Introduction: Navigating the Global Market for rear Camera Equipped Dump Truck

As the demand for enhanced safety and operational efficiency in the construction and transportation sectors grows, sourcing rear camera equipped dump trucks has become a critical challenge for international B2B buyers. These specialized vehicles are not only essential for transporting materials but are increasingly equipped with advanced camera systems that provide drivers with comprehensive visibility and situational awareness. This guide aims to navigate the complexities of the global market for rear camera equipped dump trucks, offering insights into various types of camera systems, their applications, and the latest technological advancements.

Buyers will find a thorough exploration of essential factors such as supplier vetting processes, cost considerations, and the regulatory landscape across different regions, including Africa, South America, the Middle East, and Europe, with specific attention to markets like Nigeria and Germany. By addressing common challenges and providing actionable insights, this guide empowers B2B buyers to make informed purchasing decisions that align with their operational needs and budget constraints. Whether you are looking to enhance safety protocols, reduce liability risks, or improve overall fleet management, understanding the intricacies of rear camera equipped dump trucks will be crucial in achieving your business objectives.

Understanding rear Camera Equipped Dump Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Rearview Camera Systems | Basic rear-facing camera with live video feed to driver’s monitor. | Construction, landscaping, and municipal projects. | Pros: Cost-effective, easy installation. Cons: Limited visibility; primarily only rear view. |

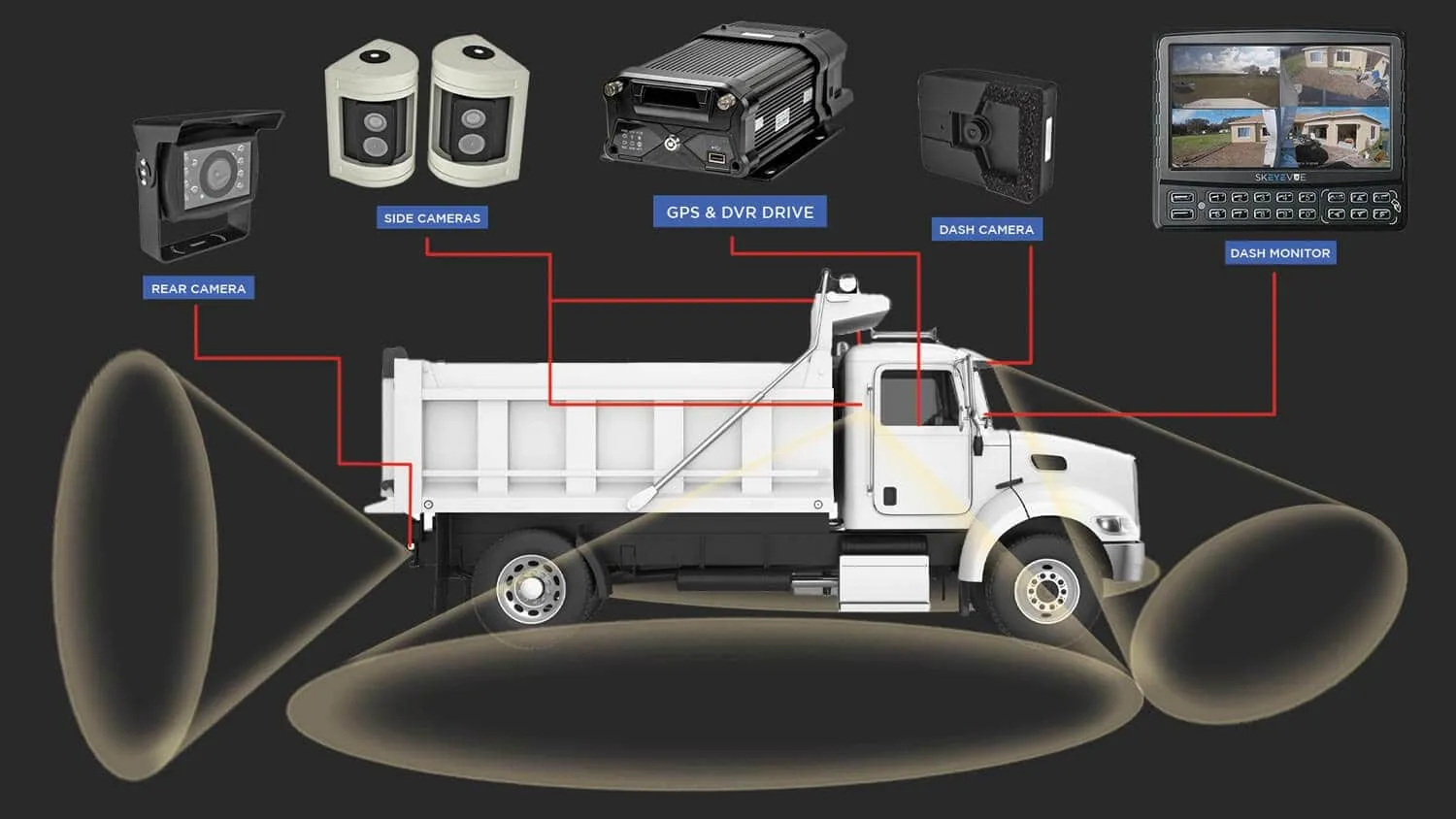

| Multi-Camera Surround Systems | Multiple cameras for 360-degree visibility; includes side and rear views. | Heavy-duty construction and aggregate transport. | Pros: Enhanced safety, comprehensive visibility. Cons: Higher initial investment, complex installation. |

| Integrated Dash Cameras | Combines rearview with forward-facing and driver-facing cameras. | Fleet management and logistics companies. | Pros: Records all angles, useful for accident disputes. Cons: More expensive, requires ongoing maintenance. |

| AI-Enhanced Camera Systems | Utilizes AI for monitoring driver behavior and providing alerts. | Safety-focused industries like mining and waste management. | Pros: Proactive safety measures, reduces liability. Cons: Higher cost, may require training for optimal use. |

| 4G Connected Mobile DVR Systems | Mobile DVR with remote access, allowing real-time monitoring. | Aggregate transport, long-haul trucking. | Pros: Real-time data access, evidence for claims. Cons: Dependence on internet connectivity, potential for data breaches. |

What Are the Characteristics of Standard Rearview Camera Systems?

