Introduction: Navigating the Global Market for solar electric cars made in china

In an era where sustainability is paramount, sourcing solar electric cars made in China presents both opportunities and challenges for international B2B buyers. The shift towards renewable energy in transportation is not just a trend but a necessity for businesses looking to reduce carbon footprints and comply with increasingly stringent regulations. However, navigating the complexities of this emerging market can be daunting, particularly for buyers from regions like Africa, South America, the Middle East, and Europe.

This comprehensive guide delves into various aspects of solar electric vehicles (SEVs) produced in China, highlighting the types available, their applications, and the latest technological advancements. It also provides insights into supplier vetting processes, cost considerations, and logistical challenges that may arise when importing these innovative vehicles. By equipping buyers with the necessary knowledge to make informed decisions, this guide empowers businesses to identify reliable suppliers and negotiate favorable terms, ultimately leading to successful procurement outcomes.

With China’s rapid advancements in solar technology and electric vehicle production, the potential for collaboration and investment is significant. This guide aims to bridge the gap between international buyers and Chinese manufacturers, fostering a clearer understanding of the market dynamics and enabling strategic partnerships that can drive sustainable growth.

Understanding solar electric cars made in china Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Pure Solar Electric Vehicle | Operates solely on solar energy; no battery backup | Urban transportation, short-distance travel | Pros: Zero emissions, low operating costs; Cons: Limited range and speed. |

| Hybrid Solar-Electric Vehicle | Combines solar panels with conventional battery systems | Long-distance travel, fleet operations | Pros: Extended range, flexible energy sources; Cons: Higher initial costs. |

| Autonomous Solar Vehicle | Features Level 4 autonomy with solar energy capability | Smart city integrations, public transport | Pros: Enhanced safety, reduced labor costs; Cons: High development costs, regulatory hurdles. |

| Solar-Powered Mini EV | Compact design optimized for city driving | Last-mile delivery, urban commuting | Pros: Space-efficient, eco-friendly; Cons: Limited passenger capacity, less powerful. |

| Solar Fleet Management | Integrated systems for managing multiple solar vehicles | Logistics, public transport systems | Pros: Streamlined operations, reduced emissions; Cons: Complex setup and maintenance. |

What Are the Characteristics of Pure Solar Electric Vehicles?

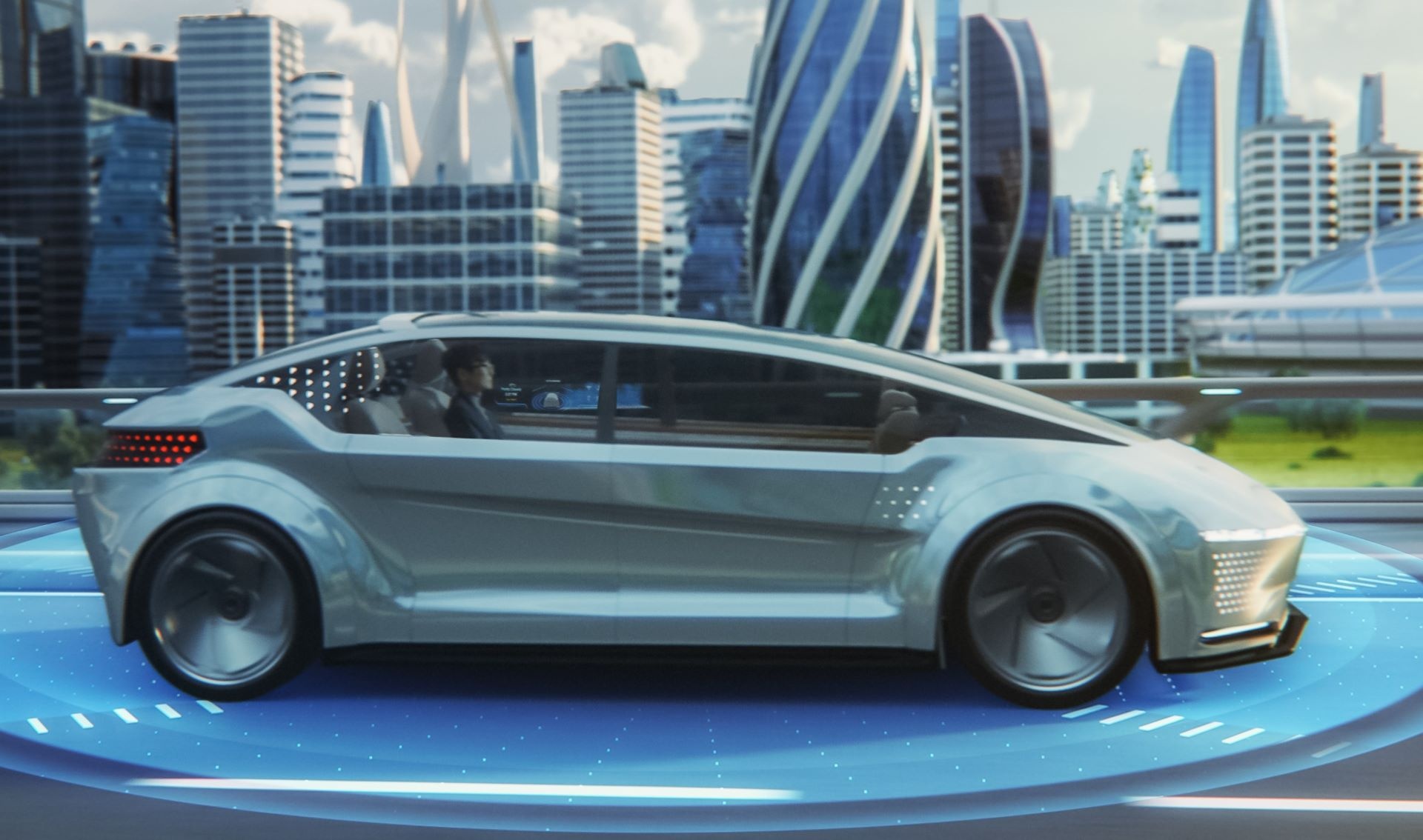

Pure solar electric vehicles, like the Tianjin model, operate solely on solar energy without the need for a battery backup. These vehicles are ideal for urban environments with ample sunlight, making them suitable for short-distance travel. B2B buyers looking for sustainable transportation solutions will find these vehicles appealing due to their zero emissions and low operating costs. However, the limited range—approximately 47 miles—can restrict their usage, especially in regions requiring longer travel distances.

