Introduction: Navigating the Global Market for knuckle Boom Truck Crane

The global market for knuckle boom truck cranes presents significant opportunities for international B2B buyers, particularly those in emerging markets such as Nigeria and Brazil. However, sourcing the right knuckle boom crane to meet specific operational needs can be a daunting task. Buyers must navigate a complex landscape of diverse models, varying specifications, and an array of suppliers, all while ensuring compliance with safety regulations and optimizing for cost-efficiency.

This comprehensive guide aims to demystify the process of selecting and purchasing knuckle boom truck cranes. It covers essential topics including types of cranes available, their applications across different industries, and critical considerations for supplier vetting. Additionally, we delve into cost factors and maintenance requirements to help buyers make informed financial decisions.

By providing actionable insights and expert recommendations, this guide empowers B2B buyers from Africa, South America, the Middle East, and Europe to confidently engage in the procurement process. Whether you are looking for a lightweight model for urban construction or a heavy-duty crane for large-scale industrial applications, this resource is designed to enhance your understanding and ensure that your investment aligns with your business objectives.

Understanding knuckle Boom Truck Crane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Light Duty Knuckle Boom | Compact design, ideal for small to medium vehicles, versatile | Material handling, construction, landscaping | Pros: Easy to transport, cost-effective. Cons: Limited lifting capacity. |

| Medium Duty Knuckle Boom | Balanced payload capacity, versatile setups, longer reach | Construction, industrial applications | Pros: Greater lifting capacity, adaptable configurations. Cons: Heavier than light-duty models. |

| Heavy Duty Knuckle Boom | High power and performance, designed for complex jobs | Heavy construction, rescue operations | Pros: Exceptional lifting capacity, robust design. Cons: Higher initial investment, requires skilled operators. |

| Super Heavy Knuckle Boom | Maximum reach and lifting performance, lightweight for power | Large-scale construction, heavy material handling | Pros: Outstanding performance, suitable for extreme tasks. Cons: Requires specialized maintenance, higher operational costs. |

| T-Cranes | Stiff boom structure, optimized for transportation | Light material handling, logistics | Pros: Efficient for small loads, easy to mount. Cons: Limited reach compared to other types. |

What are the Characteristics and Suitability of Light Duty Knuckle Boom Cranes?

Light duty knuckle boom cranes are designed for compactness and versatility, making them suitable for small to medium-sized vehicles. They excel in applications such as material handling, landscaping, and small construction tasks. When considering a purchase, buyers should evaluate the crane’s lifting capacity and the types of loads they intend to handle, as these cranes may not be suitable for heavier operations.

How Do Medium Duty Knuckle Boom Cranes Enhance Operational Efficiency?

Medium duty knuckle boom cranes offer a balanced payload capacity and a variety of configurations to optimize performance. Their longer reach makes them ideal for construction and industrial applications where versatility is key. Buyers should assess their specific operational needs, including the types of materials and distances involved in lifting, to ensure they select a crane that meets their demands while remaining cost-effective.

Why Choose Heavy Duty Knuckle Boom Cranes for Complex Jobs?

Heavy duty knuckle boom cranes are engineered for high power and performance, making them essential for complex construction and rescue operations. Their robust design allows them to handle substantial loads, which is crucial in demanding environments. Buyers should consider the initial investment and the need for skilled operators when selecting these cranes, as their capabilities come with increased operational requirements.

What Makes Super Heavy Knuckle Boom Cranes Ideal for Large-Scale Operations?

Super heavy knuckle boom cranes provide maximum reach and lifting performance while maintaining a lightweight design. This unique balance makes them suitable for large-scale construction and heavy material handling tasks. Prospective buyers should be aware of the specialized maintenance these cranes require and the potential for higher operational costs, which can affect long-term profitability.

When Should You Consider T-Cranes for Your Operations?

T-Cranes feature a stiff boom structure optimized for transportation and are particularly effective for light material handling and logistics. Their efficient design allows for easy mounting and operation, making them a great choice for businesses with smaller load requirements. However, buyers should consider the limited reach of T-Cranes and assess whether they align with their operational needs before making a purchase.

Key Industrial Applications of knuckle Boom Truck Crane

| Industry/Sector | Specific Application of knuckle Boom Truck Crane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and placing heavy materials on construction sites | Increases efficiency in material handling and reduces labor costs | Consider crane capacity, reach, and stability features |

| Logistics and Transportation | Loading and unloading cargo from trucks and containers | Enhances operational speed and reduces loading times | Evaluate compatibility with existing fleet and ease of use |

| Forestry | Loading and unloading logs and timber products | Improves safety and efficiency in timber handling | Assess crane weight capacity and attachment options |

| Oil and Gas | Lifting equipment and materials in remote locations | Facilitates operations in challenging terrains | Focus on durability and resistance to harsh environments |

| Waste Management | Collecting and transporting recyclable materials | Streamlines waste management processes and increases recycling rates | Check for specialized attachments for different waste types |

How is a Knuckle Boom Truck Crane Used in the Construction Sector?

In the construction industry, knuckle boom truck cranes are essential for lifting and placing heavy materials, such as steel beams, concrete blocks, and prefabricated components. Their articulated design allows for precise maneuvering in tight spaces, significantly enhancing operational efficiency. By reducing the reliance on manual labor for heavy lifting, these cranes lower labor costs and improve safety on-site. International buyers should prioritize cranes with high lifting capacities and stability features to ensure they meet the demands of various construction projects.

What Role Does a Knuckle Boom Truck Crane Play in Logistics and Transportation?

