Introduction: Navigating the Global Market for electric cargo 4 wheel

In the rapidly evolving landscape of logistics and transportation, sourcing electric cargo 4-wheel vehicles presents a critical challenge for international B2B buyers. As businesses globally pivot towards sustainable practices, the demand for efficient, eco-friendly transportation solutions has surged, especially in regions like Africa, South America, the Middle East, and Europe. This comprehensive guide delves into the myriad options available in the electric cargo vehicle market, exploring various types, applications, and the distinct advantages they offer over traditional fuel-based vehicles.

From compact electric mini trucks ideal for last-mile deliveries to versatile electric bikes that facilitate cargo transport in urban settings, this guide aims to provide invaluable insights into the diverse features and specifications of electric cargo vehicles. Additionally, we will cover essential aspects of supplier vetting, cost considerations, and maintenance requirements, ensuring that you make informed purchasing decisions.

By equipping B2B buyers with the knowledge needed to navigate this burgeoning market, this guide empowers businesses to enhance operational efficiency while reducing their carbon footprint. With a focus on practical applications and real-world performance metrics, you will gain the confidence to select the right electric cargo solution tailored to your specific logistical needs.

Understanding electric cargo 4 wheel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Mini Truck | Compact size, high payload capacity, fast charging capabilities | Last-mile delivery, urban logistics | Pros: Efficient for tight spaces, lower operational costs. Cons: Limited range compared to larger vehicles. |

| 4-Wheel Electric Cargo Bike | Stability with four wheels, large cargo baskets, tilting front | Delivery services, recreational use | Pros: Versatile for various terrains, easy maneuverability. Cons: Heavier than traditional bikes, lower speed. |

| Electric Utility Vehicle | Multi-purpose design, robust build, customizable configurations | Construction sites, maintenance services | Pros: High durability, adaptable to various tasks. Cons: Higher upfront cost, may require specialized training. |

| Electric Rickshaw | Lightweight, passenger and cargo capacity, compact design | Urban transport, goods delivery | Pros: Eco-friendly, cost-effective for short distances. Cons: Limited cargo space, may not handle rough terrain well. |

| Electric Pickup Truck | Larger cargo area, powerful motors, longer range | Freight transport, agriculture | Pros: High payload capacity, suitable for diverse loads. Cons: Higher purchase and maintenance costs. |

What Are the Key Characteristics of Electric Mini Trucks?

Electric mini trucks are designed for urban environments, offering a compact solution for last-mile delivery. With features such as a high payload capacity and fast charging capabilities, they allow businesses to optimize logistics while reducing operational costs. Their ability to navigate tight spaces makes them ideal for city deliveries, but potential buyers should consider their limited range compared to larger electric vehicles.

How Do 4-Wheel Electric Cargo Bikes Stand Out in the Market?

The 4-wheel electric cargo bike combines stability and versatility, making it suitable for various terrains—from city streets to rugged trails. These bikes feature large cargo baskets and a unique tilting mechanism for enhanced maneuverability. They are particularly advantageous for businesses needing to transport goods in urban settings. However, their weight and lower speed can be drawbacks for some commercial applications.

What Are the Advantages of Electric Utility Vehicles for B2B Buyers?

Electric utility vehicles offer a robust and multi-purpose design that can be customized for various applications. These vehicles are built to withstand the rigors of construction sites and maintenance tasks, providing high durability and reliability. Although they come with a higher upfront cost, their adaptability and long-term savings on fuel make them a worthwhile investment for businesses in demanding environments.

Why Are Electric Rickshaws a Cost-Effective Solution for Urban Transport?

Electric rickshaws are lightweight and compact, making them an excellent choice for urban transport and goods delivery. They provide an eco-friendly alternative for short distances and can navigate congested areas with ease. However, their limited cargo space and performance on rough terrain may pose challenges for businesses requiring more extensive transport capabilities.

What Benefits Do Electric Pickup Trucks Offer for Freight Transport?

Electric pickup trucks are designed for heavier loads and longer ranges, making them suitable for freight transport and agricultural applications. Their high payload capacity allows businesses to handle diverse loads efficiently. While the initial investment and maintenance costs may be higher, the long-term benefits of reduced fuel expenses and lower environmental impact make them an attractive option for many B2B buyers.

Key Industrial Applications of electric cargo 4 wheel

| Industry/Sector | Specific Application of electric cargo 4 wheel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Delivery | Last-mile delivery in urban areas | Reduces delivery times and operational costs while minimizing emissions | Battery range, payload capacity, and charging infrastructure availability |

| Agriculture | Transporting goods and produce within farms | Enhances efficiency in moving goods, reduces labor costs, and minimizes environmental impact | Terrain adaptability, payload specifications, and battery longevity |

| Retail and E-commerce | Store deliveries and inventory restocking | Streamlines inventory management and reduces logistics costs | Vehicle size, maneuverability in urban settings, and cargo space |

| Construction | Transporting tools and materials on-site | Increases productivity and reduces reliance on traditional fuel vehicles | Durability, load capacity, and compatibility with construction site conditions |

| Hospitality and Tourism | Shuttle services for guests and luggage | Improves guest experience and reduces carbon footprint | Comfort features, battery life for longer routes, and safety standards |

How is Electric Cargo 4 Wheel Used in the Logistics and Delivery Sector?

Electric cargo 4 wheel vehicles are increasingly utilized for last-mile delivery in urban areas, where traditional larger vehicles may struggle with traffic and narrow streets. They offer a compact solution that can navigate tight spaces while carrying significant payloads, thus enhancing delivery efficiency. The reduced operational costs associated with electric vehicles, such as lower fuel expenses and maintenance, make them particularly appealing for logistics companies. International buyers should consider battery range and charging infrastructure, especially in regions with varying levels of technological advancement.