How Do Hybrid Solar-Electric Vehicles Enhance Flexibility?

Hybrid solar-electric vehicles combine solar panels with conventional battery systems, allowing them to draw power from both sources. This versatility makes them suitable for long-distance travel and fleet operations where range and reliability are crucial. For B2B buyers, these vehicles offer the advantage of reduced fuel consumption and lower carbon footprints. However, the initial investment is higher compared to pure solar options, which may be a consideration for budget-conscious companies.

What Are the Benefits of Autonomous Solar Vehicles?

Autonomous solar vehicles represent the cutting edge of solar technology, featuring advanced self-driving capabilities powered by solar energy. They are particularly relevant for smart city initiatives and public transportation systems, providing enhanced safety and efficiency. B2B buyers interested in innovative transportation solutions may find these vehicles attractive, although the high development costs and regulatory challenges can be significant barriers to entry.

Why Choose Solar-Powered Mini EVs for Urban Use?

Solar-powered mini electric vehicles are compact and designed specifically for urban driving, making them perfect for last-mile delivery services and daily commuting. Their space-efficient design and eco-friendly operation appeal to businesses looking to reduce their carbon footprint while navigating congested city streets. However, potential buyers should consider the limited passenger capacity and less powerful performance compared to larger vehicles.

How Does Solar Fleet Management Optimize Operations?

Solar fleet management systems integrate multiple solar vehicles into a cohesive operational framework, allowing businesses to streamline logistics and public transportation services. These systems can significantly reduce emissions and fuel costs, making them attractive for companies focused on sustainability. However, the complexity of setup and ongoing maintenance can pose challenges, requiring careful planning and investment from B2B buyers looking to implement such solutions.

Key Industrial Applications of solar electric cars made in china

| Industry/Sector | Specific Application of solar electric cars made in china | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Urban Transportation | Last-mile delivery services using solar electric cars | Reduced operational costs and lower carbon footprint | Evaluate vehicle range, charging infrastructure, and local regulations. |

| Tourism and Recreation | Eco-friendly tour vehicles for tourist attractions | Enhanced customer experience and sustainability branding | Consider vehicle comfort, capacity, and solar energy efficiency. |

| Public Transportation | Solar electric buses for city transit systems | Decreased fuel costs and improved air quality | Assess vehicle capacity, maintenance support, and government incentives. |

| Agricultural Logistics | Transporting goods in sunny regions | Lower logistics costs and reduced reliance on fossil fuels | Focus on durability, load capacity, and compatibility with local terrain. |

| Remote Area Mobility | Solar electric vehicles for remote community access | Increased mobility and reduced transportation costs | Ensure vehicle robustness, range, and adaptability to local conditions. |

How Are Solar Electric Cars Used in Urban Transportation?

In urban transportation, solar electric cars serve as efficient last-mile delivery solutions. Businesses can capitalize on their zero-emission capabilities, significantly reducing operational costs while catering to environmentally conscious consumers. For B2B buyers, it is crucial to assess the vehicle’s range and the availability of charging infrastructure, particularly in urban settings across regions like Africa and South America, where logistics may vary greatly.

What Role Do Solar Electric Cars Play in Tourism and Recreation?

Solar electric vehicles can enhance the tourism experience by providing eco-friendly transportation options for visitors at attractions. This not only aligns with sustainability goals but also boosts the brand image of tourism operators. Buyers should prioritize vehicle comfort and capacity to accommodate diverse tourist groups, as well as the efficiency of solar panels, especially in sunny destinations in the Middle East and Europe.

How Can Solar Electric Buses Transform Public Transportation?

In public transportation, integrating solar electric buses can lead to significant reductions in fuel costs and improvements in air quality. These buses can operate in city transit systems, offering a sustainable alternative to traditional fossil fuel vehicles. For international buyers, understanding local government incentives, vehicle capacity, and maintenance support is essential to ensure a successful implementation in regions such as Germany and Brazil.

Why Are Solar Electric Cars Important for Agricultural Logistics?

In agricultural logistics, solar electric vehicles can transport goods in sunny regions, reducing logistics costs and reliance on fossil fuels. This is particularly beneficial in areas where traditional fuel sources are expensive or scarce. Buyers should focus on the vehicle’s durability and load capacity, as well as its compatibility with local terrain, to ensure it meets the demands of agricultural operations in diverse environments.

How Do Solar Electric Cars Enhance Mobility in Remote Areas?

Solar electric vehicles are crucial for improving mobility in remote communities, providing access to essential services and reducing transportation costs. Their reliance on solar energy makes them a viable option in regions with abundant sunlight. Buyers in these markets should evaluate the vehicle’s robustness, range, and adaptability to local conditions, ensuring they can effectively meet the transportation needs of remote populations.

