Introduction: Navigating the Global Market for 5 Ton Crane Truck

In the fast-evolving landscape of construction and logistics, sourcing a reliable 5 ton crane truck can present a significant challenge for international B2B buyers. Companies face the daunting task of navigating a myriad of options while ensuring compliance with local regulations and operational needs. This guide serves as a comprehensive resource to streamline the purchasing process, covering essential aspects such as types of crane trucks, their applications across various industries, effective supplier vetting, and a detailed analysis of costs.

With a focus on key markets in Africa, South America, the Middle East, and Europe—specifically countries like Germany and Nigeria—this guide empowers buyers with the knowledge needed to make informed purchasing decisions. By understanding the nuances of the global market, buyers can identify the right equipment that not only meets their lifting requirements but also enhances operational efficiency and safety.

From evaluating the specifications of different models to understanding the importance of after-sales support, this guide equips B2B buyers with actionable insights to navigate the complexities of sourcing a 5 ton crane truck. Whether for construction projects, telecommunications, or municipal services, the information provided here will aid in selecting the ideal crane truck that aligns with business objectives and budgetary constraints.

Understanding 5 Ton Crane Truck Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Boom Truck Crane | Mounted on a truck chassis; versatile boom length. | Construction, logistics, utility services. | Pros: High mobility, quick setup. Cons: Limited lifting height compared to larger cranes. |

| Telescopic Boom Crane | Extends and retracts for variable reach; compact. | Warehousing, shipping, and delivery. | Pros: Flexible operation in tight spaces. Cons: Requires regular maintenance for telescopic components. |

| Knuckle Boom Crane | Articulating boom for enhanced maneuverability. | Urban construction, forestry, and waste management. | Pros: Excellent for awkward loads; compact design. Cons: May have lower lifting capacity compared to straight booms. |

| Stiff Boom Crane | Rigid boom with fixed length; robust design. | Heavy lifting in industrial settings. | Pros: High stability and lifting capacity. Cons: Less flexibility in reach compared to telescopic options. |

| Truck-Mounted Crane | Integrated with the truck chassis; versatile options. | General cargo handling, municipal services. | Pros: Integrated design saves space. Cons: Limited by the truck’s payload capacity. |

What Are the Key Characteristics of Boom Truck Cranes?

Boom truck cranes are designed for high mobility and versatility, mounted on a truck chassis that allows for easy transportation across job sites. They typically feature a hydraulic boom that can extend to various lengths, making them suitable for a range of applications including construction, logistics, and utility services. Buyers should consider the crane’s lifting height and capacity, as well as the overall weight of the truck, which can affect site maneuverability.

How Do Telescopic Boom Cranes Stand Out?

Telescopic boom cranes are characterized by their ability to extend and retract, allowing for variable reach and compact storage. They are particularly advantageous in warehouse and shipping operations where space is limited. When purchasing, B2B buyers should evaluate the crane’s lifting height, maximum outreach, and the ease of extending the boom, as these factors influence operational efficiency.

What Advantages Do Knuckle Boom Cranes Offer?

Knuckle boom cranes feature an articulating arm that allows for enhanced maneuverability, making them ideal for urban construction and forestry tasks. They can handle awkward loads in tight spaces, which is a significant advantage in densely populated areas. However, buyers should be mindful of the crane’s lifting capacity and ensure it meets their specific project requirements.

Why Choose Stiff Boom Cranes for Heavy Lifting?

Stiff boom cranes are known for their robust and rigid design, providing high stability and significant lifting capacity. They are commonly used in industrial settings where heavy lifting is required. Buyers should consider the crane’s lifting moment and overall weight, as these factors will dictate its performance in demanding environments.

How Do Truck-Mounted Cranes Enhance Operational Efficiency?

Truck-mounted cranes integrate the crane with the truck chassis, offering a space-efficient solution for general cargo handling and municipal services. This design allows for quick deployment and minimizes the need for additional transportation. However, buyers must take into account the truck’s payload capacity, as it can limit the crane’s operational scope and effectiveness on larger projects.

Key Industrial Applications of 5 Ton Crane Truck

| Industry/Sector | Specific Application of 5 Ton Crane Truck | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting and placing construction materials | Enhances efficiency in material handling and reduces labor costs | Crane capacity, reach, and compatibility with existing equipment |

| Telecommunications | Installing telecommunication towers and antennas | Streamlines installation processes and improves safety | Stability features, lifting height, and outreach capabilities |

| Oil and Gas | Transporting equipment and materials on-site | Increases operational efficiency and safety in challenging environments | Durability in harsh conditions and load capacity |

| Municipal Services | Assisting with maintenance of public infrastructure | Facilitates timely repairs and reduces downtime for public services | Versatility and ease of operation for various tasks |

| Logistics and Transport | Loading and unloading goods at distribution centers | Optimizes loading times and enhances supply chain efficiency | Vehicle weight, crane weight, and operational ease |

How is the 5 Ton Crane Truck Utilized in Construction Projects?

In the construction industry, the 5 Ton Crane Truck is invaluable for lifting and placing heavy materials such as steel beams, concrete blocks, and large equipment. It solves common challenges such as time delays and labor-intensive manual handling, allowing for quicker project completion. Buyers must consider the crane’s capacity, boom length, and compatibility with various construction sites, especially in regions like Africa and South America, where terrain can vary significantly.

What Role Does the 5 Ton Crane Truck Play in Telecommunications?

Telecommunications companies utilize 5 Ton Crane Trucks to install and maintain towers and antennas. The crane’s ability to reach significant heights and its stability during operations are critical for ensuring safety and efficiency. Buyers in this sector should prioritize features like outreach capabilities and the crane’s lifting height, particularly in remote areas of the Middle East, where access can be challenging.

