Introduction: Navigating the Global Market for solar electric car

In the face of escalating energy costs and growing environmental concerns, sourcing solar electric cars presents a transformative opportunity for businesses worldwide. These innovative vehicles not only promise reduced dependency on fossil fuels but also significantly cut operational costs through their ability to harness solar energy. This comprehensive guide delves into the diverse landscape of solar electric cars, exploring various types—from compact city cars like the Squad to high-performance models like those from Aptera and Lightyear.

B2B buyers will find invaluable insights into applications suitable for different markets, supplier vetting processes, and a detailed analysis of associated costs. As international buyers from regions such as Africa, South America, the Middle East, and Europe—where solar resources are abundant—this guide empowers you to make informed purchasing decisions that align with your sustainability goals and operational needs.

By understanding the nuances of solar technology integration, vehicle performance specifications, and market trends, businesses can effectively navigate the complexities of this burgeoning sector. Whether you are looking to enhance your fleet’s sustainability or tap into the growing demand for eco-friendly transportation solutions, this guide serves as a crucial resource for leveraging solar electric cars to drive innovation and efficiency in your operations.

Understanding solar electric car Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Integrated Solar EV | Built-in solar panels for supplemental charging; off-grid capability | Fleet vehicles, delivery services | Pros: Reduced dependency on charging stations; Cons: Limited range without additional charging. |

| Solar City Car | Compact design; low-speed regulations; urban mobility focus | Urban transport, car-sharing platforms | Pros: Affordable and easy to park; Cons: May not meet high-speed transport needs. |

| Extended Range EV | High-efficiency solar panels; significant range extension | Long-distance travel, logistics | Pros: Increased operational range; Cons: Higher upfront costs for technology. |

| Solar-Powered Golf Cart | Designed for low-speed applications; ideal for closed environments | Resorts, campuses, gated communities | Pros: Eco-friendly; Cons: Limited to specific environments and uses. |

| Modular Solar EV | Swappable batteries; adaptable solar configurations | Versatile fleet operations | Pros: Flexibility in energy management; Cons: Complexity in maintenance and operation. |

What Are the Key Characteristics of Integrated Solar Electric Vehicles?

Integrated Solar Electric Vehicles (EVs) feature solar panels embedded into their design, allowing for on-the-go charging. This capability is particularly beneficial for fleet operations where vehicles can recharge during idle periods, thereby reducing reliance on traditional power sources. B2B buyers should consider the vehicle’s solar efficiency and compatibility with existing fleet management systems to maximize sustainability and cost savings.

How Do Solar City Cars Address Urban Mobility Needs?

Solar City Cars are designed for urban environments, typically complying with low-speed vehicle regulations. They provide an eco-friendly solution for short-distance travel, making them ideal for car-sharing services or daily commutes. B2B buyers focusing on urban transport solutions should assess the vehicle’s space efficiency, safety features, and ease of use, which can significantly enhance user experience in crowded cities.

Why Choose Extended Range Electric Vehicles for Long-Distance Applications?

Extended Range Electric Vehicles leverage advanced solar technology to provide substantial range extensions. Ideal for logistics and long-distance travel, these vehicles can operate more independently from charging infrastructure. For B2B buyers, evaluating the total cost of ownership, including potential fuel savings and maintenance, is crucial for justifying the investment in such technology.

What Are the Advantages of Solar-Powered Golf Carts for Specific Environments?

Solar-Powered Golf Carts are tailored for low-speed, enclosed environments such as golf courses, resorts, and campuses. They offer an eco-friendly alternative to gasoline-powered vehicles, aligning with sustainability goals. Buyers in this sector should consider the cart’s durability, maintenance needs, and operational costs to ensure it meets the specific demands of their environment.

How Do Modular Solar Electric Vehicles Enhance Fleet Flexibility?

Modular Solar Electric Vehicles feature interchangeable battery systems and customizable solar configurations, making them highly adaptable for various operational needs. This flexibility allows businesses to optimize their energy use based on specific routes and operational demands. B2B buyers should focus on the scalability of the modular systems and their compatibility with existing fleet infrastructure to ensure a seamless transition to solar mobility.

Key Industrial Applications of solar electric car

| Industry/Sector | Specific Application of Solar Electric Car | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Public Transportation | Solar-powered buses for urban transit systems | Reduced operational costs through lower fuel and maintenance expenses; enhanced sustainability image. | Evaluate solar panel efficiency, battery compatibility, and local regulations for public transport. |

| Logistics and Delivery | Solar electric vehicles for last-mile delivery services | Lower carbon footprint and fuel costs; potential for off-grid operations in remote areas. | Assess vehicle range, solar charging capabilities, and integration with existing logistics systems. |

| Tourism and Hospitality | Solar electric cars for eco-friendly tours | Attract environmentally conscious customers; reduce operational costs through solar energy. | Consider vehicle durability, comfort features, and local climate conditions for solar efficiency. |

| Agriculture | Solar electric vehicles for farm operations | Decreased reliance on fossil fuels; potential for off-grid charging in rural areas. | Focus on vehicle robustness, maintenance requirements, and compatibility with agricultural tools. |

| Corporate Fleets | Solar electric cars for employee transportation | Enhanced corporate sustainability goals; reduced fuel expenses and tax benefits. | Evaluate vehicle performance, solar charging efficiency, and total cost of ownership. |

How Can Solar Electric Cars Transform Public Transportation?

In urban transit systems, solar-powered buses are increasingly being adopted to reduce operational costs and carbon emissions. These vehicles utilize integrated solar panels to harness energy, allowing for lower fuel consumption and maintenance expenses. For international buyers, especially in regions like Africa and the Middle East, it is crucial to assess the efficiency of solar panels and the compatibility of batteries with local infrastructure to ensure compliance with public transport regulations.

