Introduction: Navigating the Global Market for new energy solar panel electric vehicles

As global demand for sustainable transportation solutions accelerates, B2B buyers face the pressing challenge of sourcing new energy solar panel electric vehicles (EVs) that align with their sustainability goals and operational needs. The rise of solar EV technology presents a unique opportunity to reduce dependence on traditional energy sources while enhancing mobility options across diverse markets. This guide serves as an essential resource for international buyers, particularly those in Africa, South America, the Middle East, and Europe, such as Saudi Arabia and Brazil, where the push for clean energy solutions is gaining momentum.

Within this comprehensive guide, readers will explore various types of solar panel electric vehicles, including urban mobility solutions like compact city cars and versatile commercial applications. We delve into crucial factors such as supplier vetting processes, cost analysis, and the integration of solar technology, ensuring that buyers are equipped to make informed purchasing decisions. With insights into the latest advancements and market trends, this guide empowers businesses to navigate the complexities of sourcing solar EVs effectively.

By understanding the benefits of solar charging systems and their potential to enhance operational efficiency, B2B buyers can position themselves at the forefront of the clean mobility revolution, contributing to a more sustainable future while meeting their organizational objectives.

Understanding new energy solar panel electric vehicles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Solar Electric Vehicles | Integrated solar panels for charging, off-grid capability | Fleet management, urban transport | Pros: Reduces charging costs; Cons: Initial investment is high. |

| Solar City Cars | Compact design, minimal parking space requirement, solar charging | Urban mobility solutions | Pros: Cost-effective urban transport; Cons: Limited speed and range. |

| Solar-Powered Golf Carts | Low-speed vehicles equipped with solar panels | Golf courses, resorts, campuses | Pros: Eco-friendly; Cons: Limited to short distances. |

| Solar Charging Trailers | Trailers equipped with solar panels for electric vehicle charging | Logistics, outdoor events | Pros: Portable charging solution; Cons: Dependence on sunlight availability. |

| Solar Buses | Large vehicles with solar panels, designed for public transport | Public transit systems | Pros: Reduces operational costs; Cons: Requires infrastructure support. |

What are the Characteristics of Solar Electric Vehicles for B2B Buyers?

Solar electric vehicles (SEVs) are notable for their integration of solar panels, allowing them to charge off-grid. This capability is particularly advantageous for businesses with fleet management needs, as it can significantly reduce fuel and charging costs. SEVs are suitable for various applications, including logistics and urban transport, making them a versatile choice for companies aiming to enhance sustainability. When considering SEVs, buyers should evaluate the total cost of ownership, potential savings, and the vehicle’s integration into existing fleet operations.

How Do Solar City Cars Address Urban Mobility Challenges?

Solar city cars are compact vehicles designed for urban environments, featuring integrated solar panels that allow for self-charging. Their small size ensures minimal parking space is required, making them ideal for congested city centers. These vehicles are primarily targeted at businesses focusing on urban mobility solutions, such as ride-sharing platforms and local delivery services. Buyers should consider factors such as vehicle range, charging capabilities, and compliance with local regulations when exploring this option.

What Advantages Do Solar-Powered Golf Carts Offer for Specific Markets?

Solar-powered golf carts are specially designed low-speed vehicles equipped with solar panels. These carts are ideal for use in golf courses, resorts, and large campuses, providing an eco-friendly alternative to traditional gas-powered options. They offer a unique solution for businesses looking to reduce their carbon footprint while maintaining operational efficiency. Buyers should assess the vehicle’s range, maintenance requirements, and suitability for their specific use cases, particularly in terms of distance and terrain.

What are the Benefits of Using Solar Charging Trailers in Logistics?

Solar charging trailers are portable units equipped with solar panels, designed to charge electric vehicles in remote locations or during outdoor events. This solution is particularly beneficial for logistics companies that operate in areas with limited access to traditional charging infrastructure. The flexibility and mobility of solar charging trailers can enhance operational efficiency. Buyers need to consider the trailer’s charging capacity, compatibility with various electric vehicles, and the geographic areas in which they operate.

How Do Solar Buses Contribute to Sustainable Public Transport?

Solar buses are large public transport vehicles that utilize solar panels for energy. They are designed to reduce operational costs and carbon emissions in public transit systems. These buses can play a significant role in cities aiming to transition to greener public transport options. When evaluating solar buses, buyers should focus on the total lifecycle costs, required infrastructure for charging, and the expected return on investment through fuel savings and potential subsidies for green initiatives.

Key Industrial Applications of new energy solar panel electric vehicles

| Industry/Sector | Specific Application of new energy solar panel electric vehicles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Urban Mobility | Solar-powered city cars for shared mobility solutions | Reduces urban emissions and congestion while offering cost-effective transport | Ensure compliance with local regulations and safety standards |

| Agriculture | Solar electric vehicles for farm operations | Enhances operational efficiency and reduces fuel costs | Look for vehicles compatible with agricultural terrains |

| Logistics and Delivery | Last-mile delivery solutions using solar EVs | Minimizes carbon footprint and operational costs | Assess battery range and solar charging capabilities |

| Tourism and Recreation | Eco-friendly transportation for tourist attractions | Attracts eco-conscious customers and reduces operational costs | Evaluate vehicle capacity and adaptability to various terrains |

| Government and Municipalities | Solar electric vehicles for public transport and fleet management | Supports sustainability initiatives and lowers maintenance costs | Consider integration with existing transport infrastructure |