How is the 5 Ton Crane Truck Beneficial for Oil and Gas Operations?

In the oil and gas sector, 5 Ton Crane Trucks are essential for transporting equipment and materials to remote drilling sites. These trucks help mitigate risks associated with manual lifting and improve operational efficiency in rugged environments. When sourcing for this application, businesses should focus on the crane’s durability, load capacity, and performance under extreme conditions, which are crucial for operations in regions like Nigeria and other oil-rich areas.

How Do Municipal Services Leverage the 5 Ton Crane Truck?

Municipal services benefit from 5 Ton Crane Trucks by using them for the maintenance and repair of public infrastructure, such as streetlights and utility lines. The cranes facilitate quick and safe access to high or hard-to-reach areas, which is vital for timely public service delivery. Buyers should consider the truck’s versatility and ease of operation, especially in European urban environments where maneuverability is essential.

What Advantages Does the 5 Ton Crane Truck Offer in Logistics and Transport?

In logistics and transport, the 5 Ton Crane Truck is employed for loading and unloading goods at distribution centers, enhancing supply chain efficiency. This application reduces loading times and minimizes the risk of injury associated with manual handling. When sourcing, businesses should evaluate the truck’s weight, crane weight, and overall operational ease to ensure it meets the demands of high-volume logistics operations, particularly in South American markets where rapid growth is observed.

3 Common User Pain Points for ‘5 Ton Crane Truck’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Crane for Specific Needs

The Problem: Many B2B buyers encounter challenges when selecting a 5-ton crane truck that meets their specific operational requirements. Factors such as lifting height, outreach, and compatibility with existing vehicles can complicate the decision-making process. Buyers may feel overwhelmed by the variety of models available, leading to uncertainty about which features are essential for their applications, especially in regions with varying terrain and load demands.

The Solution: To effectively choose the right 5-ton crane truck, buyers should begin by conducting a thorough needs assessment. This involves identifying the maximum load capacity, desired boom length, and the lifting height required for their operations. Engaging with manufacturers or dealers can provide insights into the technical specifications of different models, helping to narrow down options. Additionally, requesting demonstrations or trial periods can be invaluable. Buyers should also consider local regulations regarding crane operations, ensuring compliance to avoid future operational disruptions. By aligning the crane’s specifications with actual field requirements, businesses can make informed purchasing decisions that enhance productivity.

Scenario 2: High Maintenance and Repair Costs

The Problem: A common pain point for users of 5-ton crane trucks is the unexpected costs associated with maintenance and repairs. This issue is particularly pronounced in regions where parts availability is limited or where service providers may not have adequate technical expertise. Buyers often find themselves faced with prolonged downtimes and escalating repair bills, which can significantly impact project timelines and profitability.

The Solution: To mitigate maintenance costs, buyers should invest in a crane truck known for reliability and ease of service. Researching brands with a strong reputation for durability and readily available spare parts is essential. Establishing a relationship with local service providers or dealerships can facilitate quicker repairs and routine maintenance checks. Implementing a proactive maintenance schedule, including regular inspections and servicing, can also help in identifying potential issues before they escalate. Additionally, investing in training for operators on proper usage and care can minimize wear and tear, thus extending the lifespan of the equipment and reducing overall costs.

Scenario 3: Safety Concerns and Compliance Issues

The Problem: Safety is a paramount concern for businesses operating 5-ton crane trucks, particularly in industries such as construction and logistics. Many buyers worry about compliance with local safety regulations and the potential for accidents caused by improper operation or inadequate safety features. This concern is magnified in international markets, where regulations may vary significantly.

The Solution: To address safety concerns, it’s crucial for buyers to prioritize purchasing cranes equipped with advanced safety features such as overload protection, emergency stop mechanisms, and stabilizers. Understanding local safety regulations is vital; businesses should engage with legal experts or safety consultants to ensure full compliance. Furthermore, providing comprehensive training for operators is essential to instill safe operating practices. Regular safety audits and drills can reinforce a culture of safety within the organization. By fostering an environment where safety is prioritized, businesses not only comply with regulations but also enhance their operational efficiency and employee morale.

Strategic Material Selection Guide for 5 Ton Crane Truck

When selecting materials for a 5-ton crane truck, it is crucial to consider various factors that impact performance, durability, and compliance with international standards. Here, we analyze four common materials used in the construction of crane trucks, focusing on their properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Steel in 5 Ton Crane Trucks?

Steel is the most commonly used material in crane truck construction due to its superior strength and durability. Key properties include high tensile strength, excellent fatigue resistance, and good weldability. Steel can withstand high temperatures and pressures, making it suitable for heavy-duty applications.

Pros: Steel offers exceptional durability and can handle heavy loads without deforming. It is also widely available and relatively cost-effective compared to other materials.

Cons: Steel is susceptible to corrosion, especially in humid or saline environments, which can lead to increased maintenance costs. Additionally, its weight can impact the overall payload capacity of the crane truck.

Impact on Application: Steel’s strength allows for the construction of robust cranes capable of lifting heavy loads, but its weight may limit the maximum lifting capacity if not properly managed.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the steel used meets local standards, such as ASTM or JIS, particularly in terms of corrosion resistance. Compliance with international standards is crucial for safety and operational efficiency.

How Does Aluminum Benefit 5 Ton Crane Trucks?

Aluminum is increasingly used in crane truck construction due to its lightweight nature and resistance to corrosion. Key properties include a lower density compared to steel, good strength-to-weight ratio, and excellent resistance to oxidation.