Standard rearview camera systems are the most basic form of rear camera technology for dump trucks. They typically consist of a single rear-facing camera connected to a monitor within the cab. These systems are ideal for standard construction and landscaping applications, where cost efficiency is crucial. Buyers should consider installation simplicity and affordability, although they should be aware that these systems provide limited visibility, often only covering the rear view.

How Do Multi-Camera Surround Systems Enhance Safety?

Multi-camera surround systems offer a significant upgrade by providing 360-degree visibility through several strategically placed cameras. These systems are particularly beneficial in heavy-duty construction and aggregate transport, where maneuvering in tight spaces is common. When purchasing, companies should assess the installation requirements and potential for enhanced safety, even though the upfront investment is higher than standard systems.

What Benefits Do Integrated Dash Cameras Provide?

Integrated dash cameras combine rearview, forward-facing, and driver-facing cameras into one cohesive system. This integration is beneficial for fleet management and logistics companies that require comprehensive monitoring of their vehicles. Buyers should consider the value of having a complete record of incidents for liability protection, although the complexity and cost of these systems can be drawbacks.

How Do AI-Enhanced Camera Systems Improve Driver Safety?

AI-enhanced camera systems are designed to monitor driver behavior and provide real-time alerts for unsafe practices, such as distracted driving. These systems are particularly valuable in high-risk industries like mining and waste management. While they offer proactive safety measures that can reduce liability, companies should weigh the higher costs against the potential benefits in risk management.

What Advantages Do 4G Connected Mobile DVR Systems Offer?

4G connected mobile DVR systems allow for real-time monitoring and remote access to video footage. This feature is particularly advantageous for companies involved in aggregate transport and long-haul trucking, as it provides evidence for claims and enhances overall operational transparency. However, buyers must consider the dependence on internet connectivity and the potential risks of data breaches when evaluating these systems.

Key Industrial Applications of rear Camera Equipped Dump Truck

| Industry/Sector | Specific Application of rear Camera Equipped Dump Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Site Material Transport | Enhanced safety and efficiency in material handling | Compatibility with existing fleet, ruggedness for site conditions |

| Mining | Ore and Waste Hauling | Improved visibility in hazardous environments | Durability in extreme conditions, real-time monitoring capabilities |

| Waste Management | Refuse Collection | Increased safety during reverse maneuvers | Integration with waste management systems, camera resolution |

| Agriculture | Bulk Material Delivery | Streamlined logistics and reduced accident risks | Adaptability to various terrains, ease of installation |

| Infrastructure Development | Road Construction and Maintenance | Minimization of liability through recorded evidence | High-definition recording, remote access features |

How Do Rear Camera Equipped Dump Trucks Enhance Safety in Construction?

In the construction industry, rear camera-equipped dump trucks are instrumental for site material transport. These trucks provide drivers with enhanced visibility, allowing them to navigate busy job sites safely. The cameras help in identifying pedestrians and obstacles, significantly reducing the risk of accidents. For international buyers, particularly in regions like Africa and South America, sourcing durable systems that can withstand rugged terrain and environmental conditions is crucial.

What Are the Benefits of Using Rear Camera Equipped Dump Trucks in Mining Operations?

In mining, rear camera-equipped dump trucks facilitate ore and waste hauling in hazardous conditions. The multi-camera systems offer near 360-degree visibility, assisting drivers in avoiding obstacles and ensuring safe operation in challenging environments. Buyers from the Middle East and Europe should consider systems that provide robust performance under extreme conditions and have features for real-time monitoring to enhance operational safety.

How Do Waste Management Companies Utilize Rear Camera Technology?

Waste management companies leverage rear camera-equipped dump trucks for efficient refuse collection. These trucks enhance safety during reverse maneuvers, allowing drivers to see pedestrians and other vehicles clearly. This capability minimizes accidents and improves overall operational efficiency. When sourcing these systems, companies should focus on integration capabilities with existing waste management technologies and the quality of camera resolution to ensure clear visibility.

In What Ways Can Agriculture Benefit from Rear Camera Equipped Dump Trucks?

In agriculture, rear camera-equipped dump trucks are essential for bulk material delivery, such as soil or fertilizers. The technology aids in streamlining logistics, as drivers can monitor their surroundings more effectively, reducing the likelihood of accidents. Buyers in regions like Nigeria should prioritize systems that are adaptable to various terrains and easy to install, ensuring that they can implement these solutions without significant downtime.

How Do Rear Camera Equipped Dump Trucks Support Infrastructure Development?

For infrastructure development, rear camera-equipped dump trucks play a vital role in road construction and maintenance. They help minimize liability by recording all activities, which can be crucial in dispute situations. Buyers should look for high-definition recording capabilities and remote access features, allowing for effective monitoring and management of operations from a distance, which is particularly valuable in large-scale projects across Europe and beyond.

