Introduction: Navigating the Global Market for electric car with solar panel

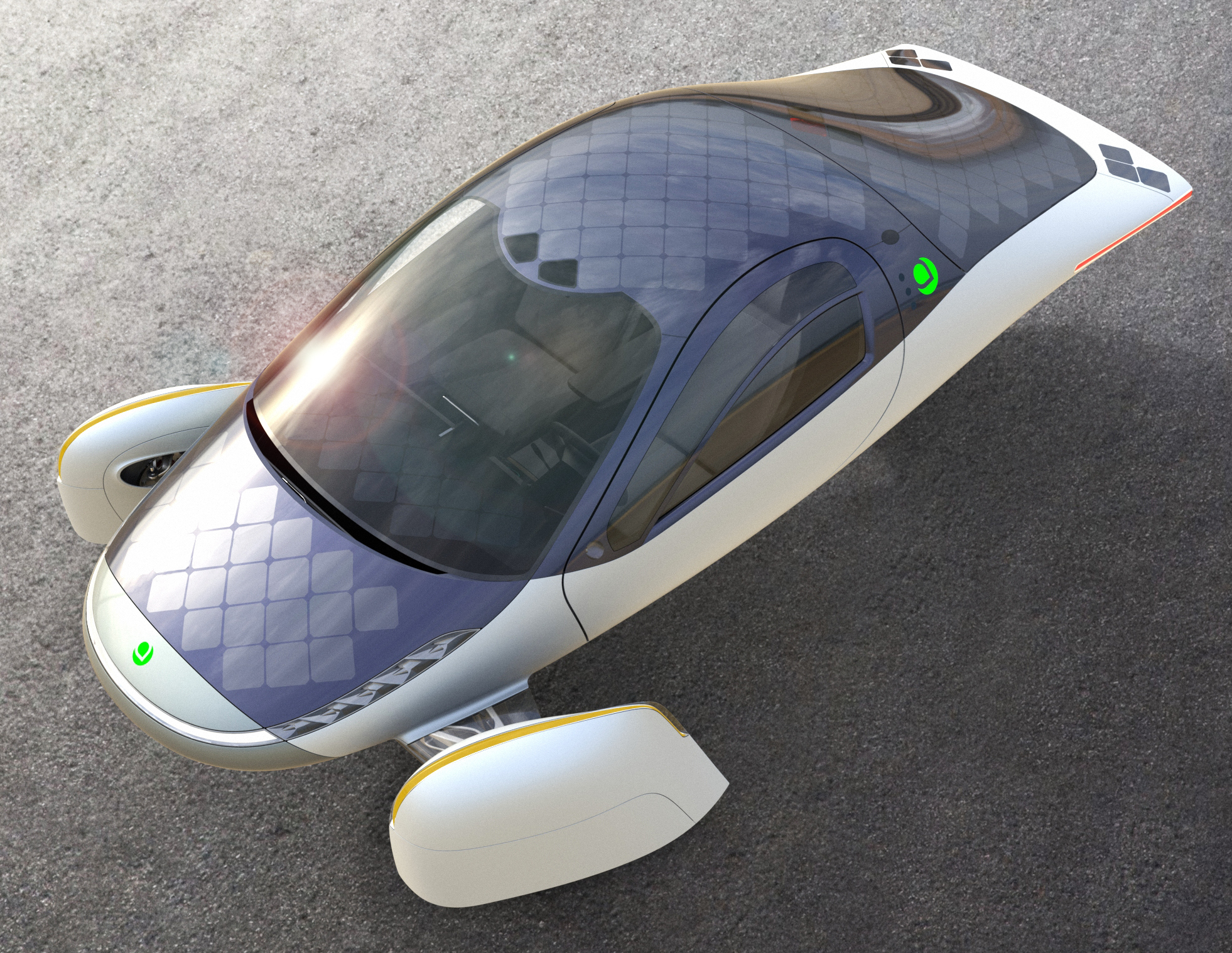

As the global demand for sustainable transportation continues to surge, international B2B buyers are increasingly challenged by the need to source electric cars with solar panels that meet both operational efficiency and environmental goals. This guide addresses the complexities of navigating the evolving market for solar-integrated electric vehicles (EVs), providing a comprehensive overview of available models, their applications, supplier vetting processes, and cost considerations. With a diverse range of offerings from innovative manufacturers like Aptera and Lightyear, businesses can find solutions tailored to their unique operational needs.

The integration of solar technology into electric vehicles presents significant advantages, such as enhanced energy independence and reduced dependency on traditional charging infrastructure. For buyers in regions such as Africa, South America, the Middle East, and Europe—where solar resources are abundant—leveraging solar power can dramatically extend driving range and lower operational costs. This guide empowers decision-makers by delivering actionable insights into the latest advancements in solar EV technology, enabling informed purchasing decisions that align with sustainability objectives.

By exploring the intricacies of this market, from product specifications to supplier reliability, B2B buyers will be equipped to capitalize on emerging opportunities in the solar electric vehicle sector, ultimately driving their organizations toward a greener, more efficient future.

Understanding electric car with solar panel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Integrated Solar EVs | Built-in solar panels that charge the main battery while driving. | Urban fleets, delivery services, rentals. | Pros: Reduces dependence on charging stations. Cons: Limited range increase from solar alone. |

| Solar-Assisted EVs | Solar panels used primarily for auxiliary systems (e.g., A/C). | Personal use, corporate fleets. | Pros: Enhances efficiency; lower energy costs. Cons: Minimal impact on overall range. |

| Microcars with Solar Technology | Compact vehicles designed for short urban trips with solar roofs. | Urban transportation, mobility solutions. | Pros: Ideal for city driving; environmentally friendly. Cons: Limited range and speed. |

| Solar-Powered Golf Carts | Small vehicles equipped with solar panels for short-distance travel. | Recreational use, resorts, campuses. | Pros: Sustainable transport option; easy to charge. Cons: Not suitable for long distances. |

| Commercial Fleet Solar Solutions | Customizable solar panel installations on fleet vehicles. | Logistics, delivery, and service industries. | Pros: Significant reduction in operational costs. Cons: Higher initial investment. |

What Are the Characteristics of Integrated Solar EVs?

