Introduction: Navigating the Global Market for kei car

Navigating the global market for kei cars presents a unique set of challenges for B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, where these compact vehicles are gaining traction. Sourcing kei cars, known for their affordability and fuel efficiency, requires a nuanced understanding of their specifications, applications, and the diverse options available from various suppliers. This guide is designed to equip international buyers with essential insights into the different types of kei cars, including trucks and vans, their practical uses in urban environments, and strategies for vetting suppliers effectively.

Within this comprehensive resource, we delve into critical topics such as cost analysis, compliance with import regulations, and the evaluation of vehicle performance. By addressing the key factors that influence purchasing decisions, this guide empowers businesses to make informed choices that align with their operational needs and budget constraints. Whether you are a fleet manager looking to enhance your logistics capabilities or a retailer aiming to diversify your automotive offerings, understanding the kei car market can unlock new opportunities. With the right knowledge, B2B buyers can confidently navigate this growing segment, ensuring they capitalize on the advantages that kei cars offer in today’s competitive landscape.

Understanding kei car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Kei Cars | Compact size, max engine displacement of 660cc, versatile designs | Urban transport, small business deliveries | Pros: Low running costs, easy parking. Cons: Limited power and cargo space. |

| Kei Trucks | Open cargo bed, robust build, same engine specifications as kei cars | Delivery services, agriculture, construction | Pros: High payload capacity, economical. Cons: Less comfort for passengers. |

| Kei Vans | Enclosed cargo space, spacious interiors, versatile seating | Logistics, transport services | Pros: High passenger capacity, flexible configurations. Cons: Slightly higher cost than kei cars. |

| Kei SUVs | Elevated ground clearance, rugged design, all-wheel drive options | Off-road applications, outdoor logistics | Pros: Better handling on rough terrain. Cons: Reduced fuel efficiency compared to kei cars. |

| Kei Microbuses | Larger passenger capacity, multiple seating arrangements | Shuttle services, group transportation | Pros: Cost-effective for large groups. Cons: Limited maneuverability in tight spaces. |

What Are the Key Characteristics of Kei Cars?

Kei cars, the hallmark of Japan’s automotive industry, are characterized by their compact size and efficient engine, with a maximum displacement of 660cc. They are designed for urban environments, making them an ideal choice for businesses needing affordable transportation solutions. Their small dimensions facilitate easy navigation through congested streets, which is particularly beneficial for delivery services in urban areas.

How Do Kei Trucks Serve B2B Needs?

Kei trucks are a robust variant of kei cars, equipped with an open cargo bed. These vehicles maintain the same engine specifications as kei cars but provide enhanced utility for businesses involved in deliveries, agriculture, and construction. Their high payload capacity and economical operation make them a preferred choice for companies looking to optimize logistics and reduce transportation costs.

What Advantages Do Kei Vans Offer Businesses?

Kei vans are designed to provide enclosed cargo space and spacious interiors, making them versatile for various applications. They can accommodate multiple passengers or be configured for cargo transport, which is ideal for logistics and transport services. While they may have a higher purchase price compared to standard kei cars, their flexibility and capacity often justify the investment for businesses requiring adaptable transportation solutions.

Why Consider Kei SUVs for Off-Road Applications?

Kei SUVs combine the compactness of kei cars with features suited for off-road conditions, such as elevated ground clearance and rugged designs. These vehicles are especially useful for businesses involved in outdoor logistics, where handling rough terrains is necessary. Although they tend to have reduced fuel efficiency compared to standard kei cars, their all-wheel drive options provide essential traction and stability in challenging environments.

How Do Kei Microbuses Cater to Group Transportation Needs?

Kei microbuses are designed for larger passenger capacities, offering multiple seating arrangements to accommodate group transportation. They are particularly advantageous for shuttle services and corporate transportation needs, providing a cost-effective solution for moving larger groups. However, their size may pose challenges in maneuverability within tight urban spaces, which is a consideration for businesses operating in densely populated areas.

Key Industrial Applications of kei car

| Industry/Sector | Specific Application of kei car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Delivery | Urban Delivery Vehicles | Enhanced maneuverability in congested areas | Focus on fuel efficiency, load capacity, and maintenance costs |

| Agriculture | Small Farm Utility Vehicles | Cost-effective transport for farm supplies | Durability, off-road capability, and payload specifications |

| Tourism and Hospitality | Compact Tour Vehicles | Affordable transport for small tourist groups | Comfort features, luggage space, and local regulations |

| Construction | On-Site Transport and Utility Vehicles | Versatile and compact transport for materials | Engine power, cargo space, and ease of access in tight areas |

| Retail | Mobile Shops and Food Trucks | Low startup costs and flexibility in location | Vehicle customization options and compliance with local laws |

How Are Kei Cars Used in Logistics and Delivery?

In the logistics and delivery sector, kei cars serve as urban delivery vehicles that can easily navigate narrow streets and tight spaces, making them ideal for last-mile delivery services. Their compact size allows businesses to reduce fuel costs and improve efficiency in congested urban environments. International buyers, particularly in regions like Africa and South America, should consider the kei car’s fuel efficiency and low maintenance requirements to ensure sustainable operations.

What Role Do Kei Cars Play in Agriculture?

Kei cars are increasingly utilized as small farm utility vehicles, providing farmers with a cost-effective solution for transporting supplies and equipment across their fields. Their compact design allows them to access areas where larger vehicles cannot operate, thus solving logistical challenges in agriculture. Buyers from the Middle East and Africa should prioritize durability and off-road capabilities when sourcing kei cars for agricultural use.

