Introduction: Navigating the Global Market for cargo scooter

Navigating the complexities of sourcing cargo scooters for diverse business needs can be daunting for international B2B buyers. As urbanization accelerates in regions like Africa, South America, the Middle East, and Europe, the demand for efficient, eco-friendly transportation solutions has surged. Cargo scooters, with their ability to transport goods swiftly and economically, present an attractive option for businesses looking to enhance logistics and delivery services. This guide aims to equip you with the knowledge necessary to make informed purchasing decisions by exploring various types of cargo scooters, their applications across different industries, and essential factors for supplier vetting.

In this comprehensive resource, we will delve into the specifications and features that matter most to B2B buyers, such as payload capacities, range, battery life, and safety features. We will also provide insights into cost considerations and financing options, ensuring you have a clear understanding of your investment. By addressing the unique challenges faced by businesses in different regions, including compliance with local regulations and market trends, this guide empowers you to navigate the global market for cargo scooters effectively. With actionable insights and expert recommendations, you can confidently select the right cargo scooter that aligns with your operational needs, ultimately driving efficiency and growth in your business.

Understanding cargo scooter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Cargo Scooter | High-torque motors, varying speeds (up to 20 mph), and customizable cargo options | Last-mile delivery, urban commuting | Pros: Eco-friendly, cost-effective. Cons: Limited range on single charge. |

| Cargo E-Scooter with Basket | Equipped with large baskets for transporting goods, often designed for pets as well | Pet transport, small package delivery | Pros: Versatile storage solutions. Cons: May not support heavier loads. |

| Heavy-Duty Cargo Scooter | Built for heavier payloads, robust construction, and higher weight capacities (up to 300 lbs) | Industrial use, construction sites | Pros: Durable and reliable for heavy loads. Cons: Higher initial investment. |

| Compact Folding Cargo Scooter | Lightweight, foldable design for easy transport and storage | Urban delivery, personal use | Pros: Space-saving, portable. Cons: Smaller cargo capacity. |

| Multi-Purpose Utility Scooter | Features adjustable racks, passenger seating, and multiple configurations | Food delivery, mobile retail | Pros: Highly adaptable for various uses. Cons: Complexity may require training. |

What Are the Characteristics of Electric Cargo Scooters?

Electric cargo scooters are designed for efficiency and versatility, often featuring high-torque motors that allow for speeds up to 20 mph. These scooters typically come with customizable options for cargo, such as detachable baskets or racks. They are particularly suitable for last-mile delivery services in urban environments, where maneuverability and eco-friendliness are crucial. B2B buyers should consider factors like battery range and charging time when evaluating these scooters for their operations.

How Do Cargo E-Scooters with Baskets Benefit Businesses?

Cargo e-scooters with integrated baskets are ideal for businesses that need to transport smaller items, including pet-related goods. Their design often accommodates various payloads while ensuring a comfortable ride. These scooters are highly applicable in pet transport services or for delivering small packages within city limits. When purchasing, businesses should assess the size of the basket and the scooter’s weight capacity to ensure it meets their operational needs.

Why Choose Heavy-Duty Cargo Scooters for Industrial Use?

Heavy-duty cargo scooters are built to withstand rigorous use, featuring robust construction and higher weight capacities, often accommodating loads of up to 300 lbs. These scooters are particularly beneficial in industrial settings, such as construction sites, where transporting tools and materials is necessary. B2B buyers should focus on durability, maintenance requirements, and warranty options when selecting these scooters for their operations, as the initial investment may be higher but can lead to long-term savings.

What Advantages Do Compact Folding Cargo Scooters Offer?

Compact folding cargo scooters are lightweight and easily portable, making them an excellent choice for urban delivery services where space is limited. Their ability to fold for storage means they can be conveniently transported in vehicles or stored in small spaces. However, their smaller cargo capacity may limit their use for larger deliveries. Businesses should evaluate the trade-off between portability and storage capacity to determine if this type suits their delivery model.

How Do Multi-Purpose Utility Scooters Adapt to Various Business Needs?

Multi-purpose utility scooters offer a flexible design with adjustable racks and seating options, making them suitable for various applications, including food delivery and mobile retail. Their adaptability allows businesses to customize the scooter for different operational needs, enhancing efficiency. However, the complexity of these scooters may require additional training for operators. When considering these scooters, businesses should weigh the benefits of versatility against the potential need for operational adjustments.

Key Industrial Applications of cargo scooter

| Industry/Sector | Specific Application of cargo scooter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Retail | Last-mile delivery for small packages | Reduces delivery costs and improves customer satisfaction | Range and payload capacity; battery life; local regulations |

| Hospitality & Tourism | Guest transport and luggage handling | Enhances guest experience and operational efficiency | Comfort features; storage options; durability for varied terrains |

| Agriculture | Transporting supplies and produce on farms | Increases efficiency in logistics and reduces manual labor | Power and range for farm terrain; load capacity; maintenance support |

| Urban Logistics | Urban transport for small businesses | Cost-effective and eco-friendly transport solution | Compliance with local laws; ease of use; serviceability |

| Healthcare | Mobile medical equipment transport | Ensures timely medical deliveries and reduces manpower | Stability and load capacity; battery reliability; safety features |

How Are Cargo Scooters Used in E-commerce and Retail?