Pros: The lightweight nature of aluminum allows for higher payload capacities and improved fuel efficiency. It also requires less maintenance due to its corrosion resistance.

Cons: Aluminum is generally more expensive than steel and may have lower tensile strength, which can be a limitation in heavy-duty applications.

Impact on Application: Aluminum cranes can be advantageous in operations requiring frequent movement and high efficiency, but they may not be suitable for extremely heavy lifting tasks.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer aluminum due to its lightweight properties, which align with fuel efficiency regulations. Compliance with European standards for material quality is essential.

What Role Does Composite Material Play in Crane Truck Design?

Composite materials, particularly fiber-reinforced polymers, are gaining traction in crane truck applications due to their unique properties. They offer high strength, low weight, and excellent corrosion resistance.

Pros: Composites are lightweight, which enhances the crane’s lifting capacity and reduces fuel consumption. They also exhibit excellent resistance to environmental factors, reducing maintenance needs.

Cons: The manufacturing process for composites can be complex and costly, which may increase the overall price of the crane truck. Additionally, they may not be as widely available as traditional materials.

Impact on Application: Composites can be particularly beneficial in specialized applications where weight savings are critical, but their cost may limit their use in standard crane truck designs.

Considerations for International Buyers: Buyers should be aware of the availability of composite materials in their region and the associated costs. Compliance with international standards for composite materials is vital for ensuring safety and performance.

How Does High-Strength Low-Alloy Steel Compare?

High-strength low-alloy (HSLA) steel is an advanced material that combines the benefits of traditional steel with improved mechanical properties. It offers enhanced strength, toughness, and weldability while being lighter than conventional steel.

Pros: HSLA steel provides excellent strength-to-weight ratios, making it suitable for high-performance crane trucks. It also exhibits good resistance to corrosion and fatigue.

Cons: The cost of HSLA steel can be higher than standard steel, which may impact the overall budget for crane truck procurement.

Impact on Application: HSLA steel enables the construction of lighter cranes that can handle heavy loads, improving operational efficiency.

Considerations for International Buyers: Buyers should verify that HSLA steel meets relevant standards, such as ASTM or DIN, to ensure compliance and safety. Its use may be more prevalent in Europe, where advanced materials are often preferred.

Summary Table of Material Selection for 5 Ton Crane Truck

| Material | Typical Use Case for 5 Ton Crane Truck | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Main structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight crane arms | Lightweight, enhances payload capacity | Higher cost, lower tensile strength | High |

| Composite Material | Specialized applications | Excellent corrosion resistance | Complex manufacturing process | High |

| High-Strength Low-Alloy Steel | High-performance crane structures | Strength-to-weight ratio | Higher cost than standard steel | Medium to High |

This material selection guide provides critical insights for B2B buyers considering a 5-ton crane truck, emphasizing the importance of material properties, advantages, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for 5 Ton Crane Truck

What Are the Key Stages in the Manufacturing Process of a 5 Ton Crane Truck?

The manufacturing process for a 5 Ton Crane Truck involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is essential to ensure the crane’s efficiency, safety, and durability.

How Is Material Prepared for 5 Ton Crane Trucks?

Material preparation begins with the selection of high-quality steel and alloys that meet the strength and weight requirements of the crane. Suppliers often utilize advanced methods such as laser cutting and CNC machining to ensure precision in the shapes and sizes of components. The materials undergo rigorous inspection to confirm that they conform to international standards, which is crucial for the structural integrity of the crane.

What Forming Techniques Are Used in Manufacturing Crane Components?

The forming stage employs various techniques, including forging, welding, and bending. For instance, the crane’s boom is typically fabricated using a combination of welding and bending processes to achieve the desired shape and strength. Advanced robotic welding systems may be utilized to ensure consistency and reduce human error. This stage is critical, as the crane must withstand significant loads while maintaining stability during operations.

How Is the Assembly Process Conducted for 5 Ton Crane Trucks?

The assembly of the crane truck is a meticulous process where all components are integrated. This includes the installation of the hydraulic systems, electrical wiring, and control mechanisms. Assembly lines often employ modular approaches to streamline the process, allowing for quick adaptations if specific components need to be replaced or upgraded. Each assembly checkpoint is vital for ensuring that all systems are functioning correctly and safely before moving on to the next stage.

What Finishing Techniques Are Applied to Enhance Durability?

Finishing processes such as painting, coating, and galvanizing are essential for protecting the crane truck from environmental factors. These processes enhance corrosion resistance and improve the overall aesthetic appeal of the crane. Manufacturers often use powder coating or multi-layer painting techniques, which provide a durable finish that can withstand harsh working conditions. Quality checks during this stage ensure that the finish meets both aesthetic and protective standards.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance (QA) is paramount in crane manufacturing. International standards such as ISO 9001 are widely adopted, ensuring that manufacturers maintain a quality management system that meets customer and regulatory requirements. Additionally, industry-specific certifications like CE and API (American Petroleum Institute) are critical, especially for cranes used in specialized sectors such as construction and oil & gas.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. Key stages include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous inspections are performed during the manufacturing process to detect and rectify defects early.

- Final Quality Control (FQC): Before shipment, cranes undergo thorough testing, including load tests and operational checks, to verify they meet all performance standards.

What Common Testing Methods Are Used to Ensure Quality?

Common testing methods for crane trucks include load testing, where cranes are subjected to loads exceeding their rated capacity to ensure structural integrity. Non-destructive testing (NDT) methods, such as ultrasonic and magnetic particle inspections, help identify any internal defects without damaging the components. Additionally, performance tests are conducted to validate operational capabilities under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must conduct due diligence when selecting suppliers. This can include:

- Supplier Audits: Regular audits can provide insights into the manufacturer’s processes and adherence to quality standards. Buyers should request access to audit reports and certifications.

