Introduction: Navigating the Global Market for electric truck lithium battery

In an era where sustainability and efficiency drive the logistics and transportation sectors, the demand for electric truck lithium batteries is surging. As international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, you face the challenge of sourcing reliable and high-performance lithium battery solutions that meet your operational needs. This guide is designed to navigate you through the complexities of the global market for electric truck lithium batteries, offering insights into various battery types, their applications, and the critical factors for supplier vetting.

Throughout this comprehensive resource, you will explore the diverse applications of lithium batteries in electric trucks, from enhancing auxiliary power units to supporting heavy-duty operations. We will also discuss cost considerations, performance metrics, and maintenance requirements that are essential for making informed purchasing decisions. By equipping you with actionable insights and detailed analyses, this guide empowers you to select the right lithium battery solutions that align with your business objectives, ensuring operational efficiency and sustainability in your fleet.

As you delve deeper, you’ll find valuable information tailored to your specific market needs, enabling you to navigate the intricacies of sourcing electric truck lithium batteries with confidence. Whether you’re in Saudi Arabia, Nigeria, or beyond, understanding these dynamics will position you to make strategic investments in your fleet’s future.

Understanding electric truck lithium battery Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lithium Iron Phosphate (LFP) | Excellent thermal stability, long cycle life, deep discharge capability | Long-haul trucking, auxiliary power units | Pros: Safety, longevity, lower maintenance. Cons: Lower energy density compared to other types. |

| Lithium Nickel Manganese Cobalt (NMC) | High energy density, balanced performance, versatile applications | Electric trucks, delivery vehicles | Pros: High capacity, efficient. Cons: Higher cost, potential thermal runaway risk. |

| Lithium Cobalt Oxide (LCO) | High energy density, compact size | Light-duty electric trucks, urban delivery | Pros: Lightweight, excellent performance. Cons: Shorter lifespan, less safe under stress. |

| Lithium Polymer (LiPo) | Flexible form factor, lightweight | Specialty vehicles, drones, sports applications | Pros: Customizable shapes, high discharge rates. Cons: Sensitive to temperature, requires careful handling. |

| Lithium Titanate (LTO) | Ultra-fast charging, long cycle life, high safety | Heavy-duty applications, public transport | Pros: Rapid recharge, excellent durability. Cons: Lower energy density, higher upfront cost. |

What Are the Characteristics and Suitability of Lithium Iron Phosphate (LFP) Batteries for Electric Trucks?

Lithium Iron Phosphate (LFP) batteries are favored for their exceptional thermal stability and safety, making them a reliable choice for long-haul trucking and auxiliary power units. Their ability to endure deep discharges without damage allows for extended usage between charges. B2B buyers should consider LFP batteries for applications requiring longevity and minimal maintenance, despite their lower energy density compared to other lithium types, which may necessitate larger battery packs for equivalent energy output.

How Do Lithium Nickel Manganese Cobalt (NMC) Batteries Serve the Electric Truck Market?

Lithium Nickel Manganese Cobalt (NMC) batteries strike a balance between high energy density and performance, making them suitable for electric trucks and delivery vehicles. Their versatility allows them to cater to various operational needs while maintaining efficiency. However, B2B buyers should weigh the higher cost and potential thermal runaway risks against their benefits, particularly in applications where weight and space are at a premium.

What Advantages Do Lithium Cobalt Oxide (LCO) Batteries Offer for Light-Duty Electric Trucks?

Lithium Cobalt Oxide (LCO) batteries are known for their high energy density and compact size, making them ideal for light-duty electric trucks and urban delivery applications. Their lightweight nature enhances vehicle performance, but B2B buyers must be aware of their shorter lifespan and safety concerns under high-stress conditions. Choosing LCO batteries may be beneficial for businesses focused on maximizing payload capacity and efficiency in urban settings.

How Are Lithium Polymer (LiPo) Batteries Used in Specialty Electric Vehicles?

Lithium Polymer (LiPo) batteries offer a flexible form factor and lightweight properties, making them suitable for specialty vehicles and applications like drones and sports. Their customizable shapes allow for creative designs in limited spaces, but B2B buyers should consider their sensitivity to temperature and handling requirements. LiPo batteries are ideal for businesses looking for high discharge rates in compact applications, but careful management is essential to ensure safety and longevity.

What Are the Benefits of Lithium Titanate (LTO) Batteries for Heavy-Duty Applications?

Lithium Titanate (LTO) batteries are recognized for their ultra-fast charging capabilities and long cycle life, making them particularly advantageous for heavy-duty applications and public transport systems. Their high safety profile adds to their appeal, though their lower energy density and higher upfront costs may deter some buyers. B2B customers should consider LTO batteries for operations that prioritize quick turnaround times and durability, especially in demanding environments.

Key Industrial Applications of electric truck lithium battery

| Industry/Sector | Specific Application of Electric Truck Lithium Battery | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Transportation | Auxiliary Power Units (APUs) in long-haul trucks | Reduces fuel consumption by eliminating engine idling, leading to significant cost savings. | Ensure compatibility with existing truck systems and check for local regulations regarding battery disposal and recycling. |

| Construction | Powering electric construction vehicles | Provides reliable, high-capacity energy storage for heavy machinery, enhancing productivity and reducing downtime. | Assess battery performance in extreme weather conditions, particularly in regions with high temperatures or humidity. |

| Public Transportation | Electric buses and coaches | Lowers operational costs through reduced maintenance and fuel expenses while contributing to sustainability goals. | Evaluate battery lifecycle and warranty terms, and ensure compliance with safety standards specific to passenger transport. |

| Agriculture | Electric farm vehicles | Supports sustainable farming practices by reducing emissions and improving efficiency in field operations. | Investigate local agricultural regulations and availability of charging infrastructure in rural areas. |

| Mining | Electric haul trucks | Improves operational efficiency and reduces environmental impact by minimizing diesel emissions. | Consider battery weight and size, as well as compatibility with mining equipment and terrain challenges. |

How Are Electric Truck Lithium Batteries Used in Logistics and Transportation?

In the logistics sector, electric truck lithium batteries are primarily utilized in Auxiliary Power Units (APUs) within long-haul trucks. These batteries allow for the operation of HVAC systems and other electrical appliances without the need for idling the truck’s engine. This not only helps in reducing fuel consumption but also extends the lifespan of the engine by minimizing wear and tear. Buyers in this sector should focus on sourcing batteries that are compatible with their fleet’s specifications and consider local regulations concerning battery recycling.