3 Common User Pain Points for ‘rear Camera Equipped Dump Truck’ & Their Solutions

Scenario 1: Navigating Tight Job Sites Safely

The Problem: Many B2B buyers, especially those in the construction and aggregate industries, face significant challenges when dump trucks operate in tight spaces at job sites. The risk of collisions with pedestrians, other vehicles, or surrounding infrastructure increases dramatically due to the limited visibility from the driver’s seat. This issue is compounded by the fact that dump trucks are often tasked with delivering materials in busy urban environments or construction zones where every inch counts. The fear of accidents can lead to higher insurance premiums, costly repairs, and potential legal liabilities.

The Solution: To address these safety concerns, investing in a multi-camera system for rear camera-equipped dump trucks is crucial. These systems should not only include a rear view but also side and front cameras, providing a near 360-degree view of the surroundings. Buyers should prioritize systems that feature high-definition video quality and low-light capabilities, ensuring clear visibility regardless of the conditions. Furthermore, integrating backup sensors and audible alarms can alert the driver to nearby obstacles, enhancing safety during operation. When sourcing these systems, ensure they are customizable to fit the specific dimensions and operational needs of the truck. Regular training for drivers on how to effectively utilize these camera systems will also maximize their benefits, ensuring safer navigation of tight job sites.

Scenario 2: Mitigating Liability and Disputes Over Property Damage

The Problem: In sectors like construction and logistics, disputes over property damage are common, especially when dump trucks are involved. The cost of these disputes can escalate quickly, consuming time and resources. Without reliable evidence, companies often find themselves at a disadvantage when claims arise from clients or third parties, leading to financial losses and damaged reputations.

The Solution: To mitigate these risks, B2B buyers should invest in a comprehensive camera system that includes DVR functionality. A system that records continuously, even when the vehicle is not in reverse, provides invaluable footage that can be used as evidence in case of disputes. Look for systems that offer cloud storage or remote access capabilities, allowing for easy retrieval of footage. This ensures that you have documented proof of the truck’s operations and surroundings, which can be crucial in defending against illegitimate claims. Regularly reviewing footage can also highlight potential safety issues or operational inefficiencies, allowing companies to address them proactively before they lead to disputes.

Scenario 3: Ensuring Driver Safety and Reducing Fatigue

The Problem: Driver fatigue is a significant concern in the heavy equipment sector, particularly for those operating dump trucks. Long hours and the demanding nature of the job can lead to decreased alertness, increasing the risk of accidents. B2B buyers are often tasked with ensuring the safety of their drivers while also managing operational efficiency, which can be a challenging balance to strike.

The Solution: Implementing a rear camera-equipped dump truck with integrated driver fatigue monitoring systems can significantly enhance safety. These systems can track driver behavior and alert management to signs of fatigue, such as erratic steering or prolonged periods of inactivity. When selecting a system, look for features that offer real-time alerts and comprehensive reporting capabilities, allowing for timely interventions. Additionally, pairing these systems with regular training and wellness programs can help to foster a culture of safety within the organization. Encouraging drivers to take regular breaks and providing them with the necessary tools to remain alert will not only enhance safety but also improve overall productivity. By taking a proactive approach to driver well-being, companies can reduce the risk of accidents and foster a safer work environment.

Strategic Material Selection Guide for rear Camera Equipped Dump Truck

What Materials Are Commonly Used for Rear Camera Systems in Dump Trucks?

When selecting materials for rear camera systems equipped in dump trucks, it is essential to consider various factors, including durability, environmental resistance, and overall performance. Here, we analyze four common materials used in the construction of these systems, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

How Does Aluminum Perform as a Material for Rear Camera Systems?

Aluminum is frequently utilized in the manufacturing of rear camera housings due to its lightweight and corrosion-resistant properties. It typically has a temperature rating of up to 150°C and can withstand moderate pressure, making it suitable for various environmental conditions.

Pros: Aluminum is durable and resistant to rust, which is particularly beneficial in regions with high humidity or saline environments, such as coastal areas in Africa or South America. Additionally, its lightweight nature aids in reducing the overall weight of the dump truck, improving fuel efficiency.

Cons: The primary drawback of aluminum is its cost, which is higher compared to other materials like steel. Furthermore, it can be less impact-resistant than some alternatives, which may be a concern in rugged terrains.

Impact on Application: Aluminum’s corrosion resistance makes it ideal for applications involving exposure to moisture or chemicals, ensuring longevity and reliability.

International Buyer Considerations: Buyers from regions such as Europe and the Middle East may prioritize compliance with environmental regulations, which aluminum meets well due to its recyclability. Standards such as DIN may be relevant for assessing material quality.

What Role Does Stainless Steel Play in Rear Camera Systems?

Stainless steel is another popular choice for rear camera systems, particularly in harsh environments. It offers excellent corrosion resistance, withstanding temperatures up to 800°C and high-pressure conditions.

Pros: Its durability and strength make stainless steel ideal for heavy-duty applications. It is also less susceptible to deformation under stress, ensuring the camera system remains intact even in challenging conditions.

Cons: The major downside is its weight, which can add to the overall mass of the dump truck, potentially affecting fuel efficiency. Additionally, stainless steel tends to be more expensive than aluminum.

Impact on Application: Stainless steel is particularly effective in environments where exposure to corrosive materials is a concern, such as in mining or construction sites.

International Buyer Considerations: Compliance with ASTM standards is crucial for buyers in North America and Europe, ensuring that the material meets rigorous safety and performance benchmarks.

How Does Polycarbonate Benefit Rear Camera Systems?

Polycarbonate is a thermoplastic material known for its high impact resistance and optical clarity, making it an excellent choice for camera lenses.

Pros: Polycarbonate is lightweight and offers superior shatter resistance, which is critical for protecting camera components in rough working conditions. It can also be molded into complex shapes, allowing for versatile design options.

