Introduction: Navigating the Global Market for electric cargo hauler

In today’s rapidly evolving logistics landscape, sourcing electric cargo haulers presents a critical challenge for international B2B buyers. With increasing demand for sustainable transportation solutions and the need for efficient cargo management, businesses must navigate a complex market filled with various options tailored to different applications. This comprehensive guide delves into the diverse types of electric cargo haulers available, examining their unique features, performance metrics, and suitability for various industries—from urban delivery services to agricultural logistics.

We will explore vital considerations when selecting electric cargo haulers, including motor power, weight capacity, range, and supplier vetting strategies. Additionally, we provide insights into cost structures and potential return on investment, enabling businesses in regions such as Africa, South America, the Middle East, and Europe—including Germany and Nigeria—to make informed purchasing decisions.

By leveraging this guide, B2B buyers can streamline their sourcing process, ensuring they choose electric cargo haulers that not only meet operational needs but also align with sustainability goals. With a focus on actionable insights and best practices, this resource empowers businesses to confidently enter the electric cargo market, driving efficiency and reducing their carbon footprint in an increasingly competitive global economy.

Understanding electric cargo hauler Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cargo E-Bikes | Electric bikes with enhanced load capacity and stability. | Delivery services, urban commuting. | Pros: Cost-effective, environmentally friendly. Cons: Limited range compared to larger vehicles. |

| Electric Cargo Vans | Fully electric vans with larger cargo space and higher payload. | Goods transportation, logistics. | Pros: High capacity, longer range. Cons: Higher initial investment. |

| Modular Cargo Trailers | Attachments for e-bikes or electric scooters, customizable. | Last-mile delivery, agricultural transport. | Pros: Versatile, scalable. Cons: Requires compatible vehicle. |

| Heavy-Duty E-Cargo Bikes | Built for extreme loads and rugged terrains, often with dual motors. | Construction, industrial applications. | Pros: High load capacity, durable. Cons: Heavier and more expensive. |

| Recreational Cargo E-Bikes | Designed for leisure with added cargo capacity. | Family outings, recreational rentals. | Pros: Fun to ride, good for short trips. Cons: Less focus on utility. |

What are Cargo E-Bikes and Their B2B Relevance?

Cargo e-bikes are electric bicycles designed specifically for transporting goods. They often feature a robust frame, enhanced stability, and significant load capacity, making them ideal for delivery services and urban commuting. B2B buyers should consider the operational costs, including battery life and maintenance, as well as the potential for reduced delivery times in congested urban areas. These bikes offer an environmentally friendly alternative to traditional delivery vehicles, appealing to companies focused on sustainability.

How Do Electric Cargo Vans Serve Businesses?

Electric cargo vans are larger vehicles designed for transporting substantial goods over longer distances. With higher payload capacities and extended ranges, they are well-suited for logistics and goods transportation. Businesses should evaluate the total cost of ownership, including charging infrastructure and maintenance, against the benefits of reduced fuel costs and lower emissions. Investing in electric cargo vans can enhance a company’s image as environmentally responsible while also improving operational efficiency.

What Benefits Do Modular Cargo Trailers Offer?

Modular cargo trailers are designed to enhance the utility of electric bikes or scooters, providing customizable solutions for transporting various goods. They are particularly effective for last-mile delivery and agricultural transport, offering flexibility in load management. B2B buyers should consider compatibility with existing e-vehicles and the scalability of trailer options to accommodate varying cargo needs. Their versatility makes them an attractive option for businesses looking to expand their delivery capabilities without significant investment in new vehicles.

Why Choose Heavy-Duty E-Cargo Bikes for Industrial Use?

Heavy-duty e-cargo bikes are engineered to handle extreme loads and navigate rugged terrains, making them suitable for construction and industrial applications. These bikes often feature dual motors and reinforced frames, ensuring reliability under challenging conditions. When purchasing, businesses should assess the weight capacity, durability, and cost-effectiveness of heavy-duty models. They provide an efficient and robust solution for industries that require reliable transport of materials in demanding environments.

What Makes Recreational Cargo E-Bikes Attractive for Family and Leisure Use?

Recreational cargo e-bikes combine the functionality of cargo transport with a focus on leisure riding. They are ideal for family outings or rental services, offering a fun way to transport children or gear for outdoor activities. B2B buyers in the tourism and recreation sectors should evaluate the bike’s comfort, ease of use, and safety features. While they may not prioritize utility like other cargo options, their appeal lies in enhancing customer experiences and promoting active lifestyles.

Key Industrial Applications of electric cargo hauler

| Industry/Sector | Specific Application of electric cargo hauler | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Retail | Last-mile delivery solutions | Reduces delivery times and operational costs | Battery capacity, load capacity, and motor power |

| Agriculture | Transporting produce and supplies on farms | Increases efficiency in logistics and reduces fuel costs | Terrain adaptability, payload capacity, and range |

| Urban Logistics | Goods transportation within city limits | Minimizes traffic congestion and lowers emissions | Maneuverability, battery life, and ease of maintenance |

| Hospitality & Tourism | Guest transportation and luggage handling | Enhances guest experience and operational efficiency | Comfort features, load capacity, and safety specifications |

| Construction & Landscaping | Moving tools and materials on-site | Improves productivity and reduces reliance on fuel-based vehicles | Durability, weight capacity, and off-road capabilities |

How Can Electric Cargo Haulers Transform E-commerce and Retail Delivery?

