Introduction: Navigating the Global Market for small Box Trucks

In the ever-evolving landscape of logistics and transportation, sourcing small box trucks that meet specific operational needs can be a significant challenge for international B2B buyers. These versatile vehicles are essential for businesses engaged in local deliveries, e-commerce fulfillment, and urban transportation, making them a critical asset for companies across Africa, South America, the Middle East, and Europe, including markets like Vietnam and Brazil. This guide provides a comprehensive overview of small box trucks, focusing on various types, applications, and key considerations for making informed purchasing decisions.

From understanding the differences between light-duty and medium-duty box trucks to evaluating their suitability for different business models, this guide equips buyers with the insights needed to navigate the complexities of the global market. We delve into essential factors such as supplier vetting processes, cost analysis, maintenance considerations, and financing options, all designed to empower businesses in selecting the right vehicles to enhance their operational efficiency.

By leveraging the expertise and knowledge shared in this guide, B2B buyers can confidently approach their sourcing strategies, ensuring they invest in reliable and efficient small box trucks that align with their unique requirements. Ultimately, this resource aims to foster informed purchasing decisions that drive success in diverse and competitive markets.

Understanding small Box Trucks Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Light Duty Box Trucks | Typically under 10,000 lbs GVWR; compact size | Local deliveries, small furniture transport | Pros: Maneuverable, cost-effective. Cons: Limited payload capacity. |

| Medium Duty Box Trucks | GVWR between 10,001 and 26,000 lbs; often larger box | Freight transport, construction materials | Pros: Higher payload, versatile. Cons: Less fuel-efficient. |

| Refrigerated Box Trucks | Insulated box with cooling systems | Perishable goods transport, food delivery | Pros: Maintains temperature, ideal for perishables. Cons: Higher operating costs. |

| Stake Bed Box Trucks | Open flatbed with removable sides | Landscaping, construction, equipment transport | Pros: Flexible loading, easy access. Cons: Less secure for fragile items. |

| Cargo Van Box Trucks | Enclosed van-style with cargo space | Urban deliveries, courier services | Pros: Easy access, often more fuel-efficient. Cons: Limited cargo height. |

What Are Light Duty Box Trucks and Their B2B Suitability?

Light duty box trucks are designed for smaller loads, typically with a Gross Vehicle Weight Rating (GVWR) under 10,000 lbs. They are ideal for local deliveries, particularly in urban environments where maneuverability is crucial. Businesses in sectors like retail and small-scale logistics benefit from their compact size and cost-effectiveness. When purchasing, consider the truck’s payload capacity and fuel efficiency to ensure it aligns with your operational needs.

How Do Medium Duty Box Trucks Serve Businesses?

Medium duty box trucks, with a GVWR ranging from 10,001 to 26,000 lbs, are suitable for transporting heavier loads, such as construction materials or freight. Their larger box size provides ample cargo space, making them versatile for various industries, including logistics and construction. Buyers should evaluate the truck’s fuel consumption and maintenance costs, as these can impact overall operational efficiency.

Why Choose Refrigerated Box Trucks for Perishable Goods?

Refrigerated box trucks are equipped with specialized cooling systems, making them essential for transporting perishable goods like food and pharmaceuticals. These trucks maintain a consistent temperature, ensuring product integrity during transit. Businesses in the food service and distribution sectors should consider the initial investment and ongoing operational costs, as these trucks can be more expensive to maintain.

What Are the Advantages of Stake Bed Box Trucks?

Stake bed box trucks feature an open flatbed with removable sides, providing flexibility for loading and unloading. They are particularly effective for landscaping and construction applications, where large or bulky items need to be transported. While they offer easy access and versatility, buyers should be cautious about the security of fragile goods, as they are less enclosed than traditional box trucks.

How Do Cargo Van Box Trucks Differ from Traditional Box Trucks?

Cargo van box trucks combine the benefits of a van’s enclosed design with the spacious cargo area of a box truck. They are especially suited for urban deliveries and courier services due to their accessibility and often better fuel efficiency. However, businesses should assess the limitations in cargo height and overall capacity to ensure they meet their specific transportation needs.

Key Industrial Applications of small Box Trucks

| Industry/Sector | Specific Application of small Box Trucks | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Retail | Last-mile delivery of goods | Enhanced delivery efficiency and customer satisfaction | Payload capacity, fuel efficiency, and size for urban navigation |

| Construction & Renovation | Transportation of tools and materials | Streamlined project management and reduced downtime | Durability, payload capacity, and customization options |

| Food & Beverage | Distribution of perishable goods | Maintaining product integrity and timely deliveries | Refrigeration options, payload capacity, and compliance with health regulations |

| Moving & Storage | Residential and commercial moving services | Increased operational flexibility and customer service | Size options, ease of loading/unloading, and reliability |

| Health & Pharmaceuticals | Delivery of medical supplies and equipment | Ensured timely access to critical supplies | Temperature control features, security, and compliance with regulations |

How are small Box Trucks Used in E-commerce & Retail?

In the e-commerce and retail sectors, small box trucks are essential for last-mile delivery operations. They enable businesses to transport goods from distribution centers directly to consumers’ doorsteps. This application addresses challenges such as urban congestion and the need for timely deliveries. Buyers in this sector should consider payload capacity, fuel efficiency, and the vehicle’s size to navigate tight city streets effectively, particularly in regions like South America and Europe where urban environments can be challenging.

What Role Do Small Box Trucks Play in Construction & Renovation?