Integrated solar EVs, such as those from manufacturers like Aptera and Lightyear, feature solar panels that directly charge the vehicle’s main battery while in use. These vehicles are particularly suited for urban fleets and delivery services, where reducing reliance on charging infrastructure can enhance operational efficiency. When considering a purchase, B2B buyers should assess the vehicle’s solar efficiency, initial investment costs, and how much additional range the solar panels can realistically provide.

How Do Solar-Assisted EVs Enhance Efficiency?

Solar-assisted EVs, like the Toyota Prius Prime and Hyundai Ioniq 5, utilize solar panels primarily to power auxiliary systems, such as air conditioning. These vehicles are suitable for both personal and corporate use, as they can improve energy efficiency and reduce overall electricity costs. B2B buyers should evaluate the cost-benefit ratio of solar enhancements versus traditional charging methods and consider the energy savings over time.

Why Are Microcars with Solar Technology Ideal for Urban Areas?

Microcars, designed for short trips, often come equipped with solar roofs. These vehicles are perfect for urban transportation solutions, making them an attractive option for city dwellers and businesses needing efficient mobility solutions. When purchasing, B2B buyers should consider the vehicle’s size, speed, and the specific urban environment it will operate in, as well as the potential for reduced energy costs.

What Are the Benefits of Solar-Powered Golf Carts?

Solar-powered golf carts are small, efficient vehicles ideal for short-distance travel, often found in recreational areas, resorts, and campuses. Their sustainability credentials make them appealing to businesses focused on eco-friendly practices. Buyers should weigh the convenience of solar charging against the limited range and speed, especially if the vehicle will be used in varied terrains.

How Do Commercial Fleet Solar Solutions Work?

Commercial fleet solar solutions involve the installation of solar panels on fleet vehicles, allowing for significant operational cost reductions. This approach is particularly beneficial for logistics and delivery industries where fuel and electricity costs can be substantial. B2B buyers should consider the initial investment in solar technology versus long-term savings, as well as the scalability of solar solutions to fit their fleet size and operational needs.

Key Industrial Applications of electric car with solar panel

| Industry/Sector | Specific Application of electric car with solar panel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Solar-powered utility vehicles for farm operations | Reduces reliance on fossil fuels, cuts operational costs, and enhances sustainability. | Durability in outdoor conditions, compatibility with existing agricultural equipment. |

| Tourism and Hospitality | Eco-friendly shuttle services for resorts | Attracts environmentally conscious travelers and reduces carbon footprint. | Battery capacity for long-distance travel, ease of charging at remote locations. |

| Logistics and Delivery | Last-mile delivery vehicles with solar panels | Increases operational efficiency and reduces energy costs, especially in sunny regions. | Vehicle range, solar panel efficiency, and integration with logistics software. |

| Public Transportation | Solar-powered buses for urban transit systems | Lowers operational costs and emissions, enhancing public image and compliance with green regulations. | Capacity to accommodate passenger loads, safety standards, and charging infrastructure. |

| Construction | On-site transport vehicles for workers and materials | Improves mobility on job sites while promoting sustainability and reducing fuel costs. | Robust design for rough terrain, solar panel integration, and maintenance support. |

How Can Electric Cars with Solar Panels Transform the Agriculture Sector?

In the agriculture sector, electric cars with solar panels can serve as utility vehicles for transporting goods and equipment across farms. By harnessing solar energy, these vehicles can significantly reduce operational costs associated with fuel and maintenance. Buyers in this sector should consider the vehicle’s durability, ability to withstand outdoor conditions, and compatibility with existing agricultural machinery to ensure seamless integration into their operations.

What Are the Benefits of Using Solar-Powered Vehicles in Tourism and Hospitality?

In tourism and hospitality, electric cars equipped with solar panels can be utilized as eco-friendly shuttle services for transporting guests within resorts or tourist attractions. This not only appeals to environmentally conscious travelers but also helps businesses lower their carbon footprint. When sourcing these vehicles, businesses must evaluate battery capacity for extended travel and the ease of charging in remote locations to maintain service efficiency.

How Do Electric Cars with Solar Panels Enhance Logistics and Delivery Operations?

For logistics and delivery companies, solar-powered electric vehicles can be particularly advantageous for last-mile deliveries, especially in regions with ample sunlight. These vehicles can operate more efficiently by reducing energy costs and reliance on traditional charging infrastructure. Key considerations for international buyers include the vehicle’s range, the efficiency of solar panels, and the ability to integrate with existing logistics and delivery software systems.

Why Are Solar-Powered Buses Essential for Public Transportation?

Solar-powered buses can revolutionize urban public transportation by providing a sustainable alternative to fossil fuel-powered vehicles. They significantly reduce operational costs and emissions, making them appealing to municipalities looking to enhance their public image and comply with green regulations. Buyers in this sector should focus on the bus’s passenger capacity, adherence to safety standards, and the availability of charging infrastructure to support daily operations.

How Can Electric Cars with Solar Panels Benefit the Construction Industry?

In the construction industry, electric cars with solar panels can be employed as on-site transport vehicles for workers and materials, enhancing mobility and efficiency. These vehicles promote sustainability by reducing fuel costs and emissions on job sites. When sourcing these vehicles, construction companies should prioritize a robust design suitable for rough terrains, effective solar panel integration, and reliable maintenance support to ensure continuous operation.