In the e-commerce and retail sector, electric cargo haulers are increasingly being utilized for last-mile delivery solutions. With the surge in online shopping, companies are looking for efficient ways to deliver goods quickly and sustainably. Electric cargo haulers can navigate urban environments, reducing delivery times and operational costs while minimizing environmental impact. International buyers should consider factors such as battery capacity and load capacity to ensure that the hauler meets their delivery requirements.

What Role Do Electric Cargo Haulers Play in Agriculture?

Electric cargo haulers are revolutionizing agriculture by providing efficient transport for produce and supplies on farms. These vehicles can carry significant loads, allowing farmers to move goods quickly between fields and storage areas. The reduction in fuel costs and the ability to operate quietly and sustainably make them an attractive option. Buyers in regions like Africa and South America should focus on the terrain adaptability and payload capacity to meet specific agricultural needs.

How Are Electric Cargo Haulers Enhancing Urban Logistics?

In urban logistics, electric cargo haulers are proving to be invaluable for transporting goods within city limits. Their compact size allows them to navigate through congested streets, thereby minimizing traffic congestion and lowering emissions. This contributes to smarter, cleaner urban environments. Businesses must consider factors such as maneuverability and battery life when sourcing these vehicles to optimize their logistics operations.

In What Ways Are Electric Cargo Haulers Beneficial for Hospitality and Tourism?

The hospitality and tourism sectors are leveraging electric cargo haulers for guest transportation and luggage handling. By offering a unique and eco-friendly transport option, businesses can enhance the guest experience while improving operational efficiency. Electric haulers can easily navigate hotel grounds and tourist locations, making them ideal for transporting guests and their belongings. Key considerations for sourcing include comfort features and load capacity to ensure a pleasant experience for guests.

How Do Electric Cargo Haulers Support Construction and Landscaping Projects?

In construction and landscaping, electric cargo haulers are used to move tools and materials on-site, significantly improving productivity. By reducing reliance on traditional fuel-based vehicles, companies can lower their operational costs and environmental footprint. Buyers in this sector should prioritize durability and weight capacity, ensuring that the haulers can withstand the demands of rugged job sites while efficiently transporting heavy loads.

3 Common User Pain Points for ‘electric cargo hauler’ & Their Solutions

Scenario 1: Struggling with Range Anxiety During Operations

The Problem: For many B2B buyers, especially those in logistics and delivery services, range anxiety is a significant concern. This anxiety often stems from the fear that an electric cargo hauler will not cover the required distances for daily operations without needing a recharge, especially in regions with limited charging infrastructure. Buyers may worry about the battery life affecting delivery schedules or the ability to complete multiple tasks in a day, leading to potential downtime and loss of revenue.

The Solution: To effectively address this challenge, buyers should prioritize electric cargo haulers with robust battery options and extended range capabilities. When sourcing these vehicles, consider models that offer dual battery setups, as seen in some advanced e-bikes. A dual battery system can significantly enhance the range, allowing for up to 85 miles of travel, thereby reducing the frequency of recharges. Additionally, it’s crucial to assess the local charging infrastructure. Buyers can collaborate with energy providers to install fast-charging stations at strategic locations within their operations. This proactive approach not only alleviates range anxiety but also ensures operational efficiency, enabling businesses to maintain a seamless delivery schedule.

Scenario 2: Managing Heavy Loads Safely

The Problem: In industries such as agriculture or urban logistics, the need to transport heavy loads is a daily reality. However, many electric cargo haulers may struggle with stability and safety when carrying maximum weights. Buyers often face concerns about the structural integrity of the hauler under heavy loads, which can lead to accidents or damage to goods, ultimately affecting service quality and operational reliability.

The Solution: Buyers must look for electric cargo haulers specifically designed for high payload capacities, ideally those that can support weights of 440 lbs or more. When evaluating options, focus on features like hydraulic suspension and robust braking systems, which enhance stability and safety during transport. Additionally, consider integrating safety training for operators to ensure they are well-versed in loading techniques and weight distribution. This training can significantly minimize risks associated with overloading or improper handling. Investing in these safety measures not only protects cargo but also enhances the reputation of the business by ensuring reliable service delivery.

Scenario 3: Adapting to Varied Terrain Conditions

The Problem: Businesses operating in diverse geographical areas often encounter varied terrain, which can pose a challenge for standard electric cargo haulers. For instance, buyers from regions with rough roads or inclines may find that typical models lack the necessary power and traction, leading to inefficiencies and operational delays. This concern is amplified for those who need to navigate through urban environments with both smooth and rugged surfaces.

The Solution: To effectively tackle this issue, buyers should select electric cargo haulers equipped with powerful motors and specialized tires designed for all-terrain performance. Models with a peak motor output of at least 1400W and fat tires, such as 20″x3″, provide enhanced traction and stability on uneven surfaces. Additionally, consider opting for models with adjustable power settings to adapt to different terrains effectively. It’s also beneficial to conduct a thorough assessment of the operational areas to identify specific terrain challenges and ensure that the chosen hauler can handle them seamlessly. By prioritizing these features, businesses can enhance their operational flexibility and efficiency, ultimately improving service delivery across varied environments.

Strategic Material Selection Guide for electric cargo hauler

When selecting materials for electric cargo haulers, it’s essential to consider the unique demands of the application, including weight capacity, durability, and environmental conditions. Here’s an analysis of four common materials used in the construction of electric cargo haulers, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

What are the Key Properties of Aluminum in Electric Cargo Haulers?

