where efficiency and emissions are paramount. Conversely, traditional diesel trucks may still serve well for long-distance hauling, while hybrid electric trucks provide a balanced approach for businesses transitioning toward electrification. Ultimately, evaluating these alternatives in the context of your fleet’s requirements will enable informed decision-making that aligns with both financial and environmental objectives.

Essential Technical Properties and Trade Terminology for camioneta elctrica de alta velocidad

What Are the Key Technical Properties of High-Speed Electric Trucks?

When considering a high-speed electric truck (camioneta eléctrica de alta velocidad), several technical properties are essential for B2B buyers to understand. These specifications directly impact performance, cost-efficiency, and suitability for various applications.

-

Battery Capacity (kWh)

Battery capacity, measured in kilowatt-hours (kWh), determines how much energy the truck can store. A higher capacity typically translates to a longer driving range, which is crucial for businesses needing to maximize operational uptime. For instance, trucks with a capacity of 100 kWh can offer ranges exceeding 300 miles, enabling long-haul logistics without frequent charging stops. -

Torque and Horsepower

Torque (measured in lb-ft) and horsepower (measured in HP) are vital for assessing a truck’s performance. High torque is essential for heavy-duty applications, such as towing and hauling. For example, a truck with 620 lb-ft of torque can efficiently handle substantial loads, making it ideal for construction or transportation sectors. -

Payload Capacity (lbs)

Payload capacity refers to the maximum weight a truck can carry, excluding its own weight. This is critical for businesses in logistics and transportation, as it affects operational efficiency. A truck with a payload capacity of 2,625 lbs allows for substantial cargo transport, which can enhance profitability by reducing the number of trips required. -

Charging Time (minutes)

The charging time is the duration required to recharge the vehicle’s battery fully. Electric trucks with fast-charging capabilities can significantly reduce downtime. For example, a truck that can charge to 80% in 30 minutes can be more appealing to businesses that prioritize efficiency and quick turnaround times. -

Towing Capacity (lbs)

Towing capacity indicates how much weight the truck can pull behind it, which is essential for industries that require trailers for transporting goods. A truck with a towing capacity of 14,000 lbs is suitable for heavy-duty tasks, making it a valuable asset for businesses in construction, logistics, or agriculture. -

Aerodynamic Design

The aerodynamic design of a truck influences its energy efficiency and performance. A truck with a low drag coefficient can achieve better range and speed, which is crucial for businesses looking to optimize fuel consumption and reduce operational costs.

Which Trade Terms Are Important for B2B Buyers of High-Speed Electric Trucks?

Understanding trade terminology is crucial for effective communication and negotiation in the B2B landscape, especially when dealing with high-speed electric trucks.

-

OEM (Original Equipment Manufacturer)

An OEM is a company that manufactures products or components that are sold to another company for resale. In the context of electric trucks, buyers often engage with OEMs for customized vehicle specifications or parts, ensuring quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for businesses looking to negotiate bulk purchases of electric trucks or components, as it can affect pricing and inventory management. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. For B2B buyers of electric trucks, submitting an RFQ can help compare offers from various manufacturers, ensuring competitive pricing and favorable terms. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps businesses understand shipping costs, risks, and delivery responsibilities when procuring electric trucks from different regions. -

Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. For electric trucks, understanding lead times is crucial for planning logistics and ensuring timely delivery for operational needs. -

Warranty Period

The warranty period refers to the time frame during which a manufacturer guarantees the performance and quality of the truck. Knowing the warranty terms is essential for B2B buyers to assess the long-term reliability and support they can expect from their investment.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when investing in high-speed electric trucks, enhancing their operational efficiency and competitive advantage.

Navigating Market Dynamics and Sourcing Trends in the camioneta elctrica de alta velocidad Sector

What Are the Key Market Drivers for High-Speed Electric Trucks?

The high-speed electric truck market is being propelled by several global factors, notably the increasing demand for sustainable transportation solutions, advancements in battery technology, and stringent emissions regulations. Businesses across various sectors are prioritizing electric vehicles (EVs) to enhance operational efficiency and reduce their carbon footprint. The rise in urbanization, particularly in developing regions such as Africa and South America, is also stimulating demand for electric trucks that can navigate congested environments while offering higher performance metrics.

