Introduction: Navigating the Global Market for utruck Mounted Crane

In the rapidly evolving landscape of construction and logistics, sourcing a reliable truck mounted crane can be a daunting challenge for international B2B buyers. The complexity of selecting the right model—considering various lifting capacities, operational environments, and regional compliance standards—can significantly impact project efficiency and cost-effectiveness. This comprehensive guide aims to demystify the global market for truck mounted cranes, providing critical insights into the diverse types available, their specific applications across industries, and practical tips for supplier vetting.

From knuckle boom cranes designed for tight urban spaces to high-capacity telescopic models capable of reaching impressive heights, understanding the nuances of each type will empower buyers to make informed decisions. The guide also delves into essential considerations, including cost factors, maintenance requirements, and the importance of after-sales support, particularly for buyers in regions like Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Nigeria.

By equipping stakeholders with the knowledge to navigate this intricate market, this resource serves as a vital tool for enhancing operational efficiency and maximizing return on investment. Whether you are looking to expand your fleet or upgrade existing equipment, our guide will ensure that you approach your procurement process with confidence and clarity.

Understanding utruck Mounted Crane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Knuckle Boom Cranes | Articulating arm allows for greater maneuverability | Construction, logistics, and delivery | Pros: Flexible operation, compact design. Cons: May have lower lifting capacity compared to larger cranes. |

| Telescoping Cranes | Extendable boom provides variable reach and height | Heavy lifting, industrial applications | Pros: High lifting capacity, versatile. Cons: Longer setup time, may require more space. |

| Service Cranes | Specifically designed for maintenance and repair tasks | Equipment servicing, roadside assistance | Pros: Efficient for service tasks, often includes tool storage. Cons: Limited lifting capacity compared to heavy-duty cranes. |

| Material Handling Cranes | Optimized for moving bulk materials and heavy loads | Warehousing, construction, and lumber yards | Pros: Ideal for heavy payloads, fast loading/unloading. Cons: Heavier, may be less maneuverable. |

| Timber & Refuse Cranes | Specialized for handling timber and refuse materials | Forestry, waste management, recycling | Pros: Built for durability, efficient in specific applications. Cons: Limited versatility outside timber and refuse handling. |

What are Knuckle Boom Cranes and Their B2B Relevance?

Knuckle boom cranes are characterized by their articulating arms, which provide exceptional maneuverability, especially in tight spaces. This makes them ideal for construction, logistics, and delivery applications where flexibility is crucial. When considering a knuckle boom crane, B2B buyers should evaluate their operational environment, as these cranes are typically lighter and more compact, making them suitable for urban settings or areas with restricted access. However, they may not offer the same lifting capacity as larger cranes, which is a critical factor for heavy-duty applications.

How Do Telescoping Cranes Serve B2B Needs?

Telescoping cranes feature extendable booms that allow for significant reach and height adjustments, making them suitable for heavy lifting in industrial applications. These cranes are often employed in construction, manufacturing, and other sectors requiring robust lifting capabilities. Buyers should consider the maximum load capacity and boom length to ensure the crane meets their project specifications. While telescoping cranes provide versatility, they may require more space for setup and operation, which could be a limitation in confined job sites.

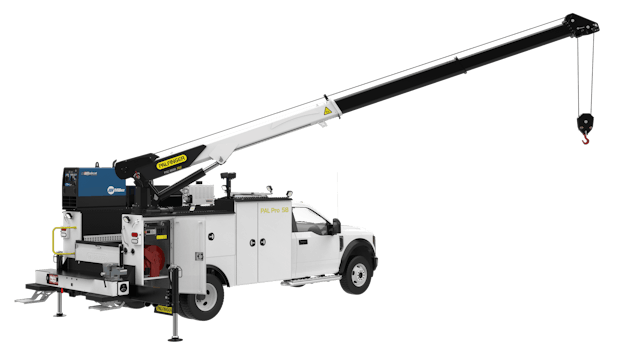

What Advantages Do Service Cranes Offer in the B2B Sector?

Service cranes are designed primarily for maintenance and repair tasks, featuring integrated tool storage and equipment handling capabilities. They are commonly used in roadside assistance and equipment servicing applications. For B2B buyers, the efficiency of service cranes can significantly enhance operational productivity, allowing for quick responses to service calls. However, their lifting capacity is generally lower than other types of cranes, which may limit their use in heavy lifting scenarios. Buyers should assess the specific service needs to determine the suitability of these cranes.

Why Choose Material Handling Cranes for Your Business?

Material handling cranes are engineered for the efficient movement of bulk materials and heavy loads, making them indispensable in warehousing, construction, and lumber yards. These cranes are optimized for fast loading and unloading, which can improve operational efficiency and reduce labor costs. When purchasing a material handling crane, B2B buyers should consider the crane’s lifting capacity and compatibility with their existing equipment. While these cranes excel in heavy payloads, their weight may impact maneuverability, which is an important factor for buyers operating in tighter spaces.

What Makes Timber & Refuse Cranes Ideal for Specific Industries?

Timber and refuse cranes are specialized machines designed to handle timber and waste materials effectively. Their robust construction ensures durability in challenging environments like forestry and waste management. B2B buyers should evaluate the specific features of these cranes, such as stability and load capacity, to ensure they align with their operational needs. While these cranes excel in their intended applications, their limited versatility may restrict their use in other sectors, making it essential for buyers to consider their long-term operational requirements.

