Introduction: Navigating the Global Market for truck Mounted Crane

In today’s competitive landscape, sourcing the right truck-mounted crane can be a daunting challenge for international B2B buyers. With diverse applications ranging from construction to logistics, the need for cranes that deliver optimal performance and reliability is paramount. This guide serves as a comprehensive resource for navigating the global market for truck-mounted cranes, addressing critical factors such as types, applications, supplier vetting, and cost analysis.

Whether you are operating in Africa, South America, the Middle East, or Europe, understanding the nuances of the truck-mounted crane market is essential for making informed purchasing decisions. Buyers will gain insights into the various models available, from knuckle boom cranes to service cranes, ensuring that they select the best equipment tailored to their specific operational needs.

Moreover, this guide will empower you to evaluate suppliers effectively, assess total cost of ownership, and identify potential return on investment. By leveraging the information contained herein, businesses can minimize risks associated with procurement and enhance their operational efficiency. As you delve into the subsequent sections, you will be equipped with the knowledge needed to secure the right truck-mounted crane that aligns with your strategic goals and operational demands.

Understanding truck Mounted Crane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Knuckle Boom Cranes | Articulated boom for flexibility; compact design | Construction, landscaping, utilities | Pros: Versatile, can handle various attachments. Cons: May have lower lifting capacity compared to larger models. |

| Telescoping Cranes | Extensible boom for greater reach; often heavier | Heavy lifting in construction, shipping | Pros: High lifting capacity, long reach. Cons: Requires more space for operation, can be less maneuverable. |

| Material Handling Cranes | Designed for specific materials like drywall | Building materials transport | Pros: Optimized for specific loads, efficient. Cons: Limited use outside of designated applications. |

| Service Cranes | Equipped for maintenance tasks; hydraulic systems | Fleet maintenance, repair services | Pros: Ideal for service vehicles, compact. Cons: Limited lifting capacity compared to other types. |

| Timber & Refuse Cranes | Specialized for timber and waste handling | Forestry, waste management | Pros: Durable and efficient for heavy loads. Cons: Niche applications may limit versatility. |

What Are Knuckle Boom Cranes and Their B2B Applications?

Knuckle boom cranes feature an articulated design that allows for increased flexibility and maneuverability. They are particularly useful in tight spaces where traditional cranes may struggle. These cranes can be equipped with various attachments, such as grapples or workman baskets, making them suitable for construction, landscaping, and utility applications. When considering a knuckle boom crane, buyers should assess their specific lifting needs and operational environments, as this type may offer lower lifting capacities compared to larger models.

How Do Telescoping Cranes Differ in Functionality?

Telescoping cranes are characterized by their extendable booms, which provide significant reach and lifting capabilities. This type is commonly used in construction and shipping industries, where heavy lifting is essential. The ability to extend the boom allows for greater versatility in positioning and load handling. However, buyers should be aware that telescoping cranes typically require more space for operation and may be less maneuverable in confined areas, making site planning a critical factor in their purchase.

What Makes Material Handling Cranes Unique?

Material handling cranes are specifically designed to transport and lift materials, such as drywall or other building supplies. They are engineered to optimize efficiency for specific loads and tasks, making them a valuable asset in the building materials industry. While these cranes excel in their designated applications, buyers should consider the potential limitations in versatility and ensure that their operational needs align with the crane’s capabilities.

Why Choose Service Cranes for Maintenance Operations?

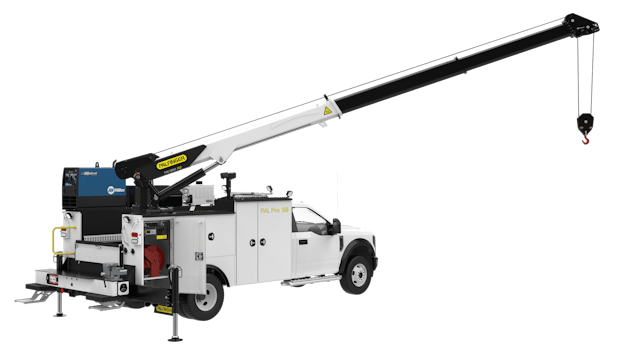

Service cranes are tailored for maintenance and repair tasks, featuring hydraulic systems that enhance their functionality. These cranes are often installed on service vehicles, making them ideal for fleet maintenance and repair services. Their compact design allows for easy maneuverability, but they typically come with lower lifting capacities compared to other crane types. Buyers should evaluate the specific maintenance tasks they need to perform to determine if a service crane meets their operational requirements.

What Are the Key Features of Timber & Refuse Cranes?

Timber and refuse cranes are specialized for handling heavy loads in forestry and waste management applications. These cranes are built for durability and efficiency, capable of managing the unique challenges associated with timber and refuse operations. While they offer robust performance in their niche applications, buyers should consider the limited versatility of these cranes and ensure that they align with their operational needs before making a purchase.

Key Industrial Applications of truck Mounted Crane

| Industry/Sector | Specific Application of Truck Mounted Crane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and placing heavy materials on-site | Reduces labor costs and enhances project efficiency | Load capacity, boom reach, and stability features |

| Logistics and Transportation | Loading and unloading cargo at delivery sites | Increases delivery speed and reduces handling damage | Versatility in attachments and ease of operation |

| Oil and Gas | Transporting equipment in remote locations | Enhances operational efficiency in challenging terrains | Durability, all-terrain capabilities, and maintenance support |

| Waste Management | Handling refuse and recyclable materials | Improves waste collection efficiency and safety | Load capacity, ease of maneuverability, and safety features |

| Forestry | Moving timber from logging sites to transport units | Streamlines operations and reduces manual labor | Adaptability to various attachments and terrain adaptability |

How Are Truck Mounted Cranes Used in the Construction Industry?