Cons: While polycarbonate is generally durable, it can be susceptible to scratching and UV degradation over time, which may impact visibility and performance.

Impact on Application: Its optical properties make polycarbonate ideal for camera lenses, ensuring high-quality image capture even in challenging lighting conditions.

International Buyer Considerations: Buyers should consider UV resistance ratings and ensure compliance with international standards for plastics, particularly in regions with high sun exposure, such as Africa and South America.

Why Is ABS Plastic Considered for Rear Camera Systems?

Acrylonitrile Butadiene Styrene (ABS) plastic is often used for housing in camera systems due to its rigidity and impact resistance.

Pros: ABS is cost-effective and easy to manufacture, making it a popular choice for many applications. It also provides good resistance to chemicals and impacts, which is beneficial in construction environments.

Cons: However, ABS has lower temperature resistance compared to metals, typically rated up to 80°C, which may limit its use in high-heat applications.

Impact on Application: Its affordability and ease of production make ABS suitable for less demanding applications, where extreme durability is not a primary concern.

International Buyer Considerations: Compliance with JIS standards may be necessary for buyers in Japan and other regions, ensuring that the material meets safety and performance requirements.

Summary Table of Material Selection for Rear Camera Systems

| Material | Typical Use Case for rear Camera Equipped Dump Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Camera housings and mounts | Lightweight and corrosion-resistant | Higher cost, less impact resistance | Medium |

| Stainless Steel | Heavy-duty camera systems | High strength and durability | Heavier, more expensive | High |

| Polycarbonate | Camera lenses | High impact resistance and clarity | Susceptible to scratching/UV damage | Medium |

| ABS Plastic | Housing for less demanding applications | Cost-effective and easy to manufacture | Lower temperature resistance | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for rear Camera Equipped Dump Truck

What Are the Key Stages in the Manufacturing Process of Rear Camera Equipped Dump Trucks?

The manufacturing process for rear camera equipped dump trucks is multifaceted, involving several critical stages that ensure both the vehicle’s structural integrity and the effectiveness of its safety features. Understanding these stages can help B2B buyers identify quality manufacturers and make informed purchasing decisions.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material preparation. Manufacturers typically utilize high-strength steel or aluminum for the truck chassis and body to ensure durability and weight efficiency. Additionally, electronic components for the camera systems, including sensors and wiring, are sourced from specialized suppliers. The quality of these materials is crucial as they directly impact the performance and safety of the dump truck.

How Is the Forming Stage Executed?

Following material preparation, the forming stage involves shaping the materials into the required components. This can include processes like stamping, bending, and welding. Advanced techniques such as laser cutting and robotic welding are often employed to enhance precision and reduce human error. The forming stage not only defines the truck’s physical structure but also integrates mounts and enclosures for the rear camera systems, ensuring they are securely positioned for optimal visibility.

What Happens During the Assembly Process?

In the assembly stage, all components—including the chassis, body, engine, and camera systems—are brought together. This process typically follows a modular approach, where sub-assemblies are constructed separately before being integrated into the final product. Quality control measures are implemented at this stage to ensure that all components fit properly and function as intended. For rear camera systems, manufacturers must ensure that the cameras are correctly aligned and calibrated to provide clear images.

How Is the Finishing Process Conducted?

The finishing stage involves painting, coating, and applying any additional features to the dump truck. Protective coatings are applied to prevent rust and wear, especially important for trucks operating in harsh environments, such as those commonly found in Africa and South America. During this stage, the functionality of the rear camera system is also tested to ensure that it meets performance standards.

What Quality Assurance Practices Are Commonly Employed?

Quality assurance (QA) is a critical aspect of the manufacturing process, particularly for rear camera equipped dump trucks. Manufacturers often adhere to international standards such as ISO 9001, which outlines requirements for quality management systems. Compliance with these standards is essential for ensuring consistent product quality and reliability.

What Are the Relevant International Standards?

Apart from ISO 9001, industry-specific standards such as CE marking for European markets and API standards for certain components may also apply. These certifications indicate that the products meet specific safety and performance criteria, which can be particularly important for B2B buyers concerned about compliance with local regulations.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are strategically integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing stages, periodic inspections are conducted to monitor adherence to quality standards. This includes testing the functionality of the rear camera systems during assembly.

- Final Quality Control (FQC): Before the dump trucks are shipped, a comprehensive inspection is performed to verify that all systems, including the rear cameras, are operational and meet the required specifications.

What Common Testing Methods Are Used?

Various testing methods are employed to ensure the quality and reliability of rear camera equipped dump trucks. These include:

- Functional Testing: This verifies that the rear camera systems operate correctly under various conditions, including different light levels and weather scenarios.

- Durability Testing: Trucks undergo stress testing to simulate real-world usage conditions, ensuring that both the truck and its camera systems can withstand operational challenges.

- Safety Testing: This includes assessing the effectiveness of safety features like backup alarms and camera visibility to prevent accidents.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in international markets such as Africa, South America, and Europe, verifying a supplier’s quality control processes is essential. Here are some actionable steps:

- Conduct Audits: Request to perform site visits and audits of the manufacturing facilities to observe quality control practices firsthand.

- Review Quality Reports: Suppliers should provide documentation detailing their quality control measures, including inspection reports and compliance certificates.

- Utilize Third-Party Inspections: Engage independent third-party inspection services to conduct assessments on behalf of your company. This adds an additional layer of assurance regarding the quality and compliance of the products.

What Are the Quality Control and Certification Nuances for International Buyers?

International buyers must also navigate various nuances when it comes to quality control and certification. For instance, compliance with local regulations in the target market can significantly affect the product’s acceptance. Buyers should be aware of:

- Regional Standards: Different regions may have varying safety and performance standards, which can affect the certification process.