What Role Do Solar Electric Cars Play in Logistics and Delivery?

In the logistics sector, solar electric vehicles are proving beneficial for last-mile delivery services. By utilizing solar energy, companies can significantly reduce their carbon footprint and fuel costs, while also enabling off-grid operations in remote areas. For B2B buyers in South America and Africa, it is essential to evaluate the vehicle’s range and solar charging capabilities, as well as how these vehicles can be integrated into existing logistics systems.

How Are Solar Electric Cars Enhancing Tourism and Hospitality?

In the tourism industry, solar electric cars are becoming popular for eco-friendly tours, appealing to environmentally conscious travelers. These vehicles not only reduce operational costs through solar energy but also enhance the business’s sustainability image. Buyers in Europe and South America should consider the vehicle’s durability and comfort features, along with local climate conditions, to optimize solar efficiency for tourist activities.

What Advantages Do Solar Electric Cars Offer in Agriculture?

Agricultural operations can benefit significantly from solar electric vehicles, which reduce reliance on fossil fuels and can be charged off-grid in rural areas. These vehicles are particularly advantageous for transporting goods and equipment across large farms, leading to cost savings and increased sustainability. Buyers must focus on the vehicle’s robustness, maintenance requirements, and how well it integrates with agricultural tools to maximize efficiency.

Why Should Corporations Consider Solar Electric Cars for Their Fleets?

For corporate fleets, solar electric cars provide an opportunity to enhance sustainability goals while reducing fuel expenses. The potential tax benefits and lower total cost of ownership make these vehicles attractive investments. International buyers should evaluate performance metrics, solar charging efficiency, and the overall cost of ownership to ensure alignment with corporate sustainability objectives.

3 Common User Pain Points for ‘solar electric car’ & Their Solutions

Scenario 1: High Initial Costs of Solar Electric Vehicles

The Problem:

Many B2B buyers, particularly in emerging markets across Africa and South America, face the challenge of high upfront costs when considering solar electric vehicles (SEVs). This initial investment can deter businesses from transitioning their fleets to more sustainable options, especially when balancing tight budgets and immediate operational costs. Buyers often worry about the return on investment (ROI) and whether the potential savings from reduced fuel and maintenance costs will offset the purchase price in the long run.

The Solution:

To address the financial barrier, businesses should explore financing options such as leasing agreements or government incentives tailored for sustainable transportation. Research local and international subsidies available for solar electric vehicles, as many countries offer tax breaks or grants to promote green technology. Additionally, creating a detailed cost-benefit analysis can help illustrate the long-term savings potential. By documenting the expected reductions in fuel costs and maintenance, buyers can present a compelling business case to stakeholders, highlighting that while the initial costs are higher, the operational savings will yield significant benefits over time.

Scenario 2: Limited Charging Infrastructure

The Problem:

In many regions, especially in parts of the Middle East and Africa, the infrastructure for charging electric vehicles remains underdeveloped. B2B buyers often express concerns about the availability of charging stations, particularly in rural areas or regions with less reliable electricity supply. This scarcity can lead to anxiety about the feasibility of integrating solar electric cars into their operations, especially for logistics and transportation companies that require dependable range and uptime.

The Solution:

B2B buyers should consider investing in solar charging stations as part of their infrastructure development strategy. By sourcing portable or modular solar charging solutions, companies can create their own charging networks that are independent of the traditional grid. This approach not only alleviates concerns about charging availability but also enhances the sustainability profile of the fleet. Furthermore, engaging with local governments to advocate for the development of solar infrastructure can foster partnerships that benefit the entire community, while also ensuring that the company’s operational needs are met.

Scenario 3: Misunderstandings About Solar Efficiency

The Problem:

A prevalent pain point among B2B buyers is the misconception regarding the efficiency and reliability of solar technology in electric vehicles. Many potential buyers are hesitant to invest in solar electric cars due to fears that solar panels will not generate enough power to meet their operational needs, especially in regions with variable weather patterns or limited sunlight hours. This skepticism can result in missed opportunities for businesses to adopt cleaner, more efficient transportation solutions.

The Solution:

To combat these misconceptions, B2B buyers should prioritize education and consultation with manufacturers and industry experts. Engaging in pilot programs that allow businesses to test solar electric vehicles in real-world conditions can help demonstrate their capabilities. Additionally, buyers should evaluate vehicles with integrated solar technology that maximizes efficiency, such as those with high-efficiency photovoltaic cells and innovative battery management systems. Providing data and case studies from similar businesses that have successfully implemented solar electric vehicles can also help alleviate concerns and showcase the reliability of solar technology. By becoming informed advocates for the technology, B2B buyers can confidently make decisions that align with their sustainability goals while addressing operational efficiency.

Strategic Material Selection Guide for solar electric car

What are the Key Materials Used in Solar Electric Cars?

When selecting materials for solar electric cars, several factors come into play, including performance, cost, and regional compliance. Below are analyses of four common materials used in the construction of solar electric vehicles (SEVs), focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

How Do Solar Cells Impact Performance in Solar Electric Cars?

Material: Monocrystalline Silicon

Monocrystalline silicon is a widely used material for solar cells in electric vehicles. It boasts high efficiency rates, typically between 15% to 22%, due to its single-crystal structure, which allows for better electron mobility. This material is highly durable and can withstand various environmental conditions, making it suitable for diverse climates.

Pros & Cons:

While monocrystalline silicon offers excellent efficiency and longevity, it is relatively expensive to produce, which can increase the overall cost of the vehicle. Manufacturing complexity is also a consideration, as the production process requires advanced technology and significant energy input.

Impact on Application:

Monocrystalline silicon’s high efficiency makes it an ideal choice for solar panels in vehicles, especially in regions with limited sunlight. However, its performance can be affected by extreme temperatures, which may be a concern in hotter climates like those in Africa or the Middle East.