In the e-commerce and retail sectors, cargo scooters serve as efficient last-mile delivery vehicles for small packages. Their compact size and maneuverability allow businesses to navigate urban environments, reducing delivery times and costs. With a payload capacity that accommodates multiple parcels, cargo scooters help streamline logistics, particularly in densely populated areas. For international buyers, it’s crucial to consider battery life and range to ensure compliance with local delivery needs and regulations.

What Role Do Cargo Scooters Play in Hospitality and Tourism?

In the hospitality and tourism industry, cargo scooters are utilized for guest transport and luggage handling. Hotels and resorts can enhance guest experiences by offering convenient transportation options within their premises. The scooters can also be used to transport supplies, improving operational efficiency. Buyers in this sector should prioritize comfort features, such as adjustable seating and ample storage, to cater to diverse guest needs and ensure a pleasant experience.

How Do Cargo Scooters Benefit the Agriculture Sector?

Cargo scooters are increasingly being adopted in agriculture for transporting supplies and produce across farms. Their ability to traverse uneven terrain while carrying significant loads makes them an invaluable asset for farmers. By reducing reliance on traditional vehicles, they lower operational costs and enhance productivity. When sourcing, businesses should focus on the scooter’s power and range to suit the specific demands of agricultural environments.

What Advantages Do Cargo Scooters Offer for Urban Logistics?

In urban logistics, cargo scooters provide a cost-effective and eco-friendly solution for small businesses needing to transport goods. Their compact design allows for easy navigation in congested streets, making them ideal for quick deliveries. Additionally, they contribute to reducing carbon footprints, aligning with sustainability goals. Key considerations for sourcing include compliance with local laws regarding electric vehicles and the ease of use for delivery personnel.

How Are Cargo Scooters Utilized in Healthcare Settings?

In healthcare, cargo scooters are employed to transport mobile medical equipment and supplies swiftly across facilities. Their ability to navigate tight spaces while carrying essential items ensures timely deliveries, which is crucial in medical settings. Buyers in this sector should look for scooters with robust stability, reliable battery performance, and safety features to protect sensitive equipment and ensure safe operation in varied environments.

3 Common User Pain Points for ‘cargo scooter’ & Their Solutions

Scenario 1: Limited Range and Battery Life Complications

The Problem: Many B2B buyers express concern over the limited range and battery life of cargo scooters, particularly in logistics and delivery sectors. For businesses relying on these vehicles for daily operations, a maximum range of 15-20 miles can be insufficient, especially when servicing large urban areas or remote locations. This limitation can lead to increased downtime for recharging, affecting operational efficiency and customer satisfaction. Additionally, in regions with unreliable electricity, the risk of battery depletion becomes a significant challenge.

The Solution: To address these concerns, B2B buyers should prioritize sourcing cargo scooters with extended battery options and improved energy management systems. For instance, consider models equipped with lithium-ion batteries that offer higher capacities and faster charging capabilities. Additionally, implementing a fleet management system that monitors battery levels and routes can optimize usage, ensuring that scooters are charged during low-demand periods. Buyers should also explore partnerships with local charging infrastructure providers to ensure access to charging stations in strategic locations, minimizing downtime during the workday.

Scenario 2: Cargo Capacity and Versatility Issues

The Problem: A common pain point for B2B buyers is the insufficient cargo capacity of many available scooters, which can restrict their utility for businesses that need to transport goods, tools, or equipment. Companies in sectors such as construction, catering, and urban delivery require vehicles that can accommodate diverse payloads without sacrificing performance. This limitation can lead to inefficiencies, as businesses may need to invest in additional transport solutions.

The Solution: Buyers should look for cargo scooters that offer customizable and modular storage solutions. Models with detachable baskets, integrated storage compartments, or expandable cargo racks can significantly enhance versatility. When sourcing, consider scooters that provide various configuration options to adapt to different payload types. Additionally, conducting a thorough analysis of the intended use cases can help identify the right specifications, such as weight limits and storage dimensions, ensuring that the selected model meets the specific needs of the business. Collaborating with manufacturers that offer customization services can further enhance the scooter’s utility for unique business requirements.

Scenario 3: Safety and Compliance Concerns

The Problem: Safety is a paramount concern for B2B buyers, particularly in industries where cargo scooters are used in high-traffic areas or for transporting valuable goods. The lack of safety features such as robust braking systems, visibility enhancements, and regulatory compliance can pose risks to both riders and the public. Buyers are often apprehensive about the legal implications of using vehicles that may not meet local safety standards, potentially leading to liabilities.

The Solution: B2B buyers should prioritize sourcing cargo scooters that meet established safety standards, such as UL2272 certification, which verifies the electrical safety of electric vehicles. Look for models equipped with advanced braking systems, bright LED lights, and reflective materials for improved visibility in urban settings. Additionally, investing in rider safety training programs can further mitigate risks, ensuring that employees are equipped with the knowledge to operate scooters safely. Buyers should also stay informed about local regulations regarding electric scooters, ensuring compliance and reducing potential legal liabilities. By choosing scooters with comprehensive safety features and fostering a culture of safety within the organization, businesses can protect their assets and enhance operational reliability.

Strategic Material Selection Guide for cargo scooter

What Are the Key Materials Used in Cargo Scooters?

When selecting materials for cargo scooters, manufacturers must consider various factors, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in cargo scooters: steel, aluminum, plastic composites, and lithium-ion batteries.