In the construction sector, truck mounted cranes are essential for lifting and placing heavy materials like steel beams, concrete blocks, and roofing materials directly on-site. These cranes help to reduce labor costs and enhance project efficiency by allowing fewer workers to handle heavy loads. For international buyers, it’s crucial to consider the crane’s load capacity and boom reach to ensure it meets the specific requirements of diverse construction sites, especially in regions with varying ground conditions.

What Role Do Truck Mounted Cranes Play in Logistics and Transportation?

In logistics and transportation, truck mounted cranes are utilized for loading and unloading cargo at delivery points. This capability accelerates the delivery process and minimizes the risk of damage during handling. Buyers should prioritize cranes that offer versatility in attachments, such as forks or grapples, to adapt to different cargo types. Additionally, ease of operation is vital for optimizing workforce efficiency in fast-paced environments.

How Are Truck Mounted Cranes Beneficial in the Oil and Gas Sector?

The oil and gas industry often requires the transportation of heavy equipment to remote locations, where traditional cranes may not operate effectively. Truck mounted cranes provide the necessary lifting capacity and maneuverability to navigate challenging terrains. For buyers in this sector, durability and maintenance support are key considerations, ensuring that the crane can withstand harsh environmental conditions while maintaining operational efficiency.

What Advantages Do Truck Mounted Cranes Offer in Waste Management?

In waste management, truck mounted cranes facilitate the handling of refuse and recyclable materials, improving collection efficiency and safety. These cranes can quickly load heavy bins and containers, reducing the time spent at each stop. When sourcing cranes for waste management, businesses should focus on load capacity and maneuverability to navigate urban environments while ensuring compliance with safety standards.

How Are Truck Mounted Cranes Used in Forestry Operations?

In forestry, truck mounted cranes are crucial for moving timber from logging sites to transport vehicles. They streamline operations by reducing the need for manual labor, which can be both time-consuming and hazardous. Buyers should consider cranes that can adapt to various attachments, such as grapples or saws, to enhance their versatility in different logging conditions, especially in rugged terrains common in many regions.

3 Common User Pain Points for ‘truck Mounted Crane’ & Their Solutions

Scenario 1: Inconsistent Lifting Capacity Affects Operational Efficiency

The Problem: Many B2B buyers in the construction and logistics industries face challenges with inconsistent lifting capacities from their truck-mounted cranes. This inconsistency can lead to delays in project timelines, increased operational costs, and potential safety hazards. Buyers may find that certain loads exceed the crane’s capacity or that the crane underperforms due to improper specifications or maintenance, resulting in a reliance on backup equipment or manual labor.

The Solution: To mitigate this issue, buyers should conduct a thorough assessment of their lifting needs before purchasing a truck-mounted crane. This involves calculating the maximum weight of loads they typically handle, including any additional attachments or tools that may be used with the crane. Buyers should choose a crane with a lifting capacity that exceeds their highest expected load by at least 20% to ensure safety and efficiency. Additionally, establishing a regular maintenance schedule is crucial to keeping the crane in optimal working condition. Engaging with reputable manufacturers who provide detailed specifications and support can further ensure that the selected crane matches operational requirements and is equipped with the necessary safety features.

Scenario 2: Difficulty Navigating Tight Spaces

The Problem: In urban settings or job sites with limited access, maneuverability becomes a significant concern for B2B buyers using truck-mounted cranes. Many cranes are not designed to operate efficiently in confined areas, leading to challenges in positioning for optimal lifting. This can result in damage to surrounding structures, increased labor costs, and prolonged project timelines due to the need for additional equipment or manual labor.

The Solution: To address maneuverability issues, buyers should consider selecting truck-mounted cranes with compact designs and features tailored for tight spaces, such as knuckle boom cranes. These cranes offer flexibility in operation, allowing for precise lifting and positioning without requiring significant space. Buyers should also invest in training for operators to enhance their skills in navigating complex job sites effectively. Moreover, utilizing crane models that include advanced control systems can improve precision and reduce the likelihood of accidents. It is advisable to consult with manufacturers about the crane’s dimensions and capabilities to ensure compatibility with specific job site constraints.

Scenario 3: Challenges with Crane Setup and Transportation

The Problem: Another common pain point for B2B buyers is the time and effort required to set up and transport truck-mounted cranes. Many operators struggle with cranes that require extensive setup procedures, leading to downtime and inefficiencies in workflow. Furthermore, cranes that are cumbersome to transport can increase logistical costs and complicate scheduling across multiple job sites.

The Solution: To streamline setup and transportation, buyers should prioritize cranes designed for quick assembly and disassembly. Models that feature integrated systems for rapid setup can significantly reduce the time spent preparing for operations. Buyers should also evaluate the transportation capabilities of the crane, including weight, dimensions, and compatibility with standard transportation vehicles. Investing in training for operators on efficient setup techniques can enhance productivity. Additionally, selecting cranes equipped with user-friendly interfaces and automation features can further simplify operations. Collaborating with suppliers who offer robust support and training resources can help ensure that teams are well-prepared to maximize their crane’s capabilities while minimizing downtime and logistical challenges.

Strategic Material Selection Guide for truck Mounted Crane

What Are the Key Materials Used in Truck Mounted Cranes?

When selecting materials for truck mounted cranes, several factors come into play, including performance, durability, cost, and compliance with international standards. Here, we analyze four common materials used in the construction of truck mounted cranes: steel, aluminum, composite materials, and high-strength plastics.

How Does Steel Perform in Truck Mounted Cranes?

