Introduction: Navigating the Global Market for electric vehicle platform

Navigating the rapidly evolving landscape of electric vehicle platforms presents a significant challenge for international B2B buyers seeking to make informed sourcing decisions. As the demand for electric vehicles (EVs) surges across regions such as Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Germany—understanding the nuances of different electric vehicle platforms becomes critical. This comprehensive guide delves into the various types of platforms currently in use, their specific applications, and the strategic advantages they offer to manufacturers and fleet operators alike.

In this guide, we explore the four primary EV platform development pathways: dedicated platforms, modified combustion platforms, hybrid platforms, and EV-first platforms. Each option presents distinct advantages and challenges that impact design freedom, scalability, and cost-efficiency. Additionally, we provide insights into supplier vetting processes, cost considerations, and the latest technological advancements that can enhance operational efficiency and reduce total cost of ownership (TCO).

By equipping B2B buyers with essential knowledge and actionable insights, this guide empowers stakeholders to navigate the complexities of the electric vehicle market confidently. Whether you are a manufacturer, fleet operator, or investor, understanding these platforms will enable you to make strategic decisions that align with your business objectives in a competitive global market.

Understanding electric vehicle platform Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dedicated EV Platform | Designed exclusively for EVs, offering maximum design freedom | OEMs focused on EV-only models | Pros: Optimal performance; Cons: High R&D costs and longer development times. |

| Modified Combustion Platform | Retrofitted from existing combustion platforms | Short-term solutions for legacy brands | Pros: Quick to market; Cons: Limited design flexibility and future viability. |

| Hybrid Platform | Supports combustion and electric powertrains | Versatile manufacturing environments | Pros: Flexible production; Cons: Compromised design and performance. |

| EV First Platform | Primarily EV-focused but adaptable to hybrids and combustion | Manufacturers transitioning to EVs | Pros: Future-proof; Cons: May require additional investment for hybrid capabilities. |

| Modular Electric Vehicle Platform | Highly customizable and adaptable for specific missions | Commercial fleets and specialized vehicles | Pros: Cost-effective and versatile; Cons: Complexity in integration and management. |

What Are the Characteristics of a Dedicated EV Platform?