Key Industrial Applications of utruck Mounted Crane

| Industry/Sector | Specific Application of utruck Mounted Crane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and placing heavy materials on construction sites | Increases efficiency and reduces labor costs | Load capacity, boom reach, and safety features |

| Logistics and Transportation | Loading and unloading freight at distribution centers | Streamlines operations and enhances delivery speed | Vehicle compatibility, weight distribution, and maneuverability |

| Oil and Gas | Hoisting equipment and materials in remote locations | Minimizes downtime and ensures safety in challenging environments | Fuel efficiency, all-terrain capability, and maintenance support |

| Agriculture | Transporting heavy machinery and supplies on farms | Improves productivity and reduces manual labor | Adaptability to varied terrain and lifting capacity |

| Utilities | Installing and maintaining power lines and infrastructure | Enhances service reliability and reduces operational delays | Reach, stability, and ease of operation in confined spaces |

How Are Truck Mounted Cranes Used in Construction?

In the construction industry, truck mounted cranes are vital for lifting and placing heavy materials such as steel beams, concrete blocks, and roofing materials. They facilitate quick setup and efficient material handling, which is crucial for meeting project deadlines. For international buyers, especially in regions like Africa and the Middle East, considerations such as load capacity, boom reach, and safety features are paramount. These cranes help mitigate risks associated with manual lifting, ensuring worker safety while optimizing labor costs.

What Role Do Truck Mounted Cranes Play in Logistics and Transportation?

In logistics and transportation, truck mounted cranes are used to load and unload freight at distribution centers, enhancing operational efficiency. They enable companies to handle heavy loads with ease, thereby improving delivery speed. B2B buyers in South America and Europe should focus on vehicle compatibility, weight distribution, and maneuverability when sourcing these cranes. By integrating truck mounted cranes into their operations, businesses can streamline processes and reduce handling times, ultimately leading to increased customer satisfaction.

How Are Truck Mounted Cranes Beneficial in the Oil and Gas Sector?

In the oil and gas sector, truck mounted cranes are essential for hoisting equipment and materials in remote locations, where traditional cranes may not be feasible. They minimize downtime and enhance safety in challenging environments, making them a valuable asset for operations in regions like Nigeria and Saudi Arabia. Buyers should prioritize fuel efficiency, all-terrain capability, and maintenance support when sourcing these cranes. The ability to quickly deploy and operate in difficult terrains can significantly impact project timelines and costs.

How Do Truck Mounted Cranes Improve Agricultural Operations?

In agriculture, truck mounted cranes assist in transporting heavy machinery and supplies across farms, significantly improving productivity and reducing the need for manual labor. They are particularly useful in regions with diverse terrain, providing farmers the ability to efficiently manage resources. For international buyers, adaptability to varied terrains and adequate lifting capacity are crucial considerations. By utilizing these cranes, agricultural businesses can enhance operational efficiency and minimize the risk of injury associated with manual lifting tasks.

What Advantages Do Truck Mounted Cranes Offer Utility Companies?

Utility companies benefit from truck mounted cranes during the installation and maintenance of power lines and infrastructure. These cranes enhance service reliability by enabling quick access to hard-to-reach locations, thus reducing operational delays. When sourcing cranes, buyers should consider factors like reach, stability, and ease of operation in confined spaces. The ability to efficiently manage utility installations and maintenance can lead to improved service delivery and customer satisfaction, making these cranes an essential tool in the sector.

3 Common User Pain Points for ‘utruck Mounted Crane’ & Their Solutions

Scenario 1: Inefficient Lifting Operations Leading to Delays

The Problem: In many industries, particularly in construction and logistics, delays caused by inefficient lifting operations can lead to significant financial losses. A B2B buyer may find that their existing truck-mounted crane is unable to handle heavy loads swiftly, resulting in downtime that affects project timelines. This challenge is compounded in regions with limited access to replacement parts or service technicians, making it difficult to resolve issues quickly. The inability to lift loads efficiently can also impact worker safety, as operators may be forced to use alternative, less safe methods.

The Solution: To address these inefficiencies, buyers should consider investing in a truck-mounted crane that offers a high lifting capacity and advanced features such as continuous rotation and proportional control. When sourcing a crane, look for models specifically designed for the type of loads and working conditions typical to your operations. For instance, cranes with knuckle boom designs can provide increased maneuverability in tight spaces, allowing operators to work more effectively. Additionally, ensuring that the crane is compatible with attachments, such as grapples or workman baskets, can further enhance its versatility and performance. Regular maintenance and training for operators on the crane’s capabilities can also help maximize efficiency and minimize downtime.

Scenario 2: Safety Concerns During Crane Operation

The Problem: Safety is a paramount concern in industries utilizing truck-mounted cranes, especially in regions with stringent regulations. B2B buyers may experience anxiety over the potential for accidents during operation, which can result in injuries, legal liabilities, and damage to equipment or property. Common issues include the risk of overloading, lack of proper safety features, and insufficient operator training. Buyers in regions with diverse weather conditions, such as the Middle East or Africa, also face challenges related to stability and control in adverse weather.

The Solution: To mitigate safety risks, it is essential to select a truck-mounted crane equipped with advanced safety features, such as overload protection systems and anti-two-blocking mechanisms. Buyers should prioritize cranes that meet international safety standards and come with a comprehensive operator manual that emphasizes safe operational practices. Furthermore, investing in operator training is critical; consider partnering with manufacturers that offer training programs or certification. Regular safety audits and maintenance checks can ensure that all safety features are functional and that operators are familiar with emergency protocols. Creating a culture of safety within the workforce will not only protect employees but also enhance overall operational efficiency.