How Does Steel Contribute to Cargo Scooter Durability?

Steel is a widely used material in the construction of cargo scooters, particularly for the frame and fork. Its key properties include high tensile strength, excellent impact resistance, and good fatigue performance. Steel can withstand significant stress and is less likely to deform under heavy loads, making it suitable for cargo applications.

Pros: Steel is relatively inexpensive, widely available, and easy to work with, allowing for cost-effective manufacturing. It also offers excellent durability and can be treated for corrosion resistance.

Cons: The main drawbacks of steel are its weight and susceptibility to rust if not properly coated. This can affect the scooter’s overall performance and maintenance requirements.

Impact on Application: Steel’s strength makes it ideal for carrying heavy loads, but its weight can limit speed and battery efficiency. For international buyers, compliance with standards such as ASTM A500 for structural steel is crucial.

Why Is Aluminum Preferred for Lightweight Designs?

Aluminum is increasingly popular in cargo scooter design due to its lightweight and corrosion-resistant properties. It has a lower density than steel, which contributes to a lighter overall scooter, enhancing speed and battery efficiency.

Pros: Aluminum is resistant to rust and can withstand various environmental conditions, making it suitable for diverse climates, particularly in regions like Africa and South America. It also offers good strength-to-weight ratios.

Cons: The primary limitation of aluminum is its higher cost compared to steel and its lower fatigue resistance. This can lead to potential structural issues if not designed properly.

Impact on Application: Aluminum is particularly beneficial for scooters intended for urban commuting in wet or humid environments. Buyers should consider compliance with standards such as ASTM B221 for aluminum extrusions.

What Role Do Plastic Composites Play in Cargo Scooter Design?

Plastic composites are utilized in various components of cargo scooters, including the deck and body panels. These materials are lightweight and can be molded into complex shapes, providing design flexibility.

Pros: Plastic composites are resistant to corrosion and can be manufactured at a lower cost than metals. They also offer good insulation properties and can be produced in various colors and finishes.

Cons: However, plastic composites may not provide the same level of structural integrity as metals, particularly under heavy loads. They can also degrade over time when exposed to UV light unless treated.

Impact on Application: The use of plastic composites can reduce the overall weight of the scooter, improving battery life. International buyers should ensure compliance with relevant standards such as ISO 9001 for quality management.

How Do Lithium-Ion Batteries Impact Performance and Cost?

Lithium-ion batteries are essential for electric cargo scooters, providing the power needed for operation. They are known for their high energy density, allowing for longer ranges and shorter charging times.

Pros: These batteries are lightweight, have a long lifespan, and can be recharged many times without significant degradation. They are also more efficient than traditional lead-acid batteries.

Cons: The primary drawbacks include higher initial costs and the need for proper disposal due to environmental concerns. Additionally, they require careful management to prevent overheating.

Impact on Application: The performance of lithium-ion batteries directly affects the scooter’s range and speed. Buyers should look for compliance with safety standards such as UL 2271 for battery systems.

Summary Table of Material Properties for Cargo Scooters

| Material | Typical Use Case for Cargo Scooter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Heavier, prone to rust | Low |

| Aluminum | Frame and lightweight components | Lightweight and corrosion-resistant | Higher cost, lower fatigue resistance | Med |

| Plastic Composites | Deck and body panels | Cost-effective and design flexibility | Lower structural integrity | Low |

| Lithium-Ion Battery | Power source for electric scooters | High energy density and efficiency | Higher initial cost, disposal issues | High |

This comprehensive analysis of materials used in cargo scooters provides valuable insights for international B2B buyers, enabling informed decisions that align with performance, cost, and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cargo scooter

What Are the Main Stages of the Cargo Scooter Manufacturing Process?

The manufacturing process of cargo scooters involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is vital to ensure that the final product meets both performance and safety standards.

Material Preparation

The first step in the manufacturing process involves selecting high-quality materials suitable for cargo scooters. Common materials include steel for the frame, high-density plastic or bamboo for the deck, and rubber for tires. Suppliers are often vetted for compliance with international standards, ensuring that raw materials are durable and environmentally friendly. This stage may also include pre-treatment processes such as cutting and shaping materials to specified dimensions.

Forming Techniques

After material preparation, various forming techniques are employed to create the scooter’s components. This includes stamping, welding, and molding processes. For instance, the scooter frame is typically welded from steel tubes to provide strength and stability. Advanced manufacturers might utilize computer numerical control (CNC) machinery to ensure precision in component fabrication. Additionally, techniques such as extrusion may be used for creating plastic parts, ensuring they meet specific design requirements.

Assembly Process

The assembly stage is where all individual components come together. This includes fitting the motor, battery, and electronic systems into the frame. Quality control checkpoints are integrated into this stage to ensure that each part is correctly installed and functioning. For example, the installation of the braking system and wiring harnesses is critical to the scooter’s safety and performance. Assembly lines may utilize a combination of manual labor and automated systems to enhance efficiency.

Finishing Touches

Finishing processes include painting, coating, and installation of additional features such as lights and displays. The finishing stage is crucial for aesthetics and protection against environmental factors. Manufacturers often apply protective coatings that prevent rust and wear, enhancing the longevity of the scooter. Additionally, this is the stage where final inspections occur to check for any cosmetic defects or functional issues.

How Is Quality Assurance Implemented During Cargo Scooter Manufacturing?