- Quality Reports: Suppliers should provide documentation detailing their QC processes, including results from IQC, IPQC, and FQC stages.

- Third-Party Inspections: Engaging independent inspectors can offer an unbiased assessment of the crane’s quality before purchase. This is especially important for buyers in regions where local regulations may differ from international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers, particularly from Africa, South America, the Middle East, and Europe, must be aware of the specific quality control nuances related to their regions. For instance, import regulations may require additional certifications or compliance with local safety standards. Understanding these requirements can help buyers avoid costly delays and ensure that their equipment meets local operational standards.

How Can Buyers Ensure Compliance with International Standards?

To ensure compliance with international standards, buyers should:

- Research Local Regulations: Understanding the specific requirements in their region can prevent issues during import.

- Request Certificates of Compliance: Suppliers should provide documentation proving adherence to both international and local standards.

- Engage Local Experts: Consulting with local experts or legal advisors can help navigate the complexities of international trade and compliance.

Conclusion

Manufacturing processes and quality assurance for 5 Ton Crane Trucks involve a detailed, multi-stage approach designed to ensure safety, efficiency, and compliance with international standards. By understanding these processes, B2B buyers can make informed decisions, ensuring they select reliable suppliers who prioritize quality and safety in their manufacturing operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘5 Ton Crane Truck’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for a 5 Ton Crane Truck. By following this checklist, you can ensure that you select a crane that meets your operational needs while also aligning with your budget and compliance requirements.

Step 1: Define Your Technical Specifications

Before initiating the search for a 5 Ton Crane Truck, it’s crucial to establish your technical requirements. This includes the maximum lifting capacity, boom length, and operational features such as hydraulic systems and control mechanisms.

- Consider the lifting height and outreach you need for your specific applications, such as construction or logistics.

- Evaluate the truck’s weight and size, ensuring it is compatible with your existing fleet and operational environment.

Step 2: Research Market Trends and Pricing

Understanding current market trends can provide you with a competitive edge when sourcing your crane. Research the average price range for new and used models to gauge what constitutes a fair deal.

- Monitor fluctuations in demand, as these can affect pricing and availability.

- Explore financing options or leasing arrangements if you are working within a tight budget.

Step 3: Evaluate Potential Suppliers

Thoroughly vetting suppliers is essential to ensure you partner with reputable manufacturers or dealers.

- Request company profiles and product catalogs to assess their credibility and range of offerings.

- Seek references from other buyers, particularly those in your industry or region, to validate the supplier’s reliability and service quality.

Step 4: Verify Compliance with International Standards

Ensuring that the crane complies with relevant international safety and quality standards is non-negotiable. This step protects your business from potential legal and operational risks.

- Check for certifications such as ISO 9001 for quality management and ISO 45001 for occupational health and safety.

- Review any local regulations specific to your region, especially if you are sourcing from international suppliers.

Step 5: Inspect Equipment Condition and Performance

If you are considering used cranes, it is vital to conduct a thorough inspection before purchasing.

- Assess the crane’s physical condition, checking for wear and tear on key components like the boom, hydraulic system, and chassis.

- Request a demonstration of the crane’s performance to ensure it meets your operational needs and performs reliably under load.

Step 6: Understand Warranty and After-Sales Support

Before finalizing your purchase, clarify the warranty terms and after-sales support offered by the supplier.

- Inquire about the duration and coverage of the warranty, including what parts and services are included.

- Evaluate the supplier’s responsiveness and availability of spare parts, which can significantly impact your operational uptime.

Step 7: Finalize Payment and Delivery Terms

Once you have selected a supplier and agreed on the specifications, it’s time to finalize payment and delivery arrangements.

- Negotiate payment terms that work for your cash flow, whether that involves upfront payment, installments, or financing options.

- Confirm delivery timelines and logistics, ensuring that you have a plan in place for transportation and setup upon arrival.

By following these steps, you can streamline the procurement process for a 5 Ton Crane Truck and make informed decisions that support your business objectives.

Comprehensive Cost and Pricing Analysis for 5 Ton Crane Truck Sourcing

What Are the Key Cost Components in Sourcing a 5 Ton Crane Truck?

When sourcing a 5 ton crane truck, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

- Materials: The cost of materials varies significantly based on the quality and type of components used. High-grade steel and advanced hydraulic systems can increase initial costs but may provide better longevity and performance.

- Labor: Labor costs encompass both skilled labor for manufacturing and assembly as well as ongoing maintenance and repair services. Regions with higher labor costs, such as parts of Europe, may see increased pricing compared to regions in Africa or South America.

- Manufacturing Overhead: This includes expenses related to factory operations, utilities, and indirect labor. Efficient manufacturing processes can reduce these costs, impacting the final price.

- Tooling: Custom tooling for specialized features can add to the upfront costs but may be necessary for specific applications. Buyers should assess whether standard models meet their needs to avoid unnecessary expenses.

- Quality Control: Ensuring the crane meets safety and operational standards often involves additional QC processes, which can affect pricing. International certifications may also be required depending on the market.

- Logistics: Shipping costs can vary widely based on distance, method (air freight vs. sea freight), and any import tariffs or duties. Buyers should consider these factors when calculating total costs.

- Margin: The supplier’s profit margin can vary based on competition, brand reputation, and demand. Understanding the market can help buyers negotiate better pricing.

How Do Price Influencers Impact the Cost of 5 Ton Crane Trucks?