What Are the Benefits of Electric Truck Lithium Batteries in Construction?

Electric truck lithium batteries are integral to powering electric construction vehicles, providing a stable and robust energy source for machinery such as excavators and cranes. The use of these batteries enhances productivity by ensuring that equipment can operate for extended periods without interruption. For international buyers, especially in regions with fluctuating temperatures, it is essential to assess the battery’s performance under extreme conditions and ensure that it meets local operational standards.

How Do Electric Truck Lithium Batteries Support Public Transportation?

In public transportation, electric buses and coaches leverage electric truck lithium batteries to deliver energy-efficient solutions that significantly lower operational costs. The batteries enable these vehicles to run longer distances on a single charge, thus enhancing service reliability. Buyers should evaluate the lifecycle of the batteries and the warranty terms to ensure long-term viability, while also ensuring compliance with safety standards specific to passenger transport.

Why Are Electric Truck Lithium Batteries Important for Agriculture?

Electric truck lithium batteries are increasingly being adopted in electric farm vehicles, contributing to more sustainable agricultural practices. These batteries facilitate efficient field operations while reducing harmful emissions associated with traditional diesel-powered equipment. For agricultural buyers, it is critical to investigate local regulations regarding emissions and the availability of charging infrastructure, particularly in rural areas where such resources may be limited.

How Do Electric Truck Lithium Batteries Enhance Mining Operations?

In the mining industry, electric haul trucks equipped with lithium batteries offer improved operational efficiency and a significant reduction in environmental impact due to lower diesel emissions. The powerful energy storage capabilities of these batteries enable continuous operation in challenging terrains. Buyers must consider the weight and size of the batteries to ensure they meet the operational demands of mining equipment while also evaluating compatibility with existing machinery.

3 Common User Pain Points for ‘electric truck lithium battery’ & Their Solutions

Scenario 1: Limited Power Capacity for Long-Haul Operations

The Problem:

B2B buyers in the trucking industry often face the challenge of insufficient power capacity in electric truck lithium batteries, especially during long-haul operations. Drivers may find themselves unable to power essential equipment in sleeper cabs for extended periods without resorting to idling the engine, which is both inefficient and costly. This limitation not only affects driver comfort but also impacts overall productivity and operational costs, as idling consumes fuel and can lead to increased wear and tear on the vehicle.

The Solution:

To address this issue, buyers should consider investing in lithium batteries that offer significantly higher energy density and longer runtime compared to traditional lead-acid batteries. For instance, lithium iron phosphate (LiFePO4) batteries can provide double the runtime for auxiliary power units (APUs), enabling drivers to use HVAC systems, appliances, and electronic devices without the need to idle the engine. When sourcing these batteries, it’s crucial to ensure compatibility with existing truck systems and to opt for models designed for deep discharge applications. Additionally, integrating smart battery management systems that offer real-time monitoring can help optimize battery usage, providing insights on remaining power and charging cycles. This proactive approach not only enhances driver comfort but also contributes to substantial fuel savings and reduced maintenance costs.

Scenario 2: High Replacement Costs Due to Short Battery Lifespan

The Problem:

Many B2B buyers are deterred by the high replacement costs associated with traditional battery systems, which typically have a limited lifespan of 1-2 years and can require frequent replacements. This recurring expense can significantly impact the overall budget for fleet operations, particularly for companies with large fleets or those operating in remote areas where battery replacement logistics can be complicated.

The Solution:

Investing in high-quality lithium batteries can mitigate these costs effectively. Unlike conventional batteries, lithium batteries, particularly those utilizing LiFePO4 technology, can endure up to 2,000 charge cycles and maintain operational efficiency for 5-10 years. When selecting batteries, it is essential to analyze the total cost of ownership, including maintenance, replacement frequency, and performance longevity. Buyers should also explore bulk purchasing options or partnerships with manufacturers to secure favorable pricing and warranties. Additionally, considering batteries with built-in diagnostic tools can help in monitoring battery health and performance, enabling early identification of potential issues before they lead to failures and costly replacements.

Scenario 3: Environmental Regulations and Sustainability Concerns

The Problem:

As environmental regulations become stricter globally, B2B buyers must adapt to increasing pressure to reduce emissions and improve sustainability within their fleets. This challenge is particularly pronounced in regions with ambitious climate goals, where traditional diesel-powered trucks are being phased out in favor of electric alternatives. Buyers face the difficulty of transitioning to electric trucks while ensuring that their battery solutions align with sustainability initiatives.

The Solution:

To navigate this landscape, buyers should prioritize sourcing electric truck lithium batteries that not only comply with environmental standards but also contribute to sustainability efforts. Selecting lithium batteries with a longer lifespan and lower carbon footprint can significantly enhance the overall sustainability of fleet operations. Additionally, buyers should consider the recyclability of battery components and partner with manufacturers that have strong sustainability practices in place. Incorporating energy management systems that optimize battery usage can further enhance efficiency, reducing the environmental impact. Engaging with suppliers who offer transparent reporting on battery lifecycle and environmental impact can also help businesses demonstrate compliance and commitment to sustainability in their operations.

Strategic Material Selection Guide for electric truck lithium battery

What Are the Key Materials Used in Electric Truck Lithium Batteries?

Electric truck lithium batteries predominantly utilize several key materials, each with unique properties and implications for performance, cost, and international compliance. Understanding these materials is crucial for B2B buyers seeking reliable and efficient battery solutions.

Lithium Iron Phosphate (LiFePO4) – A Reliable Choice for Performance

Key Properties:

LiFePO4 batteries are renowned for their thermal stability and safety. They can operate effectively at high temperatures and have a lower risk of thermal runaway compared to other lithium chemistries. Additionally, they exhibit excellent cycle life, often exceeding 2,000 charge cycles.

Pros & Cons:

The durability of LiFePO4 batteries is a significant advantage, as they can withstand deep discharges without damage. However, they tend to have a lower energy density compared to other lithium options, which can limit their application in weight-sensitive scenarios. Manufacturing complexity is moderate, making them relatively accessible in terms of production.

Impact on Application:

LiFePO4 batteries are particularly suitable for applications requiring high discharge rates, such as electric trucks used for heavy hauling. Their compatibility with various charging systems makes them versatile for international markets.

