Introduction: Navigating the Global Market for 60v eletric car electric vehicle

In today’s rapidly evolving transportation landscape, sourcing reliable and efficient 60V electric car electric vehicles presents a significant challenge for B2B buyers. As businesses and governments across Africa, South America, the Middle East, and Europe, including countries like Nigeria and Saudi Arabia, increasingly prioritize sustainable and cost-effective transportation solutions, understanding the nuances of the 60V electric vehicle market becomes crucial. This comprehensive guide delves into various types of 60V electric vehicles, their applications, and the advantages they offer over lower voltage alternatives.

From exploring the technical specifications of 60V lithium batteries to identifying key suppliers, this guide equips international buyers with the knowledge needed to make informed purchasing decisions. We address critical considerations such as performance metrics, customization options, and regulatory compliance, ensuring that your investment aligns with both operational needs and environmental goals.

By providing actionable insights into supplier vetting processes and cost analysis, this guide empowers businesses to navigate the complexities of the 60V electric vehicle market confidently. Whether you are a fleet manager, a logistics provider, or an electric vehicle distributor, you will find the resources necessary to optimize your procurement strategy and enhance your competitive edge in the global market.

Understanding 60v eletric car electric vehicle Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Scooters | Lightweight, speed up to 50 km/h, suitable for urban areas | Delivery services, urban commuting | Pros: Cost-effective, easy to maneuver. Cons: Limited range for long distances. |

| Low-Speed Electric Vehicles | Typically under 50 km/h, designed for short trips | Golf courses, resorts, urban neighborhoods | Pros: Eco-friendly, low operational cost. Cons: Limited speed and power. |

| Utility Electric Vehicles | Robust design, can carry cargo, higher battery capacity | Warehousing, agriculture, logistics | Pros: Versatile, can handle heavier loads. Cons: Higher initial investment. |

| Personal Electric Vehicles | Designed for single riders, compact, efficient | Personal transportation, short commutes | Pros: Space-efficient, good for individuals. Cons: Not suitable for passengers. |

| Customized Electric Vehicles | Tailored specifications, can include advanced features | Special projects, niche markets | Pros: Meets specific needs, high adaptability. Cons: Potentially longer lead times. |

What Are the Key Characteristics of Electric Scooters?

Electric scooters are characterized by their lightweight design and maximum speeds typically reaching up to 50 km/h. These vehicles are particularly suitable for urban environments where maneuverability and ease of parking are crucial. B2B buyers in sectors like delivery services and urban commuting can benefit from their cost-effectiveness and low maintenance requirements. However, businesses should be aware of their limited range, making them less suitable for long-distance travel.

How Do Low-Speed Electric Vehicles Differ from Other Types?

Low-speed electric vehicles (LSEVs) are designed for short-distance travel, operating at speeds below 50 km/h. They are ideal for environments such as golf courses and resort areas, where eco-friendliness and low operational costs are paramount. B2B applications include tourism and local transport services. While they offer substantial savings on fuel and maintenance, buyers must consider their limitations in speed and power compared to higher-voltage vehicles.

What Makes Utility Electric Vehicles a Good Choice for Businesses?

Utility electric vehicles are built for durability and can carry significant cargo loads, making them suitable for applications in warehousing, agriculture, and logistics. Their robust design often includes higher battery capacities, allowing them to operate efficiently over longer periods. While they provide versatility and can handle heavier loads, the initial investment can be higher than other types, which is a critical factor for budget-conscious buyers.

Why Choose Personal Electric Vehicles for Individual Use?

Personal electric vehicles are compact and designed for single riders, making them an efficient option for short commutes. They are particularly attractive for B2B buyers focused on individual transportation solutions, as they occupy less space and are easy to store. However, these vehicles are not designed to carry passengers, which limits their applicability in shared transport scenarios.

What Are the Benefits of Customized Electric Vehicles?

Customized electric vehicles can be tailored to meet specific business needs, incorporating advanced features like enhanced battery life or specialized cargo areas. This adaptability makes them suitable for niche markets and special projects. While they can effectively meet unique requirements, buyers should consider the potential for longer lead times and higher costs associated with customization.

Key Industrial Applications of 60v eletric car electric vehicle

| Industry/Sector | Specific Application of 60v Electric Car Electric Vehicle | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Logistics and Delivery | Last-Mile Delivery Solutions | Efficient transportation of goods in urban areas | Battery life, charging infrastructure, vehicle durability |

| Tourism and Recreation | Golf Carts and Personal Transport | Enhanced guest experience and eco-friendly transport | Customization options, maintenance support, battery type |

| Public Transportation | Electric Shuttle Services | Reduced carbon footprint and operational costs | Compliance with local regulations, range requirements, safety features |

| Agriculture | Utility Vehicles for Farms | Improved efficiency in farm operations | Terrain adaptability, load capacity, battery performance |

| Urban Mobility | Electric Scooters for City Commuting | Cost-effective and eco-friendly commuting solutions | Weight limits, motor power, availability of service centers |

How are 60v Electric Vehicles Transforming Key Industries?

Logistics and Delivery: How Can 60v Electric Vehicles Optimize Last-Mile Delivery?