3 Common User Pain Points for ‘electric car with solar panel’ & Their Solutions

Scenario 1: Balancing Cost and Sustainability in Fleet Management

The Problem: For many businesses, transitioning to electric vehicles (EVs) with integrated solar panels can be a daunting investment. B2B buyers often grapple with the initial costs associated with purchasing these vehicles and the necessary infrastructure to support them. This challenge is compounded in regions like Africa and South America, where economic constraints may hinder the ability to adopt such innovative technologies. Buyers may worry about whether the long-term savings in fuel and maintenance will justify the upfront expenditure, especially when they are tasked with managing tight budgets and maximizing ROI.

The Solution: To address these financial concerns, B2B buyers should conduct a thorough cost-benefit analysis that includes both direct and indirect savings from switching to electric cars with solar panels. This analysis should incorporate potential reductions in fuel costs, maintenance expenses, and government incentives for green technology adoption. Additionally, collaborating with suppliers who offer leasing options or financing plans can alleviate immediate financial burdens. Buyers can also explore partnerships with local governments or NGOs that may offer subsidies or grants for sustainable practices. By strategically planning the transition and leveraging available financial tools, businesses can minimize upfront costs while investing in a sustainable future.

Scenario 2: Ensuring Reliable Energy Supply for Off-Grid Operations

The Problem: In regions where traditional charging infrastructure is limited, businesses that rely on electric cars with solar panels may face challenges ensuring a consistent energy supply. Companies operating in remote areas, especially in parts of the Middle East and Africa, may find it difficult to maintain the performance and reliability of their solar-powered EVs. This situation can lead to operational downtime, hindering productivity and affecting service delivery.

The Solution: To overcome this challenge, businesses should integrate hybrid systems that combine solar energy with alternative charging options, such as generators or battery storage solutions. This approach ensures that vehicles remain operational even when solar generation is low due to weather conditions. Additionally, investing in high-efficiency solar panels and optimizing the positioning of the vehicles to maximize sun exposure can significantly enhance energy capture. Regular maintenance of the solar panels and battery systems is also crucial to ensure optimal performance. By developing a robust energy management strategy, businesses can effectively mitigate risks associated with reliance on solar power alone and maintain operational continuity.

Scenario 3: Navigating Technological Limitations and Performance Expectations

The Problem: Many B2B buyers are excited about the prospect of electric cars with solar panels but may not fully understand the current technological limitations. For instance, while solar panels can extend driving range, they cannot entirely replace conventional charging methods. This misunderstanding can lead to unrealistic performance expectations, resulting in dissatisfaction and potential operational disruptions when vehicles fail to meet range needs in demanding environments.

The Solution: To set accurate expectations, businesses should prioritize education and training regarding the capabilities and limitations of solar technology in electric vehicles. Engaging with manufacturers to understand the specifications and real-world performance metrics of the vehicles can help buyers make informed decisions. Additionally, conducting pilot programs with a small fleet can provide firsthand insights into operational performance, allowing businesses to assess the viability of integrating solar EVs into their operations. By fostering a culture of informed decision-making and continuous learning, organizations can better align their technological investments with their operational needs, ensuring a successful transition to solar-powered mobility.

Strategic Material Selection Guide for electric car with solar panel

When selecting materials for electric cars equipped with solar panels, it is crucial to evaluate options that enhance performance, durability, and sustainability. The following analysis covers four common materials used in the construction of electric vehicles with solar technology, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Aluminum in Electric Cars with Solar Panels?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. These properties make it ideal for electric vehicle (EV) applications, where weight reduction can significantly improve efficiency and range. Aluminum can withstand a wide range of temperatures, making it suitable for various climates.

Pros & Cons:

– Pros: Lightweight, high corrosion resistance, good thermal conductivity, recyclable.

– Cons: Higher cost compared to some steel options, requires specialized welding techniques.

Impact on Application:

Aluminum’s lightweight nature enhances the overall efficiency of the vehicle, allowing for better solar energy capture and longer ranges. However, its cost can be a limiting factor for budget-sensitive projects.

Considerations for International Buyers:

Aluminum standards vary globally, with compliance to ASTM and EN standards being crucial. Buyers in regions like Europe may prefer aluminum due to stringent emissions regulations, while those in Africa or South America might focus on cost-effectiveness.

How Does Carbon Fiber Enhance Performance in Solar Electric Vehicles?

Carbon fiber is a composite material known for its exceptional strength and rigidity while being significantly lighter than metals. It offers high resistance to fatigue and corrosion, making it suitable for high-performance electric vehicles.

Pros & Cons:

– Pros: Extremely lightweight, high strength-to-weight ratio, excellent fatigue resistance.

– Cons: High manufacturing costs, complex production processes, limited recyclability.

Impact on Application:

The use of carbon fiber can lead to substantial weight savings, improving the vehicle’s efficiency and range. However, the high cost and complexity of production may limit its use to premium models.

Considerations for International Buyers:

Buyers need to consider the availability of carbon fiber manufacturing facilities and compliance with international standards. In Europe, for instance, there is a growing demand for lightweight materials to improve EV performance.

What Role Does Polycarbonate Play in Solar Panel Integration?

Polycarbonate is a durable plastic often used in the production of solar panel covers and vehicle windows. It is known for its high impact resistance and transparency, allowing for effective solar energy capture.

Pros & Cons:

– Pros: Lightweight, high impact resistance, excellent optical clarity.

– Cons: Susceptible to scratching, can yellow over time when exposed to UV light.

Impact on Application:

Polycarbonate can enhance the efficiency of solar panels by allowing maximum sunlight penetration while providing protection against environmental factors. However, its susceptibility to UV degradation may require additional coatings or treatments.