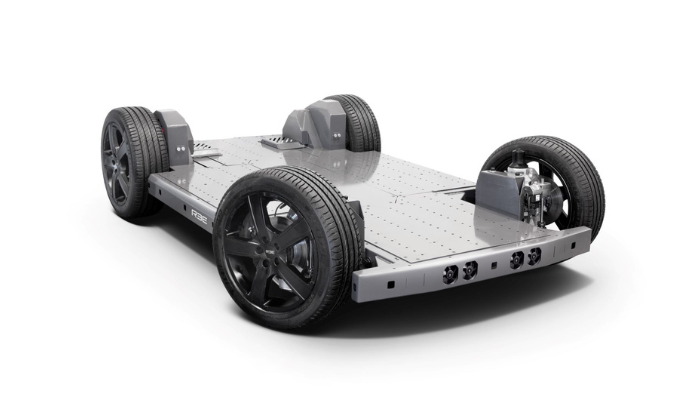

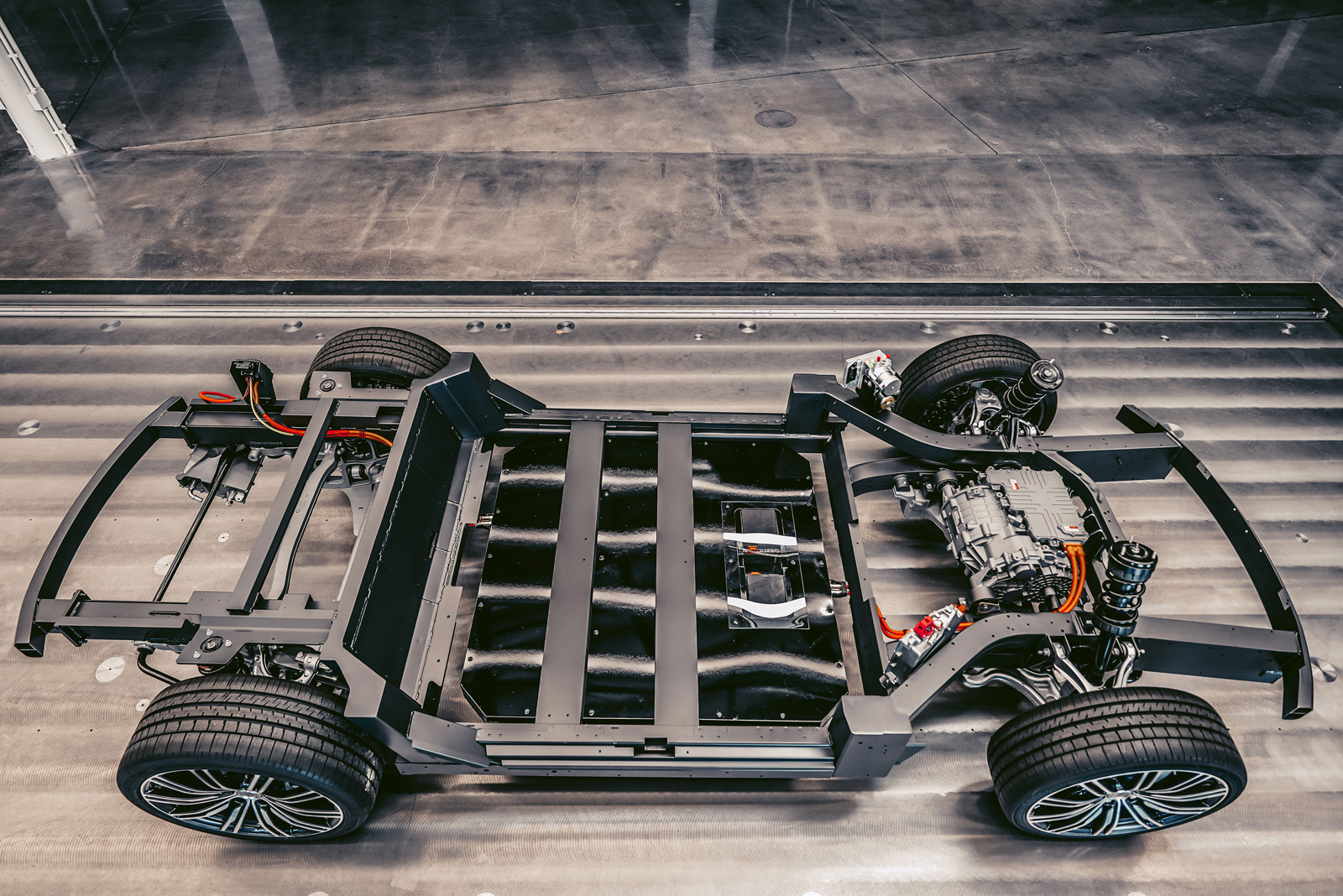

A dedicated EV platform is designed solely for electric vehicles, allowing for extensive customization and optimization. This type of platform typically features a skateboard layout, which integrates the battery and electric drive components efficiently. B2B buyers should consider the long-term benefits of investing in this platform, including superior performance and scalability. However, the high initial R&D costs and extended development timelines can pose challenges for companies with immediate market needs.

Why Choose a Modified Combustion Platform for EVs?

Modified combustion platforms are an expedient solution for manufacturers looking to introduce electric vehicles without investing in new architecture. By retrofitting existing combustion platforms, companies can quickly launch EV models. This approach is suitable for brands with legacy vehicles that need to adapt to market demands. However, buyers should be aware of the limitations in design and performance, which could hinder competitiveness in the evolving EV landscape.

How Does a Hybrid Platform Benefit Manufacturers?

Hybrid platforms are designed to accommodate both combustion and electric powertrains, providing manufacturers with operational flexibility. This type of platform allows for a diverse production line, enabling companies to produce both traditional and electric vehicles simultaneously. While this approach can reduce production costs and time, it may compromise the vehicle’s design and efficiency. B2B buyers should weigh the benefits of flexibility against potential performance drawbacks.

What Sets an EV First Platform Apart?

The EV first platform is primarily tailored for electric vehicles but retains the capability to integrate hybrid or combustion powertrains if necessary. This adaptability makes it appealing for manufacturers transitioning toward an all-electric lineup while hedging against market uncertainties. Buyers should consider the potential for future-proofing their investments, although the need for additional funding to support hybrid capabilities may be a downside.

How Do Modular Electric Vehicle Platforms Enhance Customization?

Modular electric vehicle platforms are designed for versatility, allowing for mission-specific applications tailored to unique business needs. This platform type is particularly beneficial for commercial fleets, as it can reduce development costs and time while maximizing efficiency. Buyers should evaluate the cost-effectiveness and adaptability of modular solutions against the complexities of integration and ongoing management challenges.

Key Industrial Applications of electric vehicle platform

| Industry/Sector | Specific Application of electric vehicle platform | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric buses and shuttles | Reduced operational costs, lower emissions, and improved public perception | Battery life, charging infrastructure, and maintenance support |

| Logistics and Delivery | Last-mile delivery vans and trucks | Enhanced delivery efficiency, reduced fuel costs, and improved sustainability | Vehicle range, payload capacity, and modularity for different applications |

| Agriculture | Electric tractors and farming equipment | Lower operational costs, reduced emissions, and increased efficiency in farming operations | Terrain adaptability, battery capacity, and serviceability |

| Construction | Electric construction vehicles | Lower emissions, improved site safety, and reduced noise pollution | Durability, power requirements, and compatibility with existing machinery |

| Automotive Manufacturing | Modular electric vehicle production lines | Flexibility in production, reduced time to market, and lower development costs | Scalability, customization options, and integration with existing systems |

How Are Electric Vehicle Platforms Transforming Public Transportation?

Electric vehicle platforms are increasingly being adopted for electric buses and shuttles, providing a sustainable alternative to traditional diesel-powered vehicles. These platforms allow for reduced operational costs through lower fuel consumption and maintenance expenses while significantly decreasing greenhouse gas emissions. For buyers in regions such as Africa and South America, the emphasis on charging infrastructure and battery life is crucial, as it directly impacts the feasibility of deploying electric fleets in urban settings.

What Role Do Electric Vehicle Platforms Play in Logistics and Delivery?

In the logistics sector, electric vehicle platforms are revolutionizing last-mile delivery with electric vans and trucks. These platforms enhance delivery efficiency and reduce fuel costs, which is vital for companies aiming to improve their bottom line. Buyers from Europe and the Middle East should consider vehicle range and payload capacity when sourcing these platforms, as they directly affect operational effectiveness in diverse urban and rural environments.

How Can Agriculture Benefit from Electric Vehicle Platforms?

Electric tractors and farming equipment built on electric vehicle platforms are becoming increasingly popular in agriculture. These platforms help reduce operational costs while minimizing emissions, contributing to more sustainable farming practices. Buyers in developing regions, such as parts of Africa and South America, need to focus on the adaptability of these vehicles to various terrains and their battery capacity to ensure they can meet specific agricultural demands.

Why Are Electric Vehicle Platforms Essential for Construction?

The construction industry is leveraging electric vehicle platforms for electric construction vehicles, addressing environmental concerns while enhancing site safety. These vehicles are quieter and produce fewer emissions, making them suitable for urban construction projects. Buyers must consider the durability and power requirements of these platforms, as well as their compatibility with existing machinery, to ensure they can effectively replace traditional vehicles on job sites.

How Do Electric Vehicle Platforms Enhance Automotive Manufacturing?

In automotive manufacturing, modular electric vehicle platforms enable flexible production lines that can adapt to various models and specifications. This reduces time to market and development costs while allowing manufacturers to respond quickly to market demands. For international buyers, especially in Europe and the Middle East, sourcing platforms with scalability and customization options is essential to align with evolving consumer preferences and regulatory requirements.