In the logistics sector, 60v electric vehicles are increasingly utilized for last-mile delivery solutions. Their compact size and ease of maneuverability make them ideal for navigating urban environments, reducing delivery times while minimizing carbon emissions. Businesses benefit from lower operational costs compared to traditional fuel-powered vehicles. When sourcing, companies should consider battery life, the availability of charging infrastructure, and the vehicle’s durability to withstand daily use.

Tourism and Recreation: What Role Do 60v Electric Vehicles Play in Enhancing Guest Experiences?

In the tourism industry, 60v electric vehicles such as golf carts and personal transport vehicles are widely adopted to enhance guest experiences at resorts and parks. These vehicles offer a quiet, eco-friendly way for guests to explore large areas without disturbing the natural environment. For B2B buyers, it’s crucial to evaluate customization options, maintenance support, and the type of battery used to ensure optimal performance and longevity.

Public Transportation: How Are 60v Electric Vehicles Contributing to Sustainable Urban Transport?

60v electric vehicles are making significant strides in public transportation through electric shuttle services. These vehicles help reduce urban traffic congestion and lower emissions, aligning with global sustainability goals. Businesses involved in this sector must ensure compliance with local regulations, assess range requirements, and prioritize safety features to attract environmentally conscious consumers.

Agriculture: How Are 60v Electric Vehicles Enhancing Farm Operations?

In agriculture, utility vehicles powered by 60v batteries facilitate various tasks, from transporting produce to assisting in fieldwork. Their electric nature allows for quieter operations, which is beneficial in maintaining a peaceful farming environment. Buyers should focus on the vehicle’s adaptability to different terrains, load capacity, and battery performance to meet their specific operational needs.

Urban Mobility: Why Are 60v Electric Scooters a Smart Choice for City Commuting?

Urban mobility solutions are evolving with the introduction of 60v electric scooters, providing a cost-effective and eco-friendly commuting option for city dwellers. These scooters help reduce traffic congestion and offer a convenient alternative for short-distance travel. When sourcing, businesses should consider weight limits, motor power, and the availability of service centers to ensure a reliable and efficient commuting experience.

3 Common User Pain Points for ’60v eletric car electric vehicle’ & Their Solutions

Scenario 1: Limited Range for Urban Commuting

The Problem: B2B buyers in urban areas often face the challenge of limited range when sourcing 60V electric vehicles (EVs) for short-distance commuting or last-mile delivery. Many electric vehicles in this category can struggle to cover the required distances without needing frequent recharges. This limitation can hinder operational efficiency, especially for businesses relying on timely deliveries or employee transportation.

The Solution: To address this issue, buyers should look for 60V electric vehicles that offer higher capacity batteries, such as those with 30Ah or 45Ah ratings. Additionally, it is crucial to assess the vehicle’s energy efficiency and real-world range claims under various load conditions. Buyers can enhance their fleet’s operational efficiency by implementing a strategic battery management system that includes scheduling regular charging during downtimes, such as overnight or during breaks. Furthermore, consider integrating solar charging stations in your operational areas, particularly in sunny regions, to reduce dependency on grid power and extend the effective range of your fleet.

Scenario 2: Maintenance and Repair Challenges

The Problem: Another common pain point for B2B buyers is the difficulty in maintaining and repairing 60V electric vehicles. Many businesses may not have the specialized knowledge or access to service facilities equipped to handle electric vehicle repairs. This can lead to prolonged vehicle downtime and increased operational costs, particularly in regions with limited access to technical support.

The Solution: Buyers should prioritize sourcing 60V electric vehicles from manufacturers that offer comprehensive after-sales support, including warranties, training for in-house maintenance staff, and a clear supply chain for spare parts. Establishing a partnership with the manufacturer can lead to training programs that equip your team with the necessary skills for basic maintenance and troubleshooting. Additionally, consider investing in diagnostic tools compatible with 60V EVs, which can streamline the maintenance process and reduce the reliance on external service providers.

Scenario 3: Regulatory Compliance and Licensing Issues

The Problem: In many regions, including parts of Africa and the Middle East, regulations surrounding electric vehicles can be complex and vary widely. B2B buyers may find themselves unsure about the compliance requirements for 60V electric vehicles, which can lead to delays in deployment and potential legal issues.

The Solution: To navigate regulatory challenges effectively, buyers should conduct thorough research on local laws governing electric vehicles. Engaging with local authorities and industry associations can provide insights into compliance requirements, including licensing, registration, and safety standards. Additionally, working with a knowledgeable legal consultant or a local partner who understands the regulatory landscape can simplify the process. It’s also beneficial to choose 60V electric vehicles that meet international safety and performance standards, as this can facilitate smoother compliance with local regulations and enhance marketability in different regions.

Strategic Material Selection Guide for 60v eletric car electric vehicle

What Are the Key Materials Used in 60V Electric Car Electric Vehicles?

When selecting materials for 60V electric vehicles, it is crucial to consider their properties, advantages, and limitations. The right choice can significantly impact performance, durability, and compliance with international standards. Below, we analyze four common materials used in the construction of these vehicles.

How Does Aluminum Perform in 60V Electric Car Electric Vehicles?

Aluminum is widely used in electric vehicle manufacturing due to its lightweight and excellent corrosion resistance. It typically has a temperature rating of around 600°C and can withstand moderate pressure levels, making it suitable for various structural components.