3 Common User Pain Points for ‘solar electric cars made in china’ & Their Solutions

Scenario 1: Limited Range for Urban Applications

The Problem: One of the primary challenges faced by B2B buyers considering solar electric cars made in China is the limited range of these vehicles. For instance, the Tianjin solar car boasts a maximum range of only 47 miles, which may be insufficient for businesses that require longer-distance travel or service routes. This limitation can hinder operational efficiency, particularly in regions where infrastructure for charging stations is sparse or non-existent. Buyers may worry that investing in such vehicles could lead to operational disruptions, especially in logistics or service industries where vehicles are used extensively throughout the day.

The Solution: To address this issue, B2B buyers should consider integrating solar electric cars into a multi-modal transport strategy. This approach involves using solar electric cars for short-distance urban commutes while employing traditional electric vehicles or hybrid models for longer trips. Buyers can also establish partnerships with local solar charging station providers to ensure quick charging options along key routes. Moreover, they should conduct thorough route planning to optimize the use of solar vehicles, leveraging technology to monitor energy consumption and vehicle range in real-time. This way, businesses can maximize the benefits of solar cars while mitigating range-related concerns.

Scenario 2: Initial Investment and Cost Concerns

The Problem: Many B2B buyers are deterred by the initial investment required to purchase solar electric cars. The up-front costs can be significantly higher compared to conventional vehicles, which can be a barrier for companies operating on tight budgets or those hesitant to adopt new technologies. This concern is particularly prevalent among businesses in developing regions of Africa and South America, where capital for innovation is limited, and the return on investment may not be immediately clear.

The Solution: To alleviate this financial burden, B2B buyers should explore financing options such as leasing, government incentives, or subsidies available for renewable energy projects. Engaging with financial institutions that specialize in green financing can also provide tailored solutions that minimize upfront costs. Additionally, buyers should conduct a comprehensive cost-benefit analysis to project long-term savings on fuel and maintenance, as solar electric cars typically have lower operational costs over time. By presenting a clear financial model that outlines the total cost of ownership versus traditional vehicles, companies can make more informed decisions and justify the initial investment.

Scenario 3: Technical Support and Maintenance Challenges

The Problem: Another significant pain point for B2B buyers is the lack of technical support and maintenance services for solar electric cars. Many international buyers may encounter difficulties in sourcing reliable service providers who understand the intricacies of solar technology. This can lead to prolonged downtimes, escalating maintenance costs, and frustration among fleet managers who are unfamiliar with the specific needs of solar electric vehicles.

The Solution: To combat these challenges, B2B buyers should prioritize purchasing solar electric cars from manufacturers that offer robust after-sales support and maintenance services. Conducting thorough due diligence on potential suppliers is essential; buyers should seek manufacturers with established networks for technical support in their regions. Additionally, investing in training for in-house maintenance staff can equip them with the necessary skills to perform basic repairs and upkeep on solar vehicles, reducing reliance on external service providers. Establishing a maintenance schedule that aligns with the vehicle’s operational use can also preemptively address potential issues, ensuring that the fleet remains operational and efficient.

Strategic Material Selection Guide for solar electric cars made in china

What Are the Key Materials Used in Solar Electric Cars Made in China?

In the development of solar electric cars, particularly those produced in China, several materials play a crucial role in enhancing performance, durability, and sustainability. Below is an analysis of four common materials, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Solar Panels Function in Solar Electric Cars?

Silicon

Silicon is the primary material used in solar panels due to its excellent photovoltaic properties. It has a high temperature rating, typically around 125°C, and is resistant to moisture and corrosion. Silicon solar cells can convert sunlight into electricity efficiently, making them ideal for solar electric vehicles (SEVs).

Pros & Cons:

Silicon’s durability and efficiency are significant advantages, but its manufacturing process can be complex and costly. The end product, however, is highly suitable for long-term use in vehicles.

Impact on Application:

Silicon’s compatibility with various environmental conditions makes it effective in diverse climates, which is particularly relevant for markets in Africa and South America, where sunlight is abundant.

Considerations for International Buyers:

B2B buyers should ensure that silicon panels comply with international standards such as IEC 61215 and IEC 61730. Additionally, buyers from Europe may prefer products that meet the EU’s RoHS directive to limit hazardous substances.

What Role Does Aluminum Play in Solar Electric Cars?

Aluminum

Aluminum is widely used in the structural components of solar electric cars due to its lightweight nature and corrosion resistance. It has a temperature rating of approximately 200°C and is known for its excellent strength-to-weight ratio.

Pros & Cons:

The primary advantage of aluminum is its lightweight characteristic, which enhances vehicle efficiency and performance. However, the cost of aluminum can be relatively high compared to steel, and its manufacturing process can be energy-intensive.

Impact on Application:

Aluminum’s resistance to corrosion makes it suitable for vehicles operating in humid or coastal environments, which is a consideration for buyers in the Middle East and coastal regions of Europe.

Considerations for International Buyers:

Buyers should look for compliance with standards such as ASTM B221 for aluminum extrusions. Additionally, understanding local recycling regulations can be beneficial, as aluminum is highly recyclable.

How Does Composite Material Enhance Solar Electric Cars?

Composite Materials

Composite materials, including carbon fiber and fiberglass, are increasingly used in solar electric cars for their lightweight and high-strength properties. These materials can withstand high temperatures and offer excellent fatigue resistance.

Pros & Cons:

The main advantage of composites is their ability to reduce vehicle weight significantly, improving energy efficiency. However, they can be more expensive and complex to manufacture, which may deter some manufacturers.

Impact on Application:

Composites are particularly effective in high-performance applications, making them suitable for urban environments where agility and speed are essential.

Considerations for International Buyers:

B2B buyers should verify compliance with relevant standards like ASTM D3039 for tensile properties. Additionally, buyers in Europe may have preferences for sustainable sourcing of composite materials.

What Is the Importance of Lithium in Solar Electric Vehicles?

