Introduction: Navigating the Global Market for electric car battries

In the rapidly evolving landscape of electric vehicle (EV) technology, sourcing high-quality electric car batteries presents a significant challenge for international B2B buyers. With diverse battery types such as Lithium Iron Phosphate (LFP), Nickel Manganese Cobalt (NMC), and emerging solid-state technologies, understanding their unique characteristics is crucial for making informed procurement decisions. This comprehensive guide delves into the various types of electric car batteries, their applications across different markets, and strategies for supplier vetting.

As the demand for sustainable transportation solutions grows, particularly in regions like Africa, South America, the Middle East, and Europe, buyers must navigate a complex array of options that align with their specific needs and budget constraints. This guide empowers decision-makers by providing insights into cost structures, performance metrics, and safety considerations. Furthermore, it addresses the sustainability of battery production and disposal, ensuring that your purchasing decisions contribute positively to environmental goals.

By equipping B2B buyers with essential knowledge and actionable strategies, this guide aims to simplify the sourcing process, enabling businesses to secure the most suitable electric car batteries for their operations while maximizing efficiency and sustainability.

Understanding electric car battries Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lithium Iron Phosphate (LFP) | Moderate energy density, high thermal stability | City fleets, affordable EV models | Pros: Cost-effective, safe, long cycle life. Cons: Shorter range compared to other types. |

| Nickel Manganese Cobalt (NMC) | High energy density, compact design | Long-range EVs, premium vehicles | Pros: Excellent range and performance. Cons: Higher cost, moderate thermal stability. |

| Nickel Cobalt Aluminum (NCA) | Very high energy density, premium performance | Luxury and high-performance EVs | Pros: Long range, high performance. Cons: Expensive, complex thermal management required. |

| Solid-State Batteries | Projected high energy density, excellent safety | Future applications, experimental vehicles | Pros: Greater range, faster charging, enhanced safety. Cons: Limited availability, high cost. |

| Lead-Acid Batteries | Established technology, lower energy density | Low-cost applications, legacy systems | Pros: Affordable, widely available. Cons: Heavy, shorter lifespan, less efficient. |

What Are the Key Characteristics of Lithium Iron Phosphate (LFP) Batteries?

LFP batteries are recognized for their moderate energy density and exceptional thermal stability, making them particularly suitable for city driving and moderate climates. Their long cycle life, often exceeding 3,000 charges, positions them as a reliable choice for fleet operators looking for durability and safety. B2B buyers should consider the lower cost and the growing trend among automakers to adopt LFP for entry-level vehicles, which can lead to significant savings in large-scale deployments.

How Does Nickel Manganese Cobalt (NMC) Compare in Performance?

NMC batteries are characterized by their high energy density and compact design, making them ideal for long-range electric vehicles. They balance performance and cost, appealing to manufacturers of premium EVs. For B2B buyers, the trade-off between the higher initial investment and the extended range and performance capabilities is crucial. Understanding the thermal management requirements is also essential, as NMC batteries necessitate careful handling to avoid overheating.

What Makes Nickel Cobalt Aluminum (NCA) Batteries Stand Out?

NCA batteries are known for their very high energy density, which translates to longer ranges and superior performance, particularly in luxury EVs. However, they come with a higher price tag and require complex thermal management systems. B2B purchasers must weigh the benefits of enhanced performance against the increased cost and maintenance requirements. This battery type is particularly suitable for companies focused on high-performance applications and premium offerings.

Why Are Solid-State Batteries Considered the Future?

Solid-state batteries are currently under development, promising a significant leap in energy density and safety by using solid electrolytes instead of liquid ones. This technology is expected to provide faster charging times and longer lifespans, making it an attractive option for future EV models. For B2B buyers, the key consideration will be the current limited availability and high costs associated with early adoption. However, investing in this technology could position companies advantageously as the market evolves.

Are Lead-Acid Batteries Still Relevant for B2B Applications?

Despite being an older technology, lead-acid batteries are still widely used due to their affordability and availability. They are suitable for low-cost applications and legacy systems but come with limitations in terms of energy density and lifespan. B2B buyers should consider lead-acid batteries for budget-sensitive projects, keeping in mind their heavier weight and reduced efficiency compared to modern alternatives.

Key Industrial Applications of electric car battries

| Industry/Sector | Specific Application of Electric Car Batteries | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Electric Buses and Coaches | Reduced operational costs and lower emissions; enhances public image | Battery longevity and thermal stability; support for local charging infrastructure |

| Renewable Energy Storage | Grid Energy Storage Solutions | Stabilizes energy supply and supports renewable integration | Scalability, reliability, and compatibility with existing grid systems |

| Automotive Manufacturing | Production of Electric Vehicles (EVs) | Increased market competitiveness and compliance with emissions regulations | Sourcing quality battery cells and ensuring supply chain sustainability |

| Logistics and Delivery | Electric Delivery Vans | Lower fuel costs and reduced carbon footprint; improved urban access | Battery range and charging speed; local service support for maintenance |

| Mining Operations | Electric Mining Equipment | Reduced operational costs and improved safety in hazardous environments | Custom battery solutions for high discharge applications; durability in extreme conditions |

How Are Electric Car Batteries Transforming Public Transportation?

Electric buses and coaches are increasingly being adopted in urban public transportation systems. These vehicles utilize electric car batteries to provide a cleaner alternative to traditional diesel engines, significantly reducing emissions and operational costs. The longevity and thermal stability of batteries, particularly Lithium Iron Phosphate (LFP) types, are crucial for ensuring that these vehicles perform well in various climates. International buyers should consider local charging infrastructure and maintenance support when sourcing batteries for electric public transport solutions.

What Role Do Electric Car Batteries Play in Renewable Energy Storage?

Electric car batteries are pivotal in grid energy storage solutions, helping to stabilize energy supply and facilitate the integration of renewable sources like solar and wind. These batteries store excess energy generated during peak production times and release it during periods of high demand. For businesses in this sector, the scalability and reliability of battery systems are essential. Buyers should focus on sourcing batteries that are compatible with existing grid systems and can efficiently manage energy fluctuations, particularly in developing regions with less established infrastructure.

How Are Electric Car Batteries Enhancing Automotive Manufacturing?

The automotive industry is undergoing a significant transformation with the rise of electric vehicles (EVs). Electric car batteries are at the core of this evolution, enabling manufacturers to produce vehicles that meet stringent emissions regulations. By investing in battery technology, manufacturers can enhance their market competitiveness and appeal to environmentally conscious consumers. Buyers in this sector must ensure they source high-quality battery cells while also considering sustainability in their supply chains to meet global standards.