Pros & Cons:

Aluminum’s lightweight nature enhances energy efficiency and range, which is vital for electric vehicles. However, its cost can be relatively high compared to steel, and it may require specialized welding techniques, increasing manufacturing complexity.

Impact on Application:

Aluminum is particularly effective in chassis and body panels, where weight reduction is critical for performance. It is compatible with various media, including battery fluids and environmental conditions typical in regions like Africa and the Middle East.

Considerations for International Buyers:

International buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions. The demand for lightweight materials is growing in markets like Nigeria and Saudi Arabia, where efficiency is paramount.

What Role Does Steel Play in 60V Electric Car Electric Vehicles?

Steel, particularly high-strength low-alloy (HSLA) steel, is another common material used in electric vehicles. It boasts a high tensile strength and can withstand harsh environmental conditions. Steel typically has a temperature rating of around 400°C and excellent pressure resistance.

Pros & Cons:

Steel is cost-effective and widely available, making it a popular choice for structural components. However, it is heavier than aluminum, which can negatively impact energy efficiency. Additionally, steel is prone to corrosion if not adequately treated.

Impact on Application:

Steel is commonly used in frames, axles, and other load-bearing components. Its durability makes it suitable for various terrains, especially in regions with rough road conditions like South America.

Considerations for International Buyers:

Buyers should be aware of corrosion resistance requirements and ensure compliance with standards such as ASTM A572 for structural steel. In regions like Europe, where environmental regulations are stringent, the use of galvanized steel may be preferred.

How Does Lithium-Ion Battery Technology Influence 60V Electric Car Electric Vehicles?

Lithium-ion batteries are the backbone of electric vehicles, providing the necessary energy storage. They typically have a voltage rating of 60V and can operate effectively within a temperature range of -20°C to 60°C.

Pros & Cons:

Lithium-ion batteries offer high energy density and long cycle life, making them ideal for electric vehicles. However, they can be expensive and require careful management to prevent overheating and ensure safety.

Impact on Application:

These batteries are essential for the overall performance of electric vehicles, influencing range and charging times. They are compatible with various charging systems, making them versatile for international markets.

Considerations for International Buyers:

Buyers must ensure compliance with international safety standards, such as IEC 62133 for battery safety. In emerging markets, the ability to source affordable batteries is crucial for cost-effective vehicle production.

What Is the Importance of Composite Materials in 60V Electric Car Electric Vehicles?

Composite materials, particularly carbon fiber and fiberglass, are increasingly used in electric vehicle manufacturing due to their high strength-to-weight ratio. They can withstand temperatures up to 300°C and offer excellent corrosion resistance.

Pros & Cons:

Composites are lightweight and can significantly enhance vehicle performance. However, they are often more expensive to produce and may require specialized manufacturing processes.

Impact on Application:

Composite materials are ideal for body panels and interior components, where weight savings can lead to improved efficiency. Their resistance to environmental factors makes them suitable for diverse climates.

Considerations for International Buyers:

Buyers should consider the availability of composite materials and associated manufacturing capabilities in their region. Compliance with standards like ASTM D3039 for composite testing is essential for quality assurance.

Summary Table of Material Selection for 60V Electric Vehicles

| Material | Typical Use Case for 60V Electric Car Electric Vehicle | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Chassis and body panels | Lightweight and corrosion-resistant | Higher cost and manufacturing complexity | High |

| Steel | Frames and load-bearing components | Cost-effective and widely available | Heavier and prone to corrosion | Medium |

| Lithium-Ion | Energy storage system | High energy density and long cycle life | Expensive and requires careful management | High |

| Composite | Body panels and interior components | High strength-to-weight ratio | Higher production costs and complexity | High |

This strategic material selection guide aims to assist B2B buyers in making informed decisions regarding the materials used in 60V electric vehicles, considering performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 60v eletric car electric vehicle

What Are the Main Stages in the Manufacturing Process of 60V Electric Cars?

The manufacturing process for 60V electric vehicles involves several critical stages, each designed to ensure the highest quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality materials such as lithium iron phosphate (LiFePO4) for batteries, steel for the chassis, and various electronic components. Suppliers must meet specific industry standards to ensure reliability. B2B buyers should verify the material specifications and certifications to ensure compliance with international quality standards.

-

Forming: During the forming stage, materials are shaped into components using techniques such as stamping, molding, and extrusion. Advanced machinery is often employed to achieve precision and reduce waste. The forming process is crucial for structural integrity, particularly for the vehicle’s chassis and battery housing. Buyers should inquire about the technology used and whether it adheres to international manufacturing standards.

-

Assembly: This stage involves the integration of various components, including the battery, motor, and electronic systems. Automated assembly lines are frequently used to enhance efficiency and consistency. Quality control checks are implemented throughout this process to identify defects early. Buyers can request documentation of assembly processes and any automation technologies utilized, which can impact the final product’s reliability.

-

Finishing: The finishing stage includes surface treatment, painting, and final inspections. This not only enhances the aesthetic appeal of the vehicle but also provides protective coatings to prevent corrosion and wear. Buyers should understand the finishing processes employed and any associated environmental standards that may impact product longevity.

What Key Techniques Are Employed in Manufacturing 60V Electric Vehicles?