Lithium

Lithium is a critical component in the batteries used for energy storage in solar electric cars. Lithium-ion batteries have a high energy density, typically rated at 150-250 Wh/kg, and can operate efficiently at a wide range of temperatures.

Pros & Cons:

Lithium batteries offer excellent performance and longevity, but they can be costly and require careful handling due to safety concerns.

Impact on Application:

Lithium batteries are essential for maximizing the range and efficiency of solar electric vehicles, particularly in regions with limited charging infrastructure, such as parts of Africa and South America.

Considerations for International Buyers:

Buyers should consider compliance with UN 3480 regulations for the transport of lithium batteries and ensure that suppliers adhere to ISO 9001 for quality management systems.

Summary Table of Material Selection for Solar Electric Cars

| Material | Typical Use Case for solar electric cars made in china | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon | Solar panels for energy conversion | High efficiency in energy conversion | Complex manufacturing process | High |

| Aluminum | Structural components | Lightweight and corrosion-resistant | Higher cost than steel | Medium |

| Composite | Body panels and lightweight structures | Significant weight reduction | Expensive and complex to manufacture | High |

| Lithium | Energy storage in batteries | High energy density and efficiency | Costly and requires careful handling | High |

This strategic material selection guide highlights the critical materials used in solar electric cars made in China, providing valuable insights for international B2B buyers looking to invest in this innovative technology.

In-depth Look: Manufacturing Processes and Quality Assurance for solar electric cars made in china

What Are the Main Stages in the Manufacturing Process of Solar Electric Cars in China?

The manufacturing process of solar electric cars in China involves several key stages, which are critical for ensuring both performance and quality. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials, such as lightweight metals for the chassis, advanced polymers for the body panels, and high-efficiency solar cells. Suppliers often adhere to stringent quality standards to ensure the materials meet the necessary specifications. In solar electric vehicles (SEVs), the solar panels play a crucial role, necessitating the use of high-grade silicon and durable encapsulants.

-

Forming: The forming process encompasses various techniques like stamping, extrusion, and molding. For instance, the chassis components may be stamped from sheets of aluminum, while body panels could be molded from high-strength plastics. The choice of forming technique affects the vehicle’s weight, aerodynamics, and overall efficiency, which are essential factors for solar-powered vehicles.

-

Assembly: This stage involves integrating all the components, including the solar panels, battery packs, and electric drive systems. Advanced automation and robotics are increasingly utilized to enhance precision and efficiency during assembly. Furthermore, manufacturers may implement modular designs, allowing for easier upgrades and repairs, which is particularly appealing to B2B buyers looking for long-term value.

-

Finishing: The finishing process includes painting, surface treatment, and quality checks. Solar electric vehicles often undergo specialized treatments to enhance their aerodynamics and reduce weight. Additionally, this stage is vital for ensuring aesthetic appeal and compliance with international design standards.

How Is Quality Assurance Implemented in the Production of Solar Electric Cars?

Quality assurance (QA) is a critical aspect of the manufacturing process, especially for solar electric cars, where performance and reliability are paramount. Manufacturers in China often implement a multi-layered approach to QA, which includes adherence to international and industry-specific standards.

-

International Standards: Many manufacturers seek ISO 9001 certification, which focuses on quality management systems. This certification indicates a commitment to maintaining high-quality standards across all processes, from material procurement to final assembly. Compliance with other international standards, such as ISO 14001 for environmental management, is also increasingly common.

-

Industry-Specific Certifications: Solar electric vehicle manufacturers may pursue additional certifications like CE (Conformité Européenne) for products sold in Europe, which ensures compliance with safety and health standards. Other relevant certifications may include API (American Petroleum Institute) standards for components related to energy efficiency.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify and rectify issues before they escalate. Common QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint occurs when materials and components arrive at the manufacturing facility. The quality of incoming materials is inspected to ensure they meet predefined specifications, preventing defects from entering the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, ongoing inspections are conducted to monitor the assembly and fabrication stages. This includes verifying the integrity of welds, ensuring proper alignment of components, and checking the performance of solar panels.

-

Final Quality Control (FQC): Once the vehicle assembly is complete, a comprehensive final inspection is performed. This includes testing the vehicle’s electrical systems, autonomous driving capabilities, and overall functionality. Manufacturers often conduct performance tests to ensure the vehicle meets its claimed specifications, such as range and speed.

How Can B2B Buyers Verify Supplier Quality Control Measures?

B2B buyers looking to source solar electric cars from Chinese manufacturers should take proactive steps to verify the quality control measures in place. Here are several effective strategies:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide invaluable insights into their manufacturing processes and quality control practices. During these audits, buyers can assess the adherence to international standards, review documentation, and observe production practices firsthand.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the QC processes of a supplier. These reports should outline the results of various inspections, tests, and compliance with industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of a manufacturer’s quality assurance processes. Such services can conduct random inspections during production and at final assembly, ensuring that the vehicles meet the required standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing solar electric cars from China, international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of certain quality control nuances:

-

Regulatory Compliance: Different regions have varying regulatory requirements for automotive products. Buyers must ensure that the vehicles meet local regulations, such as emissions standards and safety requirements, which may differ significantly from those in China.

-

Cultural Considerations: Understanding the cultural context of Chinese manufacturing practices can aid in better communication and expectations regarding quality assurance. Building a relationship based on transparency and trust can lead to improved cooperation.

-

Supply Chain Transparency: Buyers should prioritize suppliers who maintain transparency throughout their supply chain. This includes clear traceability of materials and components, ensuring that all parts meet the required quality standards.

