Introduction: Navigating the Global Market for titanium alloy 4 wheels electric car

The quest for sourcing high-performance titanium alloy wheels for electric cars presents a unique set of challenges for international B2B buyers. As the automotive industry increasingly shifts towards sustainable and efficient solutions, the demand for lightweight, durable materials like titanium has surged. However, navigating the global market for titanium alloy four-wheeled electric vehicles requires a keen understanding of various factors, including supplier reliability, material specifications, and cost implications.

This comprehensive guide aims to empower B2B buyers from Africa, South America, the Middle East, and Europe—particularly in regions like Saudi Arabia and Brazil—by providing valuable insights into the types and applications of titanium alloy wheels. We will delve into crucial aspects such as supplier vetting processes, the impact of design choices on performance and aerodynamics, and cost-effective sourcing strategies.

By equipping decision-makers with actionable information, this guide fosters informed purchasing decisions that align with their operational goals and sustainability initiatives. From optimizing vehicle efficiency to enhancing overall performance, understanding the intricacies of the titanium alloy wheel market can significantly influence a company’s competitive edge in the evolving electric vehicle landscape.

Understanding titanium alloy 4 wheels electric car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 3D-Printed Titanium Wheels | Customizable designs, lightweight, rapid prototyping capabilities | High-performance electric vehicles | Pros: Tailored designs, reduced weight; Cons: Higher initial costs, potential lead time issues. |

| Forged Titanium Alloy Wheels | Enhanced strength, durability, and impact resistance | Motorsports, luxury electric cars | Pros: High durability, improved performance; Cons: Expensive, limited design options. |

| Titanium Alloy Flow-Formed Wheels | Lightweight yet strong, enhanced aerodynamics | Everyday electric vehicles | Pros: Cost-effective, good balance of weight and strength; Cons: May lack the customizability of 3D-printed options. |

| Titanium Composite Wheels | Combination of titanium and other materials for optimal performance | Commercial electric fleets | Pros: Weight reduction, increased performance; Cons: More complex manufacturing process, potential higher costs. |

| Aerodynamic Titanium Wheels | Designed to minimize drag, often featuring covered spokes | High-efficiency electric cars | Pros: Improved efficiency, reduced energy consumption; Cons: Aesthetic limitations, potential compatibility issues. |

What Are the Characteristics of 3D-Printed Titanium Wheels?

3D-printed titanium wheels offer a unique advantage in customization and weight reduction. Utilizing advanced manufacturing techniques, these wheels can be tailored to specific design requirements, which is particularly beneficial for companies focused on performance and innovation. B2B buyers should consider the higher initial costs and potential lead times associated with these wheels, but the trade-off can be significant in terms of performance gains.

Why Choose Forged Titanium Alloy Wheels for Electric Cars?

Forged titanium alloy wheels are known for their superior strength and impact resistance, making them ideal for high-performance applications, such as motorsports and luxury electric vehicles. These wheels undergo a rigorous manufacturing process that enhances their durability, which is crucial for companies aiming to deliver high-quality products. However, buyers should be prepared for a higher price point and may find limited design options compared to other types.

How Do Flow-Formed Titanium Alloy Wheels Benefit Everyday Electric Vehicles?

Flow-formed titanium alloy wheels strike a balance between weight and strength, making them a popular choice for everyday electric vehicles. These wheels are more cost-effective than fully forged options while still providing significant performance benefits. B2B buyers looking for a reliable, durable solution will find these wheels appealing, although they may not offer the same level of customization as 3D-printed alternatives.

What Are the Advantages of Using Titanium Composite Wheels?

Titanium composite wheels combine titanium with other materials to achieve optimal performance and weight reduction. This type of wheel is particularly suited for commercial electric fleets, where durability and cost-effectiveness are paramount. However, the manufacturing process can be more complex, potentially leading to higher costs. Buyers should evaluate their specific needs to determine if the benefits justify the investment.

Why Are Aerodynamic Titanium Wheels Important for High-Efficiency Electric Cars?

Aerodynamic titanium wheels are designed specifically to minimize drag, which can significantly enhance the efficiency of electric vehicles. Often featuring covered spokes, these wheels help reduce energy consumption, making them an attractive option for manufacturers of high-efficiency electric cars. While they may come with aesthetic limitations and compatibility considerations, the performance benefits can outweigh these drawbacks for B2B buyers focused on efficiency.

Key Industrial Applications of titanium alloy 4 wheels electric car

| Industry/Sector | Specific Application of titanium alloy 4 wheels electric car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Lightweight wheel designs for electric vehicles | Enhanced performance and energy efficiency | Quality certification, supplier reliability, and lead times |

| Motorsports | High-performance components for racing electric cars | Competitive edge and improved lap times | Precision engineering capabilities and rapid prototyping |

| Renewable Energy Transportation | Electric buses and commercial vehicles using titanium wheels | Increased range and reduced operational costs | Compliance with local regulations and material sourcing |

| Aerospace | Electric aircraft prototypes with titanium wheel systems | Weight reduction for improved fuel efficiency | Aerospace-grade materials and certifications |

| Luxury Vehicle Production | Premium electric cars featuring titanium wheels | Brand differentiation and enhanced aesthetics | Supplier reputation and customization options |

How is Titanium Alloy Used in Automotive Manufacturing for Electric Vehicles?