Scenario 3: Challenges in Crane Maintenance and Parts Availability

The Problem: A common pain point for B2B buyers is the challenge of maintaining truck-mounted cranes, particularly in regions where access to spare parts and skilled technicians is limited. Buyers may face long lead times for repairs, leading to prolonged equipment downtime and increased operational costs. This situation is especially prevalent in remote areas or developing markets where local service support may be inadequate.

The Solution: To overcome maintenance challenges, buyers should consider purchasing truck-mounted cranes from manufacturers that provide comprehensive after-sales support, including readily available spare parts and local service networks. It is advisable to conduct thorough research on the manufacturer’s reputation for service and support before making a purchase. Additionally, implementing a proactive maintenance schedule can prevent major breakdowns; this includes regular inspections and timely replacements of wear parts. Buyers should also explore options for telematics systems that offer real-time diagnostics and maintenance alerts, allowing for quicker response times and minimizing downtime. By investing in cranes with robust support structures, buyers can ensure their equipment remains operational and efficient, even in challenging environments.

Strategic Material Selection Guide for utruck Mounted Crane

What Are the Key Materials Used in Utruck Mounted Cranes?

When selecting materials for truck-mounted cranes, several factors influence performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the construction of these cranes: Steel, Aluminum, Composite Materials, and High-Strength Alloys.

How Does Steel Contribute to the Performance of Utruck Mounted Cranes?

Steel is the most commonly used material in truck-mounted cranes due to its exceptional strength and durability. With a high tensile strength, steel can withstand significant loads and harsh environmental conditions. Its corrosion resistance can be enhanced through galvanization or coatings, making it suitable for various climates, including humid or coastal regions.

Pros: Steel offers high durability and is relatively cost-effective. It is widely available and can be easily fabricated into complex shapes, which is beneficial for intricate crane designs.

Cons: The weight of steel can be a disadvantage, potentially limiting the payload capacity of the truck. Additionally, its susceptibility to corrosion without proper treatment can lead to increased maintenance costs.

What Role Does Aluminum Play in Utruck Mounted Crane Design?

Aluminum is increasingly popular for truck-mounted cranes, particularly in applications where weight savings are critical. Its lightweight nature allows for higher payload capacities and better fuel efficiency. Aluminum also has inherent corrosion resistance, making it ideal for use in harsh environments.

Pros: The primary advantage of aluminum is its weight-to-strength ratio, which enhances the crane’s overall performance. It also requires less maintenance compared to steel.

Cons: Aluminum is generally more expensive than steel, which can impact overall project budgets. Additionally, it may not provide the same level of strength as high-grade steel, which can be a concern for heavy-duty applications.

How Do Composite Materials Enhance Utruck Mounted Crane Functionality?

Composite materials, such as fiberglass or carbon fiber, are becoming more prevalent in truck-mounted cranes due to their lightweight and high-strength properties. These materials can be engineered to provide excellent resistance to corrosion and fatigue.

Pros: Composites can significantly reduce the overall weight of the crane, allowing for increased payload capacities. They also offer superior resistance to environmental degradation.

Cons: The primary limitation of composite materials is their higher cost and complexity in manufacturing. Repairing or replacing composite components can also be more challenging than traditional materials.

What Advantages Do High-Strength Alloys Offer for Utruck Mounted Cranes?

High-strength alloys, such as titanium or specialized steel alloys, are used in applications requiring exceptional performance under extreme conditions. These materials offer superior strength and resistance to wear and fatigue.

Pros: High-strength alloys provide excellent durability and can withstand higher loads and stress levels, making them suitable for demanding applications.

Cons: The significant drawback is the high cost of these materials, which may not be justifiable for all applications. Additionally, their manufacturing processes can be complex and require specialized equipment.

Summary Table of Material Selection for Utruck Mounted Cranes

| Material | Typical Use Case for Utruck Mounted Crane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | General construction and heavy lifting | High strength and durability | Heavy weight and corrosion potential | Medium |

| Aluminum | Lightweight applications | Excellent weight-to-strength ratio | Higher cost and lower strength | High |

| Composite Materials | Specialized applications requiring weight savings | Superior resistance to corrosion | High cost and complex repairs | High |

| High-Strength Alloys | Extreme duty applications | Exceptional strength under stress | Very high cost and manufacturing complexity | High |

In conclusion, selecting the right material for truck-mounted cranes involves balancing performance, cost, and application requirements. Understanding these materials’ properties and implications allows international B2B buyers to make informed decisions that align with their operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for utruck Mounted Crane

What Are the Key Stages in the Manufacturing Process of Truck Mounted Cranes?

The manufacturing process of truck-mounted cranes involves several critical stages that ensure the final product meets rigorous standards for performance and safety. Understanding these stages can help B2B buyers make informed decisions when sourcing equipment.

Material Preparation: What Materials Are Used?

The first stage in manufacturing truck-mounted cranes is material preparation. High-strength steel is commonly used for the structural components due to its durability and resistance to deformation. Aluminum may also be utilized in lighter models to reduce overall weight while maintaining strength. Manufacturers typically source materials from certified suppliers to ensure quality and compliance with industry standards.

How Are Truck Mounted Cranes Formed?

Following material preparation, the forming process begins. This involves cutting, bending, and shaping the metal components. Advanced technologies such as CNC machining and laser cutting are often employed to achieve precise dimensions. Automated welding techniques, including robotic welding, are utilized to enhance consistency and reduce human error. These methods not only improve production efficiency but also ensure that the structural integrity of each component is upheld.

What Happens During the Assembly of Truck Mounted Cranes?