- Documentation Requirements: Ensure that all necessary documentation, such as test results and compliance certificates, is available and meets the requirements of the destination country.

- Language Barriers: Consider potential language barriers in documentation and communication, which may affect the understanding of quality standards.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when selecting suppliers for rear camera equipped dump trucks, ensuring that they invest in safe, reliable, and compliant vehicles.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘rear Camera Equipped Dump Truck’

Introduction

In the competitive landscape of heavy machinery procurement, sourcing a rear camera-equipped dump truck requires a strategic approach to ensure safety, efficiency, and compliance with regional regulations. This guide provides a step-by-step checklist tailored for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe. By following these steps, you can make informed decisions that align with your operational needs and budget.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your procurement process. Identify the specific features you require, such as camera resolution, field of view, and integration with existing vehicle systems. Consider whether you need additional functionalities like night vision, 360-degree coverage, or advanced safety alerts.

- Camera Type: Choose between wired and wireless systems based on installation feasibility and reliability.

- Recording Features: Look for systems that include DVR capabilities for incident documentation.

Step 2: Research Market Trends and Compliance Standards

Understanding current market trends and compliance standards in your region is essential for selecting the right equipment. Research local regulations regarding vehicle safety features, which can impact your purchasing decisions.

- Safety Regulations: Ensure that the camera systems meet the required safety certifications in your region, such as CE marking in Europe or specific local standards.

- Technology Trends: Stay informed about advancements in camera technology, such as AI integration for driver monitoring.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions to gauge their reliability and product quality.

- Supplier Experience: Look for suppliers with a proven track record in providing dump truck safety solutions.

- Customer Support: Assess the level of customer service and support offered, including installation assistance and warranty terms.

Step 4: Request Product Demonstrations and Trials

Engaging with suppliers to arrange product demonstrations or trials can provide valuable insights into the functionality and performance of the camera systems.

- Hands-On Experience: A live demo allows you to assess the user interface, camera clarity, and ease of installation.

- Feedback from Operators: Involve your drivers and operators in the evaluation process to gather their feedback on usability and effectiveness.

Step 5: Compare Pricing and Total Cost of Ownership

When evaluating different options, consider not just the upfront costs but the total cost of ownership over the equipment’s lifespan. This includes maintenance, potential upgrades, and any ancillary costs related to installation and training.

- Warranty and Service Agreements: Ensure that you understand the terms of warranties and any service agreements that can help mitigate future costs.

- Financing Options: Explore financing options that may be available, which can ease cash flow concerns.

Step 6: Finalize the Procurement Process

After thorough evaluation and comparison, finalize your procurement process by negotiating terms, confirming delivery timelines, and arranging payment methods.

- Contract Clarity: Ensure all terms are clearly outlined in the contract, including delivery schedules, installation services, and return policies.

- Documentation: Keep all documentation organized for future reference and compliance checks.

Step 7: Plan for Installation and Training

Once you have procured the rear camera-equipped dump truck, plan for its installation and necessary training for your operators.

- Installation Support: Coordinate with the supplier to ensure that installation is carried out professionally and efficiently.

- Driver Training: Conduct training sessions for drivers to familiarize them with the new systems, emphasizing safety protocols and effective usage.

By adhering to this checklist, B2B buyers can ensure a successful procurement process that enhances safety and operational efficiency for their fleet of dump trucks.

Comprehensive Cost and Pricing Analysis for rear Camera Equipped Dump Truck Sourcing

When sourcing rear camera-equipped dump trucks, understanding the comprehensive cost structure and pricing dynamics is essential for B2B buyers. This analysis provides insights into the various cost components, price influencers, and strategic buyer tips tailored for international markets, particularly in Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components for Rear Camera Equipped Dump Trucks?

The cost structure of rear camera-equipped dump trucks typically comprises several components:

-

Materials: The quality and type of materials used in manufacturing rear camera systems significantly impact costs. High-definition cameras, durable housings, and advanced sensors are essential for reliability and safety but may increase the overall price.

-

Labor: Skilled labor is required for both manufacturing and installing these systems. The labor cost can vary based on the region, with higher wages in developed countries compared to emerging markets.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and maintenance. Efficient manufacturing processes can lower overhead costs, which can be a critical factor in competitive pricing.

-

Tooling: Customization of camera systems may require specialized tooling, which adds to initial costs. However, these investments can lead to long-term savings if they enhance production efficiency.

-

Quality Control (QC): Ensuring the reliability and functionality of rear camera systems requires rigorous testing and quality assurance protocols. Investments in QC processes can prevent costly recalls and warranty claims.

-

Logistics: Shipping and handling costs can be significant, especially for international buyers. Factors like distance, shipping methods, and customs duties can influence the final price.

-

Margin: Manufacturers typically apply a markup on costs to ensure profitability. Understanding the typical margins in this sector can help buyers negotiate better prices.

How Do Price Influencers Affect Rear Camera Systems for Dump Trucks?

Several factors can influence the pricing of rear camera-equipped dump trucks:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders can often lead to discounts. Buyers should consider their purchasing capacity to leverage better pricing.

-

Specifications and Customization: Custom features, such as advanced driver-assist technologies or integration with existing systems, can raise prices. Clearly defining requirements can help avoid unnecessary costs.

-

Materials and Quality Certifications: Higher-quality materials and compliance with safety standards (like ISO certifications) can increase costs. Buyers should balance quality needs with budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and market position can affect pricing. Established suppliers may offer better warranties and service, justifying higher costs.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can influence total costs. Understanding these terms helps in evaluating the overall financial impact of the purchase.

