Introduction: Navigating the Global Market for camioneta electrica

In today’s rapidly evolving automotive landscape, sourcing the right camioneta electrica can pose significant challenges for international B2B buyers. With a growing emphasis on sustainability and efficiency, businesses must navigate a complex market characterized by diverse vehicle types, varying applications, and an array of suppliers. This guide is designed to demystify the global market for electric trucks, offering insights into the latest models, their specifications, and suitability for various industries.

From understanding the distinct features of electric pickups like the Chevy Silverado EV and Ram 1500 REV to evaluating their towing capacities and battery life, our comprehensive resource addresses critical aspects of the purchasing process. We delve into supplier vetting, cost considerations, and the implications of international regulations, ensuring that buyers are equipped with the knowledge necessary to make informed decisions.

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—this guide serves as an essential tool to navigate the complexities of the electric truck sector. By leveraging the insights provided, businesses can confidently select vehicles that align with their operational needs while contributing to a more sustainable future. Whether you are looking to enhance your fleet or explore new opportunities in the electric vehicle market, this guide empowers you to make strategic purchasing choices that drive success.

Understanding camioneta electrica Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full-Size Electric Pickup | High towing capacity, long range, advanced technology | Logistics, Construction, Agriculture | Pros: High load capacity, versatile for various tasks. Cons: Higher upfront cost compared to traditional trucks. |

| Mid-Size Electric Pickup | Balanced size with good range and efficiency | Urban Delivery, Small Business | Pros: Easier to maneuver, better fuel efficiency. Cons: Limited towing capacity compared to full-size models. |

| Heavy-Duty Electric Pickup | Exceptional towing and payload capabilities, robust design | Heavy Hauling, Fleet Operations | Pros: Ideal for demanding tasks, durable construction. Cons: Heavier, potentially lower range. |

| Compact Electric Pickup | Smaller footprint, economical, suitable for city driving | Last-Mile Delivery, Retail | Pros: Cost-effective, environmentally friendly. Cons: Limited cargo space and capabilities. |

| Off-Road Electric Pickup | Designed for rugged terrain, enhanced suspension and durability | Adventure Tours, Utility Work | Pros: Versatile in challenging environments, high performance. Cons: May sacrifice range for off-road capabilities. |

What are the Characteristics of Full-Size Electric Pickups?

Full-size electric pickups, such as the Chevy Silverado EV and Ram 1500 REV, are designed to meet the needs of businesses requiring significant towing and payload capabilities. With features like a maximum towing capacity of up to 14,000 lbs and ranges exceeding 350 miles, these trucks are ideal for logistics, construction, and agriculture. B2B buyers should consider their operational demands, as the higher upfront cost is offset by potential savings in fuel and maintenance.

How Do Mid-Size Electric Pickups Fit into Urban Applications?

Mid-size electric pickups offer a balance between size and efficiency, making them suitable for urban delivery and small business operations. They typically provide a range of around 350 miles, with a towing capacity sufficient for light loads. Their compact design allows for easier maneuverability in congested areas. B2B buyers should weigh their need for cargo capacity against the advantages of reduced operational costs and improved fuel efficiency.

Why Choose Heavy-Duty Electric Pickups for Fleet Operations?

Heavy-duty electric pickups are built for demanding applications, boasting superior towing and payload capabilities. These vehicles are ideal for businesses involved in heavy hauling and fleet operations, where durability and performance are critical. While they may have a heavier weight leading to reduced range, their robust design ensures they can handle tough jobs. Buyers should assess their specific use cases to justify the investment in these powerful vehicles.

What Advantages Do Compact Electric Pickups Offer for Last-Mile Delivery?

Compact electric pickups are perfect for last-mile delivery services, providing an economical and environmentally friendly solution. They feature a smaller footprint, which is advantageous for urban driving and parking. However, their limited cargo space may restrict their use for larger deliveries. B2B buyers should consider their delivery volume and city infrastructure to determine if this type suits their needs.

How Do Off-Road Electric Pickups Serve Utility Work?

Off-road electric pickups are designed for rugged environments, equipped with enhanced suspension and durability features. They are suitable for adventure tours and utility work in challenging terrains. While they may sacrifice some range for off-road capabilities, their performance in adverse conditions is unmatched. Businesses operating in remote areas or requiring versatile vehicles should evaluate the potential ROI of investing in off-road models.

Key Industrial Applications of camioneta electrica

| Industry/Sector | Specific Application of camioneta electrica | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | On-site transportation of tools and materials | Reduces fuel costs and emissions; increases efficiency | Battery range, load capacity, charging infrastructure |

| Logistics and Delivery | Last-mile delivery services | Enhances sustainability image; lowers operating costs | Vehicle range, cargo space, reliability |

| Agriculture | Farm maintenance and transportation | Increases operational efficiency; reduces carbon footprint | Terrain capability, battery life, towing capacity |

| Utilities and Services | Emergency response and maintenance operations | Ensures rapid response; reduces downtime | Reliability, service network, vehicle durability |

| Mining and Natural Resources | Transporting personnel and equipment | Lowers operational costs; improves safety measures | Off-road capability, payload capacity, battery life |

How is ‘camioneta electrica’ Used in Construction?