Aluminum is a lightweight, corrosion-resistant metal that is commonly used in electric cargo haulers. Its temperature rating typically ranges from -200°C to 600°C, making it suitable for various climates. The material’s high strength-to-weight ratio allows for increased payload capacity without significantly adding to the overall weight of the hauler.

Pros: Aluminum is durable and resistant to rust, which is crucial for outdoor applications. It also offers good machinability, making it easier to manufacture complex shapes.

Cons: While aluminum is relatively affordable, its cost can increase with thickness and treatment processes. It can also be less impact-resistant compared to steel, which may be a consideration in rugged environments.

Impact on Application: Aluminum’s corrosion resistance makes it suitable for humid or saline environments, common in coastal regions of Africa and South America.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM and DIN for aluminum alloys, particularly in regions like Germany and Nigeria where specific grades may be preferred.

How Does Steel Compare as a Material for Electric Cargo Haulers?

Steel, particularly high-strength low-alloy (HSLA) steel, is another popular choice for electric cargo haulers. It offers excellent tensile strength and is often used in structural components.

Pros: Steel is highly durable and can withstand significant wear and tear, making it ideal for heavy-duty applications. Its lower cost compared to aluminum makes it an attractive option for budget-conscious buyers.

Cons: Steel is heavier than aluminum, which can impact the overall weight and efficiency of the hauler. It is also susceptible to rust and corrosion unless properly treated.

Impact on Application: Steel’s strength makes it suitable for high-load applications, but its weight can reduce the vehicle’s range and efficiency.

Considerations for International Buyers: Buyers in the Middle East and Europe should consider the corrosion-resistant coatings available for steel to enhance durability in harsh climates.

What Role Does Composite Materials Play in Electric Cargo Haulers?

Composite materials, such as carbon fiber reinforced polymer (CFRP), are increasingly being used in electric cargo haulers due to their lightweight and strong properties. Composites can handle temperatures up to 150°C and offer excellent fatigue resistance.

Pros: Composites are lightweight, which can significantly improve the energy efficiency of electric cargo haulers. They also resist corrosion and can be molded into complex shapes.

Cons: The manufacturing process for composites can be complex and costly. Additionally, they may not be as impact-resistant as metals, which can be a drawback in certain applications.

Impact on Application: Composites are particularly beneficial for reducing the overall weight of the hauler, enhancing range and efficiency.

Considerations for International Buyers: Buyers should be aware of the specific manufacturing standards for composites in their region, as well as the availability of repair services, which can vary significantly.

How Do Plastics Fit into the Material Selection for Electric Cargo Haulers?

Plastics, such as polypropylene and polyethylene, are often used for non-structural components in electric cargo haulers, such as fenders and storage compartments. They typically have a temperature rating of -40°C to 80°C.

Pros: Plastics are lightweight, corrosion-resistant, and can be produced at a low cost. They also offer good impact resistance.

Cons: Plastics may not provide the same level of strength as metals and can degrade under UV exposure unless treated.

Impact on Application: Plastics are suitable for components that require flexibility and resistance to the elements, making them ideal for various climates.

Considerations for International Buyers: Buyers should ensure that the plastics used comply with local environmental regulations, especially in regions with strict waste management policies.

Summary Table

| Material | Typical Use Case for electric cargo hauler | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame and structural components | Lightweight and corrosion-resistant | Less impact-resistant than steel | Medium |

| Steel | Structural components | High durability and low cost | Heavier, susceptible to corrosion | Low |

| Composite | Body panels and non-structural components | Lightweight, excellent fatigue resistance | Complex and costly manufacturing | High |

| Plastics | Fenders and storage compartments | Lightweight, low cost | Lower strength, UV degradation risk | Low |

This analysis provides a comprehensive overview of the materials commonly used in electric cargo haulers, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cargo hauler

What Are the Key Stages in the Manufacturing Process of Electric Cargo Haulers?

Manufacturing electric cargo haulers involves a series of precise stages to ensure product quality and performance. The typical manufacturing process can be divided into four main stages: material preparation, forming, assembly, and finishing.

1. Material Preparation: How Are Components Selected and Processed?

The first stage of manufacturing involves selecting high-quality materials that can withstand the demands of transportation. Common materials include aluminum alloy for the frame due to its lightweight and strength properties, and durable plastics for components like fenders and battery casings.

Once materials are selected, they undergo various processes such as cutting, shaping, and treating to enhance their properties. For instance, aluminum may be anodized to increase corrosion resistance, while battery materials are often processed under controlled conditions to ensure safety and performance.

2. Forming: What Techniques Are Used to Shape Components?

In the forming stage, the prepared materials are shaped into usable components through techniques such as extrusion, stamping, and welding.

- Extrusion is commonly used for creating aluminum frames, allowing for complex shapes that provide structural integrity while minimizing weight.

- Stamping is utilized for metal parts such as brackets and mounts, ensuring precision and uniformity.

- Welding, particularly TIG or MIG welding, is crucial for assembling the frame and other structural components, providing a strong bond that can handle stress during operation.

These techniques are selected based on the design requirements and the expected load-bearing capabilities of each component.

3. Assembly: How Are Components Integrated into the Final Product?

The assembly stage is where all individual components come together to form the complete electric cargo hauler. This process typically follows a systematic approach:

- Sub-assembly of critical components such as the motor, battery, and drivetrain is done first.

- The main frame is then assembled, followed by the integration of the electrical system, including wiring and control units.