Several factors can influence the pricing of 5 ton crane trucks. These include order volume, specifications and customization, material quality, certifications, supplier reputation, and Incoterms.

- Volume/MOQ: Purchasing in larger quantities typically reduces the per-unit price. International buyers may negotiate better rates by consolidating orders or forming purchasing groups.

- Specifications and Customization: Custom features can lead to higher costs. Buyers should evaluate if standard models suffice for their operations to maintain cost efficiency.

- Materials and Quality: Higher-quality materials increase initial costs but can lower maintenance expenses over time. Buyers should consider the total cost of ownership (TCO) rather than just the upfront price.

- Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more but offer better service and warranty options.

- Incoterms: Understanding the shipping terms is critical. Incoterms dictate the responsibilities of buyers and sellers in shipping, which can affect overall costs and risk exposure.

What Buyer Tips Can Help Achieve Cost-Efficiency in Crane Truck Sourcing?

To ensure a cost-effective procurement process, buyers should consider the following tips:

- Negotiate with Suppliers: Leverage competitive quotes to negotiate better terms. Building a strong relationship with suppliers can also lead to favorable pricing and terms in the future.

- Evaluate Total Cost of Ownership: Assess not just the purchase price but ongoing maintenance, fuel efficiency, and resale value. Investing in a higher-quality crane may save costs in the long run.

- Understand Pricing Nuances for International Buyers: Different regions may have varying pricing structures due to local market conditions, tariffs, and currency fluctuations. Buyers should research these factors to avoid unexpected costs.

- Explore Financing Options: Consider financing arrangements that can ease cash flow pressures. Leasing options can provide access to equipment without large upfront costs.

Disclaimer on Indicative Pricing

It’s important to note that the prices mentioned for 5 ton crane trucks are indicative and can vary based on market conditions, supplier negotiations, and specific configurations. Buyers should conduct thorough market research and obtain multiple quotes to determine the most accurate pricing for their needs.

Alternatives Analysis: Comparing 5 Ton Crane Truck With Other Solutions

When considering the acquisition of lifting equipment, it’s essential to explore various alternatives that can fulfill similar roles to a 5 Ton Crane Truck. This analysis will compare the 5 Ton Crane Truck against two viable alternatives: the Stiff Boom Crane and the Knuckle Boom Crane. Each solution has unique attributes that cater to different operational needs and environments.

| Comparison Aspect | 5 Ton Crane Truck | Stiff Boom Crane | Knuckle Boom Crane |

|---|---|---|---|

| Performance | Lifts up to 5 tons; versatile and mobile | Lifts up to 5.6 tons; limited outreach | Lifts up to 5 tons; extensive outreach |

| Cost | Generally higher initial investment | Moderate cost; lower than truck crane | Competitive pricing; varies by model |

| Ease of Implementation | Requires a truck chassis; moderate complexity | Simpler installation; minimal chassis needed | Easy to mount on various trucks; versatile |

| Maintenance | Regular checks needed; higher complexity | Lower maintenance; simpler design | Moderate maintenance; flexible design |

| Best Use Case | Construction, heavy lifting, and transport | Industrial applications, short-distance lifts | Urban construction, tight spaces, and versatility |

What Are the Key Features of a Stiff Boom Crane Compared to a 5 Ton Crane Truck?

The Stiff Boom Crane offers a maximum lifting capacity of 5.6 tons, slightly exceeding the 5 Ton Crane Truck’s capacity. It is designed for straightforward lifting operations, making it ideal for industrial applications where space is limited. Its installation is generally simpler, often requiring less specialized equipment than a truck-mounted crane. However, its limited outreach may restrict its usability in broader applications, particularly in construction sites requiring extensive reach.

How Does a Knuckle Boom Crane Stand Up Against a 5 Ton Crane Truck?

Knuckle Boom Cranes are renowned for their flexibility and ability to maneuver in confined spaces, making them suitable for urban construction projects. They provide similar lifting capabilities as the 5 Ton Crane Truck but excel in outreach and versatility, allowing operators to handle materials with precision in tight areas. While their initial costs can be competitive, the maintenance requirements can vary based on usage and design complexity, potentially leading to higher long-term costs if not managed effectively.

Making the Right Choice: What Should B2B Buyers Consider?

When selecting the appropriate lifting solution, B2B buyers should evaluate their specific operational needs, such as the type of loads to be lifted, the working environment, and the frequency of use. The 5 Ton Crane Truck is optimal for heavy-duty applications requiring mobility and substantial lifting power, while the Stiff Boom Crane is advantageous for industrial settings with straightforward lifting tasks. Conversely, the Knuckle Boom Crane is best suited for projects demanding flexibility and precision in urban environments. By carefully assessing these factors, buyers can make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for 5 Ton Crane Truck

What Are the Key Technical Properties of a 5 Ton Crane Truck?

When considering the procurement of a 5 Ton Crane Truck, several technical specifications are crucial for B2B buyers to understand. These properties not only influence the truck’s performance but also its suitability for specific applications across various industries.