In the construction industry, electric trucks serve as vital transportation for tools and materials to and from job sites. These vehicles help address the industry’s growing need for sustainable practices by significantly reducing fuel consumption and emissions. For B2B buyers, key considerations include the vehicle’s battery range to ensure it can cover long distances on-site, load capacity for transporting heavy materials, and the availability of charging infrastructure in remote locations.

What are the Benefits of Using ‘camioneta electrica’ in Logistics and Delivery?

Electric trucks are increasingly employed in last-mile delivery services, providing a greener alternative to traditional fossil-fuel vehicles. They enhance a company’s sustainability image while lowering operating costs associated with fuel and maintenance. International buyers should focus on the vehicle’s cargo space, range, and reliability to meet the demands of urban logistics and ensure timely deliveries.

How Can Agriculture Benefit from ‘camioneta electrica’?

In agriculture, electric trucks are utilized for farm maintenance and transportation of goods. They help improve operational efficiency by allowing farmers to manage their fields and equipment with lower running costs and reduced environmental impact. Buyers in this sector must consider terrain capability, battery life for extended use, and towing capacity to handle agricultural equipment.

Why is ‘camioneta electrica’ Important for Utilities and Services?

Electric trucks play a crucial role in emergency response and maintenance operations within utility sectors. Their ability to operate quietly and with minimal emissions makes them ideal for urban environments, ensuring rapid response without disturbing local communities. Buyers need to assess the vehicle’s reliability, service network availability, and overall durability to guarantee efficient operations in critical situations.

What Role Does ‘camioneta electrica’ Play in Mining and Natural Resources?

In the mining and natural resources sector, electric trucks are used to transport personnel and equipment across challenging terrains. They contribute to lowering operational costs and enhancing safety measures by reducing noise and air pollution. Key sourcing considerations for international buyers include off-road capability to navigate rugged landscapes, payload capacity for transporting heavy loads, and battery life to support extended operations in remote locations.

3 Common User Pain Points for ‘camioneta electrica’ & Their Solutions

Scenario 1: Range Anxiety for Long-Distance Operations

The Problem:

One of the most significant challenges B2B buyers face when considering a ‘camioneta electrica’ (electric truck) is range anxiety, particularly for businesses that rely on long-distance logistics or transportation. For instance, a logistics company in South America might need to transport goods across vast distances, where charging infrastructure may be sparse. The fear of running out of battery power in remote areas can deter businesses from adopting electric trucks, leading to potential disruptions in operations and increased costs.

The Solution:

To mitigate range anxiety, it’s essential for businesses to thoroughly research and select electric trucks with robust battery capacities and extended ranges. Models like the Chevy Silverado EV, which offers up to 493 miles of range, can be particularly appealing. Additionally, companies should invest in route planning software that incorporates real-time charging station locations along with their delivery routes. This proactive approach allows businesses to identify optimal charging points ahead of time, ensuring that drivers can recharge without affecting delivery schedules. Furthermore, establishing partnerships with charging networks can provide exclusive access to fast charging stations, enhancing operational efficiency.

Scenario 2: Infrastructure Limitations in Emerging Markets

The Problem:

In regions like Africa and parts of the Middle East, the lack of sufficient charging infrastructure presents a significant barrier to the adoption of electric trucks. Companies may find themselves investing in ‘camioneta electrica’ only to discover that the necessary charging stations are either nonexistent or too far apart. This limitation can lead to operational inefficiencies, increased downtime, and higher operational costs as businesses struggle to maintain their fleets.

The Solution:

To address infrastructure limitations, businesses should consider investing in their own charging solutions. Installing dedicated charging stations at their facilities can provide a reliable energy source for their electric fleets, ensuring that vehicles are charged overnight or during downtime. Additionally, companies can collaborate with local governments or private sector partners to advocate for the expansion of public charging networks. By being part of the conversation, businesses can help shape the infrastructure landscape, ultimately benefiting the entire industry and encouraging wider adoption of electric trucks. Moreover, companies can explore mobile charging solutions or portable charging units that can be deployed to remote work sites, further enhancing operational flexibility.

Scenario 3: Total Cost of Ownership (TCO) Concerns

The Problem:

B2B buyers often grapple with the total cost of ownership (TCO) when evaluating ‘camioneta electrica’. Initial purchase prices can be high, and there may be concerns about the longevity of electric truck batteries, maintenance costs, and the potential need for replacement. For example, a construction firm in Europe may hesitate to switch from traditional diesel trucks to electric options due to uncertainties about long-term expenses.

The Solution:

To alleviate TCO concerns, businesses should conduct a comprehensive cost-benefit analysis that factors in not only the purchase price but also the long-term savings associated with electric trucks. These savings can include reduced fuel costs, lower maintenance expenses, and potential tax incentives or rebates for electric vehicle purchases. Engaging with manufacturers to understand warranty options and battery longevity can provide reassurance about the investment. Furthermore, companies should consider a phased approach to electrification, starting with a small fleet of electric trucks and gradually expanding as they gain confidence in their performance and cost-effectiveness. This strategy allows businesses to minimize risk while evaluating the operational benefits of electric trucks over time.

Strategic Material Selection Guide for camioneta electrica

What Are the Key Materials Used in Electric Pickup Trucks?

