Introduction: Navigating the Global Market for electric cargobike

In today’s rapidly evolving transportation landscape, sourcing electric cargobikes presents a significant challenge for international B2B buyers. As urban populations grow and sustainability becomes a priority, businesses across Africa, South America, the Middle East, and Europe are seeking efficient, eco-friendly solutions for their logistics and commuting needs. This guide aims to navigate the complexities of the global electric cargobike market, offering insights into various types, applications, and the latest innovations that meet diverse operational demands.

From family-oriented models designed for local deliveries to robust options suited for challenging terrains, understanding the spectrum of electric cargobikes is crucial for making informed purchasing decisions. Additionally, we delve into supplier vetting processes, cost considerations, and the importance of after-sales support—key elements that can impact your bottom line.

This comprehensive resource empowers B2B buyers by providing the knowledge necessary to evaluate options effectively, ensuring that investments align with organizational goals and operational requirements. Whether you’re in Nigeria, Saudi Arabia, or any other region, this guide serves as a valuable tool for navigating the dynamic electric cargobike market, enhancing your ability to meet transportation challenges head-on while contributing to a greener future.

Understanding electric cargobike Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Front-Loader Cargo Bikes | Large front cargo area; low center of gravity | Delivery services, family transport | Pros: Excellent stability; high cargo capacity. Cons: May be less maneuverable in tight spaces. |

| Long-Tail Cargo Bikes | Extended rear frame for carrying cargo; versatile | Urban logistics, family outings | Pros: Great for transporting children; easier to ride. Cons: Limited cargo space compared to front-loaders. |

| Utility Cargo Bikes | Heavy-duty frames; designed for tough conditions | Construction, heavy cargo transport | Pros: High durability; can handle substantial weight. Cons: Heavier; may require more effort to pedal. |

| Folding Cargo Bikes | Compact design; easily stored and transported | Small businesses, urban commuting | Pros: Space-saving; portable. Cons: Reduced cargo capacity; may sacrifice stability. |

| E-Cargo Bike Kits | Customizable components; allows for DIY assembly | Startups, custom applications | Pros: Tailored solutions; cost-effective. Cons: Requires assembly knowledge; potentially inconsistent quality. |

What Are Front-Loader Cargo Bikes and Their Benefits for Businesses?

Front-loader cargo bikes feature a large cargo area situated at the front, which offers excellent stability and balance. These bikes are ideal for businesses involved in delivery services and family transportation, as they can accommodate significant loads while remaining easy to handle. B2B buyers should consider the weight capacity and maneuverability, especially in urban environments where space can be tight. The low center of gravity enhances safety, but the design may limit access to certain areas due to its bulk.

How Do Long-Tail Cargo Bikes Cater to Urban Logistics?

Long-tail cargo bikes extend the rear frame, allowing for versatile cargo solutions. They are particularly suited for urban logistics and family outings, making them an attractive option for businesses that require flexibility. With their ability to transport children and goods comfortably, these bikes are becoming increasingly popular among families and delivery services. When purchasing, B2B buyers should evaluate the bike’s stability and the ease of loading and unloading cargo, as these factors can influence efficiency.

What Advantages Do Utility Cargo Bikes Offer for Heavy Cargo Transport?

Utility cargo bikes are designed with heavy-duty frames that can endure tough conditions, making them perfect for construction and heavy cargo transport. Their robust build allows them to carry substantial weights without compromising performance. B2B buyers in industries that require reliable transport solutions should prioritize durability and weight capacity when considering these bikes. However, potential buyers should also be aware that their heavier frames may require more effort to pedal, which could impact user experience.

Why Choose Folding Cargo Bikes for Small Business Needs?

Folding cargo bikes are designed for compactness and portability, making them an excellent choice for small businesses and urban commuting. Their ability to fold allows for easy storage and transport, which is particularly beneficial for businesses with limited space. When considering a folding cargo bike, B2B buyers should assess the trade-off between cargo capacity and portability, as these bikes may not hold as much as their non-folding counterparts. Despite this limitation, they provide a flexible solution for businesses on the go.

How Can E-Cargo Bike Kits Provide Custom Solutions for Startups?

E-cargo bike kits allow for customization and DIY assembly, catering to startups and businesses looking for tailored solutions. These kits can be particularly cost-effective, enabling businesses to create bikes that meet their specific needs. B2B buyers should consider their assembly capabilities and the quality of components, as these factors can affect the overall performance and longevity of the bike. While these kits offer flexibility, they require a certain level of technical knowledge, which may not suit all businesses.

Key Industrial Applications of electric cargobike

| Industry/Sector | Specific Application of Electric Cargobike | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Delivery | Last-mile delivery of goods in urban areas | Reduces delivery times and transportation costs | Load capacity, battery life, and compatibility with delivery systems |

| Public Transportation | Shuttle services for schools and community events | Eco-friendly alternative, lower operational costs | Reliability, safety features, and ease of maintenance |

| Food & Beverage | Transporting groceries and prepared meals | Enhances delivery efficiency and customer satisfaction | Temperature control options and storage capacity |

| Tourism & Recreation | Guided tours and rentals for tourists | Unique experience for customers, promotes local tourism | Customization options and durability for varied terrains |

| Healthcare | Mobile health clinics and patient transport | Improves access to healthcare services | Comfort, accessibility features, and battery range |

How Are Electric Cargobikes Transforming E-commerce and Delivery Services?