Knuckle boom cranes are widely used in logistics and transportation for loading and unloading cargo from trucks and containers. Their versatility allows them to handle various types of goods, including pallets, machinery, and construction materials, facilitating faster loading cycles. This efficiency translates into reduced turnaround times and increased productivity for logistics companies. Buyers in this sector should consider the crane’s compatibility with their existing fleet and the ease of operation for their drivers.

How is a Knuckle Boom Truck Crane Beneficial in the Forestry Industry?

In the forestry sector, knuckle boom cranes are instrumental in loading and unloading logs and timber products. Their ability to reach into dense forest areas and maneuver around obstacles makes them ideal for timber handling operations. By utilizing these cranes, forestry companies can enhance safety and efficiency, reducing the risk of accidents associated with manual log handling. Buyers should evaluate the crane’s weight capacity and available attachments to ensure they can accommodate various timber sizes and types.

What Advantages Does a Knuckle Boom Truck Crane Offer in Oil and Gas Operations?

In the oil and gas industry, knuckle boom cranes are crucial for lifting equipment and materials in remote and challenging terrains. Their compact design and extended reach allow for efficient operations in locations where traditional cranes may struggle. By incorporating these cranes, companies can streamline their operations, minimizing downtime and enhancing productivity. Buyers should focus on the durability of the cranes and their resistance to harsh environmental conditions, ensuring they can withstand the rigors of oil and gas operations.

How Does a Knuckle Boom Truck Crane Improve Waste Management Processes?

Knuckle boom cranes are increasingly used in waste management for collecting and transporting recyclable materials. Their flexibility and specialized attachments enable operators to efficiently handle various waste types, from construction debris to household recyclables. By improving the efficiency of waste collection and transportation, these cranes contribute to higher recycling rates and better environmental outcomes. When sourcing cranes for waste management, buyers should check for specialized attachments that cater to different waste materials, enhancing operational versatility.

3 Common User Pain Points for ‘knuckle Boom Truck Crane’ & Their Solutions

Scenario 1: Difficulty in Lifting Heavy Loads Safely

The Problem: A construction firm in Nigeria frequently faces challenges with lifting heavy materials due to the limited lifting capacity of their existing knuckle boom cranes. This limitation not only slows down project timelines but also raises safety concerns for workers operating under high-stress conditions. As projects scale up, the need for efficient and safe lifting becomes paramount, yet many companies struggle with outdated equipment that cannot handle increased loads or that lacks modern safety features.

The Solution: To address this issue, buyers should focus on sourcing knuckle boom cranes specifically designed for heavy-duty operations. It’s essential to assess the maximum lifting capacity and reach of various models. Opt for cranes equipped with advanced features such as the High Power Lifting System (HPLS) that enhance capacity without compromising on speed or safety. Additionally, investing in cranes with integrated safety systems, like overload protection and oscillation suppression, can significantly reduce the risk of accidents during operation. Conduct thorough research and consult with manufacturers to select a model that not only meets current needs but is also scalable for future projects.

Scenario 2: High Maintenance Costs and Downtime

The Problem: A logistics company in Brazil is experiencing high maintenance costs and unexpected downtime for their knuckle boom cranes, leading to project delays and increased operational costs. Frequent breakdowns and repairs are not only affecting productivity but also straining relationships with clients who rely on timely delivery and service.

The Solution: To mitigate maintenance issues, buyers should consider investing in knuckle boom cranes that offer low maintenance systems. For instance, models with self-lubricating components and durable protective coatings, like KTL (Cathodic Dip Painting), can significantly reduce the need for frequent servicing. Additionally, buyers should implement a proactive maintenance schedule that includes regular inspections and condition monitoring using remote connectivity solutions. Technologies like HiConnect can provide real-time data on crane performance, allowing for predictive maintenance rather than reactive repairs. This approach helps in minimizing downtime and ensures that cranes are always ready for operation, ultimately improving customer satisfaction.

Scenario 3: Limited Operator Training and Safety Concerns

The Problem: A construction company in South Africa is struggling with operator safety and efficiency due to limited training resources for their workforce. Many operators lack the necessary skills to maximize the use of knuckle boom cranes, leading to inefficient operations and increased risk of accidents on-site.

The Solution: To enhance operator training and safety, companies should invest in comprehensive training programs that cover both the technical aspects of operating knuckle boom cranes and safety protocols. Collaborating with manufacturers that offer certified training can ensure operators are well-equipped to handle the equipment safely and efficiently. Additionally, utilizing cranes with user-friendly control systems, such as the HiPro Control System, can facilitate easier learning curves for new operators. Implementing regular safety drills and refresher courses will also help maintain a high standard of operational safety. By prioritizing training and safety, companies can reduce accidents and improve overall productivity, ensuring a safer work environment.

Strategic Material Selection Guide for knuckle Boom Truck Crane

What Are the Key Materials Used in Knuckle Boom Truck Cranes?

Selecting the right materials for knuckle boom truck cranes is crucial for ensuring optimal performance, safety, and longevity. Here, we analyze four common materials used in the construction of these cranes, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Steel Perform as a Material for Knuckle Boom Truck Cranes?

Steel is a primary material used in knuckle boom truck cranes due to its exceptional strength and durability. It boasts high tensile strength, making it suitable for heavy lifting applications. Steel’s corrosion resistance can be enhanced through galvanization or coatings, allowing it to withstand harsh environmental conditions.

Pros: Steel offers excellent load-bearing capabilities and is readily available, making it a cost-effective choice for manufacturers. Its high durability ensures a long lifespan, even under heavy usage.

Cons: The primary disadvantage of steel is its weight, which can affect the overall payload of the crane. Additionally, the manufacturing process can be complex, requiring precise engineering to ensure safety and performance.