In the development of electric pickup trucks, the selection of materials plays a crucial role in determining performance, durability, and overall vehicle efficiency. Here, we analyze four common materials used in the construction of electric trucks, focusing on their properties, advantages and disadvantages, and considerations for international B2B buyers.

How Does Aluminum Benefit Electric Pickup Trucks?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a high strength-to-weight ratio. It can withstand temperature variations and is suitable for various manufacturing processes.

Pros & Cons: The primary advantage of aluminum is its weight, which contributes to improved energy efficiency and extended battery range. However, it can be more expensive than steel and may require specialized manufacturing techniques, which can complicate production processes.

Impact on Application: Aluminum is ideal for components that require both strength and lightness, such as body panels and frames. Its corrosion resistance makes it suitable for vehicles operating in diverse climates, including humid and coastal environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM B209 for aluminum sheet and plate. Countries like Germany and Nigeria may have specific regulations regarding material sourcing and recycling.

What Role Does Steel Play in Electric Pickup Truck Construction?

Key Properties: Steel is known for its high tensile strength and durability. It can endure high-pressure environments and is less susceptible to deformation under stress.

Pros & Cons: Steel is generally more cost-effective than aluminum, making it a popular choice for structural components. However, its weight can negatively impact battery efficiency and range. Advanced high-strength steel (AHSS) can mitigate some weight issues but may increase manufacturing complexity.

Impact on Application: Steel is often used in the chassis and structural supports of electric trucks, providing the necessary strength for towing and payload capacity. Its ability to absorb impact makes it suitable for safety-critical components.

Considerations for International Buyers: Compliance with standards like DIN EN 10025 for structural steel is essential. Buyers in regions like South America may also consider the availability of local steel production to reduce costs.

Why Is Carbon Fiber Gaining Popularity in Electric Trucks?

Key Properties: Carbon fiber is lightweight, strong, and has excellent fatigue resistance. It can withstand high temperatures and has low thermal expansion.

Pros & Cons: The primary advantage of carbon fiber is its weight-saving potential, significantly enhancing vehicle performance and efficiency. However, it is considerably more expensive than metals and requires specialized manufacturing techniques, which can limit its use in mass production.

Impact on Application: Carbon fiber is particularly beneficial for components where weight reduction is critical, such as body panels and interior structures. Its strength allows for thinner designs without compromising safety.

Considerations for International Buyers: Buyers should be aware of the specific manufacturing standards for carbon fiber composites, such as ASTM D3039. The high cost may be a barrier for markets in Africa, where budget constraints are more prevalent.

How Does Plastic Composite Material Contribute to Electric Pickup Trucks?

Key Properties: Plastic composites are lightweight, corrosion-resistant, and can be molded into complex shapes. They offer good thermal and electrical insulation.

Pros & Cons: The advantages of plastic composites include lower weight and cost compared to metals, as well as design flexibility. However, they may not provide the same level of structural integrity as metals and can be less durable in extreme conditions.

Impact on Application: Plastic composites are often used for non-structural components, such as interior panels, bumpers, and storage areas. Their resistance to corrosion makes them suitable for various environmental conditions.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile properties is essential. Buyers should also consider the environmental impact of plastic materials, especially in regions with strict sustainability regulations.

Summary of Material Selection for Electric Pickup Trucks

| Material | Typical Use Case for camioneta electrica | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Body panels, frames | Lightweight, corrosion-resistant | Higher cost, complex manufacturing | High |

| Steel | Chassis, structural supports | Cost-effective, strong | Heavier, may complicate efficiency | Medium |

| Carbon Fiber | Body panels, interior structures | Extremely lightweight, strong | Very high cost, specialized mfg | High |

| Plastic Composite | Interior panels, bumpers | Lightweight, design flexibility | Less durable, lower structural integrity | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling them to make informed decisions tailored to their specific market needs and regulatory environments.

In-depth Look: Manufacturing Processes and Quality Assurance for camioneta electrica

What Are the Key Manufacturing Processes for Electric Trucks?

The manufacturing of electric trucks, such as camionetas eléctricas, involves a series of well-defined stages designed to ensure efficiency, quality, and sustainability. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Electric Truck Production?

Material preparation begins with sourcing high-quality components that meet the specific requirements for electric vehicles. This includes lightweight materials such as aluminum and advanced composites, which are crucial for enhancing range and performance. Suppliers must adhere to strict standards to ensure that materials are not only durable but also sustainable, reflecting the growing demand for environmentally friendly practices.

During this phase, materials undergo rigorous testing to verify their properties. This can involve tensile strength tests, fatigue tests, and thermal analysis to ensure they meet the necessary specifications before being used in production.

What Techniques Are Employed in the Forming Stage?

The forming stage encompasses various techniques tailored to the specific design of the camioneta eléctrica. Advanced manufacturing processes like stamping, molding, and machining are commonly employed. For instance, aluminum components may be extruded or stamped into shape, allowing for complex geometries that contribute to aerodynamics and structural integrity.

Additionally, innovative techniques such as 3D printing are increasingly being integrated into the forming process. This allows for rapid prototyping and the ability to produce complex parts that traditional methods may not achieve efficiently. The integration of these technologies can also reduce waste, further enhancing sustainability efforts.

How Does the Assembly Process Ensure Quality?