How Can Kei Cars Enhance Tourism and Hospitality?

In the tourism and hospitality industry, kei cars can be transformed into compact tour vehicles that cater to small groups. Their affordability makes them an attractive option for tour operators looking to provide unique experiences without significant overhead costs. Buyers in Europe and Asia should focus on comfort features and luggage space to ensure a pleasant experience for tourists while complying with local vehicle regulations.

Why Are Kei Cars Valuable for Construction?

Kei cars can be utilized as on-site transport and utility vehicles in the construction industry, offering versatility for transporting materials and equipment. Their compact size allows them to maneuver in tight construction sites, enhancing operational efficiency. International buyers should evaluate engine power and cargo space to meet specific project requirements effectively.

What Advantages Do Kei Cars Offer to Retail Businesses?

In the retail sector, kei cars can be converted into mobile shops or food trucks, providing businesses with the flexibility to reach customers in various locations. Their low startup costs make them an appealing option for entrepreneurs looking to enter the market. Buyers should consider customization options and compliance with local regulations to ensure successful operations in diverse markets.

3 Common User Pain Points for ‘kei car’ & Their Solutions

Scenario 1: Navigating Import Regulations for Kei Cars

The Problem: International B2B buyers often face significant challenges when importing kei cars due to strict regulations and varying compliance standards across countries. For instance, in regions like Europe or South America, regulations regarding vehicle emissions, safety standards, and even vehicle dimensions can vary widely. This can lead to costly delays, unexpected modifications, or even the inability to legally import the vehicles, resulting in frustration and financial loss.

The Solution: To mitigate these challenges, it is essential for buyers to conduct thorough research on the specific import regulations of their target market. Collaborating with a knowledgeable customs broker or logistics partner who specializes in automotive imports can streamline the process. Buyers should also engage with suppliers who provide detailed documentation about their kei cars, including compliance certificates and emissions reports. This proactive approach not only ensures that vehicles meet local standards but also facilitates smoother customs clearance, ultimately saving time and reducing costs.

Scenario 2: Limited Availability of Spare Parts and Maintenance Services

The Problem: Another common pain point for B2B buyers is the limited availability of spare parts and maintenance services for kei cars, particularly in markets outside of Japan. Many kei models are unique to the Japanese market, and sourcing parts can become a logistical nightmare. This scarcity can lead to prolonged downtimes for fleets and increased maintenance costs, impacting overall operational efficiency.

The Solution: To address this issue, buyers should establish relationships with reliable suppliers that specialize in kei cars and their components. Consider creating a network of local automotive service providers who are familiar with kei car maintenance and can perform repairs efficiently. Additionally, investing in a small inventory of commonly used parts can be a strategic move to minimize downtime. By leveraging online platforms that specialize in Japanese Domestic Market (JDM) parts, buyers can also enhance their procurement strategy, ensuring they have access to necessary components when needed.

Scenario 3: Misunderstanding the Market Demand for Kei Cars

The Problem: Many B2B buyers may misjudge the market demand for kei cars in their regions, leading to overstock situations or underestimating the potential for sales. The compact nature of kei cars makes them appealing for urban environments; however, cultural preferences and economic conditions can significantly influence their market acceptance. This disconnect can lead to financial losses and inventory management issues.

The Solution: Conducting comprehensive market research is vital to understanding the demand for kei cars in specific regions. Buyers should analyze local consumer preferences, competition, and economic factors that influence vehicle purchases. Engaging with local automotive experts or market analysts can provide valuable insights. Additionally, pilot programs or limited initial imports can help gauge market interest before committing to larger orders. By adopting a data-driven approach and staying flexible in their inventory strategies, buyers can better align their offerings with actual market demand, reducing the risk of overstock and maximizing profitability.

Strategic Material Selection Guide for kei car

What Materials Are Commonly Used in Kei Cars?

Kei cars, known for their compact size and efficiency, utilize a variety of materials that contribute to their performance, safety, and cost-effectiveness. Understanding these materials is crucial for B2B buyers, particularly those looking to import or manufacture kei cars in regions like Africa, South America, the Middle East, and Europe.

How Does Steel Contribute to the Structure of Kei Cars?

Steel is a primary material used in the chassis and body of kei cars. Its key properties include high tensile strength and excellent durability, making it capable of withstanding impacts and providing structural integrity. Steel also offers good corrosion resistance when treated with coatings, which is essential for vehicles exposed to varying climates.

Pros: Steel is relatively inexpensive and widely available, making it a cost-effective choice for manufacturers. Its strength allows for thinner sections, reducing overall weight, which is beneficial for fuel efficiency.

Cons: The main limitation of steel is its susceptibility to rust if not properly treated. Additionally, the manufacturing process can be complex due to the need for welding and shaping, which may increase production time.

For international buyers, compliance with standards such as ASTM or JIS is crucial, as these specifications ensure quality and safety. Buyers in regions with high humidity, such as parts of Africa and the Middle East, should consider corrosion-resistant treatments.

What Role Does Aluminum Play in Kei Car Manufacturing?

Aluminum is increasingly used in kei cars, particularly for components like engine blocks, wheels, and body panels. Its lightweight nature significantly enhances fuel efficiency and performance while maintaining good strength.

Pros: The key advantage of aluminum is its excellent strength-to-weight ratio, which contributes to better fuel economy and handling. It is also resistant to corrosion, making it suitable for various environmental conditions.

Cons: However, aluminum can be more expensive than steel, leading to higher manufacturing costs. Additionally, the welding and joining processes for aluminum can be more complex, requiring specialized equipment and skills.

