Introduction: Navigating the Global Market for dump Trucks With Crane

In the competitive landscape of construction and logistics, sourcing dump trucks with cranes poses unique challenges for international B2B buyers. These versatile vehicles are essential for a range of applications, from construction projects to waste management, yet navigating the global market can be daunting. Buyers must consider various factors, including vehicle types, crane specifications, and regional compliance standards, all while ensuring cost-effectiveness and reliability.

This comprehensive guide delves into the intricacies of dump trucks with cranes, offering insights into the different types available and their specific applications. It provides detailed information on vetting suppliers to ensure quality and compliance, as well as strategies for negotiating costs effectively. By addressing key considerations, such as the importance of durability and operational efficiency, this guide empowers businesses in Africa, South America, the Middle East, and Europe—particularly in countries like Vietnam and Saudi Arabia—to make informed purchasing decisions.

With a focus on actionable insights, this resource equips B2B buyers with the knowledge they need to navigate the complexities of sourcing dump trucks with cranes. By understanding the market landscape and leveraging best practices, buyers can enhance their operational capabilities and drive success in their projects.

Understanding dump Trucks With Crane Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Dump Truck with Crane | Fixed crane mounted on the truck bed | Construction, waste management | Pros: Versatile, robust. Cons: Limited reach. |

| Articulated Dump Truck with Crane | Flexible joint allowing better maneuverability | Mining, heavy construction | Pros: Excellent off-road capability. Cons: Higher maintenance. |

| Knuckleboom Crane Dump Truck | Compact, articulated crane for tight spaces | Urban construction, landscaping | Pros: Great for confined areas. Cons: Lower lifting capacity. |

| Rear-Loader Dump Truck with Crane | Crane positioned at the rear for efficient loading | Municipal services, recycling | Pros: Efficient loading/unloading. Cons: Limited visibility. |

| Flatbed Dump Truck with Crane | Flatbed design with crane for versatility | Transporting heavy equipment | Pros: Multi-functional, easy to load/unload. Cons: Less stability with heavy loads. |

What Are the Key Characteristics of Standard Dump Trucks with Crane?

Standard dump trucks equipped with a crane feature a fixed crane mounted on the truck bed. These vehicles are typically used in construction and waste management sectors, where their robust build allows for the transport and unloading of materials. Buyers should consider the lifting capacity and reach of the crane, as these factors directly impact operational efficiency. While they offer versatility, their limited reach might necessitate additional equipment for specific tasks.

How Do Articulated Dump Trucks with Crane Stand Out?

Articulated dump trucks with cranes are distinguished by their flexible joint that enhances maneuverability, especially on rugged terrains. Commonly utilized in mining and heavy construction, these trucks can navigate challenging environments effectively. When purchasing, businesses should evaluate the truck’s off-road capabilities and maintenance requirements, as these can influence long-term operational costs. Although they excel in difficult conditions, they may require more frequent maintenance than standard models.

Why Choose a Knuckleboom Crane Dump Truck?

Knuckleboom crane dump trucks are designed with a compact, articulated crane that is ideal for working in tight spaces, making them particularly suited for urban construction and landscaping projects. Their ability to maneuver in confined areas is a significant advantage. Buyers should assess the crane’s lifting capacity and the truck’s overall stability, as these factors can affect performance. While they excel in accessibility, their lifting capacity may not match that of larger cranes.

What Are the Advantages of Rear-Loader Dump Trucks with Crane?

Rear-loader dump trucks with cranes feature cranes positioned at the rear, allowing for efficient loading and unloading of materials. These trucks are widely used in municipal services and recycling operations. When considering a purchase, companies should focus on the truck’s visibility and operational efficiency, as these are critical for safe and effective use. While they facilitate efficient loading, their rear positioning can limit visibility during operation.

How Do Flatbed Dump Trucks with Crane Offer Versatility?

Flatbed dump trucks with cranes combine the benefits of a flatbed design with the functionality of a crane, making them ideal for transporting heavy equipment. They are particularly valuable in industries that require quick loading and unloading of various materials. Buyers should evaluate the flatbed’s stability and the crane’s lifting capabilities, as these will impact overall performance. While their multi-functional nature is a significant advantage, they may experience stability issues with very heavy loads.

Key Industrial Applications of dump Trucks With Crane

| Industry/Sector | Specific Application of dump Trucks With Crane | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Material Transport and Site Setup | Efficient movement of heavy materials reduces project timelines. | Load capacity, crane reach, and compatibility with site conditions. |

| Waste Management | Collection and Disposal of Waste | Streamlined waste collection processes enhance operational efficiency. | Durability, ease of maintenance, and regulatory compliance. |

| Mining | Transporting Aggregates and Equipment | Improves logistics in remote locations, ensuring consistent supply. | Terrain adaptability, payload capacity, and crane functionality. |

| Agricultural Services | Loading and Transporting Produce | Increases productivity by facilitating quick transport to markets. | Versatility in loading attachments and fuel efficiency. |

| Infrastructure Development | Lifting and Placing Construction Materials | Enhances safety and efficiency in urban development projects. | Crane capacity, stability, and adherence to safety standards. |

How Are Dump Trucks With Crane Used in Construction?

In the construction industry, dump trucks with cranes play a crucial role in material transport and site setup. These vehicles can efficiently move heavy materials like concrete, steel, and aggregates directly to job sites, significantly reducing the time and labor costs associated with manual handling. International buyers, especially in regions such as Africa and the Middle East, should consider load capacity and crane reach to ensure that the equipment meets the demands of large-scale projects.

