Introduction: Navigating the Global Market for hydraulic Crane Truck

As global industries continue to evolve, sourcing the right hydraulic crane truck has become a critical challenge for businesses seeking to enhance operational efficiency and productivity. The demand for versatile and powerful lifting solutions is on the rise, particularly in regions like Africa, South America, the Middle East, and Europe, where infrastructure projects and heavy-duty applications are abundant. This comprehensive guide serves as a vital resource for international B2B buyers, offering insights into various types of hydraulic crane trucks, their applications across multiple sectors, and essential factors for supplier vetting.

Throughout this guide, we will explore the diverse range of hydraulic crane trucks available in the market, from heavy-duty models capable of lifting substantial loads to compact options designed for tighter spaces. Additionally, we will delve into the operational advantages these cranes provide, including enhanced mobility and efficiency for construction, mining, and utility projects. Understanding cost implications and maintenance requirements will further equip buyers with the knowledge needed to make informed purchasing decisions.

By leveraging this guide, businesses can navigate the complexities of sourcing hydraulic crane trucks, ensuring they invest in equipment that meets their specific operational needs. With a focus on actionable insights and expert recommendations, this resource empowers buyers to select the right solutions that not only enhance productivity but also align with their strategic goals in an increasingly competitive global market.

Understanding hydraulic Crane Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Hydraulic Service Crane | High lifting capacity (up to 14,000 lbs), full hydraulic extension, superior boom articulation | Construction, mining, utility services | Pros: High strength, versatile; Cons: Higher upfront cost, maintenance complexity. |

| Electric Over Hydraulic Crane | Electric-powered, quieter operation, lower fuel consumption | Urban construction, residential projects | Pros: Eco-friendly, reduced noise; Cons: Limited power in remote areas, higher initial cost. |

| Truck-Mounted Hydraulic Crane | Mounted on trucks for mobility, various reach options (up to 30 ft) | Equipment repair, forestry, agriculture | Pros: Versatile and mobile; Cons: Payload capacity may be limited by truck size. |

| Hydraulic Truck Crane | High mobility, capable of lifting heavy loads (up to 140 USt) | Infrastructure projects, heavy lifting tasks | Pros: Exceptional lifting capacity; Cons: Requires skilled operators, potentially high operational costs. |

| Compact Hydraulic Crane | Smaller footprint, ideal for tight spaces, lower capacity (up to 3,200 lbs) | Small construction sites, maintenance tasks | Pros: Space-efficient, easy to operate; Cons: Limited lifting capacity, not suitable for heavy-duty tasks. |

What are Heavy-Duty Hydraulic Service Cranes and When Should You Use Them?

Heavy-duty hydraulic service cranes are designed for challenging environments, capable of lifting substantial weights, often up to 14,000 lbs. Their full hydraulic extension and superior boom articulation enable efficient operation in various sectors, such as construction and mining. B2B buyers should consider these cranes for projects requiring high strength and reliability, although the initial investment and maintenance can be more complex compared to lighter models.

How Do Electric Over Hydraulic Cranes Benefit Urban Projects?

Electric over hydraulic cranes utilize electric power, making them quieter and more environmentally friendly than traditional hydraulic cranes. This feature is particularly beneficial in urban settings where noise pollution is a concern. They are ideal for residential construction and projects requiring minimal disruption. However, buyers should assess their power needs, as these cranes may struggle in remote areas where electricity is unavailable.

What Makes Truck-Mounted Hydraulic Cranes Versatile?

Truck-mounted hydraulic cranes combine the lifting capabilities of hydraulic systems with the mobility of a truck. With reach options of up to 30 feet, they are suitable for various applications, including equipment repair and forestry work. B2B buyers should evaluate their payload capacity in relation to the truck’s size, as this can limit the crane’s overall effectiveness in certain projects.

Why Choose Hydraulic Truck Cranes for Heavy Lifting?

Hydraulic truck cranes are renowned for their exceptional lifting capacities, often exceeding 140 USt. They are indispensable in infrastructure projects and heavy lifting tasks, offering superior mobility on job sites. However, potential buyers should be aware of the need for skilled operators and the higher operational costs associated with these powerful machines.

When is a Compact Hydraulic Crane the Right Choice?

Compact hydraulic cranes are designed for environments where space is a premium. With a lower lifting capacity of up to 3,200 lbs, they are ideal for small construction sites and maintenance tasks. These cranes are easy to operate and maneuver, making them suitable for businesses focused on efficiency in confined spaces. However, their limited capacity means they are not suitable for heavy-duty applications.

Key Industrial Applications of hydraulic Crane Truck

| Industry/Sector | Specific Application of Hydraulic Crane Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and positioning heavy materials on-site | Enhances productivity and reduces labor costs | Load capacity, reach, and durability in harsh conditions |

| Oil & Gas | Installation and maintenance of drilling equipment | Ensures timely operations and minimizes downtime | Fuel efficiency, weight, and adaptability to terrain |

| Mining & Aggregates | Transporting and setting up heavy machinery | Increases operational efficiency and safety standards | Lifting capacity, stability, and ease of transport |

| Utility Services | Assisting in power line installation and repairs | Improves response time and service reliability | Remote operation capabilities and boom articulation |

| Agriculture | Moving large equipment and materials for farming | Streamlines operations and enhances productivity | Versatility in attachments and ease of use |

How is Hydraulic Crane Truck Used in Construction?