International buyers must ensure that aluminum components meet local standards, as different regions may have varying regulations regarding automotive materials. For instance, European buyers might prioritize compliance with DIN standards.

How Is Plastic Used in Kei Cars?

Plastics are commonly used in interior components, bumpers, and trim of kei cars. They offer versatility and can be molded into complex shapes, which is advantageous for design flexibility.

Pros: The primary advantage of plastic is its lightweight nature, which helps reduce overall vehicle weight and improve fuel efficiency. Plastics also provide good resistance to corrosion and can be produced at a lower cost than metals.

Cons: On the downside, plastics may not offer the same level of durability as metals, particularly in high-impact areas. They can also degrade over time when exposed to UV light unless treated.

For buyers in regions with high sun exposure, such as parts of South America and Africa, selecting UV-stabilized plastics can enhance longevity. Compliance with environmental regulations regarding plastic use is also essential.

What About Composites in Kei Cars?

Composite materials, such as carbon fiber and fiberglass, are sometimes used in high-performance kei car models. These materials provide exceptional strength while being lightweight, making them ideal for performance applications.

Pros: The key advantage of composites is their superior strength-to-weight ratio, which enhances performance and efficiency. They also offer excellent resistance to corrosion and fatigue.

Cons: The main limitation is the high cost of composite materials and the complexity of the manufacturing processes involved, which can lead to longer production times.

International buyers should be aware of the advanced manufacturing techniques required for composites and ensure that their suppliers have the necessary expertise. Additionally, compliance with local automotive standards is critical.

Summary Table of Material Selection for Kei Cars

| Material | Typical Use Case for kei car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and body structure | High strength and durability | Susceptible to rust if untreated | Low |

| Aluminum | Engine blocks and wheels | Lightweight, corrosion-resistant | Higher cost and complex joining | Med |

| Plastic | Interior components and bumpers | Lightweight and cost-effective | Less durable in high-impact areas | Low |

| Composites | High-performance components | Superior strength-to-weight ratio | High cost and complex manufacturing | High |

Understanding these materials and their implications will help international B2B buyers make informed decisions when sourcing or manufacturing kei cars, ensuring compliance with local standards and meeting market demands effectively.

In-depth Look: Manufacturing Processes and Quality Assurance for kei car

What Are the Main Stages in the Manufacturing Process of Kei Cars?

The manufacturing of kei cars involves several critical stages, each contributing to the overall quality and efficiency of production. Understanding these processes is essential for B2B buyers who aim to ensure they source high-quality vehicles.

Material Preparation: How Are Components Selected for Kei Cars?

The manufacturing process begins with careful material selection. Kei cars are typically constructed using lightweight yet durable materials such as high-strength steel, aluminum, and plastic composites. This choice not only helps in maintaining the compact size of the vehicles but also contributes to fuel efficiency. Manufacturers often source materials from certified suppliers to ensure compliance with industry standards, which is crucial for international buyers.

Forming: What Techniques Are Used to Shape Kei Car Components?

The forming stage involves various techniques, including stamping, casting, and extrusion. For instance, body panels are usually stamped from steel sheets, while components like engine blocks may be cast. Advanced computer-aided design (CAD) systems are employed to optimize the design for strength and weight, ensuring that each component meets the stringent regulations governing kei cars. This stage is vital in ensuring that the parts fit together seamlessly during assembly.

Assembly: How Are Kei Cars Put Together?

Once the components are formed, they move to the assembly line, where skilled workers and automated systems collaborate. Assembly typically follows a modular approach, where pre-assembled units, such as the engine or transmission, are integrated into the vehicle structure. This method enhances efficiency and allows for quality control at each phase of assembly. Additionally, manufacturers often utilize just-in-time (JIT) inventory systems to minimize waste and reduce costs.

Finishing: What Processes Enhance the Aesthetics and Durability of Kei Cars?

The finishing stage includes painting and surface treatment, which are critical for aesthetics and corrosion resistance. Techniques such as electrostatic painting and powder coating are commonly used to ensure a durable finish. Manufacturers often conduct rigorous inspections during this stage to verify that the paint quality meets international standards, ensuring that the kei cars are not only visually appealing but also capable of withstanding various environmental conditions.

What Quality Assurance Measures Are Implemented in Kei Car Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of kei cars, as it ensures that each vehicle meets both safety and performance standards.

What International Standards Are Relevant for Kei Car Manufacturing?

Many kei car manufacturers adhere to international standards such as ISO 9001, which focuses on quality management systems. Compliance with these standards assures B2B buyers that the manufacturer has implemented systematic processes for maintaining quality throughout production. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) are essential for ensuring that components meet safety and performance regulations in different markets.

How Are Quality Control Checkpoints Integrated into the Manufacturing Process?

Quality control checkpoints are integrated at various stages of the manufacturing process, commonly referred to as Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC focuses on the quality of incoming materials and components, ensuring they meet specified requirements before being used in production.

- IPQC involves monitoring the manufacturing processes to detect any deviations from quality standards, allowing for immediate corrective actions.

- FQC is conducted after assembly, where the final product undergoes comprehensive testing to ensure it meets all specifications before delivery.

What Common Testing Methods Are Used in Quality Assurance for Kei Cars?

Several testing methods are utilized to validate the quality of kei cars, including:

- Durability Testing: Simulating various driving conditions to assess the vehicle’s performance and longevity.

- Crash Testing: Evaluating the safety features to comply with international safety regulations.