What Benefits Do Dump Trucks With Crane Provide in Waste Management?

In waste management, dump trucks equipped with cranes facilitate the collection and disposal of waste materials. The combination allows for the efficient loading of heavy waste into the truck bed, streamlining the collection process and enhancing operational efficiency. Buyers should prioritize durability and ease of maintenance, as these factors directly impact the vehicle’s operational lifespan and reliability in harsh environments commonly found in South America and Europe.

How Do Dump Trucks With Crane Support Mining Operations?

Mining operations benefit from dump trucks with cranes for transporting aggregates and heavy equipment across challenging terrains. The versatility of these trucks enables them to operate in remote locations, ensuring a consistent supply of materials essential for production. When sourcing, buyers must evaluate terrain adaptability, payload capacity, and the crane’s functionality to align with the specific demands of mining activities.

In What Ways Are Dump Trucks With Crane Valuable in Agricultural Services?

In agricultural services, dump trucks with cranes are utilized for loading and transporting produce efficiently. This capability allows farmers to quickly move their products to market, thus enhancing productivity and reducing spoilage. Buyers should look for vehicles that offer versatility in loading attachments and fuel efficiency, particularly in regions like South America, where access to rural areas may pose logistical challenges.

How Do Dump Trucks With Crane Enhance Infrastructure Development?

Dump trucks with cranes are vital in infrastructure development for lifting and placing construction materials, thereby improving safety and efficiency in urban projects. The ability to lift heavy loads directly onto construction sites minimizes manual labor and reduces the risk of accidents. Buyers in Europe and the Middle East should focus on crane capacity, vehicle stability, and compliance with safety standards to ensure optimal performance in urban environments.

3 Common User Pain Points for ‘dump Trucks With Crane’ & Their Solutions

Scenario 1: Difficulty in Sourcing Reliable Equipment for Diverse Projects

The Problem: B2B buyers often struggle to find dump trucks with cranes that meet their specific project needs. With a variety of tasks ranging from construction to logistics, these buyers require equipment that is not only versatile but also reliable. Issues such as equipment breakdowns, inadequate lifting capacity, or the wrong crane type can lead to project delays and increased costs. Furthermore, buyers in regions like Africa and South America may face additional challenges due to limited access to high-quality used or new equipment and the lack of local suppliers.

The Solution: To mitigate these challenges, buyers should start by conducting a comprehensive needs assessment that includes evaluating the types of materials to be moved, the weight and height requirements for lifting, and the specific terrain conditions. This assessment should guide the selection of a dump truck with a crane that fits both operational and budgetary constraints. It’s advisable to work with trusted suppliers or platforms that specialize in heavy machinery, such as Machinio or Autoline, to find options that have been vetted for quality. Additionally, engaging with local dealers who can offer maintenance and support services can greatly enhance the reliability of the equipment over time. Buyers should also consider purchasing equipment with a warranty or service package to ensure that they have support in case of mechanical issues.

Scenario 2: Navigating Compliance and Regulatory Challenges

The Problem: Buyers often face the headache of ensuring that their dump trucks with cranes comply with local regulations and safety standards. Each country or region may have different requirements regarding emissions, safety features, and operational protocols. For instance, in the Middle East and Europe, compliance with Euro emissions standards is critical, while other regions may prioritize different safety regulations. Non-compliance can result in hefty fines, project shutdowns, or even legal issues, making it imperative for buyers to stay informed.

The Solution: To navigate these regulatory challenges, it’s essential for buyers to familiarize themselves with local laws related to heavy machinery operation. This includes understanding vehicle registration requirements, emissions standards, and safety protocols. Collaborating with local authorities or industry associations can provide valuable insights into these regulations. Additionally, when sourcing dump trucks with cranes, buyers should prioritize equipment that is certified and compliant with international standards, such as ISO or CE markings. Engaging with suppliers who have a strong understanding of local regulations can also help streamline the purchasing process and ensure compliance from the outset. Lastly, buyers should consider investing in training for their operators to ensure they are well-versed in safety practices and regulatory requirements.

Scenario 3: Managing Operational Efficiency and Downtime

The Problem: Operational efficiency is crucial for B2B buyers who rely on dump trucks with cranes for their daily operations. Issues such as prolonged downtime due to equipment failure or suboptimal performance can significantly affect project timelines and profitability. Buyers often find themselves caught between the need for high-performing equipment and the reality of maintenance challenges, which can include sourcing spare parts or finding qualified technicians for repairs.

The Solution: To improve operational efficiency and minimize downtime, buyers should prioritize the selection of durable and reliable dump trucks with cranes. This includes reviewing the equipment’s maintenance history and opting for brands known for their longevity and support network. Buyers should also implement a proactive maintenance schedule that includes regular inspections, servicing, and timely repairs to prevent breakdowns. Establishing relationships with local service providers for ongoing maintenance can ensure that any issues are addressed swiftly. Furthermore, investing in telematics technology can offer real-time data on the equipment’s performance, allowing buyers to make informed decisions about maintenance needs and operational adjustments. This proactive approach not only enhances reliability but also contributes to the overall efficiency of operations, leading to better project outcomes and reduced costs.

Strategic Material Selection Guide for dump Trucks With Crane

What Materials Are Commonly Used in Dump Trucks With Cranes?