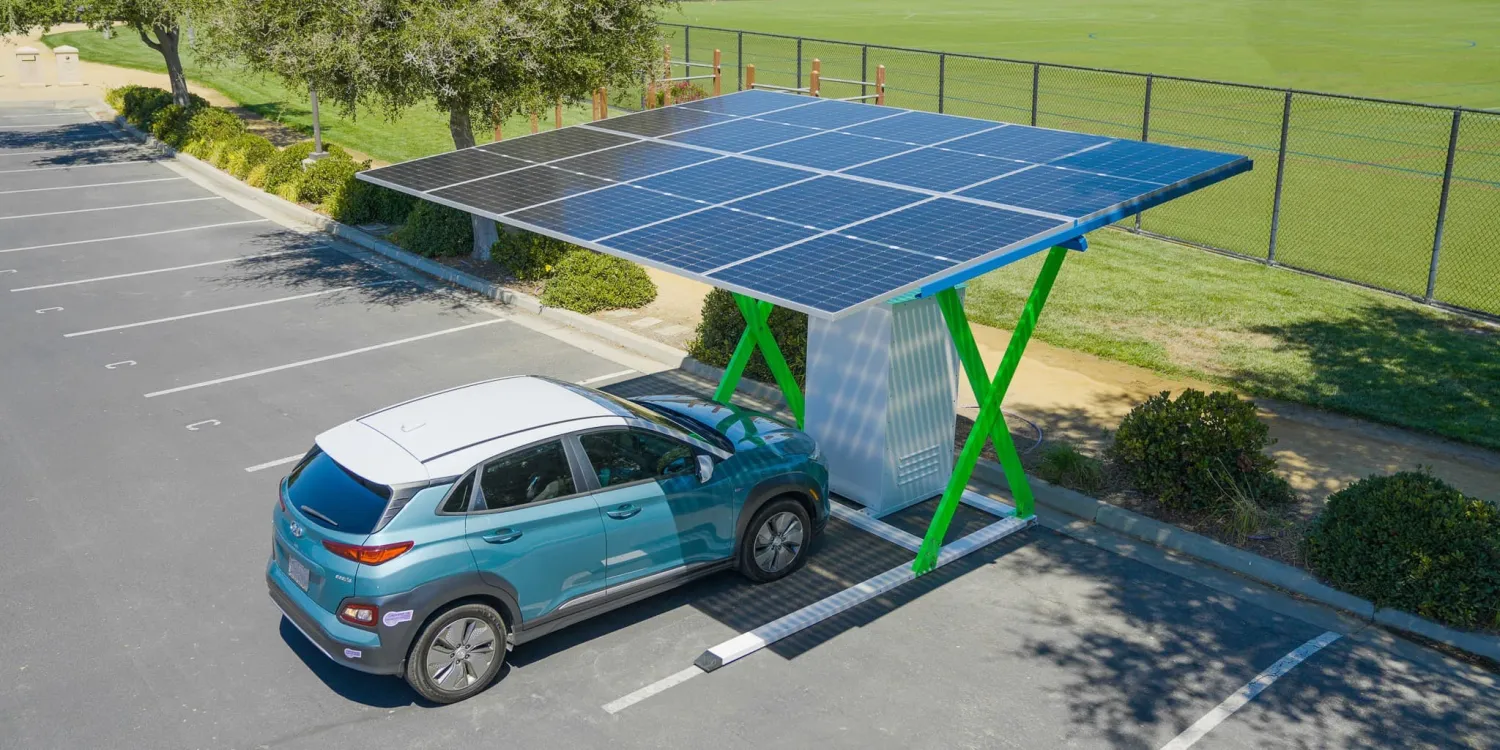

How are Solar Panel Electric Vehicles Transforming Urban Mobility?

Urban mobility is significantly enhanced through solar-powered city cars designed for shared platforms. These vehicles address urban emissions and congestion by providing a sustainable alternative for short-distance travel. Businesses can benefit from lower operational costs due to reduced reliance on traditional charging infrastructure, especially in regions with abundant sunlight. International buyers should consider local regulations regarding vehicle specifications and safety standards to ensure compliance and market acceptance.

What Role Do Solar Electric Vehicles Play in Agriculture?

In the agricultural sector, solar electric vehicles are increasingly utilized for farm operations, including transportation of goods and workers across large plots of land. By integrating solar panels, these vehicles can reduce fuel costs and reliance on grid electricity, which is particularly advantageous in remote areas. Buyers in this sector must focus on vehicles that can handle rugged terrains and are compatible with agricultural equipment, ensuring they meet operational requirements effectively.

How Can Logistics and Delivery Services Benefit from Solar EVs?

Last-mile delivery solutions leveraging solar electric vehicles are gaining traction as businesses aim to minimize their carbon footprint. These vehicles can be charged using renewable energy, leading to substantial savings on fuel costs. For international buyers, it is crucial to assess the battery range and efficiency of solar charging systems, particularly in regions with varying sunlight availability, to ensure the vehicles can meet delivery schedules without delays.

Why Are Solar Electric Vehicles Ideal for Tourism and Recreation?

Eco-friendly transportation options, such as solar electric vehicles, are increasingly popular in the tourism sector. They provide a sustainable way for tourists to explore attractions while reducing the environmental impact of travel. Businesses can attract eco-conscious customers and enhance their brand image by adopting these vehicles. Buyers should consider the vehicle’s capacity and ability to adapt to various terrains, ensuring a comfortable experience for tourists.

How Do Government and Municipalities Leverage Solar Electric Vehicles?

Governments and municipalities are adopting solar electric vehicles for public transport and fleet management to support sustainability initiatives. These vehicles not only lower operational costs through reduced maintenance and fuel expenses but also contribute to a cleaner environment. Buyers in this sector need to evaluate how these vehicles can integrate with existing transport infrastructure and comply with local regulations, ensuring a seamless transition to solar-powered solutions.

3 Common User Pain Points for ‘new energy solar panel electric vehicles’ & Their Solutions

Scenario 1: Inconsistent Solar Energy Production and Range Anxiety

The Problem: B2B buyers, particularly fleet managers in regions with variable sunlight, face significant challenges with inconsistent solar energy production. For instance, in areas where cloudy weather is prevalent, the performance of solar panel electric vehicles (EVs) may drop, leading to range anxiety. This inconsistency can disrupt operations, especially for businesses relying on timely deliveries or transportation services. The fear of running out of power can deter fleet managers from fully committing to solar EVs, impacting their sustainability goals and operational efficiency.