In the construction industry, hydraulic crane trucks are essential for lifting and positioning heavy materials such as steel beams, concrete blocks, and prefabricated structures. They address the challenges of limited space and heavy lifting requirements, enabling workers to accomplish tasks that would otherwise require extensive manual labor or multiple machines. Buyers in this sector should prioritize cranes with high load capacities and extended reach, ensuring they can operate effectively in diverse job site conditions.

What Role Does Hydraulic Crane Truck Play in Oil & Gas?

In the oil and gas sector, hydraulic crane trucks facilitate the installation and maintenance of drilling rigs and associated equipment. These cranes help minimize downtime by allowing for quick and efficient equipment handling, which is crucial in this fast-paced industry. Buyers must consider factors such as fuel efficiency and the crane’s ability to operate in rugged terrains, as well as its weight to maintain mobility on-site.

How Does Hydraulic Crane Truck Benefit Mining & Aggregates?

Hydraulic crane trucks are vital in mining and aggregates for transporting and setting up heavy machinery like crushers and conveyors. Their ability to lift substantial loads quickly enhances operational efficiency and ensures adherence to safety standards. International buyers should focus on cranes that offer robust lifting capacities and stability, particularly in challenging environments where uneven ground is common.

In What Ways Does Hydraulic Crane Truck Aid Utility Services?

Utility services utilize hydraulic crane trucks for tasks like power line installation and maintenance. These cranes significantly improve response times during repairs, ensuring that utilities can restore service quickly. Sourcing considerations should include remote operation capabilities and superior boom articulation to navigate around obstacles and reach difficult locations effectively.

How is Hydraulic Crane Truck Used in Agriculture?

In the agricultural sector, hydraulic crane trucks assist in moving large equipment and materials, such as irrigation systems and heavy machinery. This capability streamlines operations, allowing for more efficient use of time and resources on farms. Buyers should seek out cranes that offer versatility in attachments and ease of use, ensuring they can adapt to various agricultural tasks effectively.

3 Common User Pain Points for ‘hydraulic Crane Truck’ & Their Solutions

Scenario 1: Limited Lifting Capacity for Heavy Loads

The Problem: Many B2B buyers, especially those in construction or mining, often face the challenge of insufficient lifting capacity when using hydraulic crane trucks. A crane that cannot handle the required weight can lead to project delays, increased labor costs, and potential safety hazards. Buyers may find themselves in situations where they need to lift heavy equipment or materials but discover that their existing crane lacks the necessary capacity, leading to frustration and inefficiencies.

The Solution: To address this pain point, buyers should conduct a thorough analysis of their lifting requirements before purchasing or upgrading a hydraulic crane truck. This includes evaluating the maximum load weight, the height to which loads need to be lifted, and the reach required for specific job sites. When selecting a crane, consider models with adjustable lifting capacities and features that enhance versatility, such as telescopic booms or multiple attachment options. Investing in a crane with a higher maximum lifting capacity than initially needed can provide a safety buffer and accommodate future projects without the need for immediate replacement or upgrades.

Scenario 2: Inefficient Operation and Control

The Problem: B2B buyers frequently encounter issues with crane operation efficiency, particularly concerning control systems. Traditional manual controls can lead to slower operation times and increased risk of accidents due to operator error. This is especially problematic in fast-paced environments where timely lifting and placement of materials are critical to maintaining project timelines.

The Solution: To enhance operational efficiency, buyers should consider hydraulic crane trucks equipped with advanced control systems, such as proportional radio remote controls. These systems allow operators to manage lifting tasks from a safe distance, reducing the risk of accidents and improving overall workflow. Additionally, investing in training for operators on how to effectively use these control systems can significantly increase productivity. Buyers should also seek models with features like automatic load monitoring systems that help prevent overloads and enhance safety.

Scenario 3: High Maintenance Costs and Downtime

The Problem: Hydraulic crane trucks can be prone to wear and tear, leading to high maintenance costs and unexpected downtime, which can severely impact project schedules and budgets. This is particularly concerning for businesses operating in remote or challenging environments, where access to maintenance services can be limited. B2B buyers may find themselves facing significant financial strain as they cope with the consequences of an unreliable crane.

The Solution: To mitigate maintenance costs and reduce the likelihood of downtime, buyers should prioritize the selection of cranes designed for durability and ease of maintenance. Look for models that feature robust construction materials, such as high-strength steel, and those equipped with user-friendly maintenance access points. Implementing a regular maintenance schedule, along with training staff on routine checks and repairs, can extend the lifespan of the crane and prevent costly breakdowns. Furthermore, consider partnering with manufacturers or suppliers who offer comprehensive service packages, including warranties and support for parts replacement, to further safeguard against unexpected expenses.

By addressing these common pain points proactively, B2B buyers can make informed decisions that enhance operational efficiency, ensure safety, and protect their investments in hydraulic crane trucks.

Strategic Material Selection Guide for hydraulic Crane Truck

What Are the Common Materials Used in Hydraulic Crane Trucks?

When selecting materials for hydraulic crane trucks, various factors such as performance, durability, cost, and international standards come into play. Here, we analyze four common materials: Steel, Aluminum, Composite Materials, and Cast Iron, each with unique properties and implications for B2B buyers.

How Does Steel Perform in Hydraulic Crane Truck Applications?

Steel is the most widely used material in hydraulic crane construction due to its excellent strength-to-weight ratio and durability. Steel can withstand high temperatures and pressures, making it suitable for heavy-duty applications. It also offers good corrosion resistance when treated or coated.