-

Maximum Lifting Capacity

The maximum lifting capacity, typically rated at 5 tons for these cranes, indicates the maximum weight the crane can safely lift. This is a critical metric for businesses that rely on heavy lifting, as exceeding this limit can lead to operational hazards, equipment failure, or damage to goods. Understanding the lifting capacity ensures that buyers select a crane that meets their operational needs without compromising safety. -

Boom Length and Reach

The boom length, which can range from approximately 4.3 to 11.9 meters depending on the model, determines the distance from the truck to the load being lifted. A longer boom allows for greater outreach, enabling the crane to access loads in hard-to-reach areas. For businesses involved in construction or logistics, this flexibility can enhance efficiency and reduce the need for additional equipment. -

Lifting Height

The maximum lifting height, often reaching up to 13.6 meters, is essential for applications where loads need to be elevated to significant heights. This specification is particularly relevant in industries such as construction, where materials may need to be lifted to various elevations on job sites. Buyers should consider the typical height requirements of their operations when selecting a crane. -

Hydraulic System Specifications

The hydraulic system, which typically has a maximum oil flow of around 32 L/min and operates at pressures of 20 MPa, is fundamental for the crane’s lifting capabilities. A robust hydraulic system ensures smooth operation, precise control, and rapid lifting speeds. For buyers, understanding these specifications can impact the efficiency of lifting operations and overall productivity. -

Weight and Stability

The overall weight of the crane truck, often around 2.37 tons, affects its stability during operation. Heavier cranes tend to have better stability, reducing the risk of tipping when lifting heavy loads. Buyers should evaluate the weight relative to the truck’s configuration and intended use to ensure safe operations. -

Rated Lifting Moment

The rated lifting moment, expressed in ton-meters (T.M), indicates the crane’s ability to lift loads at various distances from the truck’s center. A higher rated moment provides more versatility, allowing the crane to handle loads effectively without compromising safety. This specification is critical for industries that require precise load handling.

What Are Common Trade Terms Used in 5 Ton Crane Truck Transactions?

Understanding the terminology used in the crane industry is essential for effective communication and negotiation in B2B transactions. Here are some common terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture the original products or components used in crane trucks. When sourcing equipment, buyers often prefer OEM parts for their reliability and compatibility, ensuring that the equipment functions optimally. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for buyers as it can impact budgeting and inventory management, especially for smaller companies or those entering new markets. -

RFQ (Request for Quotation)

An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. This term is vital in B2B transactions, as it helps buyers compare offers and negotiate favorable terms. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international shipping, including who is responsible for shipping costs, insurance, and risk during transit. Familiarity with these terms is essential for cross-border transactions, ensuring clarity and reducing disputes. -

Load Chart

A load chart is a graphical representation that details the lifting capacities of a crane at various boom lengths and angles. Buyers should review load charts to understand the operational limits of the crane, ensuring it meets their specific lifting needs. -

Stabilizers

Stabilizers are extensions used to enhance the stability of the crane during operation. Knowing about stabilizers is important for buyers, as they can significantly impact the crane’s performance, especially when lifting heavy loads or working on uneven surfaces.

Understanding these technical specifications and trade terms equips B2B buyers with the knowledge needed to make informed decisions when purchasing a 5 Ton Crane Truck, ensuring they select the right equipment for their operational requirements.

Navigating Market Dynamics and Sourcing Trends in the 5 Ton Crane Truck Sector

What are the Key Trends Shaping the 5 Ton Crane Truck Market?

The global 5 ton crane truck market is experiencing significant growth driven by increasing demand across various industries, including construction, logistics, and telecommunications. In regions such as Africa, South America, the Middle East, and Europe, rapid urbanization and infrastructure development are key factors fueling this demand. Buyers are increasingly looking for versatile and efficient machinery that can handle a range of lifting tasks, which is contributing to the popularity of truck-mounted cranes.

Emerging technologies are also transforming the market landscape. Innovations such as telematics and IoT integration allow for real-time monitoring of crane performance, enhancing operational efficiency and safety. Additionally, the rise of e-commerce has led to increased demand for mobile lifting solutions that can quickly adapt to various job sites. B2B buyers are now prioritizing suppliers who offer not just equipment but comprehensive solutions that include maintenance, training, and support services.

Moreover, the trend towards automation is influencing purchasing decisions. Buyers are seeking cranes that offer automated features for improved precision and reduced operator workload. This shift is evident in the growing interest in cranes with advanced hydraulic systems and remote-control capabilities, making them more user-friendly and efficient.

How is Sustainability Influencing B2B Sourcing for 5 Ton Crane Trucks?

Sustainability is becoming a critical consideration for B2B buyers in the 5 ton crane truck sector. The environmental impact of manufacturing and operating heavy machinery is prompting companies to seek suppliers that prioritize eco-friendly practices. This includes using sustainable materials in production and implementing processes that minimize waste and carbon emissions.

Ethical sourcing is equally important, as buyers are increasingly concerned about the transparency of their supply chains. Suppliers that can demonstrate responsible sourcing of raw materials and adherence to environmental regulations are more likely to attract business. Certifications such as ISO 14001 for environmental management and other ‘green’ labels can enhance a supplier’s credibility and appeal to conscientious buyers.

Additionally, the market is witnessing a rise in demand for electric or hybrid crane trucks, which offer lower emissions compared to traditional diesel models. This shift aligns with global efforts to reduce reliance on fossil fuels and combat climate change. B2B buyers are encouraged to explore options that not only meet their operational needs but also contribute positively to environmental sustainability.

What is the Historical Context of the 5 Ton Crane Truck Industry?

The evolution of crane technology has significantly influenced the development of the 5 ton crane truck segment. Initially, cranes were primarily stationary and manually operated, which limited their versatility and efficiency. The introduction of truck-mounted cranes in the mid-20th century revolutionized the industry by providing enhanced mobility and operational flexibility, making them ideal for a range of applications.

Over the decades, advancements in hydraulic technology and materials science have led to the creation of lighter, stronger cranes that offer improved lifting capacities and operational efficiency. The integration of electronic controls and telematics has further transformed crane operation, allowing for greater precision and safety. Today, the 5 ton crane truck sector stands at the intersection of innovation and practicality, catering to diverse needs across multiple industries while continuing to adapt to emerging trends and technologies.