Small box trucks are invaluable in the construction and renovation industries for transporting tools, equipment, and materials to job sites. This application helps streamline project management, ensuring that workers have the necessary supplies at their fingertips, thus reducing downtime. For international buyers, especially in Africa and the Middle East, durability, payload capacity, and the option for customized interiors to fit specific equipment are critical factors to consider when sourcing these vehicles.

How Are Small Box Trucks Used in the Food & Beverage Sector?

In the food and beverage industry, small box trucks are crucial for the distribution of perishable goods. They help maintain product integrity during transit, which is vital for customer satisfaction and regulatory compliance. Buyers should focus on vehicles equipped with refrigeration options and sufficient payload capacity. Additionally, compliance with health regulations is paramount, particularly in regions like Europe where food safety standards are stringent.

Why Are Small Box Trucks Important for Moving & Storage Services?

For moving and storage companies, small box trucks facilitate both residential and commercial moves. They provide the operational flexibility needed to handle varying load sizes while enhancing customer service through timely deliveries. When sourcing, businesses should consider size options, ease of loading and unloading, and the overall reliability of the vehicle to ensure smooth operations across diverse regions, including Africa and Brazil.

How Do Small Box Trucks Support Health & Pharmaceutical Deliveries?

In the health and pharmaceutical sectors, small box trucks are used to deliver medical supplies and equipment, ensuring timely access to critical resources. This application is essential for maintaining the continuity of care in healthcare settings. Buyers in this industry must prioritize temperature control features, vehicle security, and compliance with health regulations, especially in regions where healthcare logistics can be complex.

3 Common User Pain Points for ‘small Box Trucks’ & Their Solutions

Scenario 1: Navigating High Operating Costs

The Problem: Many B2B buyers of small box trucks face the challenge of high operating costs. Fuel prices can fluctuate significantly, impacting the overall budget. Additionally, maintenance and repair expenses can accumulate, especially for older models or those that have not been well-maintained. This situation often leads to a strain on financial resources, causing businesses to reconsider their logistics strategies.

The Solution: To effectively manage operating costs, buyers should prioritize investing in newer models with better fuel efficiency and lower maintenance needs. When sourcing box trucks, consider models that have a proven track record of reliability and durability. For example, trucks like the Ford E350 or Isuzu NPR are renowned for their efficiency. Establishing a regular maintenance schedule is also crucial; preventive care can avert costly repairs down the line. Additionally, explore telematics systems that provide real-time data on fuel consumption and driving habits, allowing businesses to optimize routes and reduce fuel expenses.

Scenario 2: Adapting to Changing Cargo Needs

The Problem: Businesses often experience fluctuations in cargo volume and types, which can lead to inefficiencies when the box truck capacity does not match their needs. For instance, a small business may find itself with too much cargo for a standard truck, or too little for a larger vehicle, leading to wasted resources or missed opportunities. This scenario can significantly hinder operational efficiency and customer satisfaction.

The Solution: To address this issue, buyers should assess their cargo needs regularly and choose a versatile box truck that can adapt to varying demands. Investing in adjustable shelving or modular cargo systems within the truck can maximize space and allow for flexible storage solutions. Furthermore, consider renting or leasing additional box trucks during peak seasons rather than purchasing outright. This approach allows businesses to scale their fleet according to demand without incurring unnecessary costs. Establishing partnerships with local rental companies can facilitate quick access to additional vehicles when needed.

Scenario 3: Compliance with Local Regulations

The Problem: Navigating the maze of local regulations regarding commercial vehicle operation can be daunting for B2B buyers, especially in international markets. Each region may have specific requirements concerning weight limits, emissions standards, and safety features. Non-compliance can lead to fines and operational disruptions, creating additional stress for business owners.

The Solution: To ensure compliance, buyers should conduct thorough research on the regulations specific to their operational areas. Engaging with local industry associations or regulatory bodies can provide valuable insights into these requirements. When selecting a box truck, ensure that it meets or exceeds local standards, particularly regarding emissions and safety features. It’s advisable to work with reputable suppliers who can provide documentation and certifications for their vehicles. Additionally, integrating compliance management software can help track regulatory changes and ensure that the fleet remains compliant over time. Regular training for drivers on compliance best practices can further mitigate risks associated with regulatory violations.

Strategic Material Selection Guide for small Box Trucks

What Are the Key Materials Used in Small Box Trucks?

When selecting materials for small box trucks, various factors such as performance, durability, cost, and compliance with international standards come into play. Below, we analyze four common materials used in the construction of small box trucks, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Steel Perform as a Material for Small Box Trucks?

Steel is one of the most widely used materials in the construction of small box trucks, particularly for the frame and chassis.

Key Properties: Steel offers high tensile strength, excellent load-bearing capabilities, and good resistance to deformation under stress. It can withstand high temperatures and pressures, making it suitable for various operational conditions.

Pros & Cons: The primary advantage of steel is its durability and strength, which ensures long service life and safety. However, steel is relatively heavy, which can affect fuel efficiency. Additionally, it is prone to corrosion if not properly treated, increasing maintenance costs.

Impact on Application: Steel’s load-bearing capabilities make it ideal for transporting heavy goods. However, its weight can limit payload capacity, which is a critical factor for businesses focused on efficiency.

Considerations for International Buyers: Compliance with standards such as ASTM A36 (for structural steel) is crucial. Buyers in regions like Africa and South America should also consider local availability and treatment options to combat corrosion due to humid climates.

What Role Does Aluminum Play in Small Box Trucks?