Considerations for International Buyers:

International buyers should be aware of the varying regulations regarding material safety and environmental impact. Compliance with standards such as ASTM and ISO is essential, especially in markets like Germany, where sustainability is a priority.

How Does Steel Contribute to the Structural Integrity of Electric Vehicles?

Steel remains a popular choice for the structural components of electric vehicles due to its strength, durability, and cost-effectiveness. It is particularly useful in areas requiring high structural integrity, such as the chassis.

Pros & Cons:

– Pros: High strength, cost-effective, widely available.

– Cons: Heavier than aluminum and composites, prone to corrosion without treatment.

Impact on Application:

While steel provides excellent structural support, its weight can negatively impact the vehicle’s range. However, advancements in high-strength steel have mitigated some of these concerns.

Considerations for International Buyers:

Steel standards are well-established globally, with compliance to ASTM and DIN standards being common. Buyers from regions like the Middle East may prefer steel for its availability and cost-effectiveness, while European buyers may focus on lightweight alternatives.

Summary Table of Material Selection for Electric Cars with Solar Panels

| Material | Typical Use Case for electric car with solar panel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Vehicle body and frame | Lightweight and corrosion-resistant | Higher cost compared to steel | Medium |

| Carbon Fiber | High-performance components | Exceptional strength-to-weight ratio | High manufacturing costs | High |

| Polycarbonate | Solar panel covers and windows | High impact resistance and clarity | Susceptible to UV degradation | Medium |

| Steel | Chassis and structural components | Cost-effective and strong | Heavier than aluminum and composites | Low |

This strategic material selection guide provides international B2B buyers with actionable insights to make informed decisions when sourcing materials for electric cars equipped with solar panels. Understanding the properties, advantages, and limitations of each material will help optimize performance while meeting regional compliance and sustainability goals.

In-depth Look: Manufacturing Processes and Quality Assurance for electric car with solar panel

What Are the Key Stages in Manufacturing Electric Cars with Solar Panels?

Manufacturing electric cars with integrated solar panels involves several critical stages, each requiring precision and adherence to industry standards. The primary stages include material preparation, forming, assembly, and finishing.

How Does Material Preparation Work in Solar Electric Vehicle Manufacturing?

Material preparation is foundational in the manufacturing process. It begins with the selection of high-quality raw materials, including aluminum, steel, and specialized polymers for the vehicle body, as well as photovoltaic cells for the solar panels. These materials must meet specific mechanical and thermal properties to ensure performance and durability.

Once materials are selected, they undergo a series of processes, including cutting, shaping, and treatment to enhance their properties. For instance, aluminum components may be anodized to improve corrosion resistance, while solar panels are treated to optimize light absorption and energy conversion efficiency. This stage sets the groundwork for the subsequent forming processes.

What Techniques Are Used in Forming Electric Vehicles with Solar Panels?

Forming is a critical stage where raw materials are transformed into the desired shapes. Techniques such as stamping, extrusion, and injection molding are commonly employed. For the vehicle chassis, stamping processes shape sheets of metal into structural components. Meanwhile, solar panels are typically fabricated using thin-film technology or crystalline silicon techniques, which involve layering photovoltaic materials to maximize energy absorption.

Advanced manufacturing techniques, such as 3D printing, are increasingly used to produce complex components with reduced waste. This not only streamlines the production process but also allows for rapid prototyping and customization, which are essential for meeting diverse market demands.

How Is Assembly Conducted in the Production of Solar Electric Vehicles?

The assembly phase combines all manufactured components into a finished vehicle. This process involves meticulous planning and coordination to ensure efficiency and quality. Electric vehicles often utilize modular assembly lines, where components are brought together at various stations.

Key assembly tasks include integrating the solar panels onto the vehicle roof, connecting the electrical systems, and installing the battery packs. Automated systems are often employed to enhance accuracy and speed, while skilled technicians oversee quality control at each stage. Collaboration with suppliers for components like batteries and solar technology is crucial to ensure compatibility and performance.

What Finishing Processes Are Essential for Quality in Electric Vehicles?

Finishing processes are the final steps before a vehicle is ready for the market. These may include painting, surface treatment, and quality inspections. The painting process not only provides aesthetic appeal but also protects the vehicle from environmental damage.

Surface treatments, such as powder coating, are applied to enhance durability. After finishing, vehicles undergo rigorous testing to ensure they meet performance and safety standards. This includes dynamic testing of the solar charging systems to confirm efficiency in real-world conditions.

What International Quality Standards Are Applicable to Electric Car Manufacturing?

Quality assurance is paramount in the manufacturing of electric cars with solar panels. Adhering to international standards such as ISO 9001 is essential for ensuring consistent quality management systems. This standard focuses on meeting customer requirements and enhancing satisfaction, which is critical for B2B buyers seeking reliable suppliers.

In addition to ISO standards, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) may apply depending on the market and vehicle specifications. These certifications assure buyers of compliance with safety and environmental regulations.

How Are Quality Control Checkpoints Implemented in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to ensure that each component meets established standards. Key QC phases include:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival to confirm they meet specifications before use in production.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring occurs at various stages to identify defects or deviations from the quality standards. This includes testing the solar panels for efficiency and the structural integrity of the vehicle components.

-

Final Quality Control (FQC): Before vehicles are shipped, a thorough final inspection ensures that all systems function correctly, and the vehicle meets performance benchmarks. This may include road testing to assess the effectiveness of the solar charging system.

What Testing Methods Are Commonly Used in Electric Vehicle Manufacturing?

Common testing methods for electric vehicles include:

-

Performance Testing: Evaluating the vehicle’s acceleration, braking, and handling characteristics under various conditions.

-

Durability Testing: Subjecting vehicles to extreme temperatures, humidity, and other environmental factors to assess longevity.

-

Electrical Testing: Ensuring the solar panels and battery systems work effectively, including stress tests to evaluate energy output.