Assembly is a critical stage in the manufacturing process, where various components—including the battery, electric motors, and chassis—are brought together. This process requires skilled labor and precision engineering to ensure that each component fits correctly and operates seamlessly.

Quality control during assembly includes several checkpoints. Initial Quality Control (IQC) verifies incoming components, In-Process Quality Control (IPQC) monitors the assembly process for deviations, and Final Quality Control (FQC) ensures that the assembled vehicle meets all specifications before it leaves the factory.

What Finishing Techniques Are Used for Electric Trucks?

Finishing techniques play a vital role in the overall quality and aesthetics of electric trucks. This stage includes painting, coating, and final inspections. The application of protective coatings is essential to enhance durability and corrosion resistance, particularly for vehicles intended for rugged environments.

Advanced painting techniques, such as electrostatic spraying, ensure an even application of paint while minimizing overspray and waste. Additionally, finishing processes often incorporate quality checks to ensure that the final product meets both aesthetic and functional standards.

What International Quality Standards Should B2B Buyers Consider?

Quality assurance in the manufacturing of camionetas eléctricas is governed by various international standards. ISO 9001 is one of the most recognized quality management standards, focusing on meeting customer expectations and delivering customer satisfaction. Compliance with this standard indicates a commitment to continuous improvement and operational excellence.

In addition to ISO standards, industry-specific certifications such as CE (Conformité Européenne) for the European market and API (American Petroleum Institute) standards for components related to energy systems are critical. These certifications provide assurance regarding the safety, performance, and environmental impact of the vehicles.

How Are Quality Control Checkpoints Implemented?

Quality control checkpoints are strategically placed throughout the manufacturing process to identify and rectify issues early.

- Incoming Quality Control (IQC): Inspect incoming materials and components to ensure they meet specified standards before use.

- In-Process Quality Control (IPQC): Monitor the assembly line to detect deviations in real-time, allowing for immediate corrective actions.

- Final Quality Control (FQC): Conduct a comprehensive inspection of the finished product, ensuring that all specifications are met before delivery.

Common testing methods include performance testing, safety testing, and environmental impact assessments. These tests are crucial for validating the vehicle’s performance under various conditions and ensuring compliance with regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Assurance?

B2B buyers must take proactive steps to verify the quality assurance practices of their suppliers. This can involve conducting audits, requesting quality assurance reports, and engaging third-party inspection services.

Audits should focus on the supplier’s adherence to international standards and internal quality management processes. Buyers should ask for documentation of quality control procedures, including details of testing methods and results.

Engaging third-party inspectors provides an objective assessment of the manufacturing processes and quality control measures in place. This is particularly important for international buyers, who may face challenges in verifying compliance from a distance.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, must navigate various nuances in quality control. This can include understanding local regulations, compliance requirements, and cultural differences in business practices.

For example, European buyers may prioritize CE certification, while buyers from Africa may focus on local compliance with regional standards. Buyers should be aware of these differences and communicate their quality expectations clearly to suppliers.

Additionally, establishing strong relationships with suppliers can facilitate better transparency and communication regarding quality assurance processes. Regular updates and open channels for feedback can help ensure that quality remains a priority throughout the manufacturing process.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing camionetas eléctricas, ensuring they meet the demands of their markets while maintaining high standards of quality and performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘camioneta electrica’

This sourcing guide provides a structured checklist for B2B buyers interested in procuring electric trucks (camioneta electrica). By following these steps, buyers can ensure a thorough evaluation of their options, align purchases with business needs, and optimize their investment in electric vehicles.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial. Consider factors such as payload capacity, towing capacity, range, and battery specifications. For example, if your operations involve heavy loads, prioritize models that offer high towing and payload capabilities to meet your business demands effectively.

Step 2: Research Market Trends and Regulations

Stay informed about the latest trends in electric vehicle technology and regional regulations. This includes knowing the incentives available for electric vehicle purchases in different countries, such as tax credits or rebates. Understanding these factors can help you make more informed decisions and potentially reduce costs.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a strong track record in electric vehicle sales and service to ensure reliability and support.

- Check for Certifications: Ensure that suppliers have the necessary certifications and compliance with local and international standards.

- Assess After-Sales Support: Evaluate the level of after-sales support offered, including warranties and maintenance services.

Step 4: Request Detailed Proposals

Once you have shortlisted potential suppliers, request detailed proposals. This should include pricing, delivery timelines, and service agreements. Compare these proposals not just on price but on the overall value, including service support and financing options.

- Evaluate Total Cost of Ownership: Look beyond the initial purchase price; consider operational costs such as maintenance, charging infrastructure, and resale value.

Step 5: Test Drive and Evaluate Performance

Whenever possible, arrange for test drives of the electric trucks you are considering. This hands-on experience will give you insights into the vehicle’s performance, comfort, and features. Pay attention to aspects such as driving range, charging time, and onboard technology.

Step 6: Negotiate Terms and Conditions

Engage in negotiations to secure favorable terms and conditions. Discuss payment plans, warranties, and service packages. Be clear about your expectations and ensure that both parties have a mutual understanding of the agreement.

- Consider Volume Discounts: If purchasing multiple vehicles, inquire about bulk purchase discounts or financing options that can optimize your budget.