Manufacturers employ various techniques throughout the production process to ensure quality and efficiency.

-

Lean Manufacturing: Many manufacturers adopt lean principles to minimize waste and optimize production efficiency. This approach can lead to cost savings, which can be passed on to B2B buyers.

-

Computer Numerical Control (CNC) Machining: CNC machines are often used for high-precision component manufacturing, ensuring that parts fit together perfectly during assembly. This technology can significantly enhance quality and reduce rework.

-

Robotics: Automation through robotics is increasingly common in the assembly phase. Robots can perform repetitive tasks with high precision, improving efficiency and reducing human error.

-

Quality Management Systems: Implementing a robust quality management system (QMS) based on ISO 9001 ensures that all processes are documented, monitored, and continuously improved.

How Is Quality Assurance Managed in the Production of 60V Electric Vehicles?

Quality assurance (QA) is a critical component of the manufacturing process for 60V electric vehicles, ensuring that products meet both international standards and customer expectations.

-

International Standards and Certifications: Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, certifications like CE mark (for European markets) and UL (for North American markets) demonstrate compliance with safety and performance standards.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This checkpoint verifies the quality of materials received from suppliers. It includes inspections and testing to ensure compliance with specifications.

– In-Process Quality Control (IPQC): During the manufacturing process, various inspections are conducted to monitor quality at different stages. This helps to catch defects early and minimize rework.

– Final Quality Control (FQC): After assembly, final inspections are performed to ensure that the finished product meets all specifications and is ready for delivery. -

Common Testing Methods:

– Electrical Testing: Ensures that the vehicle’s electrical components function correctly.

– Battery Testing: Includes capacity, cycle life, and thermal management tests to validate battery performance.

– Safety Testing: Involves crash tests, thermal runaway tests for batteries, and other safety assessments to ensure compliance with regulations.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers should adopt a proactive approach to verify the quality control processes of potential suppliers. Here are several strategies to consider:

-

Supplier Audits: Conducting audits of manufacturing facilities can provide insights into the quality control measures in place. This can include reviewing documentation, observing processes, and interviewing staff.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality control reports, including IQC, IPQC, and FQC results. This documentation should outline any issues encountered and the corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and quality control measures. This is particularly important for international transactions where buyers may be unable to visit facilities personally.

What Are the QC and Certification Nuances for International B2B Buyers?

For international buyers, understanding the nuances of quality control and certification is crucial to ensure compliance with local regulations and market expectations.

-

Regional Standards: Different regions may have specific quality standards and certifications. For instance, in Europe, compliance with the CE mark is mandatory for many products, while North America may require UL certification. Buyers should familiarize themselves with these regional requirements.

-

Documentation and Traceability: Effective documentation is essential for quality assurance. Buyers should ensure that suppliers maintain detailed records of production processes, quality checks, and certifications. This traceability can be invaluable in case of recalls or compliance investigations.

-

Cultural Considerations: When dealing with suppliers from different regions, cultural differences can impact communication and expectations regarding quality. Establishing clear guidelines and maintaining open lines of communication can help mitigate misunderstandings.

By understanding the manufacturing processes and quality assurance measures for 60V electric vehicles, B2B buyers can make informed decisions, ensuring that they source reliable and high-quality products tailored to their specific market needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ’60v eletric car electric vehicle’

In today’s rapidly evolving transportation sector, sourcing a 60V electric car requires a strategic approach to ensure that you select the right vehicle for your needs. This guide aims to equip B2B buyers with a clear, actionable checklist for procuring 60V electric vehicles that meet both operational and compliance standards.

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for the 60V electric vehicle you need. Consider factors such as battery capacity (e.g., 20Ah to 60Ah), speed requirements (less than 50 km/h for scooters), and intended use (personal transport, delivery, etc.). Clearly defined specifications will help streamline your search and ensure that you choose a vehicle that meets your operational demands.

Step 2: Research Compliance Standards

Investigate the regulatory requirements for electric vehicles in your target markets, such as Nigeria, Saudi Arabia, and European nations. Compliance with local standards is crucial to avoid legal issues and ensure safety. Check if the vehicle meets international safety certifications and environmental regulations pertinent to your region.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations. Request company profiles, case studies, and references from buyers in similar industries or regions. This will not only provide insight into their reliability but also their ability to meet your specific needs, including customization options.

Step 4: Inspect Product Quality and Specifications

Ensure that the vehicles you are considering are built with high-quality materials and technology. Look for features such as lithium batteries (LiFePO4 preferred for their longevity), robust thermal management systems, and intelligent safety management systems. Request samples or detailed product specifications to assess quality firsthand.

Step 5: Assess After-Sales Support and Warranty

Evaluate the level of after-sales support offered by the supplier. A strong warranty and responsive customer service can significantly impact your satisfaction and operational efficiency. Look for suppliers who provide comprehensive training, maintenance options, and easy access to spare parts.

Step 6: Negotiate Terms and Pricing

Once you have identified potential suppliers and vetted their products, it’s time to negotiate. Discuss pricing structures, payment terms, and delivery schedules. Be prepared to leverage your research on market pricing to ensure you receive a fair deal. Consider bulk purchasing discounts if applicable.