In summary, B2B buyers in the 5 ton crane truck market are navigating a landscape characterized by rapid technological advancements, a growing emphasis on sustainability, and a historical context that underscores the importance of mobility and efficiency in lifting solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of 5 Ton Crane Truck

-

How do I choose the right 5 Ton Crane Truck for my business needs?

Selecting the appropriate 5 Ton Crane Truck involves understanding your specific operational requirements. Consider factors such as the maximum lifting height, boom length, and outreach capabilities. Evaluate the types of materials you will be lifting and the truck’s maneuverability in your work environment. Additionally, assess the crane’s compatibility with your existing fleet and infrastructure. Collaborating with a supplier who offers customization options can also ensure that the crane aligns perfectly with your operational needs. -

What are the key features to look for in a 5 Ton Crane Truck?

When sourcing a 5 Ton Crane Truck, key features to evaluate include lifting capacity, boom length, and hydraulic system specifications. Ensure the crane has a reliable safety system, such as overload protection and stabilizers. The ease of operation, maintenance requirements, and the availability of spare parts are also crucial. Furthermore, consider the truck’s fuel efficiency and overall durability to maximize your investment and ensure long-term performance. -

What is the typical lead time for acquiring a 5 Ton Crane Truck?

The lead time for acquiring a 5 Ton Crane Truck can vary significantly based on the supplier, customization requirements, and production schedules. Generally, you can expect a lead time of 4 to 12 weeks for standard models. If you require specific customizations, such as tailored boom lengths or specialized features, this may extend the lead time. It’s advisable to communicate your timelines with potential suppliers early in the negotiation process to align expectations. -

How can I verify the credibility of a supplier for 5 Ton Crane Trucks?

To verify a supplier’s credibility, start by checking their business registration and industry certifications. Look for reviews and testimonials from previous clients, focusing on their experiences with product quality and customer service. Assess the supplier’s years of operation and expertise in the crane market. Additionally, request references and consider visiting their facilities if possible. Engaging with industry forums or trade associations can also provide insights into reputable suppliers. -

What are the common payment terms for purchasing a 5 Ton Crane Truck?

Payment terms for a 5 Ton Crane Truck can vary widely among suppliers. Common arrangements include a deposit upon order confirmation (typically 20-30%), followed by the balance due before shipment. Some suppliers may offer financing options or payment upon delivery. It’s crucial to clarify payment terms in the contract to avoid misunderstandings. Additionally, consider using secure payment methods that provide buyer protection, especially for international transactions. -

Are there customization options available for 5 Ton Crane Trucks?

Yes, many suppliers offer customization options for 5 Ton Crane Trucks to meet specific operational needs. Customizations can include modifications to boom length, lifting capacity, and hydraulic systems. You may also request additional features such as remote controls, specialized attachments, or enhanced safety systems. Discuss your specific requirements with potential suppliers to explore available customization options and ensure that the final product aligns with your operational demands. -

What shipping and logistics considerations should I keep in mind when sourcing a 5 Ton Crane Truck internationally?

When sourcing a 5 Ton Crane Truck internationally, consider factors such as shipping costs, delivery timelines, and customs regulations in your country. Ensure the supplier can provide necessary documentation for customs clearance, including bills of lading and certificates of origin. Assess the reliability of the shipping method, whether by sea or air, and factor in any potential tariffs or import duties. Collaborating with a logistics provider experienced in heavy machinery can streamline the process. -

How do I ensure quality assurance for my 5 Ton Crane Truck purchase?

To ensure quality assurance for your 5 Ton Crane Truck, request detailed specifications and performance data from the supplier. Inquire about the manufacturer’s quality control processes and certifications, such as ISO standards. It’s advisable to conduct a pre-shipment inspection to verify that the crane meets your requirements before it leaves the factory. Additionally, discuss warranty terms and after-sales support to address any potential issues that may arise post-purchase.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 10 5 Ton Crane Truck Manufacturers & Suppliers List

1. Boom Truck Cranes – Key Listings

Domain: cranenetwork.com

Registered: 2000 (25 years)

Introduction: Boom Truck Cranes for Sale: 571 results found. Key listings include: 2023 Manitex TC50155HL – $565,000; 2000 Terex BT 3470 – $36,000; 2006 Terex 4792 – $79,900; 2002 National 11105 – $75,000; 2008 National 18127 – $195,000; 2003 Terex 4700 – Price: Inquire; 2005 Altec AC26-103 – $59,500; 2007 Altec AC38-127-HL-SWS – $89,500; 2012 National NBT50 – $252,000; 2007 National 1400A – $109,000; 1999 Nati…

2. Sany Global – Loader Crane

3. Isuzu – 5 Ton Truck Mounted Telescopic Boom Crane

Domain: isuzutruckscn.com

Registered: 2015 (10 years)

Introduction: Isuzu 5 Ton Truck Mounted Telescopic Boom Crane, Work capacity: 5 tons, Engine power: 190 HP, Engine type: 4HK1-TC50, Axle drive: 4×2, Gear box: MLD 6-speed manual, Order(MOQ): 1, Customized cargo box, Durable 2120kg Truck Mounted Crane.