Considerations for International Buyers:

Buyers from regions such as Brazil and Saudi Arabia should ensure compliance with local standards (e.g., ASTM or JIS) for solar technologies. The demand for high-efficiency panels may be higher in areas with less consistent sunlight.

What Role Does Aluminum Play in Solar Electric Car Construction?

Material: Aluminum

Aluminum is a lightweight metal commonly used for the structural components of solar electric cars. Its excellent strength-to-weight ratio contributes to improved vehicle efficiency and performance. Additionally, aluminum exhibits good corrosion resistance, making it suitable for various environmental conditions.

Pros & Cons:

The primary advantage of aluminum is its lightweight nature, which enhances the vehicle’s range and efficiency. However, it can be more expensive than steel and may require specialized manufacturing techniques, which can complicate production.

Impact on Application:

Aluminum’s corrosion resistance is particularly beneficial in humid or coastal regions, where traditional materials might degrade faster. Its lightweight properties also help in optimizing battery performance by reducing the overall vehicle weight.

Considerations for International Buyers:

International buyers should consider local availability and the cost of aluminum, which can vary significantly by region. Compliance with environmental regulations regarding aluminum production and recycling should also be a priority.

How Do Composite Materials Enhance Solar Electric Cars?

Material: Carbon Fiber Reinforced Polymer (CFRP)

CFRP is an advanced material that combines carbon fibers with a polymer matrix, resulting in a lightweight yet extremely strong material. Its use in solar electric cars can lead to significant weight savings, enhancing vehicle efficiency and performance.

Pros & Cons:

CFRP offers exceptional strength and durability, but it is one of the most expensive materials available. The manufacturing process is complex and requires specialized equipment, which can increase production times and costs.

Impact on Application:

CFRP’s lightweight nature can improve the vehicle’s range and handling, making it ideal for high-performance solar electric cars. However, its high cost may limit its use to premium models or specific components.

Considerations for International Buyers:

When sourcing CFRP, buyers must evaluate local suppliers and their capabilities. Compliance with international standards for composite materials is crucial, especially in regions like Europe, where regulations may be stricter.

What Benefits Does Glass Provide in Solar Electric Cars?

Material: Tempered Glass

Tempered glass is often used in solar electric vehicles for windows and solar panel covers. It is treated to withstand high temperatures and impacts, making it safer and more durable than standard glass.

Pros & Cons:

The primary advantage of tempered glass is its strength and safety features. However, it can be heavier than alternative materials, which may affect the overall weight of the vehicle.

Impact on Application:

Tempered glass can enhance the aesthetics of solar electric cars while providing protection for solar panels. Its ability to withstand environmental stressors makes it suitable for various climates.

Considerations for International Buyers:

Buyers should ensure that the glass used meets local safety standards and regulations. Additionally, sourcing tempered glass from local manufacturers can reduce shipping costs and lead times.

Summary Table of Material Selection for Solar Electric Cars

| Material | Typical Use Case for Solar Electric Car | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Monocrystalline Silicon | Solar panels for energy generation | High efficiency and durability | High production costs | High |

| Aluminum | Structural components | Lightweight, corrosion-resistant | More expensive than steel | Medium |

| Carbon Fiber Reinforced Polymer | Body panels and structural parts | Exceptional strength and lightweight | High cost and complex manufacturing | High |

| Tempered Glass | Windows and solar panel covers | Strong and safe | Heavier than alternatives | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for solar electric car

What Are the Key Stages in the Manufacturing Process of Solar Electric Cars?

The manufacturing process of solar electric cars involves several critical stages, each designed to ensure quality and efficiency. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Solar Electric Cars?

Material preparation is foundational to the production of solar electric vehicles (SEVs). This stage involves sourcing high-quality materials that meet specific performance and sustainability criteria. For solar panels, manufacturers typically utilize monocrystalline or polycrystalline silicon, known for their efficiency and durability. Other components, such as lightweight metals for the vehicle chassis and battery materials, are also carefully selected to optimize performance and reduce weight.

To ensure consistency and reliability, suppliers must adhere to international standards. For example, ISO 9001 certification indicates that a supplier has a robust quality management system in place. B2B buyers should verify these certifications to ensure they are sourcing from reputable suppliers.

What Forming Techniques Are Used in Solar Electric Vehicle Manufacturing?

The forming stage includes techniques such as stamping, molding, and extrusion, which shape the materials into components. Advanced manufacturing technologies, such as computer numerical control (CNC) machining and 3D printing, are increasingly used to produce intricate parts with high precision.

For solar panels, the forming process involves creating the photovoltaic cells and encapsulating them in protective layers. Manufacturers often employ techniques like lamination to enhance durability and performance under various environmental conditions.

B2B buyers should inquire about the forming techniques used by potential suppliers to understand their capabilities and the potential impact on product quality.

How Are Components Assembled in Solar Electric Cars?

Assembly is a critical stage where various components come together to form the final vehicle. This stage typically involves both manual and automated processes, ensuring that the assembly is efficient while maintaining high-quality standards.

Integrating solar panels into the vehicle’s design is a significant aspect of this stage. Manufacturers must ensure that the panels are securely mounted and that the electrical connections are reliable. Quality control checkpoints during assembly, such as in-process quality control (IPQC), help to catch any defects early.

B2B buyers should request information about the assembly processes and the specific technologies employed, as this can significantly affect the final product’s performance and reliability.

What Finishing Techniques Are Essential for Solar Electric Vehicles?

The finishing stage involves applying coatings, paint, and other treatments to enhance aesthetics and protect the vehicle from environmental factors. For solar electric cars, this might include applying UV-resistant coatings to the solar panels to prolong their life.