3 Common User Pain Points for ‘electric vehicle platform’ & Their Solutions

Scenario 1: Difficulty in Customizing Electric Vehicle Platforms for Unique Needs

The Problem: Many B2B buyers, particularly those in emerging markets such as Africa and South America, face challenges in adapting electric vehicle platforms to meet their specific operational requirements. Standardized platforms often lack the flexibility needed for unique applications, leading to inefficiencies and increased costs. Companies may find themselves limited in their ability to customize features such as battery capacity, range, and cargo configurations, ultimately hindering their competitive edge in the market.

The Solution: To effectively address customization challenges, B2B buyers should seek out modular electric vehicle platforms that allow for extensive design freedom. Platforms like the REEcorner® technology enable businesses to tailor their vehicles for specific missions without the need for costly custom development. When sourcing a platform, it’s essential to evaluate vendors based on their ability to provide modularity and scalability. Engage with manufacturers that offer detailed specifications and flexible design options. Consider conducting workshops with potential platform providers to discuss your specific needs, ensuring that the chosen platform can adapt to future requirements. Additionally, leveraging data analytics and operational feedback can help refine the platform’s configuration, enhancing performance and efficiency over time.

Scenario 2: High Total Cost of Ownership (TCO) for Electric Vehicles

The Problem: One of the most pressing concerns for B2B buyers is the high total cost of ownership associated with electric vehicles. This includes not only the initial purchase price of the electric vehicle platform but also operational costs such as maintenance, energy consumption, and potential downtime. In regions with limited infrastructure, such as the Middle East and parts of Africa, these costs can skyrocket, making it challenging to justify the investment in electric vehicle technology.

The Solution: To mitigate high TCO, B2B buyers should prioritize platforms that incorporate advanced technologies aimed at reducing operational costs. Platforms that feature integrated energy-efficient designs, such as those with optimized aerodynamics and battery management systems, can significantly lower energy consumption. Buyers should conduct a thorough analysis of the total cost of ownership by evaluating different platforms and their respective efficiencies. Moreover, consider implementing predictive maintenance technologies that use AI and IoT to minimize downtime and enhance serviceability. This proactive approach can lead to substantial savings over the vehicle’s lifespan. Collaborating with platform suppliers who offer comprehensive service agreements and support can further help manage costs effectively.

Scenario 3: Integration Challenges with Existing Fleet Operations

The Problem: Many B2B buyers looking to transition to electric vehicle platforms encounter significant integration challenges with their existing fleet operations. This can include compatibility issues with current logistics and supply chain systems, as well as training needs for staff. The lack of seamless integration can lead to operational disruptions and inefficiencies, making the transition to electric vehicles more daunting.

The Solution: To overcome integration challenges, B2B buyers should select electric vehicle platforms that are designed for interoperability with various fleet management systems. When evaluating potential platforms, look for those that provide APIs and software solutions that easily integrate with existing logistics and operational tools. Prior to making a purchase, conduct a pilot program with the chosen platform to assess its compatibility and identify any gaps. Additionally, investing in staff training programs focused on new technologies and operational procedures can ease the transition process. Partnering with a platform provider that offers ongoing support and consultation can further facilitate smooth integration, ensuring that your fleet can operate efficiently while embracing electric vehicle technology.

Strategic Material Selection Guide for electric vehicle platform

What Are the Key Properties of Aluminum in Electric Vehicle Platforms?

Aluminum is a widely used material in electric vehicle (EV) platforms due to its excellent strength-to-weight ratio and corrosion resistance. It typically has a temperature rating that can withstand high operational temperatures, making it suitable for various components, including chassis and body structures. Aluminum is also recyclable, which aligns with the sustainability goals of many manufacturers.

Pros and Cons of Aluminum in EV Platforms

The primary advantage of aluminum is its lightweight nature, which contributes to improved energy efficiency and range in EVs. Additionally, its corrosion resistance extends the lifespan of components. However, aluminum can be more expensive than traditional steel, and its manufacturing processes can be complex, potentially leading to higher production costs.

For international buyers, particularly in regions like Africa and South America, sourcing aluminum may involve navigating import tariffs and compliance with local standards, such as ASTM or JIS, which could affect overall costs.

How Does Steel Compare as a Material for Electric Vehicle Platforms?

Steel, particularly high-strength steel, is another common material used in EV platforms. It offers excellent durability and impact resistance, making it ideal for structural components that require high strength. Steel has a good temperature rating and is generally less expensive than aluminum.

Pros and Cons of Steel in EV Platforms

The advantages of steel include its cost-effectiveness and ease of manufacturing, which can lead to lower production costs. However, steel is heavier than aluminum, which can negatively impact the vehicle’s range and efficiency. Additionally, steel is prone to corrosion, necessitating protective coatings that can add to manufacturing complexity.

For B2B buyers in Europe and the Middle East, understanding local regulations regarding steel grades and corrosion resistance is crucial. Compliance with standards such as DIN can also influence material selection.

What Role Does Carbon Fiber Play in Electric Vehicle Platforms?

Carbon fiber is increasingly being considered for high-performance electric vehicle platforms. It boasts exceptional strength-to-weight ratios and excellent fatigue resistance, making it suitable for performance-oriented applications. Carbon fiber can withstand high temperatures, which is beneficial for components exposed to heat.

Pros and Cons of Carbon Fiber in EV Platforms

The key advantage of carbon fiber is its lightweight nature, which significantly enhances vehicle performance and range. However, the primary drawback is its high cost and complex manufacturing process, which can deter mass adoption in budget-conscious markets.

International buyers, especially in emerging markets, may face challenges in sourcing carbon fiber due to limited local suppliers and the need for compliance with specific quality standards.

How Does Plastic Composites Impact Electric Vehicle Platform Design?