Step 7: Finalize the Purchase Agreement

After reaching an agreement, ensure that all terms are documented in a formal purchase agreement. This should include specifications, delivery timelines, payment terms, and warranty details. A clear contract protects both parties and helps mitigate future disputes.

By following these steps, B2B buyers can confidently navigate the sourcing process for 60V electric vehicles, ensuring that they select products that align with their business goals and operational needs.

Comprehensive Cost and Pricing Analysis for 60v eletric car electric vehicle Sourcing

What Are the Key Cost Components in Sourcing 60V Electric Vehicles?

When sourcing 60V electric vehicles, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The materials used in manufacturing electric vehicles significantly impact pricing. Key materials include lithium-ion batteries, chassis components, and electrical systems. For instance, lithium batteries, such as LiFePO4, are essential for performance and longevity, influencing overall costs.

-

Labor: Labor costs vary by region and are influenced by the complexity of the vehicle’s design. In countries with lower labor costs, such as those in Africa and South America, overall manufacturing expenses can be reduced, but this may affect quality control.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, including utilities, rent, and equipment depreciation. Effective management of these costs can lead to more competitive pricing.

-

Tooling: Initial investment in tooling for manufacturing specific vehicle models can be substantial. Buyers should inquire about tooling costs, especially for customized designs, as these can be amortized over larger production runs.

-

Quality Control (QC): Ensuring high quality is crucial, particularly for electric vehicles that must meet safety and performance standards. QC processes can add to costs but are necessary to avoid long-term expenses related to warranty claims and customer dissatisfaction.

-

Logistics: Shipping costs can vary significantly based on the distance from the manufacturing site to the buyer’s location. Understanding the logistics involved, including freight and potential tariffs, is essential for accurate pricing.

-

Margin: Suppliers typically add a profit margin to their costs. This margin can vary depending on the supplier’s market position, the competitive landscape, and the perceived value of the vehicle.

How Do Price Influencers Affect the Cost of 60V Electric Vehicles?

Several factors can influence the final price of 60V electric vehicles:

-

Volume/MOQ: Minimum order quantities (MOQs) can affect pricing. Larger orders often lead to discounts, making it financially advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Custom specifications can increase costs, especially if they require unique materials or manufacturing processes. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO standards) can lead to increased costs but often result in better performance and reliability, which can be crucial in competitive markets.

-

Supplier Factors: The supplier’s reputation, reliability, and experience in the electric vehicle market can influence pricing. Established suppliers may charge a premium for their expertise and proven track record.

-

Incoterms: Understanding Incoterms is vital for international shipping. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost and should be negotiated carefully.

What Are Some Effective Buyer Tips for Cost-Efficiency in Sourcing?

To maximize cost-efficiency when sourcing 60V electric vehicles, buyers should consider the following strategies:

-

Negotiation: Engaging in thorough negotiations can lead to significant cost savings. Buyers should leverage their purchasing power and market knowledge to negotiate better terms.

-

Total Cost of Ownership (TCO): Evaluate the total cost of ownership, which includes not just the purchase price but also maintenance, operation, and potential resale value. A higher initial investment may be justified by lower operating costs over the vehicle’s life.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, and the Middle East should be aware of local market conditions, currency fluctuations, and import duties. These factors can significantly affect pricing and should be factored into the sourcing strategy.

-

Supplier Diversification: Engaging multiple suppliers can mitigate risks and provide leverage in negotiations. This approach allows buyers to compare prices and ensure they are receiving competitive offers.

-

Quality Assurance: Investing in quality assurance upfront can prevent costly issues down the line. Buyers should prioritize suppliers who demonstrate a commitment to quality and reliability.

Disclaimer on Indicative Prices

Prices for 60V electric vehicles can vary widely based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and obtain multiple quotes to ensure they are making informed purchasing decisions.

Alternatives Analysis: Comparing 60v eletric car electric vehicle With Other Solutions

Introduction: Understanding Alternatives in Electric Vehicle Solutions

When evaluating the 60V electric car electric vehicle (EV), it’s essential to consider other viable alternatives that fulfill similar transportation needs. The choice of an electric vehicle solution can significantly impact operational costs, performance, and suitability for specific applications. In this analysis, we will compare the 60V electric car against two alternative solutions: 48V electric vehicles and 72V electric vehicles. Each option has unique advantages and drawbacks that cater to different market segments, especially for B2B buyers in regions like Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | 60V Electric Car Electric Vehicle | 48V Electric Vehicle | 72V Electric Vehicle |

|---|---|---|---|

| Performance | Moderate speed (<50 km/h) | Lower speed, suitable for short distances | Higher speed (>50 km/h) |

| Cost | Mid-range pricing | Generally lower cost | Higher upfront investment |

| Ease of Implementation | Simple setup, minimal infrastructure | Easy to deploy, lower tech requirements | Requires specialized knowledge |

| Maintenance | Moderate maintenance needs | Lower maintenance, simpler design | Higher maintenance due to complexity |

| Best Use Case | Short to medium commutes, urban transport | Urban short-distance transport | Long-distance travel, delivery services |

Detailed Breakdown of Alternatives

48V Electric Vehicles

48V electric vehicles are popular for urban environments, offering a cost-effective solution for short-distance travel. Their lower speed capabilities make them ideal for commuting within cities where traffic regulations limit speed. However, their performance in terms of range and power is limited, making them less suitable for longer journeys or heavier loads. The simplicity of their design translates to lower maintenance requirements, which can be a significant advantage for businesses looking to minimize operational costs.