In the e-commerce sector, electric cargobikes are revolutionizing last-mile delivery, particularly in densely populated urban areas. They can navigate traffic more efficiently than traditional vehicles, significantly reducing delivery times and costs. For international B2B buyers, considerations such as load capacity and battery life are crucial, especially in regions with varied terrain and climate conditions, such as Africa and South America. Additionally, integrating these bikes into existing logistics systems can optimize operations and enhance customer satisfaction.

What Role Do Electric Cargobikes Play in Public Transportation?

Electric cargobikes serve as an eco-friendly alternative for shuttle services, particularly in schools and community events. They provide a sustainable mode of transport that can reduce carbon footprints while offering a cost-effective solution for local governments and organizations. Buyers must prioritize reliability and safety features, ensuring that the bikes can withstand frequent use and diverse weather conditions, especially in regions like the Middle East and Europe where climate variability can impact operations.

How Can the Food & Beverage Industry Benefit from Electric Cargobikes?

In the food and beverage sector, electric cargobikes are increasingly utilized for transporting groceries and prepared meals. They enhance delivery efficiency, allowing businesses to meet customer demands swiftly while minimizing transportation costs. For businesses looking to invest, sourcing bikes with temperature control options and adequate storage capacity is essential, particularly in hot climates found in many African nations, where food safety is a priority.

Why Are Electric Cargobikes Ideal for Tourism & Recreation?

Electric cargobikes are becoming popular in the tourism and recreation industry, offering guided tours and rentals that provide unique experiences for visitors. They promote local tourism while enabling operators to cater to diverse customer needs. When sourcing, it is vital for B2B buyers to consider customization options and durability, especially in areas with rugged terrains, such as those found in South America and parts of Europe.

How Do Electric Cargobikes Enhance Healthcare Accessibility?

In healthcare, electric cargobikes are leveraged for mobile health clinics and patient transport, improving access to essential services. They enable healthcare providers to reach underserved communities effectively and efficiently. Buyers in this sector should focus on comfort and accessibility features to accommodate patients with varying mobility needs, alongside ensuring the bikes have a sufficient battery range to cover longer distances, particularly in rural areas of Africa and the Middle East.

3 Common User Pain Points for ‘electric cargobike’ & Their Solutions

Scenario 1: Navigating Infrastructure Limitations for Electric Cargo Bikes

The Problem: Many B2B buyers in regions like Africa and South America face significant challenges related to inadequate cycling infrastructure. Poor road conditions, lack of dedicated bike lanes, and limited charging stations can deter businesses from investing in electric cargo bikes. This not only affects the safety and efficiency of their operations but also raises concerns about the longevity of the bikes when used in harsh environments. Companies may hesitate to incorporate electric cargo bikes into their logistics due to fears of damage or inefficiency in navigating these conditions.

The Solution: To overcome infrastructure challenges, businesses should engage in community planning initiatives to advocate for improved cycling infrastructure. Collaborating with local governments and urban planners can lead to the development of safer bike lanes and charging stations. In the meantime, buyers should consider electric cargo bikes designed specifically for rugged terrain. Models with durable tires, robust frames, and advanced suspension systems can handle uneven surfaces more effectively. It’s also wise to invest in portable charging solutions, such as solar-powered chargers, that can be set up in remote locations to ensure the bikes remain operational, even in areas lacking infrastructure.

Scenario 2: Addressing Range Anxiety in Electric Cargo Bikes

The Problem: Range anxiety is a common concern for B2B buyers when considering electric cargo bikes. This issue is particularly relevant for businesses that require long-distance travel or frequent deliveries. In regions with limited access to charging stations, companies fear that their vehicles may run out of battery power mid-route, leading to delays and operational inefficiencies. This apprehension can hinder the decision-making process when evaluating electric cargo bike investments.

The Solution: B2B buyers should prioritize electric cargo bikes with extended battery life and effective energy management systems. When selecting a model, look for bikes equipped with high-capacity batteries that offer a longer range per charge. Additionally, implementing route planning software can help optimize delivery paths to ensure that battery consumption is minimized. Consider training staff on energy-efficient riding techniques, such as using pedal assist judiciously and maintaining a steady speed, to extend battery life further. As a precaution, having a backup battery or a portable charger can also provide peace of mind for longer routes.

Scenario 3: Balancing Initial Costs with Long-Term Savings in Electric Cargo Bikes

The Problem: While electric cargo bikes present a cost-effective alternative to traditional vehicles, the initial investment can be daunting for many businesses, especially in regions like the Middle East where capital expenditures are closely scrutinized. Buyers often weigh the upfront costs against potential savings in fuel, maintenance, and operational efficiency. This financial concern can lead to hesitation in making a purchase decision, as companies fear they may not see a return on investment (ROI) quickly enough.

The Solution: To address this concern, businesses should conduct a comprehensive cost-benefit analysis that includes not only the purchase price but also long-term savings and environmental impact. Calculate potential savings on fuel costs, maintenance expenses, and insurance premiums compared to traditional delivery vehicles. Additionally, consider the potential for increased customer satisfaction and retention by offering eco-friendly delivery options, which can enhance brand reputation and lead to new business opportunities. Seek out financing options or leasing agreements that can spread out the initial cost over time, making the transition to electric cargo bikes more financially manageable. Finally, explore government incentives or subsidies for businesses investing in sustainable transportation to further reduce upfront costs.

Strategic Material Selection Guide for electric cargobike

What Are the Key Materials for Electric Cargo Bikes?