Plastic composites, such as reinforced thermoplastics, are gaining traction in electric vehicle platforms. They offer good temperature resistance and can be engineered for specific applications, providing flexibility in design.

Pros and Cons of Plastic Composites in EV Platforms

The advantages of plastic composites include their lightweight nature and resistance to corrosion. They can also be molded into complex shapes, allowing for innovative designs. However, they may not provide the same level of structural integrity as metals, which can limit their use in critical load-bearing applications.

For B2B buyers in regions like Africa and South America, the availability of plastic composites may vary, and understanding local manufacturing capabilities is essential for effective sourcing.

Summary of Material Selection for Electric Vehicle Platforms

| Material | Typical Use Case for electric vehicle platform | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Chassis and body structures | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Steel | Structural components | Cost-effective and durable | Heavier, prone to corrosion | Low |

| Carbon Fiber | High-performance applications | Exceptional strength-to-weight ratio | High cost and complex manufacturing | High |

| Plastic Composites | Non-structural components and interior parts | Lightweight and design flexibility | Limited structural integrity | Medium |

This strategic material selection guide provides valuable insights for international B2B buyers looking to optimize their electric vehicle platforms while considering performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle platform

What Are the Main Stages of Manufacturing Electric Vehicle Platforms?

The manufacturing process for electric vehicle (EV) platforms involves several critical stages that ensure the efficient production of high-quality vehicles. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage focuses on selecting and preparing the right materials. Key materials used in EV platforms include lightweight metals (like aluminum), composites, and advanced battery materials. Suppliers must ensure that these materials meet specific standards for strength, weight, and conductivity. B2B buyers should prioritize suppliers who demonstrate rigorous material sourcing and testing practices.

-

Forming: In this stage, raw materials are shaped into components using techniques such as stamping, extrusion, and injection molding. Advanced forming techniques, like hydroforming, are increasingly popular for creating complex shapes while minimizing waste. The choice of forming technique impacts the platform’s overall weight and structural integrity, which are crucial for EV performance.

-

Assembly: The assembly stage integrates various components into a cohesive platform. This includes installing battery packs, electric motors, and control systems. Automated assembly lines often enhance efficiency and precision, but manual assembly may still be necessary for complex components. B2B buyers should ensure that their suppliers utilize a blend of automation and skilled labor to maintain high-quality standards.

-

Finishing: The final stage involves surface treatments, coatings, and quality checks. Finishing processes improve the durability and aesthetic appeal of the platform. Additionally, thorough quality checks are implemented at this stage to ensure that all components meet the required specifications.

What Key Techniques Are Used in Electric Vehicle Platform Manufacturing?

Several advanced manufacturing techniques are pivotal in producing high-quality electric vehicle platforms:

-

Additive Manufacturing: Also known as 3D printing, this technique allows for the creation of complex components that are lightweight and strong. It can significantly reduce waste and lead times, making it ideal for prototyping and low-volume production.

-

Robotics and Automation: The use of robotics in assembly lines enhances precision and reduces human error. Automated systems can perform repetitive tasks more efficiently, leading to higher production rates and consistency.

-

Lean Manufacturing: This methodology focuses on minimizing waste while maximizing productivity. Lean principles are particularly beneficial in the EV sector, where rapid innovation and cost management are crucial.

-

Digital Twin Technology: By creating a virtual representation of the manufacturing process, companies can simulate production scenarios, identify bottlenecks, and optimize workflows. This technology supports continuous improvement and proactive maintenance strategies.

How Is Quality Assurance Managed in Electric Vehicle Platform Production?

Quality assurance (QA) is a fundamental aspect of manufacturing electric vehicle platforms, ensuring that products meet international standards and customer expectations. The QA process includes adherence to relevant international and industry-specific standards.

-

Relevant International Standards: Adopting standards such as ISO 9001 (Quality Management Systems) is crucial for manufacturers. This standard ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications like CE (European Conformity) or API (American Petroleum Institute) may apply, depending on the components involved.

-

Quality Control Checkpoints: Effective quality control involves several checkpoints throughout the production process:

– Incoming Quality Control (IQC): Inspecting raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Monitoring the manufacturing process to detect and rectify issues in real-time, preventing defects from progressing.

– Final Quality Control (FQC): Conducting thorough inspections of the finished product, including functional testing and performance evaluations. -

Common Testing Methods: Various testing methods are employed to assess the quality of electric vehicle platforms, including:

– Durability Testing: Simulating real-world conditions to evaluate the platform’s performance under stress.

– Electrical Testing: Ensuring that electrical systems function correctly and safely.

– Safety Testing: Assessing the vehicle’s compliance with safety regulations, which is particularly important for markets with strict automotive standards.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, verifying a supplier’s quality control processes is essential to ensure reliable partnerships. Here are some strategies to accomplish this:

-

Conducting Audits: Regular audits of suppliers’ manufacturing facilities can provide insights into their quality control practices. Buyers should look for evidence of adherence to international standards and internal QA protocols.

-

Reviewing Quality Reports: Requesting documentation, such as quality assurance reports and compliance certificates, can help assess a supplier’s commitment to quality. These documents should detail inspection results, testing procedures, and corrective actions taken.

-

Engaging Third-Party Inspectors: Utilizing independent third-party inspection services can offer an unbiased evaluation of a supplier’s quality control processes. These inspectors can conduct detailed assessments and provide certifications that validate a supplier’s claims.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, face unique challenges in quality control for electric vehicle platforms:

-

Understanding Regional Standards: Different regions may have varying regulatory requirements and quality standards. Buyers must familiarize themselves with these nuances to ensure compliance and avoid costly delays.

-

Communication Barriers: Language and cultural differences can impact the effectiveness of quality control communications. Establishing clear lines of communication and documentation practices is vital for avoiding misunderstandings.

-

Supply Chain Transparency: Ensuring transparency throughout the supply chain can help mitigate risks associated with quality. Buyers should seek suppliers who are willing to share detailed information about their sourcing, manufacturing processes, and quality assurance practices.