Aluminum is increasingly popular in the manufacturing of small box trucks, especially for the cargo box and body panels.

Key Properties: Aluminum is lightweight, resistant to corrosion, and has good thermal conductivity. It can handle a variety of environmental conditions without significant degradation.

Pros & Cons: The main advantage of aluminum is its lightweight nature, which improves fuel efficiency and increases payload capacity. However, aluminum is generally more expensive than steel and may require specialized welding techniques, which can complicate manufacturing.

Impact on Application: Aluminum’s corrosion resistance makes it suitable for transporting goods in humid or coastal environments. However, its lower tensile strength compared to steel may limit its use in heavy-duty applications.

Considerations for International Buyers: Buyers should be aware of international standards such as ASTM B221 for aluminum extrusions. In regions like the Middle East, where high temperatures can be a factor, aluminum’s thermal properties can be beneficial.

How Does Composite Material Benefit Small Box Trucks?

Composite materials, often made from a combination of fiberglass and resin, are used for truck bodies and panels.

Key Properties: Composites are lightweight, have high strength-to-weight ratios, and excellent resistance to corrosion and impact.

Pros & Cons: The key advantage is their lightweight nature, which enhances fuel efficiency. However, composites can be more expensive to produce and may not be as easily repairable as metal.

Impact on Application: Composites are ideal for applications requiring lower weight and high durability, such as refrigerated trucks. Their resistance to moisture makes them suitable for various climates.

Considerations for International Buyers: Compliance with standards like ASTM D638 for tensile properties is essential. Buyers should also consider the availability of repair facilities for composite materials in their region.

What Are the Benefits of Using Plastic in Small Box Trucks?

Plastic, particularly high-density polyethylene (HDPE) and polypropylene, is used in various components of small box trucks.

Key Properties: Plastics are lightweight, corrosion-resistant, and can be molded into complex shapes. They also have good thermal and electrical insulation properties.

Pros & Cons: The primary advantage of plastic is its lightweight nature, which can enhance fuel efficiency. However, plastics may not withstand high temperatures as well as metals and can be less durable in heavy-duty applications.

Impact on Application: Plastic components can be beneficial for non-structural elements, such as interior fittings and storage solutions. However, they may not be suitable for load-bearing applications.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM D3350 for polyethylene. In regions with extreme temperatures, the thermal properties of plastics should be evaluated.

Summary Table of Material Selection for Small Box Trucks

| Material | Typical Use Case for small Box Trucks | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and chassis | High strength and durability | Heavy and prone to corrosion | Medium |

| Aluminum | Cargo box and body panels | Lightweight and corrosion-resistant | More expensive and complex to weld | High |

| Composite | Truck bodies and panels | Lightweight and impact-resistant | Higher production costs | High |

| Plastic | Interior fittings and storage solutions | Lightweight and easy to mold | Less durable under high stress | Low |

This strategic material selection guide provides valuable insights for B2B buyers considering the construction and performance of small box trucks, ensuring they make informed decisions that align with their operational needs and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for small Box Trucks

What Are the Main Stages of Manufacturing Small Box Trucks?

The manufacturing process of small box trucks involves several key stages, each integral to producing a reliable and efficient vehicle. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-quality materials, which typically include steel, aluminum, and composite materials for the truck’s frame, body, and cargo area. Suppliers must meet specific material standards to ensure durability and safety. For example, high-strength steel is often used to enhance structural integrity.

-

Forming: Once materials are prepared, they undergo various forming techniques. Techniques such as stamping, bending, and welding are commonly employed to create the truck’s chassis and body panels. Advanced machinery, including CNC (Computer Numerical Control) machines, ensures precision in shaping and cutting materials.

-

Assembly: After forming, the components are brought together in an assembly line. This stage includes fitting the chassis with the engine, transmission, axles, and other critical components. Automated systems may assist in streamlining the assembly process, improving efficiency and reducing human error. Quality checks are integrated throughout this phase to ensure that each part meets specifications.

-

Finishing: The final stage of manufacturing involves painting and applying protective coatings to enhance aesthetics and protect against corrosion. This stage may also include the installation of interior elements, such as seating and dashboard components. Quality assurance teams monitor the process to ensure that all finishes meet industry standards.

Which Quality Assurance Standards Are Relevant for Small Box Trucks?

Quality assurance (QA) is crucial in ensuring that small box trucks meet safety and performance standards. Various international and industry-specific standards guide manufacturers in establishing robust QA processes.

-

ISO 9001: This international standard outlines criteria for a quality management system. Adherence to ISO 9001 ensures that manufacturers maintain consistent quality in their products and services, which is critical for B2B buyers looking for reliability.

-

CE Marking: For businesses operating in Europe, CE marking indicates that a product meets EU safety, health, and environmental protection requirements. This certification is vital for ensuring compliance with European regulations, making it an important consideration for buyers in the region.

-

API Standards: Although primarily focused on the petroleum and natural gas industries, certain API (American Petroleum Institute) standards may be relevant for specific components of box trucks, particularly those related to fuel systems and safety.

How Are Quality Control Checkpoints Implemented in Manufacturing?

Quality control (QC) checkpoints are integral to ensuring that every aspect of the manufacturing process adheres to established standards. These checkpoints can be categorized into three main types:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials and components upon arrival at the manufacturing facility. Materials are checked for compliance with specifications, ensuring that only high-quality inputs are used in production.