In the automotive manufacturing sector, titanium alloy wheels are increasingly favored for electric vehicles due to their lightweight properties. This reduction in weight directly translates to improved energy efficiency and enhanced vehicle performance. For international B2B buyers, particularly in regions like Africa and South America, sourcing reliable suppliers with quality certifications is critical. The demand for high-quality materials that can withstand diverse environmental conditions is paramount, as these regions may face varying climates and terrains.

What Role Does Titanium Alloy Play in Motorsports Applications?

In motorsports, titanium alloy components are integral to the construction of high-performance electric race cars. These alloys offer superior strength-to-weight ratios, allowing for the design of lightweight wheels that can endure the extreme forces experienced during racing. For buyers in the Middle East and Europe, where motorsports are a significant cultural and economic activity, the ability to access precision-engineered parts and rapid prototyping services is essential. This ensures that teams can stay competitive and innovate continuously.

How Can Titanium Alloy Benefit Renewable Energy Transportation?

The renewable energy transportation sector, particularly electric buses and commercial vehicles, benefits from titanium alloy wheels by significantly increasing their range and reducing operational costs. The lightweight nature of titanium contributes to lower energy consumption, making these vehicles more environmentally friendly. For B2B buyers in regions focused on sustainable transportation, such as Europe, it is crucial to consider compliance with local regulations regarding vehicle emissions and sustainability. Sourcing materials that meet these standards can enhance brand reputation and marketability.

Why is Titanium Alloy Important for Aerospace Applications?

In aerospace, the use of titanium alloy wheels in electric aircraft prototypes is gaining traction due to the material’s lightweight and durable characteristics. This contributes to improved fuel efficiency and performance in flight. Buyers in the aerospace sector, especially in regions with growing aviation industries, must prioritize sourcing aerospace-grade titanium that meets stringent industry standards and certifications. Ensuring that suppliers can provide materials that withstand high-performance requirements is essential for successful aircraft development.

How Does Titanium Alloy Enhance Luxury Vehicle Production?

Luxury vehicle production increasingly incorporates titanium alloy wheels to enhance both performance and aesthetics. The use of these premium materials allows manufacturers to differentiate their electric models in a competitive market. For international B2B buyers from regions like Saudi Arabia and Brazil, understanding the customization options available for titanium wheels can provide a significant advantage. Suppliers that offer bespoke designs and have a strong reputation for quality can help luxury brands elevate their offerings and appeal to discerning consumers.

3 Common User Pain Points for ‘titanium alloy 4 wheels electric car’ & Their Solutions

Scenario 1: Challenges in Sourcing Lightweight Yet Durable Wheels

The Problem: B2B buyers, especially those in regions like Africa and South America, often struggle with sourcing titanium alloy wheels that provide a balance between lightweight construction and durability. The challenge is compounded by the lack of reliable suppliers who can ensure consistent quality and timely delivery. Many buyers have faced situations where the wheels they received did not meet the specifications or had quality issues that led to operational delays, impacting their ability to deliver on their own commitments.

The Solution: To overcome sourcing difficulties, B2B buyers should establish partnerships with reputable manufacturers known for their expertise in titanium alloy products. Conducting thorough due diligence is essential; this includes reviewing supplier certifications, past project case studies, and feedback from other clients. It is also beneficial to engage in direct communication with suppliers to discuss specific requirements, such as weight limits and performance standards. Additionally, utilizing technology like 3D printing for custom wheel designs can ensure that buyers receive products tailored to their specific needs, thus enhancing performance while minimizing weight.

Scenario 2: Navigating Regulatory Compliance and Safety Standards

The Problem: Compliance with regional automotive regulations can be a significant hurdle for B2B buyers of titanium alloy wheels for electric cars. Different countries have varying standards regarding material specifications, safety, and performance, leading to confusion and potential legal repercussions if standards are not met. Buyers from the Middle East and Europe, for instance, may encounter strict requirements that their suppliers must fulfill to ensure that their products are roadworthy and safe.

The Solution: To navigate these regulatory landscapes effectively, B2B buyers should stay informed about local regulations and standards pertinent to automotive components. Collaborating with suppliers who have a proven track record of compliance can alleviate concerns. Requesting documentation such as ISO certifications, test results, and compliance reports can provide assurance that the wheels meet necessary safety standards. Furthermore, engaging with local regulatory bodies for guidance and incorporating their feedback during the sourcing process can help ensure that all products are compliant from the outset.

Scenario 3: Balancing Cost and Performance in Wheel Selection

The Problem: One of the most significant pain points for B2B buyers is balancing cost with performance when selecting titanium alloy wheels for electric vehicles. High-performance wheels often come with a premium price tag, leading buyers to question whether the investment will yield adequate returns in terms of vehicle efficiency and longevity. This dilemma can lead to indecision or opting for cheaper alternatives that may compromise vehicle performance.

The Solution: To make informed purchasing decisions, B2B buyers should conduct a comprehensive cost-benefit analysis that considers both short-term expenditures and long-term value. This analysis should include factors such as weight reduction benefits, fuel efficiency improvements, and durability. Engaging in trials or pilot programs with different wheel types can provide firsthand insight into performance outcomes. Moreover, leveraging partnerships with manufacturers who offer warranties and performance guarantees can provide an additional layer of assurance that the investment will pay off over time. Buyers should also consider the total lifecycle costs, including maintenance and replacement, to ensure they are making the most financially sound decision.