In What Ways Are Electric Car Batteries Benefiting Logistics and Delivery Services?

Electric delivery vans are becoming a common sight in urban areas, powered by electric car batteries that offer significant advantages over traditional combustion engines. These vehicles reduce fuel costs and minimize carbon footprints, making them an attractive option for businesses focused on sustainability. When sourcing batteries for delivery applications, companies should prioritize battery range and charging speed to ensure operational efficiency. Additionally, local service support for maintenance is vital to minimize downtime.

How Are Electric Car Batteries Improving Mining Operations?

In the mining sector, electric car batteries are being integrated into mining equipment to enhance safety and reduce operational costs. These batteries provide a cleaner and quieter alternative to diesel-powered machinery, which is particularly beneficial in hazardous environments. Buyers in this field should look for custom battery solutions that cater to high discharge applications and are durable enough to withstand extreme conditions. The ability to source robust and reliable batteries can significantly improve productivity and safety in mining operations.

3 Common User Pain Points for ‘electric car battries’ & Their Solutions

Scenario 1: Navigating Battery Chemistry for Optimal Performance

The Problem: B2B buyers often struggle with selecting the right battery chemistry for their specific electric vehicle (EV) applications. With options ranging from Lithium Iron Phosphate (LFP) to Nickel Manganese Cobalt (NMC) and Nickel Cobalt Aluminum (NCA), understanding the implications of each type can be overwhelming. Buyers may face challenges such as high operational costs, insufficient range, or performance issues, especially when catering to diverse market needs across regions like Africa and South America, where climate and infrastructure vary significantly.

The Solution: To address this challenge, B2B buyers should conduct a thorough needs assessment that includes evaluating the operational environment, performance expectations, and total cost of ownership (TCO). Start by determining the primary use case for the EVs—whether they are for urban delivery, long-distance travel, or fleet operations. For instance, if the focus is on urban environments with frequent charging opportunities, LFP batteries, known for their lower cost and excellent cycle life, could be the ideal choice. On the other hand, if long-range performance is critical, opting for NMC batteries would be more suitable despite their higher initial costs. Collaborating with battery manufacturers to obtain samples for testing can also provide valuable insights into real-world performance and help in making informed procurement decisions.

Scenario 2: Overcoming Supply Chain and Sourcing Challenges

The Problem: The sourcing of electric car batteries often presents significant supply chain challenges, particularly in regions with emerging markets like Nigeria and the Middle East. B2B buyers may find themselves facing delays, fluctuating prices, and inconsistent quality, exacerbated by geopolitical tensions and resource scarcity. These challenges can lead to project delays, increased costs, and ultimately, lost business opportunities.

The Solution: To mitigate these risks, B2B buyers should establish strong relationships with multiple suppliers, including both local and international manufacturers. Diversifying the supplier base not only enhances bargaining power but also ensures a more stable supply chain. Buyers should also consider implementing just-in-time inventory strategies to reduce holding costs while ensuring that they have sufficient batteries on hand for operational needs. Additionally, engaging in long-term contracts with suppliers can lock in prices and secure supply commitments. Finally, investing in local partnerships for battery recycling and refurbishment can create a circular economy, reducing dependency on new battery production while promoting sustainability.

Scenario 3: Addressing Battery Longevity and Maintenance Concerns

The Problem: A common concern for B2B buyers is the longevity and maintenance of electric car batteries. Many organizations fear that high replacement costs and performance degradation over time could significantly impact their bottom line. In regions with extreme climates, such as the Middle East’s heat or Europe’s cold, battery performance can be further compromised, leading to increased operational costs and reduced vehicle reliability.

The Solution: To enhance battery longevity, B2B buyers should prioritize the selection of batteries with superior thermal management systems and high-quality battery management systems (BMS). These features can help maintain optimal operating conditions and extend the lifespan of the batteries. Additionally, implementing regular maintenance schedules that include monitoring battery health and conducting performance assessments can preemptively address issues before they escalate. Buyers should also consider investing in training for staff on best practices for battery care, including charging habits and storage conditions, to maximize battery performance and life cycle. Finally, exploring warranties and service agreements with battery manufacturers can provide peace of mind and financial protection against unexpected failures.

Strategic Material Selection Guide for electric car battries

What Are the Key Materials Used in Electric Car Batteries?

Electric vehicle (EV) batteries are primarily composed of various materials that significantly influence their performance, cost, and suitability for specific applications. Understanding these materials is crucial for international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe. Below, we analyze four common materials used in EV batteries, highlighting their key properties, advantages, disadvantages, and specific considerations for buyers.

How Does Lithium Iron Phosphate (LFP) Perform in Electric Car Batteries?

Lithium Iron Phosphate (LFP) is known for its excellent thermal stability and long cycle life, making it a popular choice for entry-level EVs. It typically operates effectively in temperatures ranging from -20°C to 60°C, with a corrosion resistance that enhances its durability.

Pros: LFP batteries are cost-effective, safe, and capable of enduring over 3,000 charge cycles, which makes them suitable for urban driving conditions.

Cons: However, they have a lower energy density compared to other lithium-based batteries, resulting in a shorter range. This can limit their application in high-performance or long-range electric vehicles.

Impact on Application: LFP batteries are particularly compatible with city driving and moderate climates, making them ideal for fleet vehicles in regions with similar conditions.

Considerations for International Buyers: Buyers should ensure compliance with local standards such as ASTM or JIS, particularly in regions where safety and performance regulations are stringent. The growing availability of raw materials for LFP production also makes sourcing easier for international buyers.

What Advantages Does Nickel Manganese Cobalt (NMC) Offer?

Nickel Manganese Cobalt (NMC) batteries are favored for their high energy density and good thermal stability. They typically operate well under a temperature range of -20°C to 50°C and have moderate corrosion resistance.

Pros: NMC batteries provide excellent range and performance, making them suitable for long-distance travel and high-performance EVs.

Cons: The main drawback is their higher cost and the need for careful thermal management due to moderate thermal stability. This complexity can increase manufacturing costs and logistics.

Impact on Application: NMC batteries are well-suited for applications requiring high energy output, such as premium electric vehicles.

Considerations for International Buyers: Buyers should be aware of the supply chain complexities associated with cobalt, particularly in regions where ethical sourcing is a priority. Compliance with international standards is essential to ensure product reliability and safety.

How Do Nickel Cobalt Aluminum (NCA) Batteries Compare?