-

In-Process Quality Control (IPQC): During the assembly and manufacturing stages, IPQC ensures that each process step meets quality standards. This may involve checking welds, component fits, and alignment throughout the assembly line. Real-time monitoring can help identify defects early, reducing waste and rework.

-

Final Quality Control (FQC): After assembly, each vehicle undergoes a comprehensive inspection. This includes performance testing, safety checks, and visual inspections to ensure that the finished product meets all specifications. FQC is critical for verifying that the truck is ready for the market.

What Common Testing Methods Are Used to Ensure Quality?

Testing methods play a crucial role in quality assurance for small box trucks. Manufacturers typically employ several techniques to verify that their products meet safety and performance standards.

-

Functional Testing: This involves assessing the truck’s operational capabilities, such as engine performance, braking efficiency, and steering response. Functional tests simulate real-world conditions to ensure reliability.

-

Load Testing: Load testing evaluates the truck’s capacity to carry weight safely. This is particularly important for box trucks, which are often used for transporting goods. Manufacturers must ensure that the vehicle can handle its maximum payload without compromising safety.

-

Durability Testing: This testing assesses how well the truck withstands wear and tear over time. Manufacturers may subject vehicles to extreme conditions, including temperature fluctuations and rough terrain, to gauge their resilience.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, verifying the quality control processes of suppliers is essential to ensure that they receive high-quality products. There are several strategies to achieve this:

-

Supplier Audits: Conducting audits of potential suppliers allows buyers to assess their manufacturing processes and quality control measures firsthand. This includes reviewing documentation, observing production practices, and inspecting facilities.

-

Quality Assurance Reports: Buyers should request detailed reports on quality assurance processes, including results from previous inspections and tests. These documents provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control practices. These agencies often have expertise in specific industries and can offer valuable insights into compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, must navigate specific quality control nuances. Understanding these can help mitigate risks associated with purchasing small box trucks.

-

Regulatory Compliance: Different regions have varying regulatory requirements. Buyers should familiarize themselves with local standards and ensure that their suppliers comply. For instance, compliance with emission standards may differ significantly between Europe and South America.

-

Cultural Considerations: Cultural differences can impact communication and expectations regarding quality. Buyers should establish clear lines of communication with suppliers and set realistic expectations to avoid misunderstandings.

-

Logistical Challenges: International shipping can introduce additional risks, such as damage during transit. Buyers should ensure that their suppliers implement proper packaging and handling procedures to protect products during shipping.

In conclusion, understanding the manufacturing processes and quality assurance standards for small box trucks is crucial for international B2B buyers. By focusing on supplier verification and compliance with relevant standards, businesses can ensure they make informed purchasing decisions that align with their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘small Box Trucks’

Introduction

This sourcing guide serves as a practical checklist for B2B buyers looking to procure small box trucks. With the growing demand for efficient transportation solutions across various sectors, selecting the right vehicle is crucial for operational success. This guide outlines essential steps to ensure a well-informed and strategic purchase.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the first step in sourcing small box trucks. Consider factors such as payload capacity, engine type, and box dimensions to ensure the vehicle meets your operational needs.

– Payload Capacity: Assess how much weight you typically transport to determine the necessary Gross Vehicle Weight Rating (GVWR).

– Box Dimensions: Ensure the box size aligns with the type of goods you will be transporting, maximizing space without compromising maneuverability.

Step 2: Research Market Options

Conduct thorough market research to identify available models and their features. This step helps in comparing various brands and configurations, ensuring you find the best fit for your needs.

– Brand Reputation: Investigate the reliability and performance history of different manufacturers, focusing on those known for durability and service support.

– Model Variants: Look into the different models offered by each brand to explore options that may provide better features at a competitive price.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s vital to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region to gauge their reliability.

– Supplier Credentials: Verify certifications, experience, and customer testimonials to ensure the supplier meets industry standards.

– After-Sales Support: Inquire about warranty terms, maintenance services, and parts availability to avoid future complications.

Step 4: Verify Compliance with Local Regulations

Ensure that the box trucks you are considering comply with local transportation regulations and standards. This step is crucial to avoid legal issues and ensure safe operation.

– Emissions Standards: Check that the vehicles meet environmental regulations in your region, especially if you operate in urban areas with strict emissions controls.

– Safety Compliance: Ensure the vehicles adhere to safety requirements, including features like anti-lock brakes and stability control systems.

Step 5: Assess Total Cost of Ownership

Calculate the total cost of ownership (TCO) beyond the initial purchase price. This includes maintenance, insurance, fuel efficiency, and potential financing costs.

– Maintenance Costs: Investigate the average maintenance expenses for the models you are considering to anticipate long-term costs.

– Fuel Efficiency: Compare fuel consumption ratings to assess ongoing fuel costs, which can significantly impact your budget.

Step 6: Conduct Test Drives

Before finalizing your purchase, arrange for test drives of the shortlisted trucks. This hands-on evaluation allows you to assess handling, comfort, and overall performance.

– Driving Experience: Pay attention to how the truck handles under various conditions, including tight spaces and heavy loads.

– Comfort and Usability: Evaluate the driver’s cabin features and accessibility, as these can affect driver satisfaction and productivity.

Step 7: Finalize Purchase and Negotiate Terms

Once you have selected the best option, engage in negotiations to secure favorable terms. Ensure all aspects of the deal, including payment terms and delivery timelines, are clearly defined.

– Payment Options: Explore different payment methods, including leasing or financing, to find the most manageable option for your budget.