-

Safety Testing: Conducting crash tests and evaluating safety features to ensure compliance with regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and adherence to standards directly.

-

Quality Reports: Requesting detailed quality assurance reports can provide insights into the supplier’s QC history, including failure rates and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control measures and product reliability.

What Are the Specific Quality Control Nuances for International Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is vital. Different markets may have specific regulatory requirements and quality expectations.

For instance, European buyers may prioritize CE certification, while Middle Eastern markets might focus on compliance with local regulations. Understanding these differences is crucial for ensuring that products meet local market standards and consumer expectations.

In summary, the manufacturing processes and quality assurance protocols for electric cars with solar panels are complex and multifaceted. B2B buyers must consider various factors, including the manufacturing stages, quality standards, testing methods, and verification strategies, to make informed purchasing decisions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric car with solar panel’

Introduction

This guide serves as a comprehensive checklist for B2B buyers seeking to procure electric cars equipped with solar panels. As the demand for sustainable transportation solutions grows globally, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of sourcing these vehicles is essential for making informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. This includes determining the desired range, solar panel efficiency, and battery capacity. Specific requirements will vary based on your operational needs, such as urban commuting or long-distance travel.

- Considerations:

- What is the expected daily mileage?

- What solar panel output is necessary to meet your sustainability goals?

Step 2: Research Available Models

Investigate the current market offerings for electric cars with solar panels. Various manufacturers, such as Aptera and Lightyear, provide different models with unique features. Understanding the variety will help you identify which vehicles align with your specifications and budget.

- Key Models to Explore:

- Aptera’s solar-powered vehicle with up to 40 miles of solar range daily.

- Lightyear’s advanced solar charging systems for electric mobility.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. A reliable supplier should provide detailed company profiles, case studies, and references from similar industries or regions. This step is crucial to ensure that the supplier has a proven track record in delivering quality products and services.

- What to Look For:

- Supplier certifications and compliance with international standards.

- Reviews and testimonials from previous B2B clients.

Step 4: Assess Solar Panel Technology

The efficiency and integration of solar technology within the vehicle are critical factors. Examine the solar panels’ output capacity and how well they complement the electric vehicle’s battery system. This will ensure that the vehicle can effectively utilize solar energy to extend its range.

- Considerations:

- What is the efficiency rating of the solar panels?

- How does the solar charging system function in various weather conditions?

Step 5: Request Prototypes or Demonstrations

Before finalizing your decision, request prototypes or demonstrations from suppliers. This hands-on experience allows you to assess the vehicle’s performance, solar integration, and overall user experience. It’s essential to see how the vehicle operates in real-world conditions.

- What to Observe:

- How effectively does the solar panel charge the battery?

- What is the vehicle’s performance under different driving conditions?

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, warranties, and after-sales support. Clear agreements on these aspects can prevent misunderstandings and ensure a smooth procurement process.

- Key Points to Discuss:

- Warranty coverage for both the vehicle and solar components.

- Support for maintenance and repairs post-purchase.

Step 7: Plan for Integration and Training

Finally, consider how the electric car with solar panels will be integrated into your existing fleet or operations. Training your team on the new technology will maximize its benefits and ensure a smooth transition.

- Considerations:

- What training materials or sessions does the supplier offer?

- How will you measure the effectiveness of the new vehicles in your operations?

By following these steps, B2B buyers can confidently navigate the sourcing process for electric cars with solar panels, ensuring they make informed and strategic decisions that align with their sustainability goals.

Comprehensive Cost and Pricing Analysis for electric car with solar panel Sourcing

What are the Key Cost Components for Electric Cars with Solar Panels?

When sourcing electric cars equipped with solar panels, understanding the cost structure is crucial for B2B buyers. The main cost components include:

-

Materials: The primary materials consist of high-quality solar cells, batteries, electric drive systems, and vehicle chassis. Solar cells, often made from silicon, can vary significantly in price based on efficiency and technology (monocrystalline vs. polycrystalline). The cost of lithium-ion batteries is another critical factor, influenced by market demand and raw material availability.

-

Labor: Labor costs encompass the workforce required for assembly, quality control, and design. Skilled labor is essential, particularly for the installation of solar panels and electrical systems, which can add to the overall cost.

-

Manufacturing Overhead: This includes the indirect costs of production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can reduce overhead and ultimately impact pricing.

-

Tooling: The investment in specialized tools and machinery for producing solar-integrated electric vehicles can be substantial. This upfront cost is often amortized over the production volume, affecting unit pricing.

-

Quality Control (QC): Ensuring that both the electric vehicle and solar panel systems meet safety and performance standards involves rigorous testing and quality assurance, which adds to the overall cost.

-

Logistics: Shipping costs, including transportation and storage, can vary based on the distance from manufacturing sites to the final destination. For international buyers, understanding the implications of shipping methods and tariffs is essential.

-

Margin: Manufacturers typically apply a profit margin to cover risks and ensure sustainability. This margin can vary significantly based on market conditions and competition.

How Do Price Influencers Impact the Cost of Electric Cars with Solar Panels?

Several factors influence pricing in the electric vehicle market, especially those integrating solar technology:

-

Volume/MOQ: Bulk purchasing often results in lower unit costs due to economies of scale. Buyers should consider minimum order quantities (MOQ) to negotiate better pricing.

-

Specifications and Customization: Unique specifications or custom designs can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: The choice of materials impacts both the initial cost and long-term durability. Products with recognized quality certifications may come at a premium but can provide assurance of reliability and safety.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding international commercial terms is vital for determining shipping responsibilities and costs. This can significantly influence the total landed cost of the vehicles.

What Tips Should Buyers Consider for Cost-Efficiency in Sourcing?