By addressing these common pain points with targeted strategies, B2B buyers can enhance their procurement processes, ensuring they obtain high-quality titanium alloy wheels that meet their operational needs while remaining compliant and cost-effective.

Strategic Material Selection Guide for titanium alloy 4 wheels electric car

What Are the Key Materials for Titanium Alloy Wheels in Electric Cars?

When selecting materials for titanium alloy wheels in electric vehicles, several options stand out due to their unique properties and performance characteristics. This analysis focuses on four common materials: titanium alloys, aluminum alloys, carbon fiber composites, and magnesium alloys. Each material has its own set of advantages and disadvantages that can significantly impact the performance, durability, and cost-effectiveness of electric vehicle wheels.

How Do Titanium Alloys Perform in Electric Vehicle Applications?

Key Properties: Titanium alloys are known for their high strength-to-weight ratio, excellent corrosion resistance, and ability to withstand high temperatures. They maintain structural integrity under stress, making them ideal for high-performance applications.

Pros & Cons: The primary advantage of titanium alloys is their durability and lightweight nature, which enhances vehicle efficiency. However, they are relatively expensive compared to other materials, and their manufacturing processes can be complex, requiring specialized techniques such as 3D printing for optimal results.

Impact on Application: Titanium alloys are particularly suitable for high-performance electric vehicles that require lightweight components without sacrificing strength. They are compatible with various media, including corrosive environments, making them versatile for different geographic markets.

Considerations for International Buyers: Compliance with international standards like ASTM and JIS is crucial, especially for buyers in regions such as Africa and the Middle East, where harsh environmental conditions may be prevalent. Buyers should also consider the availability of titanium alloys in local markets to avoid long lead times.

What Are the Benefits of Aluminum Alloys in Electric Vehicle Wheels?

Key Properties: Aluminum alloys are lightweight, have good corrosion resistance, and offer excellent thermal conductivity. They can be easily shaped and welded, making them a popular choice for wheel manufacturing.

Pros & Cons: The main advantage of aluminum alloys is their cost-effectiveness and ease of manufacturing. However, they may not provide the same level of strength and durability as titanium alloys, potentially leading to a shorter lifespan under extreme conditions.

Impact on Application: Aluminum alloys are suitable for standard electric vehicles where performance demands are moderate. They can withstand various environmental conditions but may require additional treatments for enhanced corrosion resistance.

Considerations for International Buyers: Buyers should ensure that aluminum alloys meet local standards and regulations, particularly in regions like South America, where specific alloy compositions may be preferred.

How Do Carbon Fiber Composites Compare for Electric Vehicle Wheels?

Key Properties: Carbon fiber composites are renowned for their exceptional strength-to-weight ratio and rigidity. They offer excellent fatigue resistance and can be molded into complex shapes.

Pros & Cons: The primary advantage of carbon fiber is its lightweight nature, which significantly improves vehicle efficiency. However, the high cost and complex manufacturing processes can be a barrier for many manufacturers. Additionally, carbon fiber may not be as impact-resistant as metals.

Impact on Application: Carbon fiber composites are ideal for high-performance electric vehicles where weight reduction is critical. They can withstand high stress but may require careful handling to avoid damage.

Considerations for International Buyers: Compliance with standards such as ASTM is essential, particularly for buyers in Europe and the Middle East, where regulations may be stricter. Availability of carbon fiber materials and skilled labor for manufacturing should also be assessed.

What Role Do Magnesium Alloys Play in Electric Vehicle Wheel Manufacturing?

Key Properties: Magnesium alloys are among the lightest structural metals, offering good strength and excellent corrosion resistance. They are also easy to machine and weld.

Pros & Cons: The main advantage of magnesium alloys is their lightweight nature, which can enhance vehicle efficiency. However, they are more prone to corrosion and can be less durable than titanium and aluminum alloys.

Impact on Application: Magnesium alloys are suitable for electric vehicles aiming for weight reduction but may not be ideal for high-performance applications due to potential durability issues.

Considerations for International Buyers: Buyers should be aware of the specific corrosion resistance requirements in their regions, especially in coastal areas or places with high humidity. Compliance with international standards is also necessary for market acceptance.

Summary Table of Material Selection for Titanium Alloy Wheels

| Material | Typical Use Case for titanium alloy 4 wheels electric car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium Alloys | High-performance electric vehicles | High strength-to-weight ratio | High cost and complex manufacturing | High |

| Aluminum Alloys | Standard electric vehicles | Cost-effective and easy to manufacture | Lower strength and durability | Medium |

| Carbon Fiber Composites | High-performance electric vehicles | Exceptional strength-to-weight ratio | High cost and complex handling | High |

| Magnesium Alloys | Lightweight electric vehicles | Lightweight and good machinability | Prone to corrosion and lower durability | Medium |

This guide provides a comprehensive overview of the materials suitable for titanium alloy wheels in electric vehicles, aiding international B2B buyers in making informed decisions based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for titanium alloy 4 wheels electric car

What Are the Main Stages of Manufacturing Titanium Alloy Wheels for Electric Cars?

The manufacturing process for titanium alloy wheels, particularly for electric vehicles (EVs), involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets the stringent performance and safety standards required in the automotive industry.

How Is Material Prepared for Titanium Alloy Wheels?