Conclusion

The manufacturing processes and quality assurance practices for electric vehicle platforms are critical for ensuring the reliability and performance of EVs. By understanding the main stages of manufacturing, key techniques, and quality control measures, B2B buyers can make informed decisions when selecting suppliers. Emphasizing quality assurance and compliance with international standards will enable buyers to navigate the complexities of the global EV market successfully.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle platform’

Introduction

In the rapidly evolving landscape of electric vehicle (EV) technology, selecting the right EV platform is critical for businesses aiming to innovate and stay competitive. This guide provides a structured checklist to assist B2B buyers in procuring electric vehicle platforms, ensuring that they make informed decisions that align with their technical and commercial needs.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. This includes considerations such as battery capacity, range, charging speeds, and compatibility with existing systems. Understanding these parameters helps in filtering platforms that meet your specific operational demands.

- Identify the intended use cases (e.g., passenger vehicles, commercial fleets).

- Determine regulatory compliance requirements relevant to your region.

Step 2: Research Different Types of EV Platforms

Familiarize yourself with the various types of electric vehicle platforms available in the market. Key types include dedicated EV platforms, hybrid platforms, and modified combustion platforms. Each type has unique characteristics and advantages.

- Evaluate the scalability and modularity of the platforms.

- Consider the long-term viability and potential for future upgrades.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; seek firsthand accounts of their reliability and service quality.

- Check for suppliers’ experience in your specific market.

- Look for testimonials and performance metrics from existing clients.

Step 4: Analyze Cost Implications

Understanding the total cost of ownership (TCO) is essential for long-term budgeting. Assess not only the initial purchase price but also maintenance costs, potential downtime, and energy efficiency of the platform.

- Compare lifecycle costs of different platforms.

- Factor in potential savings from operational efficiencies.

Step 5: Request Prototypes or Demonstrations

Whenever possible, request prototypes or demonstrations of the EV platforms you are considering. This hands-on experience can provide invaluable insights into performance, usability, and integration capabilities.

- Evaluate the ease of integration with your existing operations.

- Observe real-world performance metrics in a controlled environment.

Step 6: Verify Supplier Certifications and Compliance

Ensure that your potential suppliers meet relevant industry standards and certifications. This includes safety regulations, environmental compliance, and quality assurance certifications.

- Look for certifications such as ISO or other relevant local standards.

- Confirm adherence to regional regulations regarding electric vehicles.

Step 7: Establish a Clear Communication Plan

Once you’ve selected a supplier, establish a clear communication protocol. This should outline timelines, responsibilities, and escalation procedures for issues that may arise during the procurement and implementation phases.

- Set regular check-ins to monitor progress.

- Ensure that there are designated points of contact for both parties.

By following this checklist, B2B buyers can navigate the complexities of sourcing electric vehicle platforms more effectively, ensuring that they choose a solution that aligns with their business objectives and market demands.

Comprehensive Cost and Pricing Analysis for electric vehicle platform Sourcing

What Are the Key Cost Components in Sourcing Electric Vehicle Platforms?

When sourcing electric vehicle (EV) platforms, understanding the cost structure is crucial for B2B buyers. The primary components of the cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly affects the cost. High-performance materials, such as lightweight composites or advanced battery technologies, can increase the initial outlay. It’s essential to balance material quality with cost to ensure durability without compromising performance.

-

Labor: Skilled labor is necessary for the design and assembly of EV platforms. Regions with a higher cost of living may see increased labor costs. Additionally, the complexity of the platform can require specialized skills, further driving up costs.

-

Manufacturing Overhead: This encompasses the costs associated with running a manufacturing facility, including utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Tooling costs are often substantial, especially for custom or specialized platforms. Investing in advanced tooling technology can enhance precision and efficiency but may require significant upfront capital.

-

Quality Control: Ensuring the platform meets regulatory and industry standards necessitates robust QC processes, which can add to the overall cost. Certifications may also be required for international markets, impacting pricing.

-

Logistics: Transporting materials and finished products can incur substantial costs, particularly for international shipments. Factors such as distance, mode of transport, and customs duties need to be considered.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding standard margins in different regions can aid in negotiations.

How Do Price Influencers Affect Electric Vehicle Platform Sourcing?

Several factors can influence the pricing of electric vehicle platforms, notably:

-

Volume/MOQ: Purchasing in larger quantities can lead to significant discounts. Manufacturers often have minimum order quantities (MOQs) that can affect pricing flexibility.

-

Specifications and Customization: Customized platforms designed for specific applications can be more expensive. Clear communication of requirements can help manage costs.

-

Materials: The choice of materials can heavily influence the cost. High-grade materials may enhance performance but at a premium price.

-

Quality and Certifications: Platforms that meet international quality standards or certifications typically come at a higher price. This is particularly relevant for buyers in Europe or North America.

-

Supplier Factors: The reputation, reliability, and location of suppliers can influence pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: The terms of sale can significantly impact costs. Understanding the Incoterms agreed upon can help buyers anticipate additional charges related to shipping and handling.

What Are the Best Negotiation Tips for B2B Buyers Sourcing Electric Vehicle Platforms?

For international B2B buyers, especially from Africa, South America, the Middle East, and Europe, effective negotiation can lead to better pricing and terms. Here are some strategic tips:

-

Understand Total Cost of Ownership (TCO): Evaluate the long-term costs associated with the platform, including maintenance, energy consumption, and resale value. A lower upfront cost may not always result in the best TCO.

-

Leverage Volume Discounts: If feasible, consider bundling orders or collaborating with other buyers to increase order volumes. This can provide leverage for negotiating better prices.

-

Be Informed About Market Trends: Keeping abreast of market trends and competitor pricing can strengthen your negotiating position. Knowledge of fluctuations in material costs can also be advantageous.

-

Clarify Specifications Early: Providing clear specifications and customization needs upfront can prevent misunderstandings and additional costs later in the process.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to more favorable terms and priority in production schedules.