Additionally, manufacturers perform final inspections and quality checks at this stage to ensure the vehicle meets all specifications and standards. The final quality control (FQC) process is critical for B2B buyers, as it ensures that the product is ready for market and free of defects.

What Quality Control Standards Are Relevant for Solar Electric Cars?

Quality assurance is paramount in the manufacturing of solar electric vehicles. Adhering to international standards such as ISO 9001 is essential for maintaining quality across all manufacturing stages. Other relevant certifications may include CE marking for compliance with European safety and environmental standards, and industry-specific certifications related to electrical components.

How Are Quality Control Checkpoints Established in the Manufacturing Process?

Quality control checkpoints are established at various stages of the manufacturing process to ensure that each component meets quality standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, this step ensures that any defects are identified and corrected before the final assembly.

-

Final Quality Control (FQC): A thorough inspection of the finished product to ensure it adheres to all specifications before shipping.

B2B buyers should actively inquire about the specific quality control processes and checkpoints in place at manufacturing facilities to ensure a reliable product.

What Common Testing Methods Are Used in Quality Assurance for Solar Electric Cars?

Testing methods play a crucial role in the quality assurance process. Some common testing methods for solar electric vehicles include:

-

Performance Testing: Evaluating the efficiency of solar panels and battery systems under various conditions to ensure they meet performance specifications.

-

Durability Testing: Assessing the vehicle’s resistance to environmental factors such as UV exposure, moisture, and temperature fluctuations.

-

Safety Testing: Conducting crash tests and electrical safety assessments to ensure compliance with safety standards.

B2B buyers should request test reports and data from suppliers to verify that their products have undergone rigorous testing and meet international safety standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

To ensure that suppliers maintain high-quality standards, B2B buyers can adopt several verification strategies:

-

Supplier Audits: Conducting on-site audits to evaluate the manufacturing processes, quality control measures, and adherence to international standards.

-

Quality Reports: Requesting detailed quality reports that outline the results of various tests and inspections performed throughout the manufacturing process.

-

Third-Party Inspections: Engaging independent third-party inspection services to conduct assessments and provide unbiased evaluations of supplier practices.

-

Certification Verification: Verifying the authenticity of certifications claimed by suppliers, such as ISO 9001 or CE marking, to ensure compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of several nuances regarding quality control:

-

Regulatory Compliance: Different countries may have varying regulations regarding vehicle safety and environmental standards. It is crucial for buyers to understand these regulations to ensure compliance when importing vehicles.

-

Cultural Differences: Quality expectations may vary based on cultural norms and business practices. Building strong relationships with suppliers and communicating quality expectations clearly can mitigate misunderstandings.

-

Supply Chain Considerations: Buyers should assess the entire supply chain, as disruptions can affect the quality of the final product. Understanding the supplier’s sourcing and logistics practices is essential for ensuring consistent quality.

By taking these factors into account, B2B buyers can make informed decisions when sourcing solar electric cars, ensuring they partner with reliable suppliers committed to quality and sustainability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘solar electric car’

This guide serves as a comprehensive checklist for B2B buyers aiming to procure solar electric cars. Given the increasing demand for sustainable transportation solutions, it’s essential to approach sourcing with a strategic mindset. The following steps will help you navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring the solar electric cars meet your operational needs. Consider factors such as range, battery capacity, and solar panel efficiency.

– Range Requirements: Determine how far the vehicle needs to travel on a single charge, considering both solar and battery power.

– Performance Metrics: Assess acceleration, top speed, and other performance indicators relevant to your market.

Step 2: Identify Your Target Market

Understanding your target market’s demographics and geographical needs will guide your sourcing decisions. Different regions may have varying requirements based on climate, terrain, and urban infrastructure.

– Climate Considerations: In sunny regions, prioritize vehicles with high solar efficiency; in less sunny areas, consider battery capacity more heavily.

– Regulatory Compliance: Familiarize yourself with local laws regarding electric vehicles, as compliance can affect procurement decisions.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request detailed company profiles, including case studies and references from similar industries or regions.

– Supplier Reputation: Look for feedback from other B2B buyers regarding the supplier’s reliability and product performance.

– Certifications and Standards: Ensure the supplier adheres to international standards for electric vehicles and solar technology.

Step 4: Assess Sustainability Credentials

Sustainability is a key selling point for solar electric cars. Verify that your potential suppliers have robust sustainability practices and certifications.

– Life Cycle Analysis: Consider how the vehicle’s production, use, and disposal impact the environment.

– Material Sourcing: Investigate whether the supplier uses recycled materials or sustainable practices in manufacturing.

Step 5: Conduct a Cost-Benefit Analysis

A detailed cost-benefit analysis will help you understand the financial implications of your purchase. This includes not only the upfront costs but also long-term savings from reduced fuel and maintenance expenses.

– Total Cost of Ownership (TCO): Calculate the expected lifespan, maintenance costs, and potential savings from solar charging.

– Financing Options: Explore leasing or financing plans that may be available to ease upfront costs.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, ensure you negotiate favorable terms that protect your interests. This includes warranty coverage, delivery timelines, and service agreements.

– Warranty and Support: Clarify what warranties are offered and the extent of post-purchase support.

– Delivery and Installation: Confirm the logistics of vehicle delivery and any necessary installation of solar charging infrastructure.

Step 7: Finalize Your Procurement Plan

Consolidate all gathered information into a formal procurement plan that outlines your sourcing strategy, budget, and timelines. This will serve as a roadmap for executing your purchase.

– Stakeholder Approval: Present the plan to relevant stakeholders for buy-in and approval.

– Implementation Timeline: Create a timeline for the procurement process, including key milestones from order to delivery.

By following these steps, you can effectively navigate the procurement of solar electric cars, ensuring that you choose the right vehicles to meet your business’s sustainability goals and operational needs.