Impact on Application: Steel is compatible with a wide range of lifting tasks, including heavy construction and industrial applications. However, its weight may limit the crane’s maneuverability in tight spaces.

Considerations for International Buyers: Compliance with international standards such as ASTM or DIN is essential. Buyers in regions like Africa and South America should consider local steel quality and availability, as these can impact project timelines and costs.

What Role Does Aluminum Play in Knuckle Boom Truck Cranes?

Aluminum is increasingly being used in knuckle boom truck cranes due to its lightweight nature and resistance to corrosion. Its lower density compared to steel allows for increased payload capacity and better fuel efficiency in transport.

Pros: Aluminum provides a significant weight advantage, enhancing the crane’s maneuverability and operational efficiency. It also requires less maintenance due to its natural corrosion resistance.

Cons: While aluminum is strong, it generally has lower tensile strength compared to steel, which may limit its use in extremely heavy-duty applications. Additionally, aluminum can be more expensive than steel, impacting overall project budgets.

Impact on Application: Aluminum is particularly effective in applications requiring frequent transport or where weight is a critical factor, such as in urban environments or remote locations.

Considerations for International Buyers: Buyers should ensure that aluminum components meet relevant standards, such as JIS or ISO, particularly in regions with stringent import regulations.

How Does Composite Material Enhance Knuckle Boom Truck Cranes?

Composite materials, often a blend of resins and fibers, are gaining traction in the construction of knuckle boom truck cranes. They offer excellent strength-to-weight ratios and can be engineered for specific performance characteristics.

Pros: Composites are lightweight and can be designed to resist corrosion and fatigue, making them suitable for various environmental conditions. They also allow for innovative design possibilities.

Cons: The primary limitation of composites is their cost, which can be significantly higher than traditional materials. Additionally, their manufacturing processes can be complex and require specialized skills.

Impact on Application: Composites are ideal for applications where weight reduction is critical, such as in mobile cranes or cranes used in sensitive environments.

Considerations for International Buyers: Buyers should be aware of the certifications required for composite materials, as these may vary by region. Compliance with environmental regulations is also crucial, especially in Europe.

Why Is High-Strength Plastic Used in Knuckle Boom Truck Cranes?

High-strength plastics, such as polyethylene or nylon, are used in specific components of knuckle boom truck cranes, particularly in areas requiring flexibility and impact resistance. These materials can withstand various environmental conditions without degrading.

Pros: High-strength plastics are lightweight and resistant to chemicals and moisture, making them suitable for various applications. They also offer excellent impact resistance, which can enhance safety.

Cons: While durable, high-strength plastics may not support heavy loads as effectively as metals, limiting their use in critical structural components. Their long-term performance under extreme conditions can also be a concern.

Impact on Application: These materials are often used in non-structural components, such as covers or protective casings, where weight savings and corrosion resistance are beneficial.

Considerations for International Buyers: Buyers should ensure that high-strength plastics meet relevant industry standards and are suitable for the specific environmental conditions of their operational regions.

Summary of Material Selection for Knuckle Boom Truck Cranes

| Material | Typical Use Case for Knuckle Boom Truck Crane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components | High tensile strength | Heavy weight | Medium |

| Aluminum | Lightweight cranes for urban applications | Lightweight and corrosion resistant | Lower tensile strength | High |

| Composite | Specialized components for weight reduction | Excellent strength-to-weight ratio | High cost and complex manufacturing | High |

| High-Strength Plastic | Non-structural components | Lightweight and impact resistant | Limited load-bearing capacity | Medium |

This guide provides a comprehensive overview of materials used in knuckle boom truck cranes, enabling international B2B buyers to make informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for knuckle Boom Truck Crane

What Are the Key Manufacturing Stages for Knuckle Boom Truck Cranes?

The manufacturing process of knuckle boom truck cranes involves several critical stages, each designed to ensure that the final product meets the rigorous demands of diverse industries.

How Is Material Prepared for Knuckle Boom Truck Cranes?

The first stage in the manufacturing process is material preparation. High-quality steel is typically chosen for its strength and durability. Steel sheets are cut to size using precision cutting methods such as laser cutting or plasma cutting, ensuring accuracy in dimensions. Following this, materials undergo a thorough inspection for any defects. This initial quality check is crucial, as it sets the standard for the entire manufacturing process.

What Techniques Are Used in the Forming Process?

Once the materials are prepared, the forming process begins. This stage involves bending and shaping the steel into the desired components for the crane. Techniques such as hydraulic pressing, CNC machining, and welding are employed. Advanced robotic welding can be utilized for precision and consistency, reducing human error. The forming stage is vital for creating the boom, base, and other structural components, ensuring they can withstand heavy loads and dynamic movements.

How Does Assembly of Knuckle Boom Cranes Take Place?

The assembly phase involves bringing together all the formed components. This stage typically follows a systematic approach, where components are first assembled in smaller sections before being integrated into the complete crane structure. Skilled technicians use jigs and fixtures to ensure precise alignment and fit. Hydraulic systems, control mechanisms, and safety features are also integrated during assembly. A thorough inspection is conducted at this stage to ensure all components are correctly installed and functioning as intended.

What Finishing Processes Are Important for Knuckle Boom Cranes?

Finishing processes are essential for enhancing durability and aesthetics. Common techniques include surface treatment methods such as sandblasting, painting, and galvanizing. These processes protect the crane from corrosion and wear, particularly in harsh environmental conditions. Quality control at this stage ensures that the finish meets industry standards and customer expectations.

What Quality Assurance Practices Are Followed in Manufacturing Knuckle Boom Cranes?

Quality assurance is a critical aspect of the manufacturing process, ensuring that the cranes produced are safe, reliable, and efficient.

Which International Standards Govern Quality Assurance in Crane Manufacturing?