Considerations for International Buyers:

For buyers in regions like Africa and South America, the availability of LiFePO4 batteries is increasing, but compliance with local standards (such as ASTM and DIN) should be verified. Additionally, the preference for safety and longevity in battery life aligns well with regional operational demands.

Nickel Manganese Cobalt (NMC) – Balancing Performance and Cost

Key Properties:

NMC batteries offer a high energy density, making them suitable for applications where weight and space are critical. They perform well under a range of temperatures and have good thermal stability.

Pros & Cons:

The primary advantage of NMC batteries is their balance between performance and cost, providing a good compromise between energy density and longevity. However, they are more expensive to manufacture due to the complexity of sourcing and processing nickel, manganese, and cobalt.

Impact on Application:

NMC batteries are ideal for electric trucks that require longer ranges and higher power outputs. Their compatibility with advanced battery management systems enhances their performance in demanding applications.

Considerations for International Buyers:

Buyers from Europe and the Middle East may face stricter regulations regarding cobalt sourcing due to ethical concerns. Understanding the supply chain and ensuring compliance with international standards is critical for procurement.

Lithium Nickel Cobalt Aluminum Oxide (NCA) – High Performance for Specialized Applications

Key Properties:

NCA batteries are known for their high energy density and excellent lifecycle performance. They can operate efficiently at elevated temperatures and have a long lifespan.

Pros & Cons:

The key advantage of NCA is its superior energy density, making it suitable for high-performance electric trucks. However, the reliance on cobalt raises concerns regarding supply chain sustainability and cost volatility.

Impact on Application:

NCA batteries are particularly suited for high-performance applications, such as electric trucks requiring rapid acceleration and extended range. Their specific media compatibility makes them a preferred choice for specialized vehicles.

Considerations for International Buyers:

For buyers in regions like Saudi Arabia and Nigeria, understanding the implications of cobalt sourcing is essential. Compliance with international sustainability standards can influence purchasing decisions.

Graphite – Essential for Anode Materials

Key Properties:

Graphite is commonly used as an anode material in lithium batteries due to its excellent conductivity and stability. It can effectively handle high charge and discharge rates.

Pros & Cons:

Graphite’s durability and cost-effectiveness make it a popular choice. However, its performance can degrade at high temperatures, and sourcing quality graphite can be a challenge.

Impact on Application:

Graphite is crucial for ensuring the efficiency and longevity of electric truck lithium batteries, impacting overall vehicle performance.

Considerations for International Buyers:

Buyers should be aware of the environmental impact of graphite mining and ensure that suppliers adhere to sustainable practices. Compliance with local regulations regarding material sourcing is also essential.

Summary Table of Key Materials for Electric Truck Lithium Batteries

| Material | Typical Use Case for electric truck lithium battery | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium Iron Phosphate (LiFePO4) | Heavy-duty electric trucks requiring safety and longevity | Excellent thermal stability and cycle life | Lower energy density compared to other lithium types | Medium |

| Nickel Manganese Cobalt (NMC) | Long-range electric trucks needing high energy density | Good balance of performance and cost | Higher manufacturing costs due to material complexity | High |

| Lithium Nickel Cobalt Aluminum Oxide (NCA) | High-performance electric trucks with rapid acceleration | Superior energy density | Cobalt supply chain sustainability concerns | High |

| Graphite | Anode material in lithium batteries for electric trucks | Cost-effective and durable | Performance degradation at high temperatures | Low |

This guide serves as a strategic reference for international B2B buyers, helping them make informed decisions regarding material selection for electric truck lithium batteries.

In-depth Look: Manufacturing Processes and Quality Assurance for electric truck lithium battery

What Are the Key Stages in the Manufacturing Process of Electric Truck Lithium Batteries?

The manufacturing of electric truck lithium batteries is a complex process that involves several stages, each critical to ensuring the final product meets performance and safety standards.

Material Preparation: How Are Raw Materials Sourced and Processed?

The first stage involves sourcing high-quality raw materials, including lithium, cobalt, nickel, and graphite. These materials must undergo purification processes to remove impurities that could affect battery performance. Advanced techniques such as hydrometallurgy and pyrometallurgy are commonly employed to extract and refine these materials. For manufacturers targeting international markets, especially in Africa, South America, and the Middle East, sourcing materials from local suppliers can reduce costs and improve supply chain efficiency.

Forming: What Techniques Are Used to Create Battery Cells?

In the forming stage, the purified materials are processed into battery cells. This includes mixing the active materials with binders and solvents to create a slurry, which is then coated onto metal foils. The coated foils are dried and cut into specific dimensions before being stacked or wound into cylindrical or prismatic shapes. Advanced techniques such as laser cutting and automated stacking improve precision and consistency. Manufacturers often utilize robotics in this stage to enhance speed and reduce human error, which is particularly beneficial for large-scale production.