Pros: Steel is highly durable and can endure harsh working environments, making it ideal for construction and heavy lifting. Its manufacturing processes are well-established, leading to lower production costs.

Cons: The weight of steel can limit the payload capacity of the crane truck. Additionally, untreated steel is susceptible to rust, which can lead to increased maintenance costs.

Impact on Application: Steel is compatible with various hydraulic fluids and can handle the stresses of heavy lifting without deforming.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial. Buyers in regions like Europe and the Middle East often prefer steel that meets specific certification requirements to ensure quality and safety.

What Advantages Does Aluminum Offer for Hydraulic Crane Trucks?

Aluminum is increasingly popular in crane truck construction due to its lightweight nature, which enhances mobility and fuel efficiency. It has good corrosion resistance, especially when anodized, and can perform well in diverse environmental conditions.

Pros: The reduced weight of aluminum allows for higher payload capacities and better fuel economy. It also offers excellent resistance to corrosion, which is beneficial in humid or coastal environments.

Cons: Aluminum is generally more expensive than steel and may not provide the same level of strength under extreme loads. Its manufacturing processes can also be more complex, leading to higher production costs.

Impact on Application: Aluminum is compatible with various hydraulic fluids, but its lower strength limits its use in extremely heavy-duty applications.

Considerations for International Buyers: Buyers should ensure that aluminum components meet international standards, such as JIS for Japan or ASTM for the U.S. This is particularly important in regions like Africa and South America, where material sourcing can vary.

How Do Composite Materials Enhance Hydraulic Crane Truck Performance?

Composite materials, such as fiberglass and carbon fiber, are gaining traction in hydraulic crane applications due to their high strength-to-weight ratios and resistance to corrosion and fatigue.

Pros: Composites are significantly lighter than metals, allowing for better fuel efficiency and increased payload capacities. They also resist corrosion and do not require protective coatings.

Cons: The cost of composite materials can be high, and their manufacturing processes are often more complex and time-consuming. Additionally, composites may not perform as well under extreme temperatures.

Impact on Application: Composites are compatible with hydraulic fluids but may not be suitable for high-temperature applications.

Considerations for International Buyers: Compliance with specific industry standards is essential, especially in regions like Europe, where regulations regarding material safety and performance are stringent.

What Role Does Cast Iron Play in Hydraulic Crane Truck Design?

Cast iron is commonly used in components requiring high wear resistance and strength, such as bases and frames. Its excellent damping properties make it suitable for reducing vibrations.

Pros: Cast iron is durable and can withstand heavy loads, making it ideal for stationary components. It also has good wear resistance, extending the lifespan of parts.

Cons: The weight of cast iron can be a disadvantage in mobile applications, as it may reduce overall payload capacity. It is also prone to corrosion if not properly treated.

Impact on Application: Cast iron is compatible with various hydraulic systems but may require additional protective measures in corrosive environments.

Considerations for International Buyers: Buyers should check for compliance with international standards, especially in regions like the Middle East, where environmental conditions can be harsh.

Summary Table of Material Properties for Hydraulic Crane Trucks

| Material | Typical Use Case for Hydraulic Crane Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components and booms | High durability and strength | Heavy weight can limit payload | Medium |

| Aluminum | Lightweight cranes and components | Enhanced fuel efficiency | Higher cost and lower strength | High |

| Composite | Specialized lightweight components | Excellent strength-to-weight ratio | High cost and complex manufacturing | High |

| Cast Iron | Bases and frames | Excellent wear resistance | Heavy and prone to corrosion | Medium |

This strategic material selection guide provides a comprehensive overview for B2B buyers, enabling informed decisions based on performance, cost, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic Crane Truck

What Are the Main Stages in the Manufacturing Process of Hydraulic Crane Trucks?

The manufacturing process of hydraulic crane trucks involves several key stages, each critical to ensuring the final product meets performance and safety standards.

Material Preparation

The first stage involves selecting and preparing materials, primarily high-strength steel, which is essential for the structural integrity and durability of the crane. This includes cutting the steel sheets and plates to specified dimensions using CNC (Computer Numerical Control) machines. The precision in this initial phase is crucial as it affects the overall strength and weight distribution of the crane.

Forming Techniques

Following material preparation, the forming process takes place. This typically involves advanced techniques such as bending, welding, and machining. For instance, hydraulic presses may be used to shape the steel into beams and booms. Welding is particularly vital, as it connects different components, ensuring they can withstand significant loads. Automated welding systems enhance consistency and reduce human error, critical in maintaining quality standards.

Assembly Process

Once the components are formed, they move to the assembly stage. Here, various parts, including the boom, chassis, hydraulic systems, and control units, are integrated. This stage often employs modular assembly techniques, allowing for efficient construction while ensuring that each part meets specifications. Quality control checkpoints are crucial during assembly to verify alignment, fit, and operational readiness.

Finishing Touches

The final stage involves finishing processes such as painting and coating to protect against corrosion and enhance aesthetic appeal. This may include sandblasting to prepare surfaces and applying specialized coatings that meet international standards for durability. Finishing touches are not merely cosmetic; they play a significant role in extending the crane’s lifespan, particularly in harsh operating environments.

How Is Quality Assurance Implemented in Hydraulic Crane Truck Manufacturing?

Quality assurance (QA) is a fundamental component in the production of hydraulic crane trucks, ensuring that each unit meets both safety and performance standards.

What International Standards Are Relevant for Hydraulic Crane Quality Assurance?