Conclusion

The manufacturing processes and quality assurance measures for solar electric cars in China are intricate and crucial for delivering high-performance vehicles to the international market. By understanding these processes, B2B buyers can make informed decisions, ensuring they partner with manufacturers who prioritize quality and compliance. This knowledge not only enhances procurement strategies but also supports long-term sustainability goals in the automotive sector.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solar electric cars made in china’

This guide serves as a practical checklist for international B2B buyers looking to procure solar electric cars made in China. The rise of sustainable transportation options makes it crucial for buyers to understand the key factors involved in sourcing these innovative vehicles. Here’s a step-by-step checklist to streamline your procurement process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the solar electric cars meet your operational needs. Consider factors such as seating capacity, range, solar power generation capabilities, and autonomous driving features. This clarity will help you communicate effectively with suppliers and avoid misunderstandings later on.

Step 2: Research the Market Landscape

Conduct thorough market research to identify potential suppliers in China. Look for companies that specialize in solar electric vehicles and have a proven track record in the industry. Utilize platforms like Alibaba, industry trade shows, and automotive expos to gather information about manufacturers and their offerings.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience with solar electric cars specifically, and consider their production capacity and technological advancements. This step is vital to ensure that you partner with a reliable manufacturer.

Step 4: Verify Certifications and Compliance

Ensure that your chosen suppliers comply with international standards and regulations for electric vehicles. Look for certifications such as ISO 9001 for quality management and CE or UL certifications that validate product safety. This verification process is important for mitigating risks related to safety and reliability.

Step 5: Request Product Samples

Before finalizing any orders, request product samples to evaluate quality firsthand. This allows you to assess the materials, craftsmanship, and overall performance of the solar electric cars. Pay attention to the vehicle’s solar panel efficiency and battery performance, as these are critical for the vehicle’s operational success.

Step 6: Discuss After-Sales Support and Warranty

Inquire about the after-sales support and warranty options provided by the supplier. Understanding the terms of service, including repair, maintenance, and parts availability, is crucial for long-term operational efficiency. A solid warranty can protect your investment and ensure peace of mind.

Step 7: Negotiate Terms and Finalize Contracts

Once you’ve selected a supplier, negotiate the terms of purchase, including pricing, delivery schedules, and payment methods. Ensure that all agreements are documented in a formal contract to protect both parties. Clear terms will help establish a mutual understanding and foster a strong business relationship.

By following this checklist, B2B buyers can navigate the complexities of sourcing solar electric cars from China, ensuring they make informed decisions that align with their business goals and sustainability initiatives.

Comprehensive Cost and Pricing Analysis for solar electric cars made in china Sourcing

What Are the Key Cost Components for Sourcing Solar Electric Cars Made in China?

When considering the procurement of solar electric cars from China, it’s essential to understand the cost structure involved. The main components influencing costs include:

-

Materials: The primary materials for solar electric cars include high-efficiency solar panels, lightweight composites, and advanced battery technology. The cost of these materials can vary significantly based on market conditions and technological advancements. For instance, solar panels are subject to fluctuations in silicon prices, while battery costs are influenced by lithium and cobalt markets.

-

Labor: Labor costs in China are generally lower than in Western countries, but they can vary by region and skill level. Skilled labor for advanced technologies, such as autonomous driving systems, may command higher wages. Understanding the local labor market is critical when calculating total costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and indirect labor. Efficient manufacturing processes and economies of scale can help reduce these overheads, making it advantageous for buyers who can commit to larger orders.

-

Tooling: Custom tooling for specific vehicle designs can represent a significant upfront investment. Buyers should consider whether they require bespoke solutions or if off-the-shelf components will suffice, as this can impact initial costs.

-

Quality Control (QC): Ensuring that the vehicles meet international standards often necessitates additional QC measures, which can add to the overall cost. Buyers should evaluate the supplier’s QC processes and certifications to mitigate risks associated with product quality.

-

Logistics: Shipping costs can vary based on the mode of transport, distance, and current freight rates. Additionally, import duties and tariffs should be factored in, especially for buyers in regions with stringent trade regulations.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s position in the market, competition, and the perceived value of their product.

How Do Price Influencers Affect Sourcing Decisions for Solar Electric Cars?

Several factors can influence the final price of solar electric cars, impacting international B2B buyers:

-

Volume/MOQ: Larger orders often come with discounts, as suppliers benefit from economies of scale. Buyers should assess their needs and negotiate for better pricing based on expected order volumes.

-

Specifications and Customization: Custom features or advanced technology integrations can increase costs. Buyers must balance their requirements with budget constraints, ensuring that any additional features offer a clear return on investment.

-

Materials: The choice of materials directly affects the vehicle’s performance and cost. High-quality materials may incur higher upfront costs but can lead to lower total ownership costs through enhanced durability and efficiency.

-

Quality and Certifications: Suppliers with recognized quality certifications may charge a premium, but this can provide peace of mind regarding compliance with international standards. Buyers should prioritize suppliers with proven track records in quality assurance.

-

Supplier Factors: Relationships with suppliers can influence pricing. Established partnerships may lead to better terms and pricing flexibility. It’s beneficial for buyers to conduct thorough supplier evaluations before making commitments.

-

Incoterms: Understanding Incoterms is crucial for determining responsibility for shipping costs and risks. Buyers should clarify terms to avoid unexpected expenses during transportation.

What Negotiation Tips Should B2B Buyers Consider for Solar Electric Cars?

-

Conduct Thorough Research: Understand market prices and competitor offerings to strengthen your negotiating position. This knowledge will help you identify fair pricing and negotiate better terms.

-

Leverage Long-Term Relationships: Building long-term relationships with suppliers can lead to more favorable pricing and terms. Consistent communication can also enhance collaboration and responsiveness to your needs.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also maintenance, operational costs, and resale value. A lower upfront cost might not equate to better value if the total cost of ownership is higher.