Nickel Cobalt Aluminum (NCA) batteries are recognized for their very high energy density and good cycle life. They can operate effectively in a temperature range of -20°C to 45°C and exhibit moderate corrosion resistance.

Pros: NCA batteries deliver high performance and are commonly used in luxury and performance-oriented EVs, offering a longer range.

Cons: However, they are expensive and require more complex thermal management systems, which can complicate manufacturing and increase costs.

Impact on Application: NCA batteries are ideal for applications where performance and range are critical, such as in high-end electric vehicles.

Considerations for International Buyers: Buyers should consider the implications of sourcing materials like cobalt and aluminum, which may be subject to market fluctuations. Understanding local regulations regarding battery materials is crucial for compliance.

What Future Potential Do Solid-State Batteries Hold?

Solid-state batteries, still in development, promise to revolutionize the EV battery landscape. They are projected to have double the energy density of current lithium-ion batteries and excellent thermal stability.

Pros: Their solid electrolyte enhances safety and reduces the risk of overheating, making them a highly desirable option for future EVs.

Cons: Currently, solid-state batteries are costly and not widely available, limiting their immediate application in the market.

Impact on Application: Once commercially viable, they could significantly enhance the range and safety of electric vehicles.

Considerations for International Buyers: Buyers should keep an eye on advancements in solid-state technology and potential regulatory changes that may affect their adoption and integration into existing supply chains.

Summary of Material Selection for Electric Car Batteries

| Material | Typical Use Case for Electric Car Batteries | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Lithium Iron Phosphate (LFP) | Entry-level EVs and fleet vehicles | Excellent thermal stability and long cycle life | Lower energy density limits range | Low |

| Nickel Manganese Cobalt (NMC) | Long-range and high-performance EVs | High energy density and excellent performance | Higher cost and thermal management needs | Medium |

| Nickel Cobalt Aluminum (NCA) | Luxury and performance EVs | Very high energy density | Expensive with complex thermal management | High |

| Solid-State Batteries | Future EV applications | Double energy density and enhanced safety | Currently costly and limited availability | High |

Understanding these materials and their implications will empower B2B buyers to make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car battries

What Are the Main Stages of Manufacturing Electric Car Batteries?

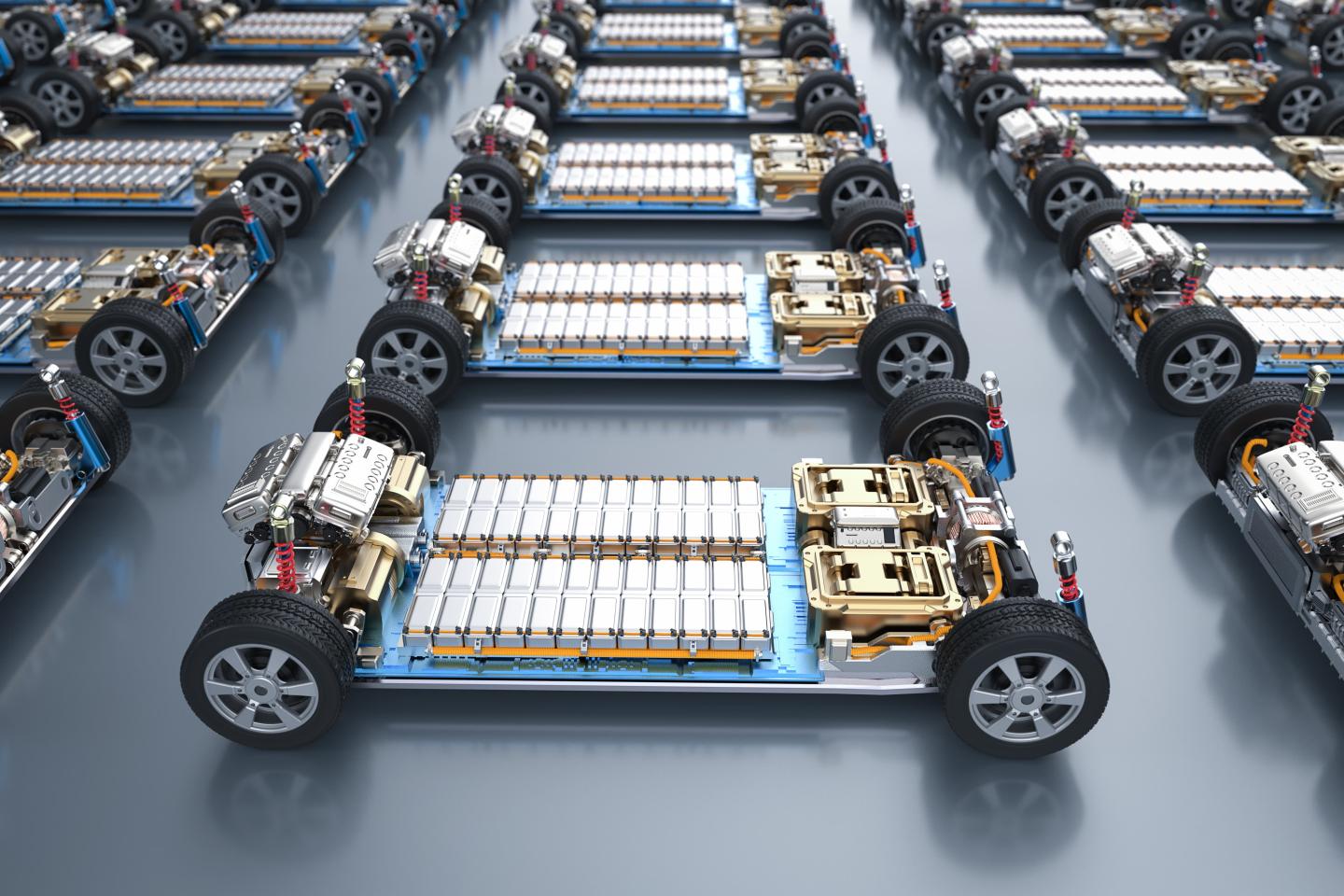

The manufacturing of electric vehicle (EV) batteries is a complex process that typically involves several stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the performance, safety, and longevity of the batteries.

How Is Material Prepared for EV Battery Manufacturing?

Material preparation is the initial stage, where raw materials are sourced and processed. This includes the extraction and refinement of essential components like lithium, cobalt, nickel, and manganese. In the case of Lithium Iron Phosphate (LFP) batteries, iron and phosphate are also critical. The quality of these materials directly impacts the energy density, cost, and thermal stability of the batteries.