The first stage involves sourcing high-quality titanium alloys, which are often selected for their strength-to-weight ratio and corrosion resistance. The raw material is typically in the form of titanium ingots or powder, depending on the manufacturing technique. Advanced techniques like 3D printing are increasingly being used to create components with complex geometries, allowing for weight optimization without sacrificing strength. Once the material is acquired, it undergoes a series of processes including melting, casting, or powder metallurgy to achieve the desired shape and properties.

What Forming Techniques Are Utilized in Titanium Wheel Manufacturing?

After material preparation, the next step is forming. Common forming techniques include:

-

Forging: This process involves shaping the titanium alloy through localized compressive forces. It enhances the material’s mechanical properties and results in a denser, stronger product.

-

Casting: In this method, the molten titanium alloy is poured into molds to create the wheel’s shape. Although casting can be less expensive, it may not provide the same mechanical benefits as forging.

-

3D Printing: This innovative technique allows for the creation of intricate designs that can significantly reduce weight. The use of titanium powder in additive manufacturing has gained traction, particularly for components like wheel spokes and hubs.

Each of these techniques can be tailored to meet specific design requirements, ensuring that the wheels are not only lightweight but also capable of withstanding the rigors of high-performance driving.

What Are the Key Assembly and Finishing Processes for Titanium Alloy Wheels?

Once the components are formed, the assembly process begins. This typically involves fitting various parts together, such as the rim, spokes, and hub. Precision is key; any misalignment can lead to performance issues.

The finishing stage includes surface treatments that enhance durability and aesthetics. Common finishing techniques include:

- Anodizing: This process increases corrosion resistance and allows for color customization.

- Polishing: Aesthetic appeal is often enhanced through polishing, which provides a smooth finish and can improve aerodynamics.

- Coating: Protective coatings can be applied to resist environmental damage and improve the lifespan of the wheels.

How Are Quality Assurance Processes Implemented in Titanium Alloy Wheel Manufacturing?

Quality assurance (QA) is vital in the manufacturing of titanium alloy wheels to ensure compliance with international standards and customer expectations. Key components of QA include adherence to ISO 9001 standards, which outline a framework for effective quality management systems.

What Are the Key Quality Control Checkpoints During Manufacturing?

Quality control (QC) checkpoints are integrated throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected for quality and compliance with specifications before they are used in production.

-

In-Process Quality Control (IPQC): Continuous monitoring occurs during the forming and assembly stages to catch any defects early in the process.

-

Final Quality Control (FQC): Finished products undergo rigorous testing for dimensional accuracy, strength, and surface integrity. Common testing methods include:

- Non-destructive testing (NDT): Techniques such as ultrasonic testing or X-ray inspection assess structural integrity without damaging the wheels.

- Mechanical testing: This includes tensile strength tests and fatigue tests to ensure that the wheels can withstand operational stresses.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source titanium alloy wheels should consider several strategies to verify supplier QC:

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and adherence to quality standards.

-

Documentation Review: Request detailed QC reports and certifications from the supplier, including compliance with international standards like ISO and industry-specific certifications such as CE and API.

-

Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of the supplier’s quality control processes.

What QC and Certification Nuances Should International B2B Buyers Be Aware Of?

When engaging with suppliers from different regions, B2B buyers must navigate various QC and certification nuances. For instance, in regions like Africa and South America, local standards may differ significantly from those in Europe or the Middle East. It is crucial for buyers to understand these differences and ensure that their suppliers are compliant with both local and international standards.

Additionally, buyers should be aware of the lead times and logistics involved in sourcing materials from different regions. Establishing clear communication with suppliers about quality expectations and delivery timelines can mitigate potential issues and enhance the overall procurement process.

Conclusion

In summary, the manufacturing processes and quality assurance measures for titanium alloy wheels in electric vehicles are intricate and highly specialized. By understanding the key stages of manufacturing, the importance of quality control, and how to verify supplier compliance, B2B buyers can make informed decisions that align with their performance and safety requirements. Engaging with reputable suppliers who prioritize quality and adhere to international standards will ultimately enhance the reliability and success of their electric vehicle offerings.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium alloy 4 wheels electric car’

In the rapidly evolving electric vehicle (EV) market, sourcing titanium alloy wheels is pivotal for optimizing performance, weight, and sustainability. This guide will provide a structured checklist for international B2B buyers aiming to procure high-quality titanium alloy wheels for electric cars.

Step 1: Define Your Technical Specifications

Establishing precise technical specifications is critical for ensuring that the wheels meet your vehicle’s performance and safety standards. Consider factors such as weight, strength, diameter, and compatibility with your electric vehicle’s braking and suspension systems.

– Weight Optimization: Aim for lightweight options that enhance efficiency.

– Durability Requirements: Specify resistance to corrosion and fatigue, especially in harsh environments.

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends in titanium alloy wheel manufacturing, including advancements in 3D printing technologies and aerodynamics. Innovations such as honeycomb structures can significantly reduce weight without sacrificing strength, as demonstrated in racing applications.

– Aerodynamic Design: Look for wheels that minimize drag and enhance overall vehicle efficiency.

– Sustainability Practices: Consider suppliers that utilize eco-friendly production methods.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Assess their experience with titanium alloys and electric vehicle components to ensure they can meet your needs.