What Strategic Tips Can Help Buyers Optimize Costs?

-

Negotiation: Buyers should be prepared to negotiate on price, especially when purchasing in bulk. Leverage multiple quotes to create competition among suppliers.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the initial purchase price. Consider factors such as maintenance, warranty, and potential downtime.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can affect the total cost. Understanding local regulations can prevent unexpected expenses.

-

Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and access to new technologies.

Disclaimer on Indicative Prices

Prices for rear camera-equipped dump trucks can vary widely based on the above factors. It is crucial for buyers to conduct thorough market research and obtain multiple quotes to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing rear Camera Equipped Dump Truck With Other Solutions

Introduction: Exploring Alternatives to Rear Camera Equipped Dump Trucks

In the realm of heavy-duty vehicles, particularly dump trucks, safety and operational efficiency are paramount. While rear camera-equipped dump trucks offer significant advantages, exploring alternative solutions can help businesses make informed decisions tailored to their specific needs. This analysis compares rear camera-equipped dump trucks with other viable technologies, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Rear Camera Equipped Dump Truck | Advanced Multi-Camera Systems | Dash Cameras with AI Features |

|---|---|---|---|

| Performance | Provides rear visibility; limited to back view | Offers 360-degree visibility; monitors all angles | Front and rear visibility; AI monitors driving behavior |

| Cost | Moderate initial investment; ongoing maintenance costs | Higher upfront cost; potential for reduced liability costs | Lower initial cost; may require subscription for AI features |

| Ease of Implementation | Typically easy to install; requires minimal training | More complex installation; requires operator training | Straightforward installation; user-friendly interface |

| Maintenance | Regular checks needed; potential for camera damage | High durability; requires periodic system updates | Minimal maintenance; AI features may require software updates |

| Best Use Case | Ideal for urban environments with frequent reversing | Best for construction sites with high maneuvering needs | Suitable for fleet management and monitoring driver behavior |

Detailed Breakdown of Alternatives

Advanced Multi-Camera Systems

These systems offer a significant upgrade over traditional rear cameras by providing comprehensive 360-degree visibility around the vehicle. This feature is crucial for dump trucks operating in complex environments such as construction sites, where obstacles can appear from any direction. While these systems come with a higher upfront cost and may require more extensive training for operators, they can significantly reduce the risk of accidents and liability claims. The ability to monitor all angles enhances safety and operational efficiency, making them a strong contender for businesses prioritizing safety.

Dash Cameras with AI Features

Dash cameras equipped with artificial intelligence provide a unique blend of safety and data analytics. These cameras not only capture footage from the front and rear but also analyze driving behavior, alerting fleet managers to issues such as distracted driving or fatigue. The initial investment for these systems is typically lower than that of multi-camera systems, and they can be easily installed in existing vehicles. However, the potential additional costs of AI subscriptions and software updates should be considered. This solution is particularly beneficial for companies looking to enhance fleet management and driver safety without a significant capital outlay.

Conclusion: Choosing the Right Solution for Your Business Needs

Selecting the appropriate safety solution for dump trucks involves assessing various factors, including operational environment, budget constraints, and specific safety requirements. Rear camera-equipped dump trucks are effective for straightforward applications, while advanced multi-camera systems excel in complex job sites where visibility is crucial. Meanwhile, dash cameras with AI features provide an affordable alternative that emphasizes driver behavior and fleet management. B2B buyers should evaluate these options against their unique operational needs to determine the best fit, ensuring both safety and efficiency in their heavy-duty operations.

Essential Technical Properties and Trade Terminology for rear Camera Equipped Dump Truck

What Are the Key Technical Properties of Rear Camera Equipped Dump Trucks?

When evaluating rear camera equipped dump trucks, understanding their technical specifications is crucial for making informed purchasing decisions. Here are some critical properties that should be considered:

-

Camera Resolution and Field of View (FOV)

The resolution of the camera (typically measured in megapixels) directly impacts the clarity of the images captured. A higher resolution allows for better detail, which is essential for identifying obstacles or hazards. The field of view indicates how wide the camera can see; a wider FOV is beneficial for comprehensive visibility, particularly in busy work environments. -

Durability and Weather Resistance

Given the harsh conditions dump trucks often operate in, the durability of the camera system is paramount. Look for cameras that are built with rugged materials and are rated for weather resistance (e.g., IP67 rating), ensuring they can withstand dust, moisture, and temperature extremes. This reliability minimizes maintenance costs and enhances safety. -

Night Vision Capability

Night vision technology is essential for safe operation in low-light conditions. Cameras equipped with infrared (IR) capabilities can capture clear images even in complete darkness, allowing operators to reverse and navigate safely during nighttime or in poorly lit job sites. -

Recording and Storage Options

The ability to record footage is a significant advantage. Many rear camera systems come with integrated DVRs (Digital Video Recorders) that store video footage for later review. Consider systems that offer sufficient storage capacity and the ability to access recorded footage remotely, as this can be invaluable in legal disputes or accident investigations. -

Integration with Other Safety Systems

Advanced dump truck camera systems can integrate with other safety technologies, such as backup alarms and sensor systems. This integration not only enhances overall safety but also provides real-time alerts to drivers about potential hazards, significantly reducing the risk of accidents. -

Power Supply and Connectivity

Understanding the power requirements and connectivity options of the camera system is essential. Systems that utilize both hardwiring and wireless options offer flexibility in installation and can be adapted to various truck models.

What Are Common Trade Terms in the Rear Camera Equipped Dump Truck Industry?

