Introduction: Navigating the Global Market for electric vehicle india

Navigating the rapidly evolving landscape of electric vehicles (EVs) in India presents a unique challenge for international B2B buyers seeking reliable sourcing options. With India poised to become a significant player in the global EV market, understanding the diverse range of electric vehicles available—from compact models to luxury options—becomes imperative. This guide offers a thorough exploration of the various types of electric vehicles, their applications across different sectors, and detailed insights into supplier vetting processes.

By delving into critical factors such as pricing, performance specifications, and market trends, this guide empowers international buyers from regions like Africa, South America, the Middle East, and Europe—particularly in countries such as Saudi Arabia and Germany—to make informed purchasing decisions. The comprehensive nature of this resource ensures that buyers are equipped with the necessary knowledge to navigate the complexities of sourcing electric vehicles in India, enabling them to identify the best options tailored to their specific needs and budget.

Furthermore, as the demand for sustainable transportation solutions grows globally, this guide highlights the importance of aligning procurement strategies with market dynamics, ensuring that businesses not only meet their operational requirements but also contribute positively to environmental sustainability.

Understanding electric vehicle india Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Battery Electric Vehicle (BEV) | Fully electric with no internal combustion engine; powered solely by batteries. | Fleet management, logistics, urban transport. | Pros: Zero emissions, lower operating costs. Cons: Limited range compared to hybrids, longer refueling time. |

| Plug-in Hybrid Electric Vehicle (PHEV) | Combines a conventional engine with an electric motor and battery; can run on either or both. | Corporate fleets, government contracts, rental services. | Pros: Flexibility in range, reduced fuel costs. Cons: More complex maintenance, potential higher upfront costs. |

| Hybrid Electric Vehicle (HEV) | Uses both an internal combustion engine and an electric motor; cannot be charged externally. | Public transport, ride-sharing services, delivery vehicles. | Pros: Better fuel efficiency than conventional vehicles. Cons: Less electric-only driving range, more emissions than BEVs. |

| Two-Wheeler Electric Vehicle (2W EV) | Electric-powered scooters and motorcycles; typically smaller and more agile. | Last-mile delivery, urban commuting, ride-hailing. | Pros: Lower purchase price, ease of maneuverability. Cons: Limited cargo capacity, shorter range compared to cars. |

| Commercial Electric Vehicle (CEV) | Designed for heavy-duty applications; includes electric trucks and buses. | Freight transport, public transport, construction. | Pros: High torque for heavy loads, significant fuel savings. Cons: Higher initial investment, infrastructure development needed for charging. |

What are Battery Electric Vehicles (BEVs) and Their Suitability for B2B Buyers?

Battery Electric Vehicles (BEVs) are entirely powered by electricity, utilizing a large battery pack to drive electric motors. They are particularly suitable for businesses focused on sustainability, as they produce zero emissions. B2B buyers should consider BEVs for fleet management in urban areas where environmental regulations are stringent. Key purchasing considerations include battery range, charging infrastructure availability, and total cost of ownership, as lower operating costs can lead to significant savings over time.

How Do Plug-in Hybrid Electric Vehicles (PHEVs) Fit into Business Needs?

Plug-in Hybrid Electric Vehicles (PHEVs) offer the flexibility of operating on both electric and gasoline power. This dual capability makes them ideal for businesses that require longer ranges without the anxiety of running out of charge. PHEVs are especially relevant for corporate fleets and government contracts where varied travel distances are common. When purchasing, businesses should evaluate the balance between electric range and overall fuel efficiency, as well as the potential for reduced emissions in urban environments.

What Makes Hybrid Electric Vehicles (HEVs) Attractive for Commercial Use?

Hybrid Electric Vehicles (HEVs) combine a conventional engine with an electric motor, optimizing fuel efficiency without the need for external charging. They are well-suited for public transport systems and ride-sharing services that benefit from their improved fuel economy. B2B buyers should weigh the advantages of better fuel efficiency against the limitations in electric-only driving range. Maintenance complexity and the potential for higher emissions compared to BEVs may also influence purchasing decisions.

Why Choose Two-Wheeler Electric Vehicles (2W EVs) for Last-Mile Delivery?

Two-Wheeler Electric Vehicles (2W EVs) are compact, agile, and economical, making them ideal for last-mile delivery services and urban commuting. Their lower purchase prices and operational costs appeal to businesses looking to optimize logistics. When considering 2W EVs, buyers should assess range, charging options, and the specific needs of their delivery operations, as these factors can significantly impact efficiency and service quality.

What Are the Benefits of Commercial Electric Vehicles (CEVs) for Heavy-Duty Applications?

Commercial Electric Vehicles (CEVs) are designed for heavy-duty tasks, including electric trucks and buses. They are particularly beneficial for freight transport and public transport systems, offering high torque for moving heavy loads while significantly reducing fuel costs. B2B buyers should consider the initial investment against long-term savings and the need for charging infrastructure. The growing focus on sustainability in logistics and transportation further emphasizes the relevance of CEVs in modern business strategies.

Key Industrial Applications of electric vehicle india

| Industry/Sector | Specific Application of electric vehicle india | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric buses for urban transit | Reduced operational costs and emissions | Battery capacity, charging infrastructure, local regulations |

| Logistics and Delivery | Electric delivery vans | Lower fuel costs and enhanced sustainability | Range, payload capacity, fleet management software |

| Agriculture | Electric tractors and farm equipment | Increased efficiency and reduced fuel dependency | Compatibility with existing machinery, battery life, terrain adaptability |

| Tourism | Electric vehicles for eco-friendly tours | Enhanced customer experience and branding | Vehicle range, charging stations, maintenance support |

| Construction | Electric construction vehicles | Lower noise pollution and reduced emissions | Durability, battery performance, service availability |

How Are Electric Vehicles Transforming Public Transportation in India?