When selecting materials for electric cargo bikes, manufacturers must consider various factors that influence performance, durability, and cost. Below are analyses of four common materials used in the construction of electric cargo bikes, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Aluminum Influence Electric Cargo Bike Performance?

Aluminum is widely used in the frame construction of electric cargo bikes due to its lightweight nature and excellent strength-to-weight ratio. It typically has good corrosion resistance, making it suitable for various environments, including humid and coastal areas. The material can withstand moderate temperature variations, which is beneficial for regions with fluctuating climates.

Pros: Aluminum frames are durable and offer a good balance of performance and weight. They are easier to manufacture than some alternatives, allowing for complex designs that enhance aerodynamics and functionality.

Cons: While generally cost-effective, high-quality aluminum can be more expensive than steel. Additionally, its fatigue resistance is lower than that of steel, which may lead to issues in high-stress applications.

Impact on Application: Aluminum’s lightweight nature allows for better energy efficiency in electric cargo bikes, making them easier to handle and maneuver.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding material safety and environmental impact. Standards such as ASTM and ISO may apply, influencing material selection.

What Role Does Steel Play in Electric Cargo Bikes?

Steel is another common material used, particularly for the frames and cargo areas of electric cargo bikes. Known for its high strength and durability, steel offers excellent resistance to deformation and impact.

Pros: Steel is relatively inexpensive and can be easily welded, allowing for robust construction. Its high tensile strength ensures that the bike can carry heavy loads without compromising structural integrity.

Cons: The primary drawback of steel is its weight, which can negatively impact the bike’s overall performance and handling. Additionally, steel is prone to corrosion if not properly treated, which can be a concern in humid or coastal environments.

Impact on Application: Steel’s strength makes it ideal for heavy-duty cargo applications, but its weight may reduce the bike’s efficiency, particularly in hilly terrains.

International Considerations: Buyers in the Middle East and Europe should consider local corrosion resistance standards, as well as the implications of using steel in terms of weight and energy efficiency.

How Does Carbon Fiber Enhance Electric Cargo Bikes?

Carbon fiber is increasingly being used in high-end electric cargo bikes due to its exceptional strength-to-weight ratio and rigidity. It is particularly advantageous for performance-oriented models.

Pros: Carbon fiber is lightweight and offers superior stiffness, which enhances ride quality and responsiveness. It is also highly resistant to corrosion and environmental degradation.

Cons: The major limitation of carbon fiber is its cost, which can be significantly higher than aluminum or steel. Additionally, manufacturing processes are complex, requiring specialized techniques that may not be readily available in all regions.

Impact on Application: The use of carbon fiber can lead to improved performance and efficiency, making it ideal for urban commuting and long-distance travel.

International Considerations: Buyers should be aware of the need for specialized knowledge in maintenance and repair, as carbon fiber components may require specific tools and techniques.

What Is the Importance of Composite Materials in Electric Cargo Bikes?

Composite materials, often a blend of carbon fiber and other materials, are gaining traction in electric cargo bike design. They provide a unique combination of lightweight properties and strength.

Pros: Composites can be tailored to specific performance needs, offering versatility in design. They typically exhibit excellent fatigue resistance and can be engineered to provide specific mechanical properties.

Cons: The complexity of manufacturing and higher costs compared to traditional materials can be a barrier. Additionally, the recycling and disposal of composites can pose environmental challenges.

Impact on Application: Composites can enhance the overall performance of electric cargo bikes, making them suitable for demanding applications where weight and strength are critical.

International Considerations: Buyers should evaluate the sustainability practices of manufacturers and ensure compliance with international standards regarding material use and disposal.

Summary of Material Selection for Electric Cargo Bikes

| Material | Typical Use Case for electric cargobike | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frame construction | Lightweight and corrosion-resistant | Lower fatigue resistance | Medium |

| Steel | Heavy-duty cargo areas | High strength and low cost | Heavier and prone to corrosion | Low |

| Carbon Fiber | High-performance models | Superior strength-to-weight ratio | High cost and complex manufacturing | High |

| Composite | Specialized applications | Customizable performance properties | Higher costs and environmental concerns | High |

This analysis provides a comprehensive overview of material options for electric cargo bikes, enabling international B2B buyers to make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for electric cargobike

What Are the Main Stages of Manufacturing Electric Cargo Bikes?

The manufacturing of electric cargo bikes involves several critical stages that ensure the final product is both durable and efficient. The process typically includes material preparation, forming, assembly, and finishing.

How is Material Prepared for Electric Cargo Bikes?

The first step in manufacturing electric cargo bikes is material preparation, which focuses on selecting high-quality materials. Manufacturers often use aluminum or steel for the frame due to their strength-to-weight ratio, while components like the battery casing may require lightweight plastics. During this stage, raw materials are sourced from certified suppliers to ensure compliance with international quality standards.

What Forming Techniques Are Commonly Used?

Once materials are prepared, the forming stage begins. This can involve various techniques such as:

- Metal Stamping: Used for creating intricate shapes from metal sheets, including frame components.

- Welding: Essential for joining metal parts, ensuring structural integrity.

- Molding: Used for producing plastic parts like battery enclosures or ergonomic grips.

These techniques are chosen based on the design specifications and performance requirements of the electric cargo bike.

How Are Electric Cargo Bikes Assembled?

The assembly stage involves integrating all components, including the frame, wheels, electric motor, battery, and electronic controls. This process typically follows a modular approach, allowing for efficient assembly and easier repairs. Key assembly techniques include:

- Torque Control: Ensures that bolts and screws are tightened to precise specifications, which is crucial for safety.