Moreover, the sourcing of materials must align with sustainability practices. B2B buyers should inquire about suppliers’ compliance with environmental regulations and ethical sourcing, especially when dealing with materials like cobalt, which has faced scrutiny over mining practices.

What Techniques Are Used in the Forming Stage?

Once materials are prepared, they undergo the forming stage, where they are transformed into battery cells. This includes several processes such as:

- Electrode Preparation: The active materials are mixed with binders and solvents to create a slurry, which is then coated onto metal foils to form the electrodes.

- Drying: The coated electrodes are dried to remove solvents, enhancing the adhesion of the active materials.

- Cutting and Stacking: The dried electrodes are cut to size and stacked or wound to create the cell structure.

Advanced techniques, such as laser cutting and precision coating, are employed to ensure uniformity and efficiency, which are crucial for performance consistency.

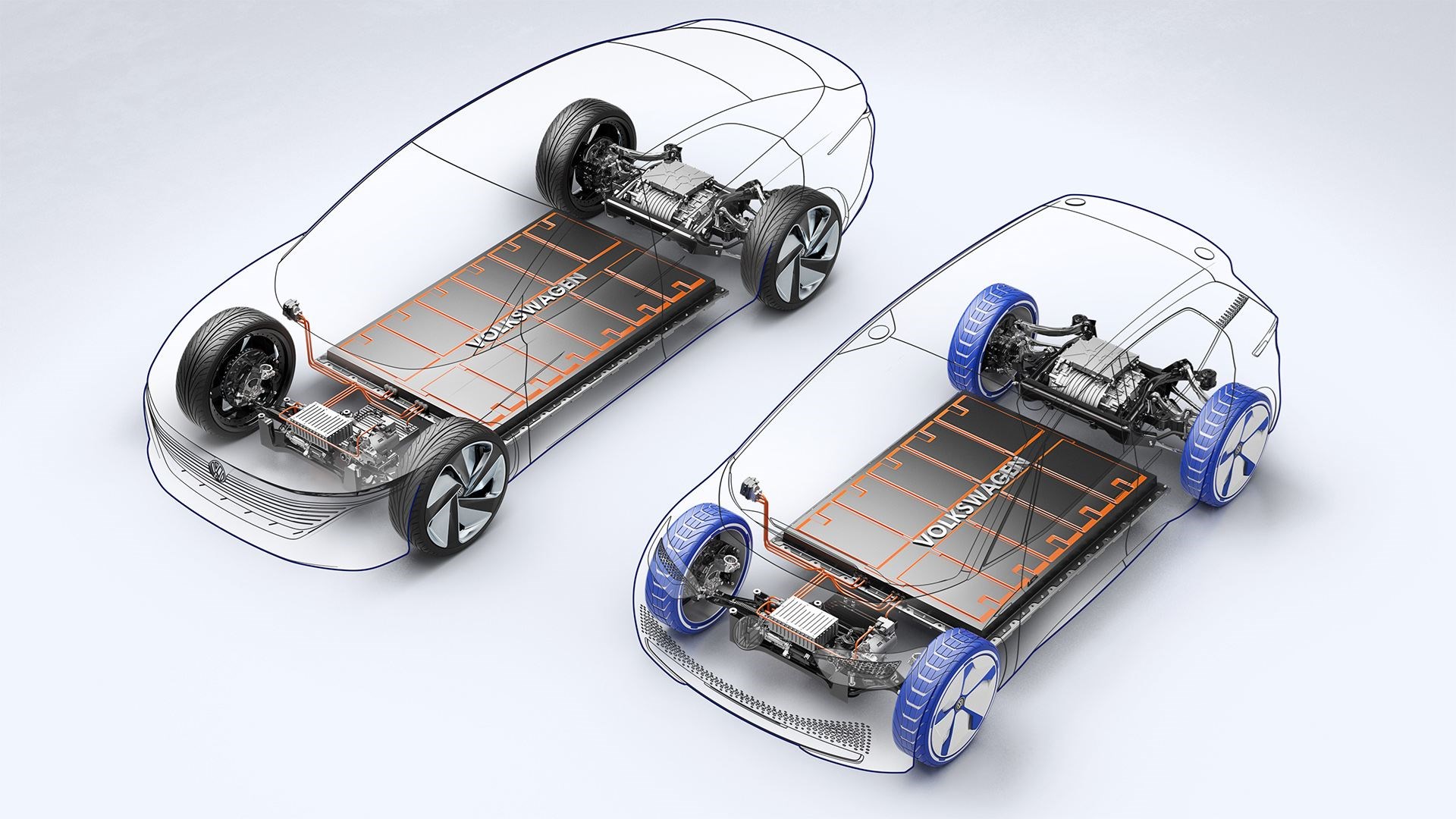

How Are EV Batteries Assembled?

The assembly stage involves integrating the individual cells into battery packs. This includes:

- Cell Connection: Cells are connected in series or parallel configurations depending on the desired voltage and capacity.

- Module Housing: The assembled cells are encased in protective housings that provide thermal management and structural integrity.

- Battery Management System (BMS) Integration: A BMS is integrated to monitor the health and performance of the battery, ensuring safe operation.

Quality during this stage is vital, as improper assembly can lead to performance issues or safety hazards, such as thermal runaway.

What Finishing Processes Are Involved in Battery Manufacturing?

The finishing stage includes final inspections and testing of the battery packs. This may involve:

- Charging Cycles: Initial charging to ensure functionality.

- Performance Testing: Evaluating the battery’s energy density, cycle life, and thermal stability under various conditions.

- Quality Assurance Checks: Verifying that the product meets specifications and regulatory standards.

This stage is crucial for ensuring that the batteries meet the rigorous demands of the automotive industry.

How Is Quality Assurance Implemented in EV Battery Manufacturing?

Quality assurance (QA) is an essential aspect of battery manufacturing, ensuring that products meet international standards and customer expectations. Various international and industry-specific standards guide this process.

What International Standards Are Relevant for EV Battery Quality?

One of the primary international standards is ISO 9001, which focuses on quality management systems. Compliance with ISO 9001 indicates that a manufacturer has established processes to ensure consistent quality and customer satisfaction. Other relevant standards may include:

- CE Marking: Ensures compliance with European safety, health, and environmental protection standards.

- API Standards: Often relevant in the context of battery components sourced from oil and gas industries.

B2B buyers should prioritize suppliers with certifications that align with their target markets, particularly when considering exports to regions with strict regulatory environments.

What Are the Key Quality Control Checkpoints in Battery Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): Assessment of raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing checks during the manufacturing stages to catch defects early.