The Solution: To mitigate this issue, B2B buyers should consider investing in solar EVs equipped with advanced energy management systems that optimize energy usage and enhance battery efficiency. When sourcing these vehicles, ensure they have high-efficiency solar panels capable of performing well even in low-light conditions. Additionally, implementing a hybrid charging strategy can provide a backup power source, ensuring that vehicles are not solely reliant on solar energy. For fleet operators, integrating a monitoring system that tracks solar energy production and consumption in real-time can help manage range anxiety effectively. This data-driven approach enables proactive decision-making, allowing operators to plan routes and charging schedules better.

Scenario 2: High Initial Investment and Long-Term ROI Concerns

The Problem: Many businesses are deterred by the high upfront costs associated with purchasing solar panel electric vehicles. B2B buyers often grapple with justifying these expenses when traditional vehicles may appear more economical in the short term. The concern is not just about the initial financial outlay; there’s also apprehension regarding the long-term return on investment (ROI) and whether the savings from fuel and maintenance will outweigh the costs of solar technology.

The Solution: To address these concerns, buyers should conduct a comprehensive cost-benefit analysis that factors in potential savings from reduced fuel costs, lower maintenance expenses, and possible government incentives for sustainable practices. Engaging with manufacturers who offer financing options or leasing programs can alleviate the burden of upfront costs. Furthermore, buyers can explore case studies from similar businesses that have successfully integrated solar EVs into their fleets, showcasing their long-term savings and environmental impact. By aligning the investment with corporate sustainability goals, B2B buyers can make a compelling case for the transition to solar EVs, highlighting not just financial benefits but also positive brand positioning in an increasingly eco-conscious market.

Scenario 3: Limited Charging Infrastructure and Maintenance Support

The Problem: In many regions, especially in emerging markets, the lack of robust charging infrastructure poses a significant barrier to adopting solar panel electric vehicles. B2B buyers may find that their operational areas are not equipped with sufficient charging stations, which can lead to operational disruptions. Additionally, concerns about the availability of maintenance support for solar technology can make businesses hesitant to fully commit to these vehicles.

The Solution: To overcome the challenge of limited charging infrastructure, businesses should prioritize partnerships with local governments or organizations to advocate for the development of solar charging stations. Investing in portable solar chargers or mobile charging solutions can also provide flexibility, allowing vehicles to recharge during work hours in locations with direct sunlight. Moreover, when selecting solar EVs, it’s crucial to choose manufacturers that offer comprehensive maintenance packages and training for local service personnel. This proactive approach ensures that any technical issues can be promptly addressed, reducing downtime. By fostering relationships with service providers and investing in community infrastructure, B2B buyers can create a supportive ecosystem for their solar EV fleets, enhancing operational resilience.

Strategic Material Selection Guide for new energy solar panel electric vehicles

What Are the Key Materials for New Energy Solar Panel Electric Vehicles?

In the rapidly evolving sector of solar panel electric vehicles (EVs), selecting the right materials is crucial for optimizing performance, durability, and cost-effectiveness. Here, we analyze four common materials used in the construction of these vehicles, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Do Photovoltaic (PV) Cells Contribute to Solar EV Performance?

Key Properties: Photovoltaic cells are the heart of solar panels, converting sunlight into electricity. High-efficiency silicon-based PV cells typically operate effectively at temperatures ranging from -40°C to +85°C. They exhibit excellent corrosion resistance, which is essential for vehicles operating in diverse climates.

Pros & Cons: The primary advantage of silicon PV cells is their high energy conversion efficiency, often exceeding 20%. However, they can be relatively expensive and require complex manufacturing processes. Additionally, the fragility of silicon can lead to durability issues if not properly encapsulated.

Impact on Application: PV cells are compatible with various battery systems, allowing for flexible energy storage solutions. Their performance can be influenced by factors such as shading and orientation, which are critical considerations for vehicle design.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should prioritize suppliers that adhere to international standards such as IEC 61215 for PV module performance. Understanding local climate conditions is also vital for optimizing energy capture.

What Role Does Aluminum Play in Solar Panel Electric Vehicles?

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance and a melting point of approximately 660°C. Its low density makes it ideal for vehicle applications where weight reduction is crucial.

Pros & Cons: The main advantage of aluminum is its strength-to-weight ratio, which enhances vehicle efficiency. However, aluminum can be more expensive than steel and may require specialized welding techniques, increasing manufacturing complexity.

Impact on Application: Aluminum’s lightweight nature contributes to improved range and efficiency in solar EVs. It is particularly beneficial in regions with high temperatures, as it helps reduce the overall thermal load on the vehicle.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions. Additionally, understanding local availability and pricing fluctuations is essential for cost-effective sourcing.

How Does Composite Material Enhance Solar EV Durability?

Key Properties: Composite materials, often a blend of fiberglass and resin, offer high strength-to-weight ratios and excellent resistance to environmental factors. They can withstand temperatures up to 120°C and are resistant to corrosion and UV degradation.

Pros & Cons: Composites provide significant weight savings and design flexibility, allowing for innovative vehicle shapes. However, they can be more expensive than traditional materials and may require specialized manufacturing processes.

Impact on Application: The use of composites can enhance the longevity of solar EVs, making them suitable for harsh environments, such as those found in parts of Africa and South America.

Considerations for International Buyers: Compliance with standards like ASTM D638 for tensile strength is crucial. Buyers should also consider the availability of composite materials in their region, as sourcing can vary significantly.

What Is the Importance of High-Performance Glass in Solar EVs?

Key Properties: High-performance glass used in solar panels is designed to be both lightweight and impact-resistant, with a typical thickness of 3-6 mm. It can withstand extreme weather conditions and has a low thermal expansion coefficient.

Pros & Cons: The primary advantage of high-performance glass is its ability to protect PV cells while allowing maximum light transmission. However, it can be heavier than alternative materials, potentially impacting vehicle weight and efficiency.