Electric buses are becoming a crucial component of urban transit systems in India, offering significant advantages in reducing operational costs and emissions. With rising fuel prices and environmental concerns, municipalities are increasingly investing in electric fleets. International buyers looking to source electric buses should consider battery capacity and the availability of charging infrastructure, as these factors are critical for maintaining service efficiency. Additionally, understanding local regulations regarding public transportation can aid in seamless integration into existing systems.

What Role Do Electric Vehicles Play in Logistics and Delivery Services?

In the logistics sector, electric delivery vans are gaining traction as businesses seek to lower fuel costs and enhance sustainability. These vehicles are particularly effective for last-mile delivery, where environmental impact and operational efficiency are paramount. For B2B buyers, it is essential to evaluate the range and payload capacity of electric vans to ensure they meet specific delivery needs. Furthermore, investing in fleet management software can optimize routes and monitor vehicle performance, providing additional operational benefits.

How Can Electric Tractors Revolutionize Agriculture in India?

Electric tractors and farm equipment are transforming agricultural practices in India by increasing efficiency and reducing reliance on fossil fuels. These vehicles can significantly lower operational costs, particularly in fuel-heavy farming operations. Buyers from international markets should assess compatibility with existing machinery and consider battery life and terrain adaptability to ensure that electric tractors meet their agricultural needs effectively. This transition not only enhances productivity but also aligns with global sustainability goals.

In What Ways Are Electric Vehicles Enhancing Tourism Experiences?

Electric vehicles are increasingly being used for eco-friendly tours in tourist destinations across India, providing a unique and sustainable travel experience. Tour operators benefit from enhanced customer satisfaction and improved brand image by offering electric vehicle options. For B2B buyers in the tourism sector, key considerations include vehicle range and the availability of charging stations in popular tourist areas. Ensuring reliable maintenance support is also vital for minimizing downtime during peak tourist seasons.

How Do Electric Vehicles Contribute to Sustainable Construction Practices?

Electric construction vehicles are making a significant impact by reducing noise pollution and emissions on job sites. This shift not only enhances compliance with environmental regulations but also improves worker safety and comfort. B2B buyers in the construction sector should prioritize durability and battery performance when sourcing electric vehicles, as these factors can influence operational efficiency. Additionally, ensuring the availability of service and support is crucial for maintaining productivity on construction sites.

3 Common User Pain Points for ‘electric vehicle india’ & Their Solutions

Scenario 1: Navigating the Complex Pricing Landscape of Electric Vehicles in India

The Problem: For international B2B buyers looking to invest in electric vehicles (EVs) in India, the pricing structure can be overwhelming. With a range of models from different manufacturers, prices can vary significantly based on features, battery capacity, and brand reputation. For instance, while the Tata Nexon EV starts at approximately ₹12.49 Lakh, luxury options like the MG Cyberster can exceed ₹75 Lakh. This disparity complicates budget allocation and ROI analysis, making it difficult to identify which models provide the best value for their specific needs.

The Solution: To effectively navigate this pricing landscape, B2B buyers should start by conducting a comprehensive market analysis that compares prices and features of electric vehicles across brands. Utilize reliable automotive platforms to access real-time data on pricing, specifications, and user reviews. Establish a clear set of criteria based on your operational requirements—such as battery range, charging time, and service availability. Engage with local dealers to negotiate bulk purchase discounts and inquire about financing options that could ease upfront costs. Additionally, consider exploring government incentives and subsidies for EV purchases in India, which can significantly lower the overall expenditure.

Scenario 2: Overcoming Range Anxiety in Electric Vehicle Fleets

The Problem: A common concern among businesses looking to adopt electric vehicles for their fleets is “range anxiety.” Many international buyers worry about the limited range of EVs, especially in a diverse country like India, where infrastructure for charging stations may not yet be fully developed. This anxiety can hinder the transition to electric fleets, as companies fear interruptions in operations due to inadequate charging solutions.

The Solution: To mitigate range anxiety, B2B buyers should prioritize sourcing electric vehicles that offer a higher battery capacity and longer mileage per charge. For example, models like the Mahindra BE 6 boast a range of up to 683 km, making them suitable for longer routes. Conduct a thorough assessment of the operational routes and charging infrastructure available in the regions where the vehicles will be deployed. Collaborate with local charging network providers to establish partnerships that ensure easy access to charging stations. Additionally, consider investing in on-site charging solutions to maintain your fleet’s operational readiness without relying solely on public charging facilities.

Scenario 3: Addressing Maintenance and Service Support for Electric Vehicles

The Problem: Many B2B buyers are apprehensive about the maintenance and service support for electric vehicles, particularly when sourcing from a market like India. Concerns about the availability of trained technicians, spare parts, and service centers can lead to fears of operational downtime and increased costs. This uncertainty can deter businesses from making the switch to electric vehicles.

The Solution: To ensure reliable maintenance and service support for electric vehicles, B2B buyers should partner with manufacturers that have established service networks and provide comprehensive training programs for technicians. Research the availability of authorized service centers for the brands you are considering, and assess their proximity to your operational hubs. Inquire about warranty terms and post-purchase support to understand the long-term commitments from the manufacturers. Furthermore, consider developing a maintenance schedule based on manufacturer recommendations and engage with service providers to set up regular check-ups. This proactive approach will not only enhance the longevity of the vehicles but also instill confidence in your transition to an electric fleet.