Quality assurance (QA) is a fundamental aspect of the cargo scooter manufacturing process. Implementing robust QA protocols ensures that products meet both international standards and customer expectations.

What Are Relevant International Standards for Cargo Scooters?

For cargo scooters, compliance with international standards such as ISO 9001 is essential. This standard focuses on maintaining quality management systems and ensuring consistent product quality. Furthermore, regional certifications like CE for Europe and other industry-specific standards may apply, depending on the target market. These certifications indicate that products have been tested for safety and performance, which is crucial for B2B buyers.

What Are the Quality Control Checkpoints During Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process to ensure each component and final product meets quality standards. Key checkpoints include:

- Incoming Quality Control (IQC): This is the first line of defense where raw materials are inspected for quality and compliance before entering the production line.

- In-Process Quality Control (IPQC): During assembly, ongoing checks are performed to monitor the installation of components. This includes verifying the alignment of parts and the functionality of electronic systems.

- Final Quality Control (FQC): Once assembly is complete, the final product undergoes a thorough inspection. This includes testing the scooter’s speed, braking system, and battery performance under various conditions.

What Common Testing Methods Are Used for Cargo Scooters?

Common testing methods for cargo scooters include:

- Performance Testing: Assessing speed, range, and acceleration to ensure the scooter meets specified performance criteria.

- Safety Testing: Verifying braking efficiency, stability, and load capacity to ensure compliance with safety standards.

- Environmental Testing: Subjecting the scooter to extreme conditions (temperature, humidity) to evaluate durability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is crucial. Here are effective strategies:

Conducting Audits

Performing supplier audits can provide insights into their manufacturing processes and quality control measures. An audit may include evaluating their production facility, examining QA procedures, and reviewing compliance with international standards. This firsthand assessment can help buyers gauge the supplier’s commitment to quality.

Reviewing Quality Assurance Reports

Requesting quality assurance reports from suppliers is another way to verify their QC practices. These reports should include information about testing results, compliance with standards, and any corrective actions taken for non-conformities. Transparent suppliers will readily provide this documentation.

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can offer an unbiased evaluation of the supplier’s quality control practices. These services can conduct inspections at various stages of production, ensuring that the cargo scooters meet the required specifications before shipment.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International B2B buyers should be aware of specific nuances related to quality control and certifications. For example, different regions may have varying regulatory requirements, which can affect product compliance. Buyers from Africa, South America, the Middle East, and Europe must ensure that their suppliers understand and adhere to local laws and regulations.

Additionally, understanding the certification processes in each region can help buyers make informed decisions. For instance, while CE certification is essential for products sold in Europe, other regions may have distinct certification requirements that need to be met.

Conclusion

In summary, the manufacturing processes and quality assurance protocols for cargo scooters are intricate and essential for producing safe, reliable, and high-performance vehicles. For B2B buyers, understanding these processes, verifying supplier quality controls, and navigating international standards and certifications can significantly impact purchasing decisions. By prioritizing quality and compliance, businesses can ensure they invest in products that meet both their operational needs and customer expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cargo scooter’

When sourcing cargo scooters for B2B purposes, a systematic approach can significantly streamline the procurement process. This checklist serves as a practical guide to ensure that you make informed decisions while navigating the complexities of supplier selection and product specifications.

Step 1: Define Your Technical Specifications

Establishing clear technical requirements is essential for ensuring that the cargo scooters meet your operational needs. Consider factors such as maximum payload capacity, range, speed, and battery type. For instance, a scooter with a 1000-watt motor and a range of 20 miles may be ideal for urban deliveries, while a lower capacity might suffice for shorter, lighter tasks.

Step 2: Research Market Trends and Regulations

Understanding market trends can help you identify the most suitable cargo scooter models and features that resonate with your target audience. Additionally, familiarize yourself with local regulations regarding electric scooters in your region, as compliance is critical for legal operation. Check if there are any specific safety standards or certifications required for your market, such as UL2272 compliance.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their production capacity, quality control measures, and after-sales support to ensure they can meet your demands consistently.

– Look for: Established suppliers with a track record of reliability and positive customer feedback.

Step 4: Request Product Samples

Once you have shortlisted potential suppliers, request samples of the cargo scooters to evaluate their quality and performance. Testing the products allows you to assess comfort, durability, and functionality firsthand. Ensure that the scooters align with your defined specifications and can withstand the intended use.

– Key aspects to test: Battery life, ease of use, and loading capacity.

Step 5: Verify Supplier Certifications

Supplier certifications are a vital aspect of ensuring product quality and safety. Confirm that the scooters comply with relevant safety and environmental standards. Certifications like ISO 9001 (quality management) and CE marking (European compliance) can provide assurance of the supplier’s commitment to quality.

– Important certifications: UL2272 for electrical safety and other local compliance marks.

Step 6: Negotiate Terms and Conditions

Negotiating favorable terms can lead to a beneficial partnership for both parties. Discuss pricing, payment terms, delivery timelines, and warranty conditions. It’s also wise to clarify return policies and service level agreements to mitigate risks associated with product defects or delays.

– Consider: Bulk purchase discounts or long-term partnership agreements for better pricing.

Step 7: Plan for After-Sales Support and Maintenance

Post-purchase support is essential for maintaining the performance of your cargo scooters. Ensure that your supplier offers adequate after-sales service, including maintenance, spare parts availability, and customer support. A reliable support system can help minimize downtime and enhance the longevity of your investment.