– Supplier Certifications: Verify certifications such as ISO 9001 to ensure quality management practices.

– Production Capabilities: Inquire about their manufacturing processes and technologies used for titanium wheel production.

Step 4: Request Samples and Conduct Testing

Always request samples of the wheels before making a bulk purchase. Testing the samples under real-world conditions will provide insights into their performance and durability.

– Performance Testing: Assess weight, strength, and aerodynamics through controlled testing.

– Compatibility Checks: Ensure that the wheels fit your vehicle specifications without modification.

Step 5: Negotiate Pricing and Terms

Once you have identified suitable suppliers, engage in negotiations to secure favorable pricing and terms. Understand the total cost of ownership, including shipping, tariffs, and potential after-sales support.

– Bulk Purchase Discounts: Discuss pricing structures for larger orders to maximize savings.

– Payment Terms: Agree on flexible payment options that align with your procurement budget.

Step 6: Establish Quality Control Measures

Implement quality control procedures to monitor the production and delivery of the wheels. This step is essential to maintain high standards and ensure that the wheels meet your specifications.

– Inspection Protocols: Develop a checklist for inspecting the quality upon delivery.

– Feedback Loop: Set up a communication channel with the supplier for ongoing feedback and improvements.

Step 7: Plan for Logistics and Distribution

Finally, develop a logistics strategy to manage the transportation of the wheels from the supplier to your facility. Consider factors such as shipping time, costs, and customs regulations, especially for international shipments.

– Customs Clearance: Ensure all necessary documentation is in place to facilitate smooth customs processing.

– Local Distribution: Plan for efficient distribution within your target markets to minimize delays.

By following this structured approach, B2B buyers can effectively navigate the sourcing process for titanium alloy wheels, ensuring they select the best products for their electric vehicles while optimizing for performance and cost.

Comprehensive Cost and Pricing Analysis for titanium alloy 4 wheels electric car Sourcing

What Are the Key Cost Components of Sourcing Titanium Alloy Wheels for Electric Cars?

When sourcing titanium alloy wheels for electric vehicles, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: Titanium alloy is significantly more expensive than traditional materials due to its superior strength-to-weight ratio and corrosion resistance. The price of titanium can fluctuate based on global market trends, affecting overall costs.

-

Labor: Skilled labor is required for the manufacturing and assembly of titanium wheels, particularly when precision and quality are paramount. Labor costs can vary widely depending on the region, with higher costs typically seen in developed markets.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and facility operations. Given the advanced technologies often used in titanium wheel production, overhead costs can be substantial.

-

Tooling: The initial investment in tooling for titanium wheels can be high due to the specialized equipment needed for precise machining and finishing processes. This cost is usually amortized over the production run.

-

Quality Control (QC): Ensuring that each wheel meets the required specifications necessitates rigorous quality control processes. This can include both in-line inspections during manufacturing and end-of-line testing.

-

Logistics: Transportation costs for shipping titanium wheels can vary based on distance, weight, and shipping methods. International shipments may incur additional fees, including customs duties and tariffs.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit. This margin can vary based on market conditions and supplier positioning.

How Do Price Influencers Affect the Cost of Titanium Alloy Wheels?

Several factors can influence pricing in the B2B market for titanium alloy wheels:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders may qualify for volume discounts, reducing the per-unit cost.

-

Specifications and Customization: Custom designs or specific performance requirements can increase costs. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Quality and Certifications: Wheels that meet specific industry standards or certifications may come at a premium. Buyers should assess whether these certifications are necessary for their applications.

-

Supplier Factors: Supplier reputation and reliability can impact pricing. Established suppliers may charge higher prices due to their experience and quality assurance practices.

-

Incoterms: The terms of sale can affect overall costs. Understanding responsibilities related to shipping, insurance, and customs clearance is crucial for calculating total expenses.

What Are the Best Buyer Tips for Sourcing Titanium Alloy Wheels Internationally?

For international buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, here are several tips to consider:

-

Negotiate Pricing: Always seek to negotiate pricing and terms. Suppliers may have flexibility, especially for larger orders or long-term contracts.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership (TCO) rather than just the purchase price. Consider factors such as durability, maintenance, and potential resale value when assessing cost efficiency.

-

Understand Pricing Nuances: Be aware of local market conditions, currency fluctuations, and economic factors that may affect pricing. This knowledge can empower buyers during negotiations.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, exclusive offers, and improved service levels.

-

Assess Logistics and Delivery: Consider the full logistics of sourcing, including shipping timelines, customs regulations, and potential delays. A well-planned logistics strategy can mitigate unexpected costs.