– Delivery and Setup: Confirm delivery schedules and any setup services included in the purchase to ensure a smooth transition into your operations.

By following this checklist, B2B buyers can navigate the complexities of sourcing small box trucks and make informed decisions that align with their business needs.

Comprehensive Cost and Pricing Analysis for small Box Trucks Sourcing

When sourcing small box trucks, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. The cost of these vehicles is influenced by various components, including materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

What Are the Key Cost Components for Small Box Trucks?

-

Materials: The primary materials used in box truck manufacturing include steel, aluminum, and various plastics. The quality and source of these materials can significantly impact the overall cost. For instance, high-grade steel may be more expensive but offers better durability and safety features.

-

Labor: Labor costs vary by region and the skill level required for assembly and quality assurance. Regions with higher labor costs, such as Europe, may lead to higher overall truck prices compared to countries in South America or Africa where labor can be more cost-effective.

-

Manufacturing Overhead: This includes costs associated with running the manufacturing facility, including utilities, equipment maintenance, and indirect labor. Efficient manufacturing processes can help reduce overhead costs, thereby lowering the final price for buyers.

-

Tooling: The initial investment in tooling for production can be substantial. Custom designs or unique specifications may require additional tooling costs, which can be passed on to buyers.

-

Quality Control (QC): Rigorous QC processes ensure that the trucks meet safety and performance standards. While this can increase initial costs, it often leads to lower maintenance costs and better performance in the long run.

-

Logistics: Transportation costs for delivering box trucks can vary significantly depending on distance, shipping methods, and the volume of trucks ordered. Buyers should consider these costs when evaluating total expenses.

-

Margin: Manufacturers typically include a profit margin in their pricing. This margin can fluctuate based on market demand, competition, and the uniqueness of the truck’s features.

What Influences Pricing for Small Box Trucks?

Several factors can influence the pricing of small box trucks:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts, making it advantageous for businesses planning to purchase multiple units.

-

Specifications and Customization: Tailored specifications such as engine types, cargo capacities, and additional features can increase costs. Buyers should weigh the benefits of customization against the added expense.

-

Material Quality and Certifications: Trucks built with higher-quality materials or those that meet specific certifications (e.g., safety, emissions) typically command higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established manufacturers may charge a premium for their proven track record.

-

Incoterms: Understanding Incoterms is crucial for international buyers as they dictate responsibilities for shipping, risk, and insurance, which can impact overall costs.

What Are Effective Buyer Tips for Negotiating Small Box Truck Prices?

-

Conduct Thorough Market Research: Understanding the average market prices for different models can empower buyers during negotiations.

-

Negotiate on Volume: If planning a bulk purchase, leverage this to negotiate better pricing or additional services such as extended warranties.

-

Evaluate Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, fuel efficiency, and resale value when calculating TCO. This perspective can justify a higher upfront cost if long-term savings are evident.

-

Understand Pricing Nuances for International Transactions: Be aware of potential tariffs, import duties, and exchange rates that can affect pricing. Buyers in regions like Africa or South America may encounter different financial implications than those in Europe.

-

Request Detailed Quotes: Ensure that quotes include breakdowns of all costs involved, including shipping and potential tariffs, to avoid unexpected expenses.

Disclaimer on Indicative Prices

Prices for small box trucks can fluctuate based on market conditions, availability, and regional economic factors. It is advisable for buyers to consult multiple sources and obtain detailed quotes to ensure accurate budgeting for their acquisitions.

Alternatives Analysis: Comparing small Box Trucks With Other Solutions

Introduction to Alternative Solutions for Small Box Trucks

When considering logistics and transportation needs, small box trucks are a popular choice for businesses looking to transport goods efficiently. However, it’s essential to explore alternative solutions that may offer different benefits or efficiencies. This analysis compares small box trucks with two viable alternatives: cargo vans and freight services. Each option has unique characteristics that can influence a business’s decision based on their specific requirements.

Comparison Table

| Comparison Aspect | Small Box Trucks | Cargo Vans | Freight Services |

|---|---|---|---|

| Performance | High capacity, stable | Moderate capacity, agile | Very high capacity, scalable |

| Cost | Mid-range purchase/lease | Lower initial cost | Variable based on distance |

| Ease of Implementation | Requires more training | Easier to drive, no special training | Minimal setup, just scheduling |

| Maintenance | Moderate, parts availability | Lower, fewer mechanical issues | Varies, dependent on provider |

| Best Use Case | Regular deliveries, bulky items | Small to medium loads, urban deliveries | Large shipments, inter-city transport |

Detailed Breakdown of Alternatives

Cargo Vans: Are They a Viable Option for My Business?

Cargo vans are a flexible alternative to small box trucks, particularly suitable for urban deliveries. They typically have a lower initial purchase cost and are easier to drive, requiring no specialized training. However, their cargo capacity is limited compared to box trucks, making them less ideal for transporting larger or bulkier items. Businesses focused on quick, agile deliveries in congested areas may find cargo vans to be a more efficient choice, especially when maneuverability is a concern. However, they may not offer the same level of protection for goods during transport, which can be a drawback.

Freight Services: When to Consider Outsourcing Transportation?

Freight services provide an alternative for businesses that require the transportation of large shipments over long distances without the need for maintaining a fleet. This option is particularly advantageous for companies looking to scale their logistics operations without the overhead costs associated with vehicle ownership. The downside is that freight services can be more variable in cost and may involve longer lead times for delivery, especially if using less-than-truckload (LTL) services. This solution is best suited for businesses that prioritize capacity and scalability over immediate access to vehicles.