-

Be Prepared to Walk Away: If a supplier cannot meet your pricing expectations, be ready to explore other options. This stance can sometimes lead to better offers from suppliers eager to secure your business.

-

Consider Local Regulations: Buyers should be aware of local regulations regarding electric vehicles and solar technology, as compliance can impact costs and potential subsidies or incentives.

Final Thoughts

While the costs associated with sourcing solar electric cars from China can vary widely, understanding the key components and influencers will empower B2B buyers to make informed decisions. Buyers should approach negotiations strategically, focusing on total cost considerations and leveraging supplier relationships to optimize their procurement strategy. Keep in mind that indicative prices can fluctuate based on market conditions, so continuous monitoring and flexibility are essential for successful sourcing.

Alternatives Analysis: Comparing solar electric cars made in china With Other Solutions

Understanding Alternatives in Solar Electric Vehicles

As the demand for sustainable transportation solutions rises, B2B buyers are increasingly evaluating various technologies. Solar electric cars, particularly those made in China, offer an innovative approach to reducing carbon emissions. However, it’s essential to consider alternative solutions that may align better with specific operational needs, budget constraints, and environmental goals. This analysis compares solar electric cars made in China with electric vehicles (EVs) powered by traditional charging methods and hybrid electric vehicles (HEVs).

Comparison Table

| Comparison Aspect | Solar Electric Cars Made In China | Electric Vehicles (EVs) | Hybrid Electric Vehicles (HEVs) |

|---|---|---|---|

| Performance | Max range: 74.8 km (47 miles); Max speed: 79.2 km/h (49 mph) | Range: 250-500 km (155-310 miles); Speed varies | Range: 600-800 km (373-497 miles combined) |

| Cost | Initial investment may be high; potential long-term savings on energy | Varies widely; typically higher than traditional cars | Generally lower initial cost than EVs; fuel-efficient |

| Ease of Implementation | Limited infrastructure; suitable for sunny regions | Widely available charging stations; adaptable in various regions | Established fuel infrastructure; easier to integrate |

| Maintenance | Minimal moving parts; low maintenance expected | Regular maintenance; battery replacement required | Regular maintenance; hybrid systems add complexity |

| Best Use Case | Urban areas with consistent sunlight; eco-conscious consumers | Long-distance travel; diverse operational needs | Versatile; combines electric and gasoline benefits |

Detailed Breakdown of Alternatives

Electric Vehicles (EVs)

Electric vehicles powered by traditional charging methods represent a robust alternative. With a range that can exceed 500 km, they are suitable for longer commutes and diverse geographical regions. EVs benefit from an expanding network of charging stations, making them convenient for urban and rural users alike. However, the initial investment can be significantly higher than solar electric cars, and ongoing maintenance, particularly for battery systems, can add to ownership costs.

Hybrid Electric Vehicles (HEVs)

Hybrid electric vehicles combine an internal combustion engine with an electric propulsion system, allowing for greater flexibility in fuel usage. HEVs typically offer a longer range than both solar electric cars and pure EVs, making them ideal for regions with less consistent sunlight. They are often less expensive than full electric vehicles, which can be appealing for budget-conscious buyers. However, the complexity of having both electric and gasoline systems can lead to higher maintenance costs compared to the simpler designs of solar electric cars.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating solar electric cars made in China against alternatives like traditional EVs and HEVs, B2B buyers should consider their specific requirements. For businesses operating in sunny regions with short commuting distances, solar electric cars may offer a cost-effective and eco-friendly solution. Conversely, for organizations needing greater range and flexibility, traditional electric or hybrid vehicles may be more appropriate. Ultimately, aligning vehicle choice with operational demands, budget, and sustainability goals will ensure the best return on investment.

Essential Technical Properties and Trade Terminology for solar electric cars made in china

What Are the Key Technical Properties of Solar Electric Cars Made in China?

When evaluating solar electric cars, particularly those manufactured in China, international B2B buyers should be aware of several critical specifications that impact performance, efficiency, and suitability for various markets. Here are the essential technical properties to consider:

-

Maximum Daily Power Generation

This specification indicates how much energy the solar panels can generate in a day under optimal sunlight conditions. For instance, the Tianjin solar car can produce up to 7.6 kWh on sunny days. Understanding this metric is crucial for assessing the vehicle’s operational viability in different climates, especially in regions with high solar exposure, such as parts of Africa and South America. -

Battery Energy Density

The energy density of the battery, measured in watt-hours per kilogram (Wh/kg), determines how much energy can be stored in a given weight of the battery. The Tianjin model features a battery with an energy density of 330 Wh/kg. Higher energy densities allow for lighter batteries, which can enhance vehicle range and performance—an important consideration for buyers focused on efficiency and operational costs. -

Vehicle Range

The maximum distance the vehicle can travel on a single charge is a critical factor for potential buyers. The Tianjin solar car has a tested range of approximately 74.8 km (about 47 miles). Understanding the range helps B2B buyers evaluate the vehicle’s suitability for urban commuting or longer journeys, particularly in regions where charging infrastructure may be limited. -

Autonomous Driving Level

The level of autonomy, categorized by the SAE (Society of Automotive Engineers) standards, indicates how much human intervention is required while driving. The Tianjin vehicle boasts Level 4 autonomy, meaning it can operate without human oversight under specific conditions. This feature is vital for buyers interested in advanced technologies that can enhance safety and reduce operational costs. -

Vehicle Dimensions and Weight

Specifications regarding the dimensions (length, width, height) and weight (e.g., 1,020 kg for the Tianjin) are important for logistics, parking, and regulatory compliance. Smaller, lighter vehicles can be more efficient in dense urban environments, making them attractive to buyers in city-focused markets.