- Quality checks are performed at this stage to ensure that all components fit correctly and function as intended.

Advanced manufacturing technologies, such as robotics and automation, are often employed in assembly to improve efficiency and precision.

4. Finishing: What Processes Ensure the Final Product Meets Standards?

The finishing stage involves several processes aimed at enhancing both aesthetics and functionality.

- Painting and Coating: The frame and other components are typically painted or coated to provide a protective finish against environmental factors. Powder coating is a popular choice for its durability and variety of color options.

- Final Assembly and Testing: After finishing, the cargo hauler undergoes final assembly, where accessories such as lights and racks are added. Comprehensive testing follows to ensure that the bike meets performance standards, including load capacity and range.

What Quality Assurance Standards Are Critical for Electric Cargo Haulers?

Quality assurance is vital in manufacturing electric cargo haulers, especially for international B2B buyers who require reliable and compliant products. Key international standards include:

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring consistent quality in manufacturing processes. Compliance indicates that a manufacturer has established effective quality control measures.

- CE Marking: For products sold in Europe, CE marking ensures compliance with health, safety, and environmental protection standards.

- API Certification: Relevant for components like batteries, API standards help ensure reliability and safety in high-stakes applications.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) is integrated into each manufacturing stage, with specific checkpoints established to ensure compliance with standards and specifications. Key QC checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC involves regular inspections at various stages to identify and rectify any defects early.

- Final Quality Control (FQC): This stage occurs before the product is shipped, ensuring that the final cargo hauler meets all performance and safety specifications through rigorous testing.

What Common Testing Methods Are Employed in Quality Assurance?

To ensure the reliability of electric cargo haulers, manufacturers employ various testing methods, including:

- Load Testing: To verify that the hauler can handle its maximum payload, manufacturers conduct load tests that simulate real-world usage.

- Battery Testing: Battery performance is assessed through cycle testing, which evaluates charge and discharge cycles to ensure longevity and reliability.

- Safety Testing: This includes tests for braking efficiency, stability, and electrical safety to comply with international standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is crucial for ensuring product reliability. Here are some actionable steps:

- Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request access to audit reports and corrective action records.

- Review Certifications: Buyers should verify that suppliers hold relevant certifications (e.g., ISO, CE) and check their validity through official channels.

- Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the manufacturing and quality control processes, ensuring compliance with specified standards.

What Are the Unique QC Considerations for International Markets?

When sourcing electric cargo haulers from international suppliers, especially in regions like Africa, South America, the Middle East, and Europe, buyers should be aware of specific quality control nuances:

- Local Regulations: Different regions have varying regulations and standards. Buyers should familiarize themselves with local requirements to ensure compliance.

- Cultural Differences in Quality Standards: Understanding the cultural context of quality perception can aid in setting expectations and fostering better supplier relationships.

- Logistics and Supply Chain Challenges: International shipping can introduce risks such as damage during transit. Buyers should ensure that suppliers have robust packaging and handling protocols in place.

In conclusion, the manufacturing processes and quality assurance measures for electric cargo haulers are designed to meet the growing demand for reliable and efficient transportation solutions. By understanding these processes and actively engaging in supplier verification, B2B buyers can make informed decisions and secure high-quality products for their markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cargo hauler’

Introduction

This guide serves as a practical checklist for B2B buyers aiming to source electric cargo haulers. As demand for sustainable and efficient transportation solutions grows, selecting the right electric cargo bike is crucial for enhancing operational efficiency and reducing environmental impact. This checklist will help you navigate the complexities of procurement, ensuring you make informed decisions that align with your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements of the electric cargo hauler you need. Consider factors such as motor power, battery capacity, and weight capacity, as these directly affect performance and usability.

– Motor Power: Look for models with at least 750 watts for optimal performance under load.

– Battery Capacity: Ensure the range meets your operational needs, with options for single or dual batteries for extended range.

Step 2: Assess the Payload Capacity

Evaluate the maximum load the electric cargo hauler can handle. This is vital for ensuring that the bike can transport the goods or equipment you intend to carry without compromising safety or performance.

– Total Payload: Consider both the rider’s weight and the cargo; many models support between 300 to 440 pounds.

– Design Specifications: Check for features like reinforced frames or suspension systems that enhance stability under heavy loads.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. This step is essential to ensure that you are partnering with a reliable manufacturer capable of meeting your needs.

– Request Documentation: Ask for company profiles, certifications, and case studies to assess their credibility.

– Seek References: Contact previous clients in similar industries to gauge satisfaction and performance reliability.

Step 4: Verify Compliance with Local Regulations

Understanding and adhering to local regulations concerning electric cargo haulers is crucial. Different regions may have specific requirements regarding speed limits, motor power, and usage zones.

– Legal Classifications: Familiarize yourself with Class 1, 2, or 3 e-bike classifications applicable in your area.

– Safety Standards: Ensure the products meet relevant safety certifications (e.g., UL2849) for peace of mind.

Step 5: Inspect Warranty and After-Sales Support

Review the warranty terms and after-sales support offered by the supplier. This is critical for protecting your investment and ensuring long-term satisfaction.

– Warranty Duration: Look for at least a one-year warranty, with options for extension.

– Customer Support: Evaluate the supplier’s responsiveness and availability for technical support, repairs, or replacement parts.

Step 6: Consider Customization Options

Determine if the supplier offers customization for the electric cargo hauler to better suit your business needs. This could include modifications to design, color, or added features.

