Introduction: Navigating the Global Market for electric vehicle with eec

In an era where sustainability and efficiency are paramount, sourcing electric vehicles with EEC certification presents a unique challenge for international B2B buyers. As the demand for eco-friendly transportation solutions rises, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the intricacies of the EEC market becomes essential. This guide delves into the diverse types of electric vehicles available, their applications across various industries, and the critical factors to consider when vetting suppliers.

By addressing key aspects such as regulatory compliance, cost analysis, and the evolving landscape of charging infrastructure, this comprehensive resource equips buyers with actionable insights to make informed purchasing decisions. With a focus on empowering businesses in emerging markets and established economies alike, we explore how to navigate the complexities of sourcing EEC electric vehicles effectively.

Ultimately, this guide aims to bridge the gap between innovative technology and practical implementation, ensuring that B2B buyers can confidently invest in sustainable transportation solutions that align with their operational needs and environmental goals. Whether you are looking to revamp your fleet or explore new market opportunities, understanding the EEC electric vehicle landscape is crucial for driving your business forward.

Understanding electric vehicle with eec Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Battery Electric Vehicle (BEV) | Fully electric, zero emissions, long-range capabilities | Urban logistics, fleet management, personal transport | Pros: Low operating costs, environmental benefits. Cons: Initial high purchase price, charging infrastructure needed. |

| Plug-in Hybrid Electric Vehicle (PHEV) | Combines electric and gasoline power, versatile range | Delivery services, mixed-use fleets | Pros: Flexibility of power sources, reduced range anxiety. Cons: More complex maintenance, potential for higher emissions than BEVs. |

| Low-Speed Electric Vehicle (LSEV) | Limited to lower speeds, typically used in urban settings | Campus transport, gated communities, tourism | Pros: Lower cost, easy to maneuver. Cons: Limited range and speed, not suitable for long-distance travel. |

| Electric Utility Vehicle (EUV) | Designed for specific utility tasks, rugged design | Construction sites, agriculture, municipal services | Pros: High durability, specialized features. Cons: Higher upfront costs, may require specialized training for operators. |

| Electric Sightseeing Bus | Large capacity, designed for tourism and urban transport | City tours, public transportation | Pros: Eco-friendly, can carry many passengers. Cons: Requires significant investment, dependent on public infrastructure. |

What Are the Key Characteristics of Battery Electric Vehicles (BEVs)?

Battery Electric Vehicles (BEVs) are fully electric, utilizing rechargeable batteries to power an electric motor. They are known for their zero emissions and can offer extended driving ranges, making them ideal for urban logistics and fleet management. B2B buyers should consider the initial investment, as BEVs can be more expensive upfront. However, they provide significant savings on fuel and maintenance costs over time, especially in markets with supportive charging infrastructure.

How Do Plug-in Hybrid Electric Vehicles (PHEVs) Benefit Businesses?

Plug-in Hybrid Electric Vehicles (PHEVs) combine electric and gasoline power, providing versatility for businesses with varying travel needs. They are particularly suitable for delivery services and mixed-use fleets, as they can operate on electric power for shorter trips while still having the gasoline engine for longer distances. Buyers should weigh the benefits of reduced range anxiety against the complexity of maintenance and the potential for higher emissions compared to fully electric options.

Why Choose Low-Speed Electric Vehicles (LSEVs) for Urban Applications?

Low-Speed Electric Vehicles (LSEVs) are designed for urban environments and are limited to lower speeds, making them ideal for applications such as campus transport or gated communities. They are cost-effective and easy to maneuver, making them appealing for businesses looking to reduce operational costs. However, their limited speed and range may not suit all operational needs, particularly for longer distances.

What Advantages Do Electric Utility Vehicles (EUVs) Offer for Specialized Tasks?

Electric Utility Vehicles (EUVs) are ruggedly designed for specific utility tasks, such as construction and agriculture. Their durability and specialized features make them suitable for demanding work environments. While they may come with a higher upfront cost, the long-term savings on fuel and maintenance can offset this investment. Businesses should also consider the need for operator training due to the unique features of these vehicles.

How Do Electric Sightseeing Buses Enhance Urban Tourism?

Electric Sightseeing Buses are designed to transport large groups of passengers in an eco-friendly manner, making them ideal for city tours and public transportation systems. They contribute to reducing urban pollution and can enhance the overall tourist experience. However, the initial investment is significant, and businesses must consider the reliance on public charging infrastructure to ensure operational efficiency.

Key Industrial Applications of electric vehicle with eec

| Industry/Sector | Specific Application of electric vehicle with eec | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric buses for urban transit | Reduced operational costs and emissions; improved public perception | Compliance with local regulations; availability of charging infrastructure |

| Logistics and Delivery | Electric delivery vans for last-mile logistics | Lower fuel costs; enhanced sustainability; reduced noise pollution | Range capabilities; payload capacity; maintenance support |

| Tourism and Hospitality | Electric sightseeing vehicles for tours | Enhanced guest experience; lower environmental impact | Vehicle customization options; battery life; safety features |

| Agriculture | Electric utility vehicles for farm operations | Reduced operational costs; lower emissions; quieter operation | Terrain adaptability; battery life; service availability |

| Municipal Services | Electric vehicles for waste collection and street cleaning | Lower emissions and noise; operational cost savings | Durability; compatibility with existing fleet; maintenance support |

How Are Electric Vehicles with EEC Transforming Public Transportation?