Strategic Material Selection Guide for electric vehicle india

What are the Key Materials Used in Electric Vehicles in India?

When it comes to electric vehicles (EVs) in India, the selection of materials is crucial for performance, safety, and cost-effectiveness. Understanding the properties, advantages, and limitations of these materials can help international B2B buyers make informed decisions.

How Does Aluminum Benefit Electric Vehicle Manufacturing?

Aluminum is widely used in electric vehicle manufacturing due to its lightweight and high strength-to-weight ratio. It offers excellent corrosion resistance, making it suitable for various environmental conditions. Aluminum components can withstand a temperature range of -50°C to 150°C, which is essential for battery housings and structural elements.

Pros include reduced vehicle weight, which enhances energy efficiency and range. However, the cons include a higher cost compared to steel and more complex manufacturing processes, such as welding and joining techniques. For international buyers, especially from Europe and the Middle East, compliance with standards like DIN and ASTM is critical, as is the understanding of recycling regulations for aluminum.

Why is Steel Still a Popular Choice for Electric Vehicles?

Steel remains a staple in electric vehicle construction, particularly for structural components and chassis. It offers high strength and durability, with a temperature rating of up to 600°C, making it suitable for various applications.

The advantages of steel include its lower cost and ease of manufacturing, which can be beneficial for mass production. However, its disadvantages are its weight, which can reduce vehicle efficiency, and susceptibility to corrosion if not properly treated. Buyers from regions like Africa and South America should consider the availability of high-strength steel grades that meet local standards.

What Role Does Carbon Fiber Play in Electric Vehicle Design?

Carbon fiber is increasingly being used in high-performance electric vehicles due to its exceptional strength and lightweight properties. It has a temperature resistance of up to 200°C and excellent fatigue resistance, making it ideal for components like body panels and structural reinforcements.

The key advantage of carbon fiber is its ability to significantly reduce vehicle weight, which enhances range and performance. However, its key limitation is the high cost and complexity of manufacturing, which can deter mass-market applications. International buyers should be aware of the specific certifications required for carbon fiber components, particularly in European markets where stringent safety regulations apply.

How Does Lithium-Ion Battery Technology Impact Material Selection?

Lithium-ion batteries are the heart of electric vehicles, necessitating careful material selection for optimal performance. These batteries operate effectively within a temperature range of -20°C to 60°C and require materials that can withstand these conditions.

The advantages of lithium-ion technology include high energy density and long cycle life, making them suitable for electric vehicles. However, the disadvantages include the potential for thermal runaway and the need for complex battery management systems. Buyers from regions with extreme temperatures, such as the Middle East, must consider thermal management solutions and local regulations regarding battery disposal and recycling.

Summary Table of Material Selection for Electric Vehicles in India

| Material | Typical Use Case for electric vehicle india | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Battery housings, structural components | Lightweight, corrosion-resistant | Higher cost, complex manufacturing | Medium |

| Steel | Chassis, structural elements | Low cost, easy to manufacture | Heavier, corrosion susceptibility | Low |

| Carbon Fiber | Body panels, structural reinforcements | High strength-to-weight ratio | High cost, complex manufacturing | High |

| Lithium-Ion | Energy storage systems | High energy density, long life | Risk of thermal runaway, complexity | Medium |

This guide serves as a foundational resource for international B2B buyers looking to navigate the complexities of material selection in the burgeoning electric vehicle market in India. Understanding these materials’ properties and implications can lead to better product performance and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle india

What Are the Key Stages in the Manufacturing Process of Electric Vehicles in India?

The manufacturing of electric vehicles (EVs) in India involves several critical stages, each contributing to the overall quality and efficiency of the final product. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials, including metals, plastics, and battery components. Suppliers must adhere to international standards to ensure that materials are suitable for EV production. Advanced materials such as lightweight composites and high-strength steel are often prioritized to enhance the vehicle’s performance and efficiency.

-

Forming: In this stage, raw materials are shaped into components using various techniques. Common methods include stamping, casting, and extrusion. For instance, body panels are typically formed using stamping techniques, while battery housings may be cast. The choice of forming method can significantly influence the vehicle’s weight, durability, and manufacturing cost.

-

Assembly: Once components are ready, they are assembled into the vehicle. This process often employs automation and robotics to enhance precision and reduce labor costs. For example, robotic arms may be used for welding and painting, ensuring uniformity and high-quality finishes. The assembly line is designed to optimize workflow, allowing for the simultaneous production of multiple EV models.

-

Finishing: The final stage involves quality checks, painting, and the installation of electrical components. This step is crucial as it directly impacts the vehicle’s aesthetics and functionality. Advanced quality control measures are implemented to detect defects, ensuring that only vehicles meeting stringent standards are delivered to customers.

How Is Quality Assurance Implemented in Electric Vehicle Manufacturing?

Quality assurance (QA) in the electric vehicle sector is paramount, given the safety and performance expectations from consumers and regulatory bodies. Manufacturers in India typically adhere to several international and industry-specific standards, including ISO 9001, CE, and API certifications.

-

International Standards: ISO 9001 provides a framework for ensuring consistent quality management systems. It helps manufacturers establish processes that meet customer and regulatory requirements. Compliance with CE marking ensures that products meet EU safety, health, and environmental protection standards, which is particularly important for international buyers from Europe.