Manufacturers of knuckle boom truck cranes must adhere to various international standards, including ISO 9001, which outlines requirements for a quality management system. This certification demonstrates a commitment to quality and continuous improvement. Additionally, industry-specific certifications such as CE marking in Europe and API standards in certain markets are crucial. These certifications ensure that the cranes meet safety and performance criteria recognized globally.

What Are the Key Quality Control Checkpoints in Crane Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process. Incoming Quality Control (IQC) checks the quality of raw materials upon arrival. In-Process Quality Control (IPQC) monitors the manufacturing stages to catch any defects early, while Final Quality Control (FQC) involves comprehensive testing of the completed crane. Each of these checkpoints is crucial for maintaining product integrity and safety.

What Testing Methods Are Commonly Used for Knuckle Boom Cranes?

Common testing methods include load testing, where cranes are subjected to maximum load conditions to verify their performance. Non-destructive testing (NDT) techniques, such as ultrasonic or magnetic particle inspection, are used to identify internal flaws without damaging the components. Additionally, functional testing ensures that all hydraulic systems and controls operate correctly under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, verifying the quality control processes of potential suppliers is essential to ensure product reliability.

What Steps Can Buyers Take to Audit Suppliers for Quality Control?

Buyers can conduct on-site audits of suppliers to evaluate their manufacturing processes and quality control systems. During these audits, buyers should assess compliance with international standards and review documentation related to quality management practices. Additionally, requesting copies of quality certifications and reports on previous inspections can provide insights into the supplier’s commitment to quality.

How Important Are Third-Party Inspections in the Procurement Process?

Engaging third-party inspection services is another effective way for buyers to ensure quality. These independent entities can conduct thorough assessments of the manufacturing processes and final products, providing unbiased reports on compliance with industry standards. This is particularly important for buyers from regions such as Africa, South America, and the Middle East, where local regulations may differ from international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when sourcing knuckle boom truck cranes. Understanding the specific quality control nuances associated with various markets is crucial.

How Do Regional Regulations Affect Quality Control Standards?

Different regions may have varying regulations and standards that affect crane manufacturing and quality assurance. For example, buyers in Europe must ensure compliance with CE marking requirements, while those in the Middle East may focus on local safety standards. Buyers should familiarize themselves with these regulations to ensure that their suppliers meet all necessary criteria.

What Should Buyers Know About Warranty and After-Sales Support?

Lastly, understanding warranty terms and after-sales support is essential for B2B buyers. Manufacturers often provide warranties that cover defects in materials and workmanship. Buyers should inquire about the duration of the warranty, what it covers, and the manufacturer’s procedures for handling claims. Additionally, robust after-sales support can significantly enhance the value of the purchase, ensuring that any issues can be promptly addressed.

In conclusion, the manufacturing processes and quality assurance practices for knuckle boom truck cranes are complex and multifaceted. By understanding these processes, B2B buyers can make informed decisions, ensuring that they select high-quality, reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘knuckle Boom Truck Crane’

Introduction

This practical sourcing guide aims to assist international B2B buyers in the procurement of knuckle boom truck cranes. By following these steps, you will ensure that your investment meets your operational needs, adheres to industry standards, and aligns with your budgetary constraints.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first step in selecting the right knuckle boom crane for your operations. Consider factors such as lifting capacity, reach, and the types of loads you will be handling. Specific applications may require additional features, such as remote control capabilities or specialized attachments for enhanced functionality.

Step 2: Identify Your Application Needs

Understanding the specific applications for which the crane will be used is crucial. Different industries, such as construction, logistics, or waste management, may require different configurations. Assess the operational environment—urban vs. rural—and any potential constraints, such as space limitations or terrain types, to ensure the crane can perform effectively.

Step 3: Evaluate Potential Suppliers

Before making a purchase, it is essential to conduct a thorough evaluation of potential suppliers. Request company profiles, product catalogs, and customer testimonials. Look for suppliers with a proven track record in your region and those who can provide after-sales support, including training and maintenance services.

- Supplier Reputation: Research online reviews and industry forums to gauge customer satisfaction.

- Certifications: Verify that the supplier meets relevant industry standards and regulations.

Step 4: Check Warranty and Service Agreements

A solid warranty and service agreement can significantly impact the long-term performance of your knuckle boom crane. Review the warranty terms to ensure they cover essential components and offer sufficient duration. Additionally, inquire about service agreements that provide regular maintenance and support to minimize downtime.

Step 5: Assess Safety Features

Safety should be a top priority when selecting a knuckle boom crane. Evaluate the safety features offered by different models, such as overload protection systems, stability monitoring, and emergency shut-off controls. Compliance with local safety regulations is also vital to avoid potential liabilities.

- Operator Safety Training: Confirm that the supplier offers or recommends training programs for crane operators.

Step 6: Request Demonstrations and Trials

Whenever possible, request a demonstration of the crane in action. This allows you to assess its performance, ease of use, and suitability for your specific needs. If a trial period is available, take advantage of it to evaluate the crane’s reliability and operational efficiency in your working environment.

Step 7: Compare Total Cost of Ownership

Finally, consider the total cost of ownership (TCO) beyond the initial purchase price. Analyze ongoing operational costs, including fuel consumption, maintenance expenses, and potential downtime. A more expensive crane may offer better fuel efficiency or lower maintenance costs, ultimately providing better value in the long run.

By following these steps, you can make a well-informed decision when sourcing a knuckle boom truck crane that meets your operational needs and budget requirements.

Comprehensive Cost and Pricing Analysis for knuckle Boom Truck Crane Sourcing

What Are the Key Cost Components in Knuckle Boom Truck Crane Sourcing?