Steel is the most commonly used material in truck mounted cranes due to its excellent strength-to-weight ratio and durability. Key properties include high tensile strength and resistance to deformation under load, making it suitable for heavy lifting applications. Steel also exhibits good temperature resistance, allowing it to perform well in various climates.

Pros: Steel is highly durable and can withstand significant stress, making it ideal for heavy-duty applications. It is also cost-effective, especially for large-scale manufacturing.

Cons: The main drawback of steel is its susceptibility to corrosion, particularly in humid or coastal environments. This necessitates protective coatings or treatments, which can increase manufacturing complexity and costs.

Impact on Application: Steel’s strength makes it compatible with a wide range of lifting tasks, but its weight can limit maneuverability in some applications.

Considerations for International Buyers: Compliance with standards such as ASTM A36 or DIN 17100 is crucial. Buyers in regions with high humidity, like parts of Africa and the Middle East, should prioritize corrosion-resistant coatings.

What Are the Advantages of Aluminum in Truck Mounted Cranes?

Aluminum is gaining popularity in the truck mounted crane market due to its lightweight properties and resistance to corrosion. Key properties include a lower density than steel, which allows for easier handling and improved fuel efficiency during transport.

Pros: Aluminum’s lightweight nature enhances the crane’s lifting capacity and maneuverability. It also requires less maintenance due to its natural corrosion resistance.

Cons: While aluminum is strong, it is not as durable as steel under extreme loads. Its higher cost compared to steel can also be a deterrent for budget-conscious buyers.

Impact on Application: Aluminum cranes are particularly well-suited for applications requiring frequent transport and setup, such as in construction or event management.

Considerations for International Buyers: Buyers should ensure compliance with standards like ASTM B221. In regions like Europe, where recycling is prioritized, aluminum’s recyclability is an added advantage.

How Do Composite Materials Enhance Truck Mounted Cranes?

Composite materials, often a combination of fibers and resins, are increasingly being used in specialized applications within truck mounted cranes. Key properties include high strength-to-weight ratios and excellent fatigue resistance.

Pros: Composites can significantly reduce the overall weight of the crane, allowing for higher payloads and improved efficiency. They also offer superior resistance to corrosion and environmental degradation.

Cons: The primary limitation of composites is their cost, which can be significantly higher than traditional materials. Additionally, manufacturing processes can be complex and time-consuming.

Impact on Application: Composites are ideal for high-performance applications where weight savings are critical, such as in aerospace or specialized construction projects.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM D3039 for tensile properties. In emerging markets, cost considerations may limit the adoption of composites.

What Role Do High-Strength Plastics Play in Truck Mounted Cranes?

High-strength plastics, such as reinforced polyamides, are used in specific components of truck mounted cranes, particularly in non-structural applications. Key properties include lightweight characteristics and resistance to chemical degradation.

Pros: These materials are incredibly lightweight, which can enhance the overall efficiency of the crane. They also offer good resistance to chemicals, making them suitable for various environments.

Cons: High-strength plastics may not support heavy loads as effectively as metals, limiting their use to non-critical components. Their durability under extreme conditions can also be a concern.

Impact on Application: Ideal for applications where weight reduction is essential, such as in mobile cranes that require frequent repositioning.

Considerations for International Buyers: Compliance with standards like ASTM D638 is important. Buyers should also consider the environmental impact and recyclability of plastics, especially in regions with stringent regulations.

Summary Table of Material Selection for Truck Mounted Cranes

| Material | Typical Use Case for truck Mounted Crane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy lifting applications | High durability and strength | Susceptible to corrosion | Medium |

| Aluminum | Frequent transport and setup | Lightweight and corrosion-resistant | Higher cost and lower load capacity | High |

| Composite | High-performance, specialized applications | Excellent strength-to-weight ratio | High cost and complex manufacturing | High |

| High-Strength Plastics | Non-structural components | Lightweight and chemical resistance | Limited load-bearing capacity | Medium |

This analysis provides a comprehensive overview of the materials used in truck mounted cranes, offering B2B buyers critical insights for informed decision-making.

In-depth Look: Manufacturing Processes and Quality Assurance for truck Mounted Crane

What Are the Main Stages of Manufacturing Truck Mounted Cranes?

The manufacturing of truck mounted cranes involves several critical stages, each integral to ensuring the final product meets the rigorous demands of various industries. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The first step in manufacturing truck mounted cranes is the selection and preparation of materials. High-strength steel is typically the primary material used due to its durability and ability to withstand heavy loads. Manufacturers often perform metallurgical testing to ensure the steel meets specific tensile and yield strength requirements. Additionally, materials undergo surface treatment processes such as shot blasting or sandblasting to remove impurities and improve adhesion for subsequent coatings. -

Forming

After preparing the materials, the next stage involves forming. This can include processes such as cutting, bending, and welding. Advanced CNC (Computer Numerical Control) machines are commonly employed for precision cutting and shaping of metal components. For cranes with complex geometries, techniques like hydroforming may also be utilized. Welding is a critical operation where various components, such as the boom and chassis, are joined. Manufacturers often use robotic welding systems to ensure consistency and quality in weld integrity. -

Assembly

The assembly phase is where individual components come together to form the crane. This stage involves a systematic approach to ensure that all parts fit perfectly and function correctly. Components such as hydraulic systems, control systems, and safety features are integrated into the crane during this phase. Assembly lines are typically organized to allow for efficient workflow, reducing the risk of errors. Quality control checkpoints are established at various stages of assembly to catch any discrepancies early in the process. -

Finishing

The finishing stage encompasses surface treatments and final inspections. Painting and coating processes protect the crane from corrosion and environmental damage. Manufacturers often use powder coating or electrostatic painting for a durable finish. Following the application of these coatings, cranes undergo thorough inspections to ensure that all components are functional and that the finish meets aesthetic and durability standards.