Disclaimer on Indicative Prices

Prices for titanium alloy wheels can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and request quotes from multiple suppliers to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing titanium alloy 4 wheels electric car With Other Solutions

Exploring Alternatives to Titanium Alloy 4 Wheels Electric Cars

In the evolving landscape of electric vehicles, the choice of materials and technologies significantly impacts performance, cost, and sustainability. This analysis compares the titanium alloy 4 wheels electric car against two alternative solutions: aluminum alloy wheels and carbon fiber wheels. Understanding these options can assist B2B buyers in making informed decisions tailored to their operational needs.

| Comparison Aspect | Titanium Alloy 4 Wheels Electric Car | Aluminum Alloy Wheels | Carbon Fiber Wheels |

|---|---|---|---|

| Performance | High strength-to-weight ratio; enhances overall vehicle efficiency. | Good strength; heavier than titanium, may affect range. | Excellent rigidity; very lightweight, enhances speed and efficiency. |

| Cost | Generally high initial investment; offers long-term durability. | Lower upfront cost; less durable than titanium. | High initial cost; potential for savings in fuel efficiency. |

| Ease of Implementation | Requires specialized manufacturing processes; may have longer lead times. | Widely available; easy to source and install. | Requires advanced manufacturing techniques; limited suppliers. |

| Maintenance | Low maintenance due to corrosion resistance; high durability. | Moderate maintenance; can corrode over time. | Minimal maintenance; susceptible to impact damage. |

| Best Use Case | Ideal for high-performance electric vehicles aiming for maximum efficiency. | Suitable for standard electric vehicles focused on cost-effectiveness. | Best for racing or high-performance applications where weight savings are critical. |

What Are the Advantages and Disadvantages of Aluminum Alloy Wheels?

Aluminum alloy wheels are a popular choice due to their affordability and availability. They provide a reasonable balance between weight and strength, making them suitable for many standard electric vehicles. However, they tend to be heavier than titanium options, which can negatively impact the vehicle’s overall efficiency and range. Additionally, aluminum wheels may corrode over time, requiring more frequent maintenance and replacements. They are best suited for businesses looking for a cost-effective solution without the need for extreme performance.

How Do Carbon Fiber Wheels Compare to Titanium Alloy Wheels?

Carbon fiber wheels present a high-end alternative, offering an impressive strength-to-weight ratio that significantly enhances vehicle performance. Their lightweight nature allows for better acceleration and improved efficiency, making them ideal for competitive racing and high-performance electric vehicles. However, the initial investment for carbon fiber wheels is typically higher than both titanium and aluminum options. Moreover, they can be more susceptible to damage from impacts, potentially leading to higher replacement costs. Companies that prioritize performance and speed over cost may find carbon fiber wheels to be an advantageous investment.

Conclusion: Which Solution is Right for Your Business?

Choosing the right wheel solution for electric vehicles depends on various factors, including performance requirements, budget constraints, and maintenance capabilities. For businesses focused on maximizing performance and efficiency, the titanium alloy 4 wheels electric car presents a compelling choice despite its higher initial cost. Conversely, aluminum alloy wheels offer a more budget-friendly option with adequate performance for everyday use, while carbon fiber wheels cater to those in need of high-performance solutions, albeit at a premium price. Evaluating these alternatives against specific operational needs will enable B2B buyers to make informed decisions that align with their strategic objectives.

Essential Technical Properties and Trade Terminology for titanium alloy 4 wheels electric car

When considering titanium alloy wheels for electric vehicles, understanding their essential technical properties and the associated industry terminology is crucial for making informed purchasing decisions. This knowledge can enhance operational efficiency and optimize vehicle performance.

What are the Key Technical Properties of Titanium Alloy Wheels?

-

Material Grade

Titanium alloys are typically classified by their grade, such as Grade 5 (Ti-6Al-4V), which is widely used in the automotive industry. This grade is known for its high strength-to-weight ratio and excellent corrosion resistance, making it ideal for lightweight applications in electric vehicles. B2B buyers should prioritize material grade to ensure durability and performance in harsh conditions. -

Weight

The weight of the wheels significantly impacts vehicle efficiency and performance. Titanium alloy wheels are notably lighter than traditional steel or aluminum wheels, which can lead to improved battery range and handling. For buyers, selecting lightweight options can result in lower energy consumption and enhanced overall vehicle dynamics. -

Tolerance

Tolerance refers to the permissible limits of variation in a physical dimension. High tolerance standards are essential for ensuring that titanium alloy wheels fit precisely on the vehicle hub. This precision is crucial for safety, performance, and minimizing wear and tear. Buyers should request detailed specifications regarding tolerances to ensure compatibility with their electric vehicle models. -

Fatigue Strength

Fatigue strength is the ability of a material to withstand cyclic loading without failure. Titanium alloys possess superior fatigue strength compared to other materials, making them ideal for high-performance applications like racing or electric vehicles that undergo constant acceleration and braking. Understanding fatigue properties is vital for buyers aiming to enhance vehicle longevity and reliability. -

Corrosion Resistance

Titanium alloys are renowned for their exceptional resistance to corrosion, particularly in harsh environments. This property is especially important for electric vehicles operating in diverse climates. Buyers should consider the corrosion resistance of wheels to minimize maintenance costs and extend the lifespan of their products. -

Manufacturing Process

The manufacturing process, such as 3D printing or forging, affects the mechanical properties of titanium wheels. Advanced techniques like 3D printing can create complex designs that optimize weight without sacrificing strength. B2B buyers should inquire about manufacturing methods to understand their impact on performance and cost.

Which Trade Terms Should B2B Buyers Know?