Once the components are formed, the assembly stage commences. This involves the systematic integration of various parts, including the boom, chassis, and hydraulic systems. During assembly, manufacturers often implement modular construction techniques, allowing for easier upgrades and repairs in the future. The cranes are also equipped with advanced hydraulic systems that facilitate smooth operation and enhanced lifting capabilities.

What Finishing Techniques Are Used in Truck Mounted Crane Production?

Finishing processes are crucial for enhancing the aesthetic appeal and longevity of truck-mounted cranes. Common techniques include painting, powder coating, and galvanizing. These methods not only improve appearance but also provide protection against corrosion, particularly important in harsh environments. Quality control checks are conducted at this stage to ensure that the finish meets the required specifications.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is a vital aspect of the manufacturing process for truck-mounted cranes. International standards such as ISO 9001 provide a framework for consistent quality management systems. Compliance with such standards indicates that the manufacturer has implemented effective processes to monitor and improve product quality.

What Industry-Specific Certifications Are Relevant?

Beyond general quality standards, industry-specific certifications also play a crucial role. For instance, cranes sold in Europe must meet CE certification requirements, which ensure compliance with health, safety, and environmental protection standards. In the oil and gas industry, API certifications may be necessary to verify that cranes can withstand rigorous operational demands.

What Are the Key Quality Control Checkpoints in Crane Manufacturing?

Throughout the manufacturing process, several quality control checkpoints are established to monitor product quality. These include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During manufacturing, regular checks are performed to identify any deviations from quality standards early in the process.

- Final Quality Control (FQC): Before delivery, a comprehensive inspection is conducted to verify that the finished crane meets all performance and safety specifications.

What Common Testing Methods Are Used for Truck Mounted Cranes?

Testing methods are crucial for validating the performance and safety of truck-mounted cranes. Common approaches include:

- Load Testing: This assesses the crane’s lifting capacity under controlled conditions.

- Functional Testing: This ensures that all operational features, such as hydraulic systems and controls, function correctly.

- Safety Testing: This involves evaluating safety systems, including overload protection and emergency stop mechanisms.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential for mitigating risks. Here are some effective strategies:

- Audits: Conducting on-site audits allows buyers to assess the manufacturing environment and quality control processes firsthand.

- Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s adherence to standards and their historical performance.

- Third-Party Inspections: Engaging independent inspection agencies can validate the manufacturer’s claims regarding product quality and compliance with international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

Quality control practices may vary significantly across regions, influenced by local regulations and industry standards. For instance, buyers from Africa and South America might encounter different compliance requirements than those in Europe or the Middle East. Therefore, understanding these nuances is essential for ensuring that the products meet the necessary standards for their intended market.

Additionally, B2B buyers should consider the logistical aspects of quality control, such as transportation and customs regulations, which can impact delivery timelines and overall project success.

Conclusion: Ensuring Quality in Truck Mounted Crane Procurement

In conclusion, understanding the manufacturing processes and quality assurance protocols for truck-mounted cranes is crucial for B2B buyers looking to make informed purchasing decisions. By paying attention to material preparation, forming, assembly, finishing, and rigorous quality control standards, buyers can ensure that they procure reliable, high-quality cranes that meet their operational needs. Establishing strong partnerships with reputable manufacturers and conducting thorough due diligence can further enhance procurement success in diverse international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘utruck Mounted Crane’

Introduction

When sourcing a truck-mounted crane, B2B buyers must navigate a complex landscape of technical specifications, supplier reliability, and regional compliance. This step-by-step checklist is designed to streamline your procurement process, ensuring that you make informed decisions that align with your operational needs and strategic goals.

Step 1: Define Your Technical Specifications

Begin by outlining the specific technical requirements of the crane you need. Consider factors such as lifting capacity, boom length, and operational reach.

– Lifting Capacity: Ensure the crane can handle the maximum load you expect to lift.

– Boom Length: Determine the reach necessary for your typical job sites.

– Hydraulic Features: Assess hydraulic power options and control systems that suit your operational needs.

Step 2: Identify Your Application Needs

Understanding the applications for which the crane will be used is crucial. Different industries may require varying features and capabilities.

– Industry Requirements: Whether for construction, logistics, or forestry, clarify the specific needs of your sector.

– Terrain Considerations: Evaluate if the crane will operate in rugged or urban environments, which could impact its specifications.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. This step ensures you partner with reliable manufacturers that meet your quality standards.

– Supplier Reputation: Request company profiles and references from other buyers in your industry.

– Product Range: Check if they offer a variety of models that may suit your future needs, ensuring long-term compatibility with your operations.

Step 4: Verify Compliance with Regional Standards

Ensure that the cranes meet local regulations and safety standards specific to your region, especially in countries with stringent compliance requirements.

– Safety Standards: Confirm adherence to international standards such as ANSI and OSHA, as well as local regulations in your target market.

– Quality Certifications: Look for certifications that indicate a commitment to quality and safety, such as ISO or CE markings.

Step 5: Assess After-Sales Support and Warranty

After-sales service can significantly impact the lifespan and efficiency of your crane. Evaluate the warranty and support services offered by suppliers.

– Warranty Terms: Look for comprehensive warranty options that cover parts and labor for a substantial period.

– Maintenance Services: Inquire about ongoing maintenance support, training for operators, and availability of spare parts.

Step 6: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that include pricing, delivery times, and any additional costs.

– Transparent Pricing: Ensure that quotes cover all aspects, including installation and training, to avoid hidden costs later.

– Lead Times: Consider the delivery timelines, especially if your project schedule is tight.

Step 7: Conduct a Final Review and Make a Decision

Before finalizing your purchase, conduct a comprehensive review of all information gathered. Ensure that the selected crane aligns with your operational needs and budget.