What Are the Key Quality Control Practices for Truck Mounted Cranes?

Quality assurance in the manufacturing of truck mounted cranes is vital to ensure safety, reliability, and compliance with international standards. Key practices include adherence to international standards, quality checkpoints during production, and various testing methods.

-

International Standards Compliance

Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific standards such as CE marking in Europe or API standards for cranes used in oil and gas applications are critical for ensuring safety and performance. -

Quality Control Checkpoints

Manufacturers implement several quality control checkpoints throughout the production process. Incoming Quality Control (IQC) checks the quality of raw materials upon receipt, ensuring they meet specifications. In-Process Quality Control (IPQC) involves inspections during the manufacturing stages to identify issues early, while Final Quality Control (FQC) focuses on the finished product, ensuring it meets all design and safety requirements before delivery. -

Common Testing Methods

Various testing methods are employed to validate the performance and safety of truck mounted cranes. These may include load testing, where cranes are subjected to loads exceeding their rated capacity to verify structural integrity. Non-destructive testing (NDT) techniques, such as ultrasonic or magnetic particle testing, are also commonly used to detect internal flaws in welds and materials without causing damage.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several methods to ensure compliance and quality.

-

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. These audits should assess compliance with international standards, review production practices, and evaluate the effectiveness of quality control checkpoints. Buyers can request audit reports or even conduct on-site visits to ensure that suppliers adhere to necessary quality standards. -

Requesting Quality Assurance Documentation

Suppliers should be able to provide relevant documentation, including ISO certifications, quality control manuals, and test reports. This documentation serves as evidence of the supplier’s commitment to quality and their adherence to international standards. Buyers can request these documents during the procurement process to ensure that they are partnering with a reliable manufacturer. -

Engaging Third-Party Inspection Services

Utilizing third-party inspection services can offer an additional layer of assurance. Independent inspectors can evaluate the manufacturing processes, conduct tests, and review quality control practices to ensure compliance with agreed standards. This approach is particularly beneficial for buyers unfamiliar with local manufacturing practices or when sourcing from international suppliers.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must navigate several nuances regarding quality control and certification when sourcing truck mounted cranes. These considerations can significantly impact procurement decisions.

-

Understanding Regional Compliance Requirements

Different regions have specific compliance requirements that manufacturers must meet. For instance, cranes sold in Europe must comply with CE marking, indicating they meet EU safety and performance standards. In contrast, buyers in the Middle East may require compliance with local regulations that differ from international standards. Understanding these requirements is essential for ensuring that the cranes meet local laws and safety regulations. -

Evaluating Supplier Capability for Customization

Many buyers require cranes tailored to specific applications or regional needs. It’s essential to assess whether suppliers have the capability to customize their products while maintaining quality. This includes evaluating their manufacturing flexibility, lead times, and ability to implement design changes without compromising quality assurance processes. -

Monitoring Post-Purchase Support and Warranty

Quality control does not end with the purchase of the crane. Buyers should evaluate the supplier’s post-purchase support, including maintenance services, spare parts availability, and warranty terms. Understanding the level of support offered can help mitigate risks associated with equipment downtime and ensure long-term satisfaction with the investment.

In conclusion, the manufacturing and quality assurance processes for truck mounted cranes are complex and multifaceted. B2B buyers must be diligent in evaluating suppliers to ensure they meet the necessary quality standards and compliance requirements, ultimately leading to successful operational outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘truck Mounted Crane’

To assist B2B buyers in procuring a truck-mounted crane, this guide provides a practical checklist designed to streamline the sourcing process. With specific considerations for various regions, including Africa, South America, the Middle East, and Europe, this guide emphasizes essential steps to ensure a successful purchase.

Step 1: Define Your Technical Specifications

Identifying your specific lifting requirements is crucial before engaging with suppliers. Consider factors such as maximum load capacity, boom length, and operational environment.

– Load Capacity: Determine the weight limits you’ll frequently encounter to select a crane that can handle your heaviest loads efficiently.

– Boom Length: Assess the reach you require for your projects, ensuring the crane can operate effectively in confined spaces.

Step 2: Research and Identify Reputable Suppliers

Conduct thorough research to find credible suppliers with a strong market presence. Look for companies that specialize in truck-mounted cranes and have positive reviews from past clients.

– Industry Experience: Opt for suppliers with a proven track record in your region and industry to ensure they understand local regulations and requirements.

– Product Range: Ensure they offer a variety of models that suit your technical specifications, as well as customization options.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it is essential to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Quality Assurance: Inquire about certifications, such as ISO or CE markings, that validate their adherence to international safety and quality standards.

– After-Sales Support: Assess the level of support provided post-purchase, including warranties, maintenance services, and availability of spare parts.

Step 4: Request Detailed Quotations

Once you have shortlisted potential suppliers, request detailed quotations that break down costs associated with the crane, including shipping, installation, and training.

– Transparent Pricing: Ensure the quote outlines all potential fees to avoid unexpected costs later in the process.

– Comparison: Use the quotations to compare not just prices but also service levels, warranty terms, and delivery timelines.

Step 5: Assess Compliance with Local Regulations

Verify that the cranes comply with local safety and operational regulations. This step is crucial to avoid legal complications and ensure the safety of your operations.

– Documentation: Request documentation that demonstrates compliance with local regulations, which can vary significantly across regions.

– Certification: Check if the supplier has experience dealing with local regulatory bodies, which can facilitate a smoother procurement process.

Step 6: Conduct a Site Visit or Virtual Tour

If possible, visit the supplier’s facility or request a virtual tour to inspect the crane models and manufacturing processes.

– Quality Control: Observing the production environment can give insights into the quality control measures in place.