Emerging technologies are reshaping sourcing trends within this sector. The integration of advanced telematics and connectivity features into electric trucks is becoming standard, providing fleet operators with real-time data on vehicle performance, maintenance needs, and charging patterns. Additionally, the growing popularity of direct-to-consumer sales models is influencing how international buyers source vehicles, allowing for a more streamlined purchasing process. As competition intensifies, companies that emphasize innovation and adaptability in their offerings are likely to gain a significant advantage.

How Are Sustainability and Ethical Sourcing Impacting the High-Speed Electric Truck Sector?

Sustainability is a cornerstone of the high-speed electric truck market, influencing everything from production processes to end-of-life vehicle management. The environmental impact of sourcing materials for electric trucks—especially lithium for batteries—has led to heightened scrutiny of supply chains. International buyers are increasingly focusing on ethical sourcing practices, ensuring that suppliers adhere to environmental standards and labor rights.

Moreover, the demand for ‘green’ certifications is growing. Buyers are looking for trucks made from recycled materials or those produced using renewable energy sources. Certifications such as ISO 14001 for environmental management systems or the Global Reporting Initiative (GRI) standards are becoming essential credentials for suppliers aiming to attract eco-conscious buyers. Companies that prioritize sustainability not only enhance their brand reputation but also align themselves with the values of an increasingly environmentally aware market.

What Is the Evolution of High-Speed Electric Trucks and Its Relevance to B2B Buyers?

The evolution of high-speed electric trucks has been rapid and transformative, rooted in technological advancements that have redefined the capabilities of commercial vehicles. Initially perceived as niche products, electric trucks have evolved into robust contenders in the logistics and transportation industries. Early models, characterized by limited range and performance, have given way to sophisticated vehicles like the Ram 1500 REV and Chevy Silverado EV, which offer impressive towing capacities and extended ranges.

This historical context is vital for B2B buyers as it highlights the shifting landscape of vehicle capabilities and the growing acceptance of electric solutions in traditional markets. Understanding the trajectory of electric truck development equips buyers with insights into future trends and innovations, enabling them to make informed sourcing decisions that align with their business goals and sustainability initiatives.

Frequently Asked Questions (FAQs) for B2B Buyers of camioneta elctrica de alta velocidad

-

How do I evaluate suppliers for high-speed electric trucks?

When sourcing high-speed electric trucks, consider several critical factors. Start by verifying the supplier’s industry experience and reputation through client testimonials and case studies. Assess their production capabilities, quality control processes, and compliance with international standards. It’s also essential to inquire about their supply chain reliability and after-sales service. Conducting factory visits or audits can provide deeper insights into their operations. Finally, check for certifications related to sustainability and electric vehicle manufacturing to ensure they align with your corporate values and compliance requirements. -

What are the key specifications to look for in high-speed electric trucks?

For B2B buyers, the most important specifications include battery capacity, range, and charging time. A higher battery capacity translates to longer operational periods, while a range of at least 300 miles is advisable for diverse applications. Consider the truck’s towing and payload capacities, which should meet your operational needs. Additionally, look for advanced features like regenerative braking, smart technology for fleet management, and safety systems. Customization options for vehicle design and tech integrations can also enhance usability and brand alignment. -

What is the minimum order quantity (MOQ) for high-speed electric trucks?

Minimum order quantities can vary significantly between manufacturers. Some may require a MOQ of 10-20 units, while others may be open to smaller orders, especially for first-time buyers or pilot programs. It’s advisable to discuss your projected needs with the supplier to negotiate favorable terms. Additionally, inquire about potential discounts for larger orders, as these can significantly impact your overall budget. Understanding the supplier’s production schedule can also help align your order timing with their capacity. -

What payment terms should I expect when purchasing electric trucks?

Payment terms for high-speed electric trucks typically range from upfront payments to installment plans. Many suppliers may require a deposit (often 20-30%) upon order confirmation, with the balance due upon delivery or within a specified period post-delivery. It’s important to clarify these terms upfront to avoid any misunderstandings. Additionally, consider discussing options for letters of credit or escrow services for added security in international transactions, especially when dealing with significant amounts. -

How can I ensure quality assurance for electric trucks?