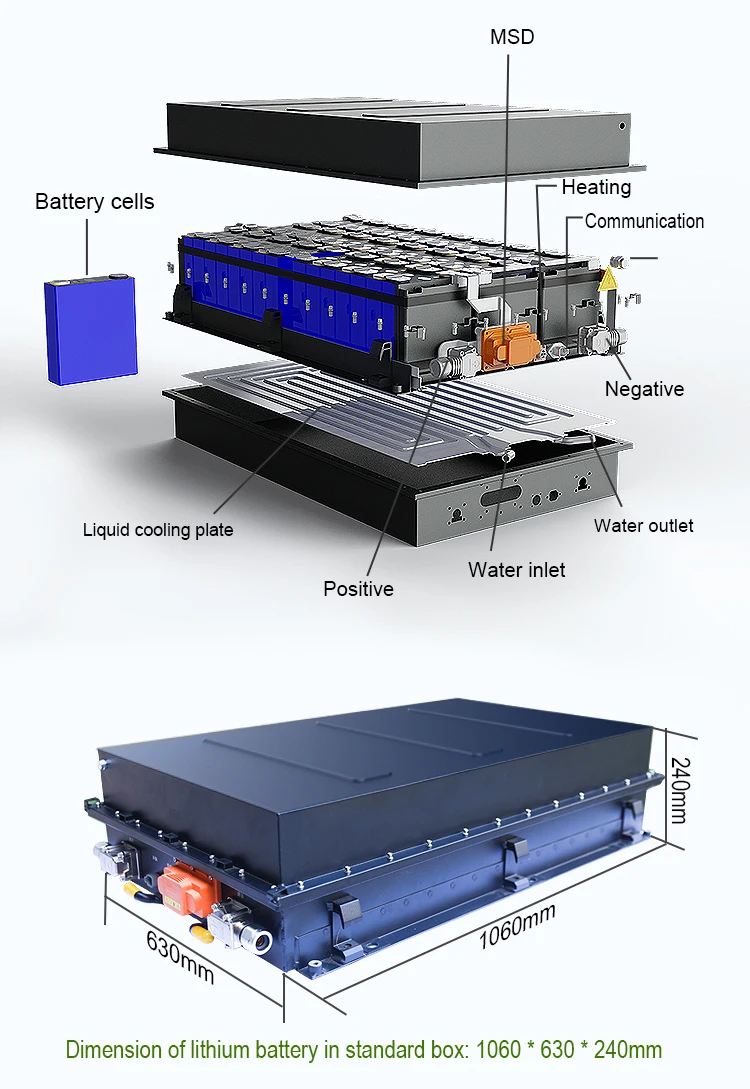

Assembly: How Are Battery Cells Integrated into Packs?

The assembly process integrates multiple battery cells into larger packs, which can be configured to meet specific voltage and capacity requirements for electric trucks. This involves connecting cells with busbars and incorporating protective circuitry to manage energy flow. The assembly must be performed in controlled environments to prevent contamination. Manufacturers often use automated assembly lines to ensure high efficiency and minimize labor costs. For international buyers, understanding the customization capabilities of a manufacturer can be vital for aligning with specific vehicle requirements.

Finishing: What Quality Measures Are Taken Before Shipping?

The finishing stage includes several crucial processes, such as encapsulation and insulation, to enhance the battery’s durability and safety. Thermal management systems may also be integrated to prevent overheating during operation. Before shipping, the batteries undergo a series of tests to confirm they meet regulatory standards and performance specifications. This stage is essential for ensuring that the final product can withstand the rigorous demands of heavy-duty applications.

What Quality Assurance Practices Are Essential for Electric Truck Lithium Batteries?

Quality assurance is a fundamental aspect of the manufacturing process, especially for products like lithium batteries that must adhere to strict safety and performance standards.

Which International Standards Should Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards such as ISO 9001 for quality management systems, which ensures that manufacturers maintain high-quality practices throughout production. Industry-specific certifications like CE for European markets and UL for North American markets are also crucial, as they indicate compliance with safety regulations. For buyers in regions like Africa and South America, understanding local certifications can help ensure the product meets regional compliance requirements.

What Are the Key Quality Control Checkpoints During Production?

Quality control (QC) checkpoints are integral to maintaining product integrity. Typical checkpoints include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, continuous monitoring is conducted to detect any deviations from quality standards.

- Final Quality Control (FQC): Before shipping, the finished batteries undergo rigorous testing, including performance assessments, safety evaluations, and environmental impact analyses.

Buyers should inquire about these checkpoints to ensure that the manufacturer employs a thorough QC process.

What Common Testing Methods Are Used to Ensure Battery Quality?

Common testing methods for electric truck lithium batteries include:

- Capacity Testing: Measures the total energy storage capacity of the battery.

- Cycle Life Testing: Evaluates how many charge-discharge cycles the battery can endure before performance degradation.

- Thermal Stability Testing: Assesses how the battery performs under extreme temperature conditions.

- Short-Circuit Testing: Simulates accidental short-circuit scenarios to ensure safety features function correctly.

These tests are crucial for validating the performance and safety of batteries in real-world applications.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, verifying a supplier’s quality control measures is essential to ensure product reliability. Here are several approaches:

What Role Do Audits and Reports Play in Supplier Verification?

Conducting supplier audits is an effective way to assess the manufacturing processes and QC measures in place. Buyers can request detailed reports on the results of these audits, which should include information on compliance with international standards and any corrective actions taken. This transparency is critical for building trust in the supplier relationship.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing processes. These inspections can occur at various stages, including raw material sourcing, production, and final testing. Third-party certifications can serve as additional assurance that the supplier adheres to industry best practices.

What Are the Specific QC and Certification Nuances for Different Regions?

Different regions have unique regulatory environments that can impact the certification and QC processes. For example, buyers in Europe may need to ensure that products comply with the REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulations, while those in the Middle East may need to adhere to Gulf Standards Organization (GSO) requirements. Understanding these nuances can help buyers navigate the complexities of international trade and ensure compliance with local regulations.

By comprehensively understanding the manufacturing processes and quality assurance practices for electric truck lithium batteries, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to enhanced operational efficiency and product reliability in their fleets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric truck lithium battery’

This guide is designed to assist B2B buyers in the strategic procurement of lithium batteries for electric trucks. As the demand for electric vehicles rises, understanding the nuances of sourcing high-quality lithium batteries is essential for ensuring operational efficiency and cost-effectiveness.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial to ensure that the lithium batteries meet your operational needs. Consider factors such as voltage requirements, capacity (Ah), and compatibility with existing systems. Additionally, identify the expected lifecycle and performance metrics, including charge cycles and discharge rates, to align with your fleet’s usage patterns.

Step 2: Research Industry Standards and Regulations

Familiarize yourself with industry standards and regulations pertinent to lithium batteries in your region. Compliance with safety standards, such as UN 38.3 for transportation, and local environmental regulations is essential to avoid legal complications. Ensure that the products you consider meet these criteria to maintain operational integrity and safety.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s vital to conduct a thorough evaluation. Request detailed company profiles, product specifications, and case studies from businesses that have purchased similar products. Pay attention to their experience in the industry and seek references from buyers in your region to gauge reliability and performance.

Step 4: Verify Supplier Certifications

Confirm that your potential suppliers possess relevant certifications, such as ISO 9001 for quality management and ISO 14001 for environmental management. These certifications indicate a commitment to quality and sustainability, which are particularly important in the growing electric vehicle market. Additionally, check for specific certifications related to battery performance and safety.

Step 5: Assess Warranty and After-Sales Support

A robust warranty and comprehensive after-sales support can significantly impact your long-term satisfaction with the product. Evaluate the terms of the warranty, including duration and coverage for defects or performance issues. Additionally, inquire about the availability of technical support and spare parts, as this can affect downtime and maintenance costs.