– Operational Testing: If feasible, test the crane models to assess their performance and suitability for your specific needs.

Step 7: Finalize the Purchase Agreement

Once you have completed the evaluations and are satisfied with your chosen supplier, finalize the purchase agreement. Ensure all terms discussed are included in the contract.

– Clear Terms: Outline payment schedules, delivery timelines, and responsibilities for installation and training.

– Legal Review: Consider having a legal expert review the contract to protect your interests and ensure all aspects are covered.

By following these steps, B2B buyers can effectively navigate the procurement process for truck-mounted cranes, ensuring a successful investment that meets their operational needs.

Comprehensive Cost and Pricing Analysis for truck Mounted Crane Sourcing

What Are the Key Cost Components in Truck Mounted Crane Manufacturing?

When sourcing truck mounted cranes, understanding the cost structure is crucial for B2B buyers. The primary components contributing to the overall cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The raw materials used in manufacturing cranes, such as steel and hydraulic components, significantly influence pricing. High-quality materials not only enhance durability but also add to the initial cost.

-

Labor: Labor costs can vary based on the region and the skill level required for manufacturing and assembly. In regions with higher labor costs, such as Western Europe, the total cost may be elevated compared to lower-cost regions.

-

Manufacturing Overhead: This includes indirect costs related to production, such as facility maintenance and utilities. Companies often allocate these costs proportionately to the cranes produced.

-

Tooling: The initial investment in tools and machinery for production can impact pricing, particularly for custom models. Advanced tooling may also require higher upfront costs but can improve efficiency in the long run.

-

Quality Control: Stringent QC processes ensure the cranes meet safety and operational standards. This can add to costs but is essential for compliance and reliability.

-

Logistics: Transportation costs from the manufacturing facility to the buyer’s location are significant, especially for international shipments. Factors such as shipping method and distance play a crucial role in logistics costs.

-

Margin: Suppliers will typically add a profit margin on top of the aforementioned costs, which can vary widely depending on market conditions and competition.

What Price Influencers Should Buyers Consider When Sourcing Truck Mounted Cranes?

Several factors can influence the pricing of truck mounted cranes, and understanding these can aid buyers in making informed decisions.

-

Volume/MOQ: Larger orders often attract discounts due to economies of scale. Buyers should inquire about minimum order quantities (MOQ) to negotiate better pricing.

-

Specifications and Customization: Custom features or specifications can significantly increase the price. Buyers should clearly define their needs upfront to avoid unexpected costs.

-

Materials and Quality Certifications: The choice of materials and the presence of quality certifications (like ISO standards) can impact both cost and reliability. Higher-quality cranes may come at a premium but offer better performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established manufacturers may charge more due to their proven track record and support services.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) is essential for international buyers. They define the responsibilities of buyers and sellers in shipping, which can affect overall costs, especially for logistics.

What Tips Can Buyers Use to Negotiate Better Prices for Truck Mounted Cranes?

Effective negotiation can lead to significant cost savings when sourcing truck mounted cranes. Here are some tips:

-

Research Market Prices: Understanding the market rates for different crane types and configurations can give buyers leverage during negotiations.

-

Consider Total Cost of Ownership (TCO): While the initial price is important, buyers should also consider maintenance, operational costs, and potential downtime. A more expensive crane may offer better reliability and lower long-term costs.

-

Build Relationships with Suppliers: Establishing a strong relationship with suppliers can lead to better terms, such as lower prices or favorable payment options.

-

Be Clear About Requirements: Clearly communicate specifications and expectations to avoid misunderstandings that could lead to increased costs.

-

Explore Financing Options: Many suppliers offer financing plans which can ease the burden of upfront costs. Exploring these options can also provide flexibility in budgeting.

Conclusion

Sourcing truck mounted cranes involves a complex interplay of cost components and pricing influencers. By understanding these elements and employing strategic negotiation tactics, B2B buyers can optimize their sourcing strategy, ensuring they receive the best value for their investment. It is advisable to remain informed about market conditions and supplier capabilities to navigate this procurement effectively.

Disclaimer: Pricing can vary significantly based on factors such as location, specifications, and market demand. It is recommended to obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing truck Mounted Crane With Other Solutions

Understanding the Alternatives to Truck Mounted Cranes

When considering lifting solutions for heavy equipment and materials, truck mounted cranes are a popular choice due to their versatility and efficiency. However, businesses must evaluate various alternatives to ensure they select the right equipment for their specific needs. This analysis compares truck mounted cranes with two viable alternatives: telehandlers and traditional cranes.

Comparison Table

| Comparison Aspect | Truck Mounted Crane | Telehandler | Traditional Crane |

|---|---|---|---|

| Performance | High versatility with multiple attachments | Good for lifting and reaching in tight spaces | Excellent for heavy lifts over long distances |

| Cost | Moderate initial investment; lower operating costs | Higher initial cost; versatile but requires skilled operators | High upfront costs; significant operational expenses |

| Ease of Implementation | Quick setup and operation; can be mounted on various trucks | Requires specialized training; can be cumbersome in small areas | Long setup time; needs flat, stable ground |

| Maintenance | Generally low; regular inspections needed | Moderate; mechanical systems can require frequent service | High; complex systems often need professional maintenance |

| Best Use Case | Construction, delivery, and maintenance tasks | Agriculture, construction, and warehouse work | Heavy industrial lifting, construction sites |

Detailed Breakdown of Alternatives

Telehandlers: Pros and Cons

Telehandlers, or telescopic handlers, are versatile machines that combine the features of a forklift and a crane. They excel in lifting and extending loads to heights that a standard forklift cannot reach. Their compact size allows for maneuverability in tight spaces, making them ideal for construction sites and agricultural applications. However, telehandlers can have a higher initial cost and require skilled operators for safe handling. Additionally, while they are versatile, they may not offer the same load capacities as truck mounted cranes for certain applications.