In the public transportation sector, electric buses equipped with EEC technology are becoming increasingly popular. These vehicles reduce operational costs by minimizing fuel expenses and maintenance needs while significantly lowering emissions. This transition not only enhances the sustainability of urban transit systems but also improves public perception, attracting environmentally conscious riders. For international buyers, key considerations include ensuring compliance with local regulations and the availability of sufficient charging infrastructure to support these electric fleets.

What Role Do Electric Vehicles with EEC Play in Logistics and Delivery?

Electric delivery vans utilizing EEC technology are revolutionizing last-mile logistics. These vehicles provide substantial savings in fuel costs and enhance sustainability efforts, appealing to businesses focused on reducing their carbon footprint. Additionally, they contribute to lower noise pollution, a crucial factor in urban environments. Buyers in regions like Africa and South America should focus on range capabilities and payload capacity to ensure that the vehicles meet their operational needs, alongside reliable maintenance support to maximize uptime.

How Are Electric Vehicles with EEC Enhancing Tourism and Hospitality?

In the tourism and hospitality industries, electric sightseeing vehicles are gaining traction as an eco-friendly transportation option for tours. These vehicles not only enhance the guest experience by providing a quieter and more pleasant ride but also contribute to a lower environmental impact, aligning with the growing demand for sustainable travel options. When sourcing these vehicles, businesses should consider customization options, battery life, and safety features to ensure a seamless integration into their service offerings.

What Benefits Do Electric Vehicles with EEC Offer to Agriculture?

Electric utility vehicles equipped with EEC technology are increasingly utilized in agricultural operations. These vehicles help reduce operational costs through lower fuel consumption and emissions, while their quieter operation minimizes disturbances to livestock and wildlife. For international B2B buyers, it is essential to evaluate the vehicle’s adaptability to various terrains, battery life for extended use, and the availability of service support to ensure reliability in demanding agricultural environments.

How Are Electric Vehicles with EEC Impacting Municipal Services?

Municipal services are leveraging electric vehicles with EEC technology for waste collection and street cleaning. These vehicles provide significant benefits, including reduced emissions, noise pollution, and operational cost savings. As cities strive for greener initiatives, the adoption of electric municipal vehicles becomes vital. Buyers should prioritize vehicle durability, compatibility with existing fleets, and ongoing maintenance support to ensure a smooth transition to electric solutions.

3 Common User Pain Points for ‘electric vehicle with eec’ & Their Solutions

Scenario 1: Limited Charging Infrastructure for Fleet Operations

The Problem: B2B buyers managing logistics and transportation fleets often face a significant challenge: the lack of reliable charging infrastructure. Many electric vehicles with EEC require regular charging, and without adequate charging stations at depots or strategic locations, operations can suffer from downtime. This issue is particularly pronounced in regions such as Africa and South America, where the installation of charging stations is still in its infancy, creating barriers to adopting electric vehicles for commercial use.

The Solution: To mitigate this challenge, businesses should prioritize partnerships with local governments and utility companies to advocate for the development of charging infrastructure. Additionally, companies can explore installing on-site charging stations at their depots, ensuring that their fleets are consistently charged and ready for operation. When sourcing electric vehicles, buyers should also consider models that support fast charging capabilities, which can significantly reduce charging time and improve fleet efficiency. Conducting a site assessment before making purchasing decisions can help identify the best locations for charging stations, maximizing uptime and operational efficiency.

Scenario 2: Concerns Over Vehicle Performance and Range

The Problem: B2B buyers are often apprehensive about the performance and range of electric vehicles with EEC, particularly in industries requiring long-distance travel or heavy cargo transport. Concerns may arise about whether these vehicles can meet the demands of rigorous operational schedules and varied terrain, especially in developing markets where road conditions can be unpredictable.

The Solution: To address these concerns, buyers should conduct comprehensive market research to identify electric vehicle models that have proven performance metrics and favorable reviews from similar businesses. It is also crucial to evaluate the vehicle specifications, including battery capacity and range under different conditions. Implementing a pilot program where a limited number of vehicles are tested in real-world scenarios can provide invaluable insights into their performance. Furthermore, investing in training for drivers on how to maximize the efficiency of electric vehicles—such as optimal driving habits and understanding the vehicle’s energy management systems—can significantly enhance performance and alleviate range anxiety.

Scenario 3: Regulatory Compliance and Understanding EEC Standards

The Problem: Navigating the complex regulatory landscape surrounding electric vehicles can be daunting for B2B buyers, especially those new to the EEC market. Regulations regarding emissions, vehicle safety, and import/export standards can vary widely across regions, such as in Europe and the Middle East, leading to confusion and potential compliance issues that could delay vehicle deployment.

The Solution: Buyers should engage with industry experts and consultants who specialize in EEC regulations to gain a clear understanding of the requirements specific to their operational regions. Joining industry associations can also provide access to resources and updates on regulatory changes. When sourcing electric vehicles, businesses must ensure that they select models that meet or exceed local regulatory standards, which not only simplifies compliance but also enhances marketability. Regular training and workshops for procurement and compliance teams can further ensure that the company remains updated on regulatory shifts, thus avoiding costly fines and operational disruptions.

Strategic Material Selection Guide for electric vehicle with eec

What Are the Key Materials Used in Electric Vehicles with EEC?

When selecting materials for electric vehicles (EVs) equipped with Electric Equipment Certification (EEC), it is essential to consider properties that enhance performance, durability, and compliance with international standards. Below, we analyze four commonly used materials in the manufacturing of EEC electric vehicles, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Benefit Electric Vehicle Manufacturing?