72V Electric Vehicles

In contrast, 72V electric vehicles provide superior performance, capable of higher speeds and extended ranges. This makes them suitable for applications such as delivery services or longer commutes. While the initial investment is higher, the efficiency and capabilities of 72V vehicles can offer a better return on investment in the long run. However, they require more specialized maintenance and knowledge for operation, which may pose a challenge for businesses without the necessary expertise.

Conclusion: Choosing the Right Electric Vehicle Solution

Selecting the appropriate electric vehicle solution depends on the specific needs of your business. For companies focused on short-distance urban transport, the 48V electric vehicle may be the most economical choice. Conversely, if your operations involve longer distances and higher speed requirements, investing in a 72V electric vehicle could yield better results despite the higher costs. The 60V electric car strikes a balance between these two options, making it a practical choice for businesses needing moderate performance without excessive complexity. Ultimately, B2B buyers should consider factors such as operational costs, maintenance capabilities, and the intended use case to make an informed decision.

Essential Technical Properties and Trade Terminology for 60v eletric car electric vehicle

What Are the Key Technical Properties of a 60V Electric Vehicle?

When considering the procurement of 60V electric vehicles, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some of the critical specifications to focus on:

-

Battery Type and Capacity

The primary power source for a 60V electric vehicle is its battery, commonly Lithium Iron Phosphate (LiFePO4). The capacity, typically ranging from 20Ah to 60Ah, directly affects the vehicle’s range and performance. A higher capacity battery can provide longer operational time, which is essential for commercial applications such as delivery services or fleet management. -

Rated Voltage and Current

The rated voltage of 60V is standard for low-speed electric vehicles, ensuring compatibility with various components such as motors and controllers. The charging current, often set at 5A, influences the charging time and efficiency. Understanding these parameters helps buyers select vehicles that meet their operational needs without compromising safety or performance. -

Motor Power

The motor power, usually between 800W and 1000W for 60V electric vehicles, determines the vehicle’s speed and ability to climb inclines. This specification is particularly important for buyers in hilly regions or urban environments where acceleration and hill-climbing capabilities are critical for utility vehicles or personal transport. -

Weight and Size

The weight of the vehicle, often around 15.8 kg for battery systems, impacts the overall efficiency and handling. A lightweight vehicle can offer better energy efficiency and maneuverability, making it suitable for urban settings. The dimensions (e.g., 183X165X320 mm for the battery) also matter for storage and transport considerations during shipping and logistics. -

Communication Protocols

Many modern electric vehicles utilize communication protocols like RS485 for battery management systems. This specification is vital for integrating the vehicle with fleet management systems and ensuring real-time monitoring of battery health and performance, which can reduce downtime and maintenance costs. -

Durability Ratings

Durability features such as dust and waterproof ratings are essential for vehicles operating in diverse environments. Buyers should consider these ratings to ensure the longevity and reliability of the vehicles in various weather conditions, especially in regions with extreme climates.

What Common Trade Terms Should You Know When Purchasing 60V Electric Vehicles?

Understanding trade terminology is essential for successful negotiations and procurement processes. Here are some key terms relevant to B2B transactions in the electric vehicle sector:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products or components that are used in another company’s end products. In the context of 60V electric vehicles, OEMs may supply batteries, motors, or electronic control units, which can be crucial for ensuring quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and cash flow. Understanding the MOQ can help buyers negotiate better terms and assess whether a supplier can meet their needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This term is vital for buyers looking to compare prices and terms from multiple suppliers, ensuring they obtain competitive offers for 60V electric vehicles. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of sellers and buyers in global trade. Familiarity with these terms helps clarify shipping costs, risk transfers, and delivery obligations, essential for managing international procurement of electric vehicles. -

Lead Time

Lead time refers to the time taken from placing an order until the product is delivered. Understanding lead times is crucial for planning and ensuring that procurement aligns with operational needs, especially in markets where electric vehicles are in high demand. -

Warranty and Service Agreements

These terms outline the terms under which a supplier will repair or replace faulty products. A solid warranty and service agreement can significantly impact long-term costs and operational efficiency, making it a critical consideration for B2B buyers.

By grasping these technical properties and trade terminologies, international B2B buyers can navigate the procurement of 60V electric vehicles more effectively, ensuring they make informed decisions that align with their operational requirements and market dynamics.

Navigating Market Dynamics and Sourcing Trends in the 60v eletric car electric vehicle Sector

What Are the Key Market Dynamics Influencing the 60V Electric Car Sector?

The global market for 60V electric vehicles (EVs) is experiencing significant growth, driven by a combination of technological advancements, rising environmental concerns, and increasing urbanization. In regions such as Africa, South America, the Middle East, and Europe, the demand for sustainable and cost-effective transportation solutions is on the rise. The transition to electric mobility is being propelled by government initiatives aimed at reducing carbon footprints, promoting energy independence, and enhancing public health.