To maximize value when sourcing electric cars with solar panels, buyers should consider the following strategies:

-

Negotiation: Engage in thorough negotiations with suppliers. Leveraging volume purchasing can provide leverage in price discussions.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but also maintenance, fuel savings from solar energy, and potential tax incentives. A lower upfront cost may not always yield the best long-term value.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, regional tariffs, and import duties that can affect the final cost. Establishing relationships with local distributors can help navigate these complexities.

Conclusion

The sourcing of electric cars with solar panels involves a multifaceted cost structure and is influenced by numerous pricing factors. By understanding these components, B2B buyers can make informed decisions that align with their sustainability goals while optimizing their procurement strategy. Always seek to clarify pricing terms and conditions to avoid surprises and ensure that the total cost aligns with your budget and operational expectations.

Alternatives Analysis: Comparing electric car with solar panel With Other Solutions

Exploring Viable Alternatives to Electric Cars with Solar Panels

In the quest for sustainable mobility solutions, electric cars equipped with solar panels present a promising option. However, it’s essential to evaluate other viable alternatives that can achieve similar environmental and operational goals. This analysis compares the ‘Electric Car with Solar Panel’ against two notable alternatives: traditional electric vehicles (EVs) without solar integration and hydrogen fuel cell vehicles (HFCVs).

| Comparison Aspect | Electric Car With Solar Panel | Traditional Electric Vehicle | Hydrogen Fuel Cell Vehicle |

|---|---|---|---|

| Performance | Limited range from solar; up to 40 miles/day | High range (200-400 miles) | High range (300-400 miles) with quick refueling |

| Cost | Higher initial investment; lower operating costs | Moderate initial cost; low operating costs | High initial cost; moderate operating costs |

| Ease of Implementation | Moderate; requires solar panel installation | Easy; widespread charging infrastructure | Challenging; limited refueling stations |

| Maintenance | Low; solar panels require minimal upkeep | Low; standard EV maintenance | Moderate; fuel cell systems need specialized care |

| Best Use Case | Ideal for urban commuting and off-grid scenarios | General commuting and long-distance travel | Heavy-duty applications and public transport |

What Are the Pros and Cons of Traditional Electric Vehicles?

Traditional electric vehicles (EVs) are designed to operate solely on battery power, utilizing a well-established charging infrastructure. The primary advantage of these vehicles is their extensive range, allowing for longer trips without the need for frequent recharging. Moreover, the maintenance requirements are generally low, similar to that of conventional vehicles, as they have fewer moving parts compared to internal combustion engines. However, traditional EVs do not harness renewable energy directly, which can lead to higher carbon footprints depending on the electricity source. Additionally, the upfront costs can be significant, though they tend to have lower operating costs over time.

How Do Hydrogen Fuel Cell Vehicles Compare?

Hydrogen fuel cell vehicles (HFCVs) represent a cutting-edge alternative to both electric cars and solar-integrated vehicles. These vehicles convert hydrogen into electricity, offering high range and quick refueling times—typically under five minutes. This makes HFCVs particularly suitable for commercial applications and public transport systems. However, the challenges include a limited refueling infrastructure and higher initial costs associated with hydrogen production and distribution. Furthermore, while HFCVs produce only water vapor as a byproduct, the environmental impact depends heavily on the hydrogen production method.

Making the Right Choice: Which Solution Fits Your Needs?

When evaluating mobility solutions, B2B buyers must consider various factors, including operational needs, environmental impact, and cost-effectiveness. For businesses operating in urban areas with limited driving distances, electric cars with solar panels may provide a sustainable and cost-efficient option. Conversely, companies requiring longer ranges or faster refueling times might find traditional electric vehicles or hydrogen fuel cell vehicles more suitable. Ultimately, the choice will depend on specific use cases, regional infrastructure, and sustainability goals, ensuring that the selected solution aligns with both operational efficiency and environmental responsibility.

Essential Technical Properties and Trade Terminology for electric car with solar panel

What Are the Key Technical Properties of Electric Cars with Solar Panels?

When considering electric cars equipped with solar panels, several technical properties are crucial for evaluating their efficiency, reliability, and overall value in a B2B context. Here are some critical specifications:

-

Solar Panel Efficiency

Solar panel efficiency is defined as the percentage of sunlight that is converted into usable electricity. Most modern solar panels for vehicles have an efficiency rate of about 20-22%. For B2B buyers, understanding this metric is vital as it directly impacts the vehicle’s ability to harness solar energy effectively, thereby influencing operational costs and sustainability goals. -

Battery Capacity (kWh)

This specification refers to the total energy that the vehicle’s battery can store, measured in kilowatt-hours (kWh). For instance, a vehicle with a 60 kWh battery can theoretically provide enough energy to drive approximately 200-300 miles on a single charge. High battery capacity is essential for B2B buyers focusing on fleet management or long-distance logistics, as it determines the range and usability of the vehicle. -

Range Extender Capability

This property indicates the additional distance a vehicle can travel using solar energy compared to traditional charging methods. For example, some vehicles can gain up to 12 miles of range per day from their solar panels under optimal conditions. Understanding the range extender capabilities helps businesses evaluate the vehicle’s efficiency in off-grid scenarios and its alignment with sustainability initiatives. -

Material Grade of Solar Cells

The material grade of solar cells used in electric vehicles can vary, with monocrystalline and polycrystalline being the most common types. Monocrystalline panels generally offer higher efficiency and better performance in low-light conditions but come at a higher cost. For B2B buyers, knowing the material grade aids in assessing the long-term durability and performance of the vehicle. -

Integration Technology

This refers to how well the solar panels are integrated into the vehicle’s design. Advanced integration technologies can enhance aesthetics and aerodynamics while maximizing energy capture. For businesses, evaluating integration technology is important for ensuring that the vehicle aligns with branding and operational needs. -

Charging Time

This specification indicates how long it takes to fully charge the vehicle’s battery using solar energy versus traditional charging methods. Understanding charging times helps businesses plan their operational schedules and assess the practicality of using solar-powered vehicles in various environments.