-

Consider Local Suppliers: In regions like Africa or South America, sourcing from local suppliers may reduce logistics costs and lead times.

Conclusion

Sourcing electric vehicle platforms requires a comprehensive understanding of cost structures and pricing influencers. By focusing on key components like materials and labor, and leveraging negotiation strategies, B2B buyers can optimize their sourcing process. It is essential to approach each deal with a keen awareness of both immediate costs and long-term implications, ensuring that investments yield the best possible returns.

Alternatives Analysis: Comparing electric vehicle platform With Other Solutions

Exploring Alternatives to Electric Vehicle Platforms: A Comparative Analysis

As industries transition towards sustainable solutions, the exploration of alternatives to traditional electric vehicle (EV) platforms becomes essential. B2B buyers, particularly in emerging markets such as Africa and South America, must evaluate various technologies that fulfill similar objectives while considering regional demands, infrastructure, and operational efficiencies.

| Comparison Aspect | Electric Vehicle Platform | Modular Electric Vehicle Platform | Modified Combustion Platform |

|---|---|---|---|

| Performance | High efficiency, tailored for EV specs | Versatile, can handle various configurations | Lower performance, limited EV capabilities |

| Cost | High initial R&D investment | Potentially lower, but dependent on customization | Generally lower upfront costs |

| Ease of Implementation | Complex, requires extensive development | Easier to implement due to modularity | Quick adaptation from existing models |

| Maintenance | Specialized service needs, may be costly | Simplified maintenance due to modular design | Easier maintenance but limited lifecycle |

| Best Use Case | Ideal for dedicated EV manufacturers | Suitable for flexible fleet operations | Good for manufacturers transitioning to EVs |

Understanding Modular Electric Vehicle Platforms

Modular electric vehicle platforms, like the REEcorner® technology, offer a flexible and customizable approach to EV design. These platforms can adapt to mission-specific applications, allowing fleet operators to tailor vehicles to their precise requirements. The modularity reduces development costs and time, making it an attractive option for businesses with diverse transportation needs. However, the initial investment in technology and the need for bespoke configurations can be challenges for some organizations.

Evaluating Modified Combustion Platforms

Modified combustion platforms provide a transitional solution for manufacturers looking to enter the EV market without extensive redesigns. By retrofitting existing combustion platforms, companies can quickly bring serviceable EVs to market, which is particularly advantageous for those with limited R&D budgets. However, this approach often results in compromised performance and design limitations, making it less suitable for businesses aiming for long-term sustainability and innovation in their fleets.

Conclusion: How to Choose the Right Solution for Your Business

When selecting the most suitable platform for electric vehicles, B2B buyers should consider their specific operational requirements, budget constraints, and long-term sustainability goals. While dedicated electric vehicle platforms offer superior performance and future-proofing, modular solutions provide flexibility and lower initial costs. Modified combustion platforms may serve as a stopgap but can hinder future innovation. Assessing these alternatives against business objectives will enable organizations to make informed decisions that align with their strategic vision in a rapidly evolving market.

Essential Technical Properties and Trade Terminology for electric vehicle platform

What Are the Key Technical Properties of Electric Vehicle Platforms?

When evaluating electric vehicle (EV) platforms, understanding critical technical properties is essential for B2B buyers. These properties directly influence the performance, scalability, and adaptability of EVs in various markets. Here are some of the most important specifications to consider:

-

Material Grade

The choice of materials—such as aluminum, high-strength steel, or composites—affects the vehicle’s weight, durability, and cost. Lightweight materials enhance efficiency by reducing energy consumption, which is crucial for maximizing range. For manufacturers, selecting the right material grade can lead to significant cost savings and improved vehicle performance over time. -

Battery Capacity and Chemistry

Battery capacity, measured in kilowatt-hours (kWh), determines the range and performance of an EV. The chemistry (e.g., lithium-ion, solid-state) also impacts energy density, charging speed, and lifecycle. Understanding these factors allows buyers to align their procurement strategies with market demands for longer ranges and faster charging times, which are increasingly prioritized by consumers. -

Platform Modularity

Modularity refers to the design flexibility of an EV platform, allowing manufacturers to adapt it for various vehicle types, from passenger cars to commercial vehicles. A modular platform can reduce development costs and time-to-market, making it a strategic advantage for OEMs. Buyers should assess the scalability of platforms to ensure they can accommodate future needs without significant re-engineering. -

Powertrain Configuration

Powertrain options—whether dedicated electric, hybrid, or flexible (capable of supporting multiple powertrains)—play a critical role in defining vehicle capabilities. A flexible platform can cater to diverse market demands, allowing manufacturers to pivot quickly in response to changing consumer preferences. This flexibility is particularly advantageous in regions with varying infrastructure readiness for EVs. -

Charging Infrastructure Compatibility

Compatibility with different charging standards (e.g., CCS, CHAdeMO) is vital for ensuring widespread usability. Platforms designed with versatile charging solutions can appeal to a broader customer base, particularly in emerging markets where infrastructure may be inconsistent. Buyers should consider how charging compatibility aligns with their operational needs. -

Thermal Management Systems

Effective thermal management is essential for maintaining battery performance and longevity. Platforms equipped with advanced thermal management systems can optimize battery temperature, enhancing safety and efficiency. Understanding this property helps B2B buyers ensure that the platforms they invest in will deliver reliable performance across various environmental conditions.

What Are Common Trade Terms in the Electric Vehicle Industry?