– Comparative Analysis: Weigh the pros and cons of each supplier based on your checklist.

– Decision Matrix: Use a decision matrix to visualize how each option meets your criteria, aiding in a balanced decision-making process.

By following this checklist, you can streamline your procurement process and ensure that you select a truck-mounted crane that meets both your operational requirements and budget constraints.

Comprehensive Cost and Pricing Analysis for utruck Mounted Crane Sourcing

What Are the Key Cost Components for Truck Mounted Cranes?

When sourcing truck mounted cranes, understanding the comprehensive cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: High-quality steel, hydraulic systems, and electronic components are fundamental to crane construction. The choice of materials significantly influences the durability and performance of the crane, which can vary based on the manufacturer’s standards.

-

Labor: Skilled labor is required for both manufacturing and assembly. Labor costs can fluctuate based on geographical location and the complexity of the crane design.

-

Manufacturing Overhead: This encompasses utilities, facility maintenance, and equipment depreciation. Manufacturers with advanced technology may have lower overhead costs due to automation, which can lead to more competitive pricing.

-

Tooling: The costs associated with the specialized tools and machinery needed for production can be substantial. Manufacturers that invest in modern tooling may achieve greater efficiency and precision, potentially reducing overall costs.

-

Quality Control (QC): Rigorous testing and quality assurance processes ensure that cranes meet safety and performance standards. The expense of QC can vary; however, investing in thorough testing can mitigate long-term risks for buyers.

-

Logistics: Transportation costs are critical, especially for international shipments. This includes freight, customs duties, and insurance. Buyers should be aware that logistics costs can vary significantly based on the shipping method and distance.

-

Margin: Manufacturers typically apply a profit margin to cover their operational costs and risks. This margin can be influenced by market demand, brand reputation, and product uniqueness.

How Do Volume and Customization Affect Pricing?

Pricing for truck mounted cranes is often influenced by the volume of the order and the degree of customization required.

-

Volume/MOQ: Larger orders usually qualify for bulk pricing discounts. Manufacturers are more willing to negotiate terms for high-volume purchases, which can significantly lower the per-unit cost.

-

Specifications and Customization: Custom features, such as specialized booms or additional safety systems, can increase the price. Buyers should clearly outline their needs to avoid unexpected costs and ensure the crane meets specific operational requirements.

What Role Do Materials and Quality Certifications Play in Pricing?

The choice of materials and the presence of quality certifications can significantly impact pricing structures.

-

Materials: High-performance materials designed for specific applications may incur higher costs but can lead to better longevity and efficiency. It’s essential for buyers to balance initial costs with the expected lifespan and performance of the crane.

-

Quality Certifications: Compliance with international safety and operational standards can enhance the crane’s marketability and justify higher prices. Buyers should inquire about certifications such as ISO or CE, which can indicate a manufacturer’s commitment to quality.

What Supplier Factors Should Buyers Consider?

When sourcing truck mounted cranes, several supplier-related factors can influence pricing:

-

Reputation and Experience: Established manufacturers with a proven track record may charge a premium for their products, reflecting their reliability and service.

-

After-Sales Support: Companies that offer robust after-sales service, including maintenance and spare parts availability, may justify higher prices due to the reduced risk of downtime.

How Can International Buyers Optimize Costs and Negotiate Effectively?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiation: Engage in discussions regarding pricing, payment terms, and delivery schedules. Building a relationship with suppliers can lead to better deals.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, operational costs, and potential resale value. A lower upfront cost may lead to higher long-term expenses if the crane is less durable.

-

Pricing Nuances: Be aware of the implications of Incoterms, which define responsibilities for shipping and risk. Understanding these terms can help avoid unexpected costs and delays.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices for truck mounted cranes can vary widely, it’s essential for buyers to conduct thorough market research and cost analysis. By understanding the intricate cost components, pricing influencers, and effective negotiation strategies, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing utruck Mounted Crane With Other Solutions

Exploring Alternatives to Utruck Mounted Cranes for Lifting Solutions

In the world of heavy lifting and material handling, various solutions exist to meet diverse operational requirements. While truck-mounted cranes are a popular choice due to their versatility and mobility, it’s essential for B2B buyers to consider alternative lifting technologies that may better suit specific applications. Below, we compare truck-mounted cranes against two viable alternatives: telehandlers and crawler cranes.

| Comparison Aspect | Utruck Mounted Crane | Telehandler | Crawler Crane |

|---|---|---|---|

| Performance | High lifting capacity; suitable for road transport | Good for lifting and placing materials; limited reach | Excellent for heavy loads; superior stability on uneven ground |

| Cost | Moderate initial investment; ongoing maintenance costs | Generally lower purchase price; higher operating costs | High initial investment; cost-effective for large projects |

| Ease of Implementation | Requires a truck chassis; operator training needed | Simple setup; requires minimal training | Complex setup; skilled operators needed |

| Maintenance | Regular inspections; hydraulic system upkeep | Easier maintenance; fewer moving parts | High maintenance; regular inspections required |

| Best Use Case | Urban construction and delivery | Agricultural and construction sites with moderate loads | Heavy construction, mining, and industrial applications |

In-Depth Look at Alternatives

Telehandlers

Telehandlers are versatile machines that combine the functionality of a forklift and a crane. They feature a telescopic boom that can reach heights similar to that of a truck-mounted crane but generally have a lower lifting capacity. Their lower purchase price makes them an attractive option for businesses with budget constraints. However, they can be limited in terms of reach and stability when lifting heavy loads, particularly on uneven terrain.