- Final Quality Control (FQC): Comprehensive testing of finished products before they are shipped, ensuring they meet performance criteria.

These checkpoints are critical for maintaining high standards and minimizing defects.

What Common Testing Methods Are Used in Battery Quality Assurance?

Common testing methods in battery quality assurance include:

- Electrical Testing: Measures voltage, capacity, and internal resistance.

- Thermal Testing: Assesses the battery’s performance under various temperature conditions.

- Cycle Life Testing: Evaluates how many charge-discharge cycles a battery can endure before performance degrades.

These tests ensure that the batteries are reliable and safe for use in electric vehicles.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can implement several strategies to verify a supplier’s quality control processes:

- Audits: Conducting regular audits of suppliers can provide insight into their manufacturing practices and adherence to quality standards.

- Reports: Requesting detailed QC reports and documentation can help buyers understand the supplier’s testing methods and results.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of a supplier’s quality processes.

What Are the QC Nuances for International B2B Buyers?

For international B2B buyers, particularly those in regions like Africa, South America, and the Middle East, understanding local regulations and standards is crucial. Buyers should ensure that suppliers are compliant not only with international standards but also with local regulations that may vary significantly across different regions.

Moreover, language barriers and cultural differences may affect communication, making it essential for buyers to establish clear channels for feedback and quality discussions with suppliers.

In conclusion, the manufacturing processes and quality assurance of electric car batteries involve a detailed and rigorous approach. By understanding these processes, B2B buyers can make informed decisions and build strong partnerships with reliable suppliers in the growing electric vehicle market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car battries’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers seeking to procure electric car batteries. With the growing demand for electric vehicles (EVs) across various regions, including Africa, South America, the Middle East, and Europe, understanding the intricacies of battery sourcing is essential. This guide will help you navigate the complexities of battery types, supplier evaluation, and compliance requirements to make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the first step in sourcing electric car batteries. This includes determining the battery chemistry (e.g., Lithium Iron Phosphate, Nickel Manganese Cobalt), capacity, voltage, and cycle life that meet your specific application needs. Different battery types offer unique advantages, such as energy density or thermal stability, which can influence performance and cost.

- Key Considerations:

- Assess the expected range and performance of your electric vehicles.

- Consider environmental factors such as temperature variations in your region.

Step 2: Research Market Trends and Innovations

Understanding current market trends and technological innovations can provide a competitive edge. Stay informed about emerging battery technologies, such as solid-state batteries, which promise greater efficiency and safety. This knowledge will help you anticipate future needs and align your procurement strategy accordingly.

- Key Considerations:

- Monitor industry reports and publications for insights on battery advancements.

- Engage with industry experts or attend relevant conferences for networking opportunities.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is crucial to thoroughly vet potential suppliers. Request detailed company profiles, including their manufacturing capabilities, quality control processes, and sustainability practices. Look for suppliers with a proven track record in your region to ensure reliability and support.

- Key Considerations:

- Ask for case studies or references from similar industries.

- Verify the supplier’s certifications and compliance with international standards.

Step 4: Assess Pricing and Payment Terms

Understanding pricing structures and payment terms is essential for effective budgeting. Different battery types and suppliers may have varying price points based on factors like material costs, production methods, and geographic location. Negotiate terms that align with your financial capabilities while ensuring you receive high-quality products.

- Key Considerations:

- Compare quotes from multiple suppliers to gauge market rates.

- Consider long-term contracts for better pricing and supply stability.

Step 5: Verify Quality Assurance Processes

Quality assurance is critical when sourcing electric car batteries, as they constitute a significant portion of an EV’s total value. Confirm that your suppliers have robust quality control measures in place, including testing protocols for battery performance, safety, and durability. This step will minimize the risk of failures and ensure compliance with safety regulations.

- Key Considerations:

- Inquire about the testing methods used and any certifications obtained.

- Review the supplier’s warranty and return policy for defective products.

Step 6: Consider Logistics and Supply Chain Management

Efficient logistics and supply chain management are vital for timely delivery and inventory management. Assess the supplier’s capabilities in terms of shipping options, lead times, and their ability to handle customs regulations if sourcing internationally. A reliable logistics plan will help ensure that your operations remain uninterrupted.

- Key Considerations:

- Evaluate suppliers’ geographical proximity to your operations.

- Discuss potential risks and contingencies related to supply chain disruptions.

Step 7: Plan for After-Sales Support and Maintenance

Finally, factor in after-sales support and maintenance services as part of your procurement strategy. Reliable suppliers should offer technical assistance, training, and resources for battery maintenance. This support will help maximize battery lifespan and performance, ensuring a better return on investment.

- Key Considerations:

- Determine the level of support provided post-purchase.

- Ask about training programs for your technical staff on battery management systems.

By following these steps, you can streamline your sourcing process and make informed decisions that align with your business objectives in the electric vehicle market.

Comprehensive Cost and Pricing Analysis for electric car battries Sourcing

What Are the Key Cost Components in Sourcing Electric Car Batteries?

When sourcing electric vehicle (EV) batteries, understanding the cost structure is crucial for B2B buyers. The main components contributing to the overall cost include:

-

Materials: The raw materials for EV batteries, such as lithium, nickel, cobalt, and manganese, significantly influence pricing. The volatility of these commodity prices can lead to fluctuations in battery costs. For instance, lithium prices have seen substantial increases due to rising demand for EVs.

-

Labor: Labor costs vary by region and can impact the manufacturing price. Countries with lower labor costs may offer more competitive pricing, but buyers should also consider the expertise and quality of labor in these regions.

-

Manufacturing Overhead: This encompasses the costs associated with facilities, equipment maintenance, and utilities. High-capacity production plants may benefit from economies of scale, which can lower per-unit costs.

-

Tooling: Specialized equipment required for battery production can represent a significant initial investment. The cost of tooling is often amortized over the production volume, impacting pricing for smaller orders.

-

Quality Control (QC): Ensuring battery safety and performance requires rigorous QC processes. Investments in testing and certification can increase upfront costs but are essential for compliance and reliability.

-

Logistics: Shipping and handling are vital components, especially for international buyers. Transportation costs can vary based on distance, mode of transport, and Incoterms, affecting the total landed cost of the batteries.

-

Margin: Suppliers typically add a profit margin to cover risks and operational expenses. This margin can vary based on market competition, supplier reputation, and relationship with the buyer.

How Do Pricing Influencers Affect Battery Sourcing?