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. When sourcing titanium alloy wheels, understanding OEM relationships can be crucial for ensuring compatibility and performance, particularly for electric vehicles. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Buyers should be aware of MOQs to gauge the feasibility of purchasing titanium alloy wheels, especially when considering inventory levels and budget constraints. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically outlines specifications, quantities, and terms of purchase. B2B buyers should prepare a detailed RFQ to ensure they receive accurate pricing and conditions tailored to their needs. -

Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risk, and insurance responsibilities when importing titanium alloy wheels. -

Lead Time

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is essential for B2B buyers to plan production schedules and inventory management effectively. Buyers should always inquire about lead times to avoid disruptions in their supply chain. -

Certification Standards

Certification standards, such as ISO or ASTM, ensure that products meet specific quality and safety requirements. For titanium alloy wheels, compliance with these standards is crucial to guarantee performance and reliability. Buyers should prioritize suppliers that adhere to recognized certification standards to mitigate risks.

By understanding these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing titanium alloy wheels for electric vehicles, ultimately enhancing performance and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the titanium alloy 4 wheels electric car Sector

What Are the Current Market Dynamics and Key Trends in the Titanium Alloy 4 Wheels Electric Car Sector?

The titanium alloy sector for electric vehicles (EVs) is witnessing transformative growth driven by several global factors. The increasing demand for lightweight materials to enhance vehicle performance and energy efficiency is paramount. Titanium alloys are favored for their high strength-to-weight ratio, making them ideal for components like wheels that require durability without adding excess weight. This trend is particularly relevant as manufacturers target improved range and efficiency, which are critical selling points for EVs.

Emerging technologies such as 3D printing are reshaping sourcing strategies. Companies are leveraging additive manufacturing to produce complex titanium parts with reduced lead times and material waste. For instance, firms like Materialise have successfully created lightweight components for racing applications, demonstrating the potential for rapid prototyping and customization in the automotive sector. International B2B buyers should also monitor advancements in aerodynamics, as studies show that up to 25% of aerodynamic drag can be attributed to wheel design. Innovations in wheel covers and designs that conceal spokes are becoming increasingly popular.

In regions like Africa, South America, the Middle East, and Europe, the market dynamics are influenced by regional regulatory frameworks that favor sustainable practices. As governments push for greener technologies, international buyers must align their sourcing strategies with local compliance standards to capitalize on market opportunities.

How Is Sustainability Influencing Sourcing in the Titanium Alloy Electric Car Sector?

Sustainability is a pivotal consideration in the titanium alloy market for electric vehicles. The environmental impact of titanium extraction and processing is significant, prompting a shift towards more sustainable practices in sourcing. B2B buyers are increasingly prioritizing suppliers that demonstrate commitment to ethical sourcing and environmental stewardship. This includes sourcing titanium from certified, responsible mines that adhere to stringent environmental regulations.

Moreover, the adoption of ‘green’ certifications is becoming critical in supplier selection. Certifications such as ISO 14001 for environmental management and the Responsible Titanium Initiative are indicators of a supplier’s commitment to sustainable practices. Buyers should seek partnerships with manufacturers that utilize recycled titanium and innovative production techniques that minimize carbon footprints.

The importance of ethical supply chains cannot be overstated; buyers must ensure that their sourcing strategies align with global sustainability goals. As the market evolves, companies that prioritize sustainability will likely gain a competitive edge, appealing to environmentally-conscious consumers and investors alike.

How Has the Titanium Alloy Market Evolved Over Time?

The evolution of the titanium alloy market in the automotive sector reflects broader trends in material science and engineering. Initially, titanium was primarily used in aerospace applications due to its high strength and lightweight properties. However, as electric vehicles gained traction, the automotive industry recognized the potential of titanium alloys for improving performance and efficiency.

Over the last decade, advancements in manufacturing processes, particularly 3D printing, have revolutionized how titanium components are produced. This has enabled automotive engineers to create intricate designs that enhance performance while reducing weight. The increasing focus on sustainability and ethical sourcing has also transformed the supply chain dynamics, compelling manufacturers to adopt more responsible practices.

As the electric vehicle market continues to grow, the role of titanium alloys is expected to expand, with innovations paving the way for even more efficient and sustainable automotive solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of titanium alloy 4 wheels electric car

-

How do I solve issues with sourcing titanium alloy wheels for electric cars?

When sourcing titanium alloy wheels, begin by identifying reliable suppliers with a proven track record in the automotive industry. Conduct thorough due diligence by checking certifications, customer reviews, and past project portfolios. Engage with multiple suppliers to compare their offerings, including material specifications, manufacturing capabilities, and lead times. Establish clear communication regarding your requirements, including compliance with international standards, to avoid any potential issues during production and delivery. -

What is the best material for lightweight electric car wheels?

Titanium alloy is considered one of the best materials for lightweight electric car wheels due to its high strength-to-weight ratio and corrosion resistance. This alloy offers significant weight savings compared to traditional materials like aluminum or steel, which enhances the vehicle’s efficiency and performance. Furthermore, the properties of titanium allow for intricate designs and improved aerodynamics, making it an ideal choice for electric vehicles aiming for optimal performance and energy efficiency. -

What are the minimum order quantities (MOQs) for titanium alloy wheels?

Minimum order quantities for titanium alloy wheels can vary significantly among suppliers, typically ranging from 50 to 200 units. Factors influencing MOQs include the complexity of the wheel design, customization options, and the supplier’s production capacity. For international buyers, it’s crucial to discuss MOQs upfront to align with your project needs and budget constraints. Some suppliers may offer flexibility for smaller orders, especially if you are willing to pay a premium or engage in a long-term partnership. -

How can I ensure the quality of titanium alloy wheels?