- Emissions Testing: Ensuring that the vehicle adheres to environmental standards, particularly important for buyers in regions with strict emissions regulations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is crucial. Here are several methods to consider:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality assurance measures, and compliance with international standards firsthand.

- Quality Reports: Requesting detailed reports on quality control metrics and testing outcomes can provide insights into a supplier’s commitment to quality.

- Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased evaluation of the manufacturer’s quality control processes, ensuring that the products meet the required standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing kei cars from international suppliers, buyers should be aware of specific quality control nuances:

- Regulatory Compliance: Different regions have varying standards and regulations. For example, European buyers must ensure that the kei cars comply with EU regulations, while buyers from Africa or the Middle East may have different requirements.

- Cultural Differences in Quality Expectations: Understanding the cultural context of manufacturing practices can aid in negotiating quality expectations. Japanese manufacturers, for instance, often have a strong focus on meticulous craftsmanship and continuous improvement (Kaizen).

- Logistics and Transportation Considerations: Quality can be affected during transportation. Buyers should discuss packaging and shipping methods with suppliers to minimize damage and ensure quality retention during transit.

By understanding the manufacturing processes and quality assurance measures of kei cars, B2B buyers can make informed decisions and establish reliable partnerships with manufacturers that prioritize quality and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kei car’

Introduction

This sourcing guide is designed to assist B2B buyers in efficiently procuring kei cars, a popular choice for urban transportation due to their compact size, fuel efficiency, and affordability. By following this structured checklist, buyers can navigate the complexities of the kei car market, ensuring they make informed decisions that align with their operational needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital when sourcing kei cars. Determine the required dimensions, engine capacity (maximum 660cc), and features such as fuel efficiency and cargo capacity. This clarity will help you filter suppliers and vehicles that meet your specific operational requirements.

Step 2: Research the Market Trends

Understanding the current market trends for kei cars is essential for making informed purchasing decisions. Analyze factors such as popular models, pricing fluctuations, and demand in your target regions. Stay informed about emerging trends, such as electric kei cars, which may affect your sourcing strategy.

Step 3: Identify Reputable Suppliers

Finding reputable suppliers is crucial for ensuring product quality and reliability. Look for suppliers with established track records in the kei car market, preferably those who have experience exporting to your region. Verify their credentials by checking customer reviews, industry certifications, and case studies that showcase their performance.

Step 4: Request Detailed Product Information

Before making a purchase, request comprehensive product information from potential suppliers. This should include specifications, warranty details, maintenance requirements, and after-sales support. Understanding these aspects will help you assess the total cost of ownership and the potential return on investment.

- Key Points to Consider:

- Warranty coverage and duration

- Availability of spare parts and service centers

- Support for vehicle compliance with local regulations

Step 5: Evaluate Pricing Structures

Conduct a thorough evaluation of the pricing structures offered by different suppliers. Compare the base prices of vehicles alongside additional costs such as shipping, customs duties, and taxes. Understanding the complete financial picture will enable you to negotiate better terms and avoid unexpected expenses.

Step 6: Arrange for Quality Inspections

Prior to finalizing any purchase, arrange for quality inspections of the kei cars. This may involve third-party inspection services to evaluate the condition of the vehicles and verify that they meet the agreed-upon specifications. Ensuring quality at this stage can save you from costly issues down the line.

Step 7: Establish Clear Communication Channels

Effective communication with your chosen supplier is essential throughout the sourcing process. Establish clear channels for updates on order status, shipping timelines, and any potential issues that may arise. Regular communication fosters a strong supplier relationship and ensures that both parties are aligned on expectations.

By following these steps, B2B buyers can streamline their sourcing process for kei cars, ensuring they select vehicles that meet their needs while minimizing risks and maximizing value.

Comprehensive Cost and Pricing Analysis for kei car Sourcing

Understanding the cost structure and pricing of kei cars is essential for international B2B buyers looking to source these compact vehicles. A comprehensive analysis reveals various cost components and pricing influencers that can significantly impact sourcing decisions.

What Are the Key Cost Components in Kei Car Manufacturing?

Materials: The materials used in kei cars, primarily lightweight metals and durable plastics, are critical for maintaining the vehicle’s compactness and fuel efficiency. The choice of materials can affect both the initial cost and the longevity of the vehicle, influencing the total cost of ownership.

Labor: Labor costs can vary based on the region where the kei cars are manufactured. Japan has a skilled workforce, but labor costs may be higher than in emerging markets. For B2B buyers, understanding the labor market in the supplier’s country can provide insight into potential cost variations.

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and administrative expenses. Efficient production processes and advanced technologies can help reduce these overhead costs, leading to competitive pricing for buyers.

Tooling: The initial investment in tooling for production lines can be substantial. However, this cost can be amortized over a larger production volume, which is why negotiating minimum order quantities (MOQs) can be beneficial for both buyers and suppliers.

Quality Control (QC): Ensuring that kei cars meet safety and quality standards is paramount. QC processes can add to the overall cost but are essential for maintaining brand reputation and customer satisfaction. Buyers should inquire about the certifications and quality assurance measures employed by suppliers.

Logistics: Transportation costs, including shipping and handling, can significantly affect the final price of kei cars. The choice of Incoterms (International Commercial Terms) will dictate who bears the shipping costs and risks, impacting the overall financial arrangement.

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the supplier’s pricing strategy can provide leverage during negotiations.

What Influences Pricing in Kei Car Sourcing?