Several factors can influence the pricing of EV batteries, particularly for B2B buyers:

-

Volume/MOQ: Purchasing in bulk can lead to significant discounts. Suppliers often have minimum order quantities (MOQs), and meeting these thresholds can provide better pricing.

-

Specifications and Customization: Custom battery designs or specific chemistries, such as Lithium Iron Phosphate (LFP) or Nickel Manganese Cobalt (NMC), can alter costs. Tailored solutions may incur additional R&D expenses, impacting overall pricing.

-

Materials Quality and Certifications: Higher-quality materials and certifications (like ISO or UL) ensure safety and performance but can also drive up costs. Buyers should weigh the long-term benefits of investing in quality against initial expenditure.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Established suppliers with advanced technology may command higher prices but offer superior quality and reliability.

-

Incoterms: Understanding Incoterms is crucial for cost management. Different terms dictate who bears the responsibility for shipping costs and risks, impacting the total cost of ownership.

What Are Effective Buyer Tips for Negotiating Battery Prices?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiate: Always negotiate pricing and payment terms. Suppliers may have flexibility, especially for larger orders or long-term contracts.

-

Evaluate Total Cost of Ownership (TCO): Consider the long-term costs associated with battery performance, maintenance, and potential recycling. A lower upfront cost may not equate to overall savings.

-

Research and Compare Suppliers: Conduct thorough market research to identify multiple suppliers. Compare their offerings, quality, and customer service to make informed decisions.

-

Leverage Regional Insights: Understanding local market conditions, regulations, and incentives can provide leverage in negotiations, especially in emerging markets.

-

Stay Informed on Material Trends: Keep abreast of market trends for raw materials. Timing your purchases when prices are favorable can lead to significant savings.

Disclaimer on Indicative Prices

Prices for EV batteries can vary widely based on the factors discussed above. The information provided serves as a general guideline and may not reflect current market conditions or specific supplier quotes. Always consult with suppliers for accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing electric car battries With Other Solutions

Introduction: Exploring Alternatives to Electric Car Batteries

In the rapidly evolving landscape of transportation, electric vehicle (EV) batteries are the most prominent energy solution for powering electric cars. However, as the demand for sustainable and efficient transportation solutions grows, businesses must consider alternative technologies that can serve similar purposes. This analysis compares electric car batteries with hydrogen fuel cells and biofuel systems, highlighting their unique attributes, benefits, and limitations.

Comparison Table

| Comparison Aspect | Electric Car Batteries | Hydrogen Fuel Cells | Biofuel Systems |

|---|---|---|---|

| Performance | High energy density and efficiency; suitable for various driving conditions | Quick refueling and long range; less efficient than batteries | Varies by type; typically lower energy density compared to batteries |

| Cost | Moderate to high initial investment; long-term savings through reduced fuel costs | High initial costs; infrastructure investments needed | Generally lower initial costs; variable based on feedstock |

| Ease of Implementation | Widely available infrastructure; established supply chains | Limited refueling infrastructure; significant investment required | Existing infrastructure in some regions; easier to implement in agricultural settings |

| Maintenance | Regular battery checks; recycling needed at end-of-life | Lower maintenance; fuel cell longevity; hydrogen sourcing challenges | Infrastructure maintenance; feedstock sourcing management |

| Best Use Case | Urban and suburban use; fleets; commercial vehicles | Long-haul transportation; heavy-duty vehicles; remote areas | Agricultural applications; mixed-fuel systems; regional transport |

Detailed Breakdown of Alternatives

Hydrogen Fuel Cells: What Are Their Benefits and Drawbacks?

Hydrogen fuel cells convert hydrogen into electricity, providing a clean energy source with water vapor as the only byproduct. Their performance advantage lies in quick refueling and longer ranges, making them ideal for heavy-duty and long-distance vehicles. However, the cost of producing, storing, and transporting hydrogen remains high, and the necessary refueling infrastructure is still underdeveloped in many regions. Additionally, hydrogen production methods can vary in sustainability, depending on whether they rely on fossil fuels or renewable sources.

Biofuel Systems: How Do They Compare?

Biofuels, derived from organic materials such as crops and waste, offer a renewable alternative to traditional fossil fuels. They can be integrated into existing combustion engine systems with minimal modifications, making them easier to implement in regions with established agricultural practices. While biofuels can provide lower initial costs and leverage existing infrastructure, their energy density is generally lower than that of electric car batteries. Moreover, sourcing feedstock can raise sustainability concerns, particularly regarding land use and food production.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating energy solutions for electric vehicles, B2B buyers must consider various factors, including performance, cost, ease of implementation, and maintenance. Electric car batteries excel in urban environments and are supported by a growing infrastructure. Conversely, hydrogen fuel cells may serve specialized applications such as heavy-duty transport, while biofuels can provide a transitional solution in areas with agricultural capabilities. Ultimately, the choice depends on specific operational needs, regional infrastructure, and sustainability goals, guiding businesses towards the most suitable energy technology for their fleet.

Essential Technical Properties and Trade Terminology for electric car battries

What Are the Key Technical Properties of Electric Car Batteries?

Understanding the technical specifications of electric car batteries is crucial for B2B buyers, particularly in emerging markets like Africa, South America, the Middle East, and Europe. Here are several essential properties to consider:

1. Energy Density

Energy density refers to the amount of energy a battery can store relative to its weight or volume, measured in watt-hours per kilogram (Wh/kg) or watt-hours per liter (Wh/L). Higher energy density means longer driving ranges for electric vehicles (EVs), which is a critical factor for fleet operators and consumers alike. In regions with vast distances between charging stations, prioritizing higher energy density is essential.

2. Cycle Life

Cycle life indicates how many complete charge and discharge cycles a battery can undergo before its capacity significantly diminishes, typically expressed in number of cycles. A battery with a longer cycle life offers better value over time, reducing the frequency of replacements. B2B buyers should assess this property to ensure they are investing in batteries that can withstand regular usage.

3. Thermal Stability

Thermal stability describes a battery’s ability to maintain performance and safety under varying temperature conditions. Batteries with high thermal stability are less prone to overheating and thermal runaway, which is vital for operational safety. This feature is especially important in regions with extreme climates, where battery performance can significantly impact vehicle reliability.

4. Charge Time

Charge time is the duration required to recharge a battery to a specific capacity, typically measured in hours. Shorter charge times enhance the usability of EVs, making them more appealing for commercial applications where downtime is costly. Buyers should consider charge time in the context of their operational needs and available charging infrastructure.