To ensure quality assurance, request detailed information about the manufacturer’s quality control processes and certifications. Many reputable suppliers will have ISO certifications or equivalent, demonstrating adherence to international quality standards. Conducting pre-shipment inspections is also crucial; consider hiring a third-party inspection service to verify the trucks meet your specifications before they leave the factory. Establishing a clear return policy and warranty terms will provide additional protection against potential defects or issues. -

What logistics considerations should I keep in mind when importing electric trucks?

Logistics for importing electric trucks involve several key considerations. First, determine the best shipping method—container shipping is common for large vehicles. Ensure the supplier can provide necessary documentation, including compliance certificates and customs paperwork. Understand the import tariffs and taxes applicable in your country, as these can significantly affect your total cost. Finally, work with a reliable freight forwarder who is experienced in handling vehicle imports to navigate any potential challenges. -

What are the customization options for high-speed electric trucks?

Customization options can vary by manufacturer but often include modifications to vehicle design, payload configurations, and technological features. Buyers may request specific colors, branding, or interior layouts that suit their operational needs. Additionally, advanced tech integrations, such as fleet management software or telematics systems, can often be included. Discuss your requirements early in the sourcing process to ensure the supplier can accommodate your customization requests and to assess any associated costs. -

How can I find reliable suppliers of high-speed electric trucks?

Finding reliable suppliers can involve several strategies. Start by researching industry directories and trade shows focused on electric vehicles. Networking with industry peers and attending webinars or conferences can provide valuable recommendations. Utilize online platforms like LinkedIn to connect with manufacturers and request quotes. Additionally, consider engaging sourcing agents or consultants who specialize in electric vehicles, as they can leverage their networks to identify reputable suppliers and streamline the procurement process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Camioneta Elctrica De Alta Velocidad Manufacturers & Suppliers List

1. Chevrolet – Chevy Silverado EV 2026

Domain: es.chevrolet.com

Registered: 1994 (31 years)

Introduction: Modelo: Chevy Silverado EV 2026

Tipo: Camioneta eléctrica

Precio desde: $52,800*

Precio como se muestra: $86,600*

Autonomía: Hasta 493 millas según la EPA*

Torque máximo: Hasta 775 lb-ft con Wide Open Watts*

Capacidad de remolque: Hasta 12,500 lb*

Pantalla táctil de infoentretenimiento: 17.7 pulgadas en diagonal

Centro de información al conductor: 11 pulgadas en diagonal

Número de tomacorrientes: …

2. Ram – Ram 1500 REV

Domain: es.ramtrucks.com

Registered: 2003 (22 years)

Introduction: {“model”:”Ram 1500 REV”,”type”:”electric truck”,”range”:”350 miles”,”towing_capacity”:”14,000 lbs”,”payload_capacity”:”2,625 lbs”,”storage_capacity”:”15 ft 3″,”acceleration”:”0 to 60 mph in 4.4 seconds”,”horsepower”:”654 hp”,”torque”:”620 lb-ft”,”versions”:[“Big Horn®/Lone Star”,”Laramie®”,”Limited”,”Tungsten”],”features”:{“front_trunk_storage”:”more than double the Tesla Cybertruck’s front trunk”…

3. ZEEKR – 001 Shooting Brake 100% Eléctrico

Domain: zeekrlife.com

Registered: 2021 (4 years)

Introduction: {“model”:”ZEEKR 001″,”type”:”Shooting Brake 100% eléctrico”,”autonomy_km”:”620 km (WLTP)”,”acceleration”:”0-100 km/h en 3.8 s (AWD)”,”max_speed”:”200 km/h”,”charging_time”:”30 min (con cargador de 300 kW/hr)”,”battery_capacity”:”100 KWH”,”motor”:”Sistema de accionamiento del motor sincrono de imanes permanentes de alto rendimiento”,”exterior_features”:[“Puertas de apertura automática”,”Luces Matri…

4. LINGBOX – Modelo EC01

Domain: es.jinpeng-global.com

Registered: 2023 (2 years)