Emerging trends in B2B sourcing include the integration of smart technologies such as IoT and AI for fleet management, which can optimize operations and reduce costs. Additionally, partnerships with local manufacturers are becoming essential for international buyers to navigate regulatory landscapes and tap into regional markets effectively. Customization is another key trend, as businesses seek tailored solutions that meet specific operational needs, particularly in sectors like logistics and public transportation.

Furthermore, the push for higher efficiency and performance in electric vehicles is leading to innovations in battery technology, particularly in lithium-ion and LiFePO4 batteries. As competition intensifies, buyers are increasingly looking for suppliers that can provide not only quality products but also robust after-sales support and warranty services.

How Is Sustainability Reshaping Sourcing Practices in the 60V Electric Vehicle Market?

Sustainability is no longer just a buzzword; it has become a critical criterion for B2B sourcing in the 60V electric vehicle sector. The environmental impact of sourcing decisions is under scrutiny, with businesses seeking to minimize their carbon footprints throughout the supply chain. This shift is encouraging companies to adopt ethical sourcing practices, including the use of responsibly sourced materials and adherence to labor rights.

Buyers are increasingly interested in suppliers who can provide certifications such as ISO 14001 for environmental management and adherence to global standards for ethical manufacturing practices. Furthermore, the incorporation of recycled materials in battery production and the development of energy-efficient manufacturing processes are gaining traction.

In addition to ethical sourcing, sustainability certifications can enhance a company’s reputation and appeal to environmentally-conscious consumers. As the global marketplace evolves, B2B buyers must prioritize partnerships with suppliers who are committed to sustainability, ensuring that their sourcing strategies align with broader corporate social responsibility goals.

What Is the Historical Context of 60V Electric Vehicles in the B2B Landscape?

The evolution of 60V electric vehicles can be traced back to the early 2000s when the demand for alternative transportation solutions began to rise in response to increasing fuel prices and environmental concerns. Initially, these vehicles were primarily used in niche markets such as golf carts and small utility vehicles. However, as battery technology improved and urban congestion intensified, the 60V segment began to attract attention from a broader audience, including businesses focused on last-mile delivery and public transport.

Over the past decade, the 60V electric vehicle market has expanded significantly, driven by advancements in battery technology and increasing consumer awareness of the benefits of electric mobility. The emergence of competitive pricing and the availability of government incentives have further accelerated adoption, making 60V electric vehicles an attractive option for businesses looking to reduce operational costs and enhance their sustainability profiles.

In conclusion, the 60V electric vehicle sector is poised for continued growth, influenced by technological innovations, sustainability imperatives, and evolving market dynamics. For international B2B buyers, understanding these trends is essential for making informed sourcing decisions that align with both business objectives and environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of 60v eletric car electric vehicle

-

How do I choose the right 60V electric vehicle for my business needs?

Choosing the right 60V electric vehicle involves assessing your specific requirements, including the intended use, load capacity, and range. For businesses focused on short-distance travel, such as last-mile delivery or local commuting, a 60V vehicle can provide an efficient solution. Consider factors like vehicle weight, battery capacity (commonly ranging from 20Ah to 60Ah), and whether you need customization options. Engaging with suppliers that offer tailored solutions can help ensure the vehicle aligns with your operational needs. -

What are the advantages of 60V electric vehicles compared to other voltages?

60V electric vehicles strike a balance between performance and cost-effectiveness. They generally offer better speed and range than 48V options, making them suitable for various applications, including urban commuting and light cargo transport. While 72V vehicles provide higher power and speed, 60V models are often more affordable and easier to maintain, making them a practical choice for businesses with moderate performance requirements. -

What customization options are available for 60V electric vehicles?

Most manufacturers offer customization options for 60V electric vehicles to meet specific business needs. Common customizations include battery capacity adjustments, vehicle design modifications, and additional features like GPS tracking or cargo space enhancements. When sourcing from suppliers, inquire about their ability to accommodate your customization requests and any associated costs or lead times to ensure your vehicle aligns with your operational goals. -

What is the typical minimum order quantity (MOQ) for 60V electric vehicles?

The minimum order quantity for 60V electric vehicles can vary significantly between manufacturers. Generally, MOQs range from 5 to 50 units, depending on the supplier and the customization level required. When negotiating with suppliers, clarify the MOQ and explore potential flexibility, especially if you are a smaller business or new to the market. Some suppliers may offer sample units for testing before committing to larger orders. -

What payment terms should I expect when sourcing 60V electric vehicles?

Payment terms can vary widely among suppliers. Common arrangements include a deposit (usually 30-50%) upfront, with the balance due upon shipment or delivery. Some manufacturers may offer financing options or extended payment plans for larger orders. Always ensure to review the payment terms carefully and confirm that they align with your cash flow capabilities, especially when purchasing from international suppliers. -

How can I ensure the quality of 60V electric vehicles from suppliers?

To ensure quality, conduct thorough research on potential suppliers. Look for manufacturers with ISO certifications or other industry standards, as these often indicate a commitment to quality assurance. Request product samples or visit production facilities if possible. Additionally, seek testimonials or case studies from other businesses that have sourced from the supplier. Establishing clear quality control measures in your purchase agreement can also safeguard against defects. -

What logistics considerations should I keep in mind when importing 60V electric vehicles?