Several factors can influence the pricing of kei cars, including:

Volume/MOQ: Higher order volumes can lead to bulk pricing discounts. Suppliers are often willing to negotiate lower prices for larger orders, making it advantageous for buyers to assess their needs carefully.

Specifications/Customization: Custom features or specifications can increase the cost. Buyers should clearly communicate their requirements and consider the trade-off between customization and cost.

Materials and Quality: The choice of high-quality materials or advanced technology can drive up costs. Buyers should evaluate the balance between cost and quality to determine the best options for their market.

Supplier Factors: Supplier reputation, experience, and financial stability can influence pricing. Established suppliers may charge a premium for their reliability and service.

Incoterms: The choice of Incoterms can affect the total cost. Understanding responsibilities for shipping, insurance, and tariffs can help buyers avoid unexpected expenses.

What Tips Can Help Buyers Negotiate Better Prices?

B2B buyers should consider the following strategies to enhance their sourcing experience:

-

Negotiate Wisely: Leverage volume commitments and long-term partnerships to negotiate better terms. Suppliers are often more flexible with pricing when they see potential for repeat business.

-

Focus on Cost-Efficiency: Evaluate the total cost of ownership, including maintenance and fuel efficiency, rather than just the initial purchase price. This approach can lead to better long-term value.

-

Understand Pricing Nuances: Be aware that prices can vary based on market conditions, currency fluctuations, and geopolitical factors. Staying informed can help buyers make timely decisions.

-

Research and Compare: Conduct thorough research on multiple suppliers to compare prices and terms. This competitive analysis can empower buyers during negotiations.

-

Clarify Payment Terms: Ensure payment terms are clearly defined to avoid cash flow issues. Flexible payment options may also be available for larger orders.

Disclaimer on Indicative Prices

The prices mentioned in various sources are indicative and may fluctuate based on market conditions, specific vehicle specifications, and other factors. Buyers should always request updated quotes from suppliers to ensure accurate pricing.

Alternatives Analysis: Comparing kei car With Other Solutions

Exploring Alternatives to Kei Cars for Urban Transportation Solutions

When considering urban transportation solutions, kei cars offer unique advantages, particularly in densely populated areas. However, there are viable alternatives that may better suit specific needs or preferences. This analysis compares kei cars against two alternatives: compact sedans and electric scooters. Each option has distinct characteristics that can influence a B2B buyer’s decision-making process.

Comparison Table

| Comparison Aspect | Kei Car | Compact Sedan | Electric Scooter |

|---|---|---|---|

| Performance | Max 63 HP, 660cc engine | Generally 100-200 HP, larger engines | Varies, typically 1-3 HP |

| Cost | Low initial cost ($1,500-$5,000) | Moderate initial cost ($15,000-$30,000) | Low cost ($300-$1,500) |

| Ease of Implementation | Simple registration in Japan and select markets | Standard process, requires more documentation | Minimal, often no registration needed |

| Maintenance | Low cost, simple mechanics | Moderate, parts readily available | Low, fewer parts, often self-service |

| Best Use Case | Urban commuting, tight spaces | Family transport, longer distances | Short commutes, eco-friendly options |

Detailed Breakdown of Alternatives

Compact Sedan

Compact sedans, such as the Toyota Corolla or Honda Civic, provide a balance between performance and space. They typically feature more powerful engines than kei cars, making them suitable for longer trips or diverse terrains. While their initial purchase price is significantly higher, they offer more space and comfort for passengers and cargo. However, in urban settings where parking space is limited, compact sedans may be less practical than kei cars. Moreover, the maintenance costs can be higher due to the complexity of their systems.

Electric Scooter

Electric scooters represent a modern solution for short-distance travel, particularly in urban environments. With minimal costs and maintenance requirements, they provide an eco-friendly alternative to traditional vehicles. They are easy to maneuver and park, making them ideal for congested city areas. However, their limited range and speed compared to kei cars may restrict their usability for longer commutes. Additionally, they often lack the cargo capacity required for business applications, which could be a disadvantage for B2B buyers needing transport for goods or services.

Conclusion: How to Choose the Right Solution for Your Needs

In choosing the right transportation solution, B2B buyers should assess their specific operational requirements and urban environments. Kei cars are ideal for businesses focused on cost-efficiency and navigating congested city streets. Compact sedans may be more suitable for companies needing additional space and comfort for employees or clients. Meanwhile, electric scooters can serve as a supplementary mode of transport for short distances, especially in eco-conscious markets. Ultimately, the decision should be based on a thorough evaluation of performance, cost, and practical application within the intended operational context.

Essential Technical Properties and Trade Terminology for kei car

What Are the Key Technical Properties of Kei Cars?

When considering kei cars for international markets, understanding their essential technical properties is crucial for B2B buyers. Here are some vital specifications:

1. Engine Displacement (660cc)

Kei cars are restricted to a maximum engine displacement of 660cc. This limitation is essential as it categorizes the vehicle as a light vehicle (keijidosha) under Japanese law. For B2B buyers, this means lower taxes and insurance costs, making kei cars an economically viable option for businesses in regions where fuel efficiency is paramount.