Navigating the electric vehicle industry requires familiarity with specific jargon and trade terminology. Here are some common terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the EV sector, OEMs are crucial as they design and manufacture the platforms that other companies use to build their vehicles. Understanding the role of OEMs helps buyers identify reliable partners in the supply chain. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. This term is vital for buyers to understand when negotiating contracts, as it can significantly impact inventory costs and production planning. Buyers should assess their needs against suppliers’ MOQs to ensure they can meet demand without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to submit price proposals for specific products or services. It is a critical step in procurement, allowing buyers to compare costs and terms. Crafting a clear RFQ can lead to better pricing and service conditions from suppliers. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms used in international contracts to define the responsibilities of buyers and sellers. Familiarity with these terms is crucial for buyers, especially when sourcing platforms globally, as they dictate shipping costs, risks, and responsibilities. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with the purchase and operation of a vehicle over its lifetime, including maintenance, fuel, and resale value. Understanding TCO enables buyers to make informed decisions about investments in EV platforms, ensuring long-term cost efficiency. -

FCEV (Fuel Cell Electric Vehicle)

An FCEV is a type of electric vehicle that uses a fuel cell to generate electricity from hydrogen, offering an alternative to traditional battery-electric vehicles. Understanding FCEVs is essential for buyers exploring diverse powertrain options in the evolving EV market.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when selecting electric vehicle platforms, ultimately driving better outcomes for their businesses.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle platform Sector

What Are the Global Drivers and Key Trends in the Electric Vehicle Platform Market?

The electric vehicle (EV) platform sector is experiencing a transformative phase, driven by several global factors. The increasing urgency to combat climate change has led governments worldwide to implement stringent emissions regulations and incentivize EV adoption. In regions such as Europe, Africa, and South America, local policies are fostering a burgeoning market for electric mobility. This transition is further accelerated by advancements in battery technology, which are enhancing vehicle range and reducing costs, making EVs more appealing to consumers and businesses alike.

Current B2B technology trends indicate a shift toward modular and scalable platforms. Companies like REE Auto are pioneering modular designs that allow for mission-specific applications, providing significant flexibility for fleet operators. This adaptability is crucial for international buyers looking to tailor vehicles to local market demands, particularly in emerging economies where customization can drive competitive advantage. Additionally, the emergence of dedicated EV platforms is becoming a focal point for manufacturers aiming to optimize performance and efficiency, showcasing a clear divergence from traditional combustion-engine architectures.

Market dynamics also reflect a growing interest in partnerships and collaborations among OEMs (Original Equipment Manufacturers) and technology firms. Companies are seeking synergies to leverage expertise in software, battery technology, and vehicle design, creating a collaborative ecosystem that can respond rapidly to evolving market needs. As the EV platform landscape matures, international B2B buyers must stay informed about these developments to make strategic sourcing decisions that align with both their operational goals and the broader industry trends.

How Is Sustainability and Ethical Sourcing Impacting the Electric Vehicle Platform Sector?

Sustainability is at the forefront of the electric vehicle platform sector, significantly influencing sourcing practices. The environmental impact of battery production and raw material extraction has garnered attention, prompting buyers to prioritize ethical sourcing in their supply chains. This includes seeking suppliers who adhere to responsible mining practices and use recycled materials, which helps mitigate the ecological footprint of EV production.

Furthermore, the emphasis on sustainability extends to the entire lifecycle of the vehicle, from manufacturing to end-of-life recycling. B2B buyers are increasingly looking for partners who can provide ‘green’ certifications, ensuring that the materials used in EV platforms meet rigorous environmental standards. Certifications such as ISO 14001 for environmental management systems or the use of recycled aluminum and plastics can enhance a company’s sustainability profile, making them more attractive to eco-conscious consumers and stakeholders.

The push for sustainability is also driving innovation in battery technology, with a growing focus on developing batteries that are not only efficient but also environmentally friendly. This trend is vital for international buyers, as they navigate the complexities of sourcing materials that align with their sustainability goals while still meeting performance requirements. By prioritizing ethical sourcing, businesses can enhance their brand reputation and appeal to a market increasingly concerned with environmental stewardship.

What Is the Brief Evolution of Electric Vehicle Platforms and Its Relevance for B2B Buyers?

The evolution of electric vehicle platforms has been marked by a significant shift from traditional combustion-engine designs to dedicated electric architectures. Initially, many manufacturers adapted existing platforms for electric use, limiting design capabilities and performance. However, as the market matured, a clear trend emerged toward dedicated EV platforms that maximize efficiency and scalability.

Dedicated platforms, such as GM’s Ultium and Hyundai’s E-GMP, have set new benchmarks for performance, range, and modularity. These platforms allow manufacturers to produce a diverse range of vehicles from a single architecture, optimizing production costs and time-to-market. For international B2B buyers, understanding this evolution is crucial for making informed sourcing decisions. By aligning with manufacturers that utilize advanced electric platforms, businesses can benefit from cutting-edge technology and increased operational efficiencies, ensuring they remain competitive in a rapidly changing market.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle platform

-

How do I choose the right electric vehicle platform for my business needs?

Choosing the right electric vehicle (EV) platform depends on your specific operational requirements and market expectations. Consider factors such as scalability, customization options, and integration capabilities with existing systems. Evaluate whether a dedicated EV platform or a modified combustion platform aligns better with your long-term strategy. Additionally, assess the total cost of ownership, including maintenance, charging infrastructure, and supply chain logistics, to ensure the platform meets your financial and operational goals. -

What customization options are available for electric vehicle platforms?

Customization options vary significantly among EV platform providers. Many platforms offer modular designs that allow you to tailor vehicle configurations to specific mission requirements. This can include modifications to battery capacity, chassis design, and integration of proprietary technologies. When selecting a supplier, inquire about their capabilities in providing bespoke solutions, as well as lead times and costs associated with customization. -

What are the minimum order quantities (MOQ) for electric vehicle platforms?

Minimum order quantities can vary widely based on the supplier and the specific platform being procured. Some manufacturers may require a higher MOQ for specialized platforms, while others may have flexible options for smaller orders. It’s essential to discuss your anticipated volume and growth projections with potential suppliers to negotiate favorable terms that align with your production needs and market entry strategy. -

What payment terms should I expect when sourcing electric vehicle platforms?