Step 6: Compare Pricing and Payment Terms

While price shouldn’t be the sole deciding factor, it’s important to compare costs from multiple suppliers to ensure competitive pricing. Consider the total cost of ownership, which includes installation, maintenance, and potential savings from improved efficiency. Discuss payment terms and financing options, as flexible payment structures can ease cash flow management.

Step 7: Conduct a Trial Purchase

If possible, conduct a trial purchase of a small batch of batteries to evaluate their performance in real-world conditions. This step allows you to assess the quality and reliability of the batteries before committing to a larger order. Monitor their performance closely to ensure they meet your specifications and operational requirements.

By following this checklist, you can navigate the complexities of sourcing electric truck lithium batteries effectively, ensuring a decision that aligns with your operational goals and sustainability objectives.

Comprehensive Cost and Pricing Analysis for electric truck lithium battery Sourcing

What Are the Key Cost Components in Sourcing Electric Truck Lithium Batteries?

When sourcing electric truck lithium batteries, understanding the cost structure is essential for B2B buyers. The primary cost components typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts the overall cost. Lithium iron phosphate (LiFePO4) batteries, for instance, are known for their longevity and safety but can be more expensive than traditional lead-acid batteries. The cost of lithium itself, alongside other raw materials such as cobalt and nickel, can fluctuate based on market demand and geopolitical factors.

-

Labor: Labor costs vary by region and the complexity of the battery manufacturing process. Countries with higher labor costs may yield higher-priced batteries but can also ensure better craftsmanship and quality assurance.

-

Manufacturing Overhead: This encompasses costs related to facilities, utilities, and equipment depreciation. Efficient production methods can help lower these costs, but initial investments in advanced manufacturing technologies may be necessary.

-

Tooling: Tooling costs can be substantial, especially if the batteries require specific molds or machinery for production. Custom tooling for unique battery designs may result in higher upfront costs but could lead to savings in the long run through optimized production.

-

Quality Control (QC): Implementing stringent QC processes ensures that the batteries meet safety and performance standards, which can enhance the supplier’s reputation and reduce warranty claims. However, this adds to the overall cost.

-

Logistics: Shipping costs can vary widely depending on the origin, destination, and shipping method. International buyers should be aware of potential tariffs and customs duties that can affect the final price.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s market position, brand reputation, and the competitive landscape.

How Do Price Influencers Affect Electric Truck Lithium Battery Costs?

Several factors influence the pricing of electric truck lithium batteries, which international buyers must consider:

-

Volume/MOQ: Bulk purchasing often leads to discounted rates. Buyers looking to procure large quantities can negotiate better pricing, making it crucial to assess demand forecasts accurately.

-

Specifications and Customization: Customized battery solutions tailored to specific truck models or operational needs can drive up costs. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: Higher-quality materials and certifications (such as ISO or UL standards) may increase the initial investment but can lead to lower total ownership costs due to enhanced durability and performance.

-

Supplier Factors: The supplier’s reputation, experience, and reliability play a significant role in pricing. Established suppliers may charge a premium but often provide better service and support.

-

Incoterms: Understanding Incoterms is vital for international transactions. These terms define responsibilities and risks associated with shipping, influencing the total landed cost of the batteries.

What Buyer Tips Can Enhance Cost-Efficiency in Battery Sourcing?

To maximize cost-efficiency when sourcing electric truck lithium batteries, consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers regarding pricing and payment terms. Building strong relationships can lead to better deals and more favorable terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront cost. Factors such as battery lifespan, maintenance needs, and efficiency can significantly affect long-term expenses.

-

Pricing Nuances for International Buyers: International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of currency fluctuations, local regulations, and import taxes that can impact pricing. Conduct thorough research on local market conditions and supplier networks.

-

Conduct Market Research: Stay informed about market trends, emerging technologies, and potential shifts in material costs. This knowledge can empower buyers to make informed decisions and negotiate effectively.

Disclaimer on Indicative Prices

Prices for electric truck lithium batteries can vary widely based on the factors mentioned above. Buyers should always request detailed quotes from multiple suppliers and consider all associated costs to arrive at a comprehensive understanding of the pricing landscape.

Alternatives Analysis: Comparing electric truck lithium battery With Other Solutions

Exploring Alternative Solutions for Electric Truck Power Systems

When considering electric truck power systems, lithium batteries are often regarded as the leading technology due to their superior performance and longevity. However, businesses should evaluate alternative solutions to ensure they select the best option for their specific needs. This analysis compares electric truck lithium batteries against two viable alternatives: lead-acid batteries and hydrogen fuel cells. Understanding the strengths and weaknesses of each option can help B2B buyers make informed decisions.

| Comparison Aspect | Electric Truck Lithium Battery | Lead-Acid Battery | Hydrogen Fuel Cell |

|---|---|---|---|

| Performance | High energy density, long cycle life (2,000+ cycles) | Lower energy density, shorter lifespan (200-400 cycles) | High energy density, quick refueling times |

| Cost | Higher upfront cost, lower total cost of ownership | Lower initial cost, higher long-term costs due to frequent replacements | High initial investment, but potential for low operational costs |

| Ease of Implementation | Moderate, requires specialized installation | Easy installation, widely understood technology | Complex, requires infrastructure for hydrogen production and storage |

| Maintenance | Low, minimal upkeep needed | High, frequent replacements and maintenance required | Low, but requires monitoring of hydrogen systems |

| Best Use Case | Long-haul trucking, auxiliary power units | Short-haul, budget-sensitive applications | Fleets requiring rapid refueling and long range |

Understanding the Advantages and Disadvantages of Each Alternative

Lead-Acid Batteries

Lead-acid batteries have been the traditional choice for many trucking applications due to their lower upfront costs and ease of installation. However, they have significant drawbacks, including a shorter lifespan and lower energy density compared to lithium batteries. This means they require more frequent replacements, leading to higher overall costs in the long run. They are suitable for short-haul applications where weight and space are less critical, but they fall short in performance for long-haul trucking where reliability and runtime are essential.

Hydrogen Fuel Cells

Hydrogen fuel cells present an innovative alternative to traditional battery systems. They offer high energy density and quick refueling times, making them suitable for fleets requiring long-range capabilities without lengthy charging periods. However, the technology requires significant investment in infrastructure for hydrogen production and storage, which can be a barrier for many companies. Additionally, while maintenance is low, the complexity of hydrogen systems necessitates specialized knowledge, making them less accessible for some fleet operators.