– Accessory Availability: Assess the range of accessories available, such as cargo racks or additional battery options, which can enhance functionality.

– Tailored Solutions: Discuss potential customizations that can optimize the bike for specific tasks within your operations.

Step 7: Conduct a Test Ride

Finally, arrange for a test ride of the electric cargo hauler before finalizing your purchase. This hands-on experience will provide insight into the bike’s performance, comfort, and handling.

– Performance Assessment: Pay attention to how the bike handles weight and acceleration.

– Comfort and Usability: Evaluate the ergonomics and ease of use, ensuring it meets the needs of your team.

By following these steps, B2B buyers can make informed decisions when sourcing electric cargo haulers, ensuring they select models that align with their operational needs and sustainability goals.

Comprehensive Cost and Pricing Analysis for electric cargo hauler Sourcing

What Are the Key Cost Components of Electric Cargo Haulers?

When analyzing the cost structure of electric cargo haulers, several critical components must be considered. These include:

-

Materials: The primary materials used in electric cargo haulers include lightweight aluminum for the frame, lithium-ion batteries, and high-quality electric motors. The choice of materials can significantly influence the overall cost, particularly in terms of durability and performance.

-

Labor: Labor costs encompass both direct and indirect expenses related to the manufacturing process. Skilled labor is required for assembly, particularly for intricate components like the electric motor and battery systems. The labor cost varies by region and can impact the pricing for international buyers.

-

Manufacturing Overhead: This includes utilities, facility costs, and other operational expenses associated with the production process. Efficient manufacturing practices can help reduce overhead, which is crucial for competitive pricing.

-

Tooling: Initial setup costs for specialized tooling and equipment can be substantial. For custom designs, these costs may rise, affecting the pricing structure.

-

Quality Control (QC): Ensuring high-quality production involves rigorous testing and inspections, which adds to the overall cost. Certifications such as UL2849 for safety can also incur additional expenses but are essential for compliance in various markets.

-

Logistics: Transportation costs for shipping the haulers to various markets must be factored in. This includes warehousing, freight, and handling charges, which can vary widely based on location and shipping terms.

-

Margin: The profit margin set by the manufacturer is a crucial aspect of pricing. Competitive markets may drive down margins, while unique features or superior quality can allow for higher margins.

What Factors Influence Pricing for Electric Cargo Haulers?

Several factors can significantly influence the pricing of electric cargo haulers in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to discounts, making it essential for buyers to negotiate terms that align with their needs. Establishing a consistent volume can strengthen buyer-supplier relationships and lead to more favorable pricing.

-

Specifications and Customization: Custom features, such as enhanced battery capacity or specialized materials, can increase costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Quality and Certifications: Higher-quality components and compliance with international standards can raise costs. However, investing in quality can reduce long-term maintenance and operational costs.

-

Supplier Factors: The reputation and reliability of the supplier affect pricing. Established suppliers may charge more due to their brand value and service quality, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is critical for determining the total landed cost of the cargo haulers. Incoterms dictate responsibility for shipping, insurance, and tariffs, which can greatly influence pricing.

What Are the Best Negotiation and Cost-Efficiency Strategies for Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes and cost efficiency:

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, operational costs, and resale value. A more expensive model may offer better durability and efficiency, leading to lower TCO.

-

Leverage Market Knowledge: Stay informed about market trends, competitor pricing, and technological advancements. This knowledge can empower negotiations and help buyers make informed decisions.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing, priority service, and exclusive offers. Trust and reliability often translate into cost savings over time.

-

Understand Pricing Nuances: Be aware of how currency fluctuations, tariffs, and regional economic conditions can impact pricing. This understanding can help buyers negotiate more effectively and plan budgets accordingly.

What Should Buyers Keep in Mind Regarding Indicative Prices?

It is essential to note that prices for electric cargo haulers can vary widely based on the factors outlined above. Prices may also fluctuate based on market demand, availability of components, and geopolitical conditions affecting trade. Therefore, buyers should treat any indicative pricing as a starting point for negotiation rather than a fixed cost. Conducting thorough market research and engaging with multiple suppliers can yield the best possible pricing outcomes.

Alternatives Analysis: Comparing electric cargo hauler With Other Solutions

When considering the adoption of electric cargo haulers, it is essential for businesses to evaluate alternative solutions that can meet their logistical needs. This analysis will provide insights into various options available, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Electric Cargo Hauler | Cargo Vans | Traditional Cargo Bikes |

|---|---|---|---|

| Performance | Up to 28 MPH, 85-mile range | Up to 70 MPH, 300-mile range | Up to 20 MPH, 30-mile range |

| Cost | $999 – $1,499 (depending on features) | $25,000 – $60,000 (new models) | $800 – $1,500 |

| Ease of Implementation | Requires minimal training; easy to park | Requires special licensing; parking can be difficult | Minimal training; easy to maneuver |

| Maintenance | Low; battery replacement every few years | Moderate; regular servicing needed | Low; basic maintenance only |

| Best Use Case | Urban deliveries, short distances | Long-distance transport, larger loads | Local deliveries, low-volume transport |

Detailed Breakdown of Alternatives

Cargo Vans

Cargo vans are traditional vehicles widely used for transporting goods over longer distances. They offer higher speed and greater payload capacity compared to electric cargo haulers, making them suitable for larger-scale logistics operations. However, the cost of purchasing or leasing a cargo van can be substantially higher, ranging from $25,000 to $60,000. Additionally, they require specialized driver licensing and can be challenging to park in crowded urban areas. Their maintenance is moderate, as they require regular servicing and inspections, which can add to overall operational costs.