Aluminum is widely used in the automotive industry due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating of up to 600°C, making it suitable for various components, including chassis and body panels.

Pros: The primary advantage of aluminum is its strength-to-weight ratio, which enhances vehicle efficiency and performance by reducing overall weight. It is also recyclable, adding to its sustainability credentials.

Cons: However, aluminum can be more expensive than steel, and its manufacturing processes can be complex, requiring specialized techniques like welding or bonding.

Impact on Application: Aluminum’s lightweight properties significantly improve energy efficiency, especially in electric vehicles where battery weight is a concern.

Considerations for International Buyers: Buyers from regions like Africa and South America should be aware of local recycling capabilities and the availability of aluminum suppliers. Compliance with standards such as ASTM and DIN is crucial for ensuring quality.

Why Is Steel Still a Preferred Material for Electric Vehicles?

Steel remains a staple in vehicle manufacturing due to its strength and cost-effectiveness. With a high yield strength and a temperature rating of around 300°C, it is suitable for structural components.

Pros: Steel is durable and offers excellent impact resistance, making it ideal for safety-critical parts like frames and bumpers. Its lower cost compared to aluminum makes it an attractive option for budget-conscious manufacturers.

Cons: The downside is that steel is heavier, which can negatively impact the vehicle’s range and efficiency. Additionally, it is prone to corrosion unless treated.

Impact on Application: Steel is often used in areas where strength is paramount, but its weight can be a disadvantage in electric vehicles where energy efficiency is a priority.

Considerations for International Buyers: Buyers should consider the regional availability of high-strength steel grades and ensure compliance with local standards. In markets like the Middle East, where corrosion is a concern, selecting galvanized steel may be necessary.

What Role Does Composite Material Play in Electric Vehicles?

Composite materials, such as carbon fiber reinforced polymer (CFRP), are increasingly being used in electric vehicles due to their lightweight and high-strength properties. They can withstand temperatures up to 200°C.

Pros: Composites offer significant weight savings and can be molded into complex shapes, providing design flexibility. They also exhibit excellent fatigue resistance and corrosion resistance.

Cons: The primary limitation is the high cost of production and the complexity of manufacturing processes, which may not be feasible for all manufacturers.

Impact on Application: Composites are particularly beneficial in applications where weight reduction is critical, such as in battery enclosures or body panels.

Considerations for International Buyers: Buyers must ensure that composite materials meet local regulatory standards and consider the availability of specialized suppliers in regions like Europe, where advanced composite technologies are more prevalent.

How Does Copper Contribute to Electric Vehicle Performance?

Copper is essential for electrical components in electric vehicles due to its excellent conductivity and thermal properties. It can handle high temperatures and is resistant to corrosion.

Pros: Copper’s high conductivity ensures efficient energy transfer, which is critical for battery performance and overall vehicle efficiency. It is also recyclable, aligning with sustainability goals.

Cons: The main drawback is its cost, as copper is more expensive than aluminum, which can increase overall vehicle costs.

Impact on Application: Copper is primarily used in wiring, connectors, and motors, where efficient electrical performance is vital.

Considerations for International Buyers: Buyers should consider the fluctuations in copper prices and ensure compliance with international standards for electrical components, especially in markets with stringent regulations like Europe.

Summary Table of Material Selection for Electric Vehicles with EEC

| Material | Typical Use Case for electric vehicle with eec | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Chassis, body panels | Lightweight, corrosion-resistant | Higher cost, complex manufacturing | Medium |

| Steel | Structural components | Durable, cost-effective | Heavier, prone to corrosion | Low |

| Composite | Battery enclosures, body panels | Lightweight, design flexibility | High production cost, complex processes | High |

| Copper | Wiring, connectors, motors | Excellent conductivity | High cost | High |

This comprehensive analysis of materials provides B2B buyers with critical insights into the selection process for electric vehicles with EEC, emphasizing the importance of balancing performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for electric vehicle with eec

What Are the Key Stages in the Manufacturing Process of EEC Electric Vehicles?

The manufacturing of EEC electric vehicles involves a series of well-defined stages that ensure the final product meets quality and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial phase involves sourcing and preparing raw materials, including metals, composites, and batteries. Suppliers must provide materials that adhere to international standards, such as those set by ISO and the European Union’s REACH regulations, to ensure environmental compliance and safety.

-

Forming: In this stage, raw materials are shaped into components using various techniques such as stamping, molding, and extrusion. Advanced technologies like CNC machining and 3D printing are increasingly being adopted to enhance precision and reduce waste. Employing high-quality materials ensures durability and performance, which are critical for electric vehicles.

-

Assembly: The assembly process integrates all components into a cohesive vehicle. This stage often utilizes automated systems alongside skilled labor to enhance efficiency and reduce the potential for human error. Key components, such as electric motors, batteries, and control systems, must be installed with precision to ensure optimal performance.

-

Finishing: The final stage includes painting, coating, and the installation of interior features. This not only enhances the aesthetic appeal of the vehicle but also adds protective layers against environmental factors. Quality assurance checks during this phase ensure that the vehicle meets both aesthetic and functional standards.

How Is Quality Assurance Implemented in EEC Electric Vehicle Manufacturing?

Quality assurance (QA) is a critical aspect of the manufacturing process for EEC electric vehicles. It ensures that each vehicle meets international and industry-specific standards, which is essential for B2B buyers looking to mitigate risks associated with product quality.