- Quality Control Stations: After assembly, bikes undergo inspections at various checkpoints to verify that all components meet design specifications.

What Quality Assurance Standards Are Relevant for Electric Cargo Bikes?

Quality assurance is critical in the manufacturing of electric cargo bikes, especially for international B2B buyers. Several standards must be adhered to, including:

- ISO 9001: This international standard focuses on quality management systems and ensures that manufacturers consistently meet customer and regulatory requirements.

- CE Marking: Required for products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards.

- API Standards: Particularly relevant for components like batteries, ensuring they meet safety and performance criteria.

These standards not only help in maintaining product quality but also enhance the credibility of manufacturers in global markets.

What Are the Key QC Checkpoints in Electric Cargo Bike Manufacturing?

To ensure that electric cargo bikes meet high-quality standards, manufacturers implement several Quality Control (QC) checkpoints throughout the production process:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process help identify any defects early, reducing waste and rework.

- Final Quality Control (FQC): Conducted after assembly, this involves comprehensive testing of the complete bike to ensure it functions correctly and meets safety standards.

These checkpoints are vital for maintaining product consistency and reliability.

What Testing Methods Are Commonly Used for Electric Cargo Bikes?

Various testing methods are employed to evaluate the performance and safety of electric cargo bikes:

- Load Testing: Ensures the bike can support the intended cargo weight without compromising structural integrity.

- Battery Performance Testing: Evaluates the efficiency, range, and safety of the battery under different conditions.

- Electrical Safety Testing: Verifies that all electrical components meet safety standards to prevent hazards such as short circuits or overheating.

These tests help ensure that the bikes are safe for consumers and meet regulatory requirements.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take several steps to verify the quality control processes of potential suppliers:

- Supplier Audits: Conducting on-site audits can provide insights into the manufacturer’s processes, equipment, and adherence to quality standards.

- Quality Reports: Requesting documentation on past quality assessments, including IQC, IPQC, and FQC results, can help assess reliability.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate products before shipment can provide an unbiased assessment of quality.

These measures not only help mitigate risks but also build trust between buyers and suppliers.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers must navigate various nuances when it comes to quality control and certification:

- Regulatory Compliance: Different regions have distinct regulations. For example, products sold in the EU must comply with CE marking, while those in the Middle East may need to meet specific local standards.

- Supply Chain Transparency: Understanding the supply chain is vital, especially when sourcing components from multiple countries. Buyers should ensure that all suppliers meet the same quality standards.

- Cultural Considerations: Buyers from regions like Africa and South America may encounter different business practices and expectations regarding quality assurance. It’s essential to communicate clearly and establish mutual understanding.

By being aware of these nuances, B2B buyers can make more informed decisions and foster successful partnerships with manufacturers.

Conclusion: Why Quality Assurance is Crucial for Electric Cargo Bikes

In the growing market for electric cargo bikes, manufacturing processes and quality assurance play pivotal roles in delivering safe, reliable, and efficient products. By understanding the manufacturing stages, quality standards, testing methods, and verification processes, B2B buyers can effectively navigate the complexities of sourcing electric cargo bikes. This knowledge not only ensures product quality but also helps establish long-term, trustworthy relationships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘electric cargobike’

When sourcing electric cargo bikes, international B2B buyers must navigate a complex landscape of options, specifications, and suppliers. This guide provides a structured approach to help you make informed decisions, ensuring you procure the right electric cargo bikes to meet your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for selecting the right electric cargo bike. Consider factors such as payload capacity, battery range, motor power, and frame design. Key considerations include:

– Payload Capacity: Ensure the bike can handle the weight of the cargo you plan to transport.

– Battery Range: Evaluate how far the bike can travel on a single charge, especially in relation to your operational needs.

Step 2: Identify Your Target Market

Understanding your target market will guide your sourcing decisions. Different regions may have varying preferences and requirements for electric cargo bikes. Focus on:

– Local Regulations: Research any legal requirements for electric bikes in your target markets, such as motor wattage limits and safety standards.

– Consumer Preferences: Identify what features (e.g., design, ease of use) are most appealing to your target demographic.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to conduct thorough evaluations. This ensures you partner with reputable manufacturers who can meet your needs. Consider:

– Company Profiles: Review the supplier’s history, production capacity, and experience in the electric bike market.

– References and Reviews: Request testimonials from other businesses in similar industries to gauge reliability and product quality.

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the electric cargo bikes. Testing the product firsthand allows you to assess quality and performance. Look for:

– Build Quality: Examine materials and construction to ensure durability.

– Performance Metrics: Test ride the bike to evaluate handling, comfort, and motor responsiveness.

Step 5: Negotiate Terms and Pricing

Once you’ve identified suitable suppliers and products, it’s time to negotiate terms. This step is vital for securing favorable pricing and conditions. Focus on:

– Volume Discounts: Inquire about pricing breaks for larger orders, which can significantly reduce costs.

– Warranty and Support: Ensure that the supplier offers a comprehensive warranty and support services for maintenance and repairs.

Step 6: Verify Compliance with International Standards

Ensure that the electric cargo bikes comply with relevant international safety and quality standards. This is crucial for protecting your business and customers. Key standards to check include:

– CE Marking (for Europe): Indicates that the product meets EU safety requirements.

– ISO Certifications: Look for suppliers with ISO certifications, which demonstrate adherence to international quality management standards.