Traditional Cranes: Pros and Cons

Traditional cranes, such as tower or mobile cranes, are designed for heavy lifting and can handle significant loads over long distances. They are ideal for large construction projects, where extensive lifting capabilities are necessary. However, they come with a high upfront cost and substantial operational expenses, including maintenance and labor. Additionally, traditional cranes require a longer setup time and a stable, flat surface for operation, making them less flexible compared to truck mounted cranes and telehandlers.

Conclusion: How to Choose the Right Solution

Selecting the right lifting solution involves understanding your specific operational needs and constraints. For businesses engaged in diverse tasks like construction, maintenance, or delivery, truck mounted cranes offer a balance of versatility, ease of use, and lower operational costs. In contrast, if your operations demand heavy lifting in confined spaces, telehandlers may be the better choice. Alternatively, for large-scale projects requiring maximum lifting capacity, traditional cranes may be necessary despite their higher costs. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for truck Mounted Crane

What Are the Key Technical Properties of Truck Mounted Cranes?

When evaluating truck mounted cranes, several critical specifications should be considered to ensure optimal performance and suitability for specific applications. Here are the essential technical properties:

-

Maximum Lifting Capacity

This specification indicates the maximum weight a crane can lift safely, typically measured in tons or kilograms. It is crucial for B2B buyers to match this capacity with their operational requirements to prevent equipment failure or accidents. A crane with insufficient capacity may compromise safety and efficiency, leading to costly downtimes. -

Boom Length and Reach

The boom length determines how far the crane can extend to lift loads. It is measured from the pivot point to the tip of the boom and can significantly affect the crane’s versatility. Longer booms allow for lifting from greater distances, which is particularly beneficial in tight job sites. Buyers should consider the typical job site dimensions to ensure the crane can meet their operational needs. -

Gross Vehicle Weight (GVW)

The total weight of the truck mounted crane, including its load, is referred to as gross vehicle weight. This specification is vital for compliance with road regulations, especially in regions with strict transport laws. Buyers must ensure that the GVW does not exceed local legal limits to avoid fines and ensure safe transportation. -

Rotation Capability

Most truck mounted cranes offer a degree of rotation, typically 360 degrees. This feature enhances maneuverability and allows for greater operational flexibility. Understanding the rotation capabilities helps businesses optimize their workflow, especially in projects requiring precise load placement. -

Outrigger System

Outriggers provide stability during lifting operations and are crucial for maintaining balance, especially when lifting heavy loads. The type and configuration of the outrigger system can influence the crane’s stability and operational safety. Buyers should evaluate the outrigger design to ensure it meets the demands of their specific applications. -

Control System

The control system, often featuring ergonomic controls and advanced technology, impacts how easily operators can manage crane functions. A user-friendly interface can significantly enhance productivity and reduce training time for operators. Buyers should consider the sophistication of the control system when selecting a crane, as it directly affects operational efficiency.

What Are Common Trade Terminologies in the Truck Mounted Crane Industry?

Understanding industry jargon is essential for effective communication and decision-making. Here are some common trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the original equipment, such as cranes. For B2B buyers, purchasing from reputable OEMs ensures that they receive quality products backed by warranties and support, which is crucial for operational reliability. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. For international buyers, understanding MOQ is essential for budgeting and inventory planning. This term can impact purchasing decisions, especially for smaller businesses or those looking to test the market. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products. This is a critical step in procurement, allowing buyers to compare offers and negotiate better deals. Crafting a detailed RFQ can lead to more favorable terms and pricing. -

Incoterms (International Commercial Terms)

These are standard trade terms used in international sales contracts to define the responsibilities of buyers and sellers. Familiarity with Incoterms is vital for B2B buyers involved in cross-border transactions to avoid misunderstandings regarding shipping, insurance, and risk. -

Payload Capacity

This term refers to the maximum weight a truck mounted crane can transport in addition to its own weight. Understanding payload capacity helps buyers ensure that they can transport necessary equipment and materials without overloading, which can lead to legal and safety issues. -

Service Life

This refers to the expected operational lifespan of the crane, often influenced by maintenance and usage conditions. For buyers, understanding service life is essential for long-term investment planning and determining the total cost of ownership.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions that enhance operational efficiency and safety in their projects.

Navigating Market Dynamics and Sourcing Trends in the truck Mounted Crane Sector

What Are the Key Market Dynamics and Trends Affecting Truck Mounted Cranes?

The global market for truck-mounted cranes is witnessing robust growth, driven by an increase in construction activities, urbanization, and infrastructure development across emerging economies. Key markets in Africa, South America, the Middle East, and Europe are experiencing heightened demand for versatile lifting solutions that can operate in constrained environments. Innovations in technology, such as remote control operation and enhanced safety features, are becoming critical differentiators for suppliers. Additionally, the rise of e-commerce logistics has necessitated more agile and efficient loading solutions, further propelling the demand for truck-mounted cranes.

Emerging trends include a shift towards electric and hybrid crane models, reflecting a broader industry move towards sustainability. B2B buyers are increasingly prioritizing advanced features such as real-time load monitoring and telematics for improved operational efficiency. Moreover, the integration of IoT (Internet of Things) in crane technology is allowing for predictive maintenance, reducing downtime and operational costs. International buyers should be aware of the importance of regulatory compliance in their respective markets, as safety standards and emissions regulations are tightening globally.

How Is Sustainability Shaping the Truck Mounted Crane Sector?