Navigating the procurement process for rear camera equipped dump trucks involves familiarizing oneself with specific industry terminology. Here are several key terms that are frequently encountered:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts and equipment that may be marketed by another manufacturer. In the context of dump trucks, OEM parts are typically recommended for their quality and compatibility, ensuring the camera systems function optimally. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers, as it can impact inventory management and cost efficiency. Ordering below the MOQ may result in higher per-unit costs or rejection of the order. -

RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers to solicit price quotes for specific products or services. It is a crucial step in the procurement process, allowing buyers to compare costs and terms from multiple vendors. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, thereby mitigating risks associated with international trade. -

Warranty and After-Sales Support

A warranty is a guarantee provided by the manufacturer regarding the condition of the product, typically covering repairs or replacements for a specified period. Understanding warranty terms and the level of after-sales support available is essential for minimizing potential costs associated with equipment failure. -

Fleet Management Solutions

These refer to systems that help businesses track and manage their vehicles, including those equipped with rear cameras. Fleet management solutions can provide insights into vehicle performance, safety metrics, and driver behavior, contributing to improved operational efficiency.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when selecting rear camera equipped dump trucks, ultimately enhancing safety and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the rear Camera Equipped Dump Truck Sector

What Are the Key Market Dynamics and Trends Influencing the Rear Camera Equipped Dump Truck Sector?

The rear camera equipped dump truck sector is experiencing a transformative period driven by several global factors. The increasing focus on safety and regulatory compliance is a primary market driver. For instance, many countries are implementing stricter safety regulations that mandate the installation of advanced camera systems to enhance visibility and prevent accidents. Additionally, the rise in infrastructure projects, particularly in developing regions such as Africa and South America, is fueling demand for dump trucks equipped with advanced safety technologies.

Emerging technologies such as artificial intelligence (AI) and 4G connectivity are also reshaping the landscape. AI-powered camera systems can detect hazardous situations and alert drivers, thereby significantly reducing the risk of accidents. Furthermore, the integration of real-time data access allows fleet managers to monitor vehicle performance and driver behavior remotely, optimizing operations and enhancing accountability.

International buyers, particularly from regions like the Middle East and Europe, should be aware of the growing trend towards customization in camera systems. Manufacturers are now offering tailored solutions that meet specific operational needs, from multi-camera setups to advanced dash monitoring systems. This customization not only improves safety but also provides a competitive edge in operations.

How Does Sustainability Impact Sourcing for Rear Camera Equipped Dump Trucks?

Sustainability has become a critical consideration in the sourcing of rear camera equipped dump trucks. As environmental concerns grow, buyers are increasingly prioritizing eco-friendly products and ethical supply chains. The production of dump trucks and their components can have significant environmental impacts, from resource extraction to manufacturing processes. Therefore, sourcing from manufacturers who prioritize sustainable practices—such as using recycled materials and reducing waste—is essential.

Moreover, certifications for green practices are becoming more prominent. Buyers should look for suppliers who possess certifications like ISO 14001, which indicates adherence to environmental management standards. These certifications not only affirm a commitment to sustainability but can also enhance a company’s reputation and marketability.

Ethical sourcing is also paramount, particularly in regions with complex supply chains. Ensuring that suppliers adhere to fair labor practices and environmentally responsible operations can mitigate risks and enhance brand loyalty. International buyers should conduct thorough due diligence to ensure that their suppliers align with their sustainability and ethical standards.

How Has the Rear Camera Equipped Dump Truck Sector Evolved Over Time?

The evolution of rear camera equipped dump trucks can be traced back to the early 2000s when basic rearview cameras began to gain popularity in commercial vehicles. Initially, these systems were simple, providing only a rear view to aid in reversing. However, as technology advanced, so did the capabilities of these systems.

Today’s rear camera systems are sophisticated, offering multi-camera setups that provide near 360-degree visibility, integrated recording features, and real-time monitoring capabilities. The shift towards digital solutions has allowed for enhanced safety measures and operational efficiencies, making these vehicles indispensable in sectors such as construction and mining.

As global demands for safety and efficiency continue to rise, the rear camera equipped dump truck sector is expected to further innovate, integrating even more advanced technologies and sustainable practices to meet the evolving needs of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of rear Camera Equipped Dump Truck

-

How do I solve visibility issues when operating a dump truck?

To address visibility challenges, investing in a rear camera-equipped dump truck is essential. These systems typically offer multi-mounted cameras that provide a near 360° view, significantly improving situational awareness. Additionally, many advanced systems come with features like live-streaming capabilities, recording functionalities, and alerts for blind spots. By ensuring your fleet is equipped with high-quality camera systems, you can enhance safety, minimize accidents, and protect your drivers and pedestrians. -

What is the best rear camera system for dump trucks?

The best rear camera system for dump trucks combines high-definition video, multi-camera setups, and durable construction. Look for systems that offer features such as a dash monitor for real-time viewing, onboard recording to capture incidents, and remote access via a secure online portal. Systems that include side cameras are particularly beneficial for navigating tight spaces on job sites. Brands like skEYEvue and Rear View Safety offer robust solutions tailored specifically for the heavy-duty environment of dump trucks. -

What factors should I consider when sourcing rear camera-equipped dump trucks?

When sourcing rear camera-equipped dump trucks, consider factors such as the quality of the camera system, customization options, and the supplier’s reputation. Evaluate whether the system meets safety regulations in your region and if it can be integrated with your existing fleet management systems. Additionally, inquire about warranty, after-sales support, and whether the cameras are rugged enough to withstand harsh working conditions, especially in regions with extreme weather or challenging terrains. -

How can I vet suppliers of rear camera-equipped dump trucks?