– Evaluate: The supplier’s commitment to ongoing support and training for your operational team.

By following these steps, B2B buyers can effectively navigate the sourcing process for cargo scooters, ensuring that they select the right products and suppliers to meet their business needs.

Comprehensive Cost and Pricing Analysis for cargo scooter Sourcing

What Are the Key Cost Components in Cargo Scooter Manufacturing?

When sourcing cargo scooters, understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. High-quality components such as lithium-ion batteries, durable frames (often made of steel or aluminum), and advanced electronics contribute to a higher base cost. Buyers should evaluate the balance between cost and quality, particularly if they are targeting markets that demand robust performance.

-

Labor: Labor costs can vary widely based on the manufacturing location. For instance, labor in Southeast Asia may be lower than in Europe, affecting overall pricing. Understanding local wage rates and labor practices can help buyers gauge the potential costs involved in production.

-

Manufacturing Overhead: This includes expenses such as utilities, facility maintenance, and administrative costs. Efficient production processes can minimize these overheads, which can be crucial for maintaining competitive pricing.

-

Tooling: Custom tooling for specific scooter designs can require significant upfront investment. Buyers should consider whether they can leverage existing tooling or if new investments are necessary, as this will affect initial costs.

-

Quality Control (QC): Implementing stringent QC measures can increase costs but is essential for ensuring product reliability and safety, particularly for cargo scooters that may be subjected to heavy use. Buyers should inquire about the QC processes employed by manufacturers.

-

Logistics: Shipping costs can vary dramatically depending on the origin and destination. Factors such as distance, shipping method, and packaging can all influence logistics costs. Understanding the total logistics footprint is vital for accurate cost estimation.

-

Margin: Manufacturers typically include a profit margin in their pricing, which can vary based on market conditions and competition. Buyers should consider the margin when evaluating supplier quotes.

How Do Price Influencers Affect Cargo Scooter Sourcing?

Several factors influence the pricing of cargo scooters, which B2B buyers should keep in mind:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchasing often leads to discounts, making it essential for buyers to negotiate favorable terms based on volume. Understanding the MOQ requirements can also help in planning inventory and cash flow.

-

Specifications and Customization: Custom features, such as upgraded battery capacity or specialized cargo attachments, can increase costs. Buyers should clarify their specifications upfront to avoid unexpected charges.

-

Material Quality and Certifications: Higher-quality materials and certifications (such as UL or CE) can drive up costs but may be necessary for compliance in certain markets. Buyers need to assess the importance of these certifications in their target regions.

-

Supplier Factors: The reputation and reliability of suppliers play a crucial role in pricing. Established suppliers with a track record may command higher prices due to their proven quality and service.

-

Incoterms: The terms of sale (Incoterms) can significantly affect overall costs. Buyers should understand which party is responsible for shipping, insurance, and customs duties to avoid hidden costs.

What Tips Can Help B2B Buyers Optimize Their Cargo Scooter Procurement?

To enhance cost-efficiency in sourcing cargo scooters, consider the following strategies:

-

Negotiation: Effective negotiation can lead to better pricing and terms. Buyers should be prepared with market data and competitor pricing to leverage during discussions.

-

Total Cost of Ownership: Instead of focusing solely on the purchase price, consider the total cost of ownership, which includes maintenance, operational costs, and potential resale value. This holistic view can guide better long-term investment decisions.

-

Pricing Nuances for International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, tariffs, and import duties that can affect overall pricing. It’s advisable to engage local experts who understand the nuances of each market.

-

Request for Proposals (RFPs): Issuing RFPs to multiple suppliers can create competition and lead to more favorable pricing. Ensure that RFPs clearly outline specifications and expectations to receive accurate quotes.

By understanding these components and strategies, B2B buyers can make informed decisions and optimize their cargo scooter sourcing process, ensuring they receive the best value for their investment.

Alternatives Analysis: Comparing cargo scooter With Other Solutions

Understanding Alternatives to Cargo Scooters for Efficient Transportation

In today’s rapidly evolving logistics and transportation landscape, businesses are increasingly exploring various solutions to meet their cargo delivery needs. Cargo scooters have emerged as a popular choice, but it is essential for B2B buyers to consider viable alternatives that may offer distinct advantages depending on specific requirements, such as cost, performance, and operational efficiency. Below, we compare cargo scooters with two alternative solutions: electric cargo bikes and traditional delivery vans.

Comparison Table

| Comparison Aspect | Cargo Scooter | Electric Cargo Bike | Traditional Delivery Van |

|---|---|---|---|

| Performance | Up to 20 mph, range of 15-20 miles | Up to 28 mph, range of 30-50 miles | Up to 60 mph, range varies significantly |

| Cost | $369.99 – $1,299.99 | $800 – $3,000 | $25,000 – $50,000 |

| Ease of Implementation | Easy to store and transport; minimal setup required | Moderate; requires basic assembly | Requires dedicated space and training |

| Maintenance | Low maintenance; battery checks needed | Moderate; battery and tire maintenance | High; regular servicing and fuel costs |

| Best Use Case | Short-distance urban deliveries | Longer distance, multi-stop deliveries | Bulk deliveries over larger distances |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Electric Cargo Bikes?