Conclusion: How to Choose the Right Solution for Your Business?

Selecting the right transportation solution involves assessing your specific logistical needs, including the nature of the goods being transported, budget constraints, and operational flexibility. Small box trucks excel in providing a balance of capacity and control, making them ideal for businesses that frequently move large or bulky items. Cargo vans are excellent for businesses focused on urban deliveries with smaller loads, while freight services are optimal for companies that need to transport larger quantities over longer distances without the burden of fleet management. By carefully evaluating these alternatives, B2B buyers can make informed decisions that align with their operational strategies and growth objectives.

Essential Technical Properties and Trade Terminology for small Box Trucks

Understanding the essential technical properties and terminology associated with small box trucks is crucial for B2B buyers looking to make informed purchasing decisions. This section outlines critical specifications and common trade terms that can impact the procurement process and overall operational efficiency.

What Are the Key Technical Specifications for Small Box Trucks?

-

Gross Vehicle Weight Rating (GVWR)

The GVWR indicates the maximum weight a truck can safely carry, including its own weight. For small box trucks, this typically ranges from 8,000 to 14,000 lbs. Knowing the GVWR is vital for compliance with local regulations and ensuring that the vehicle can handle the intended payload without compromising safety. -

Payload Capacity

This specification refers to the maximum weight of cargo that the truck can carry, excluding its own weight. For instance, a truck with a GVWR of 10,000 lbs and an empty weight of 6,000 lbs would have a payload capacity of 4,000 lbs. Understanding payload capacity helps businesses choose the right vehicle for their shipping needs and avoid overloading, which can lead to increased wear and tear. -

Cubic Capacity of the Cargo Area

This measurement indicates the volume of cargo space available inside the truck’s box. For small box trucks, cubic capacity often ranges from 400 to 1,200 cubic feet. This specification is essential for businesses that need to transport bulk goods, as it directly impacts how much product can be loaded and delivered in one trip. -

Engine Specifications

Key engine specs, including horsepower and torque, are critical for assessing a truck’s performance. For example, a small box truck might have a V8 engine delivering 285 HP and 295 ft-lbs of torque. Higher horsepower and torque ratings can improve acceleration and load-carrying capabilities, which are vital for businesses that require quick deliveries. -

Towing Capacity

This indicates how much weight the truck can tow behind it, which is crucial for businesses that may need to haul trailers or additional equipment. A small box truck may have a towing capacity of around 6,000 lbs, allowing for versatile operation, especially in logistics and transportation sectors. -

Transmission Type

Most small box trucks feature automatic transmissions, which offer ease of use and efficiency. Knowing the type of transmission helps buyers understand fuel efficiency and driving comfort, especially in urban environments where stop-and-go traffic is common.

What Are Common Trade Terms in the Box Truck Industry?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM products is crucial for buyers looking for reliable replacements or upgrades for their trucks. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest quantity of a product that a supplier is willing to sell. For businesses purchasing multiple trucks or parts, knowing the MOQ can help in budgeting and inventory management. -

RFQ (Request for Quotation)

An RFQ is a standard business process where buyers request pricing and terms from suppliers for specific products. This term is particularly relevant for bulk purchases of trucks or components, helping buyers compare costs effectively. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international transactions to avoid disputes and ensure smooth logistics. -

Fleet Management

This term encompasses all activities related to managing a company’s vehicle fleet, including maintenance, tracking, and optimizing vehicle performance. For businesses relying on small box trucks for deliveries, effective fleet management can lead to cost savings and improved service delivery. -

Upfit

Upfitting refers to the process of customizing a truck with specialized equipment or features to meet specific business needs. Understanding the upfit options available can help businesses maximize the utility of their small box trucks.

By grasping these technical specifications and trade terms, B2B buyers can make better-informed decisions, ensuring they select the right small box trucks for their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the small Box Trucks Sector

What Are the Key Market Dynamics and Trends Impacting the Small Box Truck Sector?

The small box truck market is currently experiencing significant growth driven by the increasing demand for last-mile delivery services, particularly in urban areas. As e-commerce continues to expand, businesses require efficient logistics solutions, prompting a surge in the demand for versatile vehicles like small box trucks. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly looking for trucks that can navigate narrow streets while offering ample cargo space.

Emerging technologies are also influencing sourcing trends. The integration of telematics and fleet management systems allows businesses to optimize routes and monitor vehicle performance in real time. Additionally, online marketplaces are becoming vital sourcing platforms, enabling buyers to compare prices and specifications easily across different suppliers. As sustainability becomes a priority, many buyers are now favoring manufacturers that offer fuel-efficient and environmentally friendly options, including hybrid and electric models.

Moreover, the global supply chain landscape is evolving. International buyers must navigate fluctuating supply chain costs and potential delays due to geopolitical factors or trade regulations. This requires strategic planning and flexibility in sourcing to mitigate risks associated with procurement.

How Can Sustainability and Ethical Sourcing Impact Small Box Truck Purchases?

Sustainability is becoming a crucial consideration for B2B buyers in the small box truck sector. The environmental impact of manufacturing and operating vehicles prompts buyers to seek options that minimize their carbon footprint. Small box trucks are increasingly available with features that enhance fuel efficiency and reduce emissions, making them appealing to eco-conscious businesses.

Ethical sourcing is equally important. Buyers are now more inclined to partner with manufacturers who demonstrate commitment to ethical labor practices and sustainable material sourcing. Certifications such as ISO 14001 (Environmental Management) and LEED (Leadership in Energy and Environmental Design) can provide assurance that a supplier adheres to high environmental and ethical standards.