Step 7: Finalize Purchase and Plan for Integration

Once terms are agreed upon, finalize the purchase and plan for integration into your existing fleet. Develop a strategy for training staff on operating and maintaining electric trucks. Additionally, assess your charging infrastructure and make necessary upgrades to accommodate the new vehicles.

By following this checklist, B2B buyers can navigate the complexities of sourcing electric trucks effectively, ensuring they select the best options to meet their operational needs.

Comprehensive Cost and Pricing Analysis for camioneta electrica Sourcing

What Are the Key Cost Components for Sourcing a Camioneta Eléctrica?

When sourcing a camioneta eléctrica, understanding the cost structure is crucial. The primary cost components include:

-

Materials: The battery, electric motor, and lightweight materials (like aluminum and composites) are significant. High-quality lithium-ion batteries can account for a substantial portion of the total vehicle cost.

-

Labor: Labor costs vary significantly by region. In countries with advanced manufacturing capabilities, labor may be higher, impacting the overall price. Training and skilled labor for electric vehicle (EV) assembly can also influence costs.

-

Manufacturing Overhead: This encompasses costs associated with factory operations, utilities, and equipment maintenance. Efficient production processes can mitigate these costs.

-

Tooling: Custom molds and production tools for electric vehicle components can be expensive, particularly for unique designs or high-volume orders.

-

Quality Control (QC): Ensuring the vehicle meets safety and performance standards requires robust QC processes. This can add to the cost but is essential for compliance with international regulations.

-

Logistics: Transportation costs for shipping components and finished vehicles can fluctuate based on distance, shipping methods, and fuel prices. International buyers need to account for import duties and tariffs.

-

Margin: Suppliers will include a profit margin based on market conditions and competitive pricing strategies. Understanding the typical margins in different regions can help buyers negotiate better deals.

How Do Price Influencers Affect the Cost of a Camioneta Eléctrica?

Several factors can influence the pricing of a camioneta eléctrica:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often yield better pricing due to economies of scale. Negotiating MOQs can lead to significant cost savings.

-

Specifications and Customization: Custom features or specialized configurations can increase costs. Buyers should carefully consider what specifications are necessary versus desirable.

-

Materials and Quality Certifications: The choice of materials impacts both performance and cost. Vehicles that meet higher quality certifications may be priced higher but can offer long-term savings through durability and efficiency.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may command higher prices but offer better service and quality assurance.

-

Incoterms: Understanding shipping terms (such as FOB or CIF) is vital for calculating the total landed cost. Different terms can significantly affect pricing based on who bears the shipping and insurance costs.

What Tips Can Help Buyers Optimize Costs and Pricing for Camioneta Eléctrica?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, optimizing costs can be achieved through the following strategies:

-

Negotiation: Always be prepared to negotiate. Establish a clear understanding of your requirements and the market prices for similar vehicles to leverage during discussions.

-

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis that includes not just the purchase price but also maintenance, fuel savings, and potential tax incentives associated with EVs.

-

Pricing Nuances: Be aware of regional pricing strategies. In some markets, there may be subsidies or tax incentives for electric vehicles, which can lower the effective purchase price.

-

Supplier Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Suppliers may offer discounts or favorable terms to loyal customers.

-

Market Research: Stay informed about market trends, competitor pricing, and new technologies. This knowledge can help you make informed purchasing decisions and adjust your sourcing strategies accordingly.

Disclaimer for Indicative Prices

Prices for camioneta eléctrica can vary widely based on the specific model, features, and regional market conditions. The figures provided in this analysis are indicative and should be verified with suppliers for accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing camioneta electrica With Other Solutions

Understanding the Alternatives to Camioneta Electrica

In the evolving landscape of commercial vehicles, the camioneta electrica (electric truck) represents a significant innovation. However, for B2B buyers, exploring alternatives is crucial to making informed decisions that align with operational needs and budget constraints. This section examines how the camioneta electrica compares to other viable solutions, including traditional gasoline trucks and hybrid trucks, each of which has its own merits and drawbacks.

Comparison Table

| Comparison Aspect | Camioneta Electrica | Traditional Gasoline Truck | Hybrid Truck |

|---|---|---|---|

| Performance | Up to 493 miles range; high torque (775 lb-ft) | Moderate range; lower torque | Good range; moderate torque |

| Cost | Starting at $52,800; federal tax incentives may apply | Starting at $30,000; fuel costs add up | Starting at $35,000; better fuel efficiency |

| Ease of Implementation | Requires charging infrastructure; longer initial setup | Readily available fuel stations | Requires some charging setup; more flexible |

| Maintenance | Lower maintenance costs; fewer moving parts | Higher maintenance due to engine components | Moderate maintenance; engine and electric components |

| Best Use Case | Long-haul transport; eco-conscious businesses | General transportation needs; established fleets | Urban deliveries; businesses seeking balance |

Detailed Breakdown of Alternatives

Traditional Gasoline Truck

Traditional gasoline trucks remain a staple in many fleets due to their reliability and widespread availability. They are generally less expensive upfront compared to electric trucks, making them accessible for businesses operating on tight budgets. However, they come with ongoing fuel costs that can accumulate significantly over time, especially with fluctuating fuel prices. Additionally, the environmental impact of gasoline trucks is a growing concern for many companies striving for sustainability.