-

International Standards: Adherence to ISO 9001 is fundamental for manufacturers, as it outlines a framework for quality management systems. Additionally, compliance with CE marking and other regional standards ensures that products meet safety and performance requirements in target markets.

-

Industry-Specific Standards: Electric vehicles are subject to specialized standards, such as those set by the International Electrotechnical Commission (IEC) for electrical components. Understanding these standards is crucial for buyers who wish to ensure that their suppliers produce vehicles that are safe and reliable.

What Are the Key Quality Control Checkpoints in Electric Vehicle Production?

Quality control (QC) involves systematic checks at various stages of the manufacturing process to ensure product integrity. The key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter the production line. Suppliers are often required to provide certification and test reports to validate the quality of their materials.

-

In-Process Quality Control (IPQC): During the manufacturing process, QC teams conduct regular inspections to monitor compliance with specifications. This can include visual inspections, dimensional checks, and functional testing of critical components.

-

Final Quality Control (FQC): At the end of the assembly process, each vehicle undergoes comprehensive testing to ensure it meets all performance and safety standards. This includes road tests, battery performance evaluations, and electrical system checks.

What Testing Methods Are Commonly Used in EEC Electric Vehicle Manufacturing?

Various testing methods are employed to validate the performance and safety of EEC electric vehicles:

-

Electrical Testing: Ensures that the vehicle’s electrical systems function correctly. This includes battery discharge tests, voltage checks, and insulation resistance tests.

-

Safety Testing: Involves crash simulations and safety feature evaluations to ensure compliance with safety regulations. This is particularly important for B2B buyers who prioritize safety in their procurement decisions.

-

Durability Testing: Assesses how well the vehicle withstands various environmental conditions and operational stresses. This includes exposure to extreme temperatures, humidity, and vibration tests.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to verify the quality control practices of potential suppliers. Here are several methods to consider:

-

Supplier Audits: Conducting on-site audits of manufacturing facilities allows buyers to assess the implementation of quality management systems and compliance with international standards. This also provides an opportunity to evaluate the capability of the supplier’s QC team.

-

Requesting Quality Reports: Buyers should ask suppliers to provide detailed quality reports, including IQC, IPQC, and FQC results. These documents can offer insight into the supplier’s commitment to quality and any corrective actions taken in response to issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an independent assessment of a supplier’s quality control processes. This is particularly useful for buyers from regions like Africa and South America, where local regulations may differ from international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, especially from diverse markets such as Africa, South America, the Middle East, and Europe, face unique challenges regarding quality control. These nuances include:

-

Regulatory Compliance: Understanding the specific regulatory requirements for each target market is crucial. For example, vehicles sold in Europe must meet stringent emissions and safety regulations, while those in emerging markets may have different compliance requirements.

-

Cultural Differences: Cultural perceptions of quality and safety can vary significantly across regions. B2B buyers should be aware of these differences and ensure that their suppliers align with the expectations of their target market.

-

Supply Chain Transparency: Establishing a transparent supply chain is essential for ensuring quality. Buyers should demand full disclosure of the supply chain from their manufacturers, including sourcing, production processes, and quality assurance measures.

Conclusion: Ensuring Quality in EEC Electric Vehicle Procurement

For international B2B buyers, understanding the manufacturing processes and quality assurance measures of EEC electric vehicles is essential for making informed procurement decisions. By focusing on the key stages of manufacturing, implementing rigorous quality control measures, and verifying supplier practices, buyers can mitigate risks and ensure they are sourcing high-quality vehicles that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric vehicle with eec’

To assist B2B buyers in successfully procuring electric vehicles compliant with EEC (European Economic Community) regulations, this guide outlines essential steps to ensure a smooth and informed sourcing process.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is paramount before initiating the procurement process. Consider factors such as vehicle type (e.g., passenger cars, commercial fleets), battery capacity, range, and charging infrastructure. This clarity will help you align your needs with available models and streamline discussions with potential suppliers.

Step 2: Research Market Trends and Regulatory Compliance

Stay updated on current market trends and EEC regulations affecting electric vehicles. Understanding regional requirements, such as emissions standards and safety certifications, is crucial for compliance. Look for updates on subsidies or incentives that may impact your purchasing decisions, as these can significantly influence the total cost of ownership.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality. Request detailed company profiles, including their manufacturing capabilities, certifications, and past performance in similar markets. Additionally, seek references from other businesses that have purchased from them, as this can provide insights into their credibility and service levels.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold the necessary EEC certifications for their electric vehicles. This includes compliance with safety, environmental, and performance standards. Verification can be achieved by requesting copies of certifications and checking against regulatory bodies to confirm authenticity.

Step 5: Assess Charging Solutions and Infrastructure

Consider the availability and compatibility of charging solutions for the electric vehicles you plan to procure. Evaluate whether the supplier offers integrated charging solutions or partnerships with local charging infrastructure providers. This assessment is crucial for ensuring that your fleet can operate efficiently, especially in regions with limited charging facilities.

Step 6: Analyze Total Cost of Ownership

When evaluating electric vehicles, it’s essential to analyze the total cost of ownership (TCO), which includes purchase price, maintenance, charging costs, and potential subsidies. Compare these costs across different suppliers and models to identify the most economically viable options for your business. Consider the long-term savings associated with lower fuel and maintenance expenses typical of electric vehicles.