-

Industry-Specific Standards: In addition to general standards, EV manufacturers may also comply with automotive-specific regulations. For instance, API standards can be relevant for the production of lubricants used in electric drivetrains, while safety standards from organizations like SAE International play a crucial role in vehicle design and testing.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to ensure that any defects are identified and addressed promptly. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials and components upon arrival at the manufacturing facility. Suppliers must provide certificates of conformity to verify that materials meet specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing process, continuous monitoring is conducted at various stages, such as forming and assembly. This involves real-time inspections and measurements to ensure that components are produced to the required specifications.

-

Final Quality Control (FQC): Once assembly is complete, the finished vehicles undergo comprehensive testing and inspection. This includes functionality tests, safety checks, and performance evaluations to ensure that the vehicle operates as intended before it is delivered to customers.

What Common Testing Methods Are Used in Electric Vehicle Quality Control?

To ensure the safety and reliability of electric vehicles, manufacturers employ various testing methods, including:

- Battery Testing: Evaluating the performance, capacity, and safety of batteries is crucial. This often involves stress testing and cycle testing to simulate real-world usage scenarios.

- Crash Testing: Compliance with safety standards necessitates rigorous crash testing. This assesses the vehicle’s ability to protect occupants in the event of an accident.

- Performance Testing: Manufacturers conduct performance tests to measure acceleration, braking, and handling characteristics, ensuring that the vehicle meets performance expectations.

How Can B2B Buyers Verify Supplier Quality Control Measures?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control measures is essential. Here are actionable steps to ensure due diligence:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess their manufacturing processes, quality control systems, and compliance with international standards. This firsthand evaluation can reveal much about a supplier’s capabilities.

-

Requesting Quality Reports: Buyers should request detailed quality reports, including results from IQC, IPQC, and FQC. These reports provide insights into the supplier’s adherence to quality standards and help identify any recurring issues.

-

Third-Party Inspections: Engaging third-party inspection agencies can add an extra layer of assurance. These agencies can conduct independent evaluations of the manufacturing process and final products, ensuring that they meet the buyer’s specifications and industry standards.

What Are the Quality Control Nuances for International B2B Buyers?

Navigating the quality control landscape in India requires an understanding of local practices and international expectations. Key nuances include:

-

Cultural Differences: Understanding the local business culture can facilitate better communication and collaboration with suppliers. Building strong relationships can lead to improved transparency regarding quality control processes.

-

Regulatory Compliance: Buyers must be aware of the regulatory requirements in their home countries, as these may differ from Indian standards. Ensuring that suppliers can meet these requirements is crucial for successful international trade.

-

Customs and Certifications: For international shipments, buyers should ensure that all necessary customs documentation and certifications are in place. This includes CE marking for products destined for Europe and compliance with local regulations in the buyer’s country.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing electric vehicles from India, ensuring that they receive high-quality products that meet their needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle india’

Introduction

In the rapidly evolving market of electric vehicles (EVs) in India, international B2B buyers must navigate a complex landscape of options and suppliers. This guide serves as a practical checklist to help you streamline your sourcing process, ensuring that you make informed decisions while procuring electric vehicles that meet your business needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical specifications that your business requires from electric vehicles. Consider aspects such as battery capacity, range, performance metrics, and vehicle type (e.g., sedan, SUV). Having a detailed specification sheet will help you communicate your needs effectively to suppliers and ensure that the vehicles you consider align with your operational requirements.

- Battery Capacity: Determine the minimum kWh required for your operations.

- Range: Assess the distance the vehicle needs to cover on a single charge.

- Performance Metrics: Look for bhp ratings and acceleration capabilities suitable for your market.

Step 2: Research the Market Landscape

Conduct thorough research on the current electric vehicle market in India. Understanding the competitive landscape will enable you to identify leading manufacturers, pricing trends, and emerging technologies.

- Key Players: Focus on prominent manufacturers like Mahindra, Tata, and MG, who have a strong presence in the Indian EV market.

- Pricing Trends: Familiarize yourself with price ranges for different models to set a realistic budget.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. This step ensures that you are dealing with reputable manufacturers capable of delivering high-quality products.

- Supplier History: Investigate the supplier’s experience in the EV sector.

- Client Testimonials: Look for feedback from other businesses that have procured vehicles from them.

Step 4: Verify Compliance and Certifications

Ensure that the suppliers you are considering comply with relevant industry standards and certifications. This is vital for guaranteeing the quality and safety of the electric vehicles you intend to purchase.

- Local Regulations: Check for compliance with Indian automotive regulations and standards.

- Quality Certifications: Look for ISO certifications or other relevant quality assurance markers.

Step 5: Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals that include pricing, delivery timelines, and warranty information. This will provide you with a clearer picture of what each supplier can offer and help you make a side-by-side comparison.

- Pricing Breakdown: Ask for a detailed cost structure, including any hidden fees.

- Warranty Terms: Understand the warranty coverage for the vehicles, including battery life and maintenance.

Step 6: Conduct On-site Visits or Virtual Tours

If feasible, conduct on-site visits to the manufacturing facilities or request virtual tours. This will give you insight into the production process and the quality control measures in place, further assuring you of the supplier’s capabilities.

- Facility Conditions: Assess the cleanliness and organization of the manufacturing environment.

- Quality Assurance Processes: Inquire about the testing procedures for vehicles before they are shipped.