When selecting materials for dump trucks with cranes, several factors must be considered, including performance, durability, and cost-effectiveness. Below is an analysis of three common materials used in the construction of these vehicles.

Steel: The Backbone of Dump Trucks With Cranes

Key Properties: Steel is known for its high tensile strength, excellent ductility, and good weldability. It typically has a temperature rating of up to 400°F (204°C) and can withstand significant pressure, making it suitable for heavy-duty applications.

Pros & Cons: The primary advantage of steel is its durability and resistance to deformation under load. However, it is prone to corrosion, which can be a significant drawback in humid or coastal environments. Additionally, while steel is relatively low-cost compared to other materials, its weight can impact fuel efficiency.

Impact on Application: Steel is compatible with various media, including construction materials and heavy loads. However, it requires protective coatings or treatments to enhance corrosion resistance, especially in regions with high humidity or salt exposure.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards and regulations regarding material specifications. Common standards include ASTM and DIN for steel quality.

Aluminum: Lightweight and Corrosion-Resistant

Key Properties: Aluminum is lightweight, with a density about one-third that of steel. It has excellent corrosion resistance and can withstand temperatures up to 300°F (149°C) without significant degradation.

Pros & Cons: The primary advantage of aluminum is its weight, which enhances fuel efficiency and payload capacity. However, it is generally more expensive than steel and may not provide the same level of strength under heavy loads.

Impact on Application: Aluminum is suitable for applications where weight savings are critical, such as in crane arms and truck bodies. Its corrosion resistance makes it ideal for use in coastal areas or regions with high humidity.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades that meet their requirements, such as 6061 or 7075, and ensure compliance with relevant standards like JIS in Japan or EN in Europe.

Composite Materials: Innovative and Versatile

Key Properties: Composite materials, often made from a combination of fibers and resins, offer high strength-to-weight ratios and excellent corrosion resistance. They can withstand temperatures up to 250°F (121°C) and provide good impact resistance.

Pros & Cons: The primary advantage of composites is their lightweight nature and resistance to corrosion, which can significantly reduce maintenance costs. However, they are often more expensive and can be more complex to manufacture and repair.

Impact on Application: Composites are increasingly used in specialized applications, such as crane booms and truck bodies, where weight savings and corrosion resistance are paramount. They are compatible with various media but may require specific handling and storage conditions.

Considerations for International Buyers: Buyers should consider the availability of composite materials in their region and ensure that they meet international standards for safety and performance. Understanding the manufacturing capabilities in local markets is essential for effective sourcing.

Summary Table of Material Selection for Dump Trucks With Cranes

| Material | Typical Use Case for Dump Trucks With Crane | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis, dump beds, crane arms | High strength and durability | Prone to corrosion | Medium |

| Aluminum | Truck bodies, crane components | Lightweight and corrosion-resistant | Higher cost and lower load capacity | High |

| Composite | Crane booms, specialized truck components | Excellent strength-to-weight ratio | Expensive and complex to repair | High |

This strategic material selection guide provides B2B buyers with essential insights into the materials used in dump trucks with cranes. Understanding the properties, advantages, and limitations of each material can aid in making informed purchasing decisions that align with operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for dump Trucks With Crane

What Are the Key Stages in the Manufacturing Process of Dump Trucks with Crane?

The manufacturing of dump trucks equipped with cranes involves several critical stages, each essential for ensuring that the final product meets performance, safety, and durability standards. Here’s a breakdown of these stages:

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation. High-quality steel and aluminum alloys are typically selected for their strength-to-weight ratios, which are crucial for both the truck’s structural integrity and its payload capacity. Manufacturers often use advanced materials like high-strength low-alloy (HSLA) steel, which provides improved corrosion resistance and toughness. The materials are then cut, shaped, and treated to enhance their properties, ensuring they can withstand the rigors of heavy-duty use.

Forming: How Are Components Shaped?

The forming stage involves various techniques to shape the prepared materials into components. Common methods include stamping, bending, and welding. Stamping is used for creating flat parts like the chassis, while bending shapes the dump bed and crane arm. Robotic welding is increasingly utilized for its precision and speed, ensuring strong joints that can handle significant loads. Manufacturers often employ computer numerical control (CNC) machines to ensure consistent quality and accuracy in forming components.

Assembly: What Are the Assembly Processes?

Once all components are formed, the assembly stage begins. This involves several sub-processes, including the assembly of the chassis, installation of the crane, and integration of hydraulic systems. Each component must be carefully aligned and secured, often using advanced fastening techniques to enhance durability. During this phase, manufacturers also install electrical systems for the crane’s operation and any onboard diagnostics that aid in maintenance.

Finishing: What Finishing Techniques Are Employed?

The finishing stage is crucial for both aesthetics and protection. This includes surface treatments such as painting, galvanizing, or powder coating to prevent rust and corrosion. A quality finish not only enhances the vehicle’s appearance but also extends its lifespan, particularly in harsh environments. Manufacturers often conduct final inspections during this stage to ensure that every part meets the necessary specifications.

How Is Quality Assurance Implemented in Dump Truck Manufacturing?

Quality assurance (QA) in the manufacturing of dump trucks with cranes is vital for ensuring that products meet international standards and customer expectations. Here are the main components of QA processes.

What International Standards Are Relevant for Quality Assurance?