Electric cargo bikes are increasingly gaining traction in urban environments. They offer a higher speed and longer range compared to cargo scooters, making them suitable for longer deliveries. Their ability to navigate through traffic and tight spaces makes them ideal for city logistics. However, their higher cost and the need for more maintenance (such as battery and tire upkeep) can be a drawback for some businesses. Additionally, the larger frame of cargo bikes may not be suitable for all types of cargo.

How Do Traditional Delivery Vans Compare to Cargo Scooters?

Traditional delivery vans provide a high level of cargo capacity and speed, making them perfect for bulk deliveries over long distances. They are capable of transporting a wide variety of goods and can carry heavier loads compared to cargo scooters. However, the operational costs are significantly higher, including fuel, insurance, and maintenance. Additionally, navigating congested urban areas can be challenging for larger vehicles, potentially leading to delays in delivery times.

Conclusion: Choosing the Right Solution for Your Business Needs

When selecting the best transportation solution for your business, consider the specific requirements of your logistics operations. If your focus is on cost-effective, short-distance deliveries, cargo scooters may be the ideal choice. However, if you need to cover longer distances with a larger payload, electric cargo bikes might serve you better. For bulk deliveries over extensive areas, traditional delivery vans will likely be necessary, despite their higher operational costs. Assessing your operational needs, budget constraints, and delivery goals will enable you to make an informed decision that aligns with your business strategy.

Essential Technical Properties and Trade Terminology for cargo scooter

What Are the Essential Technical Properties of Cargo Scooters?

When considering cargo scooters for business use, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some key properties:

1. Motor Power (Wattage)

The power of the motor is typically measured in watts (W). Cargo scooters range from 300W to over 1000W. A higher wattage indicates greater torque and the ability to carry heavier loads, which is essential for businesses that require efficient transport of goods. This specification directly impacts performance, especially on inclines or rough terrains.

2. Payload Capacity

Payload capacity refers to the maximum weight a cargo scooter can safely carry. This is usually expressed in pounds (lbs) or kilograms (kg) and can range from 120 lbs to over 300 lbs. For B2B buyers, knowing the payload capacity ensures that the scooter can handle the intended cargo without compromising safety or performance.

3. Range (Distance per Charge)

The range of a cargo scooter indicates how far it can travel on a single battery charge, typically measured in miles or kilometers. A range of 15 to 20 miles is common in many models. This is a critical factor for logistics operations, as it determines the scooter’s suitability for specific delivery routes and overall efficiency.

4. Battery Type and Voltage

Most cargo scooters utilize lithium-ion batteries, with voltage ratings ranging from 36V to 48V. The battery type affects the scooter’s longevity, charging time, and overall performance. For businesses, understanding battery specifications helps in planning maintenance and operational costs.

5. Brake System

The braking system is vital for safety and performance. Common systems include disc brakes and drum brakes. A reliable brake system ensures quick stopping, particularly when carrying heavy loads. For B2B buyers, this specification is crucial to ensure compliance with safety regulations and to protect both riders and cargo.

What Are Common Trade Terms Related to Cargo Scooters?

Understanding industry jargon is equally important for effective communication and negotiation with suppliers. Here are some essential terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of cargo scooters, an OEM may provide specific components, like motors or batteries, to scooter manufacturers. For B2B buyers, knowing OEMs can help in sourcing reliable parts for maintenance or customization.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest amount of a product that a supplier is willing to sell. This term is vital for B2B buyers, as it helps in determining the initial investment required for bulk orders. Understanding MOQs can lead to cost savings and better inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers should use RFQs to compare costs and conditions across different suppliers, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping, insurance, and liability, which can significantly impact overall costs.

5. Warranty and After-Sales Support

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. Understanding warranty terms is critical for B2B buyers to ensure long-term support and maintenance, which can affect operational uptime and overall satisfaction with the cargo scooters.

By grasping these technical properties and trade terms, international B2B buyers can make well-informed decisions, ensuring that their cargo scooter purchases align with their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the cargo scooter Sector

What Are the Current Market Dynamics and Key Trends in the Cargo Scooter Sector?

The cargo scooter market is experiencing robust growth driven by urbanization, rising fuel costs, and the demand for efficient last-mile delivery solutions. Particularly in emerging markets like Africa, South America, the Middle East, and parts of Europe, businesses are increasingly recognizing the advantages of electric cargo scooters for local logistics and transport. The global shift towards eco-friendly transportation is fostering innovations in battery technology and electric drivetrains, which are becoming pivotal in the design and functionality of these scooters.

Emerging trends include the integration of smart technologies, such as IoT for fleet management and tracking, which enhances operational efficiency and reduces costs. Additionally, modular designs with customizable features are gaining traction, allowing businesses to adapt scooters for various cargo types and usage scenarios. As international B2B buyers, particularly from regions like Nigeria and Vietnam, assess their sourcing strategies, it is essential to consider suppliers that offer flexible configurations and robust after-sales support to ensure operational reliability.

Furthermore, regulatory changes aimed at promoting sustainable urban transport are likely to shape market dynamics. The introduction of incentives for electric vehicle adoption and stricter emissions regulations are pushing companies to explore electric cargo scooters as a viable alternative to traditional vehicles. Buyers should stay informed about local policies that may affect the adoption of electric scooters, ensuring their procurement strategies align with regulatory frameworks.