Step 7: Negotiate Terms and Finalize Contracts

After evaluating all proposals and conducting due diligence, enter negotiations with your chosen supplier. Ensure that all terms, including pricing, delivery schedules, and after-sales support, are clearly outlined in the contract.

- Payment Terms: Discuss payment schedules and methods.

- After-Sales Support: Clarify what support services the supplier will provide post-delivery.

By following this comprehensive checklist, international B2B buyers can effectively navigate the electric vehicle procurement process in India, ensuring they secure the best vehicles suited to their business needs.

Comprehensive Cost and Pricing Analysis for electric vehicle india Sourcing

What Are the Key Cost Components in Electric Vehicle Sourcing in India?

When evaluating the costs associated with sourcing electric vehicles (EVs) in India, it’s essential to break down the various components that contribute to the overall pricing structure. The major cost elements include:

-

Materials: The primary materials used in EV manufacturing include battery cells, electric motors, and lightweight materials like aluminum and composites. The cost of lithium, cobalt, and nickel—critical for battery production—can fluctuate significantly based on global market conditions.

-

Labor: Labor costs in India are relatively lower compared to many Western countries, but they can vary by region and skill level. Skilled labor for assembly, quality control, and engineering can add a significant amount to the overall cost.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes and advanced technology can help reduce overhead costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom or specialized vehicle designs. These costs are amortized over the production volume, making them a critical consideration for pricing.

-

Quality Control (QC): Ensuring high-quality standards necessitates investment in testing and inspection processes. High-quality certifications can also enhance a vehicle’s marketability but may increase costs.

-

Logistics: Transportation and warehousing costs can vary significantly depending on the geographical location of suppliers and manufacturers. Efficient logistics management is crucial to keeping these costs in check.

-

Margin: Finally, suppliers will add their profit margins to cover business risks, market conditions, and investment returns, which can affect pricing.

How Do Price Influencers Affect Electric Vehicle Costs?

Several factors can influence the pricing of electric vehicles in India, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate for better pricing based on projected volumes.

-

Specifications and Customization: Custom features or high-performance specifications can significantly increase costs. It’s essential to balance desired features with budget constraints.

-

Materials and Quality Certifications: The choice of materials can impact pricing; higher-quality materials may lead to better performance but at a higher cost. Certifications for safety and environmental standards can also add to expenses.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge a premium, while new entrants might offer lower prices to gain market share.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital for international buyers. These terms define the responsibilities of buyers and sellers in shipping and insurance, which can affect total landed costs.

What Are the Best Negotiation and Cost-Efficiency Strategies for International Buyers?

For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, there are several strategies to ensure cost efficiency:

-

Leverage Relationships: Building strong relationships with suppliers can facilitate better pricing and terms. Regular communication can also lead to early insights on price changes or new product offerings.

-

Focus on Total Cost of Ownership (TCO): When evaluating the pricing of electric vehicles, consider the Total Cost of Ownership, which includes maintenance, operational costs, and resale value. This holistic view can help in making more informed purchasing decisions.

-

Understand Pricing Nuances: Be aware that pricing can vary based on the economic conditions of the supplier’s country, currency fluctuations, and geopolitical factors. Conduct thorough market research to understand these dynamics.

-

Negotiate for Flexibility: Seek flexible payment terms and conditions that allow for adjustments based on market conditions. This can provide a safety net against unforeseen expenses.

-

Stay Informed on Market Trends: Regularly monitor the Indian EV market and global trends. Staying informed can empower buyers during negotiations and help identify the best times to purchase.

Conclusion: Navigating the Cost Landscape of Electric Vehicles in India

Understanding the intricate cost structure and pricing dynamics of electric vehicles in India is crucial for international B2B buyers. By focusing on key cost components, recognizing price influencers, and employing effective negotiation strategies, buyers can optimize their sourcing efforts and achieve better financial outcomes. Always remember that prices are indicative and can fluctuate based on market conditions, so continuous engagement with suppliers is essential for maintaining favorable terms.

Alternatives Analysis: Comparing electric vehicle india With Other Solutions

Introduction to Alternative Solutions for Electric Vehicles in India

As the demand for sustainable transportation solutions continues to rise, businesses and consumers are increasingly exploring alternatives to traditional fossil fuel vehicles. Electric vehicles (EVs) in India, such as those offered by brands like Mahindra and Tata, present a compelling option, but they are not the only solution available. This section compares electric vehicles in India against two viable alternatives: hybrid vehicles and hydrogen fuel cell vehicles. Each option comes with its own set of advantages and challenges, making it essential for B2B buyers to understand these differences to make informed decisions.

Comparison Table

| Comparison Aspect | Electric Vehicle India | Hybrid Vehicle | Hydrogen Fuel Cell Vehicle |

|---|---|---|---|

| Performance | High torque, instant power | Moderate, reliant on both electric and gasoline | High efficiency, quick refueling |

| Cost | ₹6.24 Lakh – ₹75 Lakh | ₹15 Lakh – ₹35 Lakh | ₹50 Lakh – ₹1.5 Crore |

| Ease of Implementation | Growing infrastructure, incentives available | Established technology, easier to transition | Limited infrastructure, higher investment |

| Maintenance | Lower than ICE vehicles, battery replacement needed | Moderate, includes both electric and ICE maintenance | Low, but specialized service required |

| Best Use Case | Urban commuting, eco-friendly fleets | Long-distance travel, versatile usage | Heavy-duty applications, long-range travel |

Detailed Breakdown of Alternatives

1. Hybrid Vehicles

Hybrid vehicles combine a traditional internal combustion engine (ICE) with an electric motor, offering improved fuel efficiency and reduced emissions. They are particularly beneficial for long-distance travel, where the gasoline engine can take over when battery power is low. The transition to hybrid technology is generally smoother for businesses already operating ICE vehicles, as they do not require extensive infrastructure changes. However, hybrid vehicles can still have higher long-term costs due to maintenance of both engine types and fuel expenses, making them less appealing for those committed to fully electric solutions.