Step 7: Plan for Logistics and Distribution

Finally, consider the logistics of transporting your electric cargo bikes to your business location. This includes shipping methods, customs regulations, and delivery timelines. Key points include:

– Shipping Options: Evaluate the cost and speed of different shipping methods to find the most efficient solution.

– Customs Clearance: Ensure that you understand the customs regulations for importing electric bikes into your target markets to avoid delays.

By following these steps, you can streamline your sourcing process for electric cargo bikes and make well-informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for electric cargobike Sourcing

What Are the Key Cost Components in Electric Cargo Bike Manufacturing?

When sourcing electric cargo bikes, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly affects the overall cost. High-quality aluminum frames, lithium-ion batteries, and durable components can enhance performance but also increase expenses. For instance, a lightweight frame might cost more initially but can reduce shipping costs due to lower weight.

-

Labor: Labor costs vary by region and influence the pricing structure. In regions with higher wages, labor-intensive processes can add to the final cost. Buyers should consider the labor environment of the manufacturing location when evaluating potential suppliers.

-

Manufacturing Overhead: This includes utilities, rent, and administrative expenses associated with the production facility. Efficient manufacturing processes can lower overhead costs, which in turn can provide better pricing for buyers.

-

Tooling: Investment in specific tools and machinery for production can be significant. Custom tooling for unique bike designs may lead to higher initial costs but could offer competitive advantages in the long run.

-

Quality Control (QC): Ensuring product quality through rigorous QC processes is essential. While it may increase costs, it helps in reducing returns and warranty claims, ultimately benefiting the buyer.

-

Logistics: Shipping costs, including freight and handling, can be substantial, especially for bulky items like cargo bikes. Buyers should factor in these costs when calculating total expenses.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the market standards for margins can aid in negotiating better terms.

How Do Price Influencers Impact Electric Cargo Bike Sourcing?

Various factors can influence the pricing of electric cargo bikes:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to reduced per-unit costs. Buyers should consider their purchasing strategy and potential for scaling orders.

-

Specifications and Customization: Customized bikes with specific features or branding can drive up costs. Buyers should weigh the need for customization against budget constraints.

-

Materials and Quality Certifications: High-quality materials and certifications (e.g., CE, ISO) can enhance the bike’s appeal but also increase costs. It’s essential to balance quality with budget.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more due to their proven quality and service, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for international transactions. They define the responsibilities of buyers and sellers, impacting shipping costs and risk. For instance, choosing Ex-Works (EXW) may lower upfront costs but increase logistical complexities.

What Tips Can Help Buyers Negotiate Better Pricing?

B2B buyers can leverage several strategies to enhance cost-efficiency:

-

Negotiation: Engage suppliers in discussions about pricing, especially when placing large orders. Highlighting long-term partnerships can lead to better terms.

-

Total Cost of Ownership (TCO): Focus on TCO rather than just the purchase price. Consider maintenance costs, battery lifespan, and potential resale value when evaluating options.

-

Pricing Nuances for International Buyers: Be aware of regional pricing differences. For buyers in Africa, South America, the Middle East, and Europe, understanding local market dynamics can help in making informed decisions.

-

Explore Multiple Suppliers: Don’t settle for the first quote. Comparing offers from various suppliers can uncover competitive pricing and better terms.

Disclaimer on Indicative Prices

While indicative prices for electric cargo bikes can range from $1,399 to over $6,999, these figures can vary significantly based on the aforementioned factors. Buyers should conduct thorough market research and engage with multiple suppliers to obtain accurate and tailored pricing for their specific needs.

Alternatives Analysis: Comparing electric cargobike With Other Solutions

Exploring Alternatives to Electric Cargobikes: What Are the Options?

In the quest for efficient urban transportation solutions, electric cargobikes have emerged as a popular choice. However, it’s essential for B2B buyers to consider various alternatives that may suit their specific operational needs. This analysis compares electric cargobikes with traditional bicycles and electric scooters, highlighting their strengths and weaknesses.

| Comparison Aspect | Electric Cargobike | Traditional Bicycle | Electric Scooter |

|---|---|---|---|

| Performance | High torque, suitable for heavy loads | Moderate performance, limited cargo | Quick acceleration, limited cargo |

| Cost | $1,700 – $7,000 | $500 – $2,000 | $300 – $1,500 |

| Ease of Implementation | Requires charging infrastructure | Minimal setup, no special needs | Easy to use, but needs charging |

| Maintenance | Moderate, battery and motor upkeep | Low, basic repairs | Moderate, battery replacement needed |

| Best Use Case | Urban deliveries, family transport | Personal commuting, light cargo | Short-distance travel, quick trips |

What Are the Advantages and Disadvantages of Traditional Bicycles?

Traditional bicycles are often the most straightforward alternative to electric cargobikes. They offer a low-cost entry point and minimal maintenance requirements. B2B buyers can benefit from their simplicity, as they require no charging infrastructure and are easy to implement. However, their performance is limited when it comes to carrying heavy loads or navigating steep terrains. This makes them less suitable for businesses that need to transport goods or multiple passengers efficiently.

How Do Electric Scooters Compare to Electric Cargobikes?

Electric scooters present another viable alternative, especially for urban settings where short-distance travel is common. They are generally more affordable than electric cargobikes, making them an attractive option for businesses looking to minimize costs. Scooters are also lightweight and easy to maneuver in crowded environments. However, their cargo capacity is limited, and they may not be suitable for transporting children or heavy goods. Moreover, the need for regular charging can be a logistical challenge for businesses relying on extended usage.