Step 7: Negotiate Terms and Conditions

Once you have shortlisted potential suppliers, enter negotiations to finalize the terms and conditions of your purchase. Pay attention to warranty offers, service agreements, and delivery timelines. Clear communication during this phase can prevent misunderstandings and ensure that both parties are aligned on expectations.

By following this checklist, B2B buyers can make informed decisions when sourcing electric vehicles with EEC compliance, ultimately enhancing their operational efficiency and sustainability efforts.

Comprehensive Cost and Pricing Analysis for electric vehicle with eec Sourcing

What Are the Key Cost Components in Sourcing EEC Electric Vehicles?

When evaluating the cost structure for EEC electric vehicles, several components must be considered. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of raw materials, such as lithium for batteries and steel for the chassis, represents a significant portion of the overall expenses. As global demand for electric vehicles rises, fluctuations in material costs can affect pricing. B2B buyers should consider suppliers that can offer competitive pricing on these materials.

-

Labor: Labor costs vary significantly by region. In countries with lower labor costs, such as parts of Africa and South America, the overall production costs may be reduced. However, it’s essential to ensure that quality is not compromised, as skilled labor is crucial for assembling electric vehicles.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities and maintenance. Efficient production processes can help minimize these costs, contributing to a more favorable pricing structure.

-

Tooling: The initial investment in tooling and equipment for manufacturing electric vehicles can be substantial. Customization requirements may necessitate additional tooling, which could impact the pricing for specific orders.

-

Quality Control (QC): Ensuring that vehicles meet international safety and regulatory standards is critical. The costs associated with QC processes can vary based on the level of compliance required by the target market, which is particularly important for international buyers.

-

Logistics: Shipping costs can vary widely based on the destination, mode of transport, and Incoterms used. Buyers should factor in these costs when calculating the total landed cost of the vehicles.

-

Margin: Supplier margins can differ based on their market positioning and the volume of vehicles being purchased. Higher order volumes typically lead to lower per-unit margins.

How Do Price Influencers Affect EEC Electric Vehicle Costs?

Several factors influence the pricing of EEC electric vehicles, which can significantly impact B2B negotiations:

-

Volume/MOQ: Purchasing larger quantities often leads to better pricing. Suppliers may offer discounts for minimum order quantities (MOQ), making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Custom features, such as upgraded batteries or advanced safety systems, can increase costs. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications can affect both cost and buyer confidence. Ensure that suppliers can provide the necessary documentation to meet regional compliance.

-

Supplier Factors: Supplier reliability, reputation, and production capacity play a crucial role in pricing. Established suppliers with a track record may command higher prices due to their perceived value.

-

Incoterms: Understanding the terms of shipping and delivery is critical. Different Incoterms can affect who bears the cost of transport and insurance, impacting the overall cost structure.

What Negotiation Tips Can Help B2B Buyers Achieve Cost-Efficiency?

To maximize cost-efficiency when sourcing EEC electric vehicles, consider the following negotiation strategies:

-

Leverage Volume Discounts: Consolidate orders to take advantage of volume discounts. Presenting a larger order can incentivize suppliers to provide better pricing.

-

Explore Total Cost of Ownership (TCO): Evaluate the TCO, which includes purchase price, maintenance, and operational costs. This holistic view can lead to more informed purchasing decisions.

-

Investigate Financing Options: Some suppliers may offer financing solutions that can ease the upfront cost burden. This can be particularly beneficial for buyers in developing regions.

-

Stay Informed on Market Trends: Regularly monitor market trends and material costs to time your purchases effectively. Awareness of price fluctuations can provide leverage in negotiations.

-

Understand Regional Pricing Nuances: Different regions may have varying pricing structures due to economic conditions, tariffs, and subsidies. Recognizing these nuances can help buyers negotiate better terms.

Conclusion: What Should International Buyers Consider When Sourcing EEC Electric Vehicles?

In summary, international B2B buyers should approach the sourcing of EEC electric vehicles with a thorough understanding of cost components and pricing influencers. By leveraging volume purchasing, understanding TCO, and staying informed on market dynamics, buyers can negotiate favorable terms and ensure a cost-effective procurement process. While indicative prices can vary widely based on the discussed factors, diligent research and strategic planning will yield the best outcomes.

Alternatives Analysis: Comparing electric vehicle with eec With Other Solutions

Understanding Alternatives to Electric Vehicles with EEC

As businesses seek sustainable and efficient transportation solutions, the emergence of electric vehicles (EVs), particularly those compliant with European Economic Community (EEC) regulations, has become a focal point. However, various alternatives exist, each with unique benefits and drawbacks. This analysis compares electric vehicles with EEC against other viable transportation solutions, helping B2B buyers make informed decisions.