5. Cost per kWh

The cost per kilowatt-hour (kWh) is a critical economic factor, representing the price of battery capacity. This metric helps B2B buyers assess the financial feasibility of integrating EV technology into their operations. Understanding this cost allows businesses to make informed decisions about their investments in electric mobility.

What Are the Common Trade Terms in the Electric Vehicle Battery Industry?

Navigating the electric vehicle battery market involves understanding specific trade terminology that can influence procurement and business decisions. Here are key terms every B2B buyer should know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of EV batteries, OEMs are crucial for ensuring that the batteries meet the specific requirements and standards set by vehicle manufacturers. Understanding OEM relationships can help buyers identify reliable suppliers.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers looking to manage inventory and procurement costs. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory or stock shortages.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request pricing and terms for a specific quantity of goods. In the electric battery market, submitting an RFQ can help buyers compare offers from different suppliers and negotiate better terms, ensuring they get competitive pricing and quality.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used in international transactions to clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border procurement, as they define who is responsible for costs and risks at various stages of the shipping process.

5. BMS (Battery Management System)

A Battery Management System (BMS) is an electronic system that manages a rechargeable battery by monitoring its state, calculating its secondary data, and controlling its environment. A robust BMS is critical for optimizing battery performance and ensuring safety, making it an important consideration for buyers when evaluating battery options.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make informed decisions, ultimately leading to successful investments in electric vehicle battery technology.

Navigating Market Dynamics and Sourcing Trends in the electric car battries Sector

What Are the Key Drivers Shaping the Electric Car Battery Market?

The electric vehicle (EV) battery market is experiencing transformative growth, driven by several global factors. Increased consumer demand for sustainable transportation, rising fuel prices, and stringent environmental regulations are pushing manufacturers to innovate and expand their EV offerings. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are particularly focused on sourcing technologies that enhance battery performance, affordability, and safety.

Emerging trends include a shift toward Lithium Iron Phosphate (LFP) batteries, which offer a cost-effective solution with enhanced thermal stability, making them suitable for diverse climates. This is particularly relevant for markets with high temperatures, such as parts of Africa and the Middle East. Additionally, the development of solid-state batteries promises to revolutionize the industry by offering higher energy densities and faster charging capabilities, although they remain in the experimental phase.

B2B buyers should also consider the growing importance of battery recycling technologies as part of the sourcing strategy. With the potential for EV batteries to account for up to 40% of a vehicle’s total cost, efficient recycling processes can mitigate supply chain risks and reduce costs. As manufacturers pivot towards sustainable practices, international buyers can leverage these trends to optimize their procurement strategies and align with global sustainability goals.

How Can Sustainability and Ethical Sourcing Influence Your B2B Decisions in the Electric Car Battery Sector?

Sustainability is not just a buzzword; it is becoming an essential criterion for B2B buyers in the electric car battery sector. The environmental impact of battery production, particularly concerning resource extraction and carbon emissions, necessitates a focus on ethical sourcing. Buyers are increasingly required to ensure that their supply chains adhere to sustainability principles, which include responsible sourcing of raw materials like lithium, cobalt, and nickel.

Many international buyers are now prioritizing suppliers who can demonstrate compliance with environmental standards and hold certifications for sustainable practices. For instance, certifications such as ISO 14001 or initiatives like the Responsible Cobalt Initiative can provide assurance that materials are sourced responsibly. Furthermore, the adoption of “green” materials, including recycled components, is gaining traction. This not only enhances the sustainability profile of the product but also appeals to environmentally conscious consumers, thereby providing a competitive edge.

By aligning sourcing strategies with sustainable practices, B2B buyers can mitigate risks associated with supply chain disruptions and enhance their brand reputation in a market that increasingly values corporate responsibility.

What Is the Historical Context of Electric Car Battery Development Relevant to B2B Buyers?

The evolution of electric car batteries has been marked by significant technological advancements and shifting market dynamics. Initially dominated by lead-acid batteries, the industry transitioned to lithium-ion technologies in the late 20th century, which dramatically improved energy density and charging times. This shift laid the groundwork for the modern electric vehicle market, enabling longer ranges and better performance.

As electric vehicles gained popularity, the demand for more efficient and sustainable battery solutions surged. In recent years, the introduction of battery chemistries like LFP and the exploration of solid-state technologies have further transformed the landscape. For B2B buyers, understanding this historical context is crucial, as it informs current sourcing decisions and highlights the importance of innovation in maintaining a competitive edge in an increasingly dynamic market. By keeping abreast of these developments, buyers can better navigate their procurement strategies and align with the ongoing evolution of the electric vehicle sector.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car battries

-

How do I choose the right type of electric car battery for my needs?

Selecting the appropriate electric car battery depends on your specific requirements, such as vehicle type, intended use, and environmental conditions. Common battery types include Lithium Iron Phosphate (LFP) for cost-effectiveness and safety, Nickel Manganese Cobalt (NMC) for high energy density, and Nickel Cobalt Aluminum (NCA) for premium performance. Consider factors like cycle life, thermal stability, and charging speed. Conduct thorough research on battery performance metrics and consult with suppliers to find the best fit for your fleet or project. -

What are the key factors to consider when vetting electric car battery suppliers?

When vetting suppliers, focus on their reputation, product quality, and certifications. Look for suppliers with a track record in the EV battery market, preferably with international experience. Request samples to assess the battery performance and compliance with safety standards. Additionally, evaluate their supply chain transparency and sustainability practices, as these factors can impact long-term reliability and corporate responsibility. Establish clear communication channels to ensure responsiveness and support throughout the procurement process. -

What is the minimum order quantity (MOQ) for electric car batteries?

Minimum order quantities for electric car batteries can vary widely among suppliers, often ranging from a few dozen to several hundred units. Factors influencing MOQ include battery type, customization options, and supplier capabilities. If you are a smaller buyer or just starting, discuss your needs with potential suppliers, as many are willing to negotiate MOQs to build relationships. Additionally, consider grouping orders with other businesses to meet MOQ requirements and optimize logistics. -

What payment terms should I expect when sourcing electric car batteries internationally?

Payment terms for international transactions can differ based on supplier policies and the buyer’s creditworthiness. Common terms include upfront payments, letter of credit, or staggered payments based on shipment milestones. Always clarify the payment structure before finalizing the agreement to avoid misunderstandings. Additionally, inquire about currency exchange rates and any potential fees related to international transactions to ensure a smooth financial process. -

How can I ensure the quality of electric car batteries I purchase?