Payment terms for electric vehicle platforms typically range from upfront payments to staggered payments based on milestones. Many suppliers may offer financing options or payment plans to help manage cash flow. It’s crucial to clarify these terms during the negotiation process and ensure they align with your budget and project timelines. Additionally, inquire about any potential discounts for early payments or bulk orders. -

How can I ensure quality assurance when sourcing electric vehicle platforms?

To ensure quality assurance, it’s vital to conduct thorough due diligence on potential suppliers. Request certifications such as ISO 9001, which indicates adherence to quality management standards. Additionally, consider visiting the manufacturing facility to assess production processes and quality control measures. Establishing clear quality benchmarks and regular communication with your supplier can also help mitigate risks associated with product quality. -

What are the logistics considerations for importing electric vehicle platforms?

Logistics for importing electric vehicle platforms involve several factors, including shipping methods, customs regulations, and lead times. Evaluate the most cost-effective shipping options based on your location and the supplier’s capabilities. Understanding import duties and local regulations is crucial to avoid unexpected costs. Collaborating with a logistics partner experienced in international trade can streamline the process and ensure timely delivery of your platforms. -

How do I vet potential suppliers for electric vehicle platforms?

Vetting suppliers requires a comprehensive approach. Start by researching their industry reputation, customer reviews, and case studies. Request references from other clients who have sourced similar platforms. Assess their production capabilities, financial stability, and compliance with international standards. It’s also beneficial to engage in preliminary discussions to gauge their responsiveness and willingness to collaborate on your specific requirements. -

What are the emerging trends in electric vehicle platform technology?

Emerging trends in electric vehicle platforms include the increasing adoption of modular and software-defined architectures, which allow for greater flexibility and customization. Innovations such as improved battery technology and enhanced vehicle-to-grid (V2G) capabilities are also shaping the future of EV platforms. Additionally, sustainability practices are becoming more important, with manufacturers focusing on eco-friendly materials and production processes to meet growing regulatory and consumer demands. Staying informed about these trends can help you make strategic decisions for your business.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Electric Vehicle Platform Manufacturers & Suppliers List

1. InsideEVs – Electric Vehicle Platforms Guide

Domain: insideevs.com

Registered: 2012 (13 years)

Introduction: The Complete Guide To Electric Vehicle Platforms outlines various EV platforms currently in use or in development in America. Key platforms include: 1. **Dedicated EV Platform**: Specifically designed for EVs, allowing maximum design freedom and scalability. 2. **Modified Combustion Platform**: Retrofitted existing combustion platforms for EV use, limiting design capabilities. 3. **Hybrid Platform…

2. REE.auto – REEcorner Technology

Domain: ree.auto

Registered: 2019 (6 years)

Introduction: REEcorner technology is a fully modular software-defined electric vehicle platform designed for commercial vehicles. Key features include:

– Modular and customizable design for mission-specific applications.

– Best-in-class function with optimal volumetric efficiency, maneuverability, serviceability, and safety.

– 36% more load capacity for a given footprint, allowing for more space for batteries….

3. Reddit – Bedrock Chassis

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – Bedrock Chassis, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Nidec – Versatile EV Platform

Domain: nidec.com

Registered: 1997 (28 years)

Introduction: Nidec is developing a versatile wheeled platform for electric vehicles (EVs), which is crucial for the dissemination of EV technology. The platform is designed to be a basic frame of a vehicle without a power unit, chassis, or body, allowing new manufacturers to purchase it and sell finished automobiles without the need to develop their own expensive platforms. Nidec’s platform aims to enhance saf…

5. Chevrolet – EV Technology

Domain: chevrolet.com

Registered: 1994 (31 years)

Introduction: Chevrolet’s EV technology features a modular battery platform that offers outstanding power, range, and performance. Key features include: 1. Flexible, modular design for various vehicle types (cars, SUVs, crossovers, trucks). 2. One Pedal Driving for energy-efficient driving. 3. Regen on Demand for regenerative braking. 4. Ultifi software platform for over-the-air updates. 5. Google built-in for …

6. Stellantis – BEV-native Platforms

Domain: stellantis.com

Registered: 2005 (20 years)

Introduction: Stellantis offers four BEV-native platforms: STLA Small, Medium, Large, and Frame, along with dedicated platforms for Smart Cars and Light Commercial Vehicles (LCVs). Each platform is designed for flexibility, scalability, and efficiency, supporting over-the-air (OTA) upgrades and next-gen technologies.

– **STLA Medium**: Ideal for C- and D-segment passenger cars, crossovers, and SUVs. Offers up…

7. EVKX – Electric Vehicle Platforms

Domain: evkx.net

Registered: 2021 (4 years)

Introduction: EV Platforms are the foundational architecture of electric vehicles (EVs) that support components like battery packs, electric motors, and electronics. There are four main types of EV platforms: 1. Retrofitting: Modifying existing internal combustion engine (ICE) platforms for electric powertrains. Examples include Volkswagen E-Golf, Ford Focus Electric, Tesla Roadster, and Nissan Leaf. 2. Hybrid:…

Strategic Sourcing Conclusion and Outlook for electric vehicle platform

In the rapidly evolving landscape of electric vehicle (EV) platforms, strategic sourcing emerges as a critical component for international B2B buyers. Understanding the diverse platform options—ranging from dedicated EV platforms to modified combustion systems—enables businesses to make informed decisions that align with their operational needs and market demands. This knowledge not only facilitates the selection of the right technology but also aids in optimizing production costs and improving time-to-market.

The versatility offered by modular platforms, such as those developed by REE Auto, exemplifies how businesses can customize solutions to meet specific application requirements, enhancing overall operational efficiency. Furthermore, as EV technology continues to advance, the importance of sustainable sourcing practices cannot be overstated, particularly for buyers in emerging markets across Africa, South America, the Middle East, and Europe.

Looking ahead, the commitment to innovation and adaptability will be paramount. As the global shift towards electrification accelerates, international B2B buyers are encouraged to engage with leading manufacturers and explore partnerships that drive technological advancements. This proactive approach will not only secure a competitive edge but also contribute to a more sustainable automotive future.