Sustainability is becoming an essential consideration in the sourcing of truck-mounted cranes. Buyers are increasingly evaluating the environmental impact of their equipment choices, with a focus on energy-efficient models and sustainable materials. The industry is witnessing a rise in the use of recyclable materials in crane manufacturing, alongside certifications such as ISO 14001, which indicates a commitment to environmentally responsible practices.

Ethical sourcing is also gaining traction among B2B buyers. Companies are keen to partner with manufacturers that prioritize fair labor practices and transparency in their supply chains. This shift not only enhances brand reputation but also aligns with the corporate social responsibility (CSR) goals of many organizations. Buyers should actively seek suppliers who can demonstrate their commitment to sustainability through certifications and clear reporting on their environmental practices.

What Is the Historical Context Behind Truck Mounted Cranes?

Truck-mounted cranes have evolved significantly since their inception in the mid-20th century. Initially designed for simple lifting tasks, advancements in hydraulic technology and material science have transformed these cranes into highly sophisticated machines capable of performing complex tasks across various industries. The introduction of articulating booms and enhanced lifting capacities has expanded their applications beyond construction to sectors such as logistics, waste management, and energy.

The evolution of regulatory standards has also influenced design and manufacturing processes, pushing manufacturers to innovate while ensuring compliance with safety and environmental regulations. As the demand for versatile, reliable, and efficient lifting solutions continues to grow, the truck-mounted crane sector remains poised for further advancements, making it a critical area for B2B investment.

Frequently Asked Questions (FAQs) for B2B Buyers of truck Mounted Crane

-

How do I choose the right truck mounted crane for my business needs?

Choosing the right truck mounted crane involves assessing your specific lifting requirements, including load capacity, boom reach, and operational environment. Evaluate the types of loads you’ll be handling and the frequency of use. Consider models that offer versatility, such as knuckle boom cranes, which can handle various attachments. Additionally, factor in the crane’s ease of operation, maintenance needs, and compatibility with your existing vehicles. Engaging with manufacturers or distributors for expert advice can also help narrow down options based on your industry. -

What are the key specifications to consider when sourcing truck mounted cranes?

When sourcing truck mounted cranes, key specifications to consider include maximum load capacity, boom length, and rotation capabilities. Look for cranes with a high tipping height and 360-degree operation for enhanced maneuverability. Weight and dimensions are crucial for ensuring compatibility with your trucks. Additionally, consider features such as hydraulic systems, control interfaces, and safety mechanisms. Always request detailed product datasheets to compare models effectively and ensure they meet your operational requirements. -

What are the advantages of using truck mounted cranes in my operations?

Truck mounted cranes offer several advantages, including increased mobility and flexibility on job sites. They can efficiently load and unload materials directly from the truck, reducing the need for additional equipment. This capability can lead to significant time and cost savings, particularly in industries such as construction and logistics. Furthermore, modern truck mounted cranes often feature advanced technology that enhances precision and operator control, resulting in safer and more efficient operations. -

How do I verify the reliability of a truck mounted crane supplier?

To verify the reliability of a truck mounted crane supplier, conduct thorough research on their reputation and history in the industry. Look for customer testimonials and case studies that demonstrate their experience and expertise. It’s beneficial to check their certifications, warranty offerings, and after-sales support. Engaging in direct communication can also provide insights into their responsiveness and willingness to address your concerns. Additionally, consider visiting their facilities if feasible, to assess their manufacturing capabilities and quality control processes. -

What customization options are available for truck mounted cranes?

Many manufacturers offer a variety of customization options for truck mounted cranes to meet specific operational needs. Customizations can include different boom lengths, lifting capacities, and attachment options, such as grapples or workman baskets. Some suppliers also provide tailored hydraulic systems and control features to enhance usability. Before making a purchase, discuss your unique requirements with the manufacturer to explore available options and ensure the crane aligns with your business operations. -

What are the typical minimum order quantities (MOQs) for truck mounted cranes?

Minimum order quantities (MOQs) for truck mounted cranes can vary significantly by supplier and region. Some manufacturers may have no MOQ for standard models, while others may require bulk orders for customized units. It’s essential to clarify this with potential suppliers during your inquiry process. Additionally, consider the potential for negotiating MOQs based on your purchasing power and long-term relationship with the supplier, especially for repeat orders. -

What payment terms should I expect when purchasing truck mounted cranes?

Payment terms for truck mounted cranes typically vary by supplier and may include options such as upfront deposits, installment payments, or net payment terms. Common practices involve a deposit (often 30-50%) upon order confirmation, with the balance due before delivery. Ensure that you understand any additional costs, such as shipping or customs duties, especially for international transactions. Discussing payment terms upfront can help establish clear expectations and facilitate a smoother purchasing process. -

How can I ensure quality assurance (QA) for truck mounted cranes?

To ensure quality assurance (QA) for truck mounted cranes, first, choose suppliers with established quality control processes and relevant certifications, such as ISO standards. Request documentation related to their QA protocols, including testing procedures for safety and performance. Additionally, consider arranging for third-party inspections or audits before final acceptance of the cranes. Building a relationship with your supplier that prioritizes transparency can also enhance trust in the quality of the products you receive.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Truck Mounted Crane Manufacturers & Suppliers List

1. Hewsco – Truck-Mounted Cranes

Domain: hewsco.com

Registered: 2002 (23 years)

Introduction: Truck-mounted cranes are versatile lifting solutions designed for various applications. They combine the mobility of a truck with the lifting capabilities of a crane, making them ideal for construction, maintenance, and logistics. Key features include a robust design for heavy loads, easy maneuverability, and quick setup times. They are equipped with advanced safety features and can be customized …

2. GROVE – TMS9000-2 Truck-Mounted Crane

Domain: manitowoc.com

Registered: 1995 (30 years)