When considering the sourcing of knuckle boom truck cranes, understanding the underlying cost structure is essential for B2B buyers. The total cost typically includes several critical components:

-

Materials: The choice of materials significantly influences the overall cost. High-quality steel and advanced hydraulic components, while more expensive, offer better durability and performance, which can lead to lower maintenance costs over time.

-

Labor: Skilled labor is necessary for the assembly and installation of knuckle boom cranes. Labor costs can vary widely depending on the region and local wage standards. In regions with high labor costs, such as Europe, this can be a significant factor in the total price.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, rent, and salaries for administrative staff. Efficient manufacturing processes can help minimize these overhead costs, potentially leading to more competitive pricing.

-

Tooling: The initial investment in tooling and machinery for production can be substantial. Suppliers that produce a high volume of cranes may spread these costs over more units, reducing the per-unit price.

-

Quality Control (QC): Ensuring that cranes meet safety and performance standards requires a robust QC process. While this adds to the cost, it is crucial for ensuring the reliability and safety of the cranes.

-

Logistics: The logistics of transporting knuckle boom cranes to the buyer’s location can significantly impact costs. This includes freight charges, customs duties, and insurance, especially when dealing with international shipments.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on market demand, competition, and the supplier’s positioning within the industry.

What Influences Pricing in Knuckle Boom Crane Procurement?

Several factors can influence the pricing of knuckle boom cranes, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger quantities often results in lower per-unit costs. Negotiating MOQs can help buyers secure better pricing.

-

Specifications and Customization: Custom features or specific requirements can increase costs. Buyers should clearly define their needs to avoid unnecessary expenses.

-

Materials and Quality Certifications: Cranes made from premium materials or those that meet international quality certifications may command higher prices. However, these investments often lead to long-term savings through reduced maintenance and increased operational efficiency.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers with a strong track record may charge more due to their perceived quality and service levels.

-

Incoterms: Understanding Incoterms is crucial for international transactions. These terms define the responsibilities of buyers and sellers in shipping, which can affect overall costs, particularly in terms of logistics and customs handling.

How Can Buyers Negotiate and Optimize Costs for Knuckle Boom Cranes?

To effectively manage costs and maximize value when sourcing knuckle boom cranes, buyers should consider the following strategies:

-

Negotiate Terms: Engaging in open discussions about pricing, payment terms, and delivery schedules can lead to more favorable agreements. Building a relationship with suppliers may also yield better deals.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operation, and eventual resale value. A crane that costs more upfront but offers lower operating costs may be a better long-term investment.

-

Understand Pricing Nuances for International Buyers: Factors such as currency fluctuations, import duties, and local market conditions can affect pricing. Buyers should factor these into their budgeting and negotiation strategies.

Conclusion: What Should Buyers Keep in Mind?

While indicative prices can provide a starting point for negotiations, it is essential to remember that final costs will vary based on specific requirements and market conditions. Buyers should conduct thorough research and engage with multiple suppliers to ensure they receive competitive pricing and high-quality products tailored to their needs.

Alternatives Analysis: Comparing knuckle Boom Truck Crane With Other Solutions

Understanding Alternatives to Knuckle Boom Truck Cranes

In the quest for efficient lifting and material handling solutions, businesses often explore various technologies to meet their operational needs. While knuckle boom truck cranes offer unique advantages, understanding their alternatives can help buyers make informed decisions. This analysis compares knuckle boom truck cranes with two viable alternatives: telescopic cranes and forklift trucks.

Comparison Table

| Comparison Aspect | Knuckle Boom Truck Crane | Telescopic Crane | Forklift Truck |

|---|---|---|---|

| Performance | High versatility, capable of lifting heavy loads at various angles | Excellent for vertical lifting, limited horizontal reach | Efficient for horizontal material handling and stacking |

| Cost | Generally higher initial investment, but cost-effective over time due to versatility | Moderate to high initial cost, with higher operating costs due to maintenance | Lower initial cost, but limited in application scope |

| Ease of Implementation | Requires specialized training for operators | Requires training and certification for operators | Easier to implement with basic training |

| Maintenance | Moderate maintenance needs; parts readily available | Higher maintenance due to complex hydraulic systems | Low maintenance requirements, straightforward repair |

| Best Use Case | Ideal for construction, loading, and unloading in tight spaces | Best for construction sites needing vertical lifts | Suited for warehouses and manufacturing environments |

Detailed Breakdown of Alternatives

Telescopic Cranes

Telescopic cranes are designed for vertical lifting, extending upward with a straight boom. They are particularly effective in construction and heavy lifting scenarios where height is a priority. The main advantage of telescopic cranes is their ability to reach significant heights with a stable base. However, their horizontal reach is limited compared to knuckle boom cranes, which can maneuver in tight spaces. Additionally, telescopic cranes may incur higher operating costs due to maintenance of their hydraulic systems.

Forklift Trucks

Forklift trucks are widely used for horizontal material handling, especially in warehouses and industrial settings. They excel in moving goods over short distances and stacking materials efficiently. The cost of acquiring a forklift is generally lower than that of a knuckle boom crane, making it an attractive option for businesses with budget constraints. However, forklifts lack the versatility of knuckle boom cranes, as they cannot lift loads vertically to the same extent or reach into confined areas. Their operational scope is thus limited compared to the multifunctional capabilities of knuckle boom cranes.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right lifting solution, B2B buyers must consider their specific operational requirements, including the types of loads being handled, the work environment, and budget constraints. Knuckle boom truck cranes offer unparalleled versatility and performance for complex lifting tasks, especially in construction or tight spaces. In contrast, telescopic cranes may be more suitable for projects requiring vertical lifting with less horizontal maneuverability, while forklifts serve well for horizontal material movement in confined areas. Assessing these factors will enable buyers to make a strategic choice that aligns with their business objectives and enhances operational efficiency.