What Common Trade Terms Should B2B Buyers Understand in the Solar Electric Vehicle Market?

Navigating the solar electric vehicle industry requires familiarity with specific trade terminology that can significantly influence procurement and partnership strategies. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of solar electric cars, understanding OEM relationships can help buyers identify quality and reliability in components sourced from Chinese manufacturers. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers to negotiate pricing and ensure that order sizes align with their market needs, particularly when entering new regions. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. When dealing with solar electric cars, an RFQ can help buyers compare costs, specifications, and delivery timelines, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is vital for B2B buyers to understand their liabilities and obligations in cross-border transactions. -

PV (Photovoltaic) Efficiency

This term refers to the ratio of electrical output from a solar panel to the incident energy from the sun. A higher PV efficiency means more energy generation from a smaller surface area, making it a significant consideration for vehicle design and performance.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions when exploring partnerships and investments in the rapidly evolving market of solar electric vehicles made in China.

Navigating Market Dynamics and Sourcing Trends in the solar electric cars made in china Sector

What Are the Key Market Dynamics and Trends Influencing Solar Electric Cars Made in China?

The solar electric car market in China is experiencing significant growth, driven by a combination of technological advancements and increasing global awareness of climate change. With China being a global leader in solar energy production, the integration of solar technology into electric vehicles (EVs) is a natural evolution. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly drawn to Chinese manufacturers due to their competitive pricing, advanced technology, and ability to produce vehicles that meet local environmental regulations.

Emerging trends in sourcing include a shift towards partnerships with local suppliers to enhance supply chain resilience and reduce lead times. Companies are also investing in Research and Development (R&D) for autonomous driving technologies and battery efficiency, making solar electric vehicles more appealing for urban environments. For instance, the Tianjin solar car, developed in collaboration with multiple universities and companies, exemplifies the rapid innovation occurring within this sector. Its design prioritizes efficiency, achieving a maximum daily power generation of 7.6 kWh on sunny days, which could cater well to markets with ample sunlight.

Additionally, as countries tighten emissions regulations and promote sustainable transportation, the demand for solar electric cars is expected to surge. International buyers should closely monitor regulatory changes in their regions, as these can significantly impact sourcing strategies and market entry.

How Can Sustainability and Ethical Sourcing Influence B2B Relationships in the Solar Electric Car Sector?

Sustainability is becoming a non-negotiable factor for B2B buyers in the solar electric car market. The environmental impact of traditional fossil fuel-powered vehicles is prompting a shift towards greener alternatives, with solar electric cars offering a compelling solution. However, sustainability extends beyond just the vehicle’s operational efficiency; it also encompasses the entire supply chain.

Ethical sourcing is crucial for international buyers who want to align their procurement strategies with their corporate social responsibility goals. This includes ensuring that materials used in manufacturing solar electric cars, such as lithium for batteries, are sourced responsibly and sustainably. Buyers should prioritize suppliers who can demonstrate compliance with international environmental standards and certifications, such as ISO 14001, which focuses on effective environmental management systems.

Furthermore, as consumers increasingly demand transparency and accountability from brands, companies that invest in sustainable practices are likely to gain a competitive edge. This trend is evident in the growing number of manufacturers adopting ‘green’ certifications and materials in their production processes. By choosing to partner with ethical suppliers, international buyers can not only reduce their environmental footprint but also enhance their brand reputation in the global marketplace.

What Is the Historical Context Behind the Solar Electric Car Market in China?

The evolution of solar electric cars in China has been marked by innovation and experimentation. While solar technology has been integrated into vehicles for decades, the first significant push for solar electric vehicles in China began around 2016 with the introduction of models like the Hanergy Solar-R. However, it was the unveiling of the Tianjin solar car in 2023 that marked a turning point, showcasing a vehicle powered solely by solar energy and developed in collaboration with numerous stakeholders in a remarkably short timeframe.

This historical context is essential for B2B buyers as it illustrates China’s commitment to advancing solar technology within the automotive sector. The rapid development of these vehicles indicates a robust ecosystem of manufacturers, research institutions, and technology developers ready to meet the growing global demand for sustainable transportation solutions. Buyers looking to enter this market can leverage this historical momentum to secure partnerships with leading Chinese manufacturers who are at the forefront of solar electric vehicle technology.

Frequently Asked Questions (FAQs) for B2B Buyers of solar electric cars made in china

-

How do I evaluate the quality of solar electric cars from Chinese manufacturers?

To assess the quality of solar electric cars, start by researching the manufacturer’s reputation and production capabilities. Look for certifications such as ISO 9001 for quality management systems and any compliance with international safety standards. Request samples or arrange for a factory visit to inspect the vehicles and manufacturing processes. Engaging in third-party inspections or audits can also provide an unbiased evaluation of product quality. Additionally, consider customer testimonials and case studies from other B2B buyers to gauge satisfaction and reliability. -

What are the key specifications to consider when sourcing solar electric cars?

When sourcing solar electric cars, prioritize specifications such as energy generation capacity, range, maximum speed, and seating arrangements. Assess the vehicle’s solar panel efficiency and battery energy density, as these directly impact performance. Additionally, consider features like autonomous driving levels and technological integrations, such as touchscreen controls. Understanding the vehicle’s intended use (urban vs. rural environments) can also inform your choice, ensuring it meets the specific needs of your market. -

What is the typical minimum order quantity (MOQ) for solar electric cars from China?

MOQs for solar electric cars can vary significantly based on the manufacturer and model. Generally, you can expect MOQs to range from 10 to 50 units for bulk orders. Some manufacturers may offer lower MOQs for trial orders or specific models. It’s crucial to communicate your requirements clearly and negotiate terms that suit your business needs. Additionally, consider the potential for future orders, as establishing a long-term relationship may provide leverage for lower MOQs. -

What payment terms are common when purchasing solar electric cars from Chinese suppliers?