As businesses aim to bolster their corporate social responsibility (CSR) initiatives, sourcing trucks made from recycled or environmentally friendly materials can enhance brand reputation. Additionally, investing in sustainable options can lead to cost savings in the long run through reduced fuel consumption and lower maintenance costs.

What Is the Historical Context of the Small Box Truck Market?

The small box truck market has evolved significantly over the past few decades. Initially designed for local deliveries, these vehicles have adapted to meet the growing demands of e-commerce and urban logistics. The introduction of advanced manufacturing techniques and materials has led to improvements in payload capacity, fuel efficiency, and overall performance.

In the late 20th century, the popularity of small box trucks surged as businesses recognized their versatility for various applications, from moving services to retail deliveries. Today, as the market continues to evolve, innovations such as electric drivetrains and enhanced safety features are shaping the future of small box trucks, making them an essential component of modern supply chains worldwide.

In summary, the small box truck sector is marked by dynamic market trends that reflect broader shifts in logistics, technology, and sustainability. International B2B buyers must stay informed and adaptable to navigate these changes effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of small Box Trucks

-

How do I choose the right small box truck for my business needs?

Choosing the right small box truck involves assessing your specific business requirements, such as payload capacity, dimensions, and engine type. Consider the types of goods you will transport, as well as the distances involved. Analyze your operational environment; for example, if you need to navigate tight urban spaces, a smaller, more maneuverable truck may be ideal. Additionally, evaluate fuel efficiency and maintenance costs to ensure long-term sustainability. Consulting with suppliers for expert recommendations based on your unique needs can also be beneficial. -

What are the common financing options for purchasing small box trucks?

Common financing options for small box trucks include bank loans, leasing agreements, and financing through third-party providers. Many suppliers offer flexible payment plans that can cater to your budget. Some buyers opt for leasing, which allows them to use the truck without a large upfront investment, while others may prefer loans for ownership. It’s advisable to shop around and compare interest rates and terms to find the best deal. Consider consulting with a financial advisor familiar with commercial vehicle purchases to explore the best options for your business. -

What is the process for importing small box trucks internationally?

The process for importing small box trucks typically involves several key steps: selecting a reliable supplier, ensuring compliance with local regulations, and arranging for shipping and customs clearance. Begin by vetting suppliers and obtaining necessary documentation, including vehicle registration and maintenance records. Ensure the trucks meet the import regulations of your country, such as emission standards. Once you finalize the purchase, coordinate with a logistics provider to handle shipping and customs processes, ensuring all duties and taxes are accounted for to avoid delays. -

How can I ensure the quality of small box trucks before purchasing?

To ensure the quality of small box trucks, conduct thorough due diligence on the supplier by reviewing their reputation, certifications, and customer feedback. Request detailed service records and inspection reports for the trucks you are interested in. If possible, arrange for an on-site inspection or hire a third-party service to assess the vehicle’s condition. Additionally, inquire about warranties or return policies to safeguard your investment. Engaging with suppliers who have a track record of reliability can significantly reduce the risk of acquiring subpar vehicles. -

What customization options are available for small box trucks?

Customization options for small box trucks can vary widely depending on the supplier. Common modifications include shelving systems, refrigeration units, and specialized loading ramps to enhance functionality. You may also consider adding branding elements, such as company logos or specific paint jobs, to promote your business. It is essential to discuss your customization needs upfront with the supplier to ensure they can accommodate your requests and provide solutions that align with your operational requirements. -

What are the minimum order quantities (MOQ) for purchasing small box trucks?

Minimum order quantities (MOQ) for small box trucks can differ based on the supplier and the specific model. Some suppliers may have an MOQ of one truck, while others might require bulk purchases to secure better pricing or specific customization options. Always clarify the MOQ with your supplier early in the negotiation process to avoid misunderstandings. If you are considering a larger fleet, it may be advantageous to negotiate terms that allow for flexibility in order size, particularly for first-time buyers. -

What payment terms should I expect when buying small box trucks?

Payment terms for small box trucks can vary depending on the supplier and your negotiation. Common arrangements include full payment upfront, deposits with the remainder upon delivery, or installment plans over an agreed period. Some suppliers may also offer financing options through third-party lenders, allowing you to spread payments over time. It is crucial to review and understand the terms of payment, including any interest rates or penalties for late payments, to ensure they align with your financial strategy. -

How do I manage logistics for receiving small box trucks from international suppliers?

Managing logistics for receiving small box trucks from international suppliers involves coordinating shipping, customs clearance, and final delivery. Start by selecting a reliable freight forwarder experienced in handling vehicle imports. They can assist with documentation, shipping schedules, and customs requirements. Ensure that you have all necessary permits and clearances in place before the vehicle arrives. Once cleared, arrange for local transportation to your facility. Keeping open communication with both the supplier and logistics provider can help mitigate any potential delays or issues during the process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 Small Box Trucks Manufacturers & Suppliers List

1. Penske – Used Light Duty Box Trucks

Domain: penskeusedtrucks.com

Registered: 2001 (24 years)

Introduction: Used Light Duty Box Trucks for Sale – Penske Used Trucks. Also known as cutaway vans, high cube vans, straight trucks, parcel vans, and 1 ton trucks (in Canada). Suitable for light duty furniture/appliances hauling and used as moving trucks. Typically feature a garage door-like rear door that rolls up. Typical inventory includes Ford E-Series trucks and GMC Savana G-Series Trucks. Dimensions and C…