Comprehensive Cost and Pricing Analysis for solar electric car Sourcing

What Are the Key Cost Components for Sourcing Solar Electric Cars?

When considering the sourcing of solar electric cars, various cost components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials represent a significant portion of the cost structure, primarily due to the high-quality photovoltaic (PV) cells used in solar panels, battery technology, and the lightweight materials that contribute to vehicle efficiency. The integration of advanced solar technology requires sourcing from specialized suppliers, which can impact costs.

Labor costs fluctuate based on the region and skill set required. Countries with advanced manufacturing capabilities may present higher labor costs but often yield better quality products due to skilled workmanship.

Manufacturing overhead encompasses all indirect costs associated with production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these overheads, thus impacting the final pricing.

Tooling is another critical component, as specialized equipment is necessary for producing solar electric vehicles. The initial investment in tooling can be significant, but it can be amortized over large production runs.

Quality Control (QC) is essential in the automotive industry, particularly for solar electric vehicles that rely heavily on technology. Robust QC processes ensure reliability and safety, which can add to costs but ultimately support a stronger market reputation.

Logistics costs vary based on the destination and the chosen Incoterms. International buyers need to factor in shipping, customs duties, and insurance, which can significantly affect total costs.

Margins typically reflect the competitive landscape and the perceived value of the technology being offered. Manufacturers may set higher margins for innovative products that promise significant environmental benefits.

How Do Price Influencers Affect the Sourcing of Solar Electric Cars?

Several factors influence pricing in the solar electric car market, particularly for B2B buyers. Volume and Minimum Order Quantity (MOQ) play a crucial role; larger orders usually command lower per-unit costs due to economies of scale. Buyers should negotiate for favorable terms based on their projected demand.

Specifications and customization also impact pricing. Vehicles tailored to specific market needs or regulatory requirements may incur additional costs. Buyers should assess their requirements carefully to avoid unnecessary expenses.

Materials quality and certifications are essential for ensuring safety and reliability. Higher-quality materials may elevate initial costs but can result in long-term savings through durability and reduced maintenance.

Supplier factors such as reputation, reliability, and the geographical location of suppliers can affect pricing. Local suppliers may reduce logistics costs, while established suppliers may offer better warranties and support.

Incoterms define the responsibilities of buyers and sellers in international transactions, influencing total costs. Understanding these terms can help buyers manage risks and avoid unexpected expenses.

What Tips Can Help B2B Buyers Negotiate Better Pricing for Solar Electric Cars?

To achieve cost efficiency, buyers should focus on negotiation strategies. Building strong relationships with suppliers can lead to better pricing and terms. Consider leveraging competitive quotes from multiple suppliers to enhance negotiating power.

Understanding the Total Cost of Ownership (TCO) is critical. This includes not just the purchase price, but also ongoing costs such as maintenance, energy consumption, and potential tax incentives for using renewable technology. Analyzing TCO can provide a clearer picture of the long-term value.

Pricing nuances for international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should be taken into account. Currency fluctuations, regional tariffs, and local market conditions can significantly affect pricing. Buyers should remain vigilant about these factors when finalizing agreements.

Lastly, it is crucial to include a disclaimer for indicative prices in discussions and agreements. Prices may vary based on market conditions and should be confirmed at the time of order placement.

In conclusion, a thorough understanding of the cost structure, price influencers, and effective negotiation strategies can empower B2B buyers to make informed decisions in the emerging market of solar electric cars.

Alternatives Analysis: Comparing solar electric car With Other Solutions

Exploring Viable Alternatives to Solar Electric Cars

As the demand for sustainable transportation solutions grows, businesses must evaluate various technologies to determine the best fit for their operational needs. Solar electric cars have emerged as a compelling option, leveraging renewable energy for mobility. However, there are alternative solutions worth considering, each with unique advantages and challenges. This analysis will compare solar electric cars with two viable alternatives: electric vehicles (EVs) powered by traditional grid electricity and hydrogen fuel cell vehicles.

| Comparison Aspect | Solar Electric Car | Electric Vehicle (EV) | Hydrogen Fuel Cell Vehicle |

|---|---|---|---|

| Performance | Up to 400 miles range; daily solar charge | 200-400 miles range; fast charging available | 300-400 miles range; quick refueling |

| Cost | Higher upfront cost; lower operating costs | Moderate upfront cost; electricity costs vary | High upfront cost; hydrogen fuel costs vary |

| Ease of Implementation | Requires sunny locations; limited by solar potential | Widely available charging infrastructure | Limited refueling stations; infrastructure still developing |

| Maintenance | Low maintenance; fewer moving parts | Moderate maintenance; battery replacement needed | Moderate to high; fuel cell maintenance required |

| Best Use Case | Urban and suburban environments with ample sunlight | Diverse applications; suitable for long-distance travel | Long-haul transport; heavy-duty applications |

Detailed Breakdown of Alternatives

Electric Vehicles (EVs)

Electric vehicles represent a well-established alternative to solar electric cars. They rely on charging from the traditional grid, offering varying ranges based on battery capacity. The infrastructure for EV charging is expanding rapidly, providing convenience in both urban and rural areas. However, the reliance on grid electricity can lead to higher operating costs, particularly in regions with expensive electricity. Additionally, battery degradation over time necessitates maintenance, which can be a significant consideration for fleet operators.

Hydrogen Fuel Cell Vehicles

Hydrogen fuel cell vehicles are gaining traction as a clean transportation alternative. They offer quick refueling times comparable to gasoline vehicles and can cover long distances with a single tank. Hydrogen fuel cells produce zero emissions, making them attractive from an environmental perspective. However, the current hydrogen infrastructure is sparse, limiting their practical use in many regions. The high cost of hydrogen production and the vehicles themselves can also pose a barrier for businesses considering this option.