Comparison Table

| Comparison Aspect | Electric Vehicle With EEC | Alternative 1: Hybrid Electric Vehicle (HEV) | Alternative 2: Compressed Natural Gas (CNG) Vehicle |

|---|---|---|---|

| Performance | High torque, instant acceleration; ideal for urban settings | Moderate performance; good fuel economy in city driving | Good performance with a range comparable to gasoline vehicles |

| Cost | Higher upfront cost, lower operational costs due to electricity savings | Moderate initial cost, fuel savings over time | Competitive initial cost, but fluctuating fuel prices can affect operating costs |

| Ease of Implementation | Requires charging infrastructure; benefits fleets with central depots | Easier to implement as it uses existing fuel infrastructure | Requires dedicated CNG refueling stations; limited availability in some regions |

| Maintenance | Lower maintenance due to fewer moving parts | Moderate maintenance; more complex than EVs but simpler than traditional vehicles | Similar to gasoline vehicles; requires regular maintenance of CNG systems |

| Best Use Case | Urban fleets, public transport, and businesses with home/work charging | Suitable for mixed driving conditions (city and highway) | Ideal for long-haul transport and areas with established CNG infrastructure |

Detailed Breakdown of Alternatives

Hybrid Electric Vehicle (HEV)

Hybrid Electric Vehicles combine a traditional internal combustion engine with an electric propulsion system. This dual system allows HEVs to achieve better fuel efficiency and lower emissions than conventional vehicles. The primary advantage is their flexibility in fuel usage, making them suitable for regions lacking robust EV infrastructure. However, HEVs can be more complex and expensive to maintain due to the dual powertrain. They are best for businesses operating in diverse environments, balancing urban and highway driving.

Compressed Natural Gas (CNG) Vehicle

CNG vehicles run on compressed natural gas, which burns cleaner than gasoline or diesel, producing fewer emissions. They are generally more affordable than electric vehicles and can offer a similar range to traditional vehicles, making them suitable for long-haul transport. CNG vehicles benefit from existing fuel infrastructure in many areas, easing implementation. However, the availability of CNG refueling stations can be a limitation in some regions, and fuel prices can be volatile, impacting operational costs.

Conclusion: Choosing the Right Transportation Solution

When selecting the most suitable transportation solution, B2B buyers should consider their specific operational needs, budget, and infrastructure availability. Electric vehicles with EEC compliance offer significant long-term savings and environmental benefits, particularly for urban fleets with access to charging stations. In contrast, hybrid vehicles provide flexibility and efficiency for varied driving conditions, while CNG vehicles may be the ideal choice for long-distance transport where infrastructure is established. By evaluating these factors, businesses can align their transportation strategies with their sustainability goals and operational requirements.

Essential Technical Properties and Trade Terminology for electric vehicle with eec

What Are the Essential Technical Properties of Electric Vehicles with EEC?

When considering electric vehicles (EVs) equipped with EEC (Economic Commission for Europe) compliance, several technical properties stand out as critical. Understanding these specifications is vital for B2B buyers to ensure they meet operational needs and regulatory standards.

-

Battery Capacity (kWh)

The battery capacity, measured in kilowatt-hours (kWh), indicates the amount of energy the battery can store. A higher capacity translates to a longer range, which is crucial for fleet operators and businesses that require reliable transportation over longer distances. For instance, EVs with a capacity of 60 kWh can typically achieve a range of 200-300 miles, making them suitable for urban and intercity logistics. -

Charging Time (Hours)

Charging time denotes how long it takes to fully charge the vehicle’s battery. Fast charging capabilities (e.g., 150 kW and above) can significantly reduce downtime, enhancing operational efficiency. Businesses should consider charging solutions that can accommodate their fleet’s needs, especially if they rely on consistent vehicle availability for deliveries or services. -

Maximum Speed (km/h)

The maximum speed of an electric vehicle is essential for compliance with local regulations and operational requirements. For example, low-speed vehicles (LSVs) often have a cap of 40 km/h, making them ideal for use in urban settings or controlled environments. Understanding speed limitations can help businesses plan their logistics accordingly. -

Payload Capacity (kg)

This specification refers to the maximum weight the vehicle can safely carry, including passengers and cargo. For businesses, especially those in logistics and delivery, knowing the payload capacity is critical for operational planning and ensuring compliance with weight regulations. -

Motor Power (kW)

The power of the electric motor, measured in kilowatts (kW), influences the vehicle’s performance and acceleration. A vehicle with a higher motor power rating typically offers better performance, which can be a deciding factor for businesses that prioritize speed and efficiency in their operations.

What Trade Terminology Should B2B Buyers Know for Electric Vehicles with EEC?

Familiarity with industry jargon is vital for effective communication and negotiation in the electric vehicle market. Here are some key terms that B2B buyers should understand:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of electric vehicles, OEMs are responsible for the design and manufacturing of EV components, such as batteries and electric motors, which can influence the quality and performance of the vehicles. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for businesses as it can impact inventory management and overall procurement costs. Buyers should negotiate MOQs to align with their operational needs and budget constraints. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. In the electric vehicle sector, submitting an RFQ can help businesses gather competitive pricing and evaluate supplier capabilities, which is crucial for making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is important for B2B buyers as they determine who is responsible for shipping costs, insurance, and customs clearance, thereby affecting overall logistics planning. -

EEC Compliance

EEC compliance refers to meeting the regulatory standards set by the Economic Commission for Europe. Understanding these regulations is crucial for B2B buyers as it ensures that the vehicles they procure are legally operable in their markets, avoiding potential legal issues and fines.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when investing in electric vehicles with EEC compliance, ensuring they align with their operational needs and regulatory requirements.

Navigating Market Dynamics and Sourcing Trends in the electric vehicle with eec Sector

What Are the Key Drivers Influencing the Electric Vehicle Market with EEC?

The electric vehicle (EV) market, particularly in the context of electric vehicles with European Economic Community (EEC) approval, is experiencing transformative growth driven by several global factors. Increasing regulatory pressures, particularly in Europe, are pushing for a transition away from internal combustion engines (ICE) by 2035, compelling manufacturers to accelerate the production of battery-electric vehicles (BEVs). Additionally, growing consumer demand for sustainable transportation options is driving innovation and investment in EV technologies.