Impact on Application: The glass’s durability ensures that solar panels remain operational in various environmental conditions, making them suitable for international markets with diverse climates.

Considerations for International Buyers: Buyers should look for compliance with standards such as ASTM C1036 for flat glass. Understanding local regulations regarding glass safety and performance is also essential.

Summary Table of Material Selection for Solar Panel Electric Vehicles

| Material | Typical Use Case for new energy solar panel electric vehicles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Photovoltaic (PV) Cells | Core component of solar panels for energy conversion | High energy conversion efficiency | Fragility and complex manufacturing | High |

| Aluminum | Structural components and body panels | Lightweight and strong | Higher cost and specialized welding needed | Med |

| Composite Materials | Body panels and structural elements | High strength-to-weight ratio | Expensive and requires specialized processes | High |

| High-Performance Glass | Protective layer for solar panels | Excellent light transmission and durability | Heavier than alternatives | Med |

This strategic guide provides essential insights into material selection for solar panel electric vehicles, aiding B2B buyers in making informed decisions that align with their operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for new energy solar panel electric vehicles

What Are the Key Stages in the Manufacturing Process of New Energy Solar Panel Electric Vehicles?

The manufacturing process of new energy solar panel electric vehicles (EVs) is complex and multifaceted, involving several critical stages. Each stage is designed to ensure that the final product meets high standards of performance and sustainability. Below are the main stages of the manufacturing process:

Material Preparation: What Materials Are Essential for Solar Panel EV Production?

The first step in the manufacturing process involves the careful selection and preparation of materials. Key components include high-efficiency photovoltaic (PV) cells, lightweight structural materials, and advanced battery technologies.

- Photovoltaic Cells: These are the heart of solar technology, converting sunlight into electrical energy. High-efficiency cells often use monocrystalline or polycrystalline silicon, which are chosen for their superior energy conversion rates.

- Structural Materials: Lightweight materials, such as aluminum and composite plastics, are utilized to enhance vehicle efficiency and performance. These materials reduce the overall weight, thereby maximizing the range and efficiency of the vehicle.

- Battery Technology: Lithium-ion batteries are commonly used due to their high energy density and longevity. Manufacturers may also explore solid-state or alternative battery technologies as they become commercially viable.

How Are Components Formed in the Production of Solar Panel EVs?

The forming stage involves shaping the raw materials into functional components. This typically includes several processes:

- Solar Panel Fabrication: The PV cells are assembled into modules using techniques such as lamination, where layers are bonded together to create a durable, weather-resistant panel.

- Chassis Formation: The vehicle’s chassis is constructed through processes like stamping and welding, ensuring structural integrity while maintaining a lightweight design.

- Battery Pack Assembly: Battery cells are assembled into packs, often utilizing automated systems for precision and efficiency.

What Techniques Are Used During the Assembly of Solar Panel Electric Vehicles?

Once components are formed, the assembly stage integrates all parts into the final product. This includes:

- Integration of Solar Panels: Solar panels are mounted onto the vehicle roof or body using specialized brackets and adhesive technologies to ensure secure attachment and optimal solar exposure.

- Electrical System Installation: Wiring for the solar charging system, battery management, and vehicle electronics is installed, ensuring seamless operation of the solar and electric systems.

- Final Assembly: This includes the installation of interior components, safety features, and quality checks to ensure that all systems are functioning correctly.

What Finishing Processes Are Involved in Solar Panel EV Manufacturing?

Finishing processes enhance the vehicle’s aesthetic appeal and durability. Key activities include:

- Surface Treatment: Coatings are applied to protect against UV degradation and enhance the vehicle’s appearance.

- Final Inspection: A thorough inspection ensures that the vehicle meets all design specifications and quality standards.

What Quality Assurance Practices Are Essential for Solar Panel Electric Vehicles?

Quality assurance (QA) is a critical aspect of the manufacturing process, ensuring that every vehicle produced meets international standards and customer expectations.

Which International and Industry-Specific Standards Should B2B Buyers Consider?

For B2B buyers, understanding relevant standards is essential for ensuring product quality and compliance. Key standards include:

- ISO 9001: This international standard outlines the criteria for a quality management system and emphasizes customer satisfaction and continuous improvement.

- CE Marking: Essential for products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards.

- API Standards: For vehicles using specific components, API (American Petroleum Institute) standards may apply, particularly in systems involving lubricants or fuels.

What Are the Key Quality Control Checkpoints in Solar Panel EV Manufacturing?

Quality control (QC) checkpoints are vital to maintaining product quality throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial checkpoint assesses the quality of raw materials and components before they enter production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for immediate corrective actions.

- Final Quality Control (FQC): The final inspection ensures that the completed vehicle meets all specifications and standards before it is shipped to customers.

What Common Testing Methods Are Used to Ensure Quality in Solar Panel EVs?

Various testing methods are employed to assess the performance and safety of solar panel electric vehicles, including:

- Performance Testing: Evaluating the efficiency of solar panels under different light conditions and measuring the vehicle’s range and charging capabilities.

- Durability Testing: Subjecting vehicles to environmental stress tests, including exposure to extreme temperatures, humidity, and UV light to ensure long-term performance.

- Safety Testing: Conducting crash tests and evaluating safety features to ensure compliance with safety regulations.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers meet high-quality standards, B2B buyers can employ several verification strategies:

- Supplier Audits: Regular audits of suppliers’ manufacturing processes and quality control systems can help ensure compliance with international standards.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC processes and any issues encountered during production.

- Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased evaluation of the supplier’s manufacturing practices and product quality.

What Are the QC and Certification Nuances for International B2B Buyers?

When sourcing solar panel electric vehicles from international suppliers, B2B buyers should consider specific nuances:

- Regulatory Compliance: Different regions have varying regulations and standards that must be adhered to. For example, CE marking is crucial for products sold in the EU, while other markets may have distinct requirements.

- Cultural Factors: Understanding cultural differences in business practices and communication styles can enhance negotiations and supplier relationships.