Conclusion: How to Choose the Right Solution for Your Business

When selecting the best transportation solution, B2B buyers should carefully assess their operational requirements, geographical factors, and budget constraints. Solar electric cars offer a sustainable option, particularly in sunny regions where off-grid capabilities can be maximized. In contrast, traditional electric vehicles provide flexibility and a more developed charging network, making them suitable for varied applications. Meanwhile, hydrogen fuel cell vehicles may excel in specific sectors such as logistics and heavy-duty transport but require further investment in infrastructure. By weighing these factors, businesses can make informed decisions that align with their sustainability goals and operational needs.

Essential Technical Properties and Trade Terminology for solar electric car

What Are the Key Technical Properties of Solar Electric Cars?

1. Solar Panel Efficiency

Solar panel efficiency is crucial for determining how effectively a solar electric car can convert sunlight into usable energy. Measured in percentage, it indicates the amount of solar energy captured and converted into electricity. High-efficiency panels (over 20%) can significantly extend the vehicle’s range and reduce reliance on grid charging, making them a vital consideration for B2B buyers aiming for sustainability and operational efficiency.

2. Battery Capacity

Battery capacity, typically measured in kilowatt-hours (kWh), denotes the total amount of energy the battery can store. A higher capacity allows for longer driving ranges between charges, which is essential for operational efficiency in various business applications, from fleet management to personal use. Understanding battery specifications helps businesses assess the total cost of ownership and operational downtime.

3. Vehicle Range

Range refers to the maximum distance a solar electric car can travel on a full charge, supplemented by solar energy. This metric is critical for businesses that require reliable transportation solutions without frequent recharging. An extended range can enhance productivity and reduce the total cost of ownership, making it a key selling point in B2B negotiations.

4. Weight and Material Composition

The weight of a vehicle directly affects its efficiency and performance. Lightweight materials, such as carbon fiber or aluminum, can enhance speed and energy efficiency. B2B buyers should prioritize vehicles that utilize advanced materials to optimize performance while ensuring durability, especially in challenging environments typical in regions like Africa and South America.

5. Charging Options

Understanding the various charging options available, including solar charging, standard AC charging, and DC fast charging, is essential for operational flexibility. Vehicles equipped with multiple charging options can cater to diverse operational needs, allowing businesses to choose the most efficient charging method based on their location and infrastructure.

6. Integration of Advanced Technologies

Features such as regenerative braking systems, smart energy management, and integrated vehicle-to-grid (V2G) technology can enhance the overall efficiency of solar electric cars. These technologies allow for better energy utilization, cost savings, and a reduced carbon footprint, appealing to environmentally conscious businesses.

What Are Common Trade Terms in the Solar Electric Vehicle Industry?

1. OEM (Original Equipment Manufacturer)

In the context of solar electric cars, OEM refers to companies that produce components or entire vehicles that are marketed under another brand. Understanding OEM relationships is crucial for B2B buyers, as it influences product quality, supply chain reliability, and warranty considerations.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest order size that a supplier is willing to accept. This term is vital for B2B negotiations, as it helps buyers understand inventory requirements and plan their procurement strategies accordingly. Knowing the MOQ can also affect pricing strategies and cash flow management.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to request price quotes for specific products or services. In the solar electric vehicle industry, an RFQ helps buyers gauge market pricing and supplier capabilities, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are globally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk management, and logistics, ensuring smoother cross-border operations.

5. TCO (Total Cost of Ownership)

TCO encompasses all costs associated with acquiring and operating a solar electric vehicle over its lifespan, including purchase price, maintenance, fuel (or energy) costs, and depreciation. This term is essential for businesses to evaluate the long-term financial implications of their investments in solar electric mobility.

6. V2G (Vehicle-to-Grid)

V2G technology allows electric vehicles to return electricity to the grid, providing potential revenue streams for businesses and enhancing energy management. Understanding V2G can be beneficial for B2B buyers interested in maximizing their investment in solar electric vehicles while contributing to grid stability.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions, enhance operational efficiency, and align their purchases with sustainability goals in the growing solar electric vehicle market.

Navigating Market Dynamics and Sourcing Trends in the solar electric car Sector

What Are the Key Market Dynamics Driving the Solar Electric Car Sector?

The solar electric car market is experiencing significant growth driven by several global factors. Increasing environmental awareness and government mandates for reduced carbon emissions are pushing the automotive industry towards sustainable solutions. In regions like Africa and South America, where traditional charging infrastructure may be lacking, solar electric vehicles (SEVs) offer a unique advantage by enabling off-grid charging through integrated solar panels. Furthermore, innovations in solar technology, such as high-efficiency photovoltaic cells, are making solar vehicles more viable and appealing to B2B buyers looking for sustainable transportation options.

Emerging trends in the B2B sector include a focus on modularity and adaptability of solar electric vehicles, allowing companies to customize vehicles for specific uses, such as urban mobility or commercial delivery services. The rise of shared mobility solutions, particularly in densely populated areas, is also influencing the design and functionality of solar electric cars, aligning with urban sustainability goals. As international buyers from regions like Brazil and Saudi Arabia increasingly seek alternative energy solutions, partnerships with manufacturers that prioritize solar technology will be essential to meet local market demands.

How Can Businesses Ensure Sustainability and Ethical Sourcing in Solar Electric Cars?

Sustainability is not just a buzzword; it is a crucial aspect of the solar electric vehicle supply chain. B2B buyers must prioritize sourcing materials that are environmentally friendly and ethically produced. This includes ensuring that suppliers of components like batteries and solar panels adhere to sustainable practices, such as minimizing waste and reducing carbon footprints. Certifications like ISO 14001 for environmental management can serve as indicators of a supplier’s commitment to sustainability.