Making the Right Choice for Your Fleet Needs

Selecting the appropriate power solution for electric trucks depends on various factors, including operational requirements, budget constraints, and long-term strategy. For businesses focused on sustainability and performance, electric truck lithium batteries offer unparalleled benefits in terms of efficiency and lifecycle cost. In contrast, lead-acid batteries may appeal to those prioritizing lower initial costs, while hydrogen fuel cells could be ideal for fleets needing rapid refueling and extended range. Ultimately, understanding the specific needs of your operations will guide you in choosing the best solution for your electric trucking requirements.

Essential Technical Properties and Trade Terminology for electric truck lithium battery

What Are the Key Technical Properties of Electric Truck Lithium Batteries?

When evaluating electric truck lithium batteries, several critical specifications are essential for making informed B2B purchasing decisions. Understanding these properties can help buyers select batteries that meet the demands of their operations.

1. Energy Density (Wh/kg)

Energy density measures the amount of energy stored per unit of weight. High energy density is vital for electric trucks as it allows for longer driving ranges without significantly increasing vehicle weight. This property is crucial for fleet operators who need to maximize efficiency and minimize operational costs.

2. Cycle Life (Number of Charge/Discharge Cycles)

Cycle life indicates how many complete charge and discharge cycles a battery can undergo before its capacity significantly degrades. Lithium batteries typically offer a longer cycle life compared to traditional lead-acid batteries, often exceeding 2,000 cycles. This longevity reduces replacement frequency, leading to lower lifetime costs for businesses.

3. Depth of Discharge (DoD)

Depth of discharge refers to the percentage of the battery’s capacity that has been used. Lithium batteries can sustain higher DoD levels—up to 95%—without damage, unlike lead-acid batteries, which are usually limited to 50%. This capability allows for more usable energy, which is a significant advantage for electric truck operators needing extended power for auxiliary systems.

4. Temperature Range

The operational temperature range indicates the environments in which the battery can function effectively. Electric truck lithium batteries designed for harsh conditions can withstand extreme temperatures, ensuring reliability across diverse climates. This property is particularly important for international buyers operating in regions with varying weather conditions, such as Africa and the Middle East.

5. Charge Time

Charge time is the duration required to fully recharge the battery. Lithium batteries generally offer faster charging capabilities compared to traditional options. Quick recharge times are essential for minimizing downtime in commercial operations, allowing fleets to maintain productivity.

What Are Common Trade Terminologies in the Electric Truck Lithium Battery Industry?

Understanding industry-specific terminology is crucial for effective communication and negotiation in the B2B landscape.

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of electric truck lithium batteries, partnering with reputable OEMs ensures that the batteries meet specific quality and performance standards, which is vital for fleet reliability.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of products that a supplier is willing to sell. Understanding MOQ is essential for buyers, especially those looking to optimize their inventory levels while meeting production demands. It helps in budgeting and supply chain planning.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific goods or services. For B2B buyers, issuing RFQs for electric truck lithium batteries allows for competitive pricing and better negotiation leverage, ensuring they secure the best possible deal.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers as it affects shipping costs, risk, and delivery timelines.

5. Battery Management System (BMS)

A BMS is a system that manages a rechargeable battery’s performance, ensuring optimal functioning and safety. For buyers, understanding BMS features is essential as they impact battery longevity, efficiency, and safety, especially in high-demand applications like electric trucks.

Conclusion

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions regarding electric truck lithium batteries. Understanding these aspects not only enhances procurement strategies but also aligns purchases with operational goals, ultimately contributing to the success of their businesses.

Navigating Market Dynamics and Sourcing Trends in the electric truck lithium battery Sector

What Are the Key Market Trends Influencing the Electric Truck Lithium Battery Sector?

The electric truck lithium battery sector is witnessing significant growth, driven by an increasing demand for sustainable transport solutions and stringent environmental regulations globally. Key markets in Africa, South America, the Middle East, and Europe are embracing electric trucks to reduce greenhouse gas emissions and improve air quality. In particular, regions like Saudi Arabia and Nigeria are investing heavily in electric mobility as part of broader economic diversification strategies.

Emerging technologies in battery chemistry, particularly lithium iron phosphate (LFP), are enhancing energy density, safety, and lifespan. Companies are increasingly adopting advanced battery management systems (BMS) that offer real-time monitoring and diagnostics, which improves operational efficiency. Moreover, the trend towards vertical integration among suppliers is reshaping sourcing strategies, allowing companies to ensure better quality control and reduce costs. B2B buyers should be aware of the growing importance of partnerships with innovative battery manufacturers to stay competitive and meet customer demands.

How Can Sustainability and Ethical Sourcing Impact the Electric Truck Lithium Battery Market?

Sustainability has become a cornerstone of sourcing strategies in the electric truck lithium battery market. Environmental impact assessments are now standard practice, focusing on the lifecycle of battery production, usage, and disposal. International B2B buyers are increasingly prioritizing suppliers who adhere to sustainable practices, such as using recycled materials and minimizing carbon footprints.

Ethical sourcing is equally crucial, particularly concerning lithium extraction. Buyers should seek suppliers who demonstrate commitment to responsible mining practices, ensuring that local communities are not adversely affected. Certifications such as ISO 14001 for environmental management and adherence to the Responsible Minerals Initiative (RMI) can serve as indicators of a supplier’s commitment to sustainability. By prioritizing suppliers with ‘green’ credentials, businesses can enhance their brand reputation and appeal to environmentally-conscious consumers.

How Has the Electric Truck Lithium Battery Sector Evolved Over Time?

The evolution of electric truck lithium batteries has been marked by rapid technological advancements and increasing market demand. Initially, lead-acid batteries dominated the market due to their lower upfront costs. However, the limitations in energy density and lifecycle prompted a shift towards lithium-ion solutions. Over the past decade, innovations in battery chemistry, particularly the development of lithium iron phosphate (LFP) batteries, have significantly improved performance metrics such as safety, longevity, and charging speed.

This shift has been accompanied by a growing recognition of the importance of battery recycling and sustainability, leading to more robust supply chains and ethical sourcing practices. As electric trucks become more mainstream, the focus is on enhancing battery performance while ensuring environmental and social responsibility, setting the stage for the next phase of growth in this sector.