What Role Does Electric Cargo 4 Wheel Play in Agriculture?

In the agricultural sector, electric cargo 4 wheel vehicles are employed to transport goods and produce within farms. They facilitate efficient movement of crops and equipment, significantly reducing labor costs and improving productivity. These vehicles are particularly beneficial in regions where environmental sustainability is a priority, as they emit zero emissions. Buyers should assess the vehicle’s adaptability to different terrains and its payload capacity to ensure it meets specific operational needs.

How Can Retail and E-commerce Benefit from Electric Cargo 4 Wheel Vehicles?

For retail and e-commerce businesses, electric cargo 4 wheel vehicles streamline the process of store deliveries and inventory restocking. They enable quick and efficient transport of goods, which is essential for maintaining inventory levels and meeting customer demands. The reduced logistics costs associated with electric vehicles enhance profitability. When sourcing these vehicles, businesses should focus on size and maneuverability to ensure they can operate effectively in urban environments.

In What Ways Do Electric Cargo 4 Wheel Vehicles Enhance Construction Operations?

In the construction industry, electric cargo 4 wheel vehicles are invaluable for transporting tools and materials on-site. Their ability to carry heavy loads while being environmentally friendly aligns with the growing emphasis on sustainability in construction practices. These vehicles increase productivity by ensuring that materials are readily available when needed, thereby minimizing downtime. Buyers should prioritize durability and load capacity when considering these vehicles for construction applications.

How Do Electric Cargo 4 Wheel Vehicles Improve Hospitality and Tourism Services?

Electric cargo 4 wheel vehicles are used in the hospitality and tourism sectors for shuttle services, transporting guests and their luggage efficiently. They enhance the guest experience while contributing to a reduced carbon footprint, aligning with the growing demand for eco-friendly travel options. For international buyers, it is crucial to consider comfort features and battery life to accommodate longer routes without compromising service quality.

3 Common User Pain Points for ‘electric cargo 4 wheel’ & Their Solutions

Scenario 1: Limited Range and Downtime Concerns

The Problem: Many businesses rely on electric cargo vehicles for last-mile deliveries, but one of the most significant challenges they face is limited range and potential downtime due to charging requirements. For instance, a logistics company operating in urban environments may find that the 100-160 km range typical of electric cargo 4-wheelers is insufficient for their daily delivery routes, especially when considering peak traffic times and the need for multiple trips. This limitation can lead to increased operational costs and decreased customer satisfaction due to delayed deliveries.

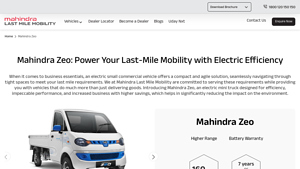

The Solution: To overcome range anxiety and reduce downtime, B2B buyers should look for electric cargo vehicles with advanced battery technologies and fast-charging capabilities. When sourcing, prioritize models like the Mahindra Zeo, which offers a robust 21.3 kWh battery with an impressive range of up to 160 km on a single charge and fast-charging options that can provide 100 km of range in just 60 minutes. Additionally, implementing a strategic charging schedule that aligns with delivery times can maximize vehicle uptime. Establishing partnerships with local charging stations or investing in on-site charging infrastructure can also facilitate quicker turnaround times, ensuring your fleet remains operational throughout the day.

Scenario 2: Navigating Diverse Terrains Safely

The Problem: Businesses operating in regions with varying terrains—such as urban centers with narrow streets or rural areas with unpaved roads—often struggle to find electric cargo vehicles that can handle diverse driving conditions. The risk of vehicle instability or breakdowns increases, particularly when transporting heavy loads over rough surfaces, leading to potential delays and damage to goods.

The Solution: To address this concern, B2B buyers should focus on electric cargo 4-wheelers designed for stability and adaptability. Vehicles with features like a robust wheelbase, wide tires, and advanced suspension systems can significantly improve performance across different terrains. For example, the ANYterrain Stabilized 4-Wheel Electric Bike is engineered for diverse landscapes, featuring a unique design that enhances balance and traction. Buyers should also consider conducting thorough testing in the intended operating environments before purchase, ensuring the vehicle meets specific stability and load requirements. Additionally, investing in driver training programs focused on handling electric vehicles in various conditions can further enhance safety and efficiency.

Scenario 3: Cost Management and Total Cost of Ownership

The Problem: While electric cargo vehicles promise lower fuel costs and reduced emissions, many businesses are still concerned about the total cost of ownership (TCO), including initial purchase price, maintenance, and battery replacement. For instance, a small business may hesitate to invest in electric cargo vehicles due to fears that the upfront costs will outweigh long-term savings, especially if they are unaware of the potential for lower operational costs and government incentives.

The Solution: To effectively manage costs, B2B buyers should conduct a comprehensive analysis of the total cost of ownership for electric cargo 4-wheelers. This includes evaluating the initial investment against expected savings on fuel, maintenance, and potential tax incentives or rebates available for electric vehicle purchases. Buyers should engage with manufacturers and dealers to understand the warranties and service plans offered, especially regarding battery longevity and replacement costs. Vehicles like the Mahindra Zeo offer extensive warranty options, providing peace of mind regarding battery life and performance. Additionally, consider utilizing fleet management software to track operational efficiency, fuel savings, and maintenance schedules to further optimize costs and enhance profitability.

Strategic Material Selection Guide for electric cargo 4 wheel

What Are the Key Materials Used in Electric Cargo 4 Wheel Vehicles?