Emerging trends include the rise of direct-to-consumer (DTC) sales models, allowing manufacturers to engage with customers more effectively. Companies like Tesla have set the bar with online configurators and seamless purchasing experiences. There is also a significant shift towards enhancing charging infrastructure, with businesses recognizing the need for workplace charging solutions to accommodate employees who may not have access to home charging. This is particularly relevant in markets across Africa, South America, and the Middle East, where infrastructure development is critical to support EV adoption.

How Can B2B Buyers Leverage Sustainability and Ethical Sourcing in the Electric Vehicle Sector?

Sustainability and ethical sourcing are becoming paramount in the electric vehicle sector. The environmental impact of sourcing materials for EV batteries—such as lithium, cobalt, and nickel—has raised concerns about ecological degradation and human rights violations in mining practices. B2B buyers must prioritize suppliers who adhere to ethical sourcing practices and who can provide certifications that verify their compliance with environmental and social governance (ESG) standards.

Investing in ‘green’ certifications and materials not only enhances a company’s reputation but also aligns with increasing consumer expectations for transparency and accountability in supply chains. By sourcing from manufacturers who utilize recycled materials or sustainable practices, buyers can contribute to reducing the overall carbon footprint of their operations while also meeting regulatory requirements that are becoming more stringent in various regions. This approach is particularly important for businesses in Europe and the Middle East, where regulatory frameworks around sustainability are rapidly evolving.

What Is the Evolution of the Electric Vehicle Market and Its Implications for B2B Buyers?

The evolution of the electric vehicle market is marked by technological advancements and shifting consumer preferences. Initially, EVs faced skepticism due to concerns over range and charging infrastructure. However, innovations in battery technology, such as the development of solid-state batteries, are addressing these issues by offering faster charging times and greater efficiency.

The transition to electric mobility has been accelerated by government incentives, making EVs more accessible. As a result, the market has expanded beyond traditional automotive manufacturers to include tech companies and startups, further diversifying the landscape. B2B buyers should take note of this evolution, as new entrants often bring innovative solutions and competitive pricing, which can be advantageous for procurement strategies.

In summary, understanding the dynamics of the electric vehicle market with EEC approval is crucial for international B2B buyers. By aligning sourcing strategies with sustainability goals and being aware of market trends, businesses can position themselves effectively in this rapidly changing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of electric vehicle with eec

-

How do I ensure the quality of EEC electric vehicles before purchase?

To ensure the quality of EEC electric vehicles, conduct thorough research on potential suppliers. Request samples and certifications, such as ISO or EEC approval, to verify compliance with international safety standards. Arrange factory visits if possible, or utilize third-party inspection services to evaluate manufacturing processes and quality control measures. Additionally, review customer testimonials and case studies to gauge previous buyers’ satisfaction and product performance. -

What are the key features to consider when sourcing EEC electric vehicles?

When sourcing EEC electric vehicles, focus on features such as battery range, charging infrastructure compatibility, and overall vehicle performance. Look for models with a minimum range of 300 miles to meet diverse operational needs. Evaluate the availability of fast-charging options and the vehicle’s adaptability to various terrains, especially if operating in rural areas. Finally, consider the vehicle’s design and comfort, as these factors can significantly influence user experience and satisfaction. -

What payment terms should I negotiate when sourcing EEC electric vehicles?

Negotiating payment terms is crucial for managing cash flow. Common terms include a deposit upfront (usually 20-30%), followed by milestone payments based on production progress, and a final payment upon delivery. Ensure that terms are clear regarding currency, payment methods (e.g., letter of credit, bank transfer), and any applicable taxes or duties. This clarity helps prevent disputes and fosters a smoother transaction process. -

What is the typical minimum order quantity (MOQ) for EEC electric vehicles?

Minimum order quantities for EEC electric vehicles can vary significantly based on the manufacturer and model. Generally, MOQs range from 10 to 50 units, depending on the supplier’s production capacity and your specific requirements. Discuss your needs directly with suppliers to explore possible flexibility in MOQs, especially if you’re looking to establish a long-term partnership or pilot program. -

How can I customize EEC electric vehicles to meet my specific needs?

Customization options for EEC electric vehicles often include modifications to design, performance specifications, and additional features. Engage directly with manufacturers to discuss your requirements and explore available options such as battery capacity adjustments, color choices, or specialized equipment for fleet applications. Ensure that any modifications comply with local regulations to avoid legal issues during operation. -

What logistics considerations should I keep in mind when importing EEC electric vehicles?

When importing EEC electric vehicles, consider shipping methods, customs clearance processes, and local regulations regarding electric vehicles. Choose between container shipping or roll-on/roll-off (RoRo) based on cost and efficiency. Ensure that all necessary documentation, including import permits and compliance certificates, is prepared in advance to avoid delays at customs. Partnering with a logistics provider experienced in automotive imports can help streamline this process. -

How can I verify the legitimacy of an EEC electric vehicle supplier?

To verify a supplier’s legitimacy, conduct a comprehensive background check that includes reviewing their business licenses, certifications, and industry reputation. Utilize platforms like Alibaba or Global Sources to find verified suppliers and check their ratings. Request references from other businesses that have worked with the supplier. A reputable supplier should be transparent and willing to provide documentation that supports their claims. -

What after-sales support should I expect from EEC electric vehicle suppliers?