Frequently Asked Questions (FAQs) for B2B Buyers of electric truck lithium battery

-

How do I choose the right lithium battery for my electric truck?

Selecting the appropriate lithium battery for your electric truck involves assessing your power needs, vehicle specifications, and intended applications. Consider factors such as battery capacity (measured in Ah), discharge rates, and operational temperature ranges. It’s also important to look for batteries designed for deep discharge capabilities, as they enhance runtime and longevity. Additionally, ensure that the battery complies with international standards and regulations pertinent to your region, which can vary significantly across Africa, South America, the Middle East, and Europe. -

What are the advantages of lithium batteries over traditional lead-acid batteries for trucks?

Lithium batteries offer several advantages over lead-acid batteries, including significantly longer life cycles—up to ten times longer—greater energy density, and lower weight. They also allow for deeper discharges without damage, providing more usable power and reducing the frequency of replacements. Furthermore, lithium batteries can enhance fuel efficiency by minimizing engine idling, which is particularly advantageous for long-haul operations. Their ability to withstand extreme temperatures and vibrations makes them ideal for heavy-duty applications in various climates. -

What is the minimum order quantity (MOQ) for electric truck lithium batteries?

Minimum order quantities (MOQs) for electric truck lithium batteries can vary widely among suppliers. Typically, MOQs range from a few units to several hundred, depending on the manufacturer’s production capabilities and inventory levels. When negotiating with suppliers, it’s advisable to inquire about bulk pricing, shipping costs, and potential discounts for larger orders. This information can significantly impact your overall procurement strategy, especially for fleet upgrades or large-scale projects. -

What payment terms should I expect when sourcing lithium batteries internationally?

Payment terms for international transactions can differ based on the supplier and the buyer’s relationship. Common arrangements include upfront payments, letter of credit, or net payment terms (e.g., 30, 60, or 90 days). It is crucial to clarify these terms before finalizing the agreement to avoid cash flow issues. Additionally, consider the impact of currency exchange rates and transaction fees on your overall costs, especially if purchasing from regions with fluctuating currencies. -

How can I ensure the quality of lithium batteries before purchasing?

To ensure quality, request certifications such as ISO 9001, CE, or UL listings from potential suppliers. It’s beneficial to conduct a factory audit, if feasible, to assess their production processes and quality control measures. Additionally, ask for product samples for testing in real-world conditions, and review customer testimonials or case studies. Engaging with suppliers who offer warranties and after-sales support can also provide peace of mind regarding product performance and reliability. -

What are the shipping options for electric truck lithium batteries?

Shipping options for lithium batteries can vary based on weight, destination, and local regulations. Common methods include air freight for faster delivery and sea freight for cost-effectiveness, particularly for bulk orders. Be aware that lithium batteries are classified as hazardous materials, which may require specific packaging and labeling. Working with logistics providers experienced in handling hazardous goods can streamline the shipping process and ensure compliance with international shipping regulations. -

Are there customization options available for electric truck lithium batteries?

Many suppliers offer customization options to meet specific operational requirements, such as varying capacities, form factors, and integration with existing systems. Customization can also extend to features like battery management systems (BMS) or connectivity for monitoring purposes. When discussing customization, be clear about your operational needs and any specific certifications required for your market. This dialogue can lead to tailored solutions that enhance performance and efficiency for your fleet. -

How can I vet suppliers when sourcing lithium batteries for electric trucks?

Vetting suppliers is crucial to mitigate risks and ensure reliability. Start by researching their reputation in the industry, looking for reviews and feedback from other B2B buyers. Verify their certifications and compliance with international standards. Establish communication to assess their responsiveness and willingness to address your concerns. Finally, consider requesting references or case studies from previous clients, especially those operating in your region, to gain insights into their performance and support capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Electric Truck Lithium Battery Manufacturers & Suppliers List