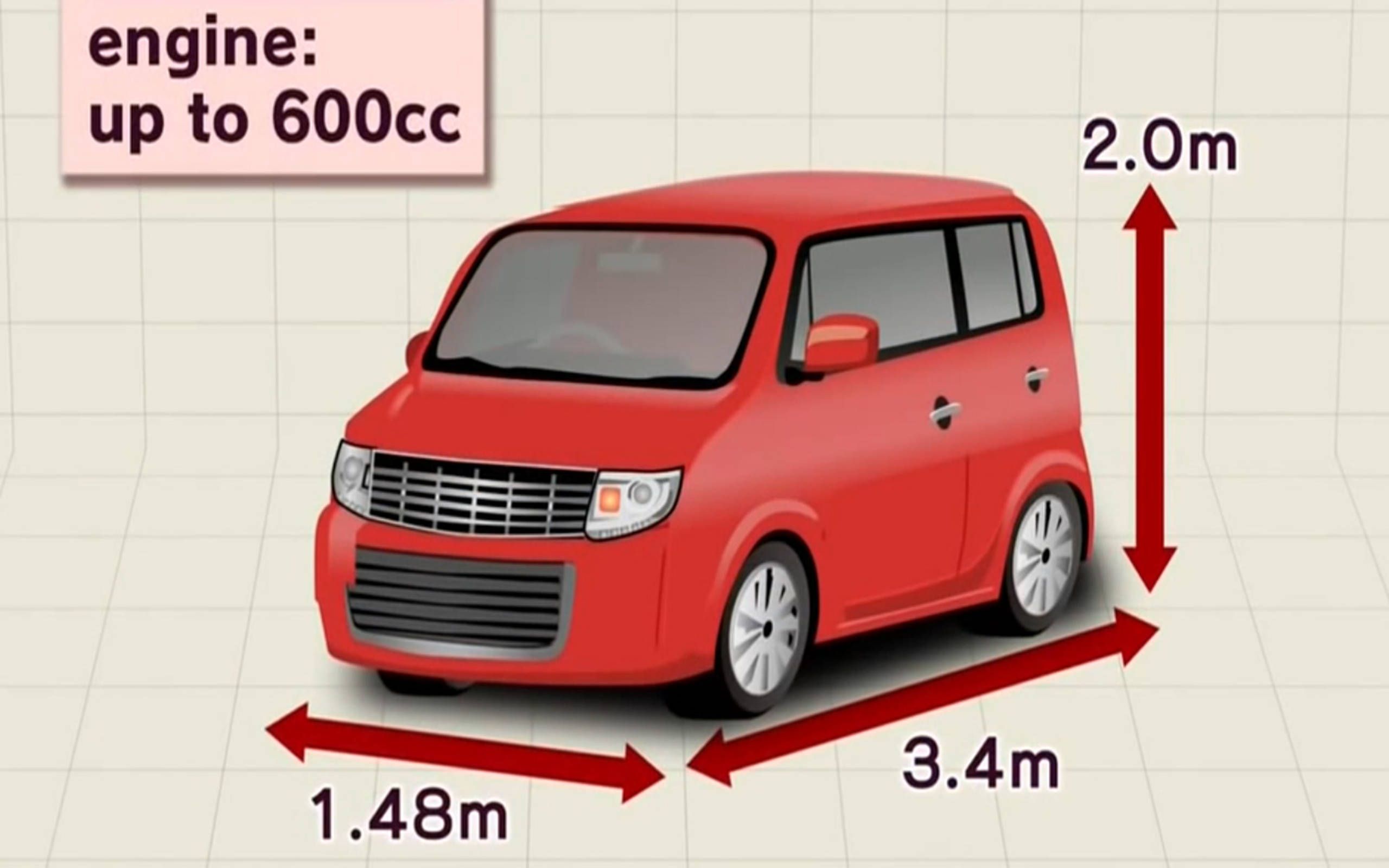

2. Dimensions (Length, Width, Height)

Kei cars must not exceed 3.4 meters in length, 1.48 meters in width, and 2.0 meters in height. These compact dimensions make them ideal for urban environments, where parking space is limited. For businesses involved in logistics or urban deliveries, kei cars can facilitate maneuverability in tight spaces, enhancing operational efficiency.

3. Gross Vehicle Weight Rating (GVWR)

The GVWR for kei cars typically falls under 1,000 kg. This specification is crucial for compliance with various international regulations regarding vehicle transport and importation. B2B buyers must consider this weight when planning shipping logistics to ensure adherence to local regulations and minimize additional costs.

4. Fuel Efficiency

Kei cars are renowned for their fuel efficiency, often achieving over 20 km/L. This property is critical for businesses looking to reduce operational costs, particularly in sectors where vehicle use is high. Lower fuel consumption directly translates to reduced environmental impact, aligning with global sustainability goals.

5. Cargo Capacity

Despite their small size, kei cars often feature versatile cargo solutions, such as foldable seats and ample storage compartments. This flexibility can be advantageous for businesses needing to transport goods without investing in larger vehicles. Understanding cargo capacity is essential for buyers in the retail and service industries.

What Are the Common Trade Terms Related to Kei Cars?

Familiarity with industry jargon can significantly enhance communication and negotiation processes for B2B buyers. Here are some common terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. In the kei car industry, understanding OEM relationships is vital for buyers looking to source parts or vehicles. This term signifies quality and compatibility, ensuring that components meet specific standards.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For kei cars, knowing the MOQ helps businesses manage inventory and cash flow efficiently. Buyers should negotiate MOQs to ensure they are not overcommitting financially while still meeting operational needs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. In the context of kei cars, an RFQ can streamline the procurement process, enabling buyers to compare offers and negotiate better deals.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is essential for kei car importers, as they dictate shipping costs, risk, and insurance responsibilities. Proper knowledge of Incoterms can prevent misunderstandings and financial losses during cross-border trade.