Moreover, the use of recycled materials in manufacturing solar electric vehicles is becoming increasingly important. B2B buyers should consider partnerships with companies that utilize recycled metals and plastics, as this can significantly reduce the environmental impact of vehicle production. Additionally, engaging in transparent supply chain practices not only enhances brand reputation but also aligns with the growing consumer demand for ethically sourced products. As global regulations tighten around sustainability, businesses that prioritize ethical sourcing will be better positioned to thrive in the solar electric vehicle market.

What is the Evolution of the Solar Electric Car Market?

The solar electric car sector has evolved significantly since the introduction of electric vehicles in the late 20th century. Initially, solar technology was limited in its application, primarily due to high costs and low efficiency. However, advancements in photovoltaic technology and battery storage have transformed solar electric vehicles into feasible alternatives to traditional combustion engines.

In recent years, companies like Aptera Motors and Lightyear have pioneered the integration of solar panels into vehicle design, enabling cars to harness solar energy for daily driving needs. This evolution has been particularly beneficial in regions with abundant sunlight, such as parts of Africa and the Middle East, where solar-powered mobility can reduce reliance on conventional energy sources. As technology continues to advance and consumer awareness grows, the solar electric car market is poised for further expansion, offering exciting opportunities for B2B buyers seeking sustainable transportation solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of solar electric car

-

How do I solve the challenge of sourcing reliable solar electric cars for my business?

To effectively source reliable solar electric cars, start by identifying reputable manufacturers and suppliers with a proven track record in the solar vehicle sector. Research their production capabilities, certifications, and customer reviews. Engage in direct communication to clarify their solar technology, warranty options, and after-sales support. Consider attending trade shows or industry conferences to establish connections and gain insights into the latest innovations. Finally, request samples or demonstrations to assess quality and performance before making a bulk purchase. -

What is the best solar electric car for urban mobility needs?

For urban mobility, compact solar electric cars such as the SQUAD Solar City Car or similar models are highly effective. These vehicles are designed for short commutes, easy parking, and maneuverability in congested areas. Their solar panels enable automatic charging, reducing reliance on grid power and enhancing sustainability. Evaluate factors such as speed, passenger capacity, and safety features to determine the best fit for your operational requirements. Additionally, consider vehicles with swappable batteries for added convenience. -

How can I customize a solar electric car to meet my specific business needs?

Customization options for solar electric cars typically include modifications in design, battery capacity, and additional features like enhanced safety or comfort elements. When approaching manufacturers, clearly outline your specific requirements, such as branding, color schemes, or technological integrations (e.g., telematics systems). Many suppliers offer bespoke solutions, so inquire about their customization capabilities and lead times. Ensure to review any associated costs and validate that modifications do not compromise vehicle performance or warranty. -

What are the minimum order quantities (MOQ) for purchasing solar electric cars?

Minimum order quantities (MOQ) for solar electric cars can vary significantly between manufacturers. Typically, larger manufacturers may require a MOQ of 10-50 units to optimize production efficiency, while smaller or niche suppliers may accommodate smaller orders. When negotiating, clarify the MOQ upfront and explore options for trial orders or pilot programs if your requirements are lower. This approach allows you to assess product quality and market demand without committing to large quantities initially. -

What payment terms should I expect when sourcing solar electric cars internationally?

Payment terms for international purchases of solar electric cars vary by supplier and region. Common terms include a deposit (often 30-50%) upon order confirmation, with the balance due before shipment or upon delivery. Some suppliers may offer financing options or payment plans to facilitate larger orders. Always review the payment terms carefully and consider using secure payment methods such as letters of credit or escrow services to mitigate risk during international transactions. -

How do I ensure quality assurance (QA) for solar electric cars?

To ensure quality assurance (QA) for solar electric cars, request detailed product specifications and certifications from manufacturers, including compliance with international safety standards. Conduct factory audits or request third-party inspections during production. Additionally, establish a clear warranty policy that covers defects and performance issues. Post-purchase, consider implementing a regular maintenance schedule to uphold vehicle performance and longevity, as well as obtaining feedback from users to address any concerns promptly. -

What logistics considerations should I keep in mind when importing solar electric cars?

When importing solar electric cars, logistics considerations include shipping methods, customs regulations, and import duties. Evaluate whether to use sea freight or air freight based on cost and urgency. Ensure compliance with local regulations regarding vehicle importation, including emissions standards and safety certifications. Additionally, factor in lead times for shipping and customs clearance, and maintain communication with your logistics provider to address any potential delays. Proper documentation is crucial to avoid complications during transit. -

How do I vet potential suppliers of solar electric cars for reliability?

To vet potential suppliers of solar electric cars, conduct thorough background checks, including their financial stability, years in business, and customer testimonials. Request references from existing clients to gauge satisfaction levels and support responsiveness. Assess their production capabilities by visiting their facilities if possible, or reviewing their manufacturing processes through virtual tours. Additionally, inquire about after-sales support, warranty policies, and availability of spare parts, as these factors contribute significantly to the reliability of your supplier partnership.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 5 Solar Electric Car Manufacturers & Suppliers List