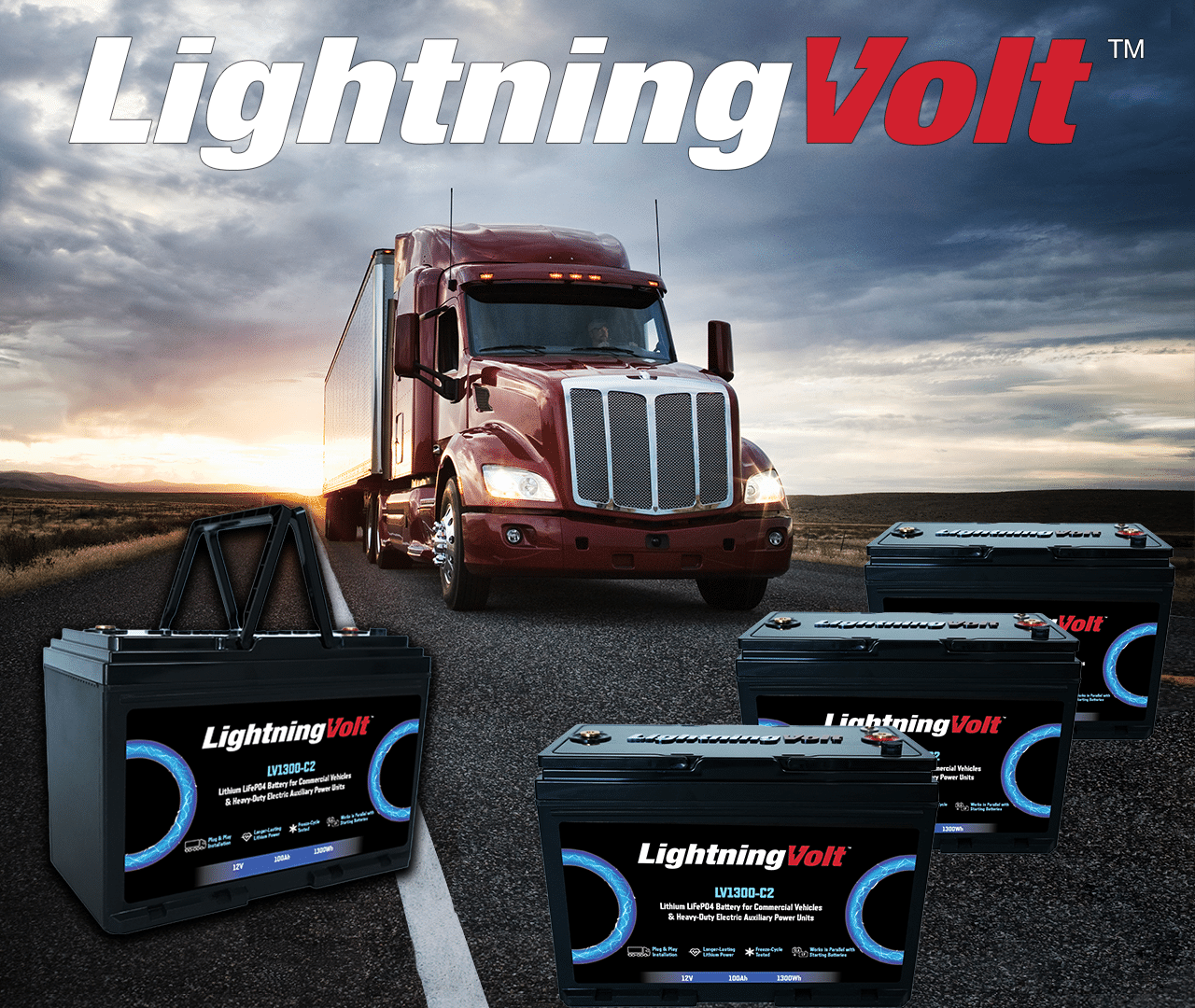

1. Road Warrior – LightningVolt 100Ah Lithium Battery

Domain: roadwarrior-inc.com

Registered: 2014 (11 years)

Introduction: Product Name: LightningVolt 100Ah Lithium Battery LFP

Type: Heavy-Duty Truck Lithium Battery

Price: Regular Price: USD 799, Sale Price: USD 669 (Save: $130)

Assembled in: Canada

Shipping: Free ground shipping

Weight: Less weight compared to traditional batteries

Case: Heavy-Duty Rugged Case

Power Control: Greater depth of discharge

Testing: Freeze-cycle tested

Discharge Rate: Near-Zero discharge r…

2. Battle Born Batteries – Lithium Power Solutions for Trucking

Domain: battlebornbatteries.com

Registered: 2016 (9 years)

Introduction: Battle Born Batteries offers lithium power solutions for the trucking industry, including the Battle Born DualFlow Power Pack, All-Electric APU (Auxiliary Power Unit) in various configurations (Deep In-Frame, Flat In-Frame, Side Frame), and Liftgate Power System. These products are designed to run hotel loads in sleeper cabin trucks, provide reliable power for liftgates, eliminate idling, and enha…

3. Lithium Storage – Lithium Batteries for Electric Trucks

Domain: lslithiumbattery.com

Registered: 2022 (3 years)

Introduction: Lithium Storage specializes in lithium batteries for electric trucks, offering both new and retrofit conversion projects. Key products include: 36V and 24V lithium-ion forklift batteries, passive and active cooling battery modules, standard pack sizes, and custom design services. The company recommends the Flexi pack as a cost-efficient custom lithium battery pack. They provide a comprehensive lin…

4. CamelBatt – Lithium Ion Battery for Heavy Trucks

Domain: camelbatt.com

Registered: 2020 (5 years)

Introduction: Product Name: Lithium Ion Battery for Heavy Truck

Application: Suitable for electric trucks, electric coaches, construction equipment, and other engineering vehicles.

Starting Power: High cranking amps for quick and reliable engine starts, even in extreme temperatures.

Auxiliary Power: Supports lighting, refrigeration units, and other equipment in commercial trucks.

Electric Drive Systems: Powers …

5. Top Bull Shop – Lithium Batteries

Domain: topbullshop.com

Registered: 2023 (2 years)

Introduction: This company, Top Bull Shop – Lithium Batteries, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Hyster – Lithium-Ion Powered Trucks

Domain: hyster.com

Registered: 1996 (29 years)

Introduction: Lithium-ion battery powered trucks from Hyster are designed for reliable and consistent operation over multiple shifts, minimizing maintenance and charging time. Key features include:

– Focused on productivity with no performance degradation and fast recharge capability.

– Eliminates the need for space-consuming battery charging and changing stations, allowing for more efficient use of operational…

7. SmartPropel – Custom Lithium Battery Solutions

Domain: smartpropel.com

Registered: 2019 (6 years)

Introduction: Custom Electric Vehicle Batteries Manufacturer & Supplier – SmartPropel Lithium Battery. Key products include: 48V 100Ah Lithium Battery Pack, 48V 200Ah Lithium Battery, 48V 300Ah Lithium Battery, 72V 100Ah Lithium Battery, 72V 120Ah Lithium Battery, 72V 150Ah Lithium Battery, 72V 180Ah Lithium Battery. Specifications: Nominal Voltage ranges from 48V to 72V, Nominal Capacity ranges from 100Ah to 3…

8. Lithium Werks – High-Performance Lithium Ion Batteries

Domain: lithiumwerks.com

Registered: 2016 (9 years)

Introduction: Lithium Ion Batteries for Fully Electric, Hybrid, and Plugin Hybrid Electric Vehicles & Trains. Key benefits include: runs cooler than other cell technologies, fast charging ability for buses and trucks, long calendar & cycle life, minimal maintenance costs for lowest total cost of ownership. Applications include: Buses (full electric, hybrid, and plug-in hybrid), Trucks (commercial delivery truck…

Strategic Sourcing Conclusion and Outlook for electric truck lithium battery

In navigating the evolving landscape of electric truck lithium batteries, strategic sourcing emerges as a critical factor for B2B buyers across diverse regions. Key takeaways highlight the advantages of lithium technology, such as enhanced energy density, reduced lifecycle costs, and significant improvements in runtime efficiency. Businesses can leverage these benefits to enhance operational sustainability while also meeting regulatory requirements for emissions reduction.

Moreover, the growing demand for electric vehicles in Africa, South America, the Middle East, and Europe underscores the urgency of aligning with reliable suppliers who can provide cutting-edge battery solutions. By investing in high-quality lithium batteries, companies not only boost their fleet’s performance but also contribute to a more sustainable transportation ecosystem.

As we look towards the future, it is essential for international B2B buyers to engage with manufacturers that offer innovative and adaptable lithium battery solutions. The potential for growth in electric truck adoption is immense, presenting a unique opportunity to lead in a greener economy. Take action now—evaluate your sourcing strategies and partner with industry leaders to ensure your fleet is equipped for the challenges ahead.