Adherence to international standards is essential for manufacturers targeting global markets. ISO 9001, which focuses on quality management systems, is a fundamental certification that indicates a commitment to quality processes. Additionally, compliance with CE marking and API (American Petroleum Institute) standards is crucial, especially for cranes used in sectors like oil and gas. These certifications reassure buyers that the equipment meets rigorous safety and performance criteria.

What Are the Key Quality Control Checkpoints?

Quality control typically includes several critical checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting materials upon arrival to ensure they meet specified standards before manufacturing begins. This step helps prevent defects from entering the production line.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections ensure that components are being produced to specifications. This includes monitoring welding quality, dimensional accuracy, and hydraulic system assembly.

-

Final Quality Control (FQC): Once assembly is complete, a thorough inspection is conducted to verify that the entire crane operates correctly. This includes load testing to confirm that the crane can handle its rated capacity safely.

What Common Testing Methods Are Used in Hydraulic Crane Quality Assurance?

Testing is a critical part of quality assurance for hydraulic crane trucks. Common methods include:

-

Load Testing: This involves applying loads to the crane to verify that it can lift its rated capacity without failure. This testing simulates real-world conditions and is essential for safety certification.

-

Hydraulic System Testing: Ensuring that the hydraulic system operates efficiently under pressure is vital. Tests check for leaks, pressure stability, and response times.

-

Operational Testing: This includes testing control systems, boom articulation, and other operational features to ensure that all functions work seamlessly and safely.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is vital to ensure reliable and safe equipment.

What Are the Best Practices for Supplier Audits?

Conducting audits is one of the most effective ways to assess a supplier’s quality control. B2B buyers should:

-

Request Documentation: Ask for quality assurance documentation, including certificates of compliance with international standards like ISO 9001 and CE marking.

-

Conduct On-site Audits: If feasible, visit the manufacturing facility to observe processes firsthand. This allows buyers to assess the quality of materials, manufacturing techniques, and testing procedures.

-

Third-Party Inspections: Engaging independent third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. These agencies can conduct pre-shipment inspections to ensure compliance with agreed-upon specifications.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers should be aware of additional nuances in quality control:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Understanding local regulations in the buyer’s region is essential for ensuring compliance and avoiding legal issues.

-

Cultural and Language Barriers: Effective communication is critical. Buyers should ensure that suppliers can provide documentation and support in a language that is accessible to them.

-

Logistics and Supply Chain Management: Quality assurance does not end with production. Buyers should consider logistics and transportation factors that might affect the crane’s condition upon arrival.

By understanding these aspects of the manufacturing processes and quality assurance for hydraulic crane trucks, B2B buyers can make informed decisions, ensuring that they acquire reliable and high-quality equipment tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydraulic Crane Truck’

When considering the procurement of hydraulic crane trucks, a systematic approach is vital to ensure you select the right equipment that meets your operational needs and budget. This step-by-step checklist will guide you through the essential factors to consider and actions to take during the sourcing process.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your hydraulic crane truck. This includes the lifting capacity, boom length, operational reach, and any specific features you may need, such as remote control or hydraulic extensions. Defining these specifications early on ensures that you focus on models that meet your operational demands, thus avoiding unnecessary purchases.

Step 2: Research Available Models

Explore various models available in the market to understand the options that align with your needs. Look for manufacturers with a diverse product line that can cater to both heavy-duty and light-duty applications. Pay attention to the specifications of each model, such as weight limits and boom articulation angles, which can significantly affect performance in different job environments.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct a thorough evaluation of potential suppliers. Request detailed company profiles, case studies, and references from clients in similar industries or regions. Verify their experience and reliability by checking online reviews and ratings, ensuring that they can provide the support and service you need post-purchase.

Step 4: Assess Warranty and Maintenance Support

Investigate the warranty options provided by manufacturers, as this can significantly impact your long-term operational costs. A robust warranty indicates the manufacturer’s confidence in their product. Additionally, inquire about the availability of maintenance services and spare parts, as timely support can minimize downtime and maintenance costs.

Step 5: Request Quotes and Compare Costs

Once you have shortlisted suppliers, request detailed quotes that outline the costs of the hydraulic crane trucks, including any additional features or accessories. Compare these quotes not just on price but also on the value offered, such as warranty length, service agreements, and included training. This comprehensive comparison will help you make an informed decision.

Step 6: Verify Compliance with Local Regulations

Ensure that the hydraulic crane truck you intend to purchase complies with local safety and operational regulations. This is particularly important in international markets where regulations may vary significantly. Consult with local authorities or industry experts to confirm that the equipment meets all necessary legal requirements.

Step 7: Finalize the Purchase and Plan for Delivery

After selecting the right supplier and model, finalize your purchase agreement. Discuss delivery timelines, installation procedures, and operator training if necessary. Proper planning for these logistics ensures that your crane truck is operational as soon as it arrives, minimizing disruption to your projects.

By following these steps, you can ensure that your procurement process for hydraulic crane trucks is thorough, strategic, and aligned with your business needs.

Comprehensive Cost and Pricing Analysis for hydraulic Crane Truck Sourcing

What Are the Key Cost Components in Hydraulic Crane Truck Manufacturing?

When sourcing hydraulic crane trucks, it is essential to understand the various cost components that contribute to the final price. The primary cost elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts cost. High-strength steel is commonly used for booms and frames, while hydraulic systems require specialized components that can increase material expenses. The fluctuating prices of raw materials, influenced by global markets, can also affect overall costs.