Introduction: Modelo: EC01, Marca: LINGBOX, Dimensiones (mm): 3584*1475*1615, Distancia entre ejes (mm): 2455, Freno trasero: Freno de tambor, Limpieza mínima del suelo (mm): 220, Peso en acera (kg): 955, Especificación de neumáticos: 165/65 R14, Torque máximo (n·m): 125, Potencia del motor máximo (KW): 35, Velocidad máxima (km/h): 101, Rango por carga (km): 220 (CLTC), Tiempo de carga (h): 1.2-15, Capacidad de…

5. Green Cars – Electric Vehicle Features

Domain: greencars.com

Registered: 1998 (27 years)

Introduction: La mayoría de los vehículos eléctricos de alta tecnología incluyen características como: 1. Conectividad avanzada con aplicaciones integradas para navegación GPS, actualizaciones de tráfico en tiempo real y sincronización con smartphones (Android Auto, Apple CarPlay, Google). 2. Funciones de asistencia al conductor que incluyen: control de crucero adaptativo, frenado automático de emergencia, adve…

6. Ray Since – EC-350 High-Speed Electric SUV

Domain: es.raysince.com

Registered: 2021 (4 years)

Introduction: {“model”:”EC-350″,”type”:”High-speed electric SUV”,”dimensions”:”3500*1550*1500 (mm)”,”max_speed”:”50-80 km/h”,”gross_weight”:”720/760 KG”,”range”:”120 km/200 km”,”battery_capacity”:”6/7.2/10.8 KWH”,”seating_capacity”:”4 seats/5 doors”,”motor_power”:”6-10 kW”,”tire_size”:”155/65R13″,”max_power”:”10 KW”,”torque”:”76 Nm”,”acceleration”:”0-100 km/h”,”drive_type”:”Rear-wheel drive”,”charging_time”:”6-…

7. Dragon Era – Coche Eléctrico TukTuk

Domain: dragon-era.com

Registered: 2024 (1 years)

Introduction: Coche eléctrico de alta velocidad Auto Rickshaw TukTuk

Precio actual: $1,500.00 (precio original: $2,001.00)

Dimensiones: 2550*1150*1800mm

Potencia del motor: 60V 3000W

Tamaño del neumático: Neumático de vacío 225/40-10

Velocidad máxima: 40 km/h

Carga máxima: 500KG

Neumáticos adicionales: 400-12

Construcción: Chasis monocasco de acero laminado en frío T16 de 1,2 mm con tratamiento anticorrosión de…

8. Tesla – Model Y SUV Eléctrico

Domain: spanish.electric-evs.com

Registered: 2023 (2 years)

Introduction: {“Nombre del producto”: “Tesla Model Y”, “Tipo”: “SUV eléctrico”, “Marca”: “Tesla”, “Lugar de origen”: “China”, “Color”: “Blanco”, “Motor”: “Izquierda”, “Estructura del cuerpo”: “Vehículo todo terreno”, “Transporte de energía”: “Eléctrico”, “Tipo de unidad”: “Tracción en las cuatro ruedas”, “Capacidad de la batería”: “60 kWh”, “Tiempo de carga”: “0.5h”, “Cantidad de orden mínima”: “5”, “Precio”: “…

Strategic Sourcing Conclusion and Outlook for camioneta elctrica de alta velocidad

In the evolving landscape of high-speed electric trucks, strategic sourcing emerges as a pivotal driver for B2B success. International buyers from regions such as Africa, South America, the Middle East, and Europe must recognize the competitive advantages offered by leading models like the Chevy Silverado EV and Ram 1500 REV. These vehicles not only deliver exceptional performance metrics, including impressive towing capabilities and cutting-edge technology, but they also align with global sustainability goals, appealing to eco-conscious consumers and businesses alike.

Investing in strategic sourcing allows companies to leverage innovation and optimize supply chains, ensuring access to the latest advancements in electric vehicle technology. By prioritizing partnerships with manufacturers committed to quality and sustainability, businesses can enhance their operational efficiency and brand reputation.

As the demand for high-speed electric trucks continues to grow, now is the time for international B2B buyers to evaluate their sourcing strategies. Engaging with suppliers who demonstrate a forward-thinking approach to electric vehicle production will be crucial in capturing market share and positioning your business for future success. Embrace this opportunity to lead in the transition to electric mobility.