International quality standards such as ISO 9001 provide a framework for manufacturers to ensure consistent quality in their processes. Compliance with these standards indicates that a manufacturer has established a quality management system (QMS) that is regularly reviewed and improved. In addition to ISO standards, industry-specific certifications such as CE marking for European markets and API standards for oil and gas applications are critical in demonstrating product compliance and safety.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to identify and address potential issues early. Common QC checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components before they enter the production line. It ensures that only materials meeting specified standards are used.

- In-Process Quality Control (IPQC): During manufacturing, regular inspections and tests are conducted to monitor ongoing processes and identify deviations from quality standards.

- Final Quality Control (FQC): After assembly, the final product undergoes comprehensive testing, including load tests for the crane and operational checks for the dump truck.

What Testing Methods Are Commonly Used?

Manufacturers typically employ a variety of testing methods to validate quality, including:

- Load Testing: Ensures that the crane can safely handle its rated load without failure.

- Functional Testing: Checks that all systems, including hydraulic and electrical components, operate correctly.

- Visual Inspections: Identify any cosmetic defects or inconsistencies that could affect performance or safety.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality assurance practices is crucial. Here are effective strategies:

What Role Do Audits and Reports Play?

Conducting supplier audits is an essential part of the verification process. These audits assess compliance with quality standards and the effectiveness of the manufacturer’s QMS. Buyers can request copies of audit reports to review the findings and any corrective actions taken.

How Important Are Third-Party Inspections?

Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing processes and the final product quality. These inspectors often carry out checks at various stages of production, providing buyers with detailed reports that can inform purchasing decisions.

What Are the Unique Quality Control Considerations for International Markets?

International buyers must also consider local regulations and standards that may differ from those in their home countries. Understanding these nuances can prevent compliance issues and ensure that products are suitable for specific markets. For instance, while CE marking is essential for products sold in Europe, different certifications may be required in Africa or South America.

Conclusion: Why Quality Matters in Dump Truck Manufacturing

In summary, the manufacturing processes and quality assurance practices for dump trucks with cranes are complex and multifaceted. B2B buyers should prioritize suppliers who demonstrate rigorous adherence to international quality standards and who are willing to provide transparency in their manufacturing and testing processes. By understanding these aspects, buyers can make informed decisions that align with their operational needs and market requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘dump Trucks With Crane’

Introduction

Sourcing dump trucks with cranes requires careful consideration to ensure that you acquire vehicles that meet your operational needs while also providing value for your investment. This guide offers a practical checklist to help international B2B buyers navigate the complexities of procurement, from defining technical specifications to evaluating suppliers and ensuring compliance with local regulations.

1. Define Your Technical Specifications

Before starting your search, clearly outline the technical requirements for your dump truck with a crane. Consider factors such as load capacity, engine power, and crane specifications.

– Load Capacity: Determine the maximum weight you will need to haul, as this will dictate the size and power of the truck.

– Crane Type: Choose between fixed or hydraulic cranes based on your operational needs, such as reach and lifting capabilities.

2. Research Available Models and Features

Conduct thorough research on the different models available in the market. This includes understanding the features that various manufacturers offer.

– Brand Reputation: Look for established brands known for durability and reliability in tough working conditions.

– Features: Identify additional features that may enhance functionality, such as onboard scales or advanced hydraulic systems.

3. Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Experience: Ensure the supplier has a proven track record in supplying dump trucks with cranes.

– Customer Feedback: Look for reviews or testimonials from previous clients to gauge the supplier’s reliability and service quality.

4. Verify Supplier Certifications

Ensure that the suppliers you are considering are certified and comply with international quality standards. This is vital for ensuring the safety and reliability of the equipment.

– Quality Certifications: Check for ISO certifications or other relevant industry standards that demonstrate the quality of their products.

– Compliance with Local Regulations: Verify that the supplier meets local regulations in your region, especially regarding emissions and safety standards.

5. Request and Compare Quotes

Gather quotes from multiple suppliers to understand the market pricing and evaluate the value offered.

– Transparent Pricing: Ensure that quotes include all potential costs, such as shipping, taxes, and any additional fees.

– Warranty and Support: Look for warranties offered by suppliers and what after-sales support is included, as this can significantly affect the total cost of ownership.

6. Inspect Equipment Before Purchase

If possible, physically inspect the dump trucks with cranes before finalizing your purchase. This step is essential to ensure the equipment meets your expectations.

– Condition Assessment: Check for signs of wear and tear, and ensure all components are in working order.

– Operational Testing: If feasible, conduct a test run to evaluate the truck’s performance and crane functionality.

7. Finalize Payment and Delivery Terms

Once you have selected a supplier and inspected the equipment, finalize the payment and delivery terms.

– Payment Terms: Negotiate favorable payment terms that suit your cash flow needs, such as installment payments.

– Delivery Schedule: Confirm a delivery timeline that aligns with your operational requirements to avoid delays in project timelines.

By following this checklist, B2B buyers can streamline the procurement process for dump trucks with cranes, ensuring that they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for dump Trucks With Crane Sourcing

What Are the Key Cost Components in Dump Trucks With Crane Sourcing?

When sourcing dump trucks with cranes, understanding the cost structure is crucial for international buyers. The primary cost components include:

- Materials: The choice of materials significantly impacts the overall cost. High-grade steel and advanced composites may increase initial expenses but offer durability and lower maintenance costs over time.

- Labor: Skilled labor is essential for manufacturing and assembly. Labor costs can vary based on the region, with some countries like Vietnam and Brazil offering lower labor costs compared to Europe.