2. Hydrogen Fuel Cell Vehicles

Hydrogen fuel cell vehicles (FCVs) use hydrogen to generate electricity, offering a sustainable alternative with zero tailpipe emissions. They are especially advantageous for heavy-duty applications where long-range and quick refueling are necessary, such as logistics and transportation companies. However, the infrastructure for hydrogen refueling is still in its infancy, which can pose a significant barrier to widespread adoption. Additionally, the cost of hydrogen vehicles tends to be higher, making them a less accessible option for many businesses compared to electric vehicles.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating the right transportation solution, B2B buyers should consider factors such as operational requirements, budget constraints, and environmental goals. Electric vehicles in India offer a robust option with significant government incentives and an expanding charging infrastructure, making them ideal for urban environments and eco-conscious fleets. Hybrid vehicles may serve as a transitional solution for businesses still reliant on ICE technology, while hydrogen fuel cell vehicles are suited for specific heavy-duty applications. By carefully assessing these alternatives, buyers can align their choice with their organizational needs and sustainability objectives.

Essential Technical Properties and Trade Terminology for electric vehicle india

What Are the Key Technical Properties of Electric Vehicles in India?

When considering electric vehicles (EVs) in the Indian market, understanding the essential technical properties is crucial for B2B buyers. Here are some of the critical specifications to evaluate:

1. Battery Capacity (kWh)

Battery capacity, measured in kilowatt-hours (kWh), indicates the amount of energy stored in the battery. This directly affects the range of the vehicle—higher capacity typically translates to longer distances between charges. For example, popular models like the Tata Harrier EV offer capacities ranging from 65 to 75 kWh, enabling a range of up to 627 km. For international buyers, selecting vehicles with optimal battery capacities is essential for ensuring that operational needs, such as route planning and charging infrastructure, are met effectively.

2. Range (km)

The range of an electric vehicle is a critical metric that defines how far the vehicle can travel on a single charge. It’s particularly important in markets like India, where charging infrastructure is still developing. Models like the Mahindra BE 6 boast ranges between 557 to 683 km, making them suitable for longer journeys and reducing downtime for charging. B2B buyers should prioritize vehicles with sufficient range to meet their specific operational requirements.

3. Power Output (bhp)

Power output, measured in brake horsepower (bhp), indicates the performance capability of the vehicle. Higher bhp translates to better acceleration and overall performance, which can be crucial for commercial applications. For instance, the Tata Harrier EV offers a power output of 235 to 390 bhp, appealing to businesses requiring robust performance for logistics or passenger transport.

4. Charging Time (hours)

Charging time refers to the duration required to recharge the battery fully. This property is vital for businesses that rely on vehicles for daily operations. Fast-charging capabilities can significantly reduce downtime. Many models now offer fast-charging options, allowing for a full charge in under an hour, which can be a game-changer for fleet operations.

5. Vehicle Weight (kg)

The weight of an electric vehicle affects its efficiency, range, and handling. Lighter vehicles generally consume less energy, thereby extending range. For instance, the Tata Nexon EV weighs around 1,400 kg, balancing durability with efficiency. B2B buyers should consider vehicle weight when evaluating operational costs and energy consumption.

Which Trade Terminology Should B2B Buyers Understand in the Electric Vehicle Market?

Familiarity with industry jargon is essential for effective communication and negotiation in the electric vehicle sector. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the EV context, OEMs are critical as they design and manufacture the vehicles or components, influencing quality and reliability. Understanding the OEM landscape in India helps buyers identify trusted partners.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the EV industry, MOQs can vary significantly based on the manufacturer and model. Knowing the MOQ helps businesses plan their procurement strategies, especially if they are looking to scale operations.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. In the electric vehicle market, an RFQ can help businesses compare costs and features across various manufacturers, enabling informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which can significantly impact the total cost of acquiring EVs. Understanding Incoterms is crucial for managing risks and costs effectively in cross-border transactions.

5. TCO (Total Cost of Ownership)

TCO is a financial estimate that helps buyers evaluate the direct and indirect costs of owning a vehicle over its entire life cycle. This includes purchase price, maintenance, insurance, and charging costs. B2B buyers should calculate TCO to ensure they make economically sound decisions when investing in electric vehicles.

By grasping these essential technical properties and trade terminologies, international B2B buyers can make informed decisions that align with their operational needs and market dynamics in India.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle india Sector

What are the Key Trends Shaping the Electric Vehicle Market in India?

The electric vehicle (EV) sector in India is rapidly evolving, driven by a confluence of global market dynamics and technological advancements. One of the primary global drivers is the increasing demand for sustainable transportation solutions, particularly in light of climate change and rising fuel prices. Countries across Africa, South America, the Middle East, and Europe are increasingly prioritizing EV adoption, creating a fertile ground for international B2B buyers seeking opportunities in the Indian market.