Crawler Cranes

Crawler cranes are designed for heavy lifting and are equipped with tracks for superior stability and mobility on rough terrain. These cranes have a high lifting capacity and can handle significant weight, making them ideal for large construction projects. However, the initial investment is considerably higher, and they require skilled operators for safe and efficient operation. Additionally, their setup can be complex, making them less convenient for quick tasks compared to truck-mounted cranes.

Making the Right Choice for Your Lifting Needs

When selecting the right lifting solution, B2B buyers should consider several factors such as the nature of the project, budget constraints, and operational efficiency. Utruck mounted cranes offer excellent mobility and versatility for urban environments, while telehandlers provide a cost-effective solution for less demanding tasks. Conversely, crawler cranes are optimal for projects requiring heavy lifting in challenging terrains but come with higher operational costs.

Ultimately, the choice between these alternatives will depend on specific project requirements and financial considerations. By evaluating each option’s strengths and weaknesses, buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for utruck Mounted Crane

What Are the Key Technical Properties of a Truck Mounted Crane?

Understanding the essential technical properties of truck mounted cranes is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. Here are several key specifications that define the performance and reliability of these cranes:

-

Maximum Lifting Capacity

This specification indicates the maximum weight the crane can lift safely. It is typically expressed in tons (e.g., 40 USt or 36.3 t). Knowing the lifting capacity is vital for buyers to ensure the crane meets their operational requirements, especially in industries such as construction, logistics, and waste management. -

Boom Length

The boom length refers to the distance from the crane’s pivot point to the end of the boom. Measured in feet or meters, this property affects how high and how far the crane can reach. For instance, a boom length of 40 ft to 169 ft provides versatility in accessing various job sites. Buyers should evaluate the required boom length based on the typical tasks their operations entail. -

Total Gross Vehicle Weight (GVW)

This specification includes the weight of the crane and its load-carrying capacity. Understanding the GVW helps in compliance with local transportation regulations and ensures the crane can be safely operated on public roads. It also aids in selecting an appropriate truck chassis that can support the crane’s weight. -

Max Tip Height

The max tip height is the maximum height the crane can reach when fully extended. This property is crucial for applications where vertical lift is necessary, such as in construction or maintenance of tall structures. Buyers should assess their specific lifting needs to ensure the crane can meet height requirements. -

Operating Radius

The operating radius defines the distance from the center of the crane’s rotation to the load being lifted. A larger operating radius allows for greater flexibility and efficiency in operations, particularly in tight spaces. Buyers need to consider their typical work environment to choose a crane with an appropriate operating radius. -

Control Systems

Modern truck mounted cranes often come equipped with advanced control systems that enhance operator efficiency and safety. These may include features like a user-friendly interface, anti-two-blocking systems, and remote control capabilities. Understanding these systems can improve operational effectiveness and reduce the risk of accidents.

What Are Common Trade Terms in the Truck Mounted Crane Industry?

Familiarizing oneself with industry jargon is essential for B2B buyers to navigate procurement processes effectively. Here are several common terms you should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to the company that manufactures the original product. In the context of truck mounted cranes, purchasing from an OEM ensures quality and compatibility with replacement parts, which is crucial for maintenance and longevity. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers as it impacts inventory management and procurement strategy. Knowing this can help in negotiating better terms or finding alternative suppliers. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers. It typically includes specifications and quantity requirements. Crafting a detailed RFQ helps ensure that suppliers provide accurate quotes, which aids in budgeting and decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in a transaction. They define aspects like shipping costs, insurance, and risk transfer. Familiarity with Incoterms is crucial for buyers to understand their obligations and ensure smooth logistics. -

Payload

Payload refers to the total weight a crane can safely carry, including the weight of the materials being lifted and any attachments. It is essential for determining whether a crane can handle specific tasks without exceeding weight limits. -

Hydraulic System

A hydraulic system uses pressurized fluid to perform work and is integral to the operation of truck mounted cranes. Understanding this system is crucial for assessing the crane’s lifting capabilities and maintenance needs.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions when sourcing truck mounted cranes, ensuring they select the right equipment for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the utruck Mounted Crane Sector

What are the Key Trends Shaping the Truck Mounted Crane Market?

The truck mounted crane market is experiencing significant growth driven by a surge in construction and infrastructure projects globally. Regions like Africa, South America, the Middle East, and Europe are witnessing a heightened demand for efficient lifting solutions due to urbanization and industrialization. Key trends include the adoption of advanced technologies such as telematics and IoT, enhancing operational efficiency and providing real-time data for better decision-making. Additionally, innovations in design, such as compact and versatile models, are gaining traction, allowing for improved maneuverability in urban settings.

Sourcing trends indicate a shift towards local suppliers to reduce lead times and transportation costs, particularly in regions like Nigeria and Saudi Arabia, where logistics can be challenging. Moreover, international buyers are increasingly favoring manufacturers that offer customizable solutions to meet specific operational requirements. The emphasis on safety features, such as overload protection and advanced control systems, is also becoming paramount as industries prioritize worker safety and compliance with stringent regulations.

How is Sustainability Influencing Sourcing Decisions in the Truck Mounted Crane Sector?

Sustainability is a critical factor in the sourcing decisions of international B2B buyers in the truck mounted crane sector. The environmental impact of manufacturing processes and the lifecycle of machinery is under scrutiny, prompting companies to seek suppliers that prioritize eco-friendly practices. This includes the use of sustainable materials and manufacturing techniques that minimize waste and energy consumption.