- Manufacturing Overhead: This includes utilities, rent, and equipment depreciation associated with the production facility. Efficient manufacturing processes can reduce overhead costs.

- Tooling: The costs related to molds, dies, and fixtures necessary for production can be substantial, especially for custom specifications.

- Quality Control (QC): Rigorous QC processes ensure that the trucks meet safety and performance standards. This may add to the cost but is essential for minimizing future liabilities.

- Logistics: Shipping costs vary based on the destination and mode of transport. For international buyers, understanding Incoterms can clarify who bears these costs.

- Margin: Suppliers typically include a margin to cover risks and ensure profitability. This can vary widely based on market conditions and supplier reputation.

How Do Price Influencers Affect Dump Trucks With Crane Costs?

Several factors influence the pricing of dump trucks with cranes:

- Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts. Buyers should consider their needs and negotiate based on anticipated volumes.

- Specifications and Customization: Custom features, such as enhanced crane capabilities or specialized dump bed configurations, can significantly increase costs. Buyers should clearly define specifications to avoid unexpected expenses.

- Materials and Quality Certifications: Trucks built with certified materials may command higher prices due to the assurance of quality and compliance with international standards. Verify certifications relevant to your region.

- Supplier Factors: Established suppliers may offer better warranties and support, which can justify higher prices. Research potential suppliers thoroughly to assess their reputation and reliability.

- Incoterms: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is essential for budgeting shipping and import duties accurately. These terms can shift cost responsibility from buyer to seller.

What Are Effective Buyer Tips for Cost-Efficiency in Dump Trucks With Crane Purchases?

International B2B buyers can leverage several strategies to enhance cost-efficiency:

- Negotiation: Engage in open discussions with suppliers about pricing, payment terms, and potential discounts. Building a strong relationship can lead to better terms.

- Total Cost of Ownership (TCO): Consider not just the purchase price but also long-term costs such as maintenance, fuel efficiency, and resale value. A slightly higher upfront cost may lead to lower operational costs over time.

- Pricing Nuances: Be aware of regional pricing differences. For instance, prices in Europe may be higher due to stringent regulations, while prices in South America may vary based on local market conditions.

- Research and Compare: Utilize platforms like Machinio and Autoline to compare prices, specifications, and supplier reviews. This can provide insights into market trends and help identify the best deals.

- Stay Updated on Market Trends: Economic conditions, regulatory changes, and technological advancements can affect pricing. Keeping abreast of these factors can assist in making informed purchasing decisions.

Disclaimer for Indicative Prices

Pricing for dump trucks with cranes can vary widely based on numerous factors including market demand, geographic location, and specific requirements. The prices mentioned in various sources should be considered indicative and subject to change based on current market conditions. Always conduct thorough due diligence when making purchasing decisions.

Alternatives Analysis: Comparing dump Trucks With Crane With Other Solutions

Introduction: Exploring Alternatives to Dump Trucks With Crane

In the realm of construction and heavy-duty transport, dump trucks with cranes offer unique advantages, combining the capabilities of material transport and lifting in one vehicle. However, businesses must assess whether this dual-functionality meets their specific operational needs or if alternative solutions might provide more efficiency or cost-effectiveness. This analysis explores viable alternatives to dump trucks with cranes, focusing on their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Dump Trucks With Crane | Articulated Dump Trucks | Flatbed Trucks with Forklifts |

|---|---|---|---|

| Performance | High versatility; can lift and transport simultaneously | Excellent for rough terrain; good load capacity | Good for transporting large loads; requires separate lifting equipment |

| Cost | Higher initial investment; versatile use can offset costs | Moderate initial cost; fuel-efficient | Lower initial cost; additional costs for lifting equipment |

| Ease of Implementation | Requires specialized training for operators | Easier to operate; less training needed | Simple operations; requires coordination between truck and forklift operators |

| Maintenance | Higher maintenance due to crane components | Moderate maintenance; robust design | Lower maintenance; fewer moving parts |

| Best Use Case | Ideal for urban construction sites needing lifting and dumping | Suitable for mining and construction in rugged terrain | Effective for logistics and transportation of large materials |

Detailed Breakdown of Alternatives

What Are Articulated Dump Trucks and Their Benefits?

Articulated dump trucks (ADTs) are designed with a pivot joint between the cab and the dump box, allowing for enhanced maneuverability in challenging terrains. Their robust build makes them ideal for construction and mining applications, especially in areas where traditional vehicles may struggle. The main advantage of ADTs is their ability to traverse uneven ground while carrying significant loads, making them a practical choice for rugged environments. However, their limited lifting capabilities necessitate the use of additional equipment for tasks that require vertical lifting.

How Do Flatbed Trucks with Forklifts Compare?

Flatbed trucks, when paired with forklifts, create a flexible solution for transporting heavy materials. This combination allows for easy loading and unloading of items that may not fit into a standard dump truck. The primary benefit of this setup is its lower initial cost compared to dump trucks with cranes. However, it requires two separate pieces of equipment, which can complicate logistics and require coordination between operators. This alternative is best suited for businesses focused on logistics, where lifting and transporting loads are done separately but efficiently.