- Logistical Considerations: International shipping and customs regulations can affect delivery timelines, so it is essential to work with suppliers who are experienced in international logistics.

In conclusion, the manufacturing processes and quality assurance practices for new energy solar panel electric vehicles are intricate and demand a thorough understanding from B2B buyers. By focusing on manufacturing stages, quality standards, testing methods, and supplier verification strategies, buyers can make informed decisions that align with their sustainability and operational goals.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘new energy solar panel electric vehicles’

Introduction

This practical sourcing guide is designed to assist B2B buyers in procuring new energy solar panel electric vehicles (EVs). With a focus on sustainability and efficiency, these vehicles represent a significant investment for businesses aiming to reduce their carbon footprint while enhancing operational capabilities. By following this step-by-step checklist, buyers can ensure they select the right solutions that align with their business goals.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for your procurement process. Consider factors such as battery capacity, solar panel efficiency, vehicle range, and operational requirements. This will help you narrow down options and ensure that the vehicles meet your specific operational needs.

- Battery Type: Decide between lithium-ion or AGM batteries based on your energy requirements and budget.

- Vehicle Range: Determine how far the vehicle needs to travel on a single charge to avoid operational disruptions.

Step 2: Assess Local Market Conditions

Understanding local market conditions is vital for successful procurement. Each region has unique regulatory frameworks, available sunlight, and infrastructure that can affect the performance and viability of solar panel EVs.

- Sunlight Availability: Research average sunlight hours in your region to evaluate the potential energy generation of solar panels.

- Regulatory Compliance: Familiarize yourself with local regulations regarding electric vehicles and any incentives that may apply.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, thorough evaluation is essential. Request detailed company profiles, case studies, and references from clients in similar industries or regions.

- Supplier Credentials: Check for certifications and compliance with international standards to ensure product quality.

- Customer Reviews: Look for testimonials or reviews from current users to gauge reliability and performance.

Step 4: Request Product Demonstrations

Product demonstrations allow you to assess the actual performance of the vehicles. Arrange for test drives or demonstrations to evaluate how the solar panels integrate with the vehicle’s operation.

- Performance Metrics: Pay attention to how well the solar panels charge the vehicle under various conditions.

- User Experience: Observe ease of use and any technological features that enhance the driving experience.

Step 5: Analyze Total Cost of Ownership (TCO)

Calculating the total cost of ownership is crucial for understanding the long-term financial implications of your investment. Consider initial purchase costs, maintenance expenses, and potential savings on fuel and energy.

- Maintenance Costs: Investigate what routine maintenance is required for both the vehicle and the solar panels.

- Energy Savings: Estimate potential savings from reduced reliance on grid electricity and fuel costs.

Step 6: Negotiate Terms and Conditions

Once you have selected a potential supplier, negotiating terms is the next step. Ensure that the contract includes warranties, service agreements, and delivery timelines.

- Warranty Coverage: Understand what is covered under warranty and the duration to protect your investment.

- Service Agreements: Discuss options for ongoing maintenance and support to ensure vehicle longevity.

Step 7: Plan for Integration and Training

After procurement, plan for the integration of solar panel EVs into your existing fleet. Provide training for staff to maximize the benefits of the new technology.

- Staff Training: Ensure that personnel are trained on the unique aspects of operating solar panel EVs.

- Integration Strategy: Develop a plan for how these vehicles will fit into your existing logistics and operations.

By following this checklist, B2B buyers can make informed decisions that not only enhance their operational efficiency but also contribute positively to environmental sustainability.

Comprehensive Cost and Pricing Analysis for new energy solar panel electric vehicles Sourcing

What Are the Key Cost Components in New Energy Solar Panel Electric Vehicles?

When sourcing new energy solar panel electric vehicles (EVs), understanding the cost structure is essential for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of materials plays a significant role in the overall pricing of solar panel EVs. Key materials include high-efficiency photovoltaic (PV) cells, batteries (Li-ion or AGM), and the structural components of the vehicle. The prices for these materials can fluctuate based on market demand, technological advancements, and availability.

-

Labor: Labor costs vary widely by region and can significantly impact the final price. Countries with lower labor costs may offer a competitive advantage, but it’s crucial to ensure that quality standards are maintained. Skilled labor for assembly and quality assurance is particularly important in the production of solar EVs.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, such as utilities, equipment maintenance, and administrative expenses. Efficient production processes can help reduce overhead, ultimately influencing pricing.

-

Tooling: Initial investment in tooling and machinery is necessary for producing solar EVs. This cost can be substantial, especially for custom designs or specialized manufacturing processes. Buyers should inquire about the tooling costs as they may affect the overall price, particularly for lower volume orders.

-

Quality Control: Ensuring that each vehicle meets the required standards incurs additional costs. Quality control processes are vital for maintaining safety and performance, especially in the competitive EV market. This cost should be factored into the total price.

-

Logistics: Transportation costs must also be considered. These include shipping from the manufacturer to the buyer’s location, customs duties, and handling fees. Efficient logistics can mitigate some of these costs, making it essential to discuss potential shipping strategies with suppliers.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary significantly based on the supplier’s market position, the exclusivity of the product, and the competitive landscape.

How Do Price Influencers Impact Sourcing Decisions for Solar Panel EVs?

Several factors influence the pricing of solar panel electric vehicles, which are crucial for B2B buyers to consider:

-

Volume/MOQ: Ordering in larger quantities can often lead to lower per-unit costs. Minimum Order Quantities (MOQs) may vary by supplier, and negotiating these terms can yield better pricing.

-

Specifications/Customization: Customization requests can lead to increased costs. Buyers should be clear about their requirements upfront to avoid unexpected price hikes later in the process.

-

Materials and Quality Certifications: The choice of materials and the certifications held by the supplier (e.g., ISO, CE) can impact pricing. High-quality, certified components often command higher prices but can lead to better performance and durability.