Common payment terms include a deposit of 30% upfront with the remaining 70% due before shipment. Some suppliers may offer alternative terms, such as letters of credit or payment upon delivery. It’s advisable to negotiate terms that ensure both parties feel secure. Additionally, consider using escrow services for large transactions to mitigate risks. Establishing clear payment terms upfront can help prevent misunderstandings and facilitate smoother transactions. -

How can I ensure proper logistics for importing solar electric cars?

To ensure effective logistics for importing solar electric cars, partner with a reliable freight forwarder experienced in handling automotive shipments. Discuss shipping options, including containerization or RORO (Roll-On/Roll-Off) methods, depending on your volume and budget. Ensure all customs documentation is prepared in advance to avoid delays. It’s also wise to consider insurance for your shipment to protect against potential damages during transit. Establishing a timeline for delivery can help manage expectations and streamline the process. -

What are the customization options available for solar electric cars?

Customization options for solar electric cars can vary by manufacturer. Common modifications include adjustments to battery capacity, solar panel configurations, interior features, and branding options. Some manufacturers may also provide the opportunity to tailor technical specifications to better suit local regulations or user preferences. Engage in discussions with potential suppliers early in the negotiation process to understand the extent of customization available and associated costs. -

How do I verify the reliability of a solar electric car supplier in China?

Verifying supplier reliability involves conducting thorough due diligence. Start by checking the company’s business license, years of operation, and export experience. Utilize platforms like Alibaba or Global Sources to read reviews and ratings from other buyers. Consider asking for references or case studies from previous clients, particularly those in your region. Engaging a third-party inspection service can provide additional assurance of the supplier’s operational capabilities and product quality. -

What are the environmental benefits of sourcing solar electric cars from China?

Sourcing solar electric cars contributes significantly to environmental sustainability by reducing reliance on fossil fuels and decreasing greenhouse gas emissions. These vehicles harness renewable solar energy, resulting in a cleaner alternative to conventional transportation. Additionally, many Chinese manufacturers are at the forefront of green technology, aiming to enhance energy efficiency and sustainability practices. By investing in solar electric cars, your business not only aligns with global sustainability goals but also appeals to environmentally-conscious consumers in your target markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Solar Electric Cars Made In China Manufacturers & Suppliers List

1. The Cool Down – Tianjin Solar Car

Domain: thecooldown.com

Registered: 2020 (5 years)

Introduction: Product Name: Tianjin Solar Car

Type: Solar-powered vehicle

Development Time: 5 months

Developers: 42 companies and 3 universities

Solar Panel Area: 87 square feet

Daily Power Output: 7.6 kilowatt-hours (on sunny days)

Carbon Pollution Reduction: 55 pounds for every 62 miles traveled

Maximum Range: 47 miles

Maximum Speed: 49 mph

Seating Capacity: 4 (1 driver + 3 passengers)

Features: Touchscreen d…

2. Examine China – Solar-Powered Vehicle

Domain: examinechina.com

Registered: 2011 (14 years)

Introduction: China’s first solar-powered vehicle, developed in Tianjin, is the first to rely solely on solar energy. It was created in five months by 42 companies and three universities. Key specifications include: seating for three plus a driver, a driver’s area with a touchscreen display and three buttons, Level 4 autonomous driving, body weight of 1,020 kg (2,250 lbs.), dimensions of 4.08 m long × 1.77 m wi…

3. Accio – Solar Panel Electric Vehicle

Domain: accio.com

Registered: 1997 (28 years)

Introduction: Key considerations: Unit Price: $0.18 – $27,900; Quantity: Product attributes: Solar Panels, Lithium Battery, 100km Range, 30km/h Max Speed, Regenerative Braking, LED Headlights, GPS Navigation, Touchscreen Display, Fast Charging, Lightweight Frame. Popular products include: 1) China EV Solar Electric Car Adult Electric Mini-Car with 4 Seats ($600-620, MOQ: 1 set); 2) Eu Certified Solar Charging A…

4. China – Electric Vehicles

Domain: technologyreview.com

Registered: 1998 (27 years)

Introduction: China has become a world leader in electric vehicles (EVs), with annual sales growing from 1.3 million to 6.8 million in just two years, making 2022 the eighth consecutive year as the largest market for EVs. The US sold about 800,000 EVs in 2022. Key factors include generous government subsidies, tax breaks, procurement contracts, and a focus on developing homegrown EV brands. The Chinese governme…

5. Reddit – Electric Vehicles in China

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Electric vehicles (EVs) in China have reached a market share of 51%, achieving over 50% in the largest car market. The EVs produced are increasingly better, indicating a competitive market that may negatively impact automakers in North America and Europe.

Strategic Sourcing Conclusion and Outlook for solar electric cars made in china

In summary, the emergence of solar electric cars, particularly the Tianjin model from China, highlights a pivotal shift in the automotive landscape toward sustainable and innovative transportation solutions. For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, strategic sourcing of these vehicles not only aligns with global sustainability goals but also provides a competitive edge in markets increasingly driven by eco-conscious consumers.

The Tianjin solar car serves as a proof of concept, demonstrating that vehicles can be powered entirely by renewable energy sources. This development opens avenues for collaboration with Chinese manufacturers who are pioneering this technology, ensuring access to cutting-edge innovations that meet the growing demand for green transportation solutions.

As you consider your sourcing strategies, now is the time to engage with the Chinese solar electric vehicle market. By investing in these advancements, you can position your business at the forefront of the sustainable mobility revolution, ultimately contributing to a cleaner, more efficient future. Embrace this opportunity to lead in your market by prioritizing partnerships that drive sustainable innovation.