To effectively vet suppliers, start by checking their industry experience and customer reviews. Look for certifications and compliance with international safety standards. Request references from other clients, especially those in similar sectors or geographical areas. It’s also prudent to visit their facilities if possible, and engage in discussions about their manufacturing processes, quality assurance measures, and after-sales service. This will help ensure that you partner with a reliable supplier. -

What are common customization options available for rear camera systems?

Customization options for rear camera systems can include varying camera placements (e.g., front, sides, and rear), video resolution choices, and integration with existing fleet management software. You may also be able to select additional features like driver fatigue monitoring, night vision capabilities, and mobile DVR recording. Discuss your specific needs with potential suppliers to ensure you receive a tailored solution that fits your operational requirements. -

What is the minimum order quantity (MOQ) for rear camera-equipped dump trucks?

Minimum order quantities for rear camera-equipped dump trucks can vary significantly depending on the supplier and your geographic location. Some manufacturers may have a MOQ of one unit, while others may require larger orders to ensure cost-effectiveness and efficient production runs. It’s advisable to communicate directly with suppliers to negotiate terms that align with your purchasing capacity and operational needs. -

What payment terms should I expect when purchasing rear camera-equipped dump trucks?

Payment terms can vary by supplier, but typical arrangements include options for full upfront payment, partial deposits with the balance due upon delivery, or installment payments. It’s essential to clarify these terms before finalizing your order. Additionally, inquire about accepted payment methods, currency options, and any financing solutions that may be available to facilitate larger purchases, especially for international transactions. -

How can I ensure quality assurance for rear camera systems?

To ensure quality assurance, request detailed specifications and certifications for the rear camera systems you are considering. Look for suppliers who have established quality control processes, including testing protocols for durability, functionality, and safety. Some manufacturers may offer warranties or guarantees, which can provide additional assurance. Consider requesting samples or demonstrations before making a bulk purchase, allowing you to assess the performance and reliability of the systems firsthand.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Rear Camera Equipped Dump Truck Manufacturers & Suppliers List

1. Lintech – Rugged Camera Systems

Domain: lintechco.com

Registered: 2009 (16 years)

Introduction: 1. Rugged, Weatherproof Construction: IP69K waterproof rating, shock-resistant. Examples: Rear View Safety Custom105, Lintech Semi Truck Camera System. 2. High-Resolution Imaging with Night Vision: 1080P AHD camera, wide-angle lens (120°–150°), infrared night vision up to 50 feet. Examples: Haloview, Lintech systems. 3. Continuous Recording and DVR Capabilities: Mobile DVR for continuous recording…

2. Deere – Next-Gen Articulated Dump Trucks

Domain: equipmentworld.com

Registered: 1996 (29 years)

Introduction: Deere’s next-generation articulated dump trucks (ADTs) include models 260, 310, 410, and 460 P-Tier. Key upgrades include a new 13.6-liter JD14 engine for the 410 and 460 models, enhancing reliability and serviceability. All models feature a button to lower the front suspension for easier access to engine components and daily service points. They are equipped with Deere’s Advanced Vision System, w…

3. Buyers Products – Rear-View Camera System

Domain: buyersproducts.com

Registered: 1997 (28 years)

Introduction: This company, Buyers Products – Rear-View Camera System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. The Dashcam Store – Extreme Duty Dashcams for Trucks

Domain: thedashcamstore.com

Registered: 2013 (12 years)

Introduction: Extreme Duty Dashcams designed for trucks and heavy duty vehicles. Key features include: 1-4 lenses, maximum video resolution of 4K UHD or 1080p Full HD, maximum framerate options of 15, 30, or 60 FPS, GPS position logging (optional or built-in), infrared capabilities (available in some models), motion detection (available in most models), viewing angles ranging from 120° to 360°, and WiFi options…

5. Red Power – Rear View Equipment Camera for Skid Steers

Domain: redpowermagazine.com

Registered: 2000 (25 years)

Introduction: Rear view equipment camera for skid steers; requires a constantly key powered camera and a screen; designed for agricultural or industrial applications; options include magnetic, wireless, solar charging systems; budget-friendly options available (e.g., $150 Amazon special); some users recommend cable-connected systems for reliability; examples of products mentioned include Vekooto camera setup an…

6. SeatronX – Heavy Equipment Camera Systems

Domain: seatronx.com

Registered: 2018 (7 years)

Introduction: Camera systems for heavy equipment vehicles include various types such as rearview, tool view, side view, and RadarEye. These systems enhance safety by improving visibility and maneuverability, preventing collisions, and supporting drivers. They can be installed on buses, coaches, cranes, forklifts, emergency vehicles, and military vehicles. Key features include automatic switching to rearview whe…

Strategic Sourcing Conclusion and Outlook for rear Camera Equipped Dump Truck

The integration of rear camera systems in dump trucks presents a compelling opportunity for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. These advanced safety solutions not only enhance operational efficiency but also significantly reduce the risk of accidents, thereby protecting both drivers and investments. As the demand for safer and more reliable construction and transportation equipment continues to grow, strategic sourcing of rear camera-equipped dump trucks can lead to substantial long-term benefits, including lower insurance costs and improved compliance with safety regulations.

Investing in high-quality camera systems, such as those offering 360-degree visibility and real-time monitoring, enables companies to mitigate risks associated with property damage claims and enhance overall fleet management. Furthermore, the ability to access recorded footage remotely can serve as a critical asset in dispute resolution and operational oversight.

As we look to the future, international buyers are encouraged to prioritize partnerships with suppliers who offer customizable and technologically advanced safety solutions. Embrace the shift towards smarter, safer dump trucks today, and position your business at the forefront of the industry. Your commitment to safety and efficiency will not only safeguard your workforce but also enhance your competitive edge in the global marketplace.