Conclusion: Choosing the Right Solution for Your Needs

When evaluating whether to invest in dump trucks with cranes or consider alternatives, B2B buyers must align their choice with operational requirements and budget constraints. If your projects demand versatility and the ability to lift and transport simultaneously, dump trucks with cranes are the ideal choice. Conversely, if your operations are primarily in rugged terrains or logistics-heavy environments, articulated dump trucks or flatbed trucks with forklifts may offer better efficiency and lower costs. Ultimately, the right solution hinges on your specific use case, terrain, and long-term operational goals.

Essential Technical Properties and Trade Terminology for dump Trucks With Crane

What Are the Key Technical Properties of Dump Trucks With Crane?

In the competitive landscape of dump trucks with cranes, understanding the technical specifications is crucial for B2B buyers. Here are some critical properties to consider:

1. Load Capacity

Load capacity refers to the maximum weight that the truck can safely carry, typically measured in pounds or tons. For dump trucks with cranes, this value is essential as it dictates the type of materials that can be transported. Higher load capacities enable businesses to handle larger quantities of materials in a single trip, which can improve operational efficiency and reduce transportation costs.

2. Crane Reach and Lift Height

The reach and lift height of the crane are key specifications that determine how far and how high loads can be lifted. These measurements are critical for operations involving loading and unloading materials in various environments. A crane with a longer reach and higher lift capability allows for greater flexibility in job sites, particularly in construction or landscaping applications.

3. Engine Power and Fuel Type

Engine power, measured in horsepower (HP), indicates the truck’s capability to perform under load. Fuel type (diesel or gasoline) affects operational costs and emissions compliance. Understanding these aspects helps buyers choose vehicles that balance power and efficiency, aligning with their business needs while adhering to local regulations, especially in environmentally sensitive areas.

4. Axle Configuration

The axle configuration of a dump truck defines its load distribution and stability. Common configurations include 4×2, 6×4, and 8×4. The choice of configuration impacts maneuverability and load-bearing capabilities, which are vital for heavy-duty applications in diverse terrains, from urban settings to rugged construction sites.

5. Suspension Type

Suspension systems, such as spring or air suspension, play a significant role in the ride quality and handling of the truck. A robust suspension system can absorb shocks and improve stability, which is particularly important when navigating uneven surfaces. This characteristic can affect the longevity of the vehicle and the quality of the transported materials.

What Are Common Trade Terms Associated With Dump Trucks With Crane?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B sector. Here are some important terms to know:

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures the original equipment. In the context of dump trucks with cranes, purchasing OEM parts can ensure compatibility and quality, which is vital for maintaining vehicle performance and safety.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ helps buyers plan their purchases effectively, especially when negotiating bulk orders for fleet upgrades or replacements.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms for specific goods or services. In the context of dump trucks with cranes, issuing an RFQ can help buyers compare offers and make informed purchasing decisions based on cost, delivery, and specifications.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers, especially when importing dump trucks with cranes from different countries, as they define who bears the costs and risks at various stages of the shipping process.

5. Tare Weight

Tare weight is the weight of the truck when it is empty. Knowing the tare weight is essential for calculating the payload capacity, which helps businesses ensure compliance with road regulations and optimize load distribution.

By understanding these technical properties and industry terms, B2B buyers can make more informed decisions when purchasing dump trucks with cranes, ultimately enhancing their operational efficiency and profitability.

Navigating Market Dynamics and Sourcing Trends in the dump Trucks With Crane Sector

What Are the Key Trends Shaping the Dump Trucks With Crane Market?

The global dump trucks with crane market is experiencing dynamic shifts driven by several key factors. First, the increasing demand for construction and infrastructure development, particularly in emerging markets across Africa, South America, the Middle East, and Europe, is propelling growth. Governments in these regions are investing heavily in public infrastructure projects, which necessitate efficient transportation and loading solutions that dump trucks with cranes provide. Additionally, advancements in technology are leading to the integration of telematics and automation in these vehicles, enabling better fleet management and operational efficiency.

Sourcing trends are also evolving with a noticeable shift toward online marketplaces and digital platforms, which facilitate easier access to a broader range of equipment. Platforms like Machinio and Autoline are pivotal for international buyers, offering extensive listings and competitive pricing, enhancing the procurement process. Furthermore, the trend towards purchasing used equipment is gaining traction, as companies seek to optimize capital expenditures while still acquiring reliable machinery.

In terms of market dynamics, fluctuating commodity prices and supply chain disruptions caused by geopolitical tensions and the COVID-19 pandemic have necessitated more strategic sourcing practices. International buyers are increasingly looking for suppliers that can offer transparency in pricing and delivery timelines, as well as robust after-sales support.

How Is Sustainability Influencing the Sourcing of Dump Trucks With Crane?

Sustainability is becoming an integral aspect of sourcing in the dump trucks with crane sector. The environmental impact of heavy machinery usage is under scrutiny, prompting buyers to consider the sustainability credentials of their suppliers. This includes evaluating the carbon footprint of manufacturing processes, fuel efficiency of the trucks, and the recyclability of materials used in construction.

Ethical sourcing practices are also gaining importance. Buyers are increasingly prioritizing suppliers that adhere to environmental regulations and possess certifications such as ISO 14001, which denotes an effective environmental management system. The use of ‘green’ materials and technologies, such as alternative fuels and electric-powered cranes, is becoming a focal point for companies aiming to reduce their ecological impact.

Moreover, the rise of corporate social responsibility (CSR) initiatives is encouraging businesses to engage in ethical supply chains. This means not only focusing on environmental sustainability but also ensuring fair labor practices and community engagement within the supply chain. Buyers who align with such values can enhance their brand reputation and appeal to a more socially conscious market.