5. JDM (Japanese Domestic Market)

JDM refers to vehicles that are manufactured specifically for the Japanese market. For international buyers, recognizing the significance of JDM can help identify vehicles with unique features tailored to local preferences. This understanding can inform purchasing decisions, especially when sourcing kei cars for niche markets.

In summary, grasping the technical properties and trade terminology surrounding kei cars is crucial for B2B buyers. It allows for informed decision-making, effective communication, and strategic planning in international transactions.

Navigating Market Dynamics and Sourcing Trends in the kei car Sector

What Are the Key Market Dynamics Influencing the Kei Car Sector?

The kei car segment has garnered significant attention globally, particularly as urbanization intensifies and fuel efficiency becomes paramount. In regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are increasingly attracted to kei cars due to their compact size, affordability, and low operating costs. These vehicles are particularly well-suited for navigating congested city streets, making them ideal for emerging markets with similar urban challenges.

Current trends highlight the rise of digital platforms for sourcing kei cars, allowing buyers to access a broader range of options directly from Japanese manufacturers and dealers. Enhanced technology in logistics and supply chain management is streamlining import processes, reducing lead times, and improving inventory management. Furthermore, the increasing interest in second-hand kei cars is reshaping market dynamics, as buyers seek value in established models that still meet regulatory standards in their respective countries.

Emerging markets are seeing a surge in demand for kei trucks and vans, which are favored for their versatility in commercial applications. Additionally, the growing emphasis on sustainability is influencing purchasing decisions, with buyers favoring vehicles that minimize environmental impact while maintaining efficiency.

How Are Sustainability and Ethical Sourcing Shaping the Kei Car Market?

Sustainability has become a pivotal factor in the sourcing of kei cars, as both consumers and businesses alike become more environmentally conscious. The production of kei cars is increasingly scrutinized for its environmental impact, prompting manufacturers to adopt greener practices. This includes the use of eco-friendly materials and technologies that reduce emissions during both manufacturing and operation.

B2B buyers are now prioritizing ethical supply chains, seeking partners who adhere to stringent environmental standards. Certification programs such as ISO 14001 for environmental management systems are becoming essential for suppliers aiming to prove their commitment to sustainability. Additionally, the integration of recycled materials in vehicle manufacturing is gaining traction, appealing to buyers focused on reducing their carbon footprint.

Furthermore, the adoption of electric kei cars is on the rise, driven by regulatory incentives and changing consumer preferences. These vehicles not only align with global sustainability goals but also offer significant long-term savings on fuel and maintenance costs. As a result, B2B buyers must consider the sustainability credentials of their kei car suppliers to ensure alignment with their corporate responsibility objectives.

What Is the Historical Context of the Kei Car Sector?

The kei car concept originated in Japan in 1949 as part of a government initiative to stimulate economic recovery following World War II. By introducing a class of vehicles that were affordable, compact, and easy to operate, the government aimed to promote personal vehicle ownership and boost the domestic auto industry. Kei cars quickly became a staple of Japanese automotive culture, evolving in design and technology while remaining true to their core attributes of practicality and efficiency.

Over the decades, kei cars have adapted to changing consumer needs and environmental regulations, maintaining their relevance in a competitive automotive landscape. As international markets begin to recognize the benefits of these vehicles, the kei car sector is poised for further growth, particularly among B2B buyers seeking cost-effective and versatile transportation solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of kei car

-

How do I find reliable suppliers for kei cars?

To find reliable suppliers for kei cars, start by researching established dealers and manufacturers in Japan. Utilize platforms like Alibaba, TradeKey, and local automotive trade shows to discover verified suppliers. It’s vital to assess their credentials, customer reviews, and industry experience. Engage in direct communication to inquire about their production capabilities and certifications. Additionally, consider visiting their facilities if possible, or request virtual tours to evaluate their operations firsthand. -

What are the typical minimum order quantities (MOQ) for kei cars?

Minimum order quantities for kei cars can vary significantly based on the supplier and the specific models you are interested in. Typically, MOQs can range from 1-10 vehicles for smaller dealers, while larger manufacturers may require higher quantities. Always clarify the MOQ upfront, as some suppliers may offer flexibility depending on your purchasing power or long-term partnership potential. Understanding these parameters can help you plan your inventory and cash flow accordingly. -

What customization options are available for kei cars?

Many suppliers offer customization options for kei cars, including modifications to color, interior features, and additional accessories. Common customizations involve enhancing safety features, installing advanced infotainment systems, or modifying the suspension for different terrains. Discuss your specific requirements with the supplier, as they may have a range of options or partnerships with aftermarket providers. Ensure any modifications comply with the regulations in your target market to avoid compliance issues. -

What payment terms are commonly offered for kei car purchases?

Payment terms for kei car purchases can differ by supplier, but standard practices include upfront deposits (typically 30-50%) with the balance due upon shipment or delivery. Some suppliers may offer financing options or extended payment plans for larger orders. It’s advisable to negotiate terms that align with your cash flow and operational needs. Always ensure that payment methods are secure, and consider using escrow services for added protection during the transaction. -

How do I ensure quality assurance when sourcing kei cars?

To ensure quality assurance when sourcing kei cars, request detailed specifications and certifications from suppliers. Conduct thorough inspections of vehicles before purchase, focusing on engine performance, body condition, and interior quality. Many suppliers offer pre-shipment inspections, which can be beneficial. Additionally, consider establishing a quality control agreement that outlines standards and expectations, allowing for recourse if the vehicles do not meet the agreed-upon criteria. -

What are the logistics considerations for importing kei cars?