Buyers are increasingly looking for ‘green’ certifications that validate a manufacturer’s commitment to sustainable practices. These certifications can enhance a company’s reputation and appeal to environmentally conscious clients. Additionally, the demand for electric or hybrid cranes is rising as businesses strive to reduce their carbon footprint. Implementing ethical supply chains that ensure fair labor practices and responsible sourcing further aligns with the growing emphasis on corporate social responsibility in the global market.

What is the Historical Context of Truck Mounted Cranes in B2B Markets?

The evolution of truck mounted cranes can be traced back to the early 20th century, when the demand for more efficient lifting solutions began to rise with the expansion of construction and industrial sectors. Initially, cranes were designed for specific applications, but as market needs diversified, manufacturers started developing versatile models that could handle various tasks.

The introduction of hydraulic technology in the mid-20th century significantly enhanced the performance and capabilities of truck mounted cranes, allowing for greater lifting capacities and improved operational efficiency. Over the years, advancements in materials and engineering have led to the creation of lighter, more durable cranes with enhanced safety features. Today, the focus has shifted towards integrating smart technologies and sustainability, reflecting the changing dynamics of global business and environmental considerations.

In summary, understanding the market dynamics and sourcing trends within the truck mounted crane sector is crucial for B2B buyers. By aligning with sustainable practices and leveraging technological advancements, companies can not only enhance operational efficiency but also contribute to a more responsible and innovative industry landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of utruck Mounted Crane

-

How do I choose the right truck mounted crane for my business needs?

Selecting the appropriate truck mounted crane involves assessing your specific lifting requirements, such as load capacity, boom length, and operational environment. Consider factors like the types of materials you will be lifting, the frequency of use, and the terrain where the crane will operate. Consulting with suppliers and reviewing product specifications can provide insights into which models best match your operational needs, ensuring efficiency and safety on the job. -

What is the best truck mounted crane for construction projects?

The ideal truck mounted crane for construction typically features a robust lifting capacity, versatile boom configurations, and excellent maneuverability. Models with knuckle boom capabilities are often preferred for their flexibility in tight spaces. Additionally, cranes designed for heavy-duty operations, such as those from reputable manufacturers like PALFINGER or GROVE, ensure reliability and performance during demanding tasks, providing a competitive edge on construction sites. -

What are the key features to look for in a truck mounted crane?

When evaluating truck mounted cranes, key features to consider include lifting capacity, boom length, stability systems, and ease of operation. Look for models equipped with advanced safety mechanisms, such as overload protection and anti-two-blocking systems. Additionally, consider cranes with user-friendly controls and maintenance-friendly designs to reduce downtime and enhance operational efficiency, which are crucial for maintaining productivity in your business. -

What are the typical payment terms for international crane purchases?

Payment terms for international crane transactions can vary significantly based on supplier policies and buyer agreements. Common arrangements include upfront payments, letters of credit, or staggered payments based on delivery milestones. It’s crucial to negotiate favorable terms that align with your cash flow while ensuring supplier trust. Always review and clarify payment terms in contracts to avoid misunderstandings and to facilitate smooth transactions. -

How can I vet suppliers for truck mounted cranes?

Vetting suppliers involves a thorough assessment of their credibility, product quality, and service offerings. Start by checking their industry reputation, customer reviews, and case studies. Request certifications and compliance documents to ensure adherence to international safety standards. Engaging in direct communication and seeking references from other clients can provide valuable insights into their reliability and customer service capabilities. -

What is the minimum order quantity (MOQ) for truck mounted cranes?

The MOQ for truck mounted cranes can vary widely among suppliers, often depending on the manufacturer’s production capabilities and market demand. Some manufacturers may have an MOQ of one unit, while others may require bulk orders to optimize production efficiency. Discussing your specific needs with suppliers can provide clarity on MOQs and may offer flexibility for smaller orders, especially for first-time buyers. -

What logistics considerations should I keep in mind when importing truck mounted cranes?

When importing truck mounted cranes, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Ensure that you understand the import duties and taxes applicable to your region. Collaborating with a reliable freight forwarder can streamline the shipping process and help navigate complex customs procedures, ensuring that your cranes arrive safely and on schedule. -

How can I ensure quality assurance for my crane purchase?

To ensure quality assurance for your truck mounted crane purchase, request detailed product specifications, performance data, and certifications from the supplier. It’s advisable to conduct a pre-shipment inspection to verify that the crane meets agreed-upon standards and specifications. Establishing a clear return policy and warranty terms can also provide additional security, allowing you to address any potential issues post-purchase effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Utruck Mounted Crane Manufacturers & Suppliers List

1. PALFINGER – Truck Mounted Cranes

Domain: palfinger.com

Registered: 1997 (28 years)

Introduction: Truck Mounted Cranes: PALFINGER offers a wide range of truck-mounted cranes designed for various lifting needs, ensuring performance and reliability. Key product categories include: 1. Knuckle Boom Cranes: Durable and versatile, with options for fly-jib, crane forks, workman basket, auger, or grapple. 2. Material Handling Cranes: Specifically designed for the North American building materials indu…

2. Hews Company – Truck Mounted Cranes & Forklifts

Domain: hewsco.com

Registered: 2002 (23 years)

Introduction: Hews Company sells, installs, and services a full product line of truck mounted cranes and forklifts. They are a distributor for premier manufacturers and product lines including Hiab Cranes, MOFFETT truck-mounted forklifts, National Telescoping Cranes/Boom Trucks, Maintainer Service Cranes, Auto Crane, and Liftmoore. The product line includes Loader Cranes, Telescoping Cranes, Service Cranes, Art…