Logistics is crucial when importing 60V electric vehicles. Consider shipping methods, lead times, and costs, as these can significantly impact your overall budget and timeline. Ensure you understand customs regulations in your country, including any tariffs or taxes applicable to electric vehicles. Collaborating with a freight forwarder experienced in handling automotive imports can streamline the process and help navigate any potential challenges. -

Are there specific regulations I need to be aware of when importing electric vehicles to my country?

Yes, regulations regarding electric vehicle imports can vary widely by country. It’s essential to research local laws concerning vehicle specifications, safety standards, and environmental regulations. Some countries may require certifications or inspections before registration. Engaging with a local legal expert or customs broker can provide valuable insights and ensure compliance, helping to avoid delays or penalties during the import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 7 60V Eletric Car Electric Vehicle Manufacturers & Suppliers List

1. Reddit – Cost-Effective Gel Batteries for 5000W Electric ATV

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 60v (5x12v) 5000w electric ATV; originally equipped with 5 x 6-dzf-20.2 12v20ah AGM batteries; considering gel batteries as a cost-effective alternative.

2. Smart Propel – High-Performance Electric Vehicles

Domain: smartpropel.com

Registered: 2019 (6 years)

Introduction: 72-volt electric vehicles generally have a speed of over 50 km/h, while 60-volt electric vehicles have a speed of less than 50 km/h. The range of a 72-volt vehicle is greater than that of a 60-volt vehicle; for example, a 72V 60Ah lithium battery can provide a range of around 150 km, compared to 130 km for a 60V 60Ah lithium battery. In terms of power, 72-volt electric scooters typically have moto…

3. Chinese Electric Cars – 60V 2000W Mini Vehicle

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Electric Cars Mini Car Chinese 60V 2000W 4 Four Wheel Adult Cheap Vehicles

4. EDACAR – High-Quality 60V Electric Vehicles

Domain: m.edacarev.com

Registered: 2023 (2 years)

Introduction: This company, EDACAR – High-Quality 60V Electric Vehicles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

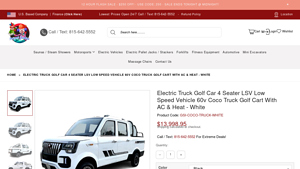

5. Electric Truck – 4 Seater LSV Golf Cart

Domain: importjunkies.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “Electric Truck Golf Car 4 Seater LSV Low Speed Vehicle 60v Coco Truck Golf Cart With AC & Heat – White”, “Product Code”: “GSI-COCO-TRUCK-WHITE”, “Regular Price”: “$13,998.95”, “Dimensions”: “3900x1450x1650mm / 154x57x65in”, “Motor”: “4000W”, “Controller”: “30 Tubes”, “Tire”: “145 Vacuum”, “Brake”: “Four Wheel Disc Brake”, “Drive Way”: “RWD”, “Maximum Cruising Range”: “70-130km / …

6. Automatic Electric Car – Small Electric Car

Domain: automaticelectriccar.com

Registered: 2018 (7 years)

Introduction: {“Product Name”:”Small Electric Car”,”Speed”:”40km/h (Economic speed) / ≤50km/h (Maximum speed)”,”Motor”:”60V 4000W”,”Battery”:”Free Maintenance Acid-lead Battery 60V/120Ah”,”Tire Size”:”135/70 R12″,”Dimensions”:”2350*1450*1550mm”,”Rated Passenger Number”:”2 persons (including the driver)”,”Curb Weight”:”740kg”,”Min Ground Clearance”:”160mm”,”Wheelbase”:”1570mm”,”Trackbase”:”1250mm”,”Grand Ability…

7. Evgo – Electric Vehicle Charging Solutions

Domain: evgo.com

Registered: 2002 (23 years)

Introduction: Types of Electric Vehicles:

1. Battery Electric Vehicles (BEVs):

– Powered solely by an electric battery, no gas engine parts.

– Capable of fast charging and L2 charging.

– Zero emissions.

2. Plug-in Hybrid Electric Vehicles (PHEVs):

– Similar to a Hybrid, but with a larger battery and electric motor.

– Has a gas tank and a charging port.

– Can charge using L2 chargers. …

Strategic Sourcing Conclusion and Outlook for 60v eletric car electric vehicle

In the rapidly evolving landscape of electric vehicles, the 60V electric car presents a compelling option for businesses seeking sustainable and efficient transportation solutions. With a focus on strategic sourcing, international buyers can leverage the benefits of 60V technology, including enhanced performance and cost-effectiveness compared to lower-voltage alternatives. The 60V electric vehicle market caters particularly well to regions like Africa, South America, the Middle East, and Europe, where urban commuting and last-mile delivery solutions are increasingly critical.

To maximize the advantages of sourcing 60V electric vehicles, businesses should prioritize partnerships with manufacturers that offer high-quality lithium battery systems, such as those from reputable suppliers. This ensures reliability and longevity, essential factors for operational success. Additionally, understanding the unique characteristics of 60V vehicles—such as their optimal speed and range for urban environments—can help buyers make informed decisions tailored to their specific needs.

Looking ahead, the demand for eco-friendly transportation solutions will only grow. As a result, now is the time for B2B buyers to engage with suppliers and explore the potential of 60V electric vehicles in their operations. By investing strategically in this technology, companies can position themselves at the forefront of the green transportation movement.