-

Labor: Skilled labor is necessary for the assembly and welding processes, which can be a significant cost factor, especially in regions with high labor costs. Investing in skilled labor can lead to better quality products, which may reduce warranty claims and maintenance costs.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can help lower overhead costs, making it crucial for suppliers to optimize their operations.

-

Tooling: Specialized tools for assembly and maintenance contribute to the initial setup cost. Suppliers with advanced tooling capabilities can offer customization options, which may come at a premium.

-

Quality Control: Implementing stringent QC measures ensures reliability and safety, particularly in heavy-duty applications. While this adds to costs, it can enhance the crane’s lifespan and reduce total ownership costs.

-

Logistics: Transportation costs can vary widely based on the distance and mode of transport. International shipping can incur additional fees and tariffs, which should be factored into the total cost.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding the market average for margins can help buyers negotiate better deals.

How Do Price Influencers Affect Hydraulic Crane Truck Sourcing?

Several factors influence the pricing of hydraulic crane trucks, which can vary based on geographic location and market conditions.

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often result in lower unit costs due to economies of scale. Buyers should negotiate MOQs to optimize pricing based on their needs.

-

Specifications and Customization: Custom specifications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected expenses during production.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but may provide long-term value through durability and compliance with safety regulations.

-

Supplier Factors: The reputation and location of the supplier can affect pricing. Established suppliers with a proven track record may charge a premium, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding Incoterms is crucial in international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, impacting the total cost.

What Are the Best Tips for Buyers Negotiating Hydraulic Crane Truck Prices?

Negotiating effectively can lead to significant savings. Here are some actionable tips for international B2B buyers:

-

Conduct Thorough Market Research: Understand the average pricing in your region and compare it with multiple suppliers to gain leverage in negotiations.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, operational efficiency, and resale value in your decision-making process.

-

Be Transparent About Needs: Clearly communicating your requirements and any potential for repeat business can encourage suppliers to offer better terms.

-

Leverage Volume Discounts: If you anticipate needing multiple units, express this to suppliers to negotiate bulk pricing or favorable payment terms.

-

Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead to better support and service.

What Should Buyers Keep in Mind Regarding Pricing Nuances in Different Regions?

Pricing for hydraulic crane trucks can vary significantly across regions such as Africa, South America, the Middle East, and Europe due to local economic conditions, import tariffs, and market demand. Buyers should be aware of these nuances:

-

Currency Fluctuations: Exchange rates can impact pricing, especially for international transactions. Locking in prices or using hedging strategies can mitigate risks.

-

Regulatory Compliance: Different regions may have varying safety and environmental regulations affecting costs. Ensure that the equipment meets local standards to avoid additional expenses.

-

Cultural Factors: Understanding cultural differences in negotiation styles can enhance communication and lead to more favorable agreements.

In conclusion, being informed about the cost structure, price influencers, and regional nuances can significantly enhance the sourcing process for hydraulic crane trucks, ultimately leading to better purchasing decisions and cost efficiency.

Alternatives Analysis: Comparing hydraulic Crane Truck With Other Solutions

Exploring Alternatives to Hydraulic Crane Trucks

When it comes to lifting and transporting heavy loads, hydraulic crane trucks are a popular choice due to their versatility and power. However, there are several alternatives that might better suit specific operational needs. In this section, we will compare hydraulic crane trucks with two viable alternatives: electric over hydraulic cranes and traditional forklifts. This analysis will help international B2B buyers make informed decisions based on their unique requirements.

| Comparison Aspect | Hydraulic Crane Truck | Electric Over Hydraulic Crane | Traditional Forklift |

|---|---|---|---|

| Performance | High lifting capacity (7,500 to 14,000 lbs), versatile for various applications | Moderate lifting capacity (up to 5,000 lbs), ideal for lighter loads | Limited to vertical lifting, usually up to 15,000 lbs |

| Cost | Higher initial investment and operational costs | Moderate initial cost, lower operational costs | Generally lower initial cost, but higher maintenance costs |

| Ease of Implementation | Requires specific training and setup | Easier to implement with less training | Minimal training needed, widely understood |

| Maintenance | Requires regular maintenance, parts can be expensive | Lower maintenance needs, fewer parts to service | Higher maintenance due to wear and tear |

| Best Use Case | Construction, heavy-duty service, remote locations | Light to medium-duty lifting in urban or industrial environments | Warehousing, distribution, and internal transport |

Understanding Electric Over Hydraulic Cranes

Electric over hydraulic cranes serve as a practical alternative for businesses that require moderate lifting capabilities without the extensive operational costs associated with hydraulic crane trucks. These cranes are designed for easier implementation and lower maintenance, making them suitable for urban settings where electric power sources are readily available. However, their lifting capacity is limited compared to hydraulic crane trucks, which can be a drawback for projects requiring heavy lifting.

Pros: Lower operational costs, easier to operate, and reduced maintenance requirements.

Cons: Limited lifting capacity, not suitable for heavy-duty applications.

Evaluating Traditional Forklifts

Traditional forklifts are a well-established solution for lifting and transporting loads within warehouses or distribution centers. They are typically more affordable upfront and require minimal training for operators. However, forklifts lack the versatility of hydraulic crane trucks and are limited to lifting vertically, which may not be suitable for all job sites, especially those requiring outreach capabilities.

Pros: Lower initial costs, ease of use, and high availability.

Cons: Limited lifting height and outreach, higher maintenance costs over time.

How to Choose the Right Solution for Your Needs

Selecting the appropriate lifting solution involves evaluating your specific operational requirements, budget constraints, and the nature of the tasks at hand. Hydraulic crane trucks excel in heavy-duty applications and environments that demand versatility and reach. In contrast, electric over hydraulic cranes are more suited for lighter loads and urban settings, while traditional forklifts are ideal for internal transport within warehouses.

Ultimately, by assessing the performance, cost, ease of implementation, and maintenance requirements of each alternative, B2B buyers can make informed decisions that align with their operational goals and financial considerations.

Essential Technical Properties and Trade Terminology for hydraulic Crane Truck

When considering a hydraulic crane truck for your operations, understanding its technical properties and trade terminology is crucial for making informed purchasing decisions. Below are key specifications and terms that every B2B buyer should be familiar with.

What are the Key Technical Specifications of Hydraulic Crane Trucks?

-

Lifting Capacity

This specification indicates the maximum weight the crane can lift, typically measured in pounds or tons. For instance, hydraulic cranes can range from 3,200 lbs to over 72,000 lbs. Understanding lifting capacity is vital because it determines the type of loads your crane can handle, directly affecting your operational efficiency and safety. -

Boom Length and Reach

The boom length refers to the arm of the crane that extends to lift loads, while reach encompasses how far the crane can extend horizontally. Common boom lengths can vary from 7 to 30 feet. A longer reach allows for greater versatility in lifting operations, enabling access to difficult locations without repositioning the truck, which is particularly beneficial in construction and maintenance tasks. -

Moment Rating

This rating represents the crane’s lifting power relative to its arm length, expressed in foot-pounds. For example, a crane with a moment rating of 10,000 ft-lbs can lift a 3,200 lb load at a distance of 3 feet from the pivot point. A higher moment rating means greater lifting capability, which is crucial for heavy-duty applications. -

Control Options

Hydraulic cranes can come with various control systems, including proportional pendant controls or wireless remote controls. These systems enhance operational safety and efficiency by allowing operators to manage lifting activities from a safe distance, minimizing the risk of accidents. -

Articulation Angles

The articulation angle defines how much the crane’s boom can move vertically, often ranging from -5 to +80 degrees. Superior articulation allows for easier loading and unloading in tight spaces, which is essential in urban environments or congested job sites. -

Hydraulic System Type

Hydraulic cranes typically use either electric over hydraulic or traditional hydraulic systems powered by the truck’s PTO (Power Take-Off). The choice of system affects the crane’s performance, fuel efficiency, and maintenance requirements. Selecting the right type can lead to significant operational cost savings.

What Common Trade Terms Should B2B Buyers Know?

-

OEM (Original Equipment Manufacturer)

OEM refers to the company that originally manufactures the crane. Understanding OEM is essential when seeking quality and reliability, as reputable manufacturers often provide better warranties and support. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This term is crucial for budgeting and inventory management, especially for businesses looking to purchase multiple cranes or accessories. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Issuing an RFQ is an important step in the procurement process, enabling buyers to compare offers and negotiate better deals. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers avoid misunderstandings and manage logistics effectively. -

Payload

Payload refers to the total weight that a crane can carry, including the weight of the crane itself and any additional equipment or materials. It’s crucial for ensuring compliance with safety regulations and optimizing transport efficiency. -

Serviceability

This term describes how easy it is to maintain and repair the crane. A serviceable crane minimizes downtime and maintenance costs, which is essential for maximizing productivity in demanding environments.

By grasping these technical properties and trade terms, B2B buyers can make more strategic decisions when investing in hydraulic crane trucks, ensuring they select equipment that meets their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the hydraulic Crane Truck Sector

What Are the Key Trends and Market Dynamics in the Hydraulic Crane Truck Sector?

The hydraulic crane truck sector is currently experiencing robust growth fueled by several global drivers. The construction and infrastructure development boom, particularly in emerging markets across Africa and South America, has increased demand for versatile and efficient lifting solutions. In the Middle East, ongoing investments in infrastructure and urban development projects are also propelling the market forward. European nations, including Germany, are seeing a shift towards more advanced, tech-integrated crane solutions, emphasizing automation and real-time data analytics to enhance operational efficiency.

Emerging technologies are reshaping sourcing trends within the sector. Increased automation, such as proportional radio remote control systems and integrated load monitoring, allows operators to manage heavy loads with precision and safety. Moreover, the rise of electric over hydraulic cranes signifies a growing preference for sustainable and energy-efficient machinery. International B2B buyers are increasingly seeking suppliers who can provide customizable solutions tailored to specific job requirements, reflecting a shift from one-size-fits-all approaches to more specialized offerings.

Market dynamics indicate a competitive landscape where manufacturers must differentiate themselves through innovation and service. Buyers are encouraged to consider not only the initial purchase price but also the total cost of ownership, including maintenance, operational efficiency, and resale value. This multi-faceted evaluation is essential for making informed sourcing decisions in a market that continues to evolve rapidly.

How Is Sustainability and Ethical Sourcing Impacting the Hydraulic Crane Truck Sector?

Sustainability has become a pivotal consideration for B2B buyers in the hydraulic crane truck sector. The environmental impact of heavy machinery is under scrutiny, prompting manufacturers to adopt greener practices. Companies are increasingly investing in hydraulic cranes that utilize eco-friendly materials and technologies, such as electric power systems, which significantly reduce fuel consumption and emissions.

Ethical sourcing is also gaining traction among buyers, who are now more conscious of the supply chain’s social and environmental implications. This includes ensuring that raw materials are sourced responsibly and that suppliers adhere to fair labor practices. Buyers are encouraged to seek out manufacturers with certifications that validate their commitment to sustainability, such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety.

Additionally, the trend towards circular economy principles is influencing sourcing strategies. This approach emphasizes the importance of reusing and recycling materials, which can lead to reduced production costs and a smaller carbon footprint. By prioritizing suppliers who are aligned with these values, B2B buyers can enhance their corporate social responsibility initiatives while ensuring a sustainable supply chain.

What Is the Historical Context of Hydraulic Crane Trucks in the B2B Market?

The hydraulic crane truck has a rich history that dates back to the early 20th century when hydraulic systems were first introduced in construction machinery. Initially, these cranes were limited in capacity and functionality, primarily used for basic lifting tasks. Over the decades, technological advancements have led to significant enhancements in design and performance.

The evolution of hydraulic cranes has been marked by innovations such as improved hydraulic pumps, advanced control systems, and the integration of electronic monitoring technologies. By the 1980s and 1990s, the introduction of computer-aided design (CAD) allowed manufacturers to optimize crane structures for better strength-to-weight ratios, enhancing lifting capacities without compromising mobility.

Today, hydraulic crane trucks are essential assets in various industries, including construction, mining, and logistics. As international B2B buyers navigate the modern marketplace, understanding the historical context of these machines can provide valuable insights into current trends and future developments in the sector.

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic Crane Truck

-

How do I select the right hydraulic crane truck for my business needs?

Choosing the right hydraulic crane truck involves assessing your specific lifting requirements, including load capacity, reach, and application type. Consider the weight of the materials you typically handle and the maximum height you need to reach. It’s also essential to evaluate the terrain and working conditions, as these factors influence crane performance. Engage with suppliers to discuss your unique needs and request demonstrations or case studies relevant to your industry to ensure the crane aligns with your operational goals. -

What factors should I consider when vetting suppliers for hydraulic crane trucks?

When vetting suppliers, prioritize their experience in the industry, reputation, and customer reviews. Ensure they comply with international quality standards and certifications, which indicate reliability and safety. Evaluate their product range and ability to offer customization options that meet your specific needs. It’s also beneficial to assess their after-sales support, warranty terms, and service agreements to ensure you receive comprehensive support post-purchase. -

What are the typical payment terms for purchasing hydraulic crane trucks?

Payment terms for hydraulic crane trucks can vary widely by supplier and region. Common arrangements include upfront payments, partial deposits followed by balance payments upon delivery, or financing options. Always clarify payment methods accepted, such as bank transfers, letters of credit, or credit terms. Discuss any potential for discounts on early payments or bulk orders, and ensure all terms are documented in your purchase agreement to avoid misunderstandings. -

What is the minimum order quantity (MOQ) when sourcing hydraulic crane trucks?

Minimum order quantities for hydraulic crane trucks can depend on the supplier and the specific model. Some suppliers may allow single-unit purchases, especially for standard models, while others might have higher MOQs for custom-built or specialized cranes. It’s advisable to inquire about flexibility in orders, especially if you are a new buyer or testing a model. Understanding the MOQ will help you plan your budget and inventory accordingly. -

How can I ensure the quality and reliability of hydraulic crane trucks?

To ensure quality and reliability, look for suppliers that provide detailed specifications, certifications, and testing reports for their cranes. Request information on the manufacturing process and materials used, as well as any warranties offered. Additionally, consider suppliers who allow third-party inspections or audits of their facilities. Engaging in a site visit, if feasible, can also give you insight into their production standards and quality control measures. -

What are the logistics considerations when importing hydraulic crane trucks?

When importing hydraulic crane trucks, consider shipping methods, customs regulations, and potential tariffs. Determine the best shipping route and mode (sea, air, or land) based on cost and urgency. Ensure that your supplier provides necessary documentation, such as bills of lading and compliance certificates, to facilitate a smooth customs clearance process. Partnering with a logistics expert can help navigate these complexities and ensure timely delivery. -

What customization options are available for hydraulic crane trucks?

Customization options for hydraulic crane trucks can include modifications to lifting capacity, boom length, and control systems. Many manufacturers offer tailored solutions based on specific industry needs, such as additional safety features or specialized attachments. Discuss your requirements with potential suppliers to explore available options. Customizing your crane can enhance efficiency and ensure it meets the unique demands of your operations. -

How can I assess the total cost of ownership for a hydraulic crane truck?

To assess the total cost of ownership, consider the purchase price, maintenance costs, fuel consumption, and potential downtime. Evaluate the longevity and reliability of the crane, as high-quality models may incur lower long-term costs despite a higher initial investment. Additionally, factor in training costs for operators and any modifications needed for your specific applications. A comprehensive cost analysis will help you make a more informed purchasing decision.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Hydraulic Crane Truck Manufacturers & Suppliers List

1. BBCranes – Auto Crane 3203PR Series

Domain: store.bbcranes.com

Registered: 2009 (16 years)

Introduction: [{‘model’: ‘Auto Crane 3203PR’, ‘stock_number’: ‘547-3203PR’, ‘price’: ‘CALL’}, {‘model’: ‘Auto Crane 3203PRX’, ‘stock_number’: ‘548-3203PRX’, ‘price’: ‘CALL’}, {‘model’: ‘Auto Crane 3203PRX’, ‘stock_number’: ‘614-3203PRX’, ‘price’: ‘CALL’}, {‘model’: ‘Auto Crane 3203PRX’, ‘stock_number’: ‘616-3203PRX’, ‘price’: ‘CALL’}, {‘model’: ‘Auto Crane 5005EH’, ‘stock_number’: ‘632-5005EH’, ‘price’: ‘CALL’}…

2. ALL Crane – Hydraulic Truck Cranes

Domain: allcrane.com

Registered: 1997 (28 years)

Introduction: Hydraulic Truck Cranes for Sale: New and Used options available from 40 to 140 USt. ALL Crane offers superior mobility, extreme lifting capacity, and flexibility for various jobs. The company provides in-house expertise, including computer modeling and job site analysis. They have 29 branches across the U.S. for support. Additional services include rental purchase options, financing assistance, sp…

3. National Crane – Boom Trucks

Domain: manitowoc.com

Registered: 1995 (30 years)

Introduction: National Crane has been a leader in boom trucks for over 40 years, offering truck-mounted hydraulic cranes with exceptional reach. Key features include:

– **Stand-Up Boom Trucks**: 8 models with capacities from 9.1 t (10 USt) to 29.9 t (33 USt) and maximum vertical reach from 17 m (56 ft) to 50.9 m (167 ft).

– **Swing Seat Boom Trucks**: 14 models with capacities from 27.2 t (30 USt) to 54.49 t (…

4. Edwards Inc – Hydraulic Truck Cranes

Domain: edwardsinc.com

Registered: 1996 (29 years)

Introduction: Hydraulic Truck Crane fleet ranges from 40 ton Manitex to 110 ton Grove. Cranes are dispatched from a computerized communication center for quick response. All operators and lift directors are NCCCO trained and certified. Load charts available for most cranes. Key models include: 110 Ton Link Belt HTT86110 (164′ boom, 90′ jib), 110 Ton Grove TMS9000E (142′ boom, 88′ jib), 100 Ton Link Belt HTC8610…

5. PALFINGER – Truck Mounted Cranes

Domain: palfinger.com

Registered: 1997 (28 years)

Introduction: Truck Mounted Cranes: PALFINGER offers a wide range of truck-mounted cranes designed for various lifting needs. Key product categories include: 1. Knuckle Boom Cranes: Durable and operator-friendly, available with options like fly-jibs and grapples for versatility. 2. Material Handling Cranes: Specifically designed for the North American building materials industry, featuring low tare weight for i…

6. Hawkeye Truck Equipment – Hydraulic Cranes

Domain: hawkeyetruckequipment.com

Registered: 1997 (28 years)

Introduction: Hawkeye Truck Equipment offers hydraulic/telescopic cranes with capacities ranging from 3,200 lb to 14,000 lb. The product line includes: Stellar 3315 (3,200 lb), Stellar 4421 (4,000 lb), Stellar 5521 (5,200 lb), Stellar 6521 (6,000 lb), Stellar 7621/7630 (7,500 lb), Stellar 9630 (9,000 lb), Stellar 10621 (10,000 lb), Stellar 10630 (10,000 lb), Stellar 12621 (12,000 lb), Stellar 12630 (12,000 lb),…

7. Gingerich Crane – Truck-Mounted Hydraulic Cranes

Domain: gingerichcrane.com

Registered: 2008 (17 years)

Introduction: This company, Gingerich Crane – Truck-Mounted Hydraulic Cranes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

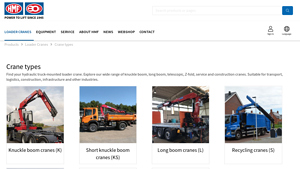

8. HMF Cranes – Versatile Lifting Solutions

Domain: hmfcranes.com

Registered: 2006 (19 years)

Introduction: {“Lifting capacity”: {“3 – 14 tm”: “Knuckle boom cranes (K)”, “15 – 31 tm”: “Short knuckle boom cranes (KS)”, “32 – 59 tm”: “Long boom cranes (L)”, “60 – 95 tm”: “Recycling cranes (S)”}, “Crane types”: [“Telescopic cranes (T)”, “Z-fold grab cranes (Z)”, “Wallboard cranes (WB)”], “Equipment”: {“Subframes”: [“For cranes 4-10 tm”, “For cranes 10-23 tm”, “For cranes 18-35 tm”, “For cranes 30-45 tm”, “…

Strategic Sourcing Conclusion and Outlook for hydraulic Crane Truck

In navigating the complex landscape of hydraulic crane truck procurement, international B2B buyers must prioritize strategic sourcing to maximize value and ensure operational efficiency. Key considerations include assessing lifting capacities, boom designs, and control systems that align with specific job requirements. The diverse range of hydraulic cranes available, from heavy-duty models to electric over hydraulic options, allows buyers to select equipment tailored to their unique operational contexts, whether in construction, mining, or logistics.

Investing in high-quality hydraulic cranes not only enhances productivity but also reduces maintenance costs and downtime, ultimately leading to improved return on investment. Furthermore, as global demand for sustainable and efficient lifting solutions grows, incorporating advanced features like proportional radio remote controls and energy-efficient designs can position businesses as leaders in their respective markets.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe are encouraged to engage with trusted suppliers who offer comprehensive support and expertise in crane selection. By adopting a proactive approach to sourcing, businesses can secure reliable, versatile equipment that meets their evolving needs and drives future growth. Connect with industry leaders today to explore the best hydraulic crane truck solutions for your operations.