Essential Technical Properties and Trade Terminology for knuckle Boom Truck Crane

What Are the Key Technical Properties of Knuckle Boom Truck Cranes?

Knuckle boom truck cranes are sophisticated pieces of machinery designed for various lifting tasks. Understanding their critical specifications can help B2B buyers make informed decisions. Here are some essential technical properties:

-

Lifting Capacity

The lifting capacity defines the maximum weight a crane can safely lift. This specification is crucial for B2B buyers, as it directly impacts the types of loads that can be handled. Knowing the lifting capacity ensures that businesses can select a crane that meets their operational requirements without risking safety or efficiency. -

Boom Length and Reach

Boom length determines how far the crane can extend and reach out to lift loads. A longer boom allows for greater operational versatility, especially in urban settings or sites with limited space. Buyers should assess their typical project requirements to choose a boom length that accommodates both standard and specialized tasks. -

Weight and Payload

The overall weight of the knuckle boom crane affects the vehicle’s payload capacity. Buyers must consider the balance between the crane’s weight and the truck’s payload capabilities to maximize efficiency without exceeding legal weight limits. This is particularly important for international buyers in regions with strict transportation regulations. -

Hydraulic System Pressure

The hydraulic system’s pressure rating indicates the force exerted by the crane when lifting loads. Higher hydraulic pressure can lead to improved lifting performance and speed, making it a vital specification for businesses needing quick turnaround times. Understanding this property helps buyers evaluate the crane’s operational efficiency. -

Material Grade and Durability

The construction materials used in knuckle boom cranes affect their durability and resistance to wear and tear. High-grade steel and advanced alloys are common in high-performance models, ensuring longevity and reducing maintenance costs. Buyers should prioritize cranes that offer superior material quality, especially for heavy-duty applications. -

Control Systems and Safety Features

Modern knuckle boom cranes often come equipped with advanced control systems that enhance operational safety and precision. Features like overload protection, remote controls, and stability monitoring systems are critical for preventing accidents. B2B buyers should look for cranes with robust safety features to ensure compliance with international safety standards.

What Are Common Trade Terms Related to Knuckle Boom Truck Cranes?

Understanding trade terminology is essential for effective negotiations and transactions in the B2B marketplace. Here are some common terms relevant to knuckle boom truck cranes:

-

OEM (Original Equipment Manufacturer)

OEM refers to the company that produces the original product components. In the context of knuckle boom cranes, working with reputable OEMs ensures that buyers receive high-quality equipment and parts, which can affect performance and reliability. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers who may need to meet specific order quantities to negotiate better pricing or ensure a consistent supply of parts for maintenance and repairs. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. For buyers of knuckle boom cranes, submitting RFQs can help gather competitive bids, allowing for informed decision-making based on cost and value. -

Incoterms (International Commercial Terms)

Incoterms are international trade terms that define the responsibilities of buyers and sellers in the shipping process. Understanding these terms is vital for B2B buyers, especially those involved in international trade, as they affect shipping costs, risks, and insurance obligations. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. For businesses that rely on knuckle boom cranes for their operations, understanding lead times is crucial for project planning and avoiding delays. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the performance and lifespan of the crane. Knowing the warranty terms is essential for B2B buyers to ensure they are protected against defects and can plan for potential maintenance costs.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed purchasing decisions, ensuring they select the right knuckle boom truck crane to meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the knuckle Boom Truck Crane Sector

What Are the Key Market Trends Influencing the Knuckle Boom Truck Crane Sector?

The knuckle boom truck crane market is experiencing significant growth driven by several global factors. Increased urbanization and infrastructure development in regions such as Africa, South America, and the Middle East are creating a surge in demand for versatile and efficient lifting solutions. International B2B buyers are particularly focused on cranes that offer not only robust performance but also advanced technology, such as remote connectivity and automated control systems, which optimize operational efficiency and safety.

Emerging trends in sourcing emphasize the importance of lightweight yet durable materials, which enhance the payload capacity and maneuverability of knuckle boom cranes. Buyers are increasingly interested in models that provide customizable features and modular designs, allowing for tailored solutions that meet specific industry requirements. For instance, the integration of advanced hydraulic systems and oscillation suppression technologies is becoming a standard expectation, offering improved stability and precision in operations.

Moreover, the market is witnessing a shift towards sustainability, with many manufacturers developing eco-friendly models that utilize less energy and minimize environmental impact. This trend is particularly relevant for international buyers who prioritize corporate social responsibility and sustainable practices in their sourcing strategies.

How Are Sustainability and Ethical Sourcing Shaping the Knuckle Boom Crane Industry?

Sustainability is a critical consideration for B2B buyers in the knuckle boom crane sector. The environmental impact of manufacturing and operating heavy machinery is under scrutiny, prompting companies to adopt greener practices. Manufacturers are now focusing on eco-friendly materials and processes, including the use of sustainable steel and low-emission hydraulic fluids, which reduce the carbon footprint associated with crane production and operation.

Ethical sourcing is also gaining traction, as buyers seek to ensure that their supply chains are responsible and transparent. This includes sourcing components from manufacturers that adhere to strict labor and environmental standards. Certifications such as ISO 14001 (Environmental Management) and ISO 45001 (Occupational Health and Safety) are increasingly important for buyers looking to partner with suppliers who prioritize sustainability and ethical practices.

Moreover, the demand for “green” certifications and materials is shaping purchasing decisions, with buyers actively seeking suppliers that can demonstrate their commitment to environmental stewardship. This trend not only helps companies meet regulatory requirements but also enhances their brand reputation among environmentally conscious consumers and stakeholders.