Traditional Cargo Bikes

Traditional cargo bikes are a cost-effective alternative for businesses focusing on local deliveries. With prices ranging from $800 to $1,500, they provide a budget-friendly option for transporting smaller loads. While they can only reach speeds of up to 20 MPH with a range of approximately 30 miles, they excel in maneuverability and ease of parking. Maintenance is minimal, but their capacity is significantly lower than that of electric cargo haulers or cargo vans, making them less suitable for larger deliveries. They are best used in urban environments where traffic congestion is a concern.

Conclusion

When deciding between an electric cargo hauler, cargo vans, and traditional cargo bikes, B2B buyers should consider their specific operational requirements. The electric cargo hauler presents an optimal solution for urban logistics, combining cost-effectiveness with efficient performance and low maintenance. Cargo vans, while capable of handling larger loads, may not be feasible for businesses with budget constraints or those needing to navigate densely populated areas. Conversely, traditional cargo bikes can be an excellent choice for smaller-scale operations but may lack the capacity and speed required for more extensive logistics needs. Ultimately, understanding these alternatives will empower buyers to make informed decisions that align with their strategic goals.

Essential Technical Properties and Trade Terminology for electric cargo hauler

What Are the Key Technical Properties of Electric Cargo Haulers?

When evaluating electric cargo haulers, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some key properties to consider:

1. Motor Power Rating

The motor power of an electric cargo hauler typically ranges from 250W to 1400W, with higher wattage indicating better performance, particularly when carrying heavy loads or climbing hills. For B2B buyers, a powerful motor translates to improved efficiency in logistics and transportation tasks, allowing businesses to maximize delivery capabilities and reduce operational costs.

2. Battery Capacity and Range

Battery capacity is measured in watt-hours (Wh) or amp-hours (Ah) and indicates how much energy the battery can store. A higher capacity allows for longer ranges, crucial for businesses needing to transport goods over extended distances without frequent recharging. For instance, a dual battery system may offer a range of up to 85 miles, which is vital for operations in urban settings or remote areas.

3. Weight Capacity

Electric cargo haulers are designed to carry substantial loads, often rated between 300 to 440 lbs or more. Understanding the weight capacity is essential for businesses to ensure compliance with safety regulations and operational efficiency. It helps in determining whether the hauler can meet specific transport needs, whether for deliveries, farming, or transporting equipment.

4. Frame Material

Most electric cargo haulers utilize aluminum alloy for their frames, providing a balance of strength and weight. The choice of material impacts durability and overall performance. For B2B buyers, investing in a robust frame means less downtime due to repairs, ultimately enhancing productivity.

5. Braking System

Electric cargo haulers typically feature hydraulic disc brakes, which provide superior stopping power and control. In commercial applications, where safety is paramount, understanding the braking system can help businesses mitigate risks associated with heavy loads and urban environments.

6. Suspension System

A quality suspension system, often hydraulic, enhances ride comfort and stability, especially when transporting goods over uneven surfaces. For companies that operate in varied terrains, investing in a hauler with a robust suspension system can improve driver satisfaction and operational efficiency.

What Are Common Trade Terms in the Electric Cargo Hauler Industry?

Familiarizing yourself with industry terminology is essential for smooth transactions and negotiations. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electric cargo haulers, understanding OEM relationships can help businesses identify quality suppliers and ensure they are sourcing reliable components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For businesses looking to purchase electric cargo haulers, knowing the MOQ helps in planning inventory and budgeting, especially when considering bulk purchases for fleet operations.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where a company solicits bids from suppliers for the purchase of products or services. Issuing an RFQ for electric cargo haulers allows businesses to compare prices, specifications, and lead times, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Understanding these terms is critical for B2B buyers, especially when importing electric cargo haulers, as they dictate shipping costs, risks, and delivery responsibilities.

5. Lead Time

Lead time refers to the amount of time from the initiation of an order until its completion. For businesses relying on electric cargo haulers for logistics, understanding lead times is vital for planning and ensuring timely delivery of goods.

6. Warranty and After-Sales Support

Warranties cover repairs or replacements for a specified period, while after-sales support includes services provided post-purchase. For B2B buyers, understanding warranty terms and the availability of support is essential for long-term investment protection and maintenance planning.

By grasping these technical properties and industry terms, B2B buyers can make more informed decisions regarding electric cargo haulers, ensuring they meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the electric cargo hauler Sector

What Are the Current Market Dynamics and Key Trends in the Electric Cargo Hauler Sector?

The electric cargo hauler sector is experiencing significant growth, driven by a combination of environmental awareness, urbanization, and technological advancements. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly recognizing the utility of electric cargo haulers for last-mile delivery and urban logistics. The rise in e-commerce has amplified demand, as businesses seek efficient, cost-effective solutions to meet their logistics needs.

Key trends include the integration of advanced technologies such as IoT and AI for fleet management and route optimization, enhancing operational efficiency. Additionally, manufacturers are focusing on producing models that cater to diverse market needs, offering varying payload capacities and battery ranges. In Europe, for instance, regulatory incentives promote electric vehicles, while in Africa, the focus is on affordability and reliability in challenging terrains. As a result, B2B buyers are urged to consider local market dynamics, such as infrastructure readiness and governmental support for electric vehicle adoption, when sourcing electric cargo haulers.