To ensure battery quality, request detailed specifications, testing reports, and certifications from suppliers. Consider conducting third-party inspections or audits, especially for large orders. Establish clear quality assurance (QA) protocols with your supplier, including performance benchmarks and warranty terms. Additionally, engage in ongoing communication and feedback with your supplier regarding any performance issues, which can help maintain quality over time. -

What logistics considerations should I keep in mind when importing electric car batteries?

Logistics for importing electric car batteries involve understanding shipping regulations, customs clearance, and transportation options. Ensure compliance with international shipping laws, particularly concerning hazardous materials, as many batteries fall under such classifications. Collaborate with logistics providers experienced in handling battery shipments to navigate potential challenges. Additionally, factor in lead times, storage requirements, and any tariffs that may apply to your imports. -

What are the environmental implications of sourcing electric car batteries?

Sourcing electric car batteries has significant environmental implications, primarily related to raw material extraction and battery disposal. Opt for suppliers that prioritize sustainable sourcing practices and use environmentally friendly materials. Inquire about battery recycling programs to minimize waste and promote a circular economy. Understanding the lifecycle impact of the batteries you purchase can enhance your brand’s sustainability credentials and align with global environmental standards. -

How do battery performance metrics influence my purchasing decisions?

Battery performance metrics such as energy density, cycle life, and charging speed are critical in determining the suitability of a battery for your applications. High energy density allows for longer ranges, while cycle life indicates longevity and cost-effectiveness over time. Consider how these metrics align with your operational needs, such as fleet usage or specific vehicle requirements. Engage with suppliers to understand how their batteries perform under various conditions, ensuring you make informed purchasing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Electric Car Battries Manufacturers & Suppliers List

1. Green Cars – EV Battery Insights

Domain: greencars.com

Registered: 1998 (27 years)

Introduction: Different Types of EV Batteries: 1. Lithium Iron Phosphate (LFP): Energy Density: Moderate, Cycle Life: Excellent (up to 3,000+ cycles), Thermal Stability: Very high, Cost: Lower than other types. Benefits: Affordable, safe, long-lasting, performs well in city driving and moderate climates. Trade-Offs: Shorter range. Used In: Base versions of Tesla Model 3 and Model Y, some BYD and Ford EVs. 2. Ni…

2. EV West – High Discharge 600A LiFePo4 Prismatic Cells

Domain: evwest.com

Registered: 2010 (15 years)

Introduction: [{‘name’: ‘High Discharge 600A LiFePo4 74AH Prismatic Cells’, ‘price’: ‘$44.00’, ‘description’: ‘Perfect for high discharge applications.’, ‘availability’: ‘In stock’}, {‘name’: ‘Tesla Model S Lithium Ion Battery 18650 EV Module’, ‘price’: ‘$1,580.00’, ‘description’: ‘Used 18650 Tesla battery modules from a 85kWh Model S with EV West BMS boards.’, ‘availability’: ‘In stock’}, {‘name’: ‘Samsung INR…

3. Reddit – Next-Gen Solid State Electric Car Battery

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Next-gen solid state electric car battery; charges in under 15 minutes; driving distance of over 500 miles; potential development timeline of 3 to 15 years depending on technology and market demands.

4. National Grid – Electric Car Batteries

Domain: nationalgrid.com

Registered: 1996 (29 years)

Introduction: Electric car batteries are lithium-ion packs consisting of over 2,000 individual cells, designed to last between 100,000 to 200,000 miles, with a life expectancy of 15 to 20 years. They come with extended warranties of eight years or 100,000 miles. Once their capacity drops to 70% or less, they can be repurposed for static energy storage systems, especially when paired with renewable energy source…

5. Electric Vehicle Council – EV Battery Recycling

Domain: electricvehiclecouncil.com.au

Introduction: This company, Electric Vehicle Council – EV Battery Recycling, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Malvern Panalytical – Electric Car Battery Solutions

Domain: malvernpanalytical.com

Registered: 2016 (9 years)

Introduction: Electric car batteries, primarily Li-ion, consist of various chemistries including nickel manganese cobalt (NMC) and Lithium Iron Phosphate (LFP). NMC offers high energy density but raises environmental concerns due to cobalt, while LFP is cheaper and safer but has lower energy density. Key components of Li-ion batteries include cathode (NMC or LFP), anode (Graphite or Silicon), separator (PVDF po…

7. Recurrent Auto – Electric Car Battery Insights

Domain: recurrentauto.com

Registered: 2020 (5 years)

Introduction: Electric car batteries, particularly lithium-ion types, can account for 30-50% of an EV’s value. A study of 20,000 cars revealed that battery replacements are rare, with only 2.5% replaced outside of major recalls. Older EVs (pre-2015) have a 13% replacement rate, while newer models (2016 and later) have under 1%. Notable recalls include the Chevrolet Bolt EV and Hyundai Kona Electric. Most replac…

8. EDF Energy – Electric Car Batteries

Domain: edfenergy.com

Registered: 2003 (22 years)

Introduction: This company, EDF Energy – Electric Car Batteries, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

9. EVBox – Lithium-Ion Battery Solutions

Domain: blog.evbox.com

Registered: 2007 (18 years)

Introduction: EV batteries are typically made of thousands of rechargeable lithium-ion cells connected to form a battery pack. The most common types of battery cells are cylindrical, prismatic, and pouch cells. Lithium-ion batteries are primarily composed of lithium, nickel, cobalt, and manganese for the cathode, and graphite for the anode, enclosed in an aluminum or steel casing. Key components of an EV batter…

Strategic Sourcing Conclusion and Outlook for electric car battries

As the global demand for electric vehicles (EVs) continues to rise, the importance of strategic sourcing for EV batteries cannot be overstated. Understanding the diverse battery chemistries—such as Lithium Iron Phosphate (LFP), Nickel Manganese Cobalt (NMC), and emerging solid-state technologies—enables B2B buyers to make informed decisions tailored to their market needs. Sourcing the right battery type can enhance vehicle performance, optimize costs, and ensure safety, particularly in the diverse climates of Africa, South America, the Middle East, and Europe.

Moreover, the strategic sourcing of raw materials is becoming increasingly crucial as manufacturers seek to mitigate supply chain risks and embrace sustainability. By prioritizing partnerships with suppliers who emphasize ethical sourcing and advanced recycling methods, businesses can not only comply with regulations but also appeal to environmentally-conscious consumers.

Looking ahead, the evolution of battery technology presents exciting opportunities. International B2B buyers are encouraged to engage with industry leaders, explore innovative solutions, and consider long-term partnerships that foster growth in the electric vehicle market. The future of transportation is electric, and your strategic sourcing decisions today will shape your competitive edge tomorrow.