Introduction: Navigating the Global Market for light Truck Cargo Van

In the ever-evolving landscape of global logistics and transportation, sourcing reliable light truck cargo vans presents a significant challenge for B2B buyers. As businesses expand across continents—from the bustling markets of Africa to the thriving economies of South America, the Middle East, and Europe—understanding the diverse options available in cargo vans becomes crucial. This guide delves into the various types of light truck cargo vans, their applications, and essential considerations for supplier vetting, ensuring that you make informed purchasing decisions tailored to your specific operational needs.

Throughout this comprehensive resource, we will explore key factors such as size specifications, payload capacities, fuel efficiency, and advanced features that enhance safety and usability. Additionally, we will provide insights into cost structures and financing options to help you navigate potential investments in cargo vans effectively. By equipping international B2B buyers with actionable knowledge, this guide empowers you to select the right cargo van that aligns with your business objectives and logistical requirements.

Whether you are a seasoned fleet manager or a new entrepreneur, understanding the nuances of light truck cargo vans will enable you to streamline your operations, optimize your supply chain, and ultimately drive business growth in your respective region. Prepare to navigate the global market with confidence and make strategic decisions that propel your business forward.

Understanding light Truck Cargo Van Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Cargo Van | Typically 9-11 feet in length, 250-300 cu. ft. cargo space | Urban deliveries, small business logistics | Pros: Good fuel efficiency, easy to maneuver. Cons: Limited cargo capacity for larger loads. |

| High-Roof Cargo Van | Increased vertical space, allowing for taller loads | Furniture delivery, electrical installations | Pros: More cargo space, better for tall items. Cons: May have higher costs and reduced fuel efficiency. |

| Electric Cargo Van | Zero emissions, lower operating costs, often with advanced tech | Eco-friendly deliveries, urban transport | Pros: Sustainable, lower running costs. Cons: Limited range and charging infrastructure may be a concern. |

| Refrigerated Cargo Van | Insulated cargo area for temperature-sensitive goods | Food transportation, pharmaceuticals | Pros: Maintains required temperatures, versatile. Cons: Higher maintenance costs, more complex systems. |

| Panel Van | Enclosed cargo space with side access, versatile configurations | General freight, tradesmen tools transport | Pros: Flexible configurations, easy access. Cons: May lack advanced safety features found in newer models. |

What Are the Characteristics of Standard Cargo Vans for B2B Use?

Standard cargo vans typically range from 9 to 11 feet in length, offering around 250 to 300 cubic feet of cargo space. They are designed for urban deliveries and small business logistics, making them ideal for companies that require efficient transportation of goods in metropolitan areas. When considering a standard cargo van, businesses should evaluate fuel efficiency, payload capacity, and maneuverability, particularly in congested environments. These vans are often equipped with basic safety features, making them a reliable choice for daily operations.

How Do High-Roof Cargo Vans Differ in Functionality?

High-roof cargo vans provide additional vertical space, accommodating taller loads that standard vans cannot. With a cargo capacity of up to 400 cubic feet, they are well-suited for industries like furniture delivery and electrical installations, where height is a critical factor. B2B buyers should consider the trade-off between increased space and potential reductions in fuel efficiency. Additionally, the higher profile of these vans may present challenges in low-clearance areas, which is essential to evaluate based on the delivery routes.

What Are the Benefits of Choosing Electric Cargo Vans?

Electric cargo vans represent a growing trend in sustainable transportation, offering zero emissions and lower operating costs. They are particularly beneficial for urban deliveries, where emissions regulations are stringent. Businesses should assess the range of electric vans, as charging infrastructure can vary by region. While the initial investment may be higher, the long-term savings on fuel and maintenance can be significant. Additionally, companies that prioritize sustainability may find electric vans enhance their brand reputation.

Why Are Refrigerated Cargo Vans Essential for Certain Industries?

Refrigerated cargo vans are crucial for transporting temperature-sensitive goods, such as food and pharmaceuticals. These vans are equipped with insulated cargo areas and temperature control systems to ensure products remain within required temperature ranges during transit. B2B buyers in the food service or healthcare sectors should consider the van’s cooling capacity, reliability, and maintenance requirements. While they provide essential services, the complexity of their systems can lead to higher operational costs.

How Do Panel Vans Offer Versatility in Cargo Transport?

Panel vans feature an enclosed cargo area and often come with side access doors, making them suitable for a wide range of applications, from general freight to transporting tools for tradesmen. Their flexible configurations allow businesses to customize the interior for specific needs, enhancing usability. However, B2B buyers should be mindful of the potential lack of advanced safety features in older models. Evaluating the balance between versatility and safety is critical for long-term operational success.

Key Industrial Applications of light Truck Cargo Van

| Industry/Sector | Specific Application of light Truck Cargo Van | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce & Retail | Last-mile delivery for small packages | Increases delivery efficiency and customer satisfaction | Consider fuel efficiency, payload capacity, and vehicle size for urban areas. |

| Construction & Trades | Transporting tools and materials to job sites | Reduces downtime and improves project timelines | Look for durability, cargo space, and ease of loading/unloading. |

| Food & Beverage | Mobile food delivery and catering services | Enhances service flexibility and expands market reach | Ensure temperature control options and compliance with local regulations. |

| Logistics & Supply Chain | Short-haul distribution between warehouses | Streamlines operations and reduces transportation costs | Evaluate fleet management capabilities and maintenance support. |

| Event Management | Transporting equipment and supplies for events | Facilitates timely setup and breakdown of events | Assess cargo space, accessibility, and reliability under varied conditions. |

How is the light Truck Cargo Van Used in E-commerce & Retail Deliveries?