When selecting materials for electric cargo 4 wheel vehicles, several factors must be considered, including performance, durability, cost, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of these vehicles: aluminum, high-strength steel, composite materials, and lithium-ion batteries.

How Does Aluminum Benefit Electric Cargo 4 Wheel Vehicles?

Aluminum is widely used in the construction of electric cargo vehicles due to its lightweight and corrosion-resistant properties. With a temperature rating of around -200°C to 600°C, aluminum maintains structural integrity under various environmental conditions.

Pros: Its lightweight nature enhances energy efficiency, allowing for longer ranges on a single charge. Additionally, aluminum is relatively easy to fabricate, reducing manufacturing complexity.

Cons: While aluminum offers excellent resistance to corrosion, it can be more expensive than traditional steel. Its lower tensile strength compared to steel may necessitate thicker sections in certain applications, which can offset weight savings.

Impact on Application: Aluminum is particularly suitable for components that require weight reduction without compromising strength, such as chassis and body panels.

Considerations for International Buyers: Buyers should be aware of compliance with standards such as ASTM B221 for aluminum extrusions. In regions like Europe and Germany, adherence to DIN standards is crucial for quality assurance.

What Role Does High-Strength Steel Play in Electric Cargo 4 Wheel Vehicles?

High-strength steel (HSS) is another common material used in electric cargo vehicles due to its exceptional strength-to-weight ratio and durability. HSS can withstand high pressure and has a temperature rating of up to 500°C.

Pros: HSS provides superior strength, making it ideal for structural components that require high load-bearing capacity. It is also cost-effective compared to aluminum.

Cons: The primary drawback of HSS is its weight, which can negatively impact energy efficiency. Moreover, it may require additional corrosion protection measures, increasing manufacturing complexity.

Impact on Application: HSS is often used in the frame and suspension systems of electric cargo vehicles, where strength and durability are paramount.

Considerations for International Buyers: Buyers must ensure compliance with standards such as ASTM A992 for structural steel and consider local regulations regarding emissions and safety.

How Do Composite Materials Enhance Electric Cargo 4 Wheel Vehicles?

Composite materials, such as fiberglass and carbon fiber, are increasingly being utilized in electric cargo vehicles for various applications. They provide excellent strength-to-weight ratios and are resistant to corrosion.

Pros: Composites are lightweight, which can significantly improve vehicle efficiency. They also offer design flexibility, allowing for aerodynamic shapes that enhance performance.

Cons: The primary limitation of composites is their higher cost and complex manufacturing processes, which can lead to longer production times.

Impact on Application: Composites are ideal for body panels and interior components, where weight savings and aesthetics are important.

Considerations for International Buyers: Compliance with standards like ASTM D3039 for composite materials is essential. Buyers in regions like Africa and South America may also need to consider local availability and sourcing challenges.

What Is the Importance of Lithium-Ion Batteries in Electric Cargo 4 Wheel Vehicles?

Lithium-ion batteries are the heart of electric cargo vehicles, providing the energy necessary for operation. They typically operate within a temperature range of -20°C to 60°C and offer high energy density.

Pros: Lithium-ion batteries are lightweight and have a long cycle life, making them suitable for commercial applications. They also charge quickly, reducing downtime.

Cons: The primary drawback is their cost, which can be significant. Additionally, they require careful management to avoid issues related to overheating or degradation.

Impact on Application: The battery’s performance directly impacts the vehicle’s range and operational efficiency, making it a critical component.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as IEC 62133 for battery safety. Additionally, understanding local regulations regarding battery disposal and recycling is crucial.

Summary Table of Material Selection for Electric Cargo 4 Wheel Vehicles

| Material | Typical Use Case for electric cargo 4 wheel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Chassis, body panels | Lightweight, corrosion-resistant | Higher cost, lower tensile strength | Medium |

| High-Strength Steel | Frame, suspension systems | Superior strength | Heavier, requires corrosion protection | Low |

| Composite Materials | Body panels, interior components | Lightweight, design flexibility | Higher cost, complex manufacturing | High |

| Lithium-Ion Batteries | Power source for electric motors | High energy density, quick charging | High cost, requires management | High |

This analysis provides a comprehensive overview of the materials critical to the performance and efficiency of electric cargo 4 wheel vehicles, aiding B2B buyers in making informed decisions.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cargo 4 wheel

What Are the Key Manufacturing Processes for Electric Cargo 4 Wheel Vehicles?

The manufacturing of electric cargo 4 wheel vehicles involves several crucial stages, each designed to ensure the vehicle meets performance, safety, and quality standards. Understanding these processes can help B2B buyers make informed decisions when sourcing vehicles for their businesses.

What Are the Main Stages of Manufacturing Electric Cargo Vehicles?

-

Material Preparation

– The first step in manufacturing electric cargo vehicles is sourcing high-quality materials such as steel, aluminum, plastics, and lithium-ion batteries. The choice of materials significantly impacts the vehicle’s weight, durability, and overall performance.

– Advanced techniques such as laser cutting and CNC machining are commonly employed to prepare raw materials, ensuring precision and efficiency. -

Forming

– Forming processes involve shaping the prepared materials into components. Techniques like stamping, bending, and welding are utilized to create the vehicle’s chassis, body panels, and structural elements.

– This stage is critical as it lays the foundation for the vehicle’s structural integrity and performance under load. -

Assembly

– The assembly process integrates all the manufactured components into a complete vehicle. This stage typically follows a modular assembly line approach, allowing for efficient production and reduced lead times.

– Key components such as the electric motor, battery pack, and control systems are installed during this phase. The assembly process often involves rigorous testing at each stage to ensure compatibility and functionality. -

Finishing

– The final stage includes painting, surface treatment, and installation of additional features such as safety systems and user interfaces. High-quality finishing not only enhances aesthetic appeal but also improves durability against environmental factors.

– Quality control checks are performed post-finishing to ensure that all components function correctly and meet regulatory standards.

How Is Quality Assurance Implemented in Electric Cargo Vehicle Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that each vehicle meets both international and industry-specific standards. For B2B buyers, understanding the QA process can provide confidence in the reliability and safety of their purchases.

What Are the Relevant International Standards for Quality Assurance?

- ISO 9001: This international standard focuses on quality management systems and is applicable to any organization, regardless of size or industry. Manufacturers of electric cargo vehicles often seek ISO 9001 certification to demonstrate their commitment to quality and continuous improvement.

- CE Marking: For manufacturers in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This marking is essential for vehicles sold within the EU market.

- API Standards: Although primarily associated with the oil and gas industry, certain API standards can apply to the manufacturing of components used in electric vehicles, particularly in battery systems.

What Are the Key Quality Control Checkpoints?

-

Incoming Quality Control (IQC)

– IQC focuses on the quality of raw materials and components as they arrive at the manufacturing facility. This involves inspecting materials for defects and verifying compliance with specifications before they enter production. -

In-Process Quality Control (IPQC)

– During the manufacturing process, IPQC is employed to monitor production activities, ensuring adherence to established quality standards. Techniques such as process audits and real-time monitoring are utilized to identify and rectify issues promptly. -

Final Quality Control (FQC)

– After assembly, FQC involves comprehensive testing of the completed vehicle. This includes performance tests, safety checks, and inspections to verify that the vehicle meets all regulatory and customer requirements.

What Common Testing Methods Are Used in Quality Assurance?

Manufacturers employ various testing methods to ensure the quality and reliability of electric cargo vehicles:

- Functional Testing: This assesses the operational capabilities of the vehicle, including acceleration, braking, and battery performance.

- Safety Testing: Compliance with safety standards is verified through crash tests, electrical safety evaluations, and environmental impact assessments.

- Durability Testing: Vehicles are subjected to rigorous testing under different conditions to assess their longevity and performance over time.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for mitigating risks associated with procurement.

What Are Effective Strategies for Supplier Verification?

-

Supplier Audits

– Conducting on-site audits of the manufacturing facility can provide insights into the supplier’s quality management practices, production processes, and adherence to standards. -

Quality Reports

– Requesting detailed quality reports and certifications from suppliers can help assess their compliance with international standards and their internal quality control measures. -

Third-Party Inspections

– Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing process and product quality. These inspections often include random sampling and comprehensive reporting.

What Are the QC and Certification Nuances for International Buyers?

B2B buyers operating in diverse markets should be aware of the following nuances regarding quality control and certification:

- Regulatory Variations: Different regions may have specific regulations and standards that electric cargo vehicles must meet. Understanding these variations is essential for compliance.

- Cultural Considerations: The approach to quality assurance may vary across cultures, influencing communication and expectations. Establishing clear guidelines and expectations can bridge these gaps.

- Supply Chain Transparency: In an increasingly globalized market, ensuring transparency throughout the supply chain is vital. Buyers should seek suppliers who are willing to provide insights into their sourcing and production practices.

By understanding the manufacturing processes and quality assurance practices for electric cargo 4 wheel vehicles, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This knowledge is essential for building partnerships with reliable suppliers and ensuring the successful integration of electric vehicles into their logistics and transportation strategies.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cargo 4 wheel’

In today’s fast-evolving logistics landscape, procuring electric cargo four-wheel vehicles is a strategic decision that can enhance operational efficiency, reduce costs, and contribute to sustainability. This guide provides a step-by-step checklist to assist international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Consider factors such as payload capacity, battery range, motor power, and vehicle dimensions. This clarity will help you identify vehicles that meet your business needs and ensure compatibility with existing operations.

- Payload Capacity: Ensure the vehicle can handle the weight of goods you typically transport.

- Battery Range: Look for vehicles that offer sufficient range for your daily routes to minimize downtime.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in electric cargo vehicles. Evaluate their market reputation, customer reviews, and industry presence. This step is crucial to ensure you partner with reliable manufacturers who can deliver quality products.

- Supplier Reputation: Check online reviews and case studies from other businesses in your region.

- Industry Experience: Look for suppliers with a proven track record in electric vehicle production.

Step 3: Evaluate Vehicle Features and Technology

Assess the features and technology of the vehicles under consideration. Advanced technology not only enhances performance but also improves safety and efficiency. Pay attention to aspects such as battery technology, charging options, and safety features.

- Battery Technology: Opt for models with high-capacity lithium-ion batteries that offer fast charging capabilities.

- Safety Features: Ensure the vehicle includes essential safety elements like stability control and advanced braking systems.

Step 4: Verify Compliance with Local Regulations

Understanding and verifying compliance with local regulations is essential to avoid legal complications. Different regions may have specific requirements regarding vehicle emissions, safety standards, and operational guidelines.

- Emissions Standards: Confirm that the electric vehicles meet the environmental regulations of your country.

- Safety Regulations: Check for compliance with local safety standards to ensure the vehicle is roadworthy.

Step 5: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that include pricing, warranties, and delivery terms. This transparency will help you make informed comparisons and negotiate better deals.

- Pricing Structure: Look for clarity on all costs, including shipping, taxes, and potential tariffs.

- Warranty Terms: Evaluate warranty coverage for both the vehicle and its components, especially the battery.

Step 6: Arrange for Test Drives and Demonstrations

Before finalizing your decision, arrange for test drives or demonstrations of the vehicles. Experiencing the vehicle’s performance firsthand can provide insights into its suitability for your specific needs.

- Performance Evaluation: Assess how the vehicle handles under load and in various driving conditions.

- Comfort and Usability: Ensure that the vehicle meets the ergonomic needs of your drivers for long-term usage.

Step 7: Finalize Contract and Terms of Service

After selecting your preferred supplier and vehicle, finalize the contract details. Ensure that all terms of service, including maintenance support and service agreements, are clearly outlined.

- Service Agreements: Confirm the availability of local service centers and maintenance schedules.

- Payment Terms: Negotiate favorable payment terms to manage cash flow effectively.

Following this checklist will empower you to make strategic, informed decisions when sourcing electric cargo four-wheel vehicles, ultimately enhancing your operational capabilities and contributing to sustainable business practices.

Comprehensive Cost and Pricing Analysis for electric cargo 4 wheel Sourcing

What Are the Key Cost Components in Sourcing Electric Cargo 4 Wheel Vehicles?

When sourcing electric cargo four-wheel vehicles, understanding the cost structure is crucial for B2B buyers aiming for profitability. Key components that contribute to the overall cost include:

-

Materials: The primary materials used in electric cargo vehicles include high-quality steel for the frame, lithium-ion batteries, electric motors, and various electronic components. The choice of materials significantly impacts the durability and performance of the vehicle, which, in turn, affects pricing.

-

Labor: Labor costs vary by region and are influenced by local wage standards, skill levels, and production efficiency. Countries with lower labor costs may offer competitive pricing, but it’s essential to assess the skills of the workforce to ensure quality production.

-

Manufacturing Overhead: This includes costs associated with the manufacturing facility, utilities, equipment maintenance, and administrative expenses. Efficient manufacturing processes can help reduce these overheads, which is often reflected in the final pricing.

-

Tooling: Tooling costs can be substantial, especially for custom designs or modifications. Buyers looking for specific features should be aware that unique tooling requirements may lead to increased costs.

-

Quality Control (QC): Robust quality control processes are vital to ensure the reliability and safety of electric cargo vehicles. Costs associated with testing and compliance certifications should be factored into the overall pricing.

-

Logistics: Transportation costs from the manufacturing facility to the buyer’s location can vary significantly based on distance, mode of transport, and shipping terms. Buyers must consider these logistics costs as part of their total expenditure.

-

Margin: Suppliers will typically add a profit margin to cover their costs and risks. Understanding the market dynamics can help buyers negotiate better margins.

How Do Price Influencers Impact Electric Cargo Vehicle Sourcing?

Several factors can influence the pricing of electric cargo vehicles, which buyers should consider:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly impact pricing. Larger orders often lead to volume discounts, making it more economical for businesses with substantial needs.

-

Specifications and Customization: Customized vehicles tailored to specific operational requirements will incur additional costs. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: The choice of materials and adherence to quality certifications can affect pricing. Vehicles that meet higher safety and performance standards may cost more but can provide better long-term value.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge a premium, but they often provide better after-sales support and warranty services.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is essential, as they define the responsibilities of buyers and sellers in the shipping process. Incoterms can influence overall cost due to variations in shipping responsibilities and liabilities.

What Buyer Tips Can Enhance Cost-Efficiency in Electric Cargo Vehicle Procurement?

To optimize cost-efficiency when sourcing electric cargo four-wheel vehicles, consider the following strategies:

-

Negotiate Effectively: Engage in open discussions with suppliers about pricing and terms. Leverage your purchasing power, especially if you are placing large orders, to negotiate better deals.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, assess the total cost of ownership, which includes maintenance, energy consumption, insurance, and potential resale value. A vehicle with a higher upfront cost may be more economical over its lifespan.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing structures influenced by local regulations, import tariffs, and market demand. Conduct thorough research to identify the most cost-effective sourcing options tailored to your region.

-

Request Indicative Prices: Always request indicative prices from multiple suppliers to gauge market rates. This practice helps in benchmarking and ensures you are not overpaying.

In summary, a comprehensive understanding of the cost structure, price influencers, and effective negotiation strategies is essential for international B2B buyers when sourcing electric cargo four-wheel vehicles. Adopting these insights can lead to more informed purchasing decisions, ultimately enhancing profitability and operational efficiency.

Alternatives Analysis: Comparing electric cargo 4 wheel With Other Solutions

Understanding Alternatives to Electric Cargo 4 Wheel Solutions

In the growing landscape of logistics and transportation, businesses are increasingly exploring various solutions to meet their cargo needs. Among these, electric cargo 4 wheel vehicles have emerged as a popular choice due to their efficiency and eco-friendliness. However, it is essential to evaluate alternative options to determine the best fit for your specific operational requirements. This analysis compares electric cargo 4 wheel vehicles with two viable alternatives: traditional gasoline-powered cargo vehicles and electric cargo bikes.

Comparison Table

| Comparison Aspect | Electric Cargo 4 Wheel | Traditional Gasoline-Powered Cargo Vehicle | Electric Cargo Bike |

|---|---|---|---|

| Performance | High payload capacity (up to 765 kg), smooth driving experience | Good performance, but less efficient in urban settings | Moderate payload capacity; ideal for short distances |

| Cost | Higher initial investment, lower operational costs (fuel savings) | Lower upfront cost, high ongoing fuel and maintenance costs | Lower initial cost; minimal operational costs |

| Ease of Implementation | Requires charging infrastructure; quick charging available | Widely available; no specialized infrastructure needed | Easy to implement; minimal space required for storage |

| Maintenance | Lower maintenance due to fewer moving parts | Higher maintenance costs and more frequent servicing needed | Low maintenance; simple mechanical components |

| Best Use Case | Urban logistics, last-mile delivery, eco-conscious businesses | Long-distance hauls, traditional logistics | Short-distance deliveries, urban commuting |

Detailed Breakdown of Alternatives

Traditional Gasoline-Powered Cargo Vehicle

Traditional cargo vehicles offer a familiar solution with a wide range of models available, making them suitable for various business needs. They are generally less expensive upfront compared to electric alternatives. However, their operational costs can be high due to fuel expenses and maintenance. Furthermore, they contribute to environmental pollution, which is increasingly becoming a concern for businesses aiming to adopt sustainable practices. For businesses that require long-distance travel or operate in areas lacking charging infrastructure, gasoline-powered vehicles may still be a practical choice.

Electric Cargo Bike

Electric cargo bikes present an innovative alternative, particularly suited for urban environments. They are designed for short-distance deliveries and offer a compact solution that can easily navigate traffic. The initial investment is relatively low, and operational costs are minimal since they are powered by electricity. However, their cargo capacity is limited compared to electric cargo 4 wheel vehicles, making them less ideal for larger loads. These bikes are perfect for businesses focused on quick, eco-friendly deliveries and can significantly enhance last-mile logistics efficiency in congested areas.

Conclusion: Choosing the Right Solution for Your Business

When selecting the most suitable transportation solution, B2B buyers should carefully consider their specific operational needs, budget constraints, and sustainability goals. Electric cargo 4 wheel vehicles are ideal for businesses focused on efficiency and eco-friendliness, particularly in urban logistics. In contrast, traditional gasoline-powered vehicles may still serve businesses needing long-distance travel without the upfront investment of electric alternatives. Lastly, electric cargo bikes are a cost-effective and environmentally friendly option for short-distance deliveries. By weighing these alternatives against their unique requirements, businesses can make an informed decision that aligns with their operational strategies and values.

Essential Technical Properties and Trade Terminology for electric cargo 4 wheel

What Are the Key Technical Properties of Electric Cargo 4 Wheel Vehicles?

When considering electric cargo 4 wheel vehicles for business, several technical properties are critical for ensuring operational efficiency and cost-effectiveness. Here are some essential specifications that B2B buyers should understand:

-

Battery Capacity (kWh): The battery capacity, measured in kilowatt-hours (kWh), determines how much energy the vehicle can store and subsequently how far it can travel on a single charge. A higher capacity allows for longer ranges, which is vital for businesses needing to cover extensive delivery routes without frequent recharging. For example, a vehicle with a 21.3 kWh battery can provide an operational range of approximately 160 km, enhancing productivity.

-

Payload Capacity (kg): This specification indicates the maximum weight the vehicle can carry, including cargo and passengers. A higher payload capacity is essential for businesses that transport heavy goods, as it reduces the need for multiple trips. For instance, a vehicle with a 765 kg payload capacity can significantly optimize logistics and improve turnaround times.

-

Motor Power (kW): The power of the electric motor, expressed in kilowatts (kW), impacts the vehicle’s acceleration and overall performance. A more powerful motor can handle steeper inclines and heavier loads, making it crucial for businesses operating in varied terrains. For example, a 30 kW motor can deliver robust performance even under full load.

-

Wheelbase (mm): The distance between the front and rear axles affects the vehicle’s stability, handling, and turning radius. A longer wheelbase can enhance stability, especially when carrying heavy loads. Conversely, a shorter wheelbase allows for better maneuverability in tight urban spaces. A wheelbase of 2500 mm is often ideal for balancing stability and agility.

-

Charging Time (hours): Understanding the charging time is critical for planning operational schedules. Fast charging capabilities can reduce downtime significantly. For example, if a vehicle can charge from 0-80% in just over an hour, it allows businesses to maximize vehicle utilization throughout the day.

-

Gradeability (%): This specification refers to the vehicle’s ability to ascend slopes without losing power. A higher gradeability percentage indicates that the vehicle can handle steeper inclines, which is particularly important for businesses operating in hilly regions or areas with varied topography.

What Are Common Trade Terms Used in the Electric Cargo 4 Wheel Industry?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are some commonly used terms:

-

OEM (Original Equipment Manufacturer): This refers to the company that produces the original products or components that are sold to other companies. In the context of electric cargo vehicles, buyers might work directly with OEMs to customize vehicles according to their specific business needs.

-

MOQ (Minimum Order Quantity): This term defines the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, understanding the MOQ is essential for budgeting and inventory planning, especially when considering bulk purchases of electric vehicles.

-

RFQ (Request for Quotation): An RFQ is a formal document that buyers send to suppliers requesting a detailed price quotation for specific products or services. This process is vital for comparing costs and terms across different suppliers of electric cargo vehicles.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers in shipping and logistics. Understanding Incoterms can help businesses manage shipping costs and risks effectively when sourcing electric cargo vehicles from different countries.

-

TCO (Total Cost of Ownership): This term encompasses all costs associated with purchasing and operating a vehicle over its lifespan, including initial purchase price, maintenance, insurance, and fuel or charging costs. B2B buyers should evaluate TCO to make informed decisions about which electric cargo vehicle offers the best long-term value.

-

Fleet Management: This refers to the processes and systems used to manage a company’s vehicle fleet. Effective fleet management can optimize vehicle utilization, reduce operational costs, and improve service delivery, making it a crucial consideration for businesses investing in electric cargo vehicles.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the electric cargo 4 wheel Sector

What Are the Current Market Dynamics and Key Trends in the Electric Cargo 4 Wheel Sector?

The electric cargo four-wheel sector is experiencing robust growth, driven by a combination of environmental concerns, urbanization, and technological advancements. Globally, the demand for electric vehicles (EVs) is being fueled by government incentives, stricter emissions regulations, and the increasing cost of traditional fuels. In regions like Africa, South America, and the Middle East, where urban infrastructure is rapidly evolving, electric cargo vehicles present a sustainable solution for last-mile delivery and logistics challenges. This trend is particularly relevant in countries like Vietnam and Germany, where the push for greener transportation is gaining traction.

Emerging technologies such as advanced battery systems and smart vehicle connectivity are reshaping sourcing strategies for B2B buyers. The shift towards higher battery efficiency and faster charging solutions is paramount, as it directly impacts operational costs and vehicle uptime. Furthermore, the integration of telematics and fleet management systems offers businesses real-time data analytics, enabling better decision-making and optimized logistics. For international B2B buyers, understanding these trends is critical for making informed procurement decisions that align with their operational goals and sustainability objectives.

How Does Sustainability Influence Sourcing Decisions in the Electric Cargo 4 Wheel Market?

Sustainability is a cornerstone of the electric cargo four-wheel sector, influencing both sourcing strategies and market dynamics. As businesses face increasing pressure to reduce their carbon footprint, the adoption of electric vehicles has become a strategic imperative. The environmental impact of traditional internal combustion engine vehicles is prompting companies to seek out electric alternatives that promise zero emissions and reduced energy consumption.

Ethical sourcing is equally important, with a growing emphasis on transparent supply chains and responsible material sourcing. B2B buyers are increasingly prioritizing manufacturers who can demonstrate compliance with environmental regulations and provide certifications for sustainable practices. Utilizing green certifications such as ISO 14001 or LEED can enhance a company’s credibility and appeal to eco-conscious consumers. Moreover, sourcing materials like lithium-ion batteries from suppliers who adhere to ethical mining practices is becoming a non-negotiable requirement for many businesses.

What Is the Brief Evolution of the Electric Cargo 4 Wheel Sector?

The evolution of the electric cargo four-wheel sector can be traced back to the early 2000s when the first wave of electric vehicles began to emerge as a response to rising fuel prices and environmental concerns. Initially, the market was limited to small passenger vehicles, but advancements in battery technology and electric drivetrains have expanded the scope to include commercial applications. The introduction of electric cargo vehicles has particularly transformed logistics and last-mile delivery, enabling businesses to meet sustainability goals without compromising efficiency.

In recent years, the sector has seen a significant increase in investment, with major automotive manufacturers entering the electric commercial vehicle space. This influx of capital has accelerated innovation, leading to improved performance, longer ranges, and lower operational costs. As the market continues to mature, B2B buyers are presented with a plethora of options that cater to diverse operational needs, making electric cargo vehicles a viable and attractive choice for modern businesses.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cargo 4 wheel

-

How do I choose the right electric cargo 4 wheeler for my business needs?

Selecting the right electric cargo vehicle involves assessing your specific operational requirements. Consider factors such as payload capacity, range, battery life, and charging infrastructure. Evaluate the terrain where the vehicle will operate; for instance, a model with a robust motor and good torque is essential for hilly areas. Additionally, analyze your business’s last-mile delivery needs and whether features like fast charging and maneuverability are necessary for urban environments. Lastly, ensure the vehicle complies with local regulations and standards. -

What are the benefits of electric cargo 4 wheelers compared to traditional fuel vehicles?

Electric cargo vehicles offer numerous advantages, including lower operational costs due to reduced fuel consumption and maintenance expenses. They have zero emissions, making them environmentally friendly and compliant with increasingly stringent regulations. Additionally, electric vehicles often provide quieter operation, enhancing customer satisfaction in urban areas. With advancements in battery technology, many electric models now feature impressive ranges, reducing the need for frequent recharging. Overall, these benefits lead to higher efficiency and potentially increased profits for businesses. -

What are the common customization options for electric cargo 4 wheelers?

Many manufacturers offer customization options to tailor electric cargo vehicles to specific business needs. Common modifications include adjusting payload capacity, installing specialized cargo boxes, or adding features like refrigeration units for perishable goods. Businesses can also request branding opportunities, such as custom paint jobs or decals. Additionally, technology upgrades like GPS tracking systems or telematics can be integrated to enhance fleet management capabilities. It’s advisable to discuss customization options with your supplier to ensure your requirements are met effectively. -

What should I consider when vetting suppliers for electric cargo 4 wheelers?

When vetting suppliers, prioritize their experience in the electric vehicle market and their reputation within the industry. Check for certifications and compliance with international quality and safety standards. Request customer testimonials and case studies to gauge their reliability. Additionally, assess their after-sales support and warranty terms, as these can impact long-term satisfaction. Finally, consider their ability to provide spare parts and service, as a robust support network is crucial for minimizing downtime. -

What is the minimum order quantity (MOQ) for electric cargo 4 wheelers?

Minimum order quantities can vary significantly between suppliers and depend on the model and customization options. Some manufacturers may offer competitive pricing for bulk orders, while others might have a lower MOQ for new buyers to encourage trial. It’s essential to communicate your needs and negotiate terms that align with your business strategy. Additionally, consider the logistics of shipping and potential tariffs, as these can affect your overall costs and delivery timelines. -

What payment terms are typically available for purchasing electric cargo vehicles?

Payment terms for electric cargo vehicles can range from upfront payments to flexible financing options. Many suppliers offer installment plans or leasing arrangements to ease the financial burden on businesses. It’s common for manufacturers to require a deposit upon order confirmation, with the balance due upon delivery. Be sure to clarify all terms and conditions, including any penalties for late payments or conditions for refunds. Understanding these terms upfront can help avoid future financial complications. -

How do I ensure quality assurance (QA) when sourcing electric cargo 4 wheelers?

To ensure quality assurance, request detailed specifications and certifications for the electric vehicles from your supplier. Conduct site visits to the manufacturing facility if possible, or ask for video inspections. It’s also beneficial to obtain samples or conduct test drives to evaluate performance before finalizing your order. Establishing clear quality expectations in your contract and outlining penalties for non-compliance can also protect your interests. Additionally, consider third-party inspections to validate the vehicle’s quality before delivery. -

What logistics considerations should I keep in mind when importing electric cargo vehicles?

When importing electric cargo vehicles, consider shipping methods, customs clearance, and local regulations. Evaluate whether you need specialized transport for larger vehicles and account for potential tariffs and taxes. Partnering with a logistics provider experienced in vehicle imports can streamline the process and help navigate regulatory challenges. Additionally, ensure that you have the necessary documentation, such as import permits and compliance certificates, to avoid delays. Finally, plan for potential delays in shipping to ensure your operations remain uninterrupted.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Electric Cargo 4 Wheel Manufacturers & Suppliers List

1. Mahindra – ZEO Electric Mini Truck

Domain: mahindralastmilemobility.com

Registered: 2022 (3 years)

Introduction: Product Name: Mahindra ZEO

Type: Electric Mini Truck

Seating Capacity: Driver + 1

Battery Capacity: 21.3 kWh

Battery Type: IP67-rated Lithium-ion

Real World Range: 160 km on a single charge

Charging: Fast charging option for 100 km range in 60 minutes

Motor: 30 kW PMS motor

Peak Torque: 114 Nm

Top Speed: 60 km/h

Payload Capacity: 765 kg

Cargo Box Size: 7.4 feet

Wheelbase: 2500 mm

Turning Radius: 4…

2. Sixthreezero – ANYterrain Stabilized 4-Wheel Electric Bike

Domain: sixthreezero.com

Registered: 2005 (20 years)

Introduction: ANYterrain Stabilized 4-Wheel Electric Bike

– Type: 4-Wheel Electric Bike

– Motor: 750 watt rear mounted motor

– Battery: 20ah Lithium with Samsung Cells

– Speed: Up to 20 mph

– Range: Up to 50 miles on a single charge (varies by rider weight, usage, and terrain)

– Weight: 120 lbs

– Brakes: Hydraulic disc brakes (front and rear)

– Tires: 4″ wide tires; Front: 16″ diameter, Rear: 20″ diameter

– Fea…

3. Dynamic Drives Giessen – INTELECTRA e-Cargo Bike

Domain: dynamic-drives-giessen.com

Registered: 2021 (4 years)

Introduction: {“product_name”: “INTELECTRA e-Cargo Bike”, “manufacturer”: “Dynamic Drives Giessen GmbH”, “drive_system”: “iSHS (chainless serial hybrid drive system)”, “payload_capacity”: “up to 400 kg”, “design”: “Modular, robust, low-maintenance, emission-free”, “applications”: “Urban logistics, trades, fleet services, family transport”, “suspension”: “Adjustable suspension performance for load application”, …

4. Vok Bikes – Cargo Solutions

Domain: vokbikes.com

Registered: 2020 (5 years)

Introduction: This company, Vok Bikes – Cargo Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

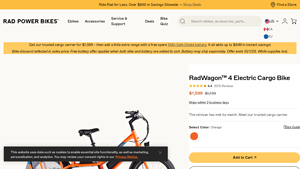

5. Rad Power Bikes – RadWagon 4 Electric Cargo Bike

Domain: radpowerbikes.com

Registered: 2015 (10 years)

Introduction: {“name”:”RadWagon 4 Electric Cargo Bike”,”price”:”$1,599″,”original_price”:”$1,799″,”savings”:”$649 in instant savings”,”top_speed”:”20 mph”,”range”:”45+ miles”,”power”:”750W”,”payload_capacity”:”350 lb”,”warranty”:”2-year warranty”,”rider_height”:”5’2″ – 6’4″”,”frame_size”:”Regular”,”inseam_length”:”24″ – 36″”,”shipping”:”Free shipping*”,”return_policy”:”30 days return”,”test_ride”:”Available at …

6. Reddit – Electric Cargo Bikes

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Four-wheeled electric cargo bikes designed to potentially replace delivery vans in NYC.

Strategic Sourcing Conclusion and Outlook for electric cargo 4 wheel

In the rapidly evolving landscape of electric cargo vehicles, strategic sourcing has become essential for international B2B buyers aiming to enhance operational efficiency and sustainability. The Mahindra Zeo exemplifies how electric mini trucks can significantly reduce operational costs while offering impressive payload capacities and advanced safety features. These vehicles are designed for the rigors of last-mile delivery, providing businesses with an environmentally friendly alternative that contributes to lower carbon footprints.

For companies in Africa, South America, the Middle East, and Europe, the integration of electric cargo solutions not only aligns with global sustainability goals but also positions them as leaders in innovation. As the demand for efficient logistics solutions grows, investing in electric cargo vehicles will be a crucial step towards maintaining competitive advantages in diverse markets.

Looking ahead, the electric cargo vehicle sector is set to expand, driven by technological advancements and increased regulatory support for green transport solutions. Now is the time for international buyers to engage with reputable manufacturers and explore the benefits of electric cargo vehicles, ensuring their businesses are well-prepared for the future of logistics. Embrace this opportunity to elevate your operational strategy and make a positive impact on the environment.