Hybrid Truck

Hybrid trucks offer a middle ground between traditional gasoline trucks and fully electric models. They utilize both a gasoline engine and an electric motor, which can result in better fuel efficiency and lower emissions than their gasoline-only counterparts. This makes them suitable for urban environments where stop-and-go driving can deplete fuel efficiency. However, hybrid trucks can still face higher maintenance costs than electric trucks due to their complex systems. Moreover, while they provide flexibility in terms of fuel sources, they may not achieve the same performance metrics as fully electric options.

Making the Right Choice for Your Business Needs

When considering the best solution for your fleet, it’s essential to evaluate your specific operational requirements, budget constraints, and sustainability goals. The camioneta electrica stands out for businesses looking to reduce their carbon footprint and benefit from lower long-term operating costs. However, if initial costs and infrastructure limitations are a concern, traditional gasoline or hybrid trucks may serve as more practical alternatives. Ultimately, a thorough assessment of your business’s unique context will guide you in selecting the most appropriate vehicle solution for your needs.

Essential Technical Properties and Trade Terminology for camioneta electrica

What Are the Essential Technical Properties of a Camioneta Eléctrica?

When evaluating a camioneta eléctrica for B2B purchasing, understanding its technical specifications is crucial. Here are key properties to consider:

1. Battery Capacity (kWh)

Battery capacity, measured in kilowatt-hours (kWh), defines the total energy stored in the vehicle’s battery. For instance, a truck with a 168 kWh battery can typically provide a range of up to 350 miles. This specification is vital for businesses that rely on long-distance transportation, as it directly influences operational efficiency and cost-effectiveness.

2. Towing Capacity (lbs)

Towing capacity indicates the maximum weight the vehicle can safely tow. For example, models like the Ram 1500 REV boast a towing capacity of up to 14,000 lbs. This feature is essential for businesses involved in logistics, construction, or any sector requiring the transport of heavy loads. A higher towing capacity can lead to increased productivity and versatility in operations.

3. Payload Capacity (lbs)

Payload capacity refers to the maximum weight a vehicle can carry in its cargo area. For instance, a camioneta eléctrica with a payload capacity of 2,625 lbs allows businesses to transport substantial goods without needing additional vehicles. Understanding this capacity helps companies assess the vehicle’s suitability for their specific logistics needs.

4. Range (Miles)

The range of a camioneta eléctrica is the distance it can travel on a single charge. For example, the Chevy Silverado EV offers a range of up to 493 miles. This specification is critical for businesses that require vehicles for extensive daily operations, as it affects route planning and charging logistics.

5. Charging Time (Hours)

Charging time is the duration required to recharge the vehicle’s battery. With fast-charging capabilities available (e.g., 350 kW), some models can gain significant range in just a few minutes. Understanding charging time is vital for businesses to minimize downtime and optimize fleet operations.

6. Drive System (AWD vs. RWD)

The drive system of a camioneta eléctrica affects its performance and handling. All-Wheel Drive (AWD) provides better traction, especially in challenging terrains, while Rear-Wheel Drive (RWD) may offer better efficiency for highway driving. Businesses should consider their operational environments when selecting the appropriate drive system.

What Trade Terms Should B2B Buyers Know When Purchasing Camionetas Eléctricas?

Familiarity with industry terminology can streamline negotiations and procurement processes. Here are common trade terms relevant to camioneta eléctrica purchases:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the context of camionetas eléctricas, understanding OEM relationships can help businesses identify reliable suppliers and assess the quality of components.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps B2B buyers plan their purchases effectively, ensuring they meet supplier requirements while optimizing inventory levels.

3. RFQ (Request for Quotation)

An RFQ is a document that invites suppliers to provide price quotations for specified products or services. Crafting a clear RFQ for camionetas eléctricas can lead to competitive pricing and better procurement outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for B2B buyers to navigate shipping and delivery logistics effectively.

5. Lifecycle Cost

Lifecycle cost encompasses all expenses related to the acquisition, operation, and disposal of a camioneta eléctrica. This metric aids businesses in assessing the long-term financial implications of their purchase decisions, beyond the initial acquisition cost.

6. Warranty Terms

Warranty terms specify the duration and coverage of repairs or replacements for a vehicle. Understanding warranty details is critical for buyers to ensure they are protected against defects and unexpected costs.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting a camioneta eléctrica that best meets their operational needs.

Navigating Market Dynamics and Sourcing Trends in the camioneta electrica Sector

What Are the Current Dynamics Shaping the Camioneta Eléctrica Market?

The camioneta eléctrica sector is experiencing a transformative shift driven by technological advancements, regulatory frameworks, and increasing consumer demand for sustainable transport solutions. Global drivers such as the decarbonization agenda and the push towards renewable energy sources are accelerating the adoption of electric vehicles (EVs). In regions like Europe, stringent emissions regulations are compelling manufacturers to innovate and expand their electric offerings, while in Africa and South America, the focus is increasingly on energy independence and reducing reliance on fossil fuels.

Emerging B2B technology trends include the integration of advanced telematics and connectivity solutions that enhance fleet management capabilities. This trend is particularly relevant for international buyers looking to optimize operational efficiency and reduce costs. Furthermore, manufacturers are adopting modular designs and flexible production methodologies to meet diverse market demands and facilitate quicker adaptation to changing regulations and consumer preferences.