How Can Sustainability and Ethical Sourcing Be Integrated into B2B Strategies for Cargo Scooters?

Sustainability is increasingly becoming a non-negotiable factor for businesses in the cargo scooter sector. The environmental impact of logistics operations necessitates a shift towards greener solutions. Electric cargo scooters, which produce zero emissions at the point of use, are an integral part of this transition. However, the sustainability narrative extends beyond the product itself; it encompasses the entire supply chain.

Ethical sourcing is crucial in mitigating environmental damage and ensuring compliance with social responsibility standards. B2B buyers should prioritize suppliers that adhere to sustainable practices, including the use of eco-friendly materials and ethical labor practices. Certifications such as ISO 14001 for environmental management or UL2272 for safety standards are indicators of responsible manufacturing processes.

Moreover, buyers should inquire about the lifecycle of the products they source, focusing on recyclability and the use of renewable resources in production. Collaborating with manufacturers who are committed to sustainability not only enhances brand reputation but also meets the growing consumer demand for environmentally responsible products.

What Is the Brief Evolution of the Cargo Scooter Market?

The cargo scooter market has evolved significantly over the past decade, transitioning from simple two-wheeled vehicles to sophisticated electric-powered scooters equipped with advanced technology. Initially designed for recreational use, scooters have now carved out a niche in urban logistics, especially in densely populated cities where traffic congestion and pollution are prevalent.

The rise of e-commerce has further accelerated this evolution, with businesses seeking efficient and cost-effective solutions for last-mile delivery. Innovations in battery technology and electric motors have enhanced the performance and range of cargo scooters, making them suitable for diverse applications—from food delivery to transporting goods in bustling urban centers.

As the market continues to mature, the focus is shifting towards integrating smart technology and sustainability, ensuring that cargo scooters not only meet the demands of modern logistics but also contribute to a greener future. This evolution presents a wealth of opportunities for international B2B buyers looking to invest in sustainable transport solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of cargo scooter

-

How do I choose the right cargo scooter for my business needs?

Selecting the right cargo scooter involves assessing your specific operational requirements. Consider factors such as load capacity, range, and speed. For example, if your delivery routes are short and require carrying heavier loads, a scooter with a higher payload capacity and robust motor is essential. Additionally, evaluate the terrain you’ll be navigating; scooters with larger tires and better suspension are ideal for rough surfaces. Lastly, look for customizable options that can adapt to different cargo types, ensuring versatility in your fleet. -

What features should I prioritize in a cargo scooter for urban logistics?

When sourcing cargo scooters for urban logistics, prioritize features that enhance efficiency and safety. Key elements include a powerful motor for quick acceleration, a significant range to minimize recharging downtime, and a durable design to withstand daily use. Safety features like LED lights, reliable braking systems, and a stable frame are critical for navigating busy city streets. Furthermore, a convertible rack or storage system can enhance cargo flexibility, allowing for the transport of various goods or even passengers. -

What is the minimum order quantity (MOQ) for cargo scooters?

The minimum order quantity (MOQ) for cargo scooters can vary significantly based on the manufacturer and the specific model. Typically, MOQs range from 10 to 100 units for bulk purchases. It’s advisable to negotiate with suppliers to find a quantity that meets your budget and operational needs. Additionally, consider the potential for volume discounts, which can make larger orders more financially viable. Always confirm the MOQ details before finalizing your procurement strategy. -

How can I vet suppliers for cargo scooters effectively?

To vet suppliers for cargo scooters, conduct thorough research and due diligence. Check for certifications such as ISO or UL that indicate adherence to quality and safety standards. Request references or case studies from previous clients to gauge reliability and service levels. Additionally, evaluate their production capacity and supply chain logistics to ensure they can meet your demand consistently. Visiting manufacturing facilities, if feasible, can provide deeper insights into their operational practices and product quality. -

What payment terms are commonly offered by cargo scooter suppliers?

Payment terms can vary widely among suppliers, but common options include net 30, 50% upfront with the remainder upon delivery, or full payment in advance. It’s crucial to discuss and negotiate these terms upfront to ensure they align with your cash flow needs. Some suppliers may also offer financing options or payment plans for larger orders. Always ensure that payment terms are clearly documented in your contract to avoid misunderstandings later. -

What customization options are available for cargo scooters?

Many manufacturers offer customization options for cargo scooters to meet specific business needs. Customizations can include alterations to payload capacity, battery specifications, or the addition of specialized storage racks. Branding opportunities, such as applying your company logo or custom colors, can also enhance brand visibility. Discuss your requirements with potential suppliers to understand the extent of customization available and any associated costs or lead times. -

How do I ensure quality assurance for bulk cargo scooter purchases?

To ensure quality assurance for bulk cargo scooter purchases, establish clear quality standards in your contract with suppliers. Request samples or prototypes to evaluate before committing to a full order. Additionally, consider implementing a third-party inspection service to assess the scooters during production and before shipment. Regular communication with the supplier throughout the manufacturing process can help address any potential quality issues early on. -

What logistics considerations should I keep in mind when importing cargo scooters?