3. HMF – Lifting Cranes

Domain: hmfcranes.com

Registered: 2006 (19 years)

Introduction: {“Lifting capacity”: {“3 – 14 tm”: {}, “15 – 31 tm”: {}, “32 – 59 tm”: {}, “60 – 95 tm”: {}}, “Crane types”: [“Knuckle boom cranes (K)”, “Short knuckle boom cranes (KS)”, “Long boom cranes (L)”, “Recycling cranes (S)”, “Telescopic cranes (T)”, “Z-fold grab cranes (Z)”, “Wallboard cranes (WB)”], “Equipment”: {“Subframes”: {}, “Front stabilizers”: {}, “Separate traverses”: {}, “Safety equipment kits…

4. Manitowoc – GROVE Truck-Mounted Cranes

Domain: manitowoc.com

Registered: 1995 (30 years)

Introduction: GROVE Truck-Mounted Cranes offer quick set-up, long reach, high capacity booms, and highway speed travel capabilities. Key specifications include:

– Max capacity: 36.3t to 115USt (100t)

– Total gross vehicle weight: 25376kg to 81416lbs (36930kg)

– Main boom length: 8.75m to 51.6m (29ft to 169ft)

– Max tip height: 39.1m to 79.3m (128.2ft to 263.4ft)

Specific models include:

1. TMS9000-2: Max…

5. Air Technical – Super-Master Truck Mounted Crane

Domain: shop.airtechnical.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Super-Master Truck Mounted Crane”, “Model Number”: “SM-6000BP”, “Price”: “$6,563.00”, “Capacity Retracted”: “6000 pounds”, “Capacity Extended”: “3000 pounds”, “Max Lift Height Retracted”: “9 ft”, “Max Lift Height Extended”: “13 ft”, “Floor to Hook Height Retracted”: “38 inches”, “Floor to Hook Height Extended”: “26 inches”, “Max Reach”: “78 inches”, “Overall Height without Cable …

6. Industrial Man Lifts – HT25KX Truck-Mounted Crane

Domain: industrialmanlifts.com

Registered: 2011 (14 years)

Introduction: HT25KX Truck-Mounted Crane 5,000lbs Lifting Capacity features: fully hydraulic system, 20′ full-hydraulic extension boom, capacity-overload shut-off system, anti-two-blocking system, remote control pendant with 25 ft. cord, load block with swivel hook safety latch. Capacity: 5,000 lbs; Rating: 25,000 ft-lbs; Boom Length: 10 – 20 ft; Hydraulic Requirements: Standard: 2 GPM @ 3000 PSI, Proportional:…

7. Altec – Boom Truck Cranes

Domain: altec.com

Registered: 1996 (29 years)

Introduction: {“Boom Truck Cranes”: [{“Model”: “AC40E-152S”, “Load Rating”: “40 t (36.3 tonne)”, “Boom Length”: “152 ft (46.3 m)”, “Boom Sections”: “6 Sections”}, {“Model”: “AC45E-127S”, “Load Rating”: “45 t (40.8 tonne)”, “Boom Length”: “127 ft (38.7 m)”, “Boom Sections”: “5 Sections”}, {“Model”: “AC65E-155S”, “Load Rating”: “65 t (59 tonne)”, “Boom Length”: “155 ft (47.2 m)”, “Boom Sections”: “6 Sections”}, {…

8. Atlas Polar – HIAB Truck Cranes

Domain: atlaspolar.com

Registered: 1997 (28 years)

Introduction: HIAB Truck Cranes are engineered for long-term dependability and value, with over 60 models available. They range in capacities from 0.8 to 80 tonne meters and have long reaches up to 25 meters. HIAB invented the first hydraulic truck mounted crane in 1947 and has been a leader in the market since its introduction in Canada in 1954. The cranes are designed with superior hydraulic systems for unmat…

9. Western Mule – Pickup Truck Cranes

Domain: westernmule.com

Registered: 1997 (28 years)

Introduction: Western Mule offers two styles of pickup truck cranes: Telescoping Boom Cranes and Fold-A-Way Bumper Cranes. The Telescoping Boom Cranes can be mounted to any solid mobile or stationary platform and feature longer boom reach with multiple length and angle settings, available in AC, DC, and manual hand-crank models. The Fold-A-Way Bumper Cranes fold down to be concealed in the bumper, improving saf…

Strategic Sourcing Conclusion and Outlook for utruck Mounted Crane

What Are the Key Takeaways for Strategic Sourcing of Truck Mounted Cranes?

In the competitive landscape of truck-mounted cranes, strategic sourcing plays a pivotal role in ensuring operational efficiency and cost-effectiveness. Buyers must assess various models that align with their specific lifting needs, considering factors such as load capacity, boom reach, and versatility of attachments. Leading manufacturers like PALFINGER and GROVE showcase innovations that enhance performance, safety, and operator comfort, making them prime candidates for procurement.

Why Is Strategic Sourcing Essential for B2B Buyers?

Investing in high-quality truck-mounted cranes not only optimizes logistics but also reduces delivery costs significantly, providing a competitive advantage in the market. Buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to leverage partnerships with reputable suppliers to access the latest technologies and support services.

How Can International Buyers Prepare for Future Opportunities?

Looking ahead, the demand for reliable lifting solutions is set to grow as industries continue to expand. B2B buyers should actively seek out innovative models and consider long-term service agreements that ensure maintenance and support. By prioritizing strategic sourcing, businesses can enhance their operational capabilities and secure a robust position in their respective markets. Engage with trusted suppliers today to explore the transformative potential of truck-mounted cranes for your operations.