Furthermore, sustainability is becoming a pivotal factor in purchasing decisions. With increasing regulations on emissions and waste management, businesses are gravitating toward suppliers that not only provide innovative solutions but also adhere to sustainable practices. The shift toward electric cargo haulers represents not just a trend, but a fundamental change in how goods are transported, making it essential for B2B buyers to stay informed about technological advancements and regulatory landscapes.

How Does Sustainability and Ethical Sourcing Influence B2B in the Electric Cargo Hauler Market?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the electric cargo hauler market. The environmental impact of traditional cargo transport methods has prompted businesses to seek greener alternatives. Electric cargo haulers significantly reduce greenhouse gas emissions and reliance on fossil fuels, making them an attractive option for companies aiming to enhance their sustainability credentials.

Moreover, ethical supply chains are gaining importance as consumers and businesses alike demand transparency in sourcing practices. Buyers should prioritize manufacturers who utilize eco-friendly materials and processes, such as recyclable battery components and sustainable manufacturing practices. Certifications like ISO 14001 (Environmental Management) and the Energy Star label are indicators of a commitment to sustainability and can guide purchasing decisions.

Incorporating ‘green’ certifications into sourcing strategies not only aligns with corporate social responsibility goals but also enhances brand reputation. As businesses face increasing pressure to demonstrate their commitment to sustainability, selecting electric cargo haulers that meet these criteria will become a crucial aspect of B2B procurement strategies.

What Is the Brief Evolution of Electric Cargo Haulers and Its Significance for B2B Buyers?

The evolution of electric cargo haulers has been marked by technological advancements and changing consumer expectations over the past few decades. Initially, electric vehicles were limited by battery technology and infrastructure. However, significant improvements in battery efficiency and charging capabilities have transformed electric cargo haulers into viable alternatives to traditional gasoline-powered vehicles.

The introduction of electric cargo bikes and haulers has opened new avenues for urban logistics, especially in densely populated areas where traditional delivery vehicles face restrictions. The ability to navigate narrow streets and reduce congestion has made electric cargo haulers a preferred choice for businesses focused on last-mile delivery.

For B2B buyers, understanding this evolution is crucial in recognizing the long-term viability and potential ROI of investing in electric cargo haulers. As the market continues to grow and innovate, staying abreast of historical trends will enable buyers to make informed decisions that align with both current needs and future developments in the logistics landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cargo hauler

-

How do I solve range anxiety when using electric cargo haulers?

Range anxiety can be mitigated by selecting electric cargo haulers with higher battery capacities and dual battery options. For example, models like the Hauler offer configurations that can achieve a maximum range of up to 85 miles with dual batteries. Additionally, planning routes and ensuring access to charging stations or portable chargers can help alleviate concerns about running out of power during operations. Understanding the typical range based on your specific load and terrain can also provide confidence in your hauler’s capabilities. -

What is the best electric cargo hauler for urban logistics?

The best electric cargo hauler for urban logistics is one that combines compact design with robust carrying capacity. The Hauler, for example, features a powerful 1400W motor and a payload capacity of up to 440 lbs, making it ideal for navigating city streets while transporting goods efficiently. Its hydraulic suspension and fat tires enhance stability and comfort on urban terrain, while integrated safety features like automatic lights and turn signals ensure visibility in busy environments. -

How do I vet suppliers for electric cargo haulers in international markets?

When vetting suppliers, it’s essential to conduct thorough due diligence. Start by checking their manufacturing certifications and quality assurance processes, such as ISO certifications. Request references or case studies from previous clients, especially those within your target region. Additionally, assess their responsiveness and customer service capabilities. Engaging in direct communication can reveal their willingness to accommodate your specific needs and provide support post-purchase. -

What customization options are available for electric cargo haulers?

Many manufacturers offer customization options to tailor electric cargo haulers to specific business needs. Customizations can include different battery capacities, color choices, or additional features like integrated storage solutions or upgraded safety systems. Before placing an order, discuss your requirements with the supplier to explore available options. This ensures that the product aligns with your operational goals and enhances efficiency. -

What are the typical minimum order quantities (MOQs) for electric cargo haulers?

Minimum order quantities for electric cargo haulers can vary significantly by supplier and region. Generally, MOQs can range from 5 to 50 units, depending on the manufacturer and the customization options you select. It’s advisable to negotiate with suppliers, especially if you’re a new buyer or if you’re seeking a trial order to test the market. Understanding their production capabilities and lead times will also help in planning your inventory and logistics effectively. -

What payment terms should I expect when purchasing electric cargo haulers internationally?

Payment terms can differ widely among suppliers and may include options such as upfront payments, partial payments, or letters of credit. Commonly, suppliers might require a 30% deposit upon order confirmation, with the balance due before shipment. Ensure to clarify terms related to foreign exchange rates, transaction fees, and payment methods. Establishing clear terms in a written agreement can safeguard both parties and streamline the transaction process. -

How can I ensure quality assurance for my electric cargo hauler order?

Quality assurance can be ensured by establishing clear specifications and standards before placing an order. Request samples or prototypes if possible, and inquire about the supplier’s quality control processes. Many reputable manufacturers will provide documentation on their testing and certification practices. Additionally, consider conducting a factory audit or hiring third-party inspection services to verify compliance with international quality standards before final acceptance of the goods. -

What logistics considerations should I be aware of when importing electric cargo haulers?