4. BOB-LIFT – 5 Ton Knuckle Boom Truck Mounted Crane

Domain: bobliftcrane.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “5 Ton Knuckle Boom Truck Mounted Crane”, “Model”: “SQ5ZA2”, “Brand”: “BOB-LIFT”, “Max Lifting Capacity”: “5000kg”, “Max Lifting Moment”: “10.5ton.m”, “Recommended Power”: “22KW”, “Hydraulic System Flow”: “35L/Min”, “Hydraulic System Pressure”: “28Mpa”, “Coil Tank Capacity”: “100L”, “Installation Space”: “1050mm”, “Self Weight”: “1850kg”, “Rotation Angle”: “400°”, “Design Features…

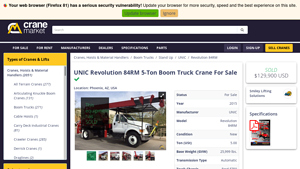

5. UNIC – UNIC Revolution 84RM

Domain: cranemarket.com

Registered: 2009 (16 years)

Introduction: {‘model’: ‘UNIC Revolution 84RM’, ‘capacity’: ‘5 tons’, ‘location’: ‘Phoenix, AZ, USA’, ‘year’: ‘2015’, ‘manufacturer’: ‘UNIC’, ‘condition’: ‘New’, ‘base_weight’: ‘25,999 lbs’, ‘transmission_type’: ‘Automatic’, ‘truck_chassis_make’: ‘Ford F750’, ‘engine’: ‘Cummins ISB Diesel’, ‘horse_power’: ‘260 HP’, ‘category’: ‘Boom Trucks’, ‘sub_category’: ‘Stand Up’, ‘crane_details’: {‘type’: ‘NEW REVOLUTION …

6. SANY – SPS12500 Truck Mounted Crane

Domain: camamach.com

Registered: 2018 (7 years)

Introduction: Product Name: SANY SPS12500 Truck Mounted Crane

Type: 5-Ton Truck Mounted Telescopic Crane

Chassis: SHACMAN

Max Lifting Capacity: 5 tons

Boom Length: 11.9 meters

Overall Weight: 13.5 tons

Price: $72,858.00

Features:

– Extra-long boom for wider operating range

– Two-stage large-span outriggers for enhanced stability

– Integrated fuel tank for easier modification

– Standard warning horn and work li…

7. KIGNRUN – 5T Flatbed Truck

Domain: csctrucks.com

Registered: 2013 (12 years)

Introduction: {“Lifting Capacity”: “5T”, “Chassis”: “KIGNRUN 4×2”, “Overall Size (LxWxH)”: “8,250×2,500×3,460mm”, “Wheelbase”: “4,500mm”, “Engine Model”: “Cummins 210hp Engine”, “Emission Standard”: “Euro 3”, “Lifting Height”: “12.8m”, “Max Reach”: “11.2m”, “Payload”: “8,290Kg”, “Max Speed”: “80km/h”, “Flatbed Size”: “4.6×2.3×0.6m”}

8. Sunbelt Rentals – Cranes and Boom Trucks

Domain: sunbeltrentals.com

Registered: 1997 (28 years)

Introduction: Cranes and Boom Trucks available for rent include: Carry Deck Crane 11 – 15 Ton, Carry Deck Crane 4 – 10 Ton, Portable Industrial Crane – Electric, and Rotating Telehandler. Various types of lifts are offered such as Electric Scissorlifts ranging from 10′ to 49′, Manlift Articulating from 30′ to 89′, and Straight Boom options from 40′ to 185′. Additional equipment includes Mast Style Lifts, One Ma…

9. Custom Truck – 5 Tons 30 ft Track Boom Crane

Domain: customtruck.com

Registered: 1996 (29 years)

Introduction: {“Product Name”: “5 tons 30 ft Track Booms/Crane”, “Model”: “605-1000”, “Lifting Capacity”: “10,000 lb (4535.9 kg)”, “Boom Length”: “30 ft (9.1 m)”, “Crane Type”: “Telescopic”, “Insulated”: “No”, “Pricing Disclaimer”: “Price is an estimation and does not include any freight/delivery charges, sales tax, titling fees, or registration fees. All pricing shown is in USD. Price is subject to change.”}

10. FORD – 2024 F-550SD Crane Truck

Domain: commercialtrucktrader.com

Registered: 2004 (21 years)

Introduction: Class 5 Crane Truck For Sale – Commercial Truck Trader

Key Makes:

– FORD (226)

– RAM (70)

– CHEVROLET (24)

– KENWORTH (19)

– FREIGHTLINER (6)

– IMT (6)

– PETERBILT (5)

– ALTEC (3)

– ETI (3)

Available Models:

– 2024 FORD F-550SD, XL, 4D Crew Cab/Chassis, Auto Crane Titan 38 Mechanics Body – $187,400

– 2024 CHEVROLET SILVERADO 5500HD with Stellar Aluminum Crane Body – $184,975

– 2024 FORD F-550, C…

Strategic Sourcing Conclusion and Outlook for 5 Ton Crane Truck

In the rapidly evolving landscape of construction and heavy lifting, the strategic sourcing of a 5-ton crane truck emerges as a pivotal investment for businesses across Africa, South America, the Middle East, and Europe. With a variety of options available, including truck-mounted cranes and boom trucks, buyers must prioritize specifications that align with their operational needs—such as lifting capacity, boom length, and hydraulic efficiency.

Emphasizing the importance of due diligence, international buyers should leverage comprehensive research and reliable supplier networks to identify equipment that meets stringent safety and performance standards. Additionally, considering the total cost of ownership, including maintenance and operational expenses, is crucial for maximizing return on investment.

As markets expand and demand for efficient lifting solutions grows, the 5-ton crane truck stands out as a versatile asset. Buyers are encouraged to engage with trusted manufacturers and dealers who can provide not only quality equipment but also after-sales support. By making informed sourcing decisions today, businesses can position themselves for success in tomorrow’s competitive environment. Invest wisely, and empower your operations with the right crane solutions.