Which Trade Terminology Is Commonly Used in the Electric Vehicle Solar Panel Industry?

Familiarity with industry-specific terminology is essential for effective communication and decision-making in B2B transactions. Here are some key terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of electric cars with solar panels, OEMs are critical for sourcing high-quality solar technology and vehicle components. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQs is essential for businesses looking to manage inventory costs and negotiate favorable purchasing terms for solar vehicles. -

RFQ (Request for Quotation)

An RFQ is a document that an organization sends to suppliers to request pricing and other terms for a specific quantity of goods. In the context of electric vehicles with solar panels, submitting RFQs can help businesses obtain competitive pricing and better understand supplier capabilities. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that are widely used in international commercial transactions. They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B buyers, especially those importing solar electric vehicles from different regions. -

TCO (Total Cost of Ownership)

TCO encompasses all costs associated with owning a vehicle over its entire lifecycle, including purchase price, maintenance, fuel (or energy), and resale value. For businesses evaluating electric cars with solar panels, calculating TCO is vital for assessing long-term financial viability. -

Sustainability Metrics

These metrics evaluate the environmental impact of products and processes, including carbon footprint and energy consumption. Understanding sustainability metrics is increasingly important for B2B buyers who prioritize eco-friendly solutions in their operations.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions about electric cars with solar panels, ensuring alignment with their business objectives and sustainability goals.

Navigating Market Dynamics and Sourcing Trends in the electric car with solar panel Sector

What Are the Key Market Dynamics and Trends Influencing the Electric Car with Solar Panel Sector?

The electric car with solar panel market is poised for significant growth driven by global sustainability goals and advancements in solar technology. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, are increasingly prioritizing renewable energy solutions to address energy scarcity and reduce dependency on fossil fuels. The integration of solar panels in electric vehicles (EVs) presents a unique value proposition, as it enhances energy autonomy and aligns with green transportation initiatives.

Emerging trends include the development of innovative solar charging systems that extend vehicle range and reduce the need for traditional charging infrastructure. Companies like Aptera and Lightyear are pioneering designs that harness solar energy efficiently, allowing for off-grid mobility. Additionally, micro-mobility solutions, such as solar-powered scooters and small vehicles, are gaining traction in urban areas, particularly in densely populated regions where space and energy efficiency are critical.

Furthermore, the rise of electric vehicle adoption in emerging markets is catalyzing investment in solar technologies. Nations in Africa and South America are exploring electric mobility as a solution to their transportation challenges, with solar panels providing a sustainable energy source in areas lacking robust electrical grids. B2B buyers should consider these market dynamics to strategically position themselves in the evolving landscape of sustainable transportation.

How Does Sustainability and Ethical Sourcing Impact the Electric Car with Solar Panel Industry?

Sustainability is at the core of the electric car with solar panel sector, as manufacturers and consumers increasingly seek to minimize their environmental impact. The integration of solar technology into electric vehicles not only reduces greenhouse gas emissions but also promotes the use of renewable energy. This shift is crucial in a world grappling with climate change, where the automotive industry is under pressure to reduce its carbon footprint.

Ethical sourcing of materials is equally important in this sector. B2B buyers should prioritize suppliers who adhere to sustainable practices, including the responsible extraction of raw materials used in batteries and solar panels. Certifications such as ISO 14001 for environmental management and adherence to the Responsible Minerals Initiative can help ensure that sourcing practices are both environmentally friendly and socially responsible.

Moreover, the use of ‘green’ materials in manufacturing processes is gaining traction. Companies are exploring alternatives like recycled metals and biodegradable composites to enhance sustainability. By choosing suppliers committed to ethical sourcing and sustainability, B2B buyers can align their procurement strategies with global sustainability goals and enhance their brand reputation in the market.

What Is the Evolution of the Electric Car with Solar Panel Market?

The evolution of electric cars with solar panels can be traced back to the early 2000s when the concept of solar mobility was merely an innovative idea. Initial attempts focused on integrating solar panels into existing vehicle designs, but these efforts were often limited by technology constraints. As solar panel efficiency improved and battery technology advanced, the feasibility of fully integrating solar energy into electric vehicles became increasingly realistic.

In recent years, manufacturers like Fisker and Hyundai have introduced models featuring solar roofs that provide supplementary energy to extend range and reduce reliance on grid charging. The rise of consumer awareness regarding climate change and the push for cleaner transportation options have further accelerated the adoption of solar EVs. Today, the market is witnessing a convergence of automotive engineering and renewable energy technology, positioning electric cars with solar panels as a viable and sustainable transportation solution for the future.

As this sector continues to evolve, B2B buyers should stay informed about technological advancements and market trends that will shape the next generation of electric mobility. Engaging with innovative suppliers and investing in sustainable solutions will be key for companies looking to thrive in this competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of electric car with solar panel

-

How do I evaluate the efficiency of solar panels for electric cars?

To assess the efficiency of solar panels for electric vehicles (EVs), consider the conversion rate of sunlight to electricity, typically around 22-23% for high-quality panels. Analyze the total surface area available for solar panel installation on the vehicle and the expected daily solar energy yield based on geographical location and sunlight availability. Additionally, evaluate how much additional range the solar panels can provide under optimal conditions, keeping in mind that while solar panels can supplement charging, they are unlikely to fully power the vehicle. -

What is the best solar electric vehicle for commercial use?