Logistics for importing kei cars involve several key factors, including shipping methods, customs clearance, and local regulations in your destination country. Choose a reputable freight forwarder familiar with automotive imports to handle the shipping process. Ensure all documentation is complete and compliant with both exporting and importing country regulations. Be aware of any tariffs or duties applicable to kei cars, and plan for transportation from the port to your final destination. -

What regulations should I be aware of when importing kei cars to my country?

When importing kei cars, it is crucial to understand the local regulations regarding vehicle specifications, emissions standards, and safety requirements. Each country has specific criteria that vehicles must meet to be roadworthy. Research the importation process, including any necessary modifications that may be required to comply with local laws. Consulting with a local customs broker can provide insights into the specific regulations and help streamline the import process. -

How can I assess the market demand for kei cars in my region?

To assess market demand for kei cars in your region, conduct market research that includes analyzing consumer preferences, local automotive trends, and economic factors. Engage with potential customers through surveys or focus groups to gauge interest and identify desired features. Additionally, review sales data from local dealerships and industry reports to understand competition and pricing strategies. This information will help you position your offering effectively and make informed purchasing decisions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Kei Car Manufacturers & Suppliers List

1. Car From Japan – Kei Cars

Domain: carfromjapan.com

Registered: 2014 (11 years)

Introduction: Kei cars are small, fuel-efficient vehicles popular in Japan for their practicality and affordability. They are ideal for navigating crowded city streets and tight parking spaces, with efficient engines that keep running costs low. Kei cars offer surprising versatility, featuring innovative design and clever storage solutions. Key details include:

– Engine Size: 660 cc

– Popular Makes: Toyota, Nis…

2. MotorTrend – Kei Cars

Domain: motortrend.com

Registered: 1998 (27 years)

Introduction: Kei cars are ultra-compact vehicles from Japan, defined by specific size and engine restrictions. They must be no longer than 11.2 feet, less than 5 feet wide, and under 6.6 feet tall. Engine displacement is limited to a maximum of 660cc, with a maximum output of 63 horsepower. Kei cars were introduced in 1949 as a response to the need for affordable personal transportation and have become popular…

3. Texas JDM – Kei Vehicles

Domain: texasjdm.com

Registered: 2016 (9 years)

Introduction: Kei vehicles, also known as kei cars, are small Japanese vehicles created in 1949 to stimulate car ownership and the automotive industry. They are limited to a length of 3.4 m (11.2 ft), width of 1.48 m (4.9 ft), height under 2.0 m (6.6 ft), and an engine displacement of under 660 cc. Kei cars enjoy benefits such as lower taxes, lower insurance rates, and fewer parking restrictions compared to ful…

4. Nissan – Roox

Domain: global.nissannews.com

Registered: 1996 (29 years)

Introduction: The new Nissan Roox redefines the Kei car segment with space, style, and tech.

5. Interac Network – Kei Cars

Domain: interacnetwork.com

Registered: 2007 (18 years)

Introduction: Kei Cars, or K-Cars, are a special class of small vehicles in Japan, designed to be compact, efficient, and affordable. They must adhere to specific government regulations: maximum length of 3.4 meters, width of 1.48 meters, height of 2 meters, and engine capacity of 660cc. Benefits of owning a K-Car include excellent fuel efficiency, lower taxes, reduced registration fees, and lower insurance pre…

6. Subaru – 1991 Sambar Kei Truck

Domain: nytimes.com

Registered: 1994 (31 years)

Introduction: Kei trucks are extremely small, slow vehicles that are popular in Japan and are gaining traction in the United States. They are characterized by their compact size and unique design, often customized by owners. The article mentions a specific model, the 1991 Subaru Sambar, which is a type of Kei truck. Despite challenges in importing and registering these vehicles due to federal and state laws, th…

7. Daihatsu – Hijet Parts

Domain: oiwagarage.co

Registered: 2022 (3 years)

Introduction: Daihatsu Hijet Parts: Brakes, Carburetor Parts, Body, Engine, Exhaust, Filters, Ignition, Steering Components, Suspension, Timing Belt Kits, Transmission; Honda Acty Parts: Truck HA3, HA4; Van HH3, HH4, HH5, HH6, HA6, HA7, HA8, HA9; Honda Vamos Parts: Van HM1, HM2; Mitsubishi Minicab Parts: Truck U41T, U42T, U61T, U62T; Subaru Sambar Parts: Truck KS3, KS4, Van KV3, KV4, Truck TT1, TT2; Suzuki Carr…

Strategic Sourcing Conclusion and Outlook for kei car

As the global automotive landscape evolves, kei cars present a unique opportunity for international B2B buyers seeking affordable, efficient, and versatile vehicles. Their compact size and low operating costs make them particularly well-suited for urban environments, which is increasingly relevant in rapidly developing regions across Africa, South America, the Middle East, and Europe. The strategic sourcing of kei cars not only enhances supply chain efficiency but also aligns with growing consumer demand for eco-friendly transportation solutions.

Investing in kei cars can yield significant advantages, such as reduced fuel expenses and maintenance costs, which can be particularly beneficial for businesses operating in crowded urban settings. Moreover, the rich variety of kei models—from trucks to vans—ensures that buyers can find vehicles tailored to their specific operational needs.

Looking ahead, the continued popularity of kei cars in both domestic and international markets highlights the importance of strategic sourcing partnerships. B2B buyers are encouraged to engage with reputable suppliers, ensuring access to quality vehicles that meet regulatory standards while also appealing to cost-sensitive consumers. Embrace the kei car revolution today and position your business for success in the evolving automotive market.