How Has the Dump Trucks With Crane Sector Evolved Over Time?

The evolution of dump trucks with cranes can be traced back to the late 20th century when construction needs began to outpace traditional transportation methods. Initially, these vehicles were primarily used in large-scale construction projects, but advancements in engineering and design have broadened their applications. The integration of hydraulic systems allowed for more efficient loading and unloading capabilities, making them indispensable in various sectors, including mining, forestry, and waste management.

As technology progressed, the advent of telematics and GPS tracking revolutionized fleet management, allowing operators to monitor vehicle performance and optimize routes in real-time. This evolution has not only enhanced operational efficiency but also contributed to cost savings and reduced environmental impact. Today, the market continues to innovate, with electric and hybrid models emerging as viable options, reflecting the industry’s shift towards sustainability and greener practices.

In summary, the dump trucks with crane sector is at a pivotal point, driven by technological advancements, sustainability concerns, and evolving buyer preferences. For international B2B buyers, understanding these dynamics is crucial for making informed sourcing decisions that align with both operational needs and corporate values.

Frequently Asked Questions (FAQs) for B2B Buyers of dump Trucks With Crane

-

1. How do I solve issues with sourcing dump trucks with cranes?

To effectively source dump trucks with cranes, first, establish clear specifications based on your operational needs, including load capacity, crane type, and vehicle dimensions. Utilize reputable online marketplaces and trade platforms to explore various options and suppliers. Engage directly with manufacturers or dealers to discuss customization possibilities and verify their certifications. Additionally, consider attending industry trade shows to meet suppliers in person and assess their offerings. Conduct thorough background checks and reviews to ensure reliability and quality before making a purchase. -

2. What is the best type of dump truck with a crane for construction projects?

The ideal dump truck with a crane for construction projects typically depends on the specific requirements of the job. For heavy-duty tasks, look for trucks with a robust chassis and high load capacity, such as those with 6×4 or 8×4 axle configurations. Consider models equipped with hydraulic cranes that offer sufficient lifting capacity and reach for your materials. Brands like CAT, Volvo, and Mercedes-Benz are well-regarded for their durability and performance. Always evaluate the crane’s specifications to ensure it meets the demands of your projects. -

3. What are the key factors to consider when vetting suppliers of dump trucks with cranes?

When vetting suppliers, assess their industry reputation, years in business, and customer reviews. Verify their compliance with international standards and certifications, such as ISO or CE marking. Request references from previous buyers to gauge their reliability and service quality. Additionally, examine their after-sales support, warranty policies, and availability of spare parts. Consider suppliers who provide comprehensive documentation and transparent pricing to avoid hidden costs. A supplier’s responsiveness and willingness to provide customization options can also indicate their commitment to customer satisfaction. -

4. What customization options are available for dump trucks with cranes?

Customization options for dump trucks with cranes vary by manufacturer and model. Common modifications include adjusting the crane’s lifting capacity and reach, selecting different dump bed sizes, and customizing the truck’s engine specifications for better fuel efficiency. Buyers can also choose additional features like hydraulic systems, safety equipment, and specialized attachments for specific tasks. Engaging directly with the manufacturer or supplier will provide insights into available options and help tailor the vehicle to meet unique operational requirements. -

5. What is the minimum order quantity (MOQ) for purchasing dump trucks with cranes?

The minimum order quantity (MOQ) for dump trucks with cranes can differ significantly based on the supplier and the market conditions. Some manufacturers may accept single-unit orders, while others may require bulk purchases to offer competitive pricing. For international buyers, MOQs may also be influenced by shipping logistics and regional regulations. It’s advisable to discuss your needs directly with suppliers and explore options for financing or leasing if the MOQ is beyond your immediate budget. -

6. What payment terms are typically offered when purchasing dump trucks with cranes?

Payment terms for dump trucks with cranes can vary widely among suppliers. Common arrangements include upfront payments, deposits followed by installment payments, or financing options through third-party lenders. International buyers should clarify payment methods, such as wire transfers or letters of credit, to ensure secure transactions. Additionally, negotiate terms that align with your cash flow and project timelines, and be aware of any potential currency exchange risks that may affect the final cost. -

7. How can I ensure quality assurance (QA) for my dump truck with a crane purchase?

To ensure quality assurance when purchasing dump trucks with cranes, request detailed inspections and certifications from the supplier. Conduct on-site inspections if possible, or consider hiring third-party inspectors to verify the vehicle’s condition and compliance with specifications. Review the manufacturer’s quality control processes and inquire about warranties or guarantees on parts and workmanship. Keeping a detailed record of all communications and agreements can also protect your interests in case of disputes. -

8. What logistics considerations should I keep in mind when importing dump trucks with cranes?

When importing dump trucks with cranes, consider logistics factors such as shipping methods, customs regulations, and delivery timelines. Ensure that the supplier provides all necessary documentation, including bills of lading and customs declarations, to facilitate smooth clearance. Evaluate the costs associated with freight forwarding, insurance, and local transportation upon arrival. Additionally, be aware of any duties or tariffs that may apply to your shipment based on the destination country’s regulations. Planning ahead can help mitigate delays and additional costs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Dump Trucks With Crane Manufacturers & Suppliers List

1. International – 2002 Durastar 4400

Domain: machinio.com

Registered: 2013 (12 years)