Current B2B tech trends include the integration of advanced battery technologies, such as lithium-ion and solid-state batteries, which enhance vehicle performance and reduce costs. Moreover, innovations in charging infrastructure, including fast-charging stations and battery swapping technologies, are crucial for addressing the range anxiety that potential consumers face. As India positions itself as a manufacturing hub for EVs, international buyers can leverage partnerships with local manufacturers to access cutting-edge technologies and competitive pricing.

Additionally, the Indian government is implementing favorable policies and incentives, such as subsidies for EV buyers and manufacturers, which are instrumental in boosting the sector’s growth. This regulatory support is particularly appealing to B2B buyers from regions like Europe, where stringent emissions regulations are pushing companies to diversify their fleets with electric options. The evolving landscape also includes a focus on local sourcing, prompting international buyers to consider joint ventures with Indian firms to optimize supply chains and reduce costs.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the EV Sector?

Sustainability is becoming an essential consideration in the electric vehicle industry, significantly influencing B2B relationships. The environmental impact of EV production and usage is a critical area of focus, as the demand for greener solutions intensifies. B2B buyers are increasingly seeking partners who prioritize sustainable practices in their supply chains, from raw material sourcing to production processes.

Ethical sourcing is paramount, particularly concerning critical materials like lithium, cobalt, and nickel used in batteries. International buyers must ensure that their suppliers adhere to ethical labor practices and environmental standards. This commitment to ethical sourcing not only mitigates risks associated with supply chain disruptions but also enhances brand reputation among environmentally conscious consumers.

Moreover, the adoption of “green” certifications and materials can serve as a differentiator in the competitive EV market. Certifications such as ISO 14001 for environmental management and adherence to the Responsible Cobalt Initiative can strengthen B2B partnerships and provide assurance to buyers about the sustainability of their sourcing practices. As the EV landscape continues to evolve, establishing an ethically sound and sustainable supply chain will be critical for securing long-term B2B relationships.

What is the Historical Context of the Electric Vehicle Sector in India?

The evolution of the electric vehicle sector in India has been shaped by various socio-economic and technological factors. Initially, the Indian market saw limited electric vehicle options, primarily due to high costs and lack of infrastructure. However, the government’s push for sustainable mobility, particularly through initiatives like the Faster Adoption and Manufacturing of Electric Vehicles (FAME) scheme, has catalyzed growth.

Over the past decade, significant investments from both domestic and international players have led to advancements in EV technology and infrastructure. This includes the establishment of manufacturing plants, research and development centers, and the expansion of charging networks. As a result, India is now poised to become one of the largest EV markets globally, attracting international B2B buyers eager to engage in this burgeoning sector. The historical context underscores the importance of strategic partnerships and adaptability in navigating the complexities of the electric vehicle landscape in India.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle india

-

How do I find reliable electric vehicle suppliers in India?

To find reliable electric vehicle suppliers in India, start by conducting thorough market research. Utilize online platforms such as trade directories, industry forums, and B2B marketplaces like IndiaMART and Alibaba. Attend trade shows and exhibitions focused on electric vehicles to connect with manufacturers and distributors directly. It’s crucial to vet suppliers by reviewing their certifications, past client testimonials, and production capabilities. Engage in preliminary discussions to assess their responsiveness and willingness to accommodate your specific requirements. -

What is the best electric vehicle model for commercial use in India?

For commercial use in India, the Mahindra BE 6 and Tata Nexon EV are excellent choices due to their balance of range, performance, and cost. The Mahindra BE 6 offers a range of 557-683 km on a single charge, making it ideal for long-distance operations. The Tata Nexon EV, with a price starting at ₹12.49 Lakh and a range of up to 489 km, is also well-suited for urban logistics. Evaluate factors like battery capacity, charging infrastructure, and total cost of ownership to determine the best fit for your needs. -

What are the minimum order quantities (MOQs) for electric vehicles in India?

Minimum order quantities (MOQs) for electric vehicles can vary significantly based on the manufacturer and the model. Typically, established manufacturers may have an MOQ ranging from 10 to 50 units for bulk purchases. Smaller manufacturers or startups might have lower MOQs to attract international buyers. Always clarify MOQs during initial negotiations, as this can impact your budgeting and inventory planning. -

What payment terms should I expect when sourcing electric vehicles from India?

Payment terms for sourcing electric vehicles from India often include a mix of upfront deposits and balance payments upon delivery. Common practices involve a 30% to 50% advance payment, with the remainder payable before shipping or upon delivery. It’s advisable to negotiate terms that suit your cash flow while ensuring the supplier’s commitment. Additionally, consider using secure payment methods like letters of credit or escrow services to mitigate risks. -

How can I ensure quality assurance when purchasing electric vehicles from Indian manufacturers?

To ensure quality assurance, request certifications and compliance documentation for the vehicles, such as ISO certifications and adherence to local safety standards. Conduct factory audits or hire third-party inspection services to assess production processes and quality controls. It’s also beneficial to request sample vehicles for evaluation before placing a bulk order. Establish clear quality benchmarks and standards in your contract to hold suppliers accountable. -

What logistics considerations should I keep in mind when importing electric vehicles from India?

Logistics considerations include evaluating shipping options, customs regulations, and import duties specific to your country. Choose between sea freight and air freight based on your timeline and budget. Collaborate with a logistics provider experienced in automotive shipments to navigate documentation and compliance requirements. Be aware of packaging standards to prevent damage during transit, and factor in potential delays due to customs clearance. -

What customization options are available for electric vehicles in India?