After-sales support is crucial for maintaining vehicle performance and addressing any issues post-purchase. Reputable suppliers typically offer warranties that cover parts and services for a specified period. They should also provide access to technical support, maintenance guidelines, and spare parts. Clarify the support terms during negotiations to ensure you have adequate resources for troubleshooting and repairs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Electric Vehicle With Eec Manufacturers & Suppliers List

1. Yunrong – Eec Electric Car

Domain: yunronev.com

Registered: 2023 (2 years)

Introduction: Eec Electric Car by Taizhou Yunrong Technology Co., Ltd. is an innovative and eco-friendly vehicle designed for sustainable transportation. Key features include:

– Cutting-edge technology combined with environmental consciousness.

– Sleek and modern design for a comfortable and luxurious driving experience.

– Equipped with advanced features and a powerful electric motor for remarkable performance….

2. Marshell – EEC Approved Electric Low Speed Vehicle DS-A2-2

Domain: marshell.net

Registered: 2004 (21 years)

Introduction: EEC Approved Electric Low Speed Vehicle (LSV) DS-A2-2; Max Speed: 40 km/h; Climbing Capacity: 30%; Controller: 48V 400A.

3. CityCoco – EEC Electric Closed Cars

Domain: citycoco.cc

Registered: 2020 (5 years)

Introduction: EEC ELECTRIC CLOSED CAR models include: 1. EEC 3000W 100Ah New Energy Mini Car – Electric Cabin Car, Closed Electric Vehicle, Passenger, Long Range. 2. New Energy EEC Mini Car – Electric Cabin Car, Closed Electric Vehicle, Passenger. 3. EEC Electric Closed Cabin Car – Tricycle, Three Wheel Car, Tuk, New Energy, Passengers.

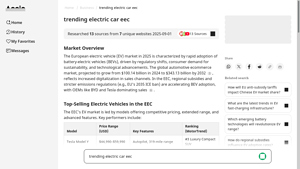

4. Accio – Top Selling Electric Vehicles

Domain: accio.com

Registered: 1997 (28 years)

Introduction: {“Top_Selling_Electric_Vehicles”:[{“Model”:”Tesla Model Y”,”Price_Range”:”$44,990–$59,990″,”Key_Features”:”Autopilot, 319-mile range”,”Ranking”:”#3 Luxury Compact SUV”},{“Model”:”Ford Mustang Mach-E”,”Price_Range”:”$37,995–$54,495″,”Key_Features”:”300-mile range, dual-motor performance”,”Ranking”:”#1 Compact SUV”},{“Model”:”Hyundai Ioniq 5″,”Price_Range”:”$39,600–$44,600″,”Key_Features”:”300-mile …

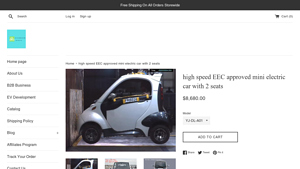

5. E-Smartway – YJ-DL-A01 Mini Electric Car

Domain: e-smartway.com

Registered: 2019 (6 years)

Introduction: High speed EEC approved mini electric car with 2 seats. Sale price: $8,680.00 (Regular price: $9,280.00). Model: YJ-DL-A01. Dimensions: 2250*1400*1642mm. Wheelbase: 1560mm. Trackbase: 1126mm/1146mm. Rated passengers: 2 persons. Curb weight: 600kgs. Minimum ground clearance: 150mm. Body structure: Self-supporting body. Suspension: Front – MacPherson type Independent suspension; Rear – Semi drag roc…

6. HDK Electric Vehicles – Eec Electric Vehicle Series

Domain: m.hdkexpress.com

Registered: 2010 (15 years)

Introduction: HDK Electric Vehicle’s Eec Electric Vehicles include various series such as TARA Series, D-Max Series, Personal Series, Golf Series, D5 Series, D3 Series, and Commercial Series. These vehicles are designed for both personal and commercial use, focusing on eco-friendly transportation solutions that reduce carbon emissions. Key features include long battery life, rapid charging capability, and intui…

7. Pinterest – High-Speed EEC Electric Cars

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: 60V 2500W High Speed EEC Electric Cars, 4 Wheels Electric Vehicle, Electric Cars, EEC Electric Vehicle, Mini Electric Car For Adults, Two Seater Electric Car, High-performance Electric Vehicle, Wholesale pricing, factory direct, bulk pricing, trusted B2B suppliers, fast shipping, free quote available.

Strategic Sourcing Conclusion and Outlook for electric vehicle with eec

As the electric vehicle (EV) market evolves, strategic sourcing becomes critical for international B2B buyers seeking to capitalize on emerging opportunities. The advantages of EEC electric vehicles, such as flexible charging solutions and eco-friendly designs, position them as viable choices for fleet operations, particularly in regions like Africa, South America, the Middle East, and Europe. Companies must prioritize establishing robust supply chains that leverage local manufacturing and innovative technologies to ensure timely access to high-quality vehicles.

Moreover, understanding regional regulations and consumer preferences will be essential in navigating the competitive landscape. Buyers should focus on sourcing vehicles that not only meet stringent emission standards but also offer features that resonate with their target markets, such as fast charging and extended range capabilities.

Looking ahead, the potential for growth in the EV sector is substantial, driven by increasing demand for sustainable transportation solutions. By investing in strategic sourcing now, businesses can position themselves as leaders in the electric vehicle market. Embrace this opportunity to innovate and collaborate with trusted manufacturers, paving the way for a sustainable future in mobility.