What Is the Historical Context Behind the Development of Knuckle Boom Cranes?

The knuckle boom crane has evolved significantly since its inception in the mid-20th century. Initially developed to provide a more flexible and compact lifting solution compared to traditional cranes, these articulated cranes quickly gained popularity in various industries, from construction to logistics. Their design, which allows for enhanced maneuverability and precision, has made them indispensable in urban settings where space is often limited.

Over the years, advancements in hydraulic technology and materials science have transformed knuckle boom cranes into highly efficient and reliable machines. Today, they are equipped with sophisticated control systems and safety features that enhance operator safety and performance, reflecting the industry’s response to evolving market demands and technological innovations. This historical context provides valuable insights for B2B buyers, illustrating the importance of selecting cranes that are not only technologically advanced but also backed by a legacy of reliability and performance.

Frequently Asked Questions (FAQs) for B2B Buyers of knuckle Boom Truck Crane

-

How do I choose the right knuckle boom crane for my business needs?

Selecting the right knuckle boom crane involves assessing your specific operational requirements, such as load capacity, reach, and working environment. Consider the types of materials you’ll be handling and the frequency of use. It’s also important to evaluate the terrain and accessibility of job sites. Consulting with suppliers to explore different models and configurations can provide valuable insights. Additionally, review the technology and safety features offered, as these can significantly enhance operational efficiency and safety. -

What are the key features to look for in a knuckle boom crane?

When sourcing a knuckle boom crane, prioritize features such as load capacity, reach, and operational flexibility. Look for advanced safety systems like overload protection and stability controls, which are critical for safe operations. Consider cranes equipped with remote control systems for enhanced maneuverability and reduced operator strain. Additionally, features like low maintenance requirements and corrosion-resistant finishes can save time and costs in the long run. Ensure the model aligns with the specific applications within your industry, whether it’s construction, logistics, or waste management. -

What are the typical payment terms for purchasing knuckle boom cranes internationally?

Payment terms for international purchases often vary by supplier and region. Common arrangements include upfront deposits ranging from 20% to 50%, with the balance due upon delivery or within a specified period post-delivery. It’s crucial to clarify these terms before finalizing the order. Some suppliers may offer financing options or payment through letters of credit, providing additional security for both parties. Always review the payment terms in the context of international trade regulations to ensure compliance and avoid potential complications. -

How do I vet suppliers when purchasing a knuckle boom crane?

Vetting suppliers is essential for ensuring quality and reliability. Start by researching their reputation in the industry; look for reviews, testimonials, and case studies. Verify their certifications and compliance with international safety standards. It’s also beneficial to request references from other clients. Consider visiting their facilities if possible, or at least conduct a video conference to assess their operations. Finally, evaluate their after-sales support, including service agreements, spare parts availability, and warranty terms, which are crucial for ongoing operations. -

What customization options are available for knuckle boom cranes?

Many manufacturers offer customization options to tailor knuckle boom cranes to your specific needs. Customizations may include modifications to boom length, lifting capacity, and attachment compatibility. You can also request specialized control systems or safety features based on your operational requirements. Discussing your unique applications with the supplier can lead to innovative solutions that enhance productivity. Ensure that any modifications comply with safety regulations and maintain the crane’s structural integrity. -

What is the minimum order quantity (MOQ) for knuckle boom cranes?

The minimum order quantity (MOQ) for knuckle boom cranes can vary significantly between suppliers. While some manufacturers may accommodate single-unit orders, others might require a minimum of two or more to optimize production and shipping costs. Discussing your needs with potential suppliers can help negotiate favorable terms. Keep in mind that ordering in bulk may provide cost advantages and faster delivery times, making it an attractive option for larger projects. -

What are the logistics considerations for importing knuckle boom cranes?

Importing knuckle boom cranes involves several logistics considerations, including shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder familiar with heavy machinery to navigate the complexities of international shipping. Ensure all documentation, such as bills of lading and customs declarations, is accurate and complete to avoid delays. Additionally, factor in the cost of insurance and duties, which can significantly impact the overall expenditure. Planning ahead for transportation logistics will facilitate a smoother import process. -

How can I ensure the quality of knuckle boom cranes before purchase?

To ensure the quality of knuckle boom cranes, request detailed specifications and performance data from suppliers. Conduct a thorough inspection of the cranes, either in person or via video, to assess build quality and operational readiness. If possible, arrange for a demonstration to see the crane in action. Reviewing quality assurance processes, such as testing protocols and certifications, is also essential. Finally, consider third-party inspections to provide an unbiased assessment of the crane’s condition and performance before finalizing your purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 Knuckle Boom Truck Crane Manufacturers & Suppliers List

1. Hiab – Knuckle Boom Cranes

Domain: hiab.com

Registered: 1996 (29 years)

Introduction: Knuckle Boom Cranes are designed for superior performance and efficiency, utilizing industry-leading technology to maximize safety and handling capabilities. They are available in various models including T-Cranes (light duty), Medium Duty Knuckle Boom Cranes, K-Cranes (for drywall handling), Heavy Range Knuckle Boom Cranes, and Super Heavy Knuckle Boom Cranes. Key features include HiConnect Remot…

2. PALFINGER – Knuckle Boom Cranes

Domain: palfinger.com

Registered: 1997 (28 years)

Introduction: Knuckle Boom Cranes are PALFINGER’s core product, known for durability and a comprehensive range of models covering various working capacities. Key features include:

– Fast, efficient, precise, and lightweight design.

– Equipped with market-leading safety systems.

– KTL Protection for superior surface coating and durability.