Customization options for electric vehicles can include modifications to battery size, interior features, and branding. Many manufacturers are open to tailoring vehicles to meet specific business needs, such as adding cargo space or specialized tech features. It’s essential to discuss your customization requirements early in the negotiation process, as this may affect pricing and lead times. Always ensure that any modifications comply with local regulations and safety standards. -

How do I evaluate the total cost of ownership for electric vehicles sourced from India?

To evaluate the total cost of ownership, consider not only the purchase price but also factors such as maintenance costs, charging infrastructure, insurance, and potential government incentives. Analyze the energy consumption of the vehicles and the availability of charging stations in your operational area. Additionally, factor in depreciation rates and resale values. A comprehensive assessment will help you make informed decisions that align with your budget and operational goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Electric Vehicle India Manufacturers & Suppliers List

1. Reuters – Indian GST Proposal on Luxury EVs

Domain: reuters.com

Registered: 1993 (32 years)

Introduction: The Indian tax panel has proposed increasing the Goods and Services Tax (GST) on luxury electric vehicles (EVs) priced above $46,000 to 28%, and to 18% for EVs priced between $23,000 and $46,000. Currently, all electric cars are taxed at 5%. The proposal is aimed at impacting sales of high-end EVs from manufacturers like Tesla, BMW, Mercedes-Benz, and BYD. Tesla’s Model Y has a base price of $65,0…

2. Ampere – Reo 80

Domain: evindia.online

Registered: 2021 (4 years)

Introduction: Popular Electric Vehicles: Ampere Reo 80 – Price: ₹ Onwards, Top Speed: -, Range: -, Waiting Period: -; Ola S1 X Gen 3 (4 kWh) – Price: ₹ Onwards, Top Speed: -, Range: -, Waiting Period: -; Ampere Magnus Neo – Price: ₹ Onwards, Top Speed: -, Range: -, Waiting Period: -; TVS iQube (2.2 kWh) – Price: ₹ Onwards, Top Speed: -, Range: -, Waiting Period: -; Ampere Nexus ST – Price: ₹ Onwards, Top Speed:…

3. Tata Motors – Electric Vehicles

Domain: ev.tatamotors.com

Registered: 2002 (23 years)

Introduction: Tata Motors offers a range of electric vehicles including: 1. Nexon.ev – Price starts at ₹12.49 Lakh* 2. Curvv.ev – Price starts at ₹17.49 Lakh* 3. Punch.ev – Price starts at ₹9.99 Lakh* 4. Tiago.ev – Price starts at ₹7.99 Lakh* 5. Tigor.ev – Price starts at ₹12.49 Lakh* 6. Harrier.ev – Price starts at ₹22.24 Lakh* All models emphasize features such as design, performance, technology, and safety. …

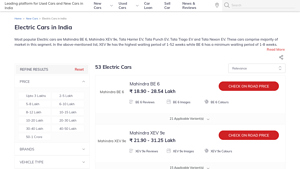

4. Mahindra – BE 6 & XEV 9e, Tata – Curvv EV

Domain: auto.hindustantimes.com

Registered: 1996 (29 years)

Introduction: Best Electric Cars in India September 2025: 1. Mahindra BE 6 – Price: ₹18.9 – 28.54 Lakhs, Battery: 79 kWh, Top Speed: 200 kmph, Range: 682 km. 2. Mahindra XEV 9e – Price: ₹21.9 – 31.25 Lakhs, Battery: 79 kWh, Top Speed: 200 kmph, Range: 656 km. 3. Tata Curvv EV – Price: ₹17.49 – 22.24 Lakhs, Battery: 55 kWh, Top Speed: 160 kmph, Range: 502 km. 4. Tata Punch EV – Price: ₹9.99 – 14.29 Lakhs, Batter…

5. Mahindra – BE 6, XEV 9e; Tata – Harrier

Domain: cartrade.com

Registered: 1998 (27 years)

Introduction: This company, Mahindra – BE 6, XEV 9e; Tata – Harrier, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Team-BHP – Electric Cars Forum

Domain: team-bhp.com

Registered: 2004 (21 years)

Introduction: Electric Cars Forum on Team-BHP includes discussions, reviews, and announcements related to various electric vehicles. Key threads include reviews of models like Mahindra XEV 9e, Tata Tiago Electric, Hyundai Creta Electric, and more. The forum also covers topics such as home charging setups, electric car sales figures, and rumors about upcoming models like the Volkswagen Polo electric and BMW’s Ne…

Strategic Sourcing Conclusion and Outlook for electric vehicle india

As the electric vehicle (EV) market in India continues to expand, international B2B buyers from regions such as Africa, South America, the Middle East, and Europe stand to gain significantly from strategic sourcing opportunities. The Indian EV landscape is characterized by a diverse range of models, with price points catering to various segments, from affordable options like the MG Comet EV to premium offerings such as the MG Cyberster. This variety enables buyers to tailor their sourcing strategies to meet specific market demands.

Strategic sourcing in this burgeoning sector not only enhances supply chain resilience but also provides access to innovative technologies and competitive pricing. By engaging with Indian manufacturers, buyers can leverage local expertise and supply chains, ultimately fostering sustainable partnerships that drive mutual growth.

Looking ahead, the Indian EV market is poised for further transformation, driven by government incentives, infrastructural advancements, and increasing consumer awareness. For international buyers, now is the opportune moment to explore collaborations that align with their sustainability goals and market strategies. Embrace the future of mobility in India—partner with local EV manufacturers to seize the opportunities that lie ahead.