-

Supplier Factors: The supplier’s reputation, experience, and financial stability can influence pricing. Established suppliers may have more robust quality assurance processes, which can justify higher costs.

-

Incoterms: Understanding the delivery terms outlined in Incoterms is vital. These terms dictate responsibility for shipping costs, insurance, and risk, which can affect the overall pricing structure.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Solar Panel EVs?

To maximize cost-efficiency when sourcing solar panel electric vehicles, buyers should consider the following strategies:

-

Negotiate Wisely: Develop a solid negotiation strategy that accounts for volume, payment terms, and delivery schedules. Building a long-term relationship with suppliers can also lead to better pricing over time.

-

Assess Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, energy savings from solar charging, and potential resale value. This holistic view can justify higher upfront costs if long-term savings are substantial.

-

Understand Pricing Nuances for International Transactions: Different regions may have varying pricing structures due to local economic conditions, tariffs, and regulations. Buyers from Africa, South America, the Middle East, and Europe should be aware of these factors when negotiating.

-

Request Indicative Pricing: Always ask for indicative pricing to understand the range of costs involved. This helps in budgeting and ensures that both parties are aligned on expectations.

In conclusion, understanding the cost components and pricing influences is essential for B2B buyers in the solar panel EV market. By leveraging negotiation tactics and considering the total cost of ownership, businesses can make informed sourcing decisions that align with their sustainability goals.

Alternatives Analysis: Comparing new energy solar panel electric vehicles With Other Solutions

Introduction to Alternative Solutions for Sustainable Mobility

As global demand for sustainable transportation options increases, businesses are exploring various technologies to meet their energy and mobility needs. Among these, new energy solar panel electric vehicles (SEVs) stand out for their innovative integration of renewable energy sources. However, other viable alternatives also exist, each offering unique advantages and challenges. This analysis aims to compare solar panel electric vehicles with alternative solutions to aid B2B buyers in making informed decisions.

Comparison Table

| Comparison Aspect | New Energy Solar Panel Electric Vehicles | Electric Vehicles (EVs) with Grid Charging | Hydrogen Fuel Cell Vehicles |

|---|---|---|---|

| Performance | Extended range via solar charging; efficient for daily commutes | High range and fast refueling capabilities | Long range; quick refueling similar to gasoline vehicles |

| Cost | Higher initial investment; potential savings on energy costs | Moderate initial costs; ongoing electricity costs | High initial investment; fuel costs vary based on infrastructure |

| Ease of Implementation | Requires sunlight; best in sunny regions | Widely available charging infrastructure | Limited refueling stations; requires specialized infrastructure |

| Maintenance | Low maintenance due to fewer moving parts | Moderate maintenance; battery replacement needed | Higher maintenance; requires specialized knowledge for fuel cells |

| Best Use Case | Urban commuting and off-grid travel | Long-distance travel and urban use | Heavy-duty applications and long-distance travel |

Detailed Breakdown of Alternatives

Electric Vehicles (EVs) with Grid Charging

Electric vehicles powered by conventional grid electricity are a popular choice for many businesses. They offer robust performance, high range, and the convenience of extensive charging networks. However, they depend heavily on the availability of charging infrastructure and can lead to increased operational costs over time due to electricity prices. Additionally, while they produce zero emissions at the tailpipe, the carbon footprint varies based on the energy source used for electricity generation. This makes them less sustainable in regions reliant on fossil fuels.

Hydrogen Fuel Cell Vehicles

Hydrogen fuel cell vehicles represent another alternative, particularly suitable for heavy-duty and long-distance applications. They can be refueled quickly, similar to traditional gasoline vehicles, making them attractive for fleet operations. However, the infrastructure for hydrogen refueling is still in its infancy, limiting accessibility. Additionally, the production of hydrogen can be energy-intensive, and its sustainability largely depends on the methods used for hydrogen generation. Thus, while offering potential advantages in specific contexts, they may not be the best fit for all operational needs.

Conclusion: Choosing the Right Solution for Your Business

When selecting the ideal transportation solution, B2B buyers should consider their specific operational needs, geographic location, and sustainability goals. New energy solar panel electric vehicles excel in urban environments with ample sunlight, providing an eco-friendly option for short-distance travel. In contrast, electric vehicles with grid charging may be more suitable for businesses requiring extensive travel across varied regions, while hydrogen fuel cell vehicles could be the best choice for heavy-duty applications needing fast refueling. Ultimately, assessing the total cost of ownership, infrastructure availability, and environmental impact will guide buyers toward the most appropriate solution for their unique circumstances.

Essential Technical Properties and Trade Terminology for new energy solar panel electric vehicles

What Are the Key Technical Properties of New Energy Solar Panel Electric Vehicles?

When considering new energy solar panel electric vehicles (EVs), understanding their technical specifications is crucial for B2B buyers. Here are some essential properties that impact performance, sustainability, and cost-effectiveness:

-

Photovoltaic (PV) Efficiency

PV efficiency indicates how effectively solar panels convert sunlight into electricity. Measured as a percentage, higher efficiency rates mean more energy generation from a smaller surface area. For B2B buyers, selecting vehicles with high-efficiency solar panels can significantly enhance operational performance, especially in regions with limited sunlight. -

Battery Compatibility and Capacity

Compatibility with various battery types (like AGM and lithium-ion) is vital for integrating solar panels with electric vehicles. Battery capacity, measured in kilowatt-hours (kWh), determines the total energy stored and influences the vehicle’s range. Understanding these specifications helps businesses ensure their fleet can meet daily operational demands without frequent recharging. -

Durability and Material Grade

The materials used in solar panels and vehicle construction, such as ETFE (ethylene tetrafluoroethylene), are important for longevity and performance. High-quality materials resist environmental factors like UV radiation, hail, and corrosion. This durability translates to lower maintenance costs and longer vehicle lifespans, making it a smart investment for fleet operators. -

Range Extension Capabilities

Range extension refers to the additional miles that can be achieved through solar charging. For example, some vehicles can add between 4.3 and 12.41 miles of range per day through solar energy. This capability is essential for businesses operating in remote areas, where traditional charging infrastructure may be lacking. -

Peak Sunlight Hours (PSH)

PSH measures the average hours of optimal sunlight available per day in a given location. It directly affects solar energy generation and, consequently, vehicle performance. B2B buyers should assess the PSH of their operational regions to determine the potential effectiveness of solar-powered vehicles in their fleets.