– Turntable Bearing allows unrestricted radius of action with a high-qual…

3. Palfinger – Knuckleboom Cranes

Domain: knuckleboomtrader.com

Registered: 2015 (10 years)

Introduction: New and Used Knuckleboom Cranes and Trucks for Sale Listings include various categories such as Building Supply, Electric Utilities, Marine Applications, Oil Fields, and Tree Removal. Key brands include Palfinger, Hiab, and Mecanil. Listings feature specifications like Max lift capacity, Max horizontal outreach, and Max vertical outreach. Examples of products include:

1. PM 100028SP knuckle boom …

4. Custom Truck – Knuckle Boom Trucks

Domain: customtruck.com

Registered: 1996 (29 years)

Introduction: Knuckle Boom Trucks, also known as picker cranes, articulating cranes, and loader cranes, feature a main boom and an outer boom that allows for articulation, making them lighter and more versatile than traditional boom cranes. They can lift capacities ranging from 1,740 lbs to 38,185 lbs and are suitable for various applications in industries such as forestry, roofing, construction, and transporta…

5. PM – Boom Truck Packages

Domain: bikboomtrucks.com

Registered: 1998 (27 years)

Introduction: PM Boom Truck Packages include various models such as: 1. PM POWERLIFT PL-74 R.M. – New Freightliner 114SD, 460 HP, 24.5′ Steel Deck 2. PM 6023 Knuckle Boom – Dodge 5500 Single Axle Chassis, 6 Speed Automatic, 75,000 miles 3. PM 8023 Knuckle Boom – Dodge 5500 Single Axle Chassis, 325 HP Cummins Turbo Diesel Engine 4. PM 11023 – 30’ Side Reach, New Freightliner M2-106 S/A, 20’ Steel Deck, Non-CDL 5…

6. JOMAC – Knuckle Boom Cranes

Domain: jomacltd.com

Registered: 2000 (25 years)

Introduction: JOMAC builds knuckle boom cranes unmatched in quality, longevity, and durability. Manufactured in the USA using 100% American-made parts and labor. Custom builds available for unique customer requirements. Features include a worm drive rotation for a smaller footprint, allowing for versatile mounting options. Comes with a 10-Year Return to Factory Warranty on the structure. Operates with a low-pre…

7. HMF – Knuckle Boom Loader Cranes

Domain: hmfcranes.com

Registered: 2006 (19 years)

Introduction: Knuckle Boom Loader Cranes – Truck-mounted; Lifting capacity: 3 – 14 tm, 15 – 31 tm, 32 – 59 tm, 60 – 95 tm; Crane types: Knuckle boom cranes (K), Short knuckle boom cranes (KS), Long boom cranes (L), Recycling cranes (S), Telescopic cranes (T), Z-fold grab cranes (Z), Wallboard cranes (WB); Equipment: Subframes, Front stabilizers, Separate traverses for various crane capacities, Safety equipment …

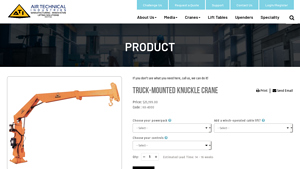

8. Air Technical – Truck-Mounted Knuckle Crane

Domain: shop.airtechnical.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Truck-Mounted Knuckle Crane”,”model_number”: “KK-4000″,”price”: “$25,199.00″,”capacity_options”: [{“capacity”: “4000 lbs”,”reach”: “72 inches”,”max_lift_height”: “72 inches”},{“capacity”: “2000 lbs”,”reach”: “120 inches”,”max_lift_height”: “168 inches”},{“capacity”: “1000 lbs”,”reach”: “160 inches”,”max_lift_height”: “204 inches”}],”powerpack_options”: [{“type”: “Standard manual …

9. QMC – Telescoping Boom Cranes

Domain: qmccranes.com

Registered: 1998 (27 years)

Introduction: Telescoping Boom Cranes: Designed for precast concrete efficiency, offering advantages over knuckleboom cranes. Key benefits include lighter weight for increased payload capacity, improved maneuverability on uneven surfaces, and higher reliability due to simpler design. QMC cranes are manufactured in the USA using American steel, emphasizing customization through Modular Design Theory for specific…

10. Altec – Truck Mounted Cranes

Domain: altec.com

Registered: 1996 (29 years)

Introduction: Altec offers truck mounted cranes including telescoping and articulating (knuckle boom) cranes. Telescopic boom truck cranes have sheave heights up to 215 feet (65.5 m) and load ratings up to 65 tons (58.9 t), suitable for electric line maintenance, construction, transmission, distribution, and tree trimming. Articulating cranes are lightweight and maneuverable, with lifting capacities up to 300 t…

Strategic Sourcing Conclusion and Outlook for knuckle Boom Truck Crane

In the evolving landscape of heavy equipment, strategic sourcing of knuckle boom truck cranes is critical for businesses aiming to enhance operational efficiency and safety. These versatile cranes, equipped with advanced technology and robust design, offer solutions tailored to diverse industry needs—from construction to logistics. B2B buyers can leverage the unique advantages of knuckle boom cranes, such as their compact size, articulated design, and high lifting capabilities, to optimize their workflows and reduce downtime.

As international markets, particularly in Africa, South America, the Middle East, and Europe, continue to expand, the importance of selecting the right crane for specific applications cannot be overstated. Buyers should prioritize suppliers that provide comprehensive support, including maintenance and training, to ensure the longevity and performance of their equipment.

Looking ahead, the demand for innovative, efficient, and reliable knuckle boom cranes will only increase. Now is the time for businesses to invest in the right equipment and forge strong partnerships with leading manufacturers. Equip your operations with the best in technology and service—reach out today to explore your options and position your business for success in the competitive global market.