For B2B buyers, understanding local market dynamics is crucial. In Germany, for instance, the government offers substantial incentives for EV purchases, promoting a robust market for electric pickups. Conversely, in Nigeria, the challenge lies in establishing reliable charging infrastructure, making partnerships with local stakeholders essential for successful market entry.

How Is Sustainability Influencing Sourcing in the Camioneta Eléctrica Sector?

Sustainability is at the core of the camioneta eléctrica movement, influencing not only product design but also sourcing strategies. The environmental impact of production processes and the lifecycle of materials used are under scrutiny. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, such as using recycled materials and adopting clean manufacturing processes.

Ethical sourcing is becoming a non-negotiable criterion for B2B buyers, particularly in regions where corporate social responsibility is a key consideration. Certifications such as ISO 14001 for environmental management systems and the use of sustainable materials are gaining traction. Buyers should seek out manufacturers who can provide transparency in their supply chains, ensuring that materials are sourced responsibly and that labor practices meet ethical standards.

Moreover, the push for a circular economy is leading to innovative approaches in the sourcing of components, such as battery recycling programs and partnerships aimed at minimizing waste. This not only reduces the environmental footprint but also enhances the long-term viability of sourcing strategies.

What Is the Historical Context of the Camioneta Eléctrica Sector?

The evolution of the camioneta eléctrica sector can be traced back to the late 20th century, with early electric vehicle concepts emerging as alternatives to traditional gasoline-powered trucks. However, it wasn’t until the 2010s that significant advancements in battery technology and electric drivetrains began to reshape the market landscape. Pioneering models like the Tesla Cybertruck and the Ford F-150 Lightning have set new benchmarks for performance and consumer expectations, demonstrating that electric trucks can compete with their gasoline counterparts in terms of capability and utility.

Today, the sector is characterized by a diverse range of offerings that cater to various market segments, from urban delivery vehicles to rugged off-road trucks. This growth trajectory indicates a robust future for the camioneta eléctrica, driven by continuous innovation and the increasing alignment of consumer preferences with sustainability goals. International B2B buyers should remain attuned to these historical trends, as they provide valuable insights into the future direction of the market and potential sourcing opportunities.

Frequently Asked Questions (FAQs) for B2B Buyers of camioneta electrica

-

How do I evaluate the performance of an electric truck for my business needs?

When assessing the performance of an electric truck, consider key metrics such as range, payload capacity, towing capability, and charging time. Look for models with a range that meets your operational requirements, especially if your routes are long. Evaluate the truck’s cargo capacity to ensure it aligns with your logistics needs. Additionally, investigate charging options, both at home and public stations, to minimize downtime. Comparing real-world performance data and customer reviews can also provide insights into reliability and efficiency. -

What is the best electric truck model for transporting goods in challenging terrains?

For transporting goods in challenging terrains, look for electric trucks with robust off-road capabilities. Models like the Ram 1500 REV, known for its excellent towing capacity and rugged design, can handle tough conditions. Check specifications for ground clearance, torque, and four-wheel drive capabilities. Additionally, consider trucks equipped with advanced traction control systems and durable tires designed for off-road use. Ensure the model has a strong reputation for reliability in adverse conditions, supported by customer feedback. -

What are the typical payment terms when purchasing electric trucks from international suppliers?

Payment terms for electric trucks can vary significantly based on the supplier and the buyer’s location. Common terms may include a deposit upon order confirmation (typically 10-30%), followed by the balance due before shipment. Some suppliers may offer financing options or letter of credit arrangements for larger orders. Always clarify terms upfront, including any potential currency exchange considerations, to avoid misunderstandings. It’s advisable to negotiate terms that provide adequate security for both parties. -

How can I verify the credibility of a supplier for electric trucks?

To verify a supplier’s credibility, start by researching their business history, customer reviews, and industry reputation. Look for certifications or memberships in relevant trade organizations, which can indicate professionalism. Request references from previous clients to gauge their satisfaction and reliability. Additionally, consider conducting a factory visit if possible, or using third-party inspection services to assess manufacturing practices and quality control measures. This due diligence can help mitigate risks in your purchasing process. -

What customization options are available for electric trucks?

Customization options for electric trucks can include modifications to size, color, interior features, and technology integrations. Many manufacturers offer packages tailored to specific industries, such as cargo management systems or enhanced safety features. Discuss your specific needs with potential suppliers to understand available configurations. Some companies may also offer bespoke solutions, allowing you to tailor the truck to your exact operational requirements, from specialized cargo areas to unique branding. -

What is the minimum order quantity (MOQ) for electric trucks in B2B transactions?

Minimum order quantities (MOQ) for electric trucks can vary widely based on the manufacturer and model. Some suppliers may have an MOQ of one unit, especially for new or smaller manufacturers, while established brands might require larger orders, often starting at five to ten units. It’s essential to discuss MOQs early in negotiations to determine if they align with your procurement strategy. Additionally, consider potential bulk discounts that may be available for larger orders. -

What are the logistics considerations when importing electric trucks?