Introduction: GROVE Truck-Mounted Cranes features include quick set-up, long reach, high capacity booms, and highway speed travel capabilities. Standard features include a front outrigger for 360° operation. Key models and specifications are as follows:

– TMS9000-2: Max capacity 115 USt (100 t), Total gross vehicle weight 80311 lbs (36428 kg), Main boom length 36 ft – 169 ft (11.2 m – 51.6 m), Max tip height 2…

3. David Round – Truck Mounted Cranes

Domain: davidround.com

Registered: 1997 (28 years)

Introduction: Truck Mounted Cranes with up to 6,000 lbs lift capacity. Models available: TM-1/4 (500 lbs capacity, 42-1/2″ boom length, 50-1/2″ overall height), TM-1/2 (1,000 lbs capacity, 48″ boom length, 60″ overall height), TM-1 (2,000 lbs capacity, 54″ boom length, 66-3/4″ overall height). Features include 360-degree boom rotation, adjustable brake for rotation control, needle type release valve, and mounte…

4. HMF Cranes – Versatile Lifting Solutions

Domain: hmfcranes.com

Registered: 2006 (19 years)

Introduction: {“Lifting capacity”: {“3 – 14 tm”: {}, “15 – 31 tm”: {}, “32 – 59 tm”: {}, “60 – 95 tm”: {}}, “Crane types”: [“Knuckle boom cranes (K)”, “Short knuckle boom cranes (KS)”, “Long boom cranes (L)”, “Recycling cranes (S)”, “Telescopic cranes (T)”, “Z-fold grab cranes (Z)”, “Wallboard cranes (WB)”], “Equipment”: {“Subframes”: {}, “Front stabilizers”: {}, “Separate traverses”: {}, “For cranes”: {“4-10 t…

5. Altec – Boom Truck Cranes

Domain: altec.com

Registered: 1996 (29 years)

Introduction: Boom Truck Cranes from Altec include the following models:

1. Swing Seat Models:

– AC40E-152S: Load Rating: 40 t (36.3 tonne), Boom Length: 152 ft (46.3 m), Boom Sections: 6

– AC45E-127S: Load Rating: 45 t (40.8 tonne), Boom Length: 127 ft (38.7 m), Boom Sections: 5

– AC65E-155S: Load Rating: 65 t (59 tonne), Boom Length: 155 ft (47.2 m), Boom Sections: 6

2. Track Mount Models:

…

6. Air Technical – Super-Master Truck Mounted Crane

Domain: shop.airtechnical.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “Super-Master Truck Mounted Crane”, “Model Number”: “SM-6000BP”, “Price”: “$6,563.00”, “Capacity Retracted”: “6000 pounds”, “Capacity Extended”: “3000 pounds”, “Max Lift Height Retracted”: “9 ft”, “Max Lift Height Extended”: “13 ft”, “Floor to Hook Height Retracted”: “38 inches”, “Floor to Hook Height Extended”: “26 inches”, “Max Reach”: “78 inches”, “Overall Height without Cable …

7. HT25KX – Truck-Mounted Crane

Domain: industrialmanlifts.com

Registered: 2011 (14 years)

Introduction: HT25KX Truck-Mounted Crane 5,000lbs Lifting Capacity features: fully hydraulic operation, 20′ full-hydraulic extension boom, capacity-overload shut-off system, anti-two-blocking system, remote control pendant with 25 ft. cord, load block with swivel hook safety latch. Capacity: 5,000 lbs; Rating: 25,000 ft-lbs; Boom Length: 10 – 20 ft; Hydraulic Requirements: Standard: 2 GPM @ 3000 PSI, 4 gal. Res…

8. Penny Engineering – Hydraulic & Electric Truck Mounted Cranes

Domain: pennyengineering.com

Registered: 2022 (3 years)

Introduction: Hydraulic & Electric Truck Mounted Cranes from Penny Engineering are designed for safe and efficient lifting tasks. Key features include:

– Electric Swing Lift Cranes: Ultra-lightweight, capable of lifting loads up to 500kg, ideal for confined spaces.

– Hydraulic Cranes: Powerful hydraulic controls, capable of lifting heavy loads up to 3300kg.

– Accessories: A full inventory of specialized acce…

9. Crane Network – Truck Mounted Telescopic Boom Cranes

Domain: cranenetwork.com

Registered: 2000 (25 years)

Introduction: Truck Mounted Telescopic Boom Cranes for Sale on Crane Network. Various manufacturers including Grove, Link-Belt, Tadano, Terex, and more. Models available include TMS9000E, HTC-8675 II, T 230, and many others. Year range from 1972 to 2025. Conditions vary from New to Damaged. Prices range from $45,000 to $695,000. Monthly payment estimates available for some listings.

Strategic Sourcing Conclusion and Outlook for truck Mounted Crane

In the evolving landscape of truck-mounted cranes, strategic sourcing emerges as a crucial component for international B2B buyers. Understanding the diverse offerings—from knuckle boom cranes to service cranes—enables buyers to select equipment tailored to their specific operational needs. The emphasis on performance, reliability, and innovative features from leading manufacturers ensures that businesses can enhance efficiency and reduce operational costs.

By leveraging the advantages of strategic sourcing, companies can not only secure high-quality equipment but also build lasting partnerships with reputable suppliers who understand the unique challenges faced in different regions, such as Africa, South America, the Middle East, and Europe. This collaborative approach fosters innovation and responsiveness to market demands.

Looking ahead, it is essential for buyers to stay informed about advancements in crane technology and market trends. Engaging with suppliers who prioritize sustainability and adaptability will position businesses favorably in a competitive marketplace. As you consider your next investment in truck-mounted cranes, take proactive steps to evaluate potential suppliers and their offerings. The right choices today can pave the way for operational excellence and long-term success.