Conclusion: Which Solution is Right for Your Business Needs?

Choosing the right transportation solution depends on your specific requirements. If your business involves frequent heavy cargo transport or family-oriented services, electric cargobikes provide unparalleled performance and versatility. However, if cost is a significant factor and your needs are more aligned with personal commuting or light deliveries, traditional bicycles or electric scooters could be more suitable. Evaluating the trade-offs in performance, cost, and maintenance will help B2B buyers make an informed decision that aligns with their operational goals.

Essential Technical Properties and Trade Terminology for electric cargobike

What Are the Key Technical Properties of Electric Cargo Bikes?

Understanding the essential specifications of electric cargo bikes is crucial for B2B buyers to make informed purchasing decisions. Here are some critical technical properties that should be considered:

1. Motor Power (Watts)

Motor power is a key specification that determines the bike’s performance, especially under load. Common motor powers for electric cargo bikes range from 250W to 750W. A higher wattage typically means better performance on inclines and with heavier loads. This is particularly important for businesses that need reliable transportation for goods or multiple passengers. Buyers should assess the expected terrain and load capacity when evaluating motor power.

2. Battery Capacity (Ah or Wh)

Battery capacity, measured in Amp-hours (Ah) or Watt-hours (Wh), indicates how much energy the battery can store. A higher capacity allows for longer distances between charges, which is crucial for businesses that rely on efficiency. For example, a bike with a 17Ah battery can provide a range of approximately 40-70 miles, depending on conditions. B2B buyers should consider how often the bike will be used and the average distance of trips to select an appropriate battery size.

3. Cargo Capacity (Pounds or Kilograms)

Cargo capacity refers to the maximum weight the bike can safely carry, including the rider and any additional cargo. Typical capacities range from 300 to 600 lbs. This specification is vital for businesses that need to transport goods or multiple passengers, as exceeding this limit can compromise safety and performance. Buyers should evaluate their typical load requirements to choose a bike that meets their needs.

4. Frame Material

The frame material affects durability, weight, and ride quality. Common materials include aluminum, steel, and carbon fiber. Aluminum is lightweight and resistant to corrosion, making it a popular choice for urban environments. Steel offers strength and durability but is heavier. Understanding the trade-offs in material properties can help businesses select a bike that fits their operational needs and budget.

5. Braking System

Electric cargo bikes may feature various braking systems, such as hydraulic disc brakes or mechanical brakes. Hydraulic disc brakes provide superior stopping power and modulation, which is essential for safely managing heavy loads. For B2B buyers, the choice of braking system can impact maintenance costs and safety, particularly in urban settings with frequent stops.

6. Tire Size and Type

Tire specifications, including size and type (e.g., fat tires, puncture-resistant), play a significant role in ride quality and versatility. Larger tires can improve stability and grip, especially when carrying heavy loads or riding on uneven terrain. Buyers should consider the typical riding conditions to choose an appropriate tire type that enhances performance and safety.

What Are Common Trade Terminology Terms in the Electric Cargo Bike Industry?

Familiarizing oneself with industry jargon can facilitate better communication and negotiations in the B2B space. Here are several important terms:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of electric cargo bikes, OEMs may supply components like motors or batteries. Understanding OEM relationships can help buyers identify quality suppliers and potential for customization.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier requires to process an order. This term is crucial for B2B buyers as it impacts inventory management and cash flow. Knowing the MOQ can help businesses plan their purchases and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. For electric cargo bikes, issuing an RFQ can help buyers compare options and negotiate better terms. It is an essential step in the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers engaged in international trade of electric cargo bikes to mitigate risks and ensure smooth transactions.

5. Lead Time

Lead time is the time taken from placing an order until it is delivered. For businesses relying on electric cargo bikes for operations, understanding lead times can help in planning and logistics, ensuring that they have the necessary vehicles when needed.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the electric cargobike Sector

What Are the Key Trends Driving the Electric Cargo Bike Market?

The electric cargo bike market is experiencing significant growth, driven by a combination of urbanization, environmental concerns, and advancements in technology. As cities become increasingly congested, businesses in regions like Africa, South America, the Middle East, and Europe are turning to electric cargo bikes as a sustainable alternative for last-mile delivery. This shift is fueled by the demand for cost-effective and efficient transportation solutions that minimize carbon footprints.

Emerging B2B tech trends are reshaping the sourcing landscape. Innovations in battery technology have resulted in lighter and more powerful batteries, enhancing the performance of electric cargo bikes. Additionally, the integration of IoT (Internet of Things) technology allows for real-time tracking of deliveries and improved fleet management, making these bikes an attractive option for logistics companies. In terms of market dynamics, there is a notable trend towards customization, with many manufacturers offering modular designs that can be tailored to specific business needs, such as transporting goods or accommodating passengers.

Moreover, the competitive pricing of electric cargo bikes has made them accessible to a broader market. Many models now fall within the $1,500 to $3,500 range, providing businesses with a financially viable alternative to traditional vehicles. International buyers should also consider regional partnerships that can facilitate local assembly or sourcing, reducing shipping costs and lead times.

How Is Sustainability Impacting Sourcing Decisions in the Electric Cargo Bike Sector?

Sustainability is becoming a cornerstone of sourcing decisions in the electric cargo bike sector. With growing awareness of climate change and environmental degradation, businesses are increasingly prioritizing eco-friendly solutions. Electric cargo bikes offer a zero-emission alternative to conventional vehicles, making them an appealing choice for companies aiming to enhance their sustainability profiles.