What Are Common Trade Terms in the New Energy Solar Panel Electric Vehicle Industry?

Familiarity with industry terminology is essential for effective communication and decision-making in B2B transactions. Here are key terms to know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of solar EVs, OEMs are crucial for providing the solar panels and components that ensure vehicles meet specific performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of goods a supplier is willing to sell. Understanding MOQs helps buyers gauge the scale of their purchases and negotiate terms effectively, particularly when sourcing components for fleet deployment. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price offers from suppliers for specific products or services. This process is essential for ensuring competitive pricing and evaluating potential suppliers for solar panel electric vehicles. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, which is crucial for B2B buyers importing solar EVs from different countries. -

Sustainability Metrics

These metrics evaluate the environmental impact of products, including emissions reductions and energy efficiency. For businesses focused on corporate social responsibility, understanding sustainability metrics is key to aligning purchases with eco-friendly initiatives.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions about integrating new energy solar panel electric vehicles into their operations, enhancing both efficiency and sustainability.

Navigating Market Dynamics and Sourcing Trends in the new energy solar panel electric vehicles Sector

What Are the Key Market Trends Shaping the New Energy Solar Panel Electric Vehicles Sector?

The new energy solar panel electric vehicle (EV) market is experiencing significant growth, driven by increasing global demand for sustainable transportation solutions. Key market dynamics include advancements in solar technology, which enable vehicles to harness solar energy efficiently for charging. For instance, companies like Lightyear and GEM are developing vehicles that can extend their driving range by integrating solar panels, thus reducing reliance on traditional charging infrastructure. This trend is particularly relevant for B2B buyers in regions such as Africa and South America, where access to reliable charging stations can be limited.

Emerging sourcing trends in this sector include a focus on local manufacturing capabilities and partnerships with tech innovators. B2B buyers are increasingly seeking suppliers that not only offer cutting-edge technology but also demonstrate a commitment to reducing carbon footprints throughout the supply chain. The integration of solar technology into electric vehicles is anticipated to enhance their appeal, especially in markets with abundant sunlight, such as the Middle East and parts of Europe. As environmental regulations tighten globally, businesses will need to adapt their sourcing strategies to align with sustainability goals while ensuring product viability and competitiveness.

How Can Businesses Ensure Sustainability and Ethical Sourcing in the New Energy Solar Panel Electric Vehicles Sector?

Sustainability plays a critical role in the sourcing of new energy solar panel electric vehicles. The environmental impact of these vehicles is significantly lower than traditional combustion engines, but businesses must also consider the sustainability of the materials used in manufacturing. Ethical sourcing is paramount, as suppliers should adhere to responsible mining and production practices for critical materials like lithium and cobalt, commonly used in batteries.

B2B buyers should look for suppliers who possess recognized sustainability certifications, such as ISO 14001 or similar “green” labels. These certifications indicate that a supplier is committed to environmental management and sustainability throughout its operations. Additionally, the use of recyclable materials in the production of solar panels and vehicle components can further enhance a company’s sustainability profile. Buyers can gain a competitive advantage by choosing partners that prioritize ethical sourcing, as consumers increasingly demand transparency and responsibility in the products they purchase.

What Is the Historical Context Behind the Rise of Solar Panel Electric Vehicles?

The evolution of solar panel electric vehicles can be traced back to the early 2000s when interest in renewable energy solutions began to gain momentum due to rising concerns about climate change and fossil fuel dependency. Initial prototypes focused on integrating solar technology into conventional electric vehicles, showcasing the potential for energy independence and reduced emissions.

As technology advanced, the market saw the emergence of dedicated solar EV manufacturers, which began to refine designs and improve efficiency. This shift was marked by the introduction of vehicles specifically designed to integrate solar panels as a primary energy source, enhancing the viability of off-grid electric mobility. Today, the sector is poised for exponential growth, with a robust pipeline of innovations aimed at addressing both urban mobility challenges and global sustainability goals. For B2B buyers, understanding this historical context is crucial for making informed sourcing decisions that align with future market trends.

Frequently Asked Questions (FAQs) for B2B Buyers of new energy solar panel electric vehicles

-

How do I evaluate the quality of new energy solar panel electric vehicles?

When assessing the quality of solar panel electric vehicles (EVs), consider the manufacturer’s reputation, certifications, and technology used. Look for vehicles that utilize high-efficiency photovoltaic cells and have undergone rigorous testing for durability and performance in various environmental conditions. Request detailed specifications, user reviews, and case studies from existing customers. Additionally, inquire about warranties and after-sales support, as this can be a strong indicator of the manufacturer’s confidence in their product. -

What is the best solar panel electric vehicle for urban mobility?

The best solar panel electric vehicle for urban mobility typically depends on your specific needs, such as passenger capacity, range, and budget. For compact, efficient urban transport, vehicles like the Squad Solar City Car stand out, offering zero emissions, space-efficient design, and integrated solar charging. Evaluate models based on energy efficiency, ease of parking, and compatibility with local regulations. Additionally, consider vehicles that allow for easy integration with existing urban transport systems. -

What factors should I consider when vetting suppliers for solar panel electric vehicles?

When vetting suppliers, prioritize their experience in the solar EV market, production capacity, and compliance with international quality standards. Review their supply chain processes and ensure they have reliable sourcing for high-quality solar components. It’s also essential to assess their financial stability and customer service capabilities. Request references from previous B2B clients to gauge their reliability and responsiveness to issues such as delivery schedules and product support. -

What are the minimum order quantities (MOQs) for solar panel electric vehicles?