Logistics considerations for importing electric trucks include shipping methods, customs regulations, and delivery timelines. Evaluate whether shipping by container or roll-on/roll-off (RoRo) is more cost-effective for your needs. Familiarize yourself with the customs regulations in your country, particularly regarding emissions standards and import tariffs for electric vehicles. Collaborating with a logistics provider experienced in vehicle imports can streamline the process, ensuring compliance and timely delivery to your location. -

How can I ensure the quality and safety of electric trucks upon delivery?

To ensure quality and safety upon delivery, conduct a thorough inspection of the vehicle upon arrival. Check for any visible damage and verify that all specifications match your order. It’s also advisable to request documentation such as the manufacturer’s warranty, maintenance records, and compliance certificates. Implement a checklist based on your operational requirements and safety standards to ensure the truck meets your expectations. Consider arranging a professional inspection or test drive to confirm functionality before putting the vehicle into service.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Camioneta Electrica Manufacturers & Suppliers List

1. Chevrolet – Chevy Silverado EV 2026

Domain: es.chevrolet.com

Registered: 1994 (31 years)

Introduction: Modelo: Chevy Silverado EV 2026

Tipo: Camioneta eléctrica

Precio desde: $52,800*

Precio como se muestra: $86,600*

Autonomía: Hasta 493 millas según la EPA*

Torque máximo: Hasta 775 lb-ft con Wide Open Watts*

Capacidad de remolque: Hasta 12,500 lb*

Pantalla táctil: 17.7 pulgadas en diagonal

Centro de información al conductor: 11 pulgadas en diagonal

Potencia externa: Hasta 10.2 kW con hasta 11 toma…

2. Ram – 1500 REV Electric Truck

Domain: es.ramtrucks.com

Registered: 2003 (22 years)

Introduction: {“model”:”Ram 1500 REV”,”type”:”electric truck”,”range_miles”:”350″,”towing_capacity_lb”:”14,000″,”payload_capacity_lb”:”2,625″,”storage_capacity_cubic_ft”:”15″,”acceleration_0_to_60″:”4.4 seconds”,”horsepower”:”654 hp”,”torque”:”620 lb-ft”,”available_versions”:[“Big Horn®/Lone Star”,”Laramie®”,”Limited”,”Tungsten”],”features”:{“front_trunk_storage”:”more than double the Tesla Cybertruck’s front t…

3. Slate – Electric Pickup Truck

Domain: greencars.com

Registered: 1998 (27 years)

Introduction: Slate es la primera camioneta eléctrica estadounidense con un precio estimado de 20,000 dólares después de incentivos. Es una camioneta biplaza compacta, mide poco menos de 175 pulgadas de largo y poco más de 70,5 pulgadas de ancho, con una capacidad de carga útil de 1433 libras y una plataforma de 50 pulgadas de ancho y 60 pulgadas de largo. Ofrece dos opciones de batería: 52,7 kWh con una autono…

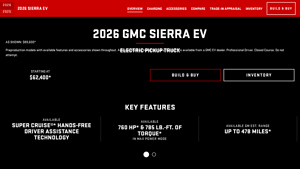

4. GMC – Key Product Details

Domain: gmc.com

Registered: 1996 (29 years)

Introduction: Key Product Details for the 2026 GMC Sierra EV:

– Starting Price: $62,400 (Elevation) to $89,600 (Denali)

– EPA-Estimated Range: Up to 460 miles (390 miles as shown)

– Max Power Mode: 760 HP and 785 LB.-FT. of torque

– Charging: 800V public DC fast charging of 100 miles in approximately 10 minutes

– Available Features:

– Super Cruise® hands-free driver assistance technology

– MultiPro™ …

5. Cadillac – Lyriq 2024

Domain: cadillac.com.mx

Registered: 1998 (27 years)

Introduction: Nombre: Cadillac Lyriq 2024

Precio: Desde $1,549,000

Tipo: Camioneta eléctrica de lujo

Motorización: Dos motores eléctricos, 500 HP, 450 lb-pie de torque

Tracción: All-Wheel Drive (AWD)

Suspensión: Delantera y trasera de 5 brazos

Modos de manejo: Selector de modos para adaptarse a condiciones del camino

Pantalla: LED de 33″ con resolución 9K

Tecnología: Google Built-In, Wireless Phone Projection (…

6. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

Strategic Sourcing Conclusion and Outlook for camioneta electrica

In the rapidly evolving landscape of electric pickups, strategic sourcing emerges as a critical component for international B2B buyers looking to capitalize on the growing demand for sustainable transportation solutions. By leveraging the unique features of models like the Chevy Silverado EV and Ram 1500 REV, businesses can align their procurement strategies with the increasing consumer preference for electric vehicles. These models not only offer impressive towing capacities and extended ranges but also promise substantial cost savings through lower fuel and maintenance expenses.

Furthermore, the ongoing advancements in charging infrastructure and battery technology present a robust opportunity for companies to integrate electric trucks into their fleets effectively. Buyers from regions like Africa, South America, the Middle East, and Europe should focus on establishing partnerships with reliable manufacturers and suppliers that can ensure a steady supply of these innovative vehicles.

As we look ahead, the electric truck market is poised for significant growth. Now is the time for businesses to act decisively—evaluate your sourcing strategies, engage with industry leaders, and invest in electric pickups that meet your operational needs. Embrace this shift towards electrification to enhance your competitive edge in the global market.