To ensure the quality of titanium alloy wheels, request detailed product specifications and certifications from suppliers. Look for compliance with industry standards such as ISO and ASTM. Additionally, consider visiting the manufacturing facility to observe quality control processes firsthand. Implement a robust quality assurance protocol that includes inspections at various production stages, and request samples for testing before committing to larger orders to mitigate risks of defects. -

What payment terms should I expect when ordering titanium alloy wheels?

Payment terms for titanium alloy wheels can vary, but common practices include a deposit (typically 30-50%) upon order confirmation, with the balance due before shipping. Some suppliers may offer payment via letters of credit or escrow services for larger transactions to ensure security for both parties. It’s advisable to negotiate terms that accommodate your cash flow while also providing the supplier with adequate assurance of payment. Always review payment policies in the context of international trade regulations. -

What customization options are available for titanium alloy wheels?

Many suppliers offer customization options for titanium alloy wheels, including sizes, finishes, and designs tailored to specific vehicle models or aesthetic preferences. You can request unique features such as aerodynamic enhancements or branding options. However, extensive customization may affect lead times and costs, so it’s essential to discuss your requirements early in the sourcing process. Ensure the supplier has the capability to deliver on your specifications without compromising quality or performance. -

How does international shipping affect the procurement of titanium alloy wheels?

International shipping can significantly impact the procurement process of titanium alloy wheels, influencing lead times and costs. It’s crucial to factor in shipping methods, customs regulations, and potential tariffs when planning your order. Work with suppliers who have experience in international logistics and can provide assistance with documentation and compliance. Establish clear timelines and communication regarding shipping expectations to ensure timely delivery and avoid unexpected delays. -

What are the best practices for vetting suppliers of titanium alloy wheels?

Vetting suppliers for titanium alloy wheels involves several best practices. Start by researching their reputation within the industry through reviews and testimonials. Request references from previous clients, and verify their manufacturing capabilities and quality control measures. Evaluate their compliance with international standards and certifications. Additionally, consider their responsiveness and willingness to engage in transparent communication. Engaging in a trial order can also help assess their reliability and product quality before committing to larger purchases.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 3 Titanium Alloy 4 Wheels Electric Car Manufacturers & Suppliers List

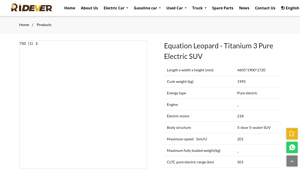

1. Equation – Leopard Titanium 3 SUV

Domain: drawell-ridever.com

Registered: 2021 (4 years)

Introduction: Equation Leopard – Titanium 3 Pure Electric SUV

– Length x Width x Height: 4605 mm x 1900 mm x 1720 mm

– Curb Weight: 1995 kg

– Energy Type: Pure Electric

– Engine: Electric Motor 218

– Body Structure: 5-door, 5-seater SUV

– Maximum Speed: 201 km/h

– CLTC Pure Electric Range: 501 km

– Model Variants: Titanium 3 2025 Model (various editions with different drive types and power outputs)

– Battery Fa…

2. HiPhi – A Electric Super Sedan

Domain: topspeed.com

Registered: 1995 (30 years)

Introduction: The HiPhi A Electric Super Sedan features include: 1. Omnidirectional Vectoring Chassis Control for optimized traction and cornering. 2. Omnidirectional Torque Vectoring for enhanced control and safety in various driving conditions. 3. 800V Electric Architecture supporting fast-charging up to 350 kW. 4. Combined power output of 1,247 horsepower. 5. Acceleration from 0-60 MPH in 2.0 seconds. 6. Top…

3. Alfa Romeo – 2025 Tonale

Domain: alfaromeousa.com

Registered: 2005 (20 years)

Introduction: 2025 Alfa Romeo Tonale

– MSRP starting at ${price}

– Available in Hybrid and Gas variants

– Performance Stats:

– Best-in-Class 285 Horsepower

– Best-in-Class 33-Mile All-Electric Range

– Most Powerful Engine in its Segment

– Best-in-Class 347 Pound-Feet of Torque

– Versions:

– Edizione Speciale:

– 130 HP and 160 HP Hybrid options

– 1.5-litre gasoline engine with 48-volt electric …

Strategic Sourcing Conclusion and Outlook for titanium alloy 4 wheels electric car

In the rapidly evolving landscape of electric vehicles (EVs), the integration of titanium alloy wheels presents a strategic opportunity for B2B buyers. The lightweight yet strong properties of titanium not only enhance vehicle performance through improved aerodynamics but also contribute to energy efficiency—critical factors for modern electric car manufacturers. Moreover, innovations in 3D printing technology enable the production of complex wheel designs that further optimize weight while maintaining structural integrity.

As international buyers from regions such as Africa, South America, the Middle East, and Europe consider sourcing titanium alloy wheels, it is essential to prioritize partnerships with suppliers who understand the nuances of this advanced material. A strategic sourcing approach will not only ensure cost-effectiveness but also align with sustainability goals, as titanium can reduce energy consumption and enhance the overall lifecycle of electric vehicles.

Looking ahead, the demand for lightweight and efficient components in the EV market is set to rise. Now is the time for B2B buyers to engage with manufacturers and innovators in the titanium sector to secure a competitive edge. By investing in high-quality titanium alloy wheels, businesses can contribute to a greener future while enhancing the performance of their electric vehicle offerings.