Minimum order quantities (MOQs) can vary significantly by manufacturer and model. Typically, MOQs for commercial vehicles may range from 10 to 50 units, depending on the supplier’s production capacity and your customization requirements. It’s advisable to negotiate MOQs based on your initial needs and future growth plans. Some manufacturers may offer lower MOQs for pilot projects or strategic partnerships, allowing you to test the market before committing to larger orders. -

What payment terms are common for international purchases of solar panel electric vehicles?

Payment terms for international transactions usually include options like letters of credit, advance payments, and payment upon delivery. Common terms might involve a 30% deposit upon order confirmation, with the balance payable prior to shipment or upon delivery. Ensure that the payment terms align with your cash flow management and risk tolerance. It’s also crucial to discuss currency exchange rates and potential fees associated with international transactions to avoid unexpected costs. -

How can I customize solar panel electric vehicles to fit my business needs?

Customization options for solar panel electric vehicles often include modifications in design, battery capacity, and additional features like enhanced solar panels or specialized interiors. Discuss your specific requirements with the supplier early in the negotiation process. Many manufacturers offer tailored solutions based on your operational needs, whether for fleet management, passenger transport, or utility applications. Be prepared to provide detailed specifications to ensure the final product meets your expectations. -

What quality assurance processes should I expect from suppliers?

Reputable suppliers of solar panel electric vehicles should have established quality assurance (QA) processes in place. This typically includes rigorous testing of materials and components, compliance with international safety standards, and regular audits of manufacturing processes. Inquire about their QA certifications, such as ISO 9001, and request documentation of test results for the vehicles you are considering. A strong QA process is critical to ensuring product reliability and longevity. -

What logistics considerations should I keep in mind when importing solar panel electric vehicles?

When importing solar panel electric vehicles, consider logistics aspects such as shipping methods, customs clearance, and potential tariffs. Work with a logistics partner experienced in handling vehicle imports to ensure compliance with local regulations and minimize delays. Evaluate shipping options based on cost, transit time, and the fragility of the vehicles. Additionally, plan for storage and distribution within your region to ensure a smooth transition from port to end-user.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 New Energy Solar Panel Electric Vehicles Manufacturers & Suppliers List

1. GEM – Solar Electric Car

Domain: gemcar.com

Registered: 1998 (27 years)

Introduction: GEM Electric Car with Solar Panels: EV solar panels charge on the go and off the grid, extending drive time between charges by up to 40%. The solar electric car design integrates solar panels seamlessly, maximizing off-grid charging efficiency and sustainability goals. Key features include:

– Sustainability: Reduces grid-tied energy consumption with all-electric, zero-emission GEM EVs.

– Conveni…

2. Aptera – Solar Electric Vehicle

Domain: aptera.us

Registered: 2019 (6 years)

Introduction: Aptera is a solar electric vehicle designed to be highly efficient, requiring no charging for most daily use. Key specifications include:

– Integrated solar cells generating ~700 watts

– Up to 40 miles of free solar-powered driving per day

– 400 miles of range per full charge

– Acceleration from 0-60 mph in less than 6 seconds

The vehicle is currently in testing and validation, with specifica…

3. TNO – Sustainable On-Board Solar Solutions for Vehicles

Domain: tno.nl

Registered: 1987 (38 years)

Introduction: This company, TNO – Sustainable On-Board Solar Solutions for Vehicles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Solar.com – EVs & Solar Panels

Domain: solar.com

Registered: 1994 (31 years)

Introduction: Electric Vehicles (EVs) and Solar Panels are complementary products that offer significant cost savings and benefits for homeowners. Key details include: 1. Cost Comparison: Charging an EV at home with solar costs approximately 2 cents per mile, compared to 14 cents per mile for gas-powered vehicles. This results in annual fuel cost savings of nearly $1,700 for an average American driving 14,000 m…

5. Arka360 – Solar-Powered Electric Vehicles

Domain: arka360.com

Registered: 2023 (2 years)

Introduction: Solar-powered electric vehicles (EVs) offer a cleaner, sustainable alternative to traditional gasoline-powered vehicles. Key advantages include: 1. Self-power generation using solar panels, reducing dependence on the electric grid. 2. Lower operating costs due to cheaper solar electricity compared to gasoline. 3. Reduced noise and fewer moving parts, simplifying maintenance. 4. Accessibility in ar…

6. Fisker – Ocean and Karma Solar Innovations

Domain: edmunds.com

Registered: 1996 (29 years)

Introduction: 1. Fisker Ocean: Solar roof on Ocean Extreme trim generates up to 1,500 miles of range per year (4 miles/day low end) or 2,000 miles in ideal conditions (5.5 miles/day high end).

2. Fisker Karma/Karma Revero: Small solar roof offers 200 watts of charging; takes over a month to charge the 20-kWh battery under average conditions.

3. Toyota Prius Prime: Optional solar panel roof for about $600; c…

Strategic Sourcing Conclusion and Outlook for new energy solar panel electric vehicles

As the demand for sustainable mobility solutions grows, strategic sourcing in the new energy solar panel electric vehicle sector presents a compelling opportunity for international B2B buyers. Companies like Lightyear, GEM, and Squad Mobility showcase innovative technologies that not only enhance vehicle efficiency but also align with global sustainability goals. By integrating solar charging systems, these vehicles reduce dependency on traditional energy sources, offering significant operational cost savings and improved performance.

Investing in solar panel electric vehicles can lead to enhanced brand reputation, as companies demonstrate their commitment to environmental stewardship. For buyers in regions such as Africa, South America, the Middle East, and Europe, leveraging local solar resources can further maximize the benefits of these vehicles, making them an ideal choice for urban mobility and off-grid applications.

Looking ahead, the market for solar panel electric vehicles is poised for significant growth. Now is the time for B2B buyers to engage with manufacturers and suppliers to explore tailored solutions that meet their unique needs. Embrace this transition towards clean mobility and position your business as a leader in sustainable practices. Act now to drive the change towards a greener future.