When importing electric cargo haulers, consider shipping methods, customs duties, and local regulations regarding e-bikes. Assess the total landed cost, including freight, insurance, and taxes, to avoid unexpected expenses. Work with logistics partners experienced in international shipping to ensure compliance with import regulations in your country. Understanding the timeline for delivery and potential delays can also help in planning your inventory and operational readiness effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Electric Cargo Hauler Manufacturers & Suppliers List

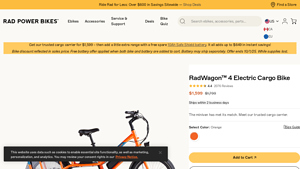

1. Rad Power Bikes – RadWagon 4 Electric Cargo Bike

Domain: radpowerbikes.com

Registered: 2015 (10 years)

Introduction: RadWagon 4 Electric Cargo Bike features a powerful 750W motor, a 48V 14Ah battery for a range of up to 45+ miles, a load capacity of 350 lbs, and a step-thru frame design for easy mounting. It includes a rear rack, integrated lights, and puncture-resistant tires. The bike is equipped with a 7-speed transmission and hydraulic disc brakes for reliable stopping power.

2. Lectric eBikes – XPedition2 Stratus White eBike

Domain: lectricebikes.com

Registered: 2018 (7 years)

Introduction: Electric Cargo eBikes from Lectric eBikes are designed with an integrated rear rack for carrying heavy loads and accommodating two or more people. Key models include:

1. XPedition2 Stratus White eBike – $1,399 (originally $1,725), 4 FREE Accessories, 4.9 rating from 540 reviews.

2. XPedition2 Raindrop Blue eBike – $1,399 (originally $1,725), 4 FREE Accessories, 4.9 rating from 540 reviews.

3. XPe…

3. Lectric – XPedition 2.0

Domain: electricbikereport.com

Registered: 2010 (15 years)

Introduction: Best Electric Cargo Bikes 2025: 1. Lectric XPedition 2.0 – Price: $1399 (base model), $1699 (mid-tier), $1999 (top-tier); Battery: 624-Wh (base), 2x 624-Wh (mid), 2x 840-Wh (top); Carrying Capacity: 300 lbs on rack, 450 lbs total; Motor: 750W rear hub, 1310W peak output, 85 Nm torque; Features: Torque sensor, suspension fork, max speed 28 mph, accessories available. 2. Aventon Abound LR – Features…

4. Radio Flyer – Flyer Via Pro Cargo eBike

Domain: radioflyer.com

Registered: 1996 (29 years)

Introduction: Flyer Via Pro Cargo eBike | SKU: 886BKS | Ages: 16+ Years | Price: $2,909.00 | Color Options: Black, Forest Green, Space Gray Blue | Size Options: Small (4’10” – 5’10”, 26″-32″ inseam), Medium (5’3″-6’3″, 28″-34″ inseam), Large (5’10”-6’10”, 30″-38″ inseam) | Features: 750W Flight Speed® motor, suspension fork, 8-speed gear shifter, high-intensity headlight, pedal assist & throttle, 30-50+ miles b…

5. Xtracycle – Electric Cargo Bikes

Domain: xtracycle.com

Registered: 1998 (27 years)

Introduction: Xtracycle Electric Cargo Bikes include: 1. The Hopper – Compact Cargo Carrier for 1-2 passengers, starting at $2499, pre-loaded with accessories, includes Hooptie & PorterRack, free shipping & assembly. 2. The Swoop – Family Bike for 1-3 passengers, starting at $4999, designed for easy handling and reliability, free shipping & assembly. 3. The RFA – Urban Commuter for 1-2 passengers, starting at $…

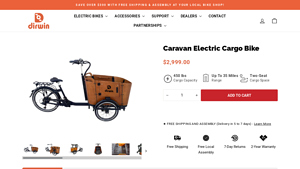

6. Dirwin – Caravan Electric Cargo Bike

Domain: dirwinbike.com

Registered: 2021 (4 years)

Introduction: {“name”:”Caravan Electric Cargo Bike”,”price”:”$2,999.00″,”cargo_capacity”:”450 lbs”,”range”:”Up To 35 Miles”,”features”:[“Two-Seat Cargo Space”,”Finely Crafted Polished Wood”,”Cushioned Seats With Seatbelts”,”20+ Cubic Feet Cargo Container”,”Tricycle Style Extra Stability”,”Water-proof rain cover”,”Durable rear rack”,”Soft floor liner”,”350W motor”,”16Ah lithium battery”,”5-level pedal assist”],”…

Strategic Sourcing Conclusion and Outlook for electric cargo hauler

In conclusion, the strategic sourcing of electric cargo haulers presents a significant opportunity for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The evolution of electric cargo bikes, exemplified by models like the Heybike Hauler, highlights the growing demand for efficient, sustainable transportation solutions capable of handling diverse cargo requirements. With features such as high payload capacities, impressive range, and robust power outputs, these vehicles not only enhance operational efficiency but also contribute to reducing carbon footprints.

The value of strategic sourcing lies in identifying suppliers that align with your business goals while ensuring quality and cost-effectiveness. As the market for electric cargo haulers continues to expand, international buyers should focus on evaluating suppliers based on performance metrics, warranty offerings, and customer support services.

Looking ahead, the integration of electric cargo haulers into logistics and transportation strategies will be crucial for companies aiming to innovate and stay competitive. Now is the time for B2B buyers to engage with manufacturers, explore partnerships, and invest in electric cargo solutions that will drive their businesses forward sustainably.