When importing cargo scooters, logistics considerations are crucial to ensure timely and cost-effective delivery. Assess shipping options, including air freight for faster delivery or sea freight for cost savings, and factor in customs clearance processes. Understanding local regulations regarding vehicle imports, including safety and environmental standards, is essential. Collaborating with a logistics partner familiar with your target markets can facilitate smoother operations and mitigate potential delays.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Cargo Scooter Manufacturers & Suppliers List

1. Hover-1 – Alpha Cargo E-Scooter

Domain: hover-1.com

Registered: 2016 (9 years)

Introduction: {‘name’: ‘Hover-1™ Alpha Cargo E-Scooter’, ‘price’: ‘$349.99’, ‘original_price’: ‘$449.99’, ‘features’: {‘motor_power’: ‘300W rated / 450W peak’, ‘max_speed’: ’16 mph’, ‘range’: ’15 miles’, ‘max_weight’: ‘220 lbs (100 kg)’, ‘battery’: ’36V/7.5Ah’, ‘tire_size’: ’12 inch’, ‘seat’: ‘cushioned leather’, ‘basket’: ‘integrated oversized basket’, ‘headlight’: ‘LED’, ‘weight’: ‘49.3 lbs (22.4 kg)’, ‘dimen…

2. GYROOR – Electric Scooter 800W

Domain: gyroorboard.com

Registered: 2017 (8 years)

Introduction: GYROOR Electric Scooter 800W (Peak) with Removable Large Middle Basket for Pets & Cargo

– Max Speed: 18.6 MPH (30 km/h)

– Max Range: Approx. 20 miles

– Motor Power: Nominal 550W (Peak 800W)

– Battery: 36V 7.8AH Lithium

– Charge Time: 5 hours

– Product Dimensions: 44″L x 9″W x 21″H

– Payload Capacity: 44-265 lbs (20-120 kg)

– Net Weight: 48.5 lbs (22 kg)

– Recommended Age: 12+ years

– Required Heig…

3. Honda – CT125, Piaggio – Apé Xtra 300, Honda – NC750X

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: User is looking for a cargo scooter that can carry tools and has more power than a 150cc scooter. They mention needing a scooter with over 200cc capacity. Suggestions include the Honda CT125 with built-in storage, the Piaggio Apé Xtra 300 trike, and the Honda NC750X motorcycle with onboard storage and automatic transmission. Other mentioned scooters include the Honda Helix and Honda Gyro. The user…

4. Barotrauma – Cargo Scooter

Domain: barotraumagame.com

Registered: 2018 (7 years)

Introduction: {“name”: “Cargo Scooter”, “type”: “Underwater Scooter”, “description”: “A battery-powered underwater propulsion device and container designed for transporting materials underwater. It allows for faster travel in water and provides light while doing so, with a storage capacity similar to a Storage Container.”, “energy_source”: “Battery Cell or Fulgurium Battery Cell”, “energy_capacity”: “1 Battery …

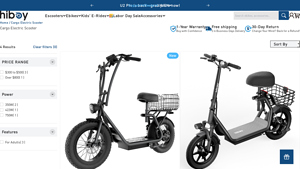

5. Hiboy – Cargo Electric Scooters

Domain: hiboy.com

Registered: 2003 (22 years)

Introduction: Cargo Electric Scooter

– Models Available: Hiboy U2 Pro, Hiboy Q2, Hiboy ECOM 14, Hiboy ECOM 14 Refurbished

– Power: 350W (2 models), 422W (1 model), 750W (1 model)

– Speed: Up to 22 mph (Hiboy ECOM 14), 20 mph (Hiboy Q2), 25 mph (Hiboy U2 Pro)

– Range: Up to 31 miles (Hiboy ECOM 14), 22 miles (Hiboy Q2), 34 miles (Hiboy U2 Pro)

– Price Range: $300 to $500 (3 models), Over $800 (1 model)

– Feature…

6. EV4 – EV4 Cargo Scooter

Domain: ev4.pl

Registered: 2014 (11 years)

Introduction: {“product_name”: “EV4 Cargo Scooter”, “versions”: [“Standing”, “Seated”], “intended_use”: “Transporting small packages and cargo”, “max_cargo_weight”: “40 kg”, “standard_motor”: {“power”: “250W brushless motor”, “battery”: “36V, 10Ah lithium-ion”}, “optional_motor”: {“power”: “500W brushless motor”, “battery”: “48V, 21Ah lithium-ion”}, “construction”: “Aviation grade aluminium”, “speed”: “20 km/h”…

Strategic Sourcing Conclusion and Outlook for cargo scooter

How Can Strategic Sourcing Maximize Your Cargo Scooter Investments?

In today’s competitive landscape, strategic sourcing is critical for international B2B buyers looking to leverage cargo scooters as a sustainable and efficient transport solution. By focusing on key factors such as performance specifications, range, and adaptability, businesses can identify scooters that align with their operational needs. For instance, options like the EcoSmart Cargo and Gyroor models provide versatile configurations for cargo transportation, making them suitable for various applications across diverse markets.

Moreover, understanding the different motor capacities and battery life can help buyers select scooters that maximize productivity while minimizing downtime. The importance of reliable suppliers cannot be overstated; partnering with manufacturers who prioritize quality and offer robust warranties can safeguard your investment.

Looking ahead, the demand for eco-friendly transportation solutions will only continue to grow, particularly in regions like Africa and South America, where urbanization is accelerating. As you evaluate your sourcing strategies, consider how cargo scooters can enhance your logistics and last-mile delivery capabilities. Embrace this opportunity to innovate your fleet—connect with trusted suppliers today to position your business for future success in a rapidly evolving market.