Introduction: Navigating the Global Market for jib Cranes

Navigating the complexities of sourcing jib cranes can be a formidable challenge for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. The diverse applications of jib cranes, from enhancing material handling efficiency in cramped spaces to supporting ergonomic lifting operations, necessitate a nuanced understanding of the various types available, including wall-mounted, floor-mounted, and portable options. As buyers strive to optimize operational productivity and safety, having access to a comprehensive guide that covers critical aspects such as supplier vetting, cost analysis, and application suitability becomes essential.

This guide is designed to empower decision-makers by providing in-depth insights into the global jib crane market. It explores the specifications and benefits of different crane types, enabling buyers to select the most suitable solutions for their unique operational needs. Additionally, it addresses the importance of partnering with reputable suppliers who can deliver quality products and reliable support. By leveraging the information presented in this guide, international B2B buyers can make informed purchasing decisions that not only meet their immediate operational requirements but also align with long-term business objectives. Whether you’re in Saudi Arabia, Vietnam, or elsewhere, this resource aims to streamline your procurement process and enhance your material handling capabilities.

Understanding jib Cranes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Wall-Mounted Jib Crane | Fixed to a wall, maximizing floor space; can be cantilevered | Manufacturing, assembly lines, warehouses | Pros: Space-saving, easy installation. Cons: Limited reach; requires wall support. |

| Floor-Mounted Jib Crane | Base-mounted for 360-degree rotation; versatile positioning | Heavy lifting in factories, docks, and warehouses | Pros: Full mobility, high load capacity. Cons: Requires floor space; installation can be complex. |

| Portable Jib Crane | Lightweight and movable; can be used in various locations | Construction sites, maintenance tasks | Pros: Flexibility, easy to relocate. Cons: Limited load capacity; less stability. |

| Articulating Jib Crane | Features a jointed arm for extended reach and maneuverability | Tight spaces, specialized lifting tasks | Pros: Versatile, excellent reach. Cons: Generally more expensive; complex operation. |

| Foundationless Jib Crane | Does not require a concrete foundation; easy to install | Temporary setups, small workshops | Pros: Quick setup, minimal floor disruption. Cons: May have lower stability for heavier loads. |

What Are the Characteristics of Wall-Mounted Jib Cranes?

Wall-mounted jib cranes are designed to be affixed to a wall, which allows for effective use of vertical space. These cranes can be configured as cantilevered models to maximize headroom and minimize obstruction. They are particularly suitable for environments where floor space is limited, such as assembly lines and warehouses. When purchasing, consider the wall’s structural integrity, as the crane’s load capacity depends on secure mounting.

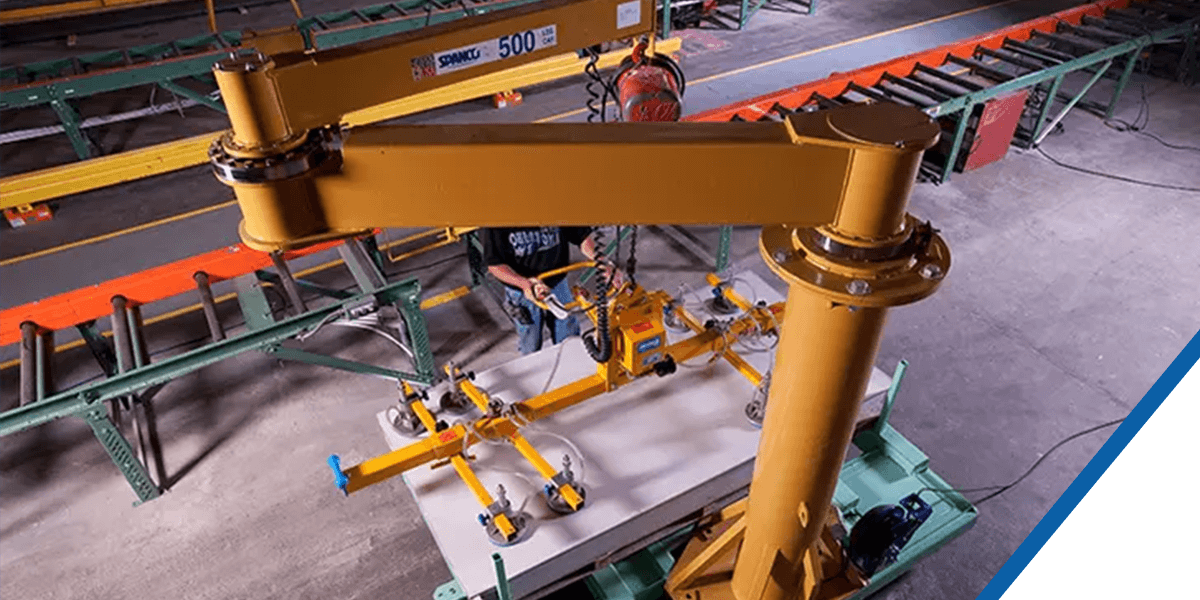

How Do Floor-Mounted Jib Cranes Operate?

Floor-mounted jib cranes are anchored to the ground and allow for a full 360-degree rotation. This type of crane is ideal for heavy lifting in manufacturing or shipping environments, where mobility and load capacity are critical. Buyers should evaluate the floor’s load-bearing capacity and the crane’s height and reach specifications to ensure it meets operational needs.

In What Situations Are Portable Jib Cranes Most Effective?

Portable jib cranes are designed for flexibility, making them ideal for construction sites or maintenance tasks where equipment needs to be moved frequently. Their lightweight construction allows for easy relocation, but this comes at the cost of load capacity and stability. Buyers should assess the specific lifting requirements and consider how often the crane will need to be moved before making a purchase.

What Advantages Do Articulating Jib Cranes Offer?

Articulating jib cranes feature a jointed arm that enhances their reach and maneuverability, making them suitable for tight spaces where traditional cranes may struggle. They are particularly beneficial for specialized lifting tasks that require precision. However, their complexity can lead to higher costs and a steeper learning curve for operators, making it essential for buyers to weigh these factors against their operational needs.

When Should You Choose Foundationless Jib Cranes?

Foundationless jib cranes are designed for quick installation without the need for a concrete base, making them perfect for temporary setups or smaller workshops. This type of crane is advantageous for operations that require minimal disruption to the existing floor layout. However, buyers should consider the stability of the crane, especially when lifting heavier loads, as this type may not provide the same level of support as foundation-mounted options.

Key Industrial Applications of jib Cranes

| Industry/Sector | Specific Application of Jib Cranes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly Line Support | Enhances productivity by facilitating quick material handling | Load capacity, reach, and mounting options |

| Warehousing | Inventory Management | Improves efficiency in loading and unloading goods | Space constraints, portability, and ease of operation |

| Construction | Material Handling on Job Sites | Reduces labor costs and minimizes injury risk | Durability, weather resistance, and lifting capacity |

| Automotive | Engine Assembly | Streamlines production processes, reducing downtime | Customization options and integration with existing systems |

| Marine and Offshore | Equipment Maintenance | Ensures safe lifting in challenging environments | Corrosion resistance and compliance with safety standards |

How Are Jib Cranes Used in Manufacturing and What Problems Do They Solve?

In the manufacturing sector, jib cranes are extensively used to support assembly lines, enabling operators to lift and move heavy components with ease. This application significantly enhances productivity by reducing the time spent on manual handling. Buyers in this sector should consider the load capacity and reach of the jib crane, as well as mounting options that fit their specific workspace configurations. Ensuring the crane can be integrated seamlessly into existing processes is also crucial for maximizing efficiency.

What Role Do Jib Cranes Play in Warehousing Operations?

In warehousing, jib cranes are vital for inventory management, particularly in loading and unloading goods from delivery trucks. Their ability to operate in tight spaces makes them ideal for maximizing storage efficiency. By streamlining the movement of materials, jib cranes help reduce the time and labor costs associated with inventory handling. Buyers should evaluate factors like portability and ease of operation, as well as the crane’s ability to fit within the warehouse’s spatial constraints.

How Do Jib Cranes Enhance Construction Site Operations?

On construction sites, jib cranes are used for material handling, particularly for lifting heavy equipment and supplies to elevated areas. This application not only reduces labor costs but also minimizes the risk of injuries associated with manual lifting. Buyers must consider the durability of the crane, especially in harsh weather conditions, and ensure it meets the necessary lifting capacities for the specific materials being handled. Compliance with local safety regulations is also a critical consideration.

How Are Jib Cranes Essential in Automotive Production?

In the automotive industry, jib cranes are frequently employed for engine assembly, where precision and efficiency are paramount. These cranes facilitate the quick and safe movement of heavy engine components, thereby streamlining production processes and reducing downtime. Buyers should look for customization options that allow integration with existing assembly lines, as well as the ability to handle specific lifting requirements unique to their operations.

What Are the Benefits of Using Jib Cranes in Marine and Offshore Applications?

In marine and offshore environments, jib cranes are essential for equipment maintenance and repair tasks. Their ability to safely lift heavy loads in challenging conditions enhances operational efficiency and worker safety. Buyers should prioritize features such as corrosion resistance and compliance with safety standards to ensure the crane can withstand the rigors of these environments. Additionally, understanding the specific lifting needs and safety regulations of the region is crucial for successful sourcing.

3 Common User Pain Points for ‘jib Cranes’ & Their Solutions

Scenario 1: Limited Space in Industrial Facilities

The Problem: Many B2B buyers face the challenge of operating in cramped industrial environments where space is at a premium. Traditional cranes often require expansive floor areas for installation and operation, making them unsuitable for facilities such as small warehouses or manufacturing plants. This can lead to inefficiencies, as workers struggle to move materials and products safely and effectively within limited confines, ultimately affecting productivity and safety.

The Solution: To address this issue, buyers should consider wall-mounted or portable jib cranes that are specifically designed for tight spaces. Wall-mounted jib cranes can be installed in corners or along walls, maximizing the use of vertical space without occupying valuable floor area. Buyers should assess their facility layout and determine the most effective crane type and configuration. A professional consultation with a jib crane distributor can help identify the best fit based on specific lifting requirements, allowing for efficient material handling without sacrificing operational flow. Additionally, opting for cranes with adjustable spans can provide further flexibility, enabling businesses to adapt to changing space and operational needs.

Scenario 2: Safety Concerns in Lifting Operations

The Problem: Safety is a paramount concern for companies that utilize jib cranes, especially in industries like construction, manufacturing, and logistics. Improper lifting techniques or equipment failures can lead to accidents, injuries, and costly downtime. B2B buyers often worry about the safety features of jib cranes, including load limits, stability, and operator training.

The Solution: To enhance safety, it’s crucial to invest in jib cranes that come equipped with built-in safety features such as overload protection, anti-collision systems, and emergency stop buttons. Buyers should thoroughly evaluate the specifications and safety certifications of potential cranes to ensure compliance with industry standards. Additionally, implementing a comprehensive training program for operators can significantly mitigate risks. This program should cover proper usage, load management, and emergency procedures. Regular maintenance checks and inspections are also essential to ensure equipment is in optimal working condition. Partnering with a supplier who offers ongoing support and training resources can provide added assurance of safety in lifting operations.

Scenario 3: High Maintenance and Operational Costs

The Problem: Many businesses are concerned about the long-term costs associated with maintaining lifting equipment, including jib cranes. Frequent breakdowns, wear and tear, and the need for specialized maintenance can inflate operational costs, making it difficult for companies to stay within budget. B2B buyers often seek solutions that minimize these ongoing expenses while ensuring reliable performance.

The Solution: To reduce maintenance costs, buyers should consider investing in high-quality jib cranes designed for durability and ease of use. Selecting cranes with fewer moving parts can lead to lower maintenance requirements and longer service life. Buyers should also evaluate the warranty and support options provided by manufacturers, as robust customer service can facilitate quick repairs and replacements when necessary. Implementing a proactive maintenance schedule, including regular inspections and lubrication, can help identify potential issues before they escalate into costly repairs. Additionally, consider investing in training for maintenance staff to ensure they are knowledgeable about the specific requirements of the jib cranes in use. This investment in quality and training can lead to significant long-term savings and operational efficiency.

Strategic Material Selection Guide for jib Cranes

What Are the Key Materials Used in Jib Cranes and Their Properties?

When selecting materials for jib cranes, it’s essential to consider the specific requirements of the application, including load capacity, environmental conditions, and operational efficiency. Here, we analyze four common materials used in jib crane construction: steel, aluminum, stainless steel, and composite materials.

How Does Steel Perform in Jib Crane Applications?

Steel is the most widely used material for jib cranes due to its excellent strength-to-weight ratio and durability. It can withstand high loads and is suitable for heavy-duty applications. Steel’s temperature and pressure ratings are high, making it ideal for environments with fluctuating conditions. However, it is susceptible to corrosion if not properly treated or coated, which can be a significant drawback in humid or saline environments.

Pros: High strength, cost-effective, widely available.

Cons: Prone to rust without protective coatings, heavier than alternatives.

Impact on Application: Suitable for heavy lifting in various industries, but requires maintenance to prevent corrosion.

Considerations for International Buyers: Compliance with ASTM standards is crucial, especially in regions with stringent safety regulations. Buyers in Africa and South America should consider local environmental conditions when selecting steel grades.

What Are the Benefits of Using Aluminum for Jib Cranes?

Aluminum is a lightweight alternative to steel, making it easier to handle and install. It is inherently resistant to corrosion, which is advantageous for outdoor applications or in coastal areas. However, aluminum has a lower tensile strength compared to steel, which may limit its use in heavy-duty applications.

Pros: Lightweight, corrosion-resistant, easy to fabricate.

Cons: Lower strength, potentially higher cost per unit weight.

Impact on Application: Ideal for applications requiring mobility and ease of installation, such as in warehouses or assembly lines.

Considerations for International Buyers: Compliance with JIS standards is often preferred in Asia, while European buyers may look for EN standards in aluminum specifications.

Why Choose Stainless Steel for Jib Cranes?

Stainless steel offers exceptional corrosion resistance and is suitable for harsh environments, including chemical processing and food manufacturing. Its strength is comparable to that of carbon steel, making it a robust choice for various applications. However, the cost of stainless steel is significantly higher, which can impact budget considerations.

Pros: Excellent corrosion resistance, strong, hygienic properties.

Cons: Higher cost, more complex manufacturing processes.

Impact on Application: Best suited for environments where hygiene and corrosion resistance are critical, such as food and pharmaceutical industries.

Considerations for International Buyers: Buyers in the Middle East and Europe may prioritize compliance with DIN standards for stainless steel, ensuring quality and safety.

What Role Do Composite Materials Play in Jib Crane Design?

Composite materials, such as fiberglass or carbon fiber, are increasingly used in jib crane construction for their lightweight and high strength characteristics. They offer excellent resistance to corrosion and environmental degradation. However, composites can be more expensive and may require specialized manufacturing techniques.

Pros: Lightweight, high strength-to-weight ratio, corrosion-resistant.

Cons: Higher manufacturing complexity, elevated costs.

Impact on Application: Suitable for specialized applications where weight reduction is crucial, such as in aerospace or high-tech industries.

Considerations for International Buyers: Buyers should ensure compliance with relevant international standards and consider the availability of composite materials in their region.

Summary Table of Material Properties for Jib Cranes

| Material | Typical Use Case for jib Cranes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty lifting in industrial settings | High strength | Prone to rust without treatment | Medium |

| Aluminum | Lightweight applications in warehouses | Corrosion-resistant | Lower strength compared to steel | Medium |

| Stainless Steel | Food processing and chemical industries | Excellent corrosion resistance | Higher cost | High |

| Composite | Specialized applications in aerospace | Lightweight and strong | Higher manufacturing complexity | High |

This guide provides a strategic overview of material selection for jib cranes, enabling international B2B buyers to make informed decisions based on their specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for jib Cranes

What Are the Main Stages in the Manufacturing Process of Jib Cranes?

The manufacturing of jib cranes involves several critical stages, each designed to ensure that the final product meets the highest standards of quality and performance. The main stages include material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage in the manufacturing process is material preparation. Manufacturers typically use high-strength steel for structural components due to its durability and load-bearing capacity. The selection process often involves assessing the material’s mechanical properties and compliance with international standards. Once selected, raw materials undergo cutting, bending, and machining to create the necessary shapes and sizes for the crane components. Advanced technologies such as laser cutting and CNC machining are commonly employed to ensure precision and efficiency.

Forming: What Techniques Are Used to Shape Jib Crane Components?

In the forming stage, various techniques are utilized to shape the components of the jib crane. Common methods include:

- Welding: Critical for joining parts, welding ensures structural integrity and durability. Manufacturers often employ automated welding techniques for consistent quality.

- Press Braking: This technique is used to create bends in metal sheets, allowing for the formation of the jib or boom at specified angles.

- Casting: Some components may be cast to create complex shapes that are difficult to achieve through traditional machining.

These forming techniques contribute to the overall strength and functionality of the jib crane.

Assembly: How Are Different Components Integrated into a Complete Jib Crane?

The assembly phase is where all the pre-manufactured components come together. Skilled technicians meticulously assemble the jib crane, ensuring that each part fits correctly and functions as intended. During this stage, manufacturers typically follow detailed assembly instructions and quality assurance protocols to maintain consistency. The use of jigs and fixtures helps to streamline the process and improve accuracy.

Finishing: What Processes Ensure the Jib Crane is Ready for Use?

Finishing processes are essential to enhance the durability and aesthetic appeal of the jib crane. This stage may include:

- Surface Treatment: Techniques such as powder coating or galvanizing are applied to prevent corrosion and extend the lifespan of the crane.

- Final Inspection: A thorough inspection is conducted to check for any defects or inconsistencies. This ensures that the crane meets both safety and performance standards before it is shipped to the customer.

What Quality Assurance Measures Are Essential for Jib Cranes?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for products like jib cranes that are used in industrial settings. To ensure compliance with international standards, manufacturers implement various QA measures throughout the production process.

Which International Standards Are Relevant for Jib Crane Quality Assurance?

Several international standards govern the quality assurance processes for jib cranes. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system. It emphasizes customer satisfaction and continual improvement, ensuring that manufacturers consistently produce high-quality products.

- CE Marking: Particularly important in Europe, CE marking indicates that the jib crane complies with EU safety, health, and environmental protection legislation.

- API Standards: For manufacturers targeting the oil and gas sector, adherence to American Petroleum Institute (API) standards is crucial for ensuring the safety and reliability of lifting equipment.

What Quality Control Checkpoints Are Commonly Used in Manufacturing?

Quality control (QC) is integrated into every stage of the manufacturing process, with specific checkpoints to monitor quality:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to verify their compliance with specifications.

- In-Process Quality Control (IPQC): During the manufacturing process, regular checks are performed to ensure that each stage meets quality standards. This includes monitoring welding quality, dimensions, and surface finishes.

- Final Quality Control (FQC): Before shipment, the finished jib crane undergoes a comprehensive inspection to confirm that it meets all performance and safety criteria.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers need to ensure that their suppliers adhere to stringent quality control measures. Here are several methods to verify supplier QC:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality control systems, and compliance with international standards.

- Quality Reports: Requesting detailed quality assurance reports from suppliers can provide insights into their QC practices and any issues encountered during production.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing process and the final product.

What Are the Nuances of Quality Control for International B2B Buyers?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control is essential. Factors to consider include:

- Local Regulations: Different countries may have specific regulations that impact the design and manufacturing of lifting equipment. Buyers should ensure that their suppliers are familiar with these regulations.

- Cultural Differences: Communication and expectations may vary across cultures. Establishing clear lines of communication can help mitigate misunderstandings related to quality standards.

- Logistics and Shipping: Quality control doesn’t end at the factory. Buyers should consider how products are packaged and transported to avoid damage during shipping, which can affect overall quality.

In conclusion, understanding the manufacturing processes and quality assurance measures for jib cranes is essential for B2B buyers. By focusing on these elements, companies can ensure they select reliable suppliers that meet their operational needs while adhering to international quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘jib Cranes’

To facilitate a successful procurement process for jib cranes, it’s essential to follow a structured approach that addresses both technical requirements and supplier reliability. This checklist serves as a practical guide to help you make informed decisions when sourcing jib cranes for your operations.

Step 1: Define Your Technical Specifications

Understanding your specific needs is critical before initiating the procurement process. Consider factors such as lifting capacity, span length, and mounting type (wall-mounted, floor-mounted, or portable). Clearly defining these specifications will ensure you select a crane that fits your operational environment and workflow.

- Capacity Requirements: Determine the maximum load you need to lift and select a jib crane that can accommodate this weight safely.

- Space Constraints: Measure the available space to ensure the crane can be installed without hindrance.

Step 2: Identify the Right Type of Jib Crane

Jib cranes come in various designs tailored to specific applications. Assess which type aligns with your operational needs, whether it be articulating, wall-mounted, or portable.

- Articulating Cranes: Ideal for tight spaces, these cranes can maneuver around obstacles.

- Portable Cranes: Suitable for applications requiring mobility, allowing you to reposition the crane as needed.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers to ensure they can meet your specifications and provide reliable products. Request company profiles, case studies, and references from similar industries or regions to verify their reputation.

- Certifications: Check if suppliers have relevant industry certifications, which can indicate their adherence to quality and safety standards.

- Delivery Capabilities: Ensure that the supplier can meet your timeline for delivery, especially if you have tight project deadlines.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that include pricing, lead times, and warranty terms. This transparency allows for easy comparison between offers.

- Breakdown of Costs: Ensure the quotation includes all costs, such as installation and additional accessories.

- Warranty Information: Understand the warranty terms for both the crane and any included hoists to protect your investment.

Step 5: Assess After-Sales Support and Maintenance Services

A supplier’s commitment to after-sales support can significantly impact your operational efficiency. Inquire about maintenance services, spare parts availability, and technical support.

- Maintenance Plans: Determine if the supplier offers scheduled maintenance services or training for your staff.

- Spare Parts Availability: Ensure that spare parts are readily available, minimizing downtime in case of equipment failure.

Step 6: Conduct Site Assessments and Compliance Checks

Before finalizing your order, conduct site assessments to ensure the installation meets safety regulations and operational needs. Compliance with local regulations is paramount to avoid potential legal issues.

- Local Regulations: Familiarize yourself with any regional safety standards that apply to crane operations.

- Site Suitability: Evaluate the installation site for any structural modifications that may be required.

Step 7: Finalize the Purchase Agreement

Once all evaluations and assessments are complete, finalize your purchase agreement with the chosen supplier. Ensure that all terms, including delivery timelines, payment schedules, and warranty conditions, are clearly outlined.

- Clarity in Terms: Both parties should have a mutual understanding of the agreement to avoid future disputes.

- Documentation: Keep all documentation organized for easy reference and compliance verification.

By following this step-by-step checklist, B2B buyers can navigate the complexities of sourcing jib cranes, ensuring they select the right equipment to enhance their operational efficiency while minimizing risks associated with procurement.

Comprehensive Cost and Pricing Analysis for jib Cranes Sourcing

What Are the Key Cost Components in Jib Cranes Sourcing?

When sourcing jib cranes, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The type of materials used significantly affects the price. Steel is commonly utilized for structural components, while specialized materials such as stainless steel may be necessary for corrosive environments. The quality of materials can also impact the crane’s durability and performance.

-

Labor: Labor costs encompass not only the manufacturing workforce but also skilled technicians for assembly and installation. Labor rates can vary widely based on geographic location and local labor market conditions.

-

Manufacturing Overhead: This includes indirect costs such as utilities, facility maintenance, and administrative expenses. Overhead rates may differ among suppliers, impacting the final price.

-

Tooling and Equipment: The initial investment in tooling and machinery to produce jib cranes can influence pricing. More advanced manufacturing processes may lead to higher costs but can also result in better quality and precision.

-

Quality Control (QC): A robust QC process ensures that the cranes meet safety and performance standards. This can add to the overall cost but is essential for reducing long-term risks and liabilities.

-

Logistics: Shipping and handling costs can vary based on the crane’s size and weight, as well as the distance to the destination. International shipping may incur additional tariffs and fees.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks, which can vary based on market conditions and competition.

How Do Pricing Influencers Affect Jib Crane Costs?

Several factors can influence the pricing of jib cranes:

-

Volume/MOQ: Larger orders often lead to volume discounts. Establishing a Minimum Order Quantity (MOQ) with suppliers can provide leverage for better pricing.

-

Specifications and Customization: Custom jib cranes designed for specific applications may incur additional costs. Clearly defining your requirements can help suppliers provide accurate quotes.

-

Materials and Quality Certifications: Cranes built with higher-grade materials or those that meet specific safety certifications (e.g., ISO, CE) tend to be more expensive. Buyers should weigh the benefits of certification against their budget constraints.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established manufacturers with a history of quality may charge higher prices but could provide better service and support.

-

Incoterms: The choice of Incoterms (International Commercial Terms) can impact costs and responsibilities in shipping. Understanding these terms is essential for managing logistics and potential hidden costs.

What Are the Best Practices for Negotiating Jib Crane Prices?

For international B2B buyers, particularly in Africa, South America, the Middle East, and Europe, negotiating jib crane prices can lead to significant savings. Here are some tips:

-

Conduct Market Research: Understand the price range for similar jib cranes in the market. This knowledge can empower your negotiation strategy.

-

Leverage Total Cost of Ownership (TCO): Consider not only the initial purchase price but also maintenance, operational, and potential downtime costs. A lower upfront cost may lead to higher TCO if the crane is of inferior quality.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms. Frequent communication and transparency can foster trust.

-

Be Open to Alternatives: If a specific crane model exceeds your budget, consider alternatives that may offer similar functionality at a lower price point.

-

Timing Matters: Prices can fluctuate based on demand and economic conditions. Timing your purchase to coincide with off-peak periods can yield better prices.

Conclusion: What Should Buyers Keep in Mind?

While this analysis provides a foundational understanding of the cost and pricing structure for jib cranes, it’s essential to approach sourcing with a comprehensive strategy. Always consult multiple suppliers, seek detailed quotations, and analyze the total cost implications. Remember that the prices indicated in this guide are for reference only and may vary based on the aforementioned factors.

Alternatives Analysis: Comparing jib Cranes With Other Solutions

Exploring Alternatives to Jib Cranes: What Are Your Options?

In the realm of industrial lifting solutions, jib cranes stand out for their versatility and efficiency. However, various alternatives may better suit specific operational needs or constraints. This analysis will compare jib cranes with two viable alternatives: overhead cranes and gantry cranes. By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions tailored to their unique requirements.

| Comparison Aspect | Jib Cranes | Overhead Cranes | Gantry Cranes |

|---|---|---|---|

| Performance | Excellent for limited spaces; 360-degree rotation; ergonomic lifting | High lifting capacity; spans large areas; can handle heavy loads | Portable; flexible positioning; good for outdoor use |

| Cost | Generally lower initial investment; maintenance costs are minimal | Higher upfront costs; significant installation expenses | Moderate costs; often more affordable than overhead cranes |

| Ease of Implementation | Quick to install; minimal structural requirements | Requires substantial overhead structure; longer installation time | Can be assembled and disassembled easily; less structural complexity |

| Maintenance | Low maintenance due to fewer components | Higher maintenance needs; complex systems | Moderate maintenance; depends on design and usage |

| Best Use Case | Ideal for confined spaces, workshops, and assembly lines | Best for large warehouses and manufacturing plants | Suitable for outdoor applications and temporary setups |

What Are the Pros and Cons of Overhead Cranes?

Overhead cranes are designed for lifting heavy loads across large areas. They provide robust performance and can accommodate significant weight capacities, making them ideal for industrial environments where heavy materials need to be moved frequently. However, the installation process can be complex and costly, requiring a substantial overhead structure that may not be feasible in all settings. Maintenance can also be more demanding, as these systems involve intricate mechanisms and electrical components.

How Do Gantry Cranes Compare in Terms of Flexibility?

Gantry cranes are characterized by their portable design, allowing for flexible positioning in various environments, including outdoor applications. They typically feature a frame that supports the lifting mechanism, making them easy to move and set up as needed. This adaptability is a significant advantage for businesses that require temporary lifting solutions. However, while they are generally more affordable than overhead cranes, their lifting capacity may be limited compared to jib cranes and overhead cranes, making them less suitable for extremely heavy loads.

Conclusion: How to Choose the Right Lifting Solution for Your Needs

When selecting the appropriate lifting solution for your business, consider the specific operational requirements, including space constraints, load capacities, and installation costs. Jib cranes excel in confined areas and offer ergonomic advantages, making them suitable for workshops and assembly lines. Overhead cranes provide high lifting capacities for larger facilities but come with higher costs and maintenance needs. Gantry cranes offer flexibility and portability for various applications but may not match the load capabilities of the other options. By carefully evaluating these factors, B2B buyers can choose the best lifting solution that aligns with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for jib Cranes

What Are the Essential Technical Properties of Jib Cranes?

When considering jib cranes for your operations, understanding their technical specifications is crucial. Here are key properties that influence performance and suitability for various applications:

-

Load Capacity

The load capacity defines the maximum weight a jib crane can lift safely. Typically measured in tons, this specification is vital for ensuring that the crane can handle the materials used in your operations. Selecting a crane with an appropriate load capacity minimizes the risk of overloading, which can lead to equipment failure and safety hazards. -

Span

The span refers to the horizontal distance from the center of the support structure to the end of the jib. A longer span allows for greater reach, enabling efficient material handling across larger work areas. However, it’s essential to balance span with load capacity, as longer spans can reduce the overall lifting capability. -

Height of Lift

This specification indicates how high the jib crane can lift loads. The height of lift is crucial in environments with height restrictions or where materials need to be moved to elevated positions. Adequate height ensures that the crane can perform its tasks without obstruction, enhancing operational efficiency. -

Rotation

Jib cranes can be designed for various degrees of rotation, often 360 degrees for floor-mounted models. The rotation capability affects maneuverability and the ease of placing loads in tight spaces. Understanding the rotation feature is essential for planning workflows and optimizing the layout of workstations. -

Material Grade

The material grade of the crane components, such as the jib and hoist, affects durability and performance. Common materials include steel and aluminum, with specific grades indicating strength and resistance to wear. Higher-grade materials typically mean a longer lifespan and lower maintenance costs, crucial for long-term investments. -

Power Source

Jib cranes can be powered manually, electrically, or through pneumatic systems. The choice of power source affects operational efficiency and safety. Electric models tend to offer better lifting speeds and reduced manual effort, making them ideal for high-frequency operations.

What Are Common Trade Terms Used in the Jib Crane Industry?

Familiarity with industry jargon is essential for effective communication in procurement and negotiations. Here are several common terms relevant to jib cranes:

-

OEM (Original Equipment Manufacturer)

This term refers to the company that manufactures the original components or systems that are used in the jib crane. Understanding OEM relationships is vital for ensuring quality and compatibility when sourcing parts or entire cranes. -

MOQ (Minimum Order Quantity)

MOQ specifies the smallest amount of a product that a supplier is willing to sell. Knowing the MOQ is important for budgeting and inventory management, especially for businesses looking to purchase multiple cranes or components. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for pricing and terms on specified products or services. This is a critical step in the purchasing process, allowing companies to compare offers and make informed decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Familiarity with Incoterms can prevent misunderstandings and ensure smooth logistics when importing cranes. -

Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for planning and ensuring that operations are not delayed due to equipment shortages. -

Maintenance Schedule

This term outlines the recommended intervals for servicing and inspecting cranes to ensure safe and efficient operation. Adhering to a maintenance schedule can significantly extend the lifespan of equipment and reduce downtime.

These technical properties and trade terms are foundational for making informed purchasing decisions regarding jib cranes, ensuring that businesses can optimize their material handling capabilities effectively.

Navigating Market Dynamics and Sourcing Trends in the jib Cranes Sector

What Are the Key Market Trends Driving the Jib Cranes Sector Globally?

The jib crane market is experiencing significant growth driven by increasing automation across various industries. As manufacturers strive for efficiency, the demand for versatile lifting solutions, such as jib cranes, continues to rise. This is particularly true in regions like Africa, South America, the Middle East, and Europe, where industrial expansion and urbanization are creating a need for effective material handling solutions. Emerging technologies, such as IoT and smart sensors, are being integrated into jib crane systems, enhancing operational efficiency and safety. For international B2B buyers, this presents an opportunity to invest in state-of-the-art equipment that can streamline operations and reduce labor costs.

Moreover, the trend toward customized solutions is gaining traction. Buyers are increasingly seeking jib cranes tailored to their specific operational needs, whether it be for tight spaces in manufacturing plants or large-scale logistics operations. This demand for customization is pushing manufacturers to innovate and offer a wider range of products, including portable and wall-mounted options. Additionally, the global focus on sustainability is influencing purchasing decisions, with buyers prioritizing suppliers that demonstrate a commitment to environmentally friendly practices.

How Important Is Sustainability and Ethical Sourcing in the Jib Cranes Market?

Sustainability and ethical sourcing have become critical factors in the procurement process for B2B buyers in the jib cranes sector. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to seek suppliers who prioritize green certifications and sustainable materials. This includes the use of recycled metals, eco-friendly coatings, and energy-efficient manufacturing practices.

Moreover, ethical supply chains are gaining importance as buyers increasingly demand transparency regarding labor practices and sourcing methods. Companies that can provide assurance of ethical sourcing are likely to stand out in a competitive market. For buyers in regions such as the Middle East and Africa, where regulatory frameworks may be evolving, aligning with suppliers who adhere to international standards can mitigate risks associated with compliance and reputation.

How Has the Jib Cranes Market Evolved Over Time?

The evolution of the jib crane market has been shaped by advancements in engineering and the growing complexity of industrial operations. Initially designed for simple lifting tasks, jib cranes have transformed into sophisticated machines capable of handling various loads and working in diverse environments. Over the decades, the introduction of new materials and technologies has enhanced the strength, durability, and efficiency of jib cranes.

Today, the market offers a range of options, from lightweight portable models to heavy-duty floor-mounted systems, catering to the unique needs of different industries. The historical context of these innovations not only reflects the changing demands of businesses but also emphasizes the importance of ongoing research and development in maintaining competitive advantage. For B2B buyers, understanding this evolution aids in making informed purchasing decisions that align with their operational requirements and future growth strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of jib Cranes

-

How do I choose the right jib crane for my facility?

Selecting the right jib crane involves assessing your specific lifting needs, workspace dimensions, and load capacity requirements. Consider factors like the type of jib crane (e.g., wall-mounted, floor-mounted, or portable) that best fits your operational environment. Additionally, evaluate the lifting height and reach necessary for your tasks. Consult with manufacturers or distributors who can provide insights based on your industry and application to ensure you select a crane that enhances efficiency and safety. -

What are the key features to look for in a jib crane?

When evaluating jib cranes, focus on features such as load capacity, reach, and mounting options. Look for ergonomic designs that minimize strain on operators and enhance safety. Consider the crane’s rotation capabilities, as 360-degree movement may be essential for your operations. Additional features like adjustable height, ease of installation, and compatibility with various hoists can also significantly impact functionality and productivity. -

What is the typical lead time for ordering and receiving a jib crane?

Lead times for jib cranes can vary based on the manufacturer, crane specifications, and customization requirements. Generally, standard models can be shipped within a few weeks, while custom solutions may take longer, often between 6 to 12 weeks. It’s crucial to communicate your needs clearly to suppliers and inquire about their production schedules to ensure timely delivery, especially if you have project deadlines to meet. -

What are the payment terms when purchasing jib cranes internationally?

Payment terms can vary by supplier and region. Common options include upfront payment, letters of credit, or payment upon delivery. When sourcing internationally, ensure you discuss and agree on terms that protect both parties. Be aware of additional costs such as shipping, customs duties, and taxes, which should be factored into your total budget. Always verify the supplier’s credibility before finalizing payment arrangements. -

How can I ensure the quality and safety of the jib crane I purchase?

To ensure quality and safety, choose suppliers that adhere to international safety standards and regulations. Request certifications for the jib cranes, such as ISO or CE markings, which indicate compliance with industry safety norms. Conduct thorough vetting of potential suppliers by reviewing their reputation, customer feedback, and product warranties. Consider arranging for third-party inspections or testing before finalizing your purchase to guarantee the crane meets your operational safety requirements. -

What is the minimum order quantity (MOQ) for jib cranes?

Minimum order quantities (MOQ) for jib cranes can vary widely among suppliers, often depending on the type and customization of the cranes. Some manufacturers may offer no MOQ for standard models, while others may require a minimum order of several units for custom designs. It’s advisable to discuss your needs directly with suppliers, as they may offer flexible options or bulk discounts that can help you manage costs effectively. -

Are there customization options available for jib cranes?

Yes, many manufacturers offer customization options for jib cranes to meet specific operational requirements. Customizations may include adjustments in load capacity, height, reach, and material specifications. You can also request features such as different mounting styles or integrated hoists. Discuss your unique needs with suppliers early in the purchasing process to explore available options and ensure the final product aligns with your operational goals. -

What logistics considerations should I keep in mind when importing jib cranes?

When importing jib cranes, consider logistics factors such as shipping methods, customs clearance, and delivery timelines. Choose a reliable freight forwarder familiar with heavy equipment to navigate international shipping regulations effectively. Understand the customs duties and taxes applicable in your region, and ensure all documentation is accurate to avoid delays. Additionally, plan for potential challenges like transportation constraints or local regulations that may affect installation and operation.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Jib Cranes Manufacturers & Suppliers List

1. Crane Depot – Jib Cranes

Domain: cranedepot.com

Registered: 2013 (12 years)

Introduction: Jib cranes are a subset of cranes that have a jib or boom attached to support a moveable hoist. They are versatile, suitable for small areas or large industrial facilities with limited space. Jib cranes are simple to operate, ergonomic, and require less maintenance due to fewer operational components. Crane Depot offers various types of jib cranes including articulating, floor mounted, foundationl…

2. Jib Cranes – Electric Chain Hoists

Domain: jibcranes.com

Registered: 1998 (27 years)

Introduction: Jib Cranes: Floor Mount, Wall Mount, Specialty Jib Cranes; Hoists: Electric Chain Hoists, Manual Chain Hoists, Wire Rope Hoists; Accessories: Lifting Clamps, Lifting Magnets, Pendants, Radio Remote Controls, Trolleys. Featured Products include: 1/8 Ton Harrington EQ Electric Chain Hoist (10ft, 15ft, 20ft lift), 1/4 Ton Harrington EQ Electric Chain Hoist (10ft, 15ft, 20ft lift), 1/2 Ton Harrington …

3. Gorbel – High-Quality I-Beam Jib Cranes

Domain: gorbel.com

Registered: 1996 (29 years)

Introduction: High-Quality I-Beam Jib Cranes designed for industrial overhead lifting solutions. Key specifications include:

– Capacity: Up to 10,000 lbs (5 tons)

– Span: Circular up to 30 ft

– Height: Up to 20 ft

– Coverage Area: Circular Coverage Area up to 360°

– Motorization: Yes

Types of I-Beam Jib Cranes:

1. Free Standing Jib Crane: Manually operated, rotates 360°, requires a 6″ reinforced concret…

4. Lifting Equipment Store – Jib Crane

Domain: liftingequipmentstore.us

Registered: 2018 (7 years)

Introduction: This company, Lifting Equipment Store – Jib Crane, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Abell-Howe – Jib Cranes

Domain: abell-howe.com

Registered: 2019 (6 years)

Introduction: Jib Crane – Abell-Howe Jib Cranes include various models such as J902 (Mast Style), J900 (Wall Mounted Tie Rod), J906FCT (Full Cantilever Wall Mounted), J950 (Full Cantilever Wall Bracketed Enclosed Track), J904L (Foundationless Light Duty Floor), J904R (Standard Duty Foundationless Pillar), J904S (Light Duty Floor Mounted, up to 1 Ton Capacity), J904B (Base Plate Mounted Heavy Duty Pillar), and J…

6. Hoists Direct – Jib Cranes

Domain: hoistsdirect.com

Registered: 2003 (22 years)

Introduction: Jib Cranes offered by Hoists Direct include various brands, capacities, types, sizes, and options for overhead lifting. Types include portable, wall-mounted, floor-mounted, and articulating jibs. Wall-mounted jibs are available in full cantilever and wall bracketed options. Floor-mounted jibs provide full 360-degree movement, with accessories for rotation stops. Articulating jibs feature a rotatin…

7. Tsoverhead Crane – Jib Cranes

Domain: tsoverheadcrane.com

Registered: 2013 (12 years)

Introduction: Jib Cranes include various types such as Floor Mounted Jib Cranes, Wall Mounted Jib Cranes, Tool Solution Jibs, and Articulated Jib Cranes. They feature a horizontal boom mounted to a vertical support structure for precise material handling. Available capacities range from 50 lbs to 5 tons, with spans up to 30 feet and height under boom options from 8 to 16 feet. Construction types include aluminu…

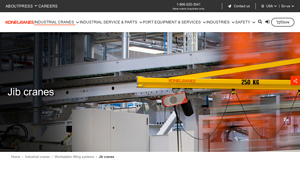

8. Konecranes – Industrial Jib Cranes

Domain: konecranes.com

Registered: 1999 (26 years)

Introduction: This company, Konecranes – Industrial Jib Cranes, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for jib Cranes

In the competitive landscape of material handling, strategic sourcing of jib cranes is essential for optimizing operational efficiency and productivity. By carefully selecting the right jib crane model—be it wall-mounted, floor-mounted, or portable—businesses can tailor their lifting solutions to specific operational needs. The versatility and ergonomic advantages of jib cranes make them an invaluable asset in industries ranging from manufacturing to logistics, particularly in regions with space constraints.

Investing in high-quality jib cranes not only reduces maintenance costs but also enhances workplace safety and employee satisfaction. As international B2B buyers from Africa, South America, the Middle East, and Europe evaluate their procurement strategies, it’s vital to partner with reputable suppliers who offer robust product support and timely delivery.

Looking ahead, the demand for innovative lifting solutions will continue to rise. Businesses should prioritize agility in their sourcing strategies to adapt to evolving market trends and technological advancements. Engage with experts in the field to explore the latest jib crane technologies and ensure your operations are equipped for future challenges. Embrace the opportunity to enhance your material handling capabilities today!