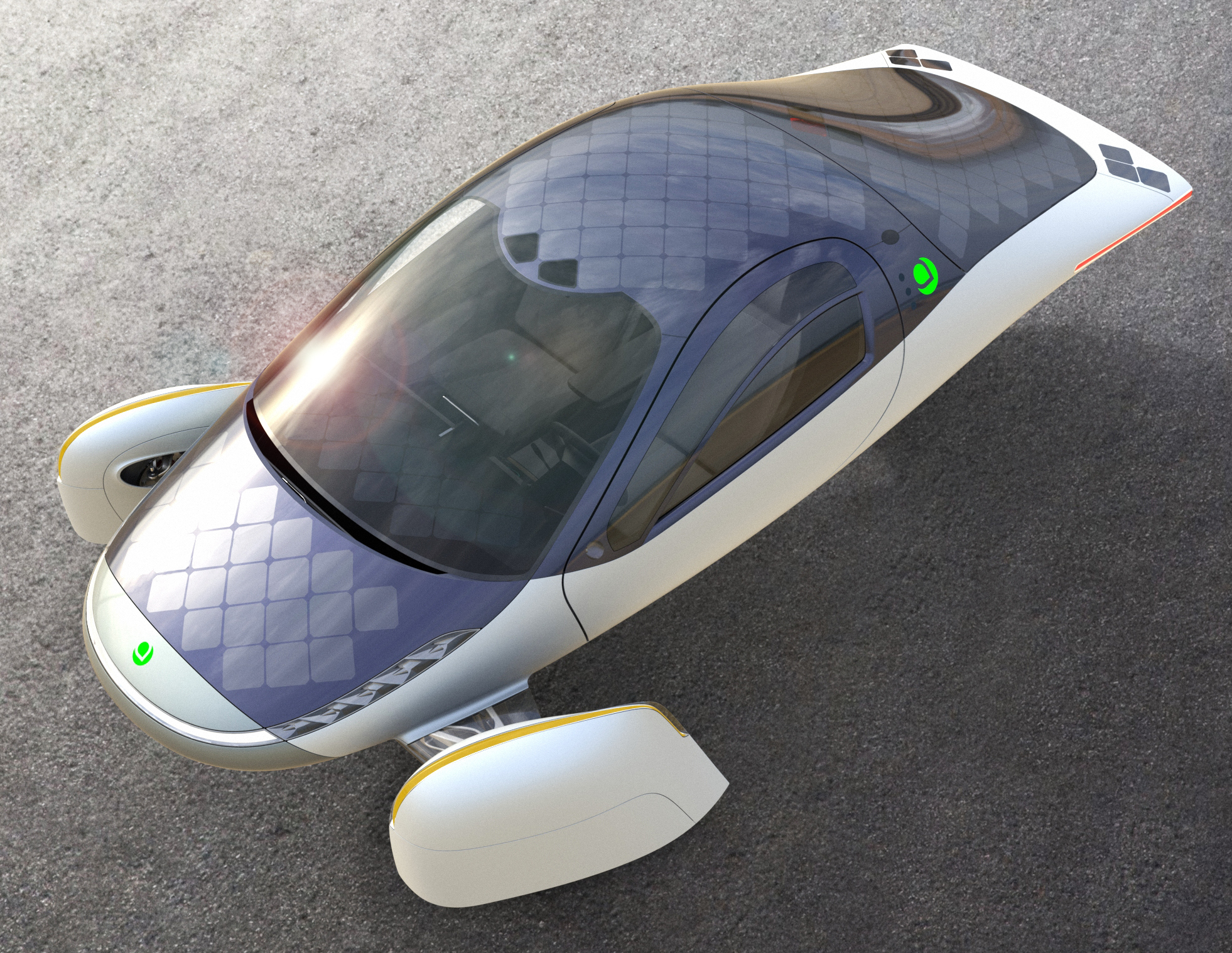

1. Aptera – Solar Electric Vehicle

Domain: aptera.us

Registered: 2019 (6 years)

Introduction: Aptera is a solar electric vehicle designed to be highly efficient and requires no charging for most daily use. Key specifications include:

– Integrated solar cells generating approximately 700 watts

– Up to 40 miles of free solar-powered driving per day

– 400 miles of range per full charge

– Acceleration from 0-60 mph in less than 6 seconds

The vehicle is currently in testing and validation,…

2. GEM – Electric Car with Solar Panels

Domain: gemcar.com

Registered: 1998 (27 years)

Introduction: GEM Electric Car with Solar Panels: EV solar panels charge on the go and off the grid, extending drive time between charges by up to 40%. The solar electric car design integrates solar panels seamlessly with the vehicle, maximizing off-grid charging efficiency and sustainability goals. Key features include:

– Sustainability: Reduces grid-tied energy consumption with all-electric, zero-emission GE…

3. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

4. Cnet – Aptera Solar EV

Domain: cnet.com

Registered: 1994 (31 years)

Introduction: This company, Cnet – Aptera Solar EV, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Repsol – Solar Cars

Domain: repsol.com

Registered: 1996 (29 years)

Introduction: Solar cars are vehicles that utilize solar energy as their primary power source. They work by converting sunlight into electricity through photovoltaic cells, which are typically mounted on the car’s surface. This electricity can then be used to power the vehicle’s electric motor. Solar cars are designed to be energy-efficient and sustainable, contributing to reduced carbon emissions and reliance …

Strategic Sourcing Conclusion and Outlook for solar electric car

In conclusion, the strategic sourcing of solar electric vehicles (SEVs) presents a transformative opportunity for businesses across diverse markets, particularly in Africa, South America, the Middle East, and Europe. As global demand for sustainable transportation solutions grows, integrating solar technology into electric vehicles not only enhances operational efficiency but also significantly reduces carbon footprints. Companies like Aptera, Lightyear, GEM, and Squad exemplify innovative approaches to solar mobility, providing products that offer extended range, reduced dependence on traditional charging infrastructure, and sustainability.

For B2B buyers, the value of strategic sourcing lies in identifying reliable partners who can deliver cutting-edge solar electric cars tailored to specific regional needs and regulatory environments. Investing in solar EVs can lead to long-term cost savings, enhanced brand reputation, and compliance with increasing environmental regulations.

Looking ahead, the solar electric vehicle market is poised for growth, driven by advancements in technology and rising consumer demand for green alternatives. We encourage international B2B buyers to explore partnerships that will not only meet current mobility needs but also pave the way for a more sustainable future. Embrace this opportunity to lead in the clean mobility revolution and drive positive change in your communities.