The best solar electric vehicle for commercial applications often depends on specific business needs. Options like the Aptera and Lightyear models are designed with integrated solar technology, allowing for off-grid charging and extending driving range. The GEM electric car with solar panels is ideal for short-range urban transportation, while microcars like the Squad offer practicality in densely populated areas. Evaluate the vehicle’s range, load capacity, and solar efficiency to determine the best fit for your operational requirements. -

What customization options are available when sourcing electric cars with solar panels?

Customization options for electric cars with solar panels can vary by manufacturer but typically include choices in battery size, solar panel capacity, exterior design, and interior features. Buyers can also request specific technology integrations, such as enhanced charging systems or fleet management software. When sourcing, engage with suppliers to discuss your specific needs, ensuring they can accommodate modifications that align with your operational goals and branding requirements. -

What are the minimum order quantities (MOQs) for electric cars with solar panels?

Minimum order quantities (MOQs) for electric cars with solar panels depend on the manufacturer and the specific vehicle model. Some manufacturers may offer flexibility for smaller orders, particularly for pilot programs, while others may require bulk orders to optimize production efficiency. It is crucial to communicate your needs directly with suppliers to understand their MOQ policies and explore potential negotiation options for your business. -

What payment terms should I expect when sourcing electric cars with solar panels?

Payment terms for electric cars with solar panels can vary widely among suppliers. Common arrangements include upfront payments, installment payments, or letters of credit, especially for larger orders. It’s essential to clarify payment expectations during negotiations, including any deposit requirements and timelines for final payment. Additionally, inquire about available financing options or partnerships that can facilitate smoother transactions. -

How do I ensure quality assurance (QA) in electric cars with solar panels?

To ensure quality assurance (QA) in electric cars with solar panels, conduct thorough supplier evaluations, including checking certifications, past performance, and customer reviews. Request detailed specifications and testing reports for the solar panels and EV systems. Implement a quality control protocol that includes inspections at various production stages and final product assessments before delivery. Establishing a clear communication channel with suppliers can also facilitate timely resolutions to any quality concerns. -

What logistics considerations should I keep in mind when importing electric cars with solar panels?

When importing electric cars with solar panels, logistics considerations include understanding international shipping regulations, customs duties, and import tariffs specific to your region. Work with experienced logistics partners to navigate these complexities and ensure compliance with local laws. Additionally, consider the transportation method (e.g., container shipping vs. roll-on/roll-off) and the associated costs. Planning for potential delays, particularly in customs clearance, will also be crucial to maintaining your supply chain. -

How do solar electric vehicles contribute to sustainability goals for businesses?

Solar electric vehicles (SEVs) significantly contribute to sustainability goals by reducing reliance on fossil fuels and lowering greenhouse gas emissions. By integrating solar technology, businesses can harness renewable energy to power their fleets, thus decreasing their carbon footprint. Additionally, adopting SEVs can enhance corporate social responsibility (CSR) profiles and appeal to environmentally conscious consumers. Businesses can further leverage these vehicles in sustainability marketing campaigns, showcasing their commitment to innovative and eco-friendly transportation solutions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Electric Car With Solar Panel Manufacturers & Suppliers List

1. Aptera – Solar Electric Vehicle

Domain: aptera.us

Registered: 2019 (6 years)

Introduction: Aptera is a solar electric vehicle designed to be highly efficient and requires no charging for most daily use. Key specifications include:

– Integrated solar cells generating approximately 700 watts

– Capable of driving up to 40 miles per day using solar power

– Total range of 400 miles per full charge

– Acceleration from 0 to 60 mph in less than 6 seconds.

The vehicle is currently in testin…

2. GEM – Solar Electric Car

Domain: gemcar.com

Introduction: GEM Electric Car with Solar Panels: EV solar panels charge on the go and off the grid, extending drive time between charges by up to 40%. The solar electric car design integrates solar panels seamlessly, maximizing off-grid charging efficiency and sustainability goals. Key features include:

– Sustainability: Reduces grid-tied energy consumption with all-electric, zero-emission GEM EVs.

– Conveni…

3. Forbes – Solar Cell Integration in Cars

Domain: forbes.com

Registered: 1993 (32 years)

Introduction: This company, Forbes – Solar Cell Integration in Cars, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Octopus EV – Electric Vehicle Leasing and Charging Solutions

Domain: octopusev.com

Registered: 2016 (9 years)

Introduction: Octopus EV offers various plans for electric vehicles (EVs) including employee benefits through salary sacrifice, personal leasing options with maintenance included, and business leasing for fleet solutions. They provide access to home chargers installed by experts, and an exclusive tariff for EV drivers called Intelligent Octopus Go, allowing charging at home for just 6p/kWh. Octopus Electroverse…

Strategic Sourcing Conclusion and Outlook for electric car with solar panel

How Can B2B Buyers Leverage the Electric Car with Solar Panel Market?

As the electric vehicle (EV) market rapidly evolves, the integration of solar panels presents a compelling opportunity for international B2B buyers. Companies like Aptera and Lightyear are pioneering solutions that not only enhance the sustainability of transportation but also reduce dependence on traditional energy sources. Strategic sourcing in this sector means aligning with manufacturers that prioritize innovative solar technology, thus enabling businesses to achieve their sustainability goals while appealing to an eco-conscious consumer base.

Investing in electric cars equipped with solar panels can yield significant long-term benefits. These vehicles can provide off-grid charging capabilities, extend driving range, and reduce overall operational costs. For regions in Africa, South America, the Middle East, and Europe, where energy infrastructure may be less reliable, the added advantage of solar charging is particularly advantageous.

Looking ahead, the demand for clean mobility solutions is set to rise. B2B buyers are encouraged to engage with manufacturers and suppliers who are at the forefront of solar EV technology. By doing so, they can position themselves as leaders in the transition towards sustainable transportation, ultimately contributing to a greener future. Now is the time to act—explore partnerships that will drive innovation and sustainability in your fleet.