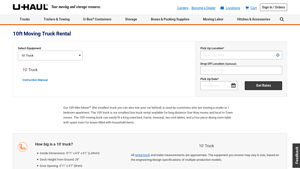

2. U-Haul – 10ft Moving Truck Rental

Domain: uhaul.com

Registered: 1995 (30 years)

Introduction: 10ft Moving Truck Rental

– Type: Mini Mover®

– Ideal for: Moving a studio or 1 bedroom apartment

– Dimensions: Inside – 9’11” x 6’3″ x 6’1″ (LxWxH)

– Deck Height from Ground: 29″

– Door Opening: 5’11” x 5’7″ (WxH)

– Max Load: 2,850 lbs.

– Gross Vehicle Weight: 8,600 lbs. max.

– Empty Weight: 5,790 lbs.

– Towing Capacity: Up to 6,000 lbs.

– Volume: 402 cu. ft.

– Loading Ramp: None

– Clearance Heigh…

3. Box Truck – Straight Truck Listings

Domain: commercialtrucktrader.com

Registered: 2004 (21 years)

Introduction: Box Truck – Straight Truck For Sale – Commercial Truck Trader

Key Product Details:

– Categories: Box Truck – Straight Truck

– Total Listings: 15,645

– Top Makes:

– FREIGHTLINER: 2,995

– CHEVROLET: 2,563

– ISUZU: 2,364

– FORD: 2,346

– INTERNATIONAL: 2,174

– HINO: 1,124

– GMC: 1,111

– RAM: 393

– KENWORTH: 151

– Available Colors:

– MORGAN: 588

– WABASH: 168

– SUPREME: 163

-…

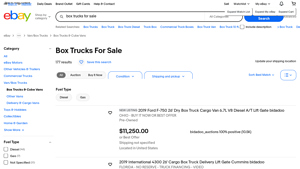

4. Box Trucks – Key Product Details

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Key product details for box trucks on eBay include:

– Fuel Types: Diesel (146 items), Gas (17 items), Not Specified (20 items)

– Makes: Chevrolet (2), Ford (22), Freightliner (55), GMC (2), International (26), Isuzu (36), Mitsubishi (2), Peterbilt (6)

– Model Years: 2022 (12), 2021 (7), 2020 (18), 2019 (25), 2018 (25), 2017 (17), 2015 (13), 2013 (6)

– For Sale By: Dealer (150), Private Seller (33)…

5. Penske – 12 Foot Moving Truck Rental

Domain: pensketruckrental.com

Registered: 1999 (26 years)

Introduction: 12 Foot Moving Truck Rental from Penske:

– Ideal for moving 1-2 rooms, such as a dorm or efficiency apartment.

– Interior dimensions: 12 ft. long x 6 ft. 6 in. wide x 6 ft. 1 in. high.

– Up to 78 sq. ft. of floor space and 450 cu. ft. of loading space.

– Load capacity: up to 3,100 lbs.

– Fuel tank: 33-gallon capacity with up to 12 mpg.

– Features: V-8 engine, automatic transmission, backup c…

6. Enterprise Trucks – Pickup Trucks

Domain: enterprisetrucks.com

Registered: 2004 (21 years)

Introduction: {“Pickup Trucks”: [{“Model”: “Standard Pickup”, “Payload”: “Up to 1,800 lbs.”, “Additional Features”: [“Air Conditioning”, “Automatic Transmission”, “AM/FM Radio”]}, {“Model”: “1/2 Ton 4-Wheel Drive Pickup”, “Payload”: “Up to 2,000 lbs.”, “Additional Features”: [“Automatic transmission”, “Air-conditioning”]}, {“Model”: “3/4 Ton Pickup”, “Payload”: “Up to 4,000 lbs.”, “Additional Features”: [“Autom…

7. Gabrielli Truck Sales – Box Trucks

Domain: gabriellitruck.com

Registered: 1996 (29 years)

Introduction: Gabrielli Truck Sales offers a wide range of box trucks for sale in NY, NJ, and CT. These versatile commercial trucks, also known as straight trucks, cube vans, or step vans, are ideal for light-duty applications and general deliveries. Customers can purchase or lease new box trucks or buy used ones. The selection includes box truck chassis-only options and box trucks with a joined chassis and cab…

Strategic Sourcing Conclusion and Outlook for small Box Trucks

In navigating the landscape of small box trucks, strategic sourcing emerges as a vital component for international B2B buyers. The diverse offerings, from light-duty models like the GMC Savana to more robust options such as the Isuzu NPR, cater to a variety of business needs, whether for logistics, delivery, or storage. Understanding the specifications and capabilities of these vehicles can significantly impact operational efficiency and cost-effectiveness.

Moreover, exploring used options can lead to substantial savings, as evidenced by the competitive pricing of models with manageable mileage. Buyers should prioritize transparency regarding vehicle history and maintenance records to make informed decisions. Strategic partnerships with reliable suppliers and financing options can further enhance procurement processes, ensuring that businesses secure the best deals while maintaining operational integrity.

Looking ahead, the demand for efficient transportation solutions in emerging markets across Africa, South America, the Middle East, and Europe will only grow. B2B buyers are encouraged to leverage this opportunity by investing in small box trucks that align with their specific logistical requirements. Embrace the future of transportation—make strategic sourcing a priority today to position your business for success in a competitive marketplace.