Introduction: Used Dump Trucks and Cranes for sale. Key products include: 1. 2002 International Durastar 4400 – Mileage: 44,625 mi, equipped with STECK 950 Crane, priced at $20,000 USD. 2. 2009 International Workstar 7400 – Mileage: 3,747 mi, features STETCO 950 Crane, sealed dump bed, priced at $18,000 USD. 3. 2009 International Workstar 7400 – Mileage: 86,218 mi, similar features as above, priced at $18,500 U…

2. Dump Trucks – Loader Crane for Sale

Domain: autoline.com

Registered: 1997 (28 years)

Introduction: Dump truck with loader crane for sale; used dump trucks available; various brands and models including Volvo, Mercedes-Benz, MAN, IVECO, DAF, and Scania; price range from $5,444 to $78,400; year of manufacture from 1980 to 2023; mileage varies from 10,250 mi to 577,900 mi; power ranges from 170 HP to 567 HP; fuel types include diesel and gas; axle configurations include 4×2, 6×4, 8×4, and more; lo…

3. ISUZU – 2024 Dump Truck NPR HD

Domain: commercialtrucktrader.com

Registered: 2004 (21 years)

Introduction: Available Trucks: 2024 ISUZU Dump Truck NPR HD, 2022 FORD Roll Off Truck F650, 2024 FORD Roll Off Truck F550, 2024 FORD Dump Truck F600, 2024 FORD Roll Off Truck F600, 2024 ISUZU Roll Off Truck NRR, 2024 CHEVROLET Dually SILVERADO 5500HD, 2024 RAM Dually 5500, 2023 CHEVROLET Roll Off Truck SILVERADO 5500MD, 2024 FORD Winch Truck F550, 2016 CHEVROLET Roll Off Truck 3500HD, 2024 FORD Roll Off Truck …

4. Palfinger – PK15500 Dump Truck with Crane

Domain: rbauction.com

Registered: 1995 (30 years)

Introduction: Dump Trucks with Crane: 2008 Palfinger PK15500 on 2008 Mercedes Axor 1833, 138,370 km, 6 Cylinder, 330 hp, Manual Transmission, 13R22.5, Spring Suspension, 4.5 m – 8 m 2 Section Boom, Out and Down Outriggers, Cordless Remote Control, 4200 mm Bed; 2008 Hiab 166E-3 on 2008 Scania P380, 311,122 km, 6 Cylinder, 380 hp, Semi A/T Transmission, 315/80R22.5, Spring Suspension, 2.8 m – 10.3 m 4 Section Boo…

5. Shutterstock – Business Integration API

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: API for business integration, supports over 10,000 integrations, suitable for small projects to corporations, trusted by developers.

6. Mercedes-Benz – Heavy Machinery

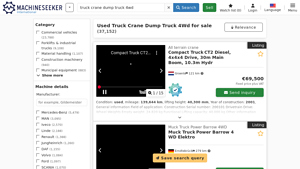

Domain: machineseeker.com

Registered: 1999 (26 years)

Introduction: Manufacturer: Mercedes-Benz, MAN, Iveco, Linde, Renault, Jungheinrich, DAF, Volvo, Ford, SCANIA, STILL, FIAT, Toyota, Manitou, Kalmar

Model: Various

Condition: New, Ex-display machine, Used, Defective

Year of manufacture: 1990-2025

Operating hours: Various

Total length: Various

Total width: Various

Total height: Various

Overall weight: Various

Drive: Wheel

Lifting capacity: Up to 40,000 kg

Empty w…

7. Construction Dump Trucks – Buy & Lease Options

Domain: planet-trucks.com

Registered: 2002 (23 years)

Introduction: {“type”:”Construction dump truck crane”,”ads_count”:34,”ad_types”:[“Buy (33)”,”Leasing (1)”],”bodywork_types”:[“Tipper”,”Construction dump”],”makes”:[“Renault (10)”,”Mercedes (8)”,”Scania (4)”,”Volvo (4)”,”Iveco (3)”,”MAN (3)”,”DAF (2)”]}

8. Puget Sound Trucks – New & Used Trucks

Domain: pugetsoundtrucks.com

Registered: 2002 (23 years)

Introduction: New & Used Crane & Bucket Trucks, Cab Chassis Trucks, Dump Trucks, Water Trucks, 4×4 Trucks, Flatbed Trucks, Fuel Trucks, Service & Utility Trucks, Trailers, Service, and Parts.

Strategic Sourcing Conclusion and Outlook for dump Trucks With Crane

In navigating the complex landscape of sourcing dump trucks with cranes, international buyers must prioritize strategic sourcing to maximize value and efficiency. Understanding the diverse options available—from used equipment to new models—enables businesses to make informed decisions that align with their operational needs and budget constraints. The integration of advanced technologies and the rising demand for versatile vehicles in sectors such as construction, mining, and logistics underscore the importance of selecting the right equipment to enhance productivity.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and efficient dump trucks with cranes is expected to grow. Buyers are encouraged to leverage comprehensive market insights and supplier networks to identify the best procurement opportunities. Collaboration with experienced suppliers can lead to favorable terms, ensuring that investments yield long-term benefits.

Looking ahead, now is the time for businesses to act decisively. By prioritizing strategic sourcing practices, international B2B buyers can secure the necessary equipment that not only meets current demands but also positions them for future growth. Engage with trusted vendors, explore diverse options, and take the next step toward enhancing your operational capabilities today.