The importance of ethical supply chains cannot be overstated. B2B buyers are now scrutinizing their suppliers for sustainable practices, from sourcing raw materials to manufacturing processes. This focus on ethical sourcing often includes the use of recycled materials, sustainable manufacturing practices, and fair labor conditions. Buyers should look for manufacturers that possess certifications such as ISO 14001 (Environmental Management) or those that utilize green materials in their production processes.

Furthermore, as consumers become more environmentally conscious, businesses leveraging sustainable practices are likely to gain a competitive edge. This trend is particularly relevant for companies in regions like Europe, where eco-labeling and green certifications can significantly influence purchasing decisions.

What Is the Historical Context Behind Electric Cargo Bikes in the B2B Market?

The concept of electric cargo bikes has evolved significantly over the past few decades. Initially seen as niche products, electric bikes gained traction in the late 20th century as urban congestion and environmental concerns began to rise. The introduction of battery-powered pedal-assist technology made it feasible for a broader audience to use bicycles for transportation, including businesses that required efficient delivery solutions.

In the early 2000s, the market began to expand as manufacturers developed more advanced models that could handle heavier loads and longer distances. This evolution was spurred by improvements in battery technology and motor efficiency, which enhanced the overall performance of electric cargo bikes. Today, they are not only recognized as practical alternatives for personal use but are also increasingly being adopted by businesses for logistics and delivery, reflecting a broader shift towards sustainable urban mobility solutions.

As electric cargo bikes continue to gain popularity, B2B buyers are well-positioned to take advantage of this trend, ensuring they remain competitive in a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of electric cargobike

-

How do I determine the right electric cargo bike for my business needs?

To find the ideal electric cargo bike for your business, assess your specific requirements such as the type of cargo you plan to transport, the distances involved, and the terrain you’ll navigate. Consider factors like cargo capacity, battery life, motor power, and overall durability. Additionally, evaluate the bike’s customization options and available accessories to ensure it meets your operational needs. Engaging with suppliers who offer trial rides or demos can also provide valuable insights before making a purchase. -

What are the key features to look for in an electric cargo bike?

When selecting an electric cargo bike, focus on features that enhance usability and efficiency. Look for a robust motor with sufficient power to handle your typical loads and inclines. A high-capacity battery is essential for longer journeys, while a spacious cargo area allows for versatility in transporting goods. Ergonomic design, including adjustable seating and a low step-through frame, can improve accessibility. Additionally, consider safety features such as lights and reflective materials for visibility in urban environments. -

What is the average lead time for electric cargo bike orders from suppliers?

Lead times for electric cargo bike orders can vary significantly based on factors such as the supplier’s location, production capacity, and customization requirements. Typically, standard orders may take anywhere from 4 to 12 weeks for delivery. However, for customized models or bulk orders, it’s advisable to discuss specific timelines with your supplier during the negotiation process to ensure timely delivery that aligns with your operational needs. -

How can I vet suppliers of electric cargo bikes effectively?

To vet suppliers, start by researching their reputation through online reviews and industry references. Look for certifications that demonstrate compliance with international quality and safety standards. Request case studies or testimonials from other B2B clients, particularly those in your region. Engage in direct communication to assess their responsiveness and willingness to address your specific needs. Additionally, consider visiting their production facilities if possible to evaluate their manufacturing processes and capabilities firsthand. -

What are the typical minimum order quantities (MOQs) for electric cargo bikes?

Minimum order quantities for electric cargo bikes can vary by supplier and are often influenced by production capabilities and the specific model requested. Generally, MOQs may range from 5 to 50 units, depending on the supplier’s business model and the complexity of the bikes. It’s advisable to discuss MOQs during initial negotiations, as some suppliers may offer flexibility, especially for new business relationships or for bulk orders. -

What payment terms are commonly offered by electric cargo bike suppliers?

Payment terms can vary widely among suppliers, but common practices include a deposit of 30-50% upfront, with the balance due upon delivery or before shipping. Some suppliers may offer net payment terms (e.g., net 30 or net 60 days) for established clients. It’s important to clearly outline payment terms in your purchase agreement to avoid any misunderstandings and to ensure that both parties are aligned on expectations. -

How do I ensure quality assurance for my electric cargo bike order?

To ensure quality assurance, request detailed specifications and quality control processes from your supplier before placing an order. Many reputable manufacturers conduct rigorous testing on their bikes, including safety and performance assessments. Consider incorporating quality checkpoints into your order, such as pre-shipment inspections or third-party audits. Establishing a clear return policy and warranty terms can also provide added security in case of defects or non-compliance with agreed specifications. -

What are the logistics considerations for importing electric cargo bikes?

When importing electric cargo bikes, consider logistics factors such as shipping methods, customs regulations, and import duties applicable to your region. Work with a logistics provider experienced in handling cargo bikes to navigate these complexities efficiently. Ensure that all documentation, including invoices, packing lists, and compliance certifications, are accurately prepared to prevent delays at customs. Additionally, factor in lead times for shipping and potential delays in transit when planning your inventory needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Electric Cargobike Manufacturers & Suppliers List

1. Specialized – Globe Haul ST

Domain: bicycling.com

Registered: 1999 (26 years)

Introduction: Best Overall: Specialized Globe Haul ST – Price: €2,500, Tires: 20 x 3.5 in., Weight: 77 lbs., Cargo Capacity: 419 lbs. Pros: One of the smallest cargo bike footprints, Excellent battery life and power delivery, Strong brakes. Cons: Lack of suspension can mean a harsh ride on rough roads, Can only carry one kiddo. Best Value: Aventon Abound – Price: $1,999 (Now $1,599), Tires: 20 x 2.4 in., Weight…

2. Ferla Family Bikes – Royce II Electric Cargo Bike

Domain: ferlafamilybikes.com

Registered: 2019 (6 years)

Introduction: Electric Bicycles for Sale at Ferla Family Bikes include various models such as:

1. **Royce II Electric Cargo Bike** – Price: $5,799. Features: low step-through design, active frame, high-capacity battery, suitable for seniors and children.

2. **Ferla Inspire Cargo Bike** – Price: $3,499 (originally $4,499). Lightweight, spacious design, crafted for quality and affordability.

3. **Royce MAX Cargo…

3. Rad Power Bikes – RadWagon™ 5

Domain: radpowerbikes.com

Registered: 2015 (10 years)

Introduction: Electric Cargo & Utility Bikes: Designed for carrying kids, gear, or groceries. Features include long-tail cargo bike for up to two passengers and moped-style utility ebike with multiple gear-storage options. Key models include:

1. RadWagon™ 5:

– For riders 4’11”-6’3″

– Speed: 28 mph

– Range: 60+ miles

– Motor: 750W

– Payload: 375 lb

– Price: $2,399

2. RadRunner™ Max:

…

4. Aventon – Cargo Ebikes: Abound SR & LR

Domain: aventon.com

Registered: 2012 (13 years)

Introduction: Cargo Ebike:

– Models: Abound SR, Abound LR

– Abound SR:

– Features: Compact cargo bike, 4G/GPS theft deterrence

– Motor: 750w

– Capacity: Carry a single passenger

– Range: Up to 60 miles

– Price: $1,899

– Abound LR:

– Features: Multifaceted cargo ebike, 4G/GPS theft deterrence

– Motor: 750w

– Capacity: Carry up to 2 passengers

– Range: Up to 50 miles

– Price: $1,9…

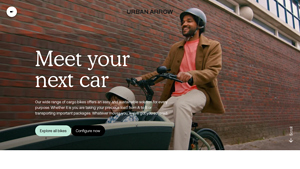

5. Urban Arrow – Electric Cargo Bikes

Domain: urbanarrow.com

Registered: 2010 (15 years)

Introduction: Urban Arrow offers a wide range of electric cargo bikes designed for various transport needs. Key features include:

– Collaboration with renowned partners like Bosch, Enviolo, and Schwalbe for high quality.

– Focus on rider experience with a smooth ride and lowered center of gravity for better road handling and balance.

– Models include FamilyNext, Shorty, Cargo, Tender, and Connected.

– Empha…

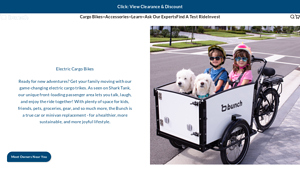

6. Bunch Bikes – Electric Cargo Bikes

Domain: bunchbike.com

Registered: 2018 (7 years)

Introduction: Electric Cargo Bikes from Bunch Bikes include:

1. The Original 4+ Upgraded Electric Cargo Bike for Families – Sale Price: $6,499, Regular Price: $4,965, Seats 4 kids, designed for hauling pets, gear, groceries, and more. Features three wheels and electric assist for easy riding.

2. The K9 4+ Upgraded Electric Cargo Bike for Dogs – Sale Price: $6,699, Regular Price: $77, designed for dogs, features…

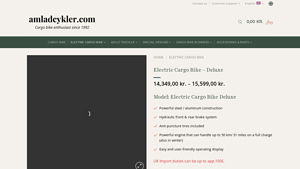

7. Amlad Cykler – Electric Cargo Bike Deluxe

Domain: amladcykler.com

Registered: 2016 (9 years)

Introduction: Product Name: Electric Cargo Bike – Deluxe

Price Range: 14,349,00 kr. – 15,599,00 kr.

Model: Electric Cargo Bike Deluxe

Construction: Steel / Aluminum

Braking System: Hydraulic front & rear brake system

Tires: Anti-puncture tires included

Range: Up to 50 km / 31 miles on a full charge (also in winter)

Display: Easy and user-friendly operating display

Battery Options: Standard, 12 ah Li-on (up to 6…

Strategic Sourcing Conclusion and Outlook for electric cargobike

What Are the Key Benefits of Strategic Sourcing for Electric Cargo Bikes?

In conclusion, the strategic sourcing of electric cargo bikes presents a transformative opportunity for businesses across diverse markets, particularly in Africa, South America, the Middle East, and Europe. By prioritizing sustainability, operational efficiency, and cost-effectiveness, companies can significantly enhance their logistics and transportation capabilities. Electric cargo bikes not only reduce carbon emissions but also lower transportation costs compared to traditional vehicles, making them an attractive alternative for urban mobility.

Investing in quality electric cargo bikes, such as those from reputable manufacturers, ensures durability and performance, essential for meeting the demands of everyday use. Additionally, the growing customization options allow businesses to tailor solutions that best fit their specific needs, whether for family transportation or commercial logistics.

How Can International Buyers Capitalize on the Electric Cargo Bike Market?

As the market evolves, international B2B buyers should actively engage with suppliers to explore innovative features and financing options. Collaboration with manufacturers can lead to mutually beneficial partnerships that drive growth and sustainability. Embrace this opportunity to stay ahead of the curve in the electric mobility revolution. The future of transportation is electric—are you ready to make the switch?