In the booming e-commerce sector, light truck cargo vans are essential for last-mile delivery services. These vehicles enable businesses to efficiently transport small packages directly to customers, enhancing service speed and customer satisfaction. For international buyers, especially in regions with dense urban areas, considerations like fuel efficiency and maneuverability in traffic become crucial. Additionally, understanding local regulations regarding vehicle sizes and emissions can guide procurement decisions.

What Role Do Cargo Vans Play in Construction & Trades?

In the construction industry, light truck cargo vans are invaluable for transporting tools, materials, and equipment to job sites. Their spacious interiors allow for organized storage, reducing downtime caused by searching for tools or making multiple trips. Buyers in this sector should prioritize durability and load capacity, ensuring the vehicle can handle heavy loads and rough terrain. Moreover, features like tie-downs and easy access are critical for efficient loading and unloading.

How Are Cargo Vans Utilized in the Food & Beverage Industry?

The food and beverage sector frequently relies on light truck cargo vans for mobile delivery and catering services. These vehicles can be equipped with refrigeration units to maintain product quality during transport. For businesses targeting international markets, compliance with food safety regulations is essential. Buyers should consider vans that offer temperature control features and easy-to-clean interiors to meet health standards while maximizing efficiency.

What Benefits Do Logistics & Supply Chain Companies Gain from Cargo Vans?

In logistics, light truck cargo vans are ideal for short-haul distribution between warehouses and retailers. Their compact size allows for easier navigation in congested urban environments, while their payload capacity meets the needs of various goods. When sourcing these vehicles, businesses should evaluate fleet management systems that offer real-time tracking and maintenance support, ensuring operational efficiency and cost-effectiveness.

How Do Event Management Companies Leverage Cargo Vans?

Event management companies utilize light truck cargo vans to transport equipment, supplies, and displays to various venues. These vans facilitate quick setup and breakdown, which is critical for meeting tight schedules. Buyers should assess the cargo space and accessibility features of the vans to accommodate diverse equipment types. Additionally, reliability in varying weather conditions is a vital consideration for ensuring successful event execution.

3 Common User Pain Points for ‘light Truck Cargo Van’ & Their Solutions

Scenario 1: Navigating Limited Cargo Space for Diverse Loads

The Problem: B2B buyers often struggle with the limitations of cargo space when using light truck cargo vans, especially when transporting a variety of goods. For instance, a logistics company may need to deliver both large furniture items and smaller packages in a single trip. The challenge lies in efficiently organizing the van’s interior to maximize space while ensuring the safety and integrity of all items. If the van is not properly configured, it can lead to delays, increased transportation costs, and potential damage to goods.

The Solution: To effectively address cargo space limitations, buyers should consider investing in modular shelving and cargo management systems that can be customized for various load types. When sourcing a light truck cargo van, choose models with flexible interior configurations, such as removable bulkheads and adjustable shelving. Additionally, using cargo straps and tie-downs can help secure items, preventing movement during transit. Buyers should also conduct thorough load planning prior to each trip. Utilizing software tools for load optimization can assist in visualizing how to fit different items efficiently, ensuring maximum utilization of space and minimizing the risk of damage.

Scenario 2: Fuel Efficiency Concerns During Long Hauls

The Problem: For businesses that rely on light truck cargo vans for long-distance deliveries, fuel efficiency is a critical concern. High fuel consumption can significantly increase operational costs, impacting profit margins. A company based in South America, for example, may find that its delivery routes through mountainous regions lead to unexpected fuel expenses due to the van’s performance under load. This scenario creates a pressing need for a balance between power and efficiency.

The Solution: To mitigate fuel efficiency issues, B2B buyers should prioritize models known for their fuel economy, particularly those that feature advanced engine technologies or hybrid options. It is essential to analyze the fuel specifications and MPG ratings of different cargo vans before purchase. Additionally, implementing regular maintenance schedules can improve engine performance and fuel efficiency. Training drivers on best practices for fuel-efficient driving, such as maintaining steady speeds and reducing idling times, can also contribute to lower fuel consumption. Finally, consider utilizing telematics systems to monitor fuel usage and optimize driving routes for more economical performance.

Scenario 3: Safety and Compliance with Regulatory Standards

The Problem: Safety and compliance with local and international transport regulations pose significant challenges for businesses operating light truck cargo vans. Companies in Europe and the Middle East, for instance, must navigate stringent safety standards, including vehicle inspections and driver certifications. Failure to comply can lead to costly fines, operational disruptions, and reputational damage.

The Solution: To ensure compliance with safety regulations, B2B buyers should conduct thorough research on the specific requirements in their operational regions. This includes understanding vehicle specifications, driver training mandates, and cargo securing regulations. Investing in cargo vans equipped with safety features such as anti-lock brakes, collision warning systems, and backup cameras is crucial for enhancing driver safety and meeting compliance standards. Moreover, establishing a robust training program for drivers on safe handling practices and emergency procedures can further mitigate risks. Regular audits of compliance status and vehicle inspections can help identify and rectify potential issues before they escalate, ensuring that the business remains in good standing with regulatory authorities.

Strategic Material Selection Guide for light Truck Cargo Van

When selecting materials for light truck cargo vans, it’s essential to consider various factors that influence performance, durability, and cost-effectiveness. Here’s an analysis of four common materials used in the construction of cargo vans, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Steel in Light Truck Cargo Vans?

Steel is a widely used material in cargo van construction due to its strength and durability. It offers excellent tensile strength, which is crucial for withstanding heavy loads. Steel also has a high temperature rating and can resist deformation under pressure, making it suitable for various operational conditions. However, it is prone to corrosion if not properly treated or coated.

Pros and Cons of Using Steel:

– Pros: High durability, excellent load-bearing capacity, and cost-effective for mass production.

– Cons: Heavier than alternative materials, susceptible to rust, and requires protective coatings, which can increase manufacturing complexity.

Impact on Application:

Steel’s robustness makes it ideal for transporting heavy goods, but its weight can affect fuel efficiency. International buyers should consider the local climate’s impact on corrosion and ensure compliance with relevant standards for protective coatings.

How Does Aluminum Compare as a Material for Cargo Vans?

Aluminum is increasingly popular in the automotive industry due to its lightweight nature and resistance to corrosion. It has a lower density than steel, which enhances fuel efficiency and payload capacity. Aluminum can also be easily extruded and formed into various shapes, allowing for innovative designs.

Pros and Cons of Using Aluminum:

– Pros: Lightweight, excellent corrosion resistance, and good thermal conductivity.

– Cons: Generally more expensive than steel, lower tensile strength, and can be more challenging to weld.

Impact on Application:

Aluminum is suitable for applications requiring high fuel efficiency and reduced weight. B2B buyers in regions with high humidity or salt exposure should prioritize aluminum for its corrosion resistance, ensuring compliance with local standards.

What Role Does Composite Material Play in Cargo Van Construction?

Composite materials, such as fiberglass and carbon fiber, are becoming increasingly relevant in cargo van production. These materials offer high strength-to-weight ratios and excellent resistance to environmental factors. Composites can be molded into complex shapes, providing design flexibility.

Pros and Cons of Using Composites:

– Pros: Lightweight, high durability, and excellent resistance to corrosion and environmental degradation.

– Cons: Higher manufacturing costs and complexity, limited recyclability, and potential challenges in repairs.

Impact on Application:

Composites are ideal for specialized applications where weight savings are critical. Buyers should consider the cost implications and ensure that local repair facilities are equipped to handle composite materials.

What Are the Benefits of Using High-Strength Steel Alloys?

High-strength steel alloys are engineered to provide superior performance compared to standard steel. They offer enhanced strength, reduced weight, and improved resistance to fatigue and wear. These alloys can be used in high-stress areas of cargo vans, such as the chassis and load-bearing components.

Pros and Cons of Using High-Strength Steel Alloys:

– Pros: Increased strength without significant weight gain, improved safety, and longevity.

– Cons: Higher cost and more complex manufacturing processes, which may require specialized equipment.

Impact on Application:

These alloys are particularly beneficial for cargo vans operating in demanding environments. Buyers should assess the cost-benefit ratio and ensure compliance with international safety standards.

Summary Table of Material Selection for Light Truck Cargo Vans

| Material | Typical Use Case for light Truck Cargo Van | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Chassis and structural components | High durability and load capacity | Heavier and prone to corrosion | Medium |

| Aluminum | Body panels and lightweight structures | Lightweight and corrosion-resistant | More expensive and lower strength | High |

| Composite | Specialized applications and interiors | Excellent strength-to-weight ratio | Higher manufacturing costs | High |

| High-Strength Steel Alloys | Load-bearing components and chassis | Superior performance and safety | Higher cost and complex manufacturing | High |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in light truck cargo vans. Understanding these properties and considerations will help B2B buyers make informed decisions that align with their operational needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for light Truck Cargo Van

What Are the Key Stages in the Manufacturing Process of Light Truck Cargo Vans?

The manufacturing process of light truck cargo vans involves several critical stages that ensure the vehicle’s quality and functionality. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

The manufacturing process begins with the selection of high-quality materials, typically steel, aluminum, and composite materials. These materials are chosen for their strength, weight, and durability, which are essential for the performance of cargo vans. The materials undergo cutting, bending, and machining to prepare them for the subsequent forming stage. -

Forming Techniques

Various forming techniques are employed to shape the materials into the required components. Common methods include stamping, welding, and extrusion. Stamping is often used for creating body panels, while welding is essential for joining components together, ensuring structural integrity. Advanced techniques like hydroforming can also be utilized for complex shapes, enhancing design flexibility and strength. -

Assembly Process

The assembly stage brings together all manufactured components, such as the chassis, engine, and cargo area. This process often employs automated assembly lines to improve efficiency and consistency. Each component is meticulously fitted, ensuring precise alignment and functionality. Skilled labor is also crucial during this stage, particularly for intricate tasks such as wiring and installing sensitive electronic systems. -

Finishing Techniques

The finishing stage involves painting and coating the cargo van to protect it from environmental factors while providing an aesthetically pleasing appearance. Techniques such as powder coating and electrocoating are common, offering durability and resistance to corrosion. Quality checks are conducted during this stage to ensure that the paint adheres properly and that there are no defects.

How Is Quality Assurance Implemented in Cargo Van Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of light truck cargo vans, ensuring that vehicles meet both international standards and customer expectations. The QA process encompasses various checkpoints and testing methods.

-

International and Industry-Specific Standards

Compliance with international standards such as ISO 9001 is essential for manufacturers to demonstrate their commitment to quality management systems. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for components related to the oil and gas sector may be required. These certifications assure B2B buyers that the products adhere to safety and environmental regulations. -

Quality Control Checkpoints

The QA process includes several key checkpoints:

-

Incoming Quality Control (IQC): This initial phase involves inspecting raw materials and components before they enter the production process. It ensures that all materials meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor the production process. This includes checks on dimensional accuracy, assembly integrity, and adherence to manufacturing protocols.

-

Final Quality Control (FQC): Once assembly is complete, the final inspection occurs. This step verifies that the finished cargo van meets all design specifications and quality standards before delivery to customers.

- Common Testing Methods for Cargo Vans

Various testing methods are employed to ensure the performance and safety of light truck cargo vans. These include:

- Dynamic Testing: Evaluates the vehicle’s performance under various driving conditions, including acceleration, braking, and cornering.

- Durability Testing: Simulates long-term use to assess the vehicle’s ability to withstand wear and tear.

- Crash Testing: Ensures that the vehicle meets safety standards by simulating collision scenarios.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in international markets such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial for ensuring product reliability and compliance with standards.

-

Supplier Audits

Conducting supplier audits can provide valuable insights into a manufacturer’s quality control processes. These audits assess the adherence to quality standards and the effectiveness of the QA systems in place. Buyers may also request audits from third-party organizations for an unbiased evaluation. -

Requesting Quality Reports

Buyers should request detailed quality reports that outline the supplier’s QA practices, including results from IQC, IPQC, and FQC. These reports should detail any non-conformance issues and corrective actions taken, providing transparency into the supplier’s commitment to quality. -

Third-Party Inspections

Engaging third-party inspection services can offer an additional layer of assurance. These independent entities can conduct inspections at various stages of production, ensuring that products meet specified standards before shipment. -

Understanding Regional Quality Nuances

B2B buyers should be aware of regional quality nuances when sourcing cargo vans. For instance, European buyers might place a higher emphasis on CE certification, while buyers in the Middle East may require compliance with local regulations. Understanding these differences can help buyers make informed decisions and ensure that the products meet their specific market requirements.

Conclusion: Ensuring Quality in Light Truck Cargo Vans

The manufacturing processes and quality assurance measures for light truck cargo vans are essential for ensuring that these vehicles meet the demands of various industries and markets. By understanding the stages of manufacturing, the importance of quality control, and how to verify supplier practices, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. This proactive approach not only mitigates risks but also fosters long-term partnerships with reliable suppliers in the global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘light Truck Cargo Van’

Introduction

Navigating the procurement of light truck cargo vans requires careful planning and thorough evaluation. This checklist is designed to guide B2B buyers through the essential steps needed to source cargo vans effectively, ensuring that you make informed decisions that align with your business needs and operational requirements.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical before initiating the sourcing process. Identify the size, payload capacity, and fuel efficiency required for your operations. Consider factors such as interior dimensions and door accessibility to ensure the vans can accommodate your specific cargo needs.

- Key Considerations:

- Loading capacity (e.g., maximum payload and volume).

- Dimensions that fit your typical cargo.

- Fuel efficiency ratings for cost-effectiveness.

Step 2: Research Potential Suppliers

Conducting comprehensive research on potential suppliers is vital to identify reliable partners. Look for companies with a strong reputation in the market and verify their experience in providing cargo vans that meet your specifications.

- Where to Look:

- Online directories and trade associations.

- Industry reviews and customer testimonials.

- Local dealerships and rental services.

Step 3: Evaluate Supplier Certifications and Compliance

Before finalizing any agreements, ensure that your chosen suppliers hold necessary certifications and comply with local regulations. This step is crucial to mitigate risks associated with quality and safety standards.

- What to Verify:

- Manufacturer certifications (e.g., ISO).

- Compliance with local and international vehicle standards.

- Warranty and service agreements for maintenance support.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes to compare costs and terms. This step helps you understand the full scope of financial commitments and ensures transparency in pricing.

- Essential Elements in Quotes:

- Base price of the cargo van.

- Additional costs (e.g., insurance, delivery fees).

- Payment terms and financing options.

Step 5: Inspect Vehicles Before Purchase

If possible, arrange for a physical inspection of the cargo vans prior to purchase. This allows you to assess their condition, verify specifications, and check for any signs of wear or damage that might affect performance.

- Inspection Checklist:

- Exterior and interior condition.

- Functionality of key features (e.g., doors, air conditioning).

- Maintenance records and service history.

Step 6: Understand After-Sales Support Options

After-sales support is a crucial factor in ensuring the longevity and reliability of your cargo vans. Confirm the level of support your supplier offers, including maintenance services and parts availability.

- Questions to Ask:

- What warranties are provided?

- Are there service packages available?

- How quickly can parts be sourced in case of repairs?

Step 7: Finalize the Contract

After assessing all factors, finalize your contract with the selected supplier. Ensure that all terms discussed are clearly documented, including delivery timelines and payment schedules.

- Contract Essentials:

- Clearly defined terms of service.

- Delivery and installation clauses.

- Conditions for warranty and returns.

By following these steps, B2B buyers can streamline the sourcing process for light truck cargo vans, ensuring they make informed decisions that meet their operational needs while minimizing risks.

Comprehensive Cost and Pricing Analysis for light Truck Cargo Van Sourcing

What Are the Key Cost Components in Sourcing Light Truck Cargo Vans?

When sourcing light truck cargo vans, understanding the cost structure is crucial for international B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality steel, aluminum, and advanced composites can enhance durability and performance but may increase initial costs. Buyers should consider the long-term benefits of investing in higher-quality materials, especially for heavy-duty applications.

-

Labor: Labor costs can vary based on the manufacturing location. For instance, labor in regions with lower wage standards may reduce production costs, but this must be weighed against potential quality issues. Understanding local labor practices and expertise can help in evaluating suppliers.

-

Manufacturing Overhead: This encompasses utilities, rent, and administrative expenses associated with production. Efficient manufacturing processes can lower overhead costs, which can be a negotiating point with suppliers.

-

Tooling: The cost of tooling is often a significant factor, particularly for custom designs. Buyers should inquire about the tooling costs associated with specific van configurations and whether these costs can be amortized over larger production volumes.

-

Quality Control (QC): Implementing robust QC measures ensures that the cargo vans meet safety and performance standards. While this may increase initial costs, it can prevent expensive recalls and repairs later on.

-

Logistics: Shipping costs can vary widely depending on the distance, mode of transport, and Incoterms agreed upon. Buyers should assess the total logistics costs, including customs duties and insurance, when calculating overall expenses.

-

Margin: Supplier margins can differ based on market conditions, brand reputation, and competition. Buyers should understand the typical margins in their region and industry to negotiate effectively.

What Influences Pricing for Light Truck Cargo Vans?

Several factors can influence the pricing of cargo vans:

-

Volume/MOQ: Larger orders often lead to better pricing due to economies of scale. Suppliers are generally more willing to negotiate on price for bulk purchases, which can significantly impact the total cost.

-

Specifications/Customization: Custom features or specifications can lead to increased costs. Buyers should clearly define their needs to avoid unnecessary expenses while ensuring the vans meet operational requirements.

-

Materials and Quality Certifications: Vans made with certified materials may come at a premium, but they often provide better performance and safety. Buyers should weigh the benefits of certifications against cost.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more, but they often provide better service and quality assurance.

-

Incoterms: The agreed-upon Incoterms dictate who bears the cost of shipping and risk during transit. Understanding these terms can help buyers avoid unexpected costs and make informed purchasing decisions.

What Buyer Tips Can Enhance Cost-Efficiency in Sourcing Cargo Vans?

For B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, several strategies can optimize sourcing costs:

-

Negotiation: Engage in open discussions with suppliers about pricing structures and potential discounts for bulk orders. Leverage competitive quotes to negotiate better terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO instead of just the initial purchase price. Consider factors such as fuel efficiency, maintenance costs, and resale value to understand the long-term financial impact.

-

Pricing Nuances for International Buyers: Different regions have distinct pricing trends influenced by local market dynamics, currency fluctuations, and import duties. Being aware of these factors can help buyers make informed decisions.

-

Supplier Relationship Management: Establish strong relationships with suppliers to foster better communication and trust. Long-term partnerships can lead to more favorable terms and priority service.

Disclaimer on Indicative Prices

Prices for light truck cargo vans can vary significantly based on the above factors, and the figures provided are indicative. Buyers should conduct thorough market research and obtain specific quotes tailored to their needs and circumstances.

Alternatives Analysis: Comparing light Truck Cargo Van With Other Solutions

Introduction

When considering logistics solutions for transporting goods, businesses often weigh the benefits of light truck cargo vans against various alternatives. Each option comes with its own set of advantages and challenges, making it crucial for international B2B buyers to analyze their specific needs. This section delves into a comparison of light truck cargo vans with two viable alternatives: box trucks and third-party logistics (3PL) services, providing insights into performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Light Truck Cargo Van | Box Truck | Third-Party Logistics (3PL) |

|---|---|---|---|

| Performance | Good fuel efficiency and maneuverability; ideal for urban areas | Higher capacity and payload; better for larger shipments | Flexible capacity; can scale with demand |

| Cost | Generally lower rental and operational costs | Higher acquisition and fuel costs due to size | Variable costs based on service level and distance |

| Ease of Implementation | Easy to rent or lease; minimal training needed for drivers | Requires more logistics planning; larger vehicles may need specific licenses | Quick setup; requires selecting and vetting providers |

| Maintenance | Lower maintenance costs; simpler repairs | Higher maintenance due to more complex systems | Outsourced maintenance; responsibility lies with the provider |

| Best Use Case | Ideal for local deliveries and small loads | Suitable for larger shipments and long-distance transport | Effective for businesses needing flexible, scalable logistics solutions |

Detailed Breakdown

What are the advantages and disadvantages of using Box Trucks?

Box trucks, also known as cube vans, offer a larger cargo space compared to light truck cargo vans, making them suitable for transporting larger items or bulk shipments. They typically have a higher payload capacity, which can be advantageous for businesses that frequently handle significant volumes. However, box trucks come with higher operational costs, including fuel consumption and maintenance. Additionally, they may be less maneuverable in urban environments, leading to potential challenges in traffic and parking.

How do Third-Party Logistics (3PL) Services compare?

Third-party logistics services provide a flexible solution for companies looking to outsource their transportation needs. They can scale their services based on the business’s demand, allowing for efficient management of varying shipment volumes. The primary advantage of 3PL is the reduction of overhead costs, as businesses do not need to invest in vehicles or drivers. However, relying on external providers can lead to less control over the shipping process, and costs can vary significantly depending on the service level required. It’s essential for businesses to thoroughly vet 3PL providers to ensure reliability and quality of service.

Conclusion

Choosing the right logistics solution hinges on understanding your specific operational needs and constraints. Light truck cargo vans offer an efficient, cost-effective solution for smaller shipments, particularly in urban environments. Box trucks may be the better choice for larger deliveries, despite higher costs and complexity. On the other hand, 3PL services present a flexible alternative that can adapt to fluctuating demand, albeit with less control over logistics. By assessing these alternatives against their business requirements, B2B buyers can make informed decisions that align with their operational goals and budget considerations.

Essential Technical Properties and Trade Terminology for light Truck Cargo Van

What Are the Key Technical Properties of Light Truck Cargo Vans?

Understanding the essential specifications of light truck cargo vans is crucial for B2B buyers to make informed purchasing decisions. Here are some critical specifications that define their functionality and value in commercial applications:

-

Gross Vehicle Weight Rating (GVWR)

GVWR refers to the maximum weight a vehicle is rated to safely carry, including its own weight plus cargo. For light cargo vans, GVWR typically ranges from 8,500 to 10,000 pounds. This specification is vital for businesses that need to transport heavy loads, as exceeding the GVWR can lead to safety hazards and legal penalties. -

Payload Capacity

This refers to the maximum weight that can be loaded into the cargo van, excluding the vehicle’s own weight. Common payload capacities for light cargo vans are between 3,000 to 4,500 pounds. Knowing the payload capacity helps businesses determine the van’s suitability for specific transportation tasks, ensuring operational efficiency and cost-effectiveness. -

Cargo Volume

Measured in cubic feet, cargo volume indicates the internal space available for transporting goods. For instance, many light cargo vans provide between 250 to 300 cubic feet of cargo space. This measurement is essential for businesses to assess how much merchandise can be transported in a single trip, which directly impacts logistics and scheduling. -

Fuel Efficiency (Miles Per Gallon – MPG)

Fuel efficiency, often expressed in MPG, is a critical property for assessing the operational costs of using a cargo van. Many light cargo vans achieve between 10 to 20 MPG, depending on load and driving conditions. Understanding fuel efficiency helps businesses budget for transportation costs and contributes to sustainability goals. -

Engine Specifications

The engine specifications, including horsepower and torque, play a significant role in a cargo van’s performance, especially when transporting heavy loads or navigating hilly terrains. Most light cargo vans are equipped with engines ranging from 4 to 8 cylinders. B2B buyers should consider engine performance to ensure that the vehicle meets their operational demands.

What Are Common Trade Terms in the Cargo Van Industry?

Familiarity with industry-specific terminology can greatly enhance communication and negotiation processes in B2B transactions. Here are some key terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the cargo van context, it signifies the original manufacturer of the vehicle or its components. Understanding OEM relationships can help buyers assess the quality and reliability of parts and service. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. In the context of cargo vans, this could pertain to the minimum number of vehicles a company must purchase to receive specific pricing or terms. Knowing the MOQ is crucial for budget planning and inventory management. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit pricing and terms for specific products or services. When considering cargo vans, submitting an RFQ can help businesses compare offers and negotiate better deals based on their unique requirements. -

Incoterms (International Commercial Terms)

These are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers involved in cross-border cargo van purchases, as they dictate shipping costs, insurance, and risk transfer. -

Tare Weight

Tare weight refers to the weight of the cargo van when it is empty. This figure is crucial for calculating payload capacity and ensuring compliance with weight regulations. B2B buyers need to consider tare weight when assessing the overall efficiency of their logistics operations.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the light Truck Cargo Van Sector

What Are the Key Market Dynamics and Trends Impacting the Light Truck Cargo Van Sector?

The light truck cargo van market is experiencing a transformative phase driven by several global factors. The surge in e-commerce, particularly in regions like Africa and South America, has heightened demand for versatile delivery solutions. This trend is further amplified by urbanization, which necessitates efficient transportation options that can maneuver through congested metropolitan areas. In Europe, especially in countries like Germany, there is a growing emphasis on last-mile delivery, pushing businesses to adopt cargo vans for their operational needs.

Technological advancements are reshaping sourcing strategies as well. The integration of telematics and fleet management systems is becoming prevalent, enabling businesses to track vehicle performance, optimize routes, and enhance fuel efficiency. Moreover, the rising trend of electric cargo vans offers a sustainable alternative, appealing to environmentally conscious consumers and businesses alike. As international buyers seek to streamline their operations, they must consider these emerging technologies to remain competitive.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing in the Light Truck Cargo Van Sector?

Sustainability is becoming a critical factor for businesses sourcing light truck cargo vans. The environmental impact of traditional fuel sources has prompted a shift towards greener alternatives. Electric cargo vans are gaining traction, offering lower emissions and operating costs, which can be particularly advantageous in regions with stringent environmental regulations.

Ethical sourcing practices are equally important. B2B buyers should prioritize suppliers that demonstrate a commitment to sustainable practices throughout their supply chains. This includes using materials that are certified for sustainability, such as recycled metals and eco-friendly coatings. Certifications such as ISO 14001 for environmental management can serve as benchmarks for assessing suppliers’ sustainability efforts. By aligning with ethical suppliers, businesses not only enhance their brand reputation but also meet the growing consumer demand for responsible sourcing.

What is the Historical Context of the Light Truck Cargo Van Market?

The evolution of the light truck cargo van market can be traced back to the mid-20th century when the demand for efficient transport solutions began to rise. Initially designed for commercial use, cargo vans were primarily utilized by businesses for local deliveries and service operations. Over the decades, advancements in automotive technology led to the development of more fuel-efficient and spacious models, expanding their appeal beyond traditional sectors.

By the late 1990s and early 2000s, the rise of e-commerce began to reshape the market landscape, with cargo vans becoming essential for last-mile deliveries. The integration of technology into fleet management has further transformed the sector, leading to improved operational efficiencies. Today, as global markets continue to evolve, the light truck cargo van sector stands at a crossroads, balancing traditional usage with the demand for sustainability and innovation.

Frequently Asked Questions (FAQs) for B2B Buyers of light Truck Cargo Van

-

How do I choose the right cargo van for my business needs?

Selecting the appropriate cargo van hinges on your specific operational requirements. Evaluate factors such as payload capacity, interior dimensions, and fuel efficiency. For businesses in urban areas, a smaller van with excellent maneuverability may be ideal, while companies involved in heavy-duty transport might require larger models with higher payload capabilities. Additionally, consider the availability of features such as air conditioning, automatic transmission, and advanced safety systems, which can enhance driver comfort and operational efficiency. -

What is the best cargo van for transporting goods internationally?

For international transportation, cargo vans that are fuel-efficient, durable, and compliant with local regulations are essential. Look for models with a high gross vehicle weight (GVW) and ample cargo space, such as those offering 250 to 300 cubic feet. Additionally, consider vans equipped with advanced safety features, such as collision warning systems and backup cameras, which can significantly reduce the risk of accidents during transit. Brands known for reliability in international markets, such as Ford and Mercedes-Benz, often provide excellent options. -

What are the typical payment terms for purchasing cargo vans in B2B transactions?

Payment terms can vary widely based on the supplier and the volume of the order. Common terms include 30, 60, or 90 days after delivery, with some suppliers offering discounts for early payment. For larger purchases, consider negotiating a payment plan that allows for staggered payments or financing options. Always clarify the terms in writing and ensure that they align with your cash flow management strategy to avoid any disruptions in your operations. -

How can I vet suppliers when sourcing cargo vans?

To effectively vet suppliers, start by researching their reputation in the industry. Look for reviews and testimonials from other B2B buyers, and check their credentials, such as certifications and compliance with international standards. Request references and verify their operational history. Additionally, consider visiting their facilities or attending trade shows to assess their inventory and capabilities firsthand. A reliable supplier will be transparent about their processes and provide comprehensive support throughout the purchasing journey. -

What customization options are available for cargo vans?

Many manufacturers offer customization options to tailor cargo vans to specific business needs. This can include shelving systems, cargo partitions, and specialized storage solutions. Additionally, consider modifications for branding, such as vinyl wraps or paint jobs that reflect your company’s identity. Discuss your requirements with suppliers to explore available options, as many are willing to collaborate on bespoke solutions that enhance operational efficiency and brand visibility. -

What logistics considerations should I keep in mind when importing cargo vans?

When importing cargo vans, assess the logistics of transportation, customs clearance, and compliance with local regulations. Work with experienced freight forwarders who can navigate international shipping routes and handle the necessary documentation. Factor in additional costs such as tariffs, duties, and insurance to ensure accurate budgeting. Planning for potential delays in customs is also crucial to maintaining your supply chain timeline. -

What is the minimum order quantity (MOQ) when sourcing cargo vans?

Minimum order quantities can differ significantly between suppliers. For larger manufacturers, MOQs may range from 5 to 10 vehicles, while smaller suppliers might allow single-unit purchases. When negotiating, consider your business’s needs and future growth potential; some suppliers may be flexible with MOQs if you establish a strong relationship. Always communicate your requirements clearly to avoid any misunderstandings during the purchasing process. -

How do I ensure quality assurance when purchasing cargo vans?

Quality assurance is vital when sourcing cargo vans, especially for long-term investments. Request detailed specifications and quality certifications from suppliers. Conduct pre-shipment inspections to verify that the vehicles meet your standards and are free of defects. Establish a clear return policy and warranty terms to protect your investment. Additionally, consider suppliers that offer after-sales support, as this can significantly enhance your operational reliability.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 9 Light Truck Cargo Van Manufacturers & Suppliers List

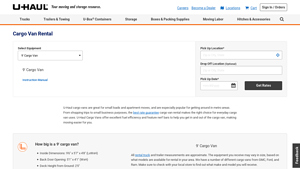

1. U-Haul – 9′ Cargo Van Rental

Domain: uhaul.com

Registered: 1995 (30 years)

Introduction: U-Haul Cargo Van Rental

– Model: 9′ Cargo Van

– Inside Dimensions: 9’6″ x 5’7″ x 4’8″ (LxWxH)

– Back Door Opening: 5’1″ x 4’1″ (WxH)

– Deck Height from Ground: 2’5″

– Max Load: 4,030 lbs.

– Gross Vehicle Weight: 9,070 lbs. max.

– Empty Weight: 4,985 lbs.

– Volume: 246 cu. ft.

– Clearance Height: 8 ft

– Fuel Type: Unleaded

– MPG: 18 (estimation)

– Fuel Tank Size: 25 gallons

– Seating Capacity: 2 ad…

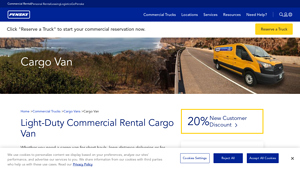

2. Penske – Cargo Van Rental

Domain: pensketruckrental.com

Registered: 1999 (26 years)

Introduction: Cargo Van Rental – Penske Truck Rental

– Type: Light-Duty Commercial Rental Cargo Van

– Extended Length: 11 ft. 11 in.

– Gross Vehicle Weight (GVW): Up to 9,000 lb.

– Payload Capacity: Up to 3,500 lb.

– Loading Space: Up to 260 cu. ft.

– Fuel Tank Capacity: Up to 31 gallons (up to 12 mpg)

– Features:

– Anti-lock brakes

– Automatic transmission

– Air conditioning

– AM/FM radio

– AUX or U…

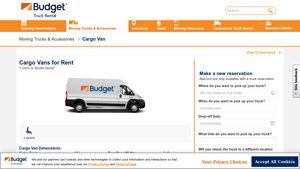

3. Budget Truck – Cargo Van Rental

Domain: budgettruck.com

Registered: 1998 (27 years)

Introduction: Cargo Van Rental Details:

– Dimensions:

– Cubic Feet: 323

– Gross Vehicle Weight (GVW): 8,600 lbs

– Payload Weight: 3,550 lbs

– Clearance: 8′ 9″

– Interior Length: 11′ 0″

– Interior Width: 4′ 5″

– Interior Height: 5′ 0″

– Rear Door Width: 5′ 1″

– Rear Door Height: 5′ 4″

– Seating: 2 seat belts/seats

– Fuel:

– Fuel Type: Gasoline

– Fuel Capacity: 25 gallons

– …

4. Hertz – Truck & Van Rental

Domain: hertz.com

Registered: 1996 (29 years)

Introduction: Truck & Van Rental offers a fleet including Standard Cargo Van (RAM Promaster or similar), Small Pickup Truck (GMC Canyon or similar), and Large Pickup Truck (RAM 1500 or similar).

5. Enterprise Trucks – Compact Cargo Van Rental

Domain: enterprisetrucks.com

Registered: 2004 (21 years)

Introduction: Compact Cargo Van Rental – Moving & Personal Use

– Payload Capacity: Up to 1,480 lbs

– Seating Capacity: 2 People

– Fuel Economy: Average 24 MPG (actual mileage may vary)

– Interior Dimensions: 83″ x 52″ x 48″ (LxHxW)

– Available with bulkhead option

– Great for medium to heavy duty dry cargo hauling

– 180 degree swing-out rear cargo doors

Standard Features:

– Air Conditioning

– Automatic Transmi…

6. Penske – Used Cargo Vans

Domain: penskeusedtrucks.com

Registered: 2001 (24 years)

Introduction: Used Cargo Vans (Panel Vans) suitable for light duty. Typical inventory includes Ford E-Series vans, GMC Savana G-Series vans, USPS/UPS delivery vans, and Mercedes/Dodge Sprinter vans. Dimensions: 10 – 12 ft. long cargo space, 3,600 lb. payload, 15,000 lbs. gross vehicle weight. Typical features: Automatic transmission, cargo screen, and tie rails. Current promotions include Manager’s Specials wit…

7. Ryder – Used Commercial Vans

Domain: ryder.com

Registered: 1995 (30 years)

Introduction: Ryder offers a selection of used commercial vans for sale, including gas cargo vans, diesel sprinter vans, and electric cargo vans. These vans are designed for last-mile deliveries and city navigation, featuring a superior turning radius and ample shelving capacity. Ryder provides flexible financing options with low monthly payments, a quick financing process, and down payments ranging from 0 to 5…

8. Reddit – Commercial Vans

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1) Mercedes Metris 2) Ram Promaster City 3) Ford Transit Connect 4) Nissan NV200

9. Badger Truck – Cargo Vans vs. Pickup Trucks

Domain: badgertruck.com

Registered: 1998 (27 years)

Introduction: Cargo Vans vs. Pickup Trucks:

1. **Pickup Trucks**:

– **Capability**: Ideal for unpaved roads and steep inclines.

– **Practicality**: Easier to load/unload due to open bed design.

– **Mileage**: Generally better fuel efficiency, especially in mid-size trucks.

– **Capacity**: High towing strength and payload capabilities, especially in heavy-duty models.

– **Seating**: Crew ca…

Strategic Sourcing Conclusion and Outlook for light Truck Cargo Van

The strategic sourcing of light truck cargo vans presents a multitude of opportunities for businesses looking to enhance their logistics and operational efficiency. Key takeaways highlight the importance of understanding vehicle specifications, such as payload capacity and fuel efficiency, which directly impact cost-effectiveness and operational suitability. International buyers, particularly from emerging markets in Africa, South America, the Middle East, and Europe, should prioritize suppliers that offer flexible rental options and diverse fleet choices to meet specific business needs.

As the demand for cargo vans grows, leveraging strategic sourcing can lead to improved supply chain resilience and reduced operational costs. By aligning with manufacturers and rental providers who understand local market dynamics, businesses can ensure they are equipped with the right vehicles for their unique logistical challenges.

Looking ahead, international B2B buyers are encouraged to explore partnerships with reputable suppliers and consider the evolving trends in cargo van technology, including fuel efficiency advancements and electric models. Engaging in strategic sourcing now will not only position your business for immediate gains but also pave the way for sustainable growth in the future.