Introduction: Navigating the Global Market for electric cargo

The growing demand for sustainable and efficient transportation solutions has positioned electric cargo as a pivotal player in the global market. International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, face the challenge of sourcing reliable electric cargo options that meet their operational needs while promoting environmental responsibility. This guide aims to illuminate the intricate landscape of electric cargo, providing insights into various types of electric cargo solutions, their diverse applications, and the factors influencing cost and supplier selection.

In this comprehensive resource, we delve into the specifications of electric cargo bikes and tricycles, highlighting their unique features, performance capabilities, and customization options. Buyers will gain essential knowledge on how to vet suppliers effectively, ensuring they align with their business values and quality standards. Additionally, we will cover cost considerations, helping businesses understand pricing structures and potential return on investment.

By equipping international B2B buyers with actionable insights and strategic guidance, this guide empowers them to make informed purchasing decisions that enhance operational efficiency and sustainability. With a focus on reliability, performance, and environmental impact, navigating the global market for electric cargo becomes a strategic advantage for businesses aiming to thrive in an increasingly eco-conscious world.

Understanding electric cargo Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cargo eBikes | Integrated rear rack, powerful motors, dual-battery options | Delivery services, urban logistics | Pros: Eco-friendly, cost-effective, customizable. Cons: Limited range compared to larger vehicles. |

| Tricycle Cargo Bikes | Three-wheel design, high stability, spacious cargo area | Family transport, event logistics | Pros: Safe for passengers, large cargo capacity. Cons: Bulkier, may require more storage space. |

| Foldable Electric Cargo Bikes | Compact design, easy storage, versatile cargo options | Small business deliveries, urban commuting | Pros: Space-saving, portable, lightweight. Cons: Limited load capacity compared to standard cargo bikes. |

| Long-Range Cargo eBikes | Extended battery life, dual-battery systems | Long-distance deliveries, remote areas | Pros: Greater range, reliable for longer routes. Cons: Higher initial investment, heavier. |

| Utility Electric Trikes | Enhanced stability, comfortable seating, multi-functional | Transporting goods, personal use | Pros: Comfortable for passengers, versatile use cases. Cons: May not be as fast as two-wheeled options. |

What are the Key Characteristics of Cargo eBikes for B2B Buyers?

Cargo eBikes are designed for efficiency in transporting goods and people. With features like an integrated rear rack and powerful motors, they are particularly suited for urban delivery services and logistics. Their ability to carry heavy loads while being eco-friendly makes them an attractive option for businesses looking to reduce their carbon footprint. Buyers should consider battery capacity and motor power, as these factors greatly influence performance and range.

How Do Tricycle Cargo Bikes Enhance Safety and Comfort?

Tricycle cargo bikes offer a stable platform for transporting larger loads or passengers, making them ideal for family transport or events. Their spacious cargo areas and safety features, such as seatbelts, ensure that valuable cargo, including children or pets, can be transported securely. B2B buyers should assess the bike’s weight capacity and overall dimensions to ensure it meets their specific needs for comfort and safety.

Why Choose Foldable Electric Cargo Bikes for Urban Deliveries?

Foldable electric cargo bikes are perfect for businesses operating in congested urban environments. Their compact design allows for easy storage when not in use, making them a viable option for small business deliveries. However, potential buyers should be aware of their limited load capacity compared to traditional cargo bikes. Evaluating the balance between portability and load requirements is crucial for B2B buyers.

What Advantages Do Long-Range Cargo eBikes Offer for Extended Deliveries?

Long-range cargo eBikes equipped with dual-battery systems provide extended operational range, making them suitable for long-distance deliveries or routes in remote areas. This feature is particularly beneficial for businesses that require reliability over varying distances. Buyers should consider the trade-off between initial investment and the potential for increased operational efficiency.

How Do Utility Electric Trikes Meet Diverse Transportation Needs?

Utility electric trikes combine comfort and functionality, making them suitable for transporting goods and passengers alike. Their design provides enhanced stability, which can be a significant advantage in bustling environments. B2B buyers should evaluate the specific use cases for which they intend to deploy these trikes, considering factors like seating capacity and cargo space to ensure they align with operational demands.

Key Industrial Applications of electric cargo

| Industry/Sector | Specific Application of Electric Cargo | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics & Delivery | Last-Mile Delivery Solutions | Reduced transportation costs and improved delivery efficiency | Battery capacity, load capacity, and range of the e-bike |

| Retail | Grocery and Goods Transportation | Increased customer satisfaction and reduced carbon footprint | Customization options for cargo space and accessories |

| Tourism & Recreation | Family-Friendly Transport for Tours and Activities | Enhanced customer experience and diversified service offerings | Safety features, stability, and passenger capacity |

| Food & Beverage | Mobile Food Delivery and Catering | Flexibility in service delivery and reduced operational costs | Durability, weather resistance, and ease of maneuverability |

| Healthcare | Patient Transport and Medical Supply Delivery | Improved service delivery and patient satisfaction | Reliability, battery life, and ease of use for staff |

How is Electric Cargo Transforming Logistics and Delivery Services?

In the logistics and delivery sector, electric cargo bikes are revolutionizing last-mile delivery solutions. With the ability to navigate congested urban areas and deliver goods efficiently, these vehicles significantly reduce transportation costs while enhancing delivery speed. They are particularly beneficial in regions with high traffic or limited access, making them ideal for both urban centers in Europe and developing cities in Africa. Buyers should consider battery capacity and load limits to meet their delivery demands.

How Can Retailers Benefit from Electric Cargo Solutions?

Retailers are increasingly adopting electric cargo bikes for grocery and goods transportation, allowing them to deliver products directly to consumers’ doorsteps. This approach not only improves customer satisfaction by providing quick and reliable service but also aligns with sustainability goals by reducing carbon emissions associated with traditional delivery vehicles. When sourcing, businesses should focus on customization options for cargo space to accommodate various product types and sizes.

What Role Do Electric Cargo Bikes Play in Tourism and Recreation?

In the tourism and recreation industry, electric cargo bikes serve as family-friendly transport options for tours and activities. They enable businesses to offer unique experiences, such as guided tours with equipment or family outings, enhancing the overall customer experience. For international buyers, particularly in regions with growing tourism sectors, safety features and passenger capacity are crucial considerations when sourcing these bikes.

How Are Electric Cargo Solutions Enhancing Food and Beverage Services?

Electric cargo bikes are transforming mobile food delivery and catering services by providing flexibility and efficiency. They allow businesses to reach customers in areas where traditional vehicles may struggle, thus reducing operational costs. Buyers in the food and beverage sector should prioritize durability and weather resistance in their sourcing to ensure reliable service under various conditions.

What Advantages Do Electric Cargo Bikes Offer in Healthcare?

In healthcare, electric cargo bikes are increasingly used for patient transport and medical supply delivery. They improve service delivery by enabling quick access to medical supplies and facilitating patient transport in urban settings. For healthcare providers, reliability and battery life are essential factors when considering electric cargo solutions, ensuring that they can maintain high standards of care.

3 Common User Pain Points for ‘electric cargo’ & Their Solutions

Scenario 1: Managing Diverse Cargo Needs Efficiently

The Problem:

B2B buyers often face challenges in managing a variety of cargo types, from heavy goods to fragile items, especially in urban environments. Businesses in sectors like logistics, retail, and food delivery may require electric cargo solutions that can adapt to fluctuating demands. A single vehicle that cannot handle multiple types of cargo can lead to inefficiencies, increased costs, and logistical nightmares, particularly when trying to meet tight delivery schedules or customer expectations.

The Solution:

To address this issue, buyers should look for electric cargo solutions that offer modularity and customization. When sourcing electric cargo bikes or vehicles, prioritize models that allow for interchangeable cargo areas or customizable racks. For example, opting for a cargo bike that features a versatile cargo area—capable of accommodating different types of containers or crates—can significantly enhance operational flexibility.

Additionally, consider investing in electric cargo solutions with integrated technology, such as tracking systems that help manage deliveries in real-time. This allows businesses to optimize routes based on the specific cargo type and volume, ensuring timely and efficient deliveries. Conducting thorough market research and engaging with suppliers who offer customizable solutions can lead to improved operational efficiency.

Scenario 2: Overcoming Range Anxiety for Long-Distance Deliveries

The Problem:

Another common pain point for B2B buyers is range anxiety—concerns about the ability of electric cargo vehicles to cover the necessary distance without running out of battery. This is particularly pressing for businesses that operate in regions where charging infrastructure is limited or unreliable. Relying on electric cargo solutions that lack adequate range can hinder service delivery and diminish customer trust.

The Solution:

To combat range anxiety, B2B buyers should focus on sourcing electric cargo solutions with extended battery capabilities and dual-battery options. When evaluating electric cargo bikes, look for models that provide a range exceeding 40 miles per charge, which can accommodate most urban delivery routes without requiring frequent recharging.

Moreover, establishing partnerships with local charging stations can enhance battery management and ensure that vehicles are always ready for use. Implementing a proactive maintenance schedule to monitor battery health and performance will also prevent unexpected downtime. Educating staff on efficient driving techniques can further extend the range of electric cargo vehicles, optimizing their use for long-distance deliveries.

Scenario 3: Ensuring Safety and Compliance for Transporting Goods

The Problem:

Safety and regulatory compliance are paramount for businesses that transport goods, especially when carrying hazardous materials or bulky cargo. B2B buyers often struggle with ensuring that their electric cargo solutions meet local regulations and safety standards, which can vary significantly across regions. Non-compliance can lead to fines, legal issues, and damaged reputations.

The Solution:

To navigate safety and compliance challenges, B2B buyers should prioritize sourcing electric cargo vehicles that come equipped with safety features such as reinforced frames, stability controls, and effective braking systems. When selecting vehicles, it’s essential to consult with manufacturers about compliance with local regulations regarding cargo transport.

Furthermore, developing an internal compliance checklist that aligns with local laws can serve as a practical tool for ensuring that all electric cargo solutions are used safely and legally. Training employees on safety protocols and the proper handling of goods can minimize risks and enhance operational efficiency. Regular audits of safety practices and equipment can help identify areas for improvement, ensuring ongoing compliance and safety in operations.

Strategic Material Selection Guide for electric cargo

What Are the Key Materials Used in Electric Cargo Bikes?

When selecting materials for electric cargo bikes, it’s essential to consider their performance properties, durability, and suitability for specific applications. Below, we analyze four common materials used in the construction of electric cargo bikes, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

Aluminum: A Lightweight Champion

Key Properties: Aluminum is known for its excellent strength-to-weight ratio, corrosion resistance, and good thermal conductivity. It can withstand a range of temperatures, making it suitable for various climates.

Pros & Cons: The lightweight nature of aluminum contributes to better energy efficiency, allowing for longer ranges on electric cargo bikes. However, it can be more expensive than steel and may require specialized manufacturing processes, which could complicate production.

Impact on Application: Aluminum’s corrosion resistance makes it ideal for regions with high humidity or salt exposure, such as coastal areas in Africa or South America.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM for material specifications. In markets like Europe and Germany, where sustainability is a priority, aluminum’s recyclability is a significant advantage.

Steel: The Traditional Workhorse

Key Properties: Steel is renowned for its high tensile strength and durability. It can withstand significant stress and is less prone to deformation under heavy loads.

Pros & Cons: While steel is generally more affordable than aluminum, it is heavier, which can affect the bike’s overall efficiency and range. Steel also has a higher susceptibility to rust, requiring protective coatings or treatments.

Impact on Application: Steel is suitable for heavy-duty cargo applications, particularly in urban environments where durability is crucial.

Considerations for International Buyers: Buyers in regions with high temperatures, such as the Middle East, should consider corrosion-resistant treatments to prolong the lifespan of steel components. Compliance with local manufacturing standards is also vital.

Carbon Fiber: The Premium Option

Key Properties: Carbon fiber boasts an exceptional strength-to-weight ratio and is highly resistant to corrosion and fatigue. It performs well in varying temperatures, making it suitable for diverse environments.

Pros & Cons: The primary advantage of carbon fiber is its lightweight nature, which enhances performance and efficiency. However, it is significantly more expensive and requires specialized manufacturing techniques, which may not be feasible for all manufacturers.

Impact on Application: Carbon fiber is ideal for high-performance electric cargo bikes aimed at premium markets, where weight and efficiency are critical.

Considerations for International Buyers: Buyers should be aware of the higher costs associated with carbon fiber and ensure that suppliers can meet quality standards such as ISO certifications. Markets in Europe may be more receptive to carbon fiber due to its performance benefits.

Plastic Composites: The Versatile Alternative

Key Properties: Plastic composites are lightweight, resistant to corrosion, and can be molded into complex shapes. They perform well under a range of conditions, including exposure to chemicals and moisture.

Pros & Cons: The flexibility in design and lower manufacturing costs make plastic composites attractive. However, they may not offer the same strength as metals, which can limit their use in load-bearing applications.

Impact on Application: Plastic composites are suitable for non-structural components, such as body panels or storage compartments, where weight reduction is essential.

Considerations for International Buyers: Buyers should verify compliance with safety standards, especially in regions with strict regulations. In markets like Africa and South America, the cost-effectiveness of plastic composites can be a significant selling point.

Summary Table of Material Selection for Electric Cargo Bikes

| Material | Typical Use Case for Electric Cargo | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame and structural components | Lightweight and corrosion-resistant | Higher cost and complex manufacturing | Medium |

| Steel | Heavy-duty frames and cargo racks | High strength and durability | Heavier and prone to rust | Low |

| Carbon Fiber | High-performance electric cargo bikes | Exceptional strength-to-weight ratio | Very expensive and specialized mfg | High |

| Plastic Composites | Non-structural components | Lightweight and versatile | Lower strength compared to metals | Low |

This strategic material selection guide provides insights that can help international B2B buyers make informed decisions when sourcing materials for electric cargo bikes, ensuring compatibility with local standards and market preferences.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cargo

What Are the Main Stages of Manufacturing Electric Cargo Bikes?

The manufacturing process for electric cargo bikes involves several critical stages that ensure the product’s quality, durability, and functionality.

Material Preparation

The first step is material preparation, where raw materials such as aluminum, steel, and composite plastics are sourced. Aluminum is often preferred for its lightweight and corrosion-resistant properties, while steel provides strength for the frame. During this stage, suppliers must ensure that the materials meet industry standards for quality and sustainability. For instance, sourcing from manufacturers who comply with ISO 14001 for environmental management can be advantageous.

Forming and Shaping Components

Once materials are prepared, the next stage is forming and shaping the components. This includes processes like cutting, welding, and bending to create the bike frame, cargo area, and other structural parts. Advanced techniques such as CNC machining and robotic welding are commonly employed to enhance precision and reduce human error. The use of computer-aided design (CAD) software in this phase allows for intricate designs that optimize load distribution and enhance safety.

Assembly of Electric Cargo Bikes

The assembly phase involves putting together the formed components, which can include the frame, wheels, electrical systems, and cargo area. This stage is crucial as it directly impacts the performance of the final product. Assembly lines are often organized to streamline the process, with dedicated teams responsible for specific subassemblies. This modular approach can enhance efficiency and allow for easier troubleshooting.

Finishing Touches and Quality Checks

The final stage involves finishing processes such as painting, coating, and adding protective elements to the bike. This not only improves aesthetics but also enhances durability against environmental factors. Quality assurance checks are integrated into this stage to ensure that each unit meets the set specifications.

What Quality Control Measures Are Essential for Electric Cargo Bikes?

Quality control (QC) is critical throughout the manufacturing process to ensure that electric cargo bikes meet international standards and customer expectations.

What International Standards Apply to Electric Cargo Bike Manufacturing?

International standards such as ISO 9001, which focuses on quality management systems, are essential for manufacturers aiming for global competitiveness. Compliance with ISO 9001 signifies that a company has implemented processes to ensure consistent quality. Additionally, certifications like CE mark (Conformité Européenne) indicate compliance with European safety standards, which is particularly important for B2B buyers in Europe.

What Are the Key QC Checkpoints in the Manufacturing Process?

The QC process typically involves several checkpoints:

- Incoming Quality Control (IQC): This initial checkpoint ensures that raw materials meet specified standards before they enter the production line.

- In-Process Quality Control (IPQC): Conducted during the manufacturing process, IPQC checks are crucial for identifying defects early on. This can include inspections of weld quality, electrical connections, and overall assembly integrity.

- Final Quality Control (FQC): This is the last checkpoint before products are shipped. FQC includes rigorous testing of performance, safety, and durability, ensuring that each bike operates effectively under various conditions.

Which Testing Methods Are Commonly Used in Electric Cargo Bike Manufacturing?

Common testing methods include:

- Load Testing: Ensures that the cargo bike can handle its advertised weight capacity without compromising structural integrity.

- Electrical Testing: Verifies the functionality and safety of the electrical components, including battery performance, motor efficiency, and wiring integrity.

- Durability Testing: Simulates various riding conditions to assess the bike’s performance over time, including vibration tests and weather resistance assessments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to ensure that their suppliers maintain stringent quality control standards. Here are several methods to verify supplier QC:

What Audit Processes Should Be Implemented?

Conducting regular audits of suppliers can provide insight into their manufacturing practices and quality management systems. Audits can be either announced or unannounced, and they should focus on assessing compliance with relevant standards like ISO 9001 and CE marking. Buyers should consider employing third-party auditors to ensure objectivity.

What Kind of QC Reports Should Be Requested?

Suppliers should provide detailed QC reports that outline their testing procedures and results. These reports can include data on IQC, IPQC, and FQC, along with documentation of any corrective actions taken in response to identified defects. Buyers should review these reports carefully to understand the supplier’s commitment to quality.

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can further enhance buyer confidence. These services can conduct independent evaluations of the manufacturing process and final products, ensuring adherence to international standards. Buyers should look for inspection companies that are recognized globally and have experience in the electric cargo bike sector.

What Nuances Should International B2B Buyers Consider?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several nuances can impact the procurement process:

How Do Import Regulations Affect Quality Assurance?

Different countries have varying import regulations that may impact the quality assurance process. For instance, buyers in Europe may face stricter compliance requirements related to safety and environmental impact. Understanding local regulations is crucial for ensuring that imported cargo bikes meet all necessary standards.

What Should Be Considered Regarding Supply Chain Transparency?

Supply chain transparency is vital for ensuring quality and sustainability. Buyers should inquire about the supply chain practices of their suppliers, including sourcing and manufacturing locations. A transparent supply chain can reduce the risk of quality issues and improve accountability.

How Can Cultural Differences Impact Quality Expectations?

Cultural differences can also play a role in quality expectations. Buyers should be aware of how different regions prioritize quality and the associated standards. Open communication with suppliers about quality expectations and standards can help bridge any gaps and foster a better partnership.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing electric cargo bikes, ensuring they receive products that meet their needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cargo’

Introduction

This guide serves as a comprehensive checklist for B2B buyers looking to procure electric cargo solutions, specifically electric cargo bikes. With the growing demand for sustainable transportation, it’s essential to approach sourcing with a strategic mindset. By following these steps, you can ensure that you make informed decisions that align with your operational needs and sustainability goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that the electric cargo bike meets your operational requirements. Consider factors such as load capacity, range, and battery life.

– Load Capacity: Assess how much weight you need to transport to select a model that can handle your heaviest loads.

– Range: Determine the distance you need the bike to cover on a single charge to avoid interruptions during operations.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in electric cargo solutions. This knowledge helps you identify models that offer advanced features and competitive pricing.

– Battery Technology: Look for innovations in battery technology that enhance performance and longevity.

– Motor Efficiency: Evaluate the power and efficiency of different motors, as this will impact the bike’s performance, especially under heavy loads.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from buyers in similar industries or regions.

– Supplier Reputation: Check online reviews and testimonials to gauge the supplier’s reliability and customer service.

– Product Portfolio: Ensure the supplier has a diverse range of models that can cater to your specific needs.

Step 4: Verify Certifications and Compliance

Ensure that the electric cargo bikes meet relevant local and international standards. Compliance with safety regulations is crucial for operational legality and safety.

– Certification Types: Look for certifications such as ISO, CE, or UL, which can signify quality and safety.

– Warranty and Support: Check the warranty terms and what post-purchase support the supplier offers to mitigate risks.

Step 5: Request Prototypes or Demonstrations

Before finalizing your purchase, request prototypes or arrange for demonstrations. This hands-on experience can provide insights into the bike’s performance and usability.

– Test Performance: Evaluate the bike’s handling, stability, and ease of use, especially when loaded.

– User Feedback: Gather feedback from potential users within your organization to ensure the bike meets their operational needs.

Step 6: Assess Total Cost of Ownership

Consider all associated costs beyond the initial purchase price, such as maintenance, insurance, and operational costs.

– Maintenance Costs: Analyze the long-term maintenance requirements and costs for parts and service.

– Energy Costs: Calculate the expected energy costs for charging to understand the bike’s overall efficiency.

Step 7: Finalize Purchase and Negotiate Terms

Once you’ve completed your evaluations, finalize your purchase and negotiate favorable terms. Ensure you understand payment terms, delivery schedules, and after-sales support.

– Contract Clarity: Review contracts carefully to avoid any hidden costs or unclear terms.

– Delivery Timeline: Confirm the expected delivery date to align with your operational schedule.

By following this checklist, you can confidently navigate the procurement of electric cargo solutions that best fit your business needs, ensuring a sustainable and efficient transportation strategy.

Comprehensive Cost and Pricing Analysis for electric cargo Sourcing

What Are the Key Cost Components in Electric Cargo Sourcing?

When sourcing electric cargo solutions, understanding the cost structure is vital for making informed purchasing decisions. The main cost components include:

-

Materials: The choice of materials significantly affects the overall cost. High-quality components, such as durable frames and advanced battery systems, increase the initial investment but can lead to better performance and longevity.

-

Labor: Labor costs vary by region and can impact pricing. In countries with lower labor costs, such as some in Africa and South America, you may find more competitive pricing. However, skilled labor for assembly and quality assurance can raise costs.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Custom tooling for specific designs or adaptations can incur additional expenses. If your project requires unique features, be prepared for higher tooling costs.

-

Quality Control (QC): Investing in stringent QC processes ensures product reliability. However, it adds to the overall cost. Certifications and testing can enhance product value, especially in regions with strict regulations.

-

Logistics: Shipping and handling costs can vary widely based on distance, mode of transport, and shipping partners. Consideration of Incoterms is crucial, as they define the responsibilities of buyers and sellers in the shipping process.

-

Margin: Suppliers will include their profit margins in the pricing structure. Understanding industry standards for margins can help you gauge whether a price is reasonable.

How Do Price Influencers Affect Electric Cargo Costs?

Several factors can influence the pricing of electric cargo products:

-

Volume and Minimum Order Quantity (MOQ): Buying in bulk can lead to significant discounts. Suppliers often have lower prices for larger orders, which can be beneficial for companies looking to scale.

-

Specifications and Customization: Custom features or specifications can increase costs. Ensure that any additional features provide real value to your operations to justify the expense.

-

Materials and Quality Certifications: Higher-quality materials typically command higher prices. Certifications (like ISO or CE) can also affect pricing, as they often require additional testing and compliance efforts.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their brand value and perceived quality.

-

Incoterms: The chosen Incoterms can influence the total cost of ownership. For example, DDP (Delivered Duty Paid) means the supplier covers all shipping and customs fees, which can simplify budgeting for buyers.

What Are Effective Buyer Tips for Negotiating Electric Cargo Prices?

When engaging in negotiations or purchasing electric cargo solutions, consider these strategies:

-

Conduct Thorough Research: Understand market rates and competitor offerings. This knowledge will empower you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not only the upfront costs but also long-term expenses like maintenance, energy consumption, and potential resale value.

-

Leverage Volume Discounts: If you anticipate needing multiple units over time, negotiate for bulk pricing or long-term contracts to lock in favorable rates.

-

Be Clear About Specifications: Clearly define your requirements to avoid unexpected costs. Changes made after the initial agreement can lead to price increases.

-

Consider Regional Variations: Pricing may vary significantly between regions. For instance, suppliers in Europe may have different pricing structures compared to those in Africa or South America due to market dynamics and local regulations.

Conclusion

Navigating the cost and pricing landscape for electric cargo sourcing requires a strategic approach. By understanding the key cost components, price influencers, and employing effective negotiation tactics, B2B buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that indicative prices can fluctuate based on market conditions, so maintaining flexibility and awareness of trends is crucial for successful procurement.

Alternatives Analysis: Comparing electric cargo With Other Solutions

Exploring Alternatives to Electric Cargo Solutions

In the quest for efficient transportation solutions, businesses often consider various alternatives to electric cargo options. Electric cargo vehicles, such as e-bikes and cargo trikes, provide a sustainable means to transport goods and people. However, depending on the operational context, other methods might be more suitable. This section outlines a comparative analysis between electric cargo solutions and two viable alternatives: traditional cargo vans and bicycle trailers.

| Comparison Aspect | Electric Cargo | Traditional Cargo Van | Bicycle Trailer |

|---|---|---|---|

| Performance | Up to 20 mph; ideal for urban settings; quiet operation | Typically faster; suitable for longer distances | Slower; dependent on the bicycle’s speed and terrain |

| Cost | Initial investment $1,200 – $2,500; lower operational costs | Higher upfront costs, generally $25,000+; higher fuel and maintenance costs | Affordable, usually $200 – $800; minimal maintenance |

| Ease of Implementation | Requires charging stations and maintenance of battery systems | Requires fuel, maintenance, and parking spaces | Easy to attach to any bike; minimal setup required |

| Maintenance | Moderate; battery replacements and regular check-ups needed | High; regular servicing and fuel management necessary | Low; basic maintenance of the trailer and bike |

| Best Use Case | Urban deliveries, short distances, eco-friendly transport | Long-distance transport, larger cargo volumes | Local deliveries, light loads, and recreational use |

What Are the Pros and Cons of Electric Cargo Solutions?

Electric cargo options offer a range of benefits, particularly in urban environments. Their performance is optimized for short distances, making them ideal for local deliveries. They are also eco-friendly, which aligns with global sustainability goals. However, the initial investment can be significant, and businesses need to consider the infrastructure for charging and battery maintenance.

How Do Traditional Cargo Vans Compare to Electric Cargo?

Traditional cargo vans are a well-established solution for transporting goods. They excel in speed and capacity, making them suitable for longer distances and larger loads. However, they come with substantial costs—both upfront and ongoing—due to fuel, insurance, and maintenance. Additionally, they contribute to congestion and pollution, which can be a drawback in urban settings. For businesses requiring extensive logistical support, traditional vans may be the preferred choice despite their environmental impact.

What Are the Advantages and Disadvantages of Bicycle Trailers?

Bicycle trailers present an economical alternative for businesses that need to transport lighter loads locally. They are easy to implement and attach to any standard bicycle, making them a flexible option for small-scale deliveries. The cost is significantly lower than both electric cargo solutions and traditional vans. However, their performance is limited by the cyclist’s ability, and they may not be suitable for heavier or bulkier items. This makes them ideal for businesses with limited logistics needs and a focus on sustainability.

How Should B2B Buyers Choose the Right Solution?

When selecting the appropriate transportation solution, B2B buyers should consider several factors, including the scale of operations, budget constraints, and environmental impact. Electric cargo solutions are ideal for businesses prioritizing eco-friendliness and urban deliveries. Traditional cargo vans may be more appropriate for larger companies with extensive transportation needs, while bicycle trailers can serve small businesses looking for cost-effective local delivery options. Ultimately, understanding specific operational requirements will guide buyers in making the best choice for their transportation needs.

Essential Technical Properties and Trade Terminology for electric cargo

What are the Key Technical Properties of Electric Cargo Bikes?

When evaluating electric cargo bikes for B2B procurement, understanding the technical specifications is crucial for making informed decisions. Here are some essential properties to consider:

-

Cargo Capacity

This specification refers to the maximum weight the bike can carry, typically measured in pounds or kilograms. A higher cargo capacity allows for more goods to be transported in a single trip, increasing operational efficiency. For instance, a cargo bike with a capacity of 450 lbs can handle larger loads, making it suitable for businesses that require frequent transportation of heavy items. -

Battery Range

The battery range indicates how far the bike can travel on a single charge, usually measured in miles. For B2B applications, a longer range is advantageous as it reduces the need for frequent recharging, allowing for more extensive delivery routes. Bikes with ranges of 20 to 35 miles are common, making them ideal for urban deliveries. -

Motor Power

This refers to the wattage of the bike’s motor, which directly influences its ability to handle various terrains and loads. A motor power of 350W or higher is typically preferred for cargo bikes, providing the necessary torque to navigate inclines and carry heavy cargo without straining. -

Frame Material

The material used for the bike’s frame affects durability, weight, and cost. Common materials include aluminum and steel, each offering different benefits. Aluminum is lightweight and resistant to rust, while steel is heavier but offers greater strength and stability. Choosing the right material can enhance the bike’s lifespan and performance in commercial applications. -

Pedal Assist Levels

This feature allows riders to select different levels of electric assistance while pedaling. Higher levels of pedal assist can significantly reduce the effort required to transport heavy loads, making the bike accessible to a wider range of users. Understanding this feature can help businesses choose bikes that meet their operational needs and employee capabilities.

What are Common Trade Terms in the Electric Cargo Industry?

Navigating the electric cargo bike market involves familiarity with specific trade terminology that can impact procurement processes. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electric cargo bikes, knowing OEM suppliers can help businesses identify reliable manufacturers that meet quality standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers as it can affect inventory management and cash flow. A higher MOQ may require larger upfront investments, which could be a consideration for smaller businesses. -

RFQ (Request for Quotation)

An RFQ is a standard business process where a buyer requests price quotes from suppliers. Issuing an RFQ can help companies compare pricing and terms among different manufacturers, ensuring they secure the best deal for their electric cargo bike purchases. -

Incoterms (International Commercial Terms)

These are a set of predefined commercial terms published by the International Chamber of Commerce that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is crucial for B2B buyers to understand shipping costs, risks, and responsibilities, especially when sourcing bikes globally. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For businesses, understanding lead times is critical for planning inventory and managing customer expectations. Longer lead times can impact operational efficiency, especially in industries requiring quick turnaround times.

By grasping these technical properties and trade terms, B2B buyers can enhance their understanding of the electric cargo market, enabling more strategic purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the electric cargo Sector

What Are the Key Market Dynamics and Trends Influencing the Electric Cargo Sector?

The electric cargo sector is experiencing rapid growth, propelled by several global drivers including urbanization, sustainability concerns, and advancements in battery technology. As cities become more congested, there is a pressing need for efficient and eco-friendly transportation solutions. Electric cargo bikes and tricycles are emerging as viable alternatives to traditional delivery vehicles, particularly in urban areas across Africa, South America, the Middle East, and Europe. International B2B buyers should note that the demand for electric cargo solutions is not just limited to logistics companies; sectors such as retail, food delivery, and even healthcare are increasingly adopting these innovative vehicles to enhance their operational efficiency.

Emerging B2B technology trends include the integration of IoT (Internet of Things) for fleet management and real-time tracking, which optimizes route planning and reduces delivery times. Additionally, the rise of e-commerce is driving the need for last-mile delivery solutions, where electric cargo bikes can significantly lower costs and environmental impact. Buyers should also be aware of regional variations in the regulatory environment, as some countries are implementing incentives for electric vehicle adoption, which can influence sourcing strategies.

How Is Sustainability Shaping the Sourcing of Electric Cargo Solutions?

Sustainability is a critical factor influencing purchasing decisions in the electric cargo sector. Companies are increasingly prioritizing environmentally friendly products that contribute to reducing carbon footprints. As a result, buyers are looking for electric cargo solutions that not only meet performance standards but also adhere to ethical sourcing practices. This includes utilizing materials that are sustainably sourced, such as recyclable aluminum and biodegradable composites, which are becoming increasingly popular in the manufacturing of electric cargo bikes.

Moreover, certifications such as ISO 14001 for environmental management and the use of ‘green’ materials can serve as indicators of a manufacturer’s commitment to sustainability. International B2B buyers should seek suppliers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly and that production processes are environmentally friendly. This approach not only enhances brand reputation but also aligns with the growing consumer demand for sustainable practices.

What Historical Developments Have Shaped the Electric Cargo Industry?

The evolution of electric cargo solutions can be traced back to the early 20th century when electric vehicles first gained traction. However, it wasn’t until the late 1990s and early 2000s, with significant advancements in battery technology, that electric cargo bikes began to emerge as a viable option for commercial use. The introduction of lithium-ion batteries dramatically improved the range and efficiency of electric vehicles, paving the way for cargo applications.

In recent years, the convergence of urbanization and sustainability has accelerated the adoption of electric cargo solutions across various sectors. As cities seek to combat air pollution and traffic congestion, electric cargo bikes and tricycles are increasingly recognized as essential tools for sustainable urban transport. This historical context is crucial for B2B buyers as it highlights the trajectory of innovation and the ongoing commitment to sustainable practices within the industry.

Conclusion

Navigating the electric cargo sector requires an understanding of current market dynamics, sustainability trends, and historical developments. International B2B buyers are encouraged to leverage these insights to make informed sourcing decisions that not only enhance operational efficiency but also align with global sustainability goals. By prioritizing ethical sourcing and staying abreast of technological advancements, businesses can position themselves competitively in this evolving market.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cargo

-

How do I solve the issue of high transportation costs with electric cargo solutions?

To mitigate high transportation costs, consider investing in electric cargo bikes, which offer lower operating expenses compared to traditional vehicles. They significantly reduce fuel costs, require less maintenance, and can navigate urban environments more efficiently, often bypassing traffic. Additionally, electric cargo bikes can carry substantial loads, making them ideal for local deliveries. Evaluating the total cost of ownership, including purchase price and operational savings, will help you determine the financial benefits of switching to electric cargo solutions. -

What is the best electric cargo bike for urban deliveries?

The best electric cargo bike for urban deliveries combines ample cargo capacity, maneuverability, and battery range. Look for models with a robust build, capable of carrying heavy loads while navigating narrow streets. A dual-battery option is advantageous for extended routes, ensuring deliveries can be made without frequent recharging. Brands like Lectric eBikes and Dirwin offer models designed specifically for urban environments, ensuring efficiency and reliability for your delivery needs. -

How can I ensure quality and safety in electric cargo bikes?

To ensure quality and safety, source electric cargo bikes from reputable manufacturers with established safety certifications. Request detailed product specifications, including load capacity, motor power, and braking systems. It’s also advisable to ask for test reports or certifications from third-party testing agencies. Establishing a quality assurance process with your suppliers can help in maintaining high standards throughout production and delivery. -

What customization options are available for electric cargo bikes?

Customization options for electric cargo bikes often include varying cargo capacities, frame sizes, and additional accessories such as racks, baskets, or weather protection. Suppliers may also offer choices in color and branding to align with your company’s image. Discuss your specific requirements with potential suppliers to ensure the bike meets your operational needs. Customization can enhance functionality and make the bikes more suitable for your target market. -

What are the typical payment terms when sourcing electric cargo bikes internationally?

Payment terms can vary significantly based on the supplier and the size of your order. Common terms include a deposit upfront (usually 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer financing options or extended payment plans for larger orders. It’s essential to negotiate favorable terms that align with your cash flow while ensuring that the supplier is reliable and capable of fulfilling your order. -

How do I vet suppliers for electric cargo bikes in international markets?

Vetting suppliers involves conducting thorough research on their reputation, production capacity, and compliance with international quality standards. Start by reviewing their business credentials, customer testimonials, and case studies. Additionally, consider arranging factory visits or audits, if possible, to assess manufacturing processes firsthand. Utilizing third-party verification services can also provide insights into supplier reliability and product quality. -

What are the logistics considerations when importing electric cargo bikes?

Logistics for importing electric cargo bikes include shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with the specific regulations of your destination country. Understand the documentation required for customs, including invoices and compliance certificates. Additionally, factor in lead times for production and shipping to avoid delays in receiving your products. Planning these logistics thoroughly can help streamline the import process. -

What are the minimum order quantities (MOQs) for electric cargo bikes?

Minimum order quantities (MOQs) for electric cargo bikes can vary widely among suppliers, ranging from as few as 5 to over 100 units. Factors influencing MOQs include the manufacturer’s production capabilities and the level of customization required. When negotiating with suppliers, inquire about their flexibility regarding MOQs, especially if you are a small or new business. Some suppliers may offer lower MOQs for initial orders to establish a partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Electric Cargo Manufacturers & Suppliers List

1. Specialized – Globe Haul ST

Domain: bicycling.com

Registered: 1999 (26 years)

Introduction: Best Overall: Specialized Globe Haul ST – Price: €2,500, Tires: 20 x 3.5 in., Weight: 77 lbs., Cargo Capacity: 419 lbs. Pros: Compact footprint, excellent battery life and power delivery, strong brakes. Cons: Lack of suspension can mean a harsh ride on rough roads, can only carry one child.

Best Value: Aventon Abound – Price: $1,999 (now $1,599), Tires: 20 x 2.4 in., Weight: 81 lbs., Cargo Capaci…

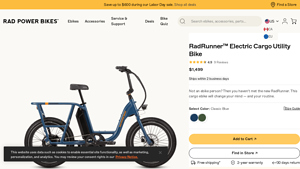

2. Rad Power Bikes – RadRunner™ Electric Cargo Utility Bike

Domain: radpowerbikes.com

Registered: 2015 (10 years)

Introduction: Product Name: RadRunner™ Electric Cargo Utility Bike

Price: $1,499

Top Speed: 20 mph

Range: 55+ miles

Power: 750W

Payload Capacity: 320 lb

Rider Height: 4’11” – 6’2″

Frame Size: Regular

Inseam Length: 26″ – 37″

Shipping: Ships within 2 business days, free shipping available

Warranty: 2-year warranty

Return Policy: 30 days return

Special Offer: Free passenger package ($109 value) with purchase, off…

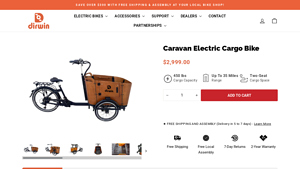

3. Dirwin – Caravan Electric Cargo Bike

Domain: dirwinbike.com

Registered: 2021 (4 years)

Introduction: {“name”:”Caravan Electric Cargo Bike”,”price”:”$2,999.00″,”cargo_capacity”:”450 lbs”,”range”:”Up to 35 Miles”,”features”:[“Two-Seat Cargo Space”,”Finely Crafted Polished Wood”,”Cushioned Seats With Seatbelts”,”20+ Cubic Feet Cargo Container”,”Tricycle Style Extra Stability”,”Water-proof rain cover”,”Durable rear rack”,”Soft floor liner”],”motor_power”:”350W”,”battery”:”16Ah lithium battery”,”pedal…

4. Lectric eBikes – Electric Cargo eBikes

Domain: lectricebikes.com

Registered: 2018 (7 years)

Introduction: Electric Cargo eBikes from Lectric eBikes® include models like XPedition2 and XP4, designed for heavy loads and multiple passengers. Key features include:

– Motor Wattage: 500W nominal, 750W nominal options

– Range: Up to 50 miles to 170 miles

– Payload Capacity: Ranges from 330 lbs to 450 lbs

– Throttle Type: Thumb and Twist options

– Color Options: Black, Blue, Green, Grey, Purple, Red, Whi…

5. Pedego – Cargo Electric Bike

Domain: pedegoelectricbikes.com

Registered: 2009 (16 years)

Introduction: { “name”: “Cargo”, “starting_price”: “$3,495”, “top_speed”: “20 MPH or 28 MPH”, “payload_capacity”: “400 LB”, “range”: “Up to 132 miles with optional range extender battery”, “features”: [ “Sport Utility e-bike”, “Vibrant color LCD display”, “Audible turn signals”, “5 levels of pedal assist”, “Water-resistant storage compartment (11.5 liters)”, “Two kickstand options (single side and center double…

6. Lectric – XPedition 2.0

Domain: electricbikereport.com

Registered: 2010 (15 years)

Introduction: Best Electric Cargo Bikes 2025: 1. Lectric XPedition 2.0 – Price: $1399 (base model), $1699 (mid-tier), $1999 (top-tier); Battery: 624-Wh (base), 2x 624-Wh (mid), 2x 840-Wh (top); Carrying Capacity: 300 lbs on rack, 450 lbs total; Motor: 750W rear hub, 1310W peak output, 85 Nm torque; Features: Torque sensor, color display, adjustable stem, suspension fork, various accessories. 2. Aventon Abound L…

7. Retrospec – Roo Rev XL Cargo Electric Bike

Domain: retrospec.com

Registered: 2000 (25 years)

Introduction: Electric Cargo Bikes are designed for hauling, commuting, and family rides. They combine stability, storage, and pedal-assist power for smooth transport. Key models include the Roo Rev XL Cargo Electric Bike ($1,999.99) and Roo Rev Cargo Electric Bike ($1,899.99), both UL2849 Certified and rated 5.0 out of 5 stars. The Roo Rev supports up to 400 lbs total capacity and is compact for city commuting…

8. Aventon – Cargo Ebike

Domain: aventon.com

Registered: 2012 (13 years)

Introduction: Cargo Ebike: 750w Motor, Up to 50 Mile Range, Class 2 Ebike, 20 MPH Top Speed, TUV Safety Certified (UL 2849), Compact cargo bike with added security features, 4G/GPS Theft Deterrence, Carry a Single Passenger, Price: $1,599 (originally $1,999), New Abound LR Ebike: Carry Up To 2 Passengers, Price: $1,999 (originally $2,399), Multifaceted cargo ebike with endless possibilities, 280 reviews.

Strategic Sourcing Conclusion and Outlook for electric cargo

In the rapidly evolving landscape of electric cargo solutions, strategic sourcing emerges as a pivotal factor for businesses aiming to enhance their operational efficiency and reduce logistics costs. International buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, should prioritize sourcing electric cargo options that align with their unique market demands and regulatory frameworks. The versatility of electric cargo bikes, such as the robust models from Lectric eBikes and Dirwin, offers businesses the ability to transport goods efficiently while minimizing their carbon footprint.

Investing in electric cargo solutions not only reflects a commitment to sustainability but also addresses the growing consumer demand for eco-friendly transportation alternatives. As urban areas become increasingly congested, electric cargo bikes provide an agile and effective means of navigating city landscapes, thus ensuring timely deliveries and enhanced customer satisfaction.

Looking ahead, international buyers are encouraged to explore partnerships with manufacturers and suppliers that emphasize quality, customization, and after-sales support. By leveraging the advantages of strategic sourcing, businesses can position themselves at the forefront of the electric cargo revolution, meeting both operational goals and environmental responsibilities. Embrace